Dynamic Analysis and Safety Assessment of Ships and Cables during Salvage Operations

Abstract

:Featured Application

Abstract

1. Introduction

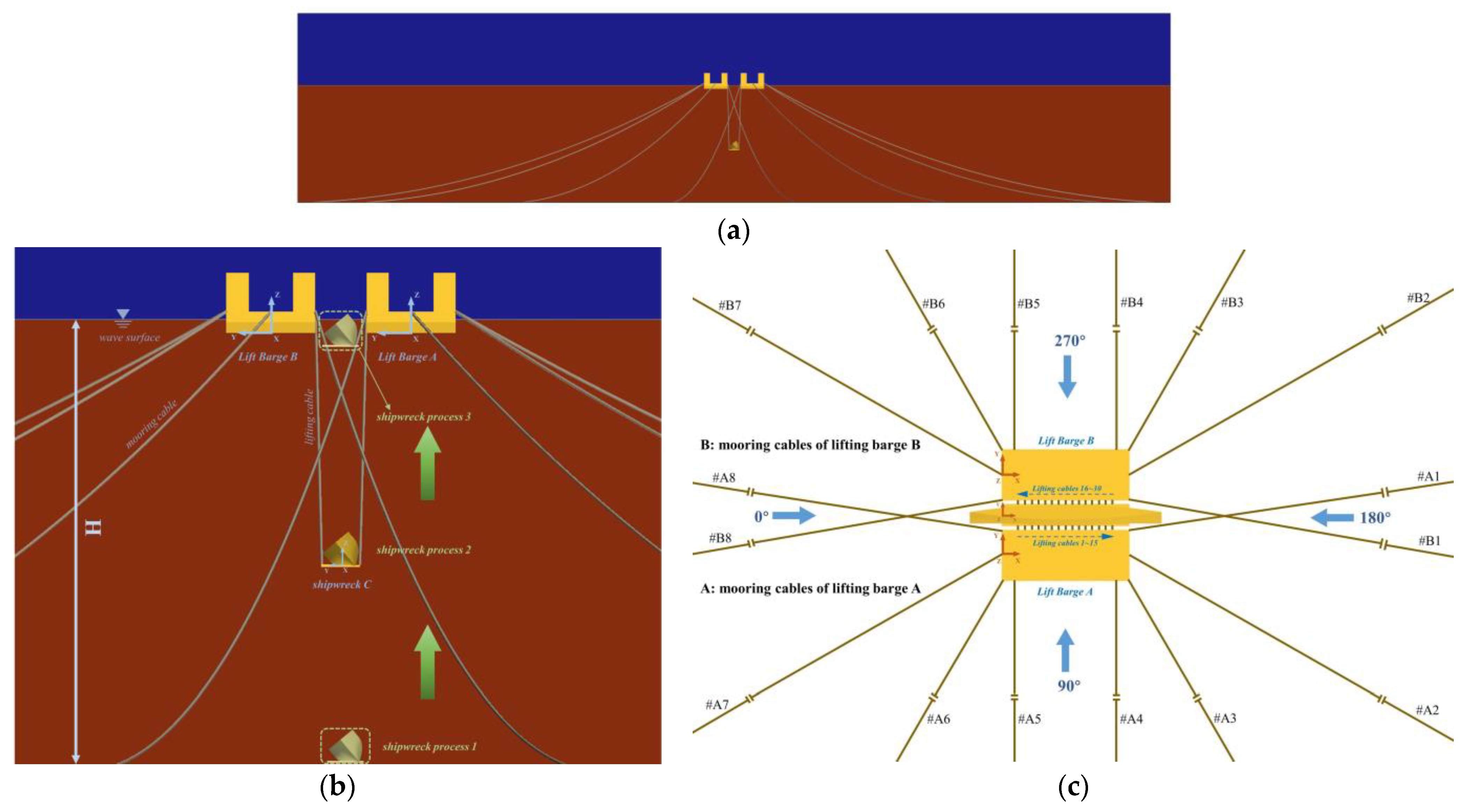

- Dividing the shipwreck retrieval process into three stages (Processes 1–3), starting from disengagement from the seabed until a portion of the structure emerges above the water’s surface. A method is developed within this framework to assess the safety of twin-barge retrieval. The assessment involves two categories: primarily quantitative assessment, followed by qualitative assessment. First, in terms of qualitative assessment, the maximum absolute motion amplitude (computed as the difference between the maximum and minimum values) [34] of the six degrees of freedom (6DOFs) of the three vessels is calculated, providing an intuitive depiction of the motion characteristics of the three vessels in distinct situations. Second, in terms of quantitative evaluation, the safety of the salvage system can be quantified by considering the safety factor of the hoisting cables along with the maximum absolute value (MA), root mean square (RMS), and coefficient of variation (CV) of the 6DOFs for the three vessels.

- Analyzing the impact of the wave direction on the salvage system to mitigate the difficulty of the salvage operation and enhance safety. A comprehensive evaluation of the three vessels’ motion responses and cables’ tension responses is conducted to determine the appropriate wave interval.

- Confining the motion of the three vessels during the salvage process and optimizing cable safety by proposing five schemes to add cables between vessels. Analyzing the impact of these schemes on the salvage system and identifying the most suitable operating approach.

- Analyzing the risk of the lifting-cable breakage, providing insights for managing unexpected situations during salvage operations, and deepening the understanding of the underlying physical principles governing the salvage process.

2. Theory

3. Models and Assessment Methods

3.1. Ship and Cable Models

3.2. Assessment Methods

