Spatial, Temporal, and Vertical Variability of Ambient Environmental Conditions in Chinese Solar Greenhouses during Winter

Abstract

:1. Introduction

2. Materials and Methods

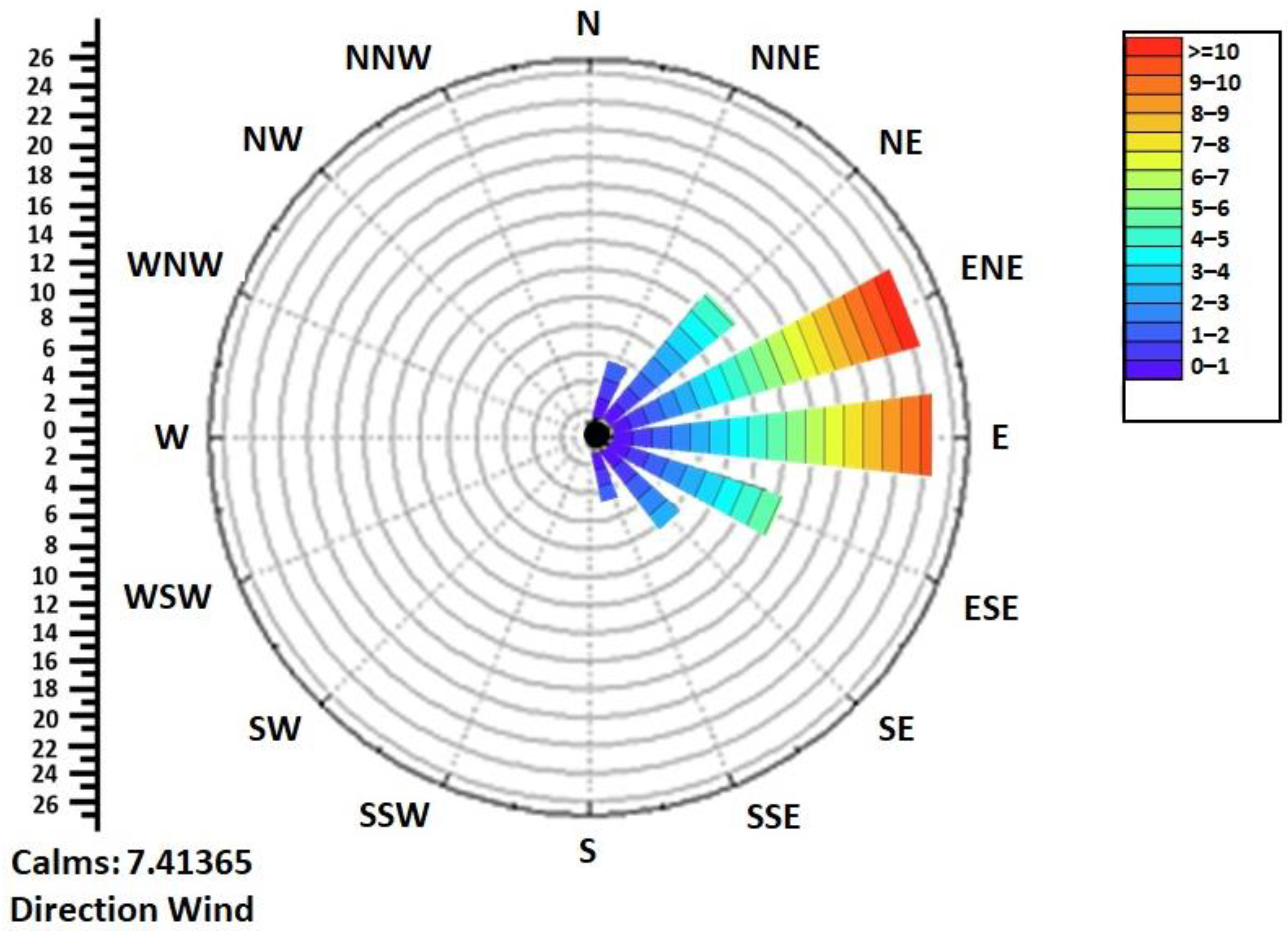