3.2.1. Assessment Elements

3.2.2. Assessment of Lifting Cables

3.2.3. Assessment of Three Vessels

- Mode 1: Assessment among different stages (intragroup scoring).

- Mode 2: Assessment among different working conditions (intergroup scoring).

4. Numerical Modelling and Validation

4.1. Numerical Modelling

4.2. Basin Test and Validation

5. Results

5.1. Dynamic Response Characteristics of the Salvage Operation

5.2. The Effect of Directions of Waves on the Salvage System

5.2.1. The Effect of Directions of Waves on the Ship’s Motion Response

5.2.2. The Effect of Directions of Waves on the Tension of Lifting Cables

5.2.3. Summaries

5.3. The Effect of Cables among Three Ships on the Salvage System

5.3.1. The Effect of Cables among Three Ships on Ships’ Motion Responses

5.3.2. The Effect of Cables among the Three Ships on the Tension of the Lifting Cables

5.3.3. Summaries

5.4. The Effect of Lifting-Cable Breakage on the Salvage System

6. Conclusions

- 1.

- Effects of waves in different directions:

- 2.

- Effects of connection cables among the three ships:

- 3.

- Effects of lifting cable breakage:

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 6DOFs | roll, pitch, yaw, surge, sway, and heave |

| MA | maximum absolute value |

| RMS | root mean square |

| CV | coefficient of variation |

| RANS | Reynolds-averaged Navier–Stokes equations |

Appendix A

References

- Pu, H.; Liu, Y.; Luo, J.; Xie, S.; Peng, Y.; Yang, Y.; Yang, Y.; Li, X.; Su, Z.; Gao, S.; et al. Development of an Unmanned Surface Vehicle for the Emergency Response Mission of the ‘Sanchi’ Oil Tanker Collision and Explosion Accident. Appl. Sci. 2020, 10, 2704. [Google Scholar] [CrossRef]

- Frodella, W.; Rossi, G.; Tanteri, L.; Rosi, A.; Lombardi, L.; Mugnai, F.; Fanti, R.; Casagli, N. A Decade from the Costa Concordia Shipwreck: Lesson Learned on the Contribution of Infrared Thermography during the Maritime Salvage Operations. Remote Sens. 2023, 15, 1347. [Google Scholar] [CrossRef]

- Gray, W. Raising titans: How do you salvage a mega-ship? New Sci. 2013, 220, 48–51. [Google Scholar] [CrossRef]

- Rogowska, J.; Wolska, L.; Namieśnik, J. Impacts of pollution derived from ship wrecks on the marine environment on the basis of s/s “Stuttgart” (Polish coast, Europe). Sci. Total Environ. 2010, 408, 5775–5783. [Google Scholar] [CrossRef]

- Henkel, L.A.; Nevins, H.; Martin, M.; Sugarman, S.; Harvey, J.T.; Ziccardi, M.H. Chronic oiling of marine birds in California by natural petroleum seeps, shipwrecks, and other sources. Mar. Pollut. Bull. 2014, 79, 155–163. [Google Scholar] [CrossRef]

- Zhang, F.; Ning, D.; Hou, J.; Du, H.; Tian, H.; Zhang, K.; Gong, Y. Semi-Active Heave Compensation for a 600-Meter Hydraulic Salvaging Claw System with Ship Motion Prediction via LSTM Neural Networks. J. Mar. Sci. Eng. 2023, 11, 998. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Stylianos, M.; Gidarakos, E. Assessment of released heavy metals from electrical and electronic equipment (EEE) existing in shipwrecks through laboratory-scale simulation reactor. J. Hazard. Mater. 2013, 250–251, 256–264. [Google Scholar] [CrossRef]

- Pehlivanides, G.; Monastiridis, K.; Tourtas, A.; Karyati, E.; Ioannidis, G.; Bejelou, K.; Antoniou, V.; Nomikou, P. The VIRTUALDiver Project. Making Greece’s Underwater Cultural Heritage Accessible to the Public. Appl. Sci. 2020, 10, 8172. [Google Scholar] [CrossRef]

- Lee, C.; Yoon, H.; Kim, D.; Na, W. Lifting forces required to salvage a sunken vessel and caisson and their response to bottom friction, buoyancy release, surface tension, water capture and water release. Ocean Eng. 2016, 125, 82–89. [Google Scholar] [CrossRef]

- Yao, Z.; Wang, W.; Jiang, Y.; Chen, S. Coupled Responses of Sewol, Twin Barges and Slings During Salvage. China Ocean Eng. 2018, 32, 226–235. [Google Scholar] [CrossRef]

- Liu, S.; Guo, Q.; Zhao, W. Research on active heave compensation for offshore crane. In Proceedings of the 26th Chinese Control and Decision Conference (2014 CCDC), Changsha, China, 31 May–2 June 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1768–1772. [Google Scholar]

- Raja Ismail, R.M.T.; That, N.D.; Ha, Q.P. Modelling and robust trajectory following for offshore container crane systems. Autom. Constr. 2015, 59, 179–187. [Google Scholar] [CrossRef]

- Kang, H.; Wu, Y.; Quen, L.K.; Tang, C.H.; Siow, C. Underwater target tracking of offshore crane system in subsea operations. In Proceedings of the 17th Asian Simulation Conference, Melaka, Malaysia, 27–29 August 2017; Springer: Singapore, 2017; pp. 126–137. [Google Scholar]

- Lee, D.; Kim, T.; Park, H.; Kim, Y. A study on the modeling and dynamic analysis of the offshore crane and payload. J. Korean Soc. Fish. Ocean. Technol. 2020, 56, 61–70. [Google Scholar] [CrossRef]

- Nam, B.W.; Kim, N.W.; Hong, S.Y. Experimental and numerical study on coupled motion responses of a floating crane vessel and a lifted subsea manifold in deep water. Int. J. Nav. Archit. Ocean Eng. 2017, 9, 552–567. [Google Scholar] [CrossRef]

- Zhang, D.; Zhao, B.; Zhu, K.; Jiang, H. Dynamic Analysis of Full-Circle Swinging Hoisting Operation of a Large Revolving Offshore Crane Vessel under Different Wave Directions. J. Mar. Sci. Eng. 2023, 11, 197. [Google Scholar] [CrossRef]