2.1. Data Collection Site

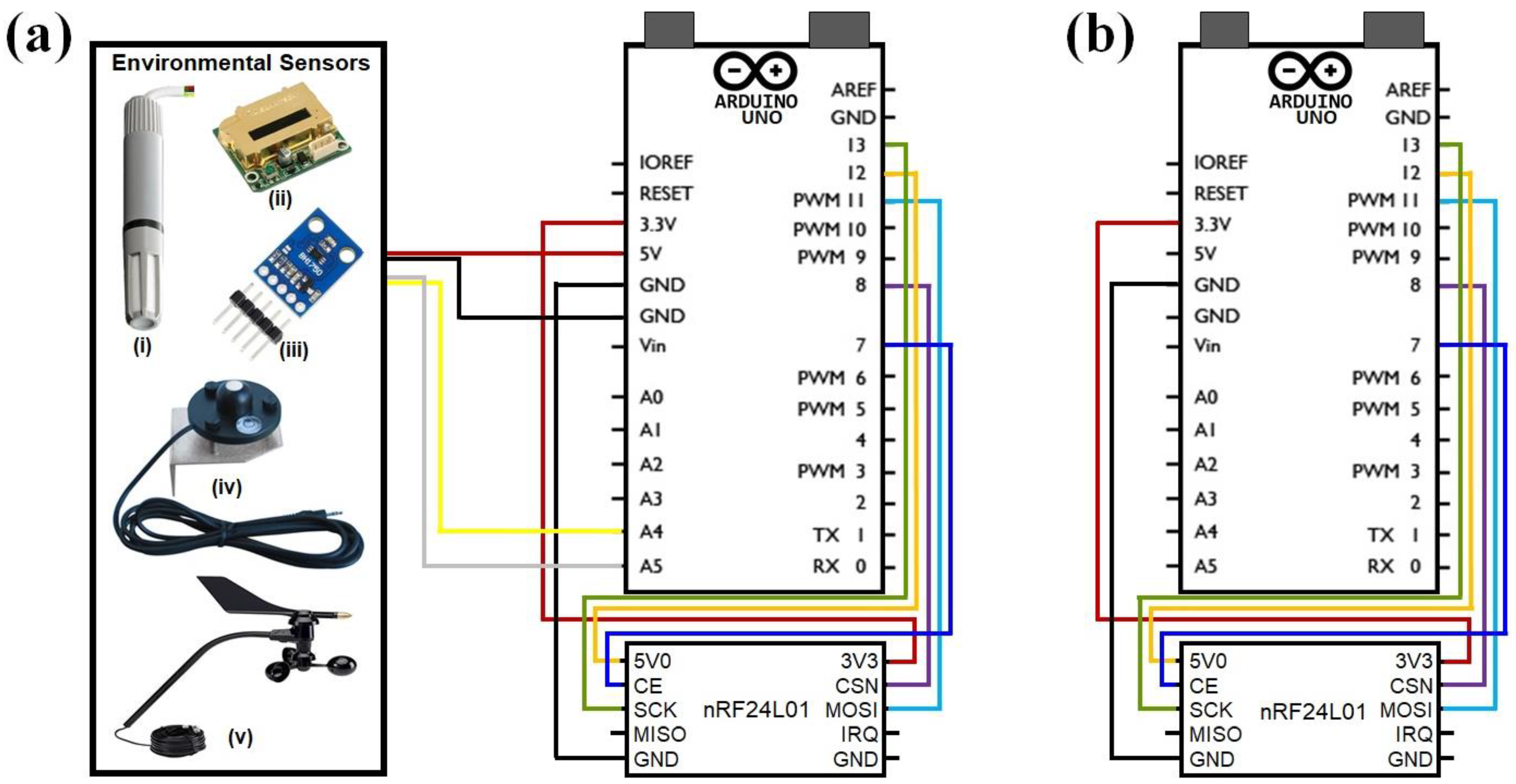

2.2. Sensors and Wireless Sensor Network (WSN)

2.3. Data Collection and Analytical Procedure

3. Results and Discussions

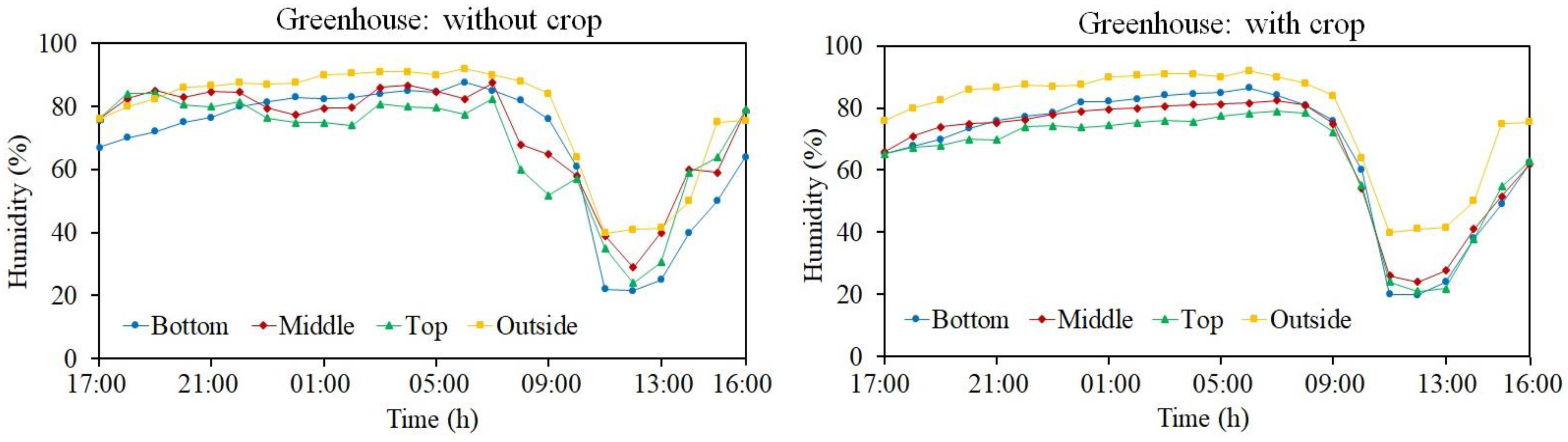