- Han, D.; Yoo, S.; Yoon, H.; Kim, M.; Kim, S.; Lee, J. Coupling analysis of finite element and finite volume method for the design and construction of FPSO crane. Autom. Constr. 2011, 20, 368–379. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, S.; Wei, Y.; Le, C.; Ding, H. Hydrodynamic characteristics of the crane vessel-three-bucket jacket foundation coupling hoisting system during the process of lowering. Ocean Eng. 2022, 250, 111034. [Google Scholar] [CrossRef]

- Xiao, W.; Li, C.; Fan, L.; Li, Q.; Tan, L. Dynamic Analysis of the Lifting Arm System in the Integrated Offshore Platform Decommissioning Equipment in Complicated Sea States. Processes 2023, 11, 645. [Google Scholar] [CrossRef]

- Kim, J.; Chung, W.; Park, S.; Jung, K.; Lee, J. Failure analysis for safety evaluation of capsizing accident of deep cement mixing vessel. Eng. Fail. Anal. 2020, 117, 104795. [Google Scholar] [CrossRef]

- Julianto, R.I.; Prabowo, A.R.; Muhayat, N.; Putranto, T.; Adiputra, R. Investigation of hull design to quantify resistance criteria using holtrop’s regression-based method and savitsky’s mathematical model: A study case of fishing vesse. J. Eng. Sci. Technol. 2021, 16, 1426–1443. [Google Scholar]

- Thomsen, J.B.; Bergua, R.; Jonkman, J.; Robertson, A.; Mendoza, N.; Brown, C.; Galinos, C.; Stiesdal, H. Modeling the TetraSpar Floating Offshore Wind Turbine Foundation as a Flexible Structure in OrcaFlex and OpenFAST. Energies 2021, 14, 7866. [Google Scholar] [CrossRef]

- Chen, M.; Yuan, G.; Li, C.B.; Zhang, X.; Li, L. Dynamic Analysis and Extreme Response Evaluation of Lifting Operation of the Offshore Wind Turbine Jacket Foundation Using a Floating Crane Vessel. J. Mar. Sci. Eng. 2022, 10, 2023. [Google Scholar] [CrossRef]

- Song, S.; Demirel, Y.K.; Atlar, M. An investigation into the effect of biofouling on the ship hydrodynamic characteristics using CFD. Ocean Eng. 2019, 175, 122–137. [Google Scholar] [CrossRef]

- Jiao, J.; Huang, S.; Soares, C.G. Numerical investigation of ship motions in cross waves using CFD. Ocean Eng. 2021, 223, 108711. [Google Scholar] [CrossRef]

- Jasak, H.; Vukčević, V.; Gatin, I.; Lalovi’c, I. CFD validation and grid sensitivity studies of full scale ship self propulsion. Int. J. Nav. Arch. Ocean Eng. 2019, 11, 33–43. [Google Scholar] [CrossRef]

- Islam, H.; Ventura, M.; Soares, C.G.; Tadros, M.; Abdelwahab, H.S. Comparison between empirical and CFD based methods for ship resistance and power prediction. Trends Mar. Technol. Eng. 2022, 1, 347–357. [Google Scholar]

- Kim, D.; Tezdogan, T. CFD-based hydrodynamic analyses of ship course keeping control and turning performance in irregular waves. Ocean Eng. 2022, 248, 110808. [Google Scholar] [CrossRef]

- Wang, J.; Wan, D. CFD study of ship stopping maneuver by overset grid technique. Ocean Eng. 2020, 197, 106895. [Google Scholar] [CrossRef]

- Andersson, J.; Shiri, A.A.; Bensow, R.E.; Yixing, J.; Chengsheng, W.; Gengyao, Q.; Deng, G.; Queutey, P.; Xing-Kaeding, Y.; Horn, P. Ship-scale CFD benchmark study of a pre-swirl duct on KVLCC2. Appl. Ocean Res. 2022, 123, 103134. [Google Scholar] [CrossRef]

- Huang, S.; Jiao, J.; Soares, C.G. Uncertainty analyses on the CFD–FEA co-simulations of ship wave loads and whipping responses. Mar. Struct. 2022, 82, 103129. [Google Scholar] [CrossRef]

- Dean, M.S. Springer Handbook of Ocean Engineering, 1st ed.; Springer: Cham, Switzerland, 2016; pp. 985–1066. [Google Scholar]

- Xin, S.; Wang, Y.; Wang, L.; Wang, X. A safety assessment approach of the salvage based on salvor–cable–wreck coupled simulations. Ocean Eng. 2023, 269, 113537. [Google Scholar] [CrossRef]

- Xin, S.; Wang, Y.; Wang, L.; Zhu, X.; Chen, S.; Zhou, D. Dynamic analysis of the mooring system of a salvage barge: A coupled time-domain method considering seabed resistance during the off-bottom stage. Ocean Eng. 2023, 275, 114078. [Google Scholar] [CrossRef]

- Guo, C.; Wang, X.; Chen, C.; Li, Y.; Hu, J. Numerical Investigation of Self-Propulsion Performance and Noise Level of DARPA Suboff Model. J. Mar. Sci. Eng. 2023, 11, 1206. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, N.; Huang, G.; Sun, Z. Experimental study on motions of tunnel element during immersion standby stage in long wave regime. Ocean Eng. 2018, 161, 29–46. [Google Scholar] [CrossRef]

- Song, Y.; Sun, Z.; Huang, G.; Chen, N.; Gao, X. An experimental investigation on the effect of the ballasting on the coupled dynamics of the tunnel immersion system. Ocean Eng. 2019, 190, 106412. [Google Scholar] [CrossRef]

- Flaus, J.M. Risk Analysis: Socio-Technical and Industrial Systems, 1st ed.; Wiley: New York, NY, USA, 2013; pp. 151–178. [Google Scholar]

- Liu, Y. Analysis of Coupled Dynamic Response Characteristics of Large Tonnage Shipwreck Salvage Multibody System in Complex Environment. Master’s Thesis, Jiangsu University of Science and Technology, Zhenjiang, China, 2020. [Google Scholar]

- Wheeler, M.P.; Matveev, K.I.; Xing, T. Numerical Study of Hydrodynamics of Heavily Loaded Hard-Chine Hulls in Calm Water. J. Mar. Sci. Eng. 2021, 9, 184. [Google Scholar] [CrossRef]

- Clark, C.G.; Lyons, D.G.; Neu, W.L. Comparison of single and overset grid techniques for CFD simulations of a surface effect ship. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014; American Society of Mechanical Engineers: New York, NY, USA, 2014; pp. V2T–V8T. [Google Scholar]

- Gu, M.; Bu, S.X.; Qiu, G.; Zeng, K.; Wu, C.; Lu, J. Validation of CFD simulation for ship roll damping using one pure car Carrier and one standard model. In Proceedings of the 15th International Ship Stability Workshop, Stockholm, Sweden, 13–15 June 2016. [Google Scholar]

- Zhao, B.; Jiang, H.; Sun, J.; Zhang, D. Research on the Hydrodynamic Performance of a Pentamaran in Calm Water and Regular Waves. Appl. Sci. 2023, 13, 4461. [Google Scholar] [CrossRef]

| Parameter | Lifting Barge A | Lifting Barge B | Shipwreck (Fully Submerged/Partially Out of Water) |

|---|---|---|---|

| Length (m) | 140 | 140 | 210 |

| Width (m) | 55.89 | 55.89 | 22.81 |

| Depth (m) | 13.3 | 13.3 | 20.85 |

| Draught (m) | 8.6 | 8.6 | 280/140/15.9 |

| Displacement (kg) | 6.39 × 107 | 6.39 × 107 | 4.83 × 107/4.45 × 107 |

| Center of gravity (m) | x = 71.26, y = −3.55, z = 7.04 | x = 71.26, y = 2.45, z = 7.04 | x = 70.56, y = −0.833, z = 6.53/6.36/6.05 |

| Salvage weight (kg) | — | — | 1.17 × 107/1.06 × 107/1.09 × 107 |

| Ixx | 2.18 × 1010 | 2.13 × 1010 | 3.52 × 109/3.31 × 109/3.13 × 109 |

| Iyy | 1.24 × 1011 | 1.24 × 1011 | 1.33 × 1011/1.31 × 1011/1.22 × 1011 |

| Izz | 1.41 × 1011 | 1.40 × 1011 | 1.33 × 1011/1.31 × 1011/1.21 × 1011 |

| Parameter | Mooring Cable | Lifting Cable |

|---|---|---|

| Diameter (m) | 0.06 | 0.124 |

| Wet weight (kg/m) | 15.78 | 67.4 |

| Axial rigidity (N) | 3.19 × 108 | 1.36 × 109 |

| Breaking force (N) | 3.24 × 106 | 1.38 × 107 |

| Category | Elements | Rule | Score (SA or ST) | Remark |

|---|---|---|---|---|

| Safety | The MA and RMS of the 6DOFs of the three vessels are chosen as the two assessment elements. | Both assessment elements in P2 are lower than the average of the corresponding assessment elements in P1 and P3. | 1 | Safe |

| One of the assessment elements in P2 exceeds the average of the corresponding assessment elements in P1 and P3, but it is not the maximum value among P1, P2, and P3. | 2 | Medium | ||

| One of the assessment elements in P2 represents the maximum value among corresponding assessment elements in P1, P2, and P3. | 3 | Unsafe | ||

| Stability | The CV of the 6DOFs of the three vessels is selected as the assessment element. | The assessment elements in P2 are lower than the average of the corresponding assessment elements in P1 and P3. | 1 | Stable |

| The assessment elements in P2 exceed the average value of the corresponding assessment elements in P1 and P3, but it is not the maximum value among P1, P2, and P3. | 2 | Medium | ||

| The assessment elements in P2 represent the maximum values among corresponding assessment elements in P1, P2, and P3. | 3 | Unstable |

| Group | Cells (Millions) | Roll (Deg) | L1 (F/106 N) | L5 (F/106 N) | L7 (F/106 N) |

|---|---|---|---|---|---|

| Coarse | 27 | 1.846 | 6.442 | 5.218 | 5.046 |

| Medium | 33 | 1.894 | 6.277 | 5.110 | 4.969 |

| Fine | 39 | 1.929 | 6.129 | 5.024 | 4.901 |

| Working Conditions | 6DOFs | Safety Score | Stability Score | Mode 1 Score | Ranking Score | Weight | Single DOF Score | Mode 2 Score | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | |||||||

| 90° | Roll | 1 | 1 | 3 | 3 | 2 | 3 | 61 | 5.000 | 1.5 | 97.500 | 256.833 |

| Pitch | 1 | 2 | 1 | 1 | 3 | 1 | 1.500 | 1.25 | 16.875 | |||

| Yaw | 2 | 1 | 1 | 1 | 1 | 1 | 4.167 | 1.25 | 36.458 | |||

| Surge | 3 | 2 | 3 | 1 | 1 | 1 | 1.000 | 1 | 11.000 | |||

| Sway | 1 | 1 | 1 | 3 | 3 | 3 | 4.167 | 1 | 50.000 | |||

| Heave | 3 | 1 | 1 | 2 | 1 | 1 | 5.000 | 1 | 45.000 | |||

| 115° | Roll | 1 | 1 | 3 | 3 | 3 | 3 | 65 | 3.667 | 1.5 | 77.000 | 212.458 |

| Pitch | 2 | 1 | 2 | 1 | 3 | 3 | 1.833 | 1.25 | 27.500 | |||

| Yaw | 2 | 3 | 1 | 1 | 1 | 3 | 1.500 | 1.25 | 20.625 | |||

| Surge | 1 | 1 | 1 | 2 | 2 | 2 | 3.000 | 1 | 27.000 | |||

| Sway | 1 | 1 | 1 | 1 | 3 | 3 | 3.333 | 1 | 33.333 | |||

| Heave | 3 | 1 | 1 | 2 | 1 | 1 | 3.000 | 1 | 27.000 | |||

| 135° | Roll | 1 | 1 | 2 | 3 | 3 | 1 | 62 | 3.333 | 1.5 | 55.000 | 209.292 |

| Pitch | 2 | 3 | 3 | 1 | 3 | 3 | 2.833 | 1.25 | 53.125 | |||

| Yaw | 1 | 3 | 1 | 1 | 1 | 1 | 3.167 | 1.25 | 31.667 | |||

| Surge | 1 | 3 | 3 | 1 | 1 | 1 | 2.333 | 1 | 23.333 | |||

| Sway | 1 | 2 | 3 | 3 | 1 | 1 | 2.500 | 1 | 27.500 | |||

| Heave | 2 | 1 | 1 | 1 | 1 | 1 | 2.667 | 1 | 18.667 | |||

| 155° | Roll | 1 | 1 | 1 | 3 | 3 | 1 | 70 | 1.667 | 1.5 | 25.000 | 252.583 |

| Pitch | 3 | 3 | 3 | 3 | 3 | 3 | 4.667 | 1.25 | 105.000 | |||

| Yaw | 1 | 1 | 1 | 3 | 1 | 3 | 1.500 | 1.25 | 18.750 | |||

| Surge | 2 | 3 | 2 | 3 | 2 | 2 | 3.667 | 1 | 51.333 | |||

| Sway | 1 | 1 | 1 | 1 | 2 | 3 | 3.500 | 1 | 31.500 | |||

| Heave | 2 | 2 | 1 | 2 | 1 | 1 | 2.333 | 1 | 21.000 | |||

| 180° | Roll | 1 | 1 | 2 | 3 | 1 | 1 | 57 | 1.333 | 1.5 | 18.000 | 198.875 |

| Pitch | 2 | 2 | 2 | 2 | 3 | 2 | 4.167 | 1.25 | 67.708 | |||

| Yaw | 1 | 1 | 1 | 1 | 3 | 1 | 4.667 | 1.25 | 46.667 | |||

| Surge | 1 | 1 | 1 | 1 | 1 | 1 | 5.000 | 1 | 30.000 | |||

| Sway | 1 | 2 | 1 | 3 | 1 | 3 | 1.500 | 1 | 16.500 | |||

| Heave | 2 | 2 | 1 | 3 | 1 | 1 | 2.000 | 1 | 20.000 | |||

| Mode | Broken Cable Number for Lifting-Barge A | Broken Cable Number for Lifting-Barge B |

|---|---|---|

| Mode 1 | #1, #15 | #16, #30 |

| Mode 2 | #3, #13 | #18, #28 |

| Mode 3 | #5, #11 | #20, #26 |

| Mode 4 | #7, #8 | #22, #23 |

| Mode 5 | #1, #2, #14, #15 | #16, #17, #29, #30 |

| Mode 6 | #2, #3, #13, #14 | #17, #18, #28, #29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, H.; Chen, S.; Sun, G.; Gong, Y. Dynamic Analysis and Safety Assessment of Ships and Cables during Salvage Operations. Appl. Sci. 2023, 13, 9420. https://doi.org/10.3390/app13169420

Zou H, Chen S, Sun G, Gong Y. Dynamic Analysis and Safety Assessment of Ships and Cables during Salvage Operations. Applied Sciences. 2023; 13(16):9420. https://doi.org/10.3390/app13169420

Chicago/Turabian StyleZou, Han, Shengtao Chen, Gang Sun, and Yongjun Gong. 2023. "Dynamic Analysis and Safety Assessment of Ships and Cables during Salvage Operations" Applied Sciences 13, no. 16: 9420. https://doi.org/10.3390/app13169420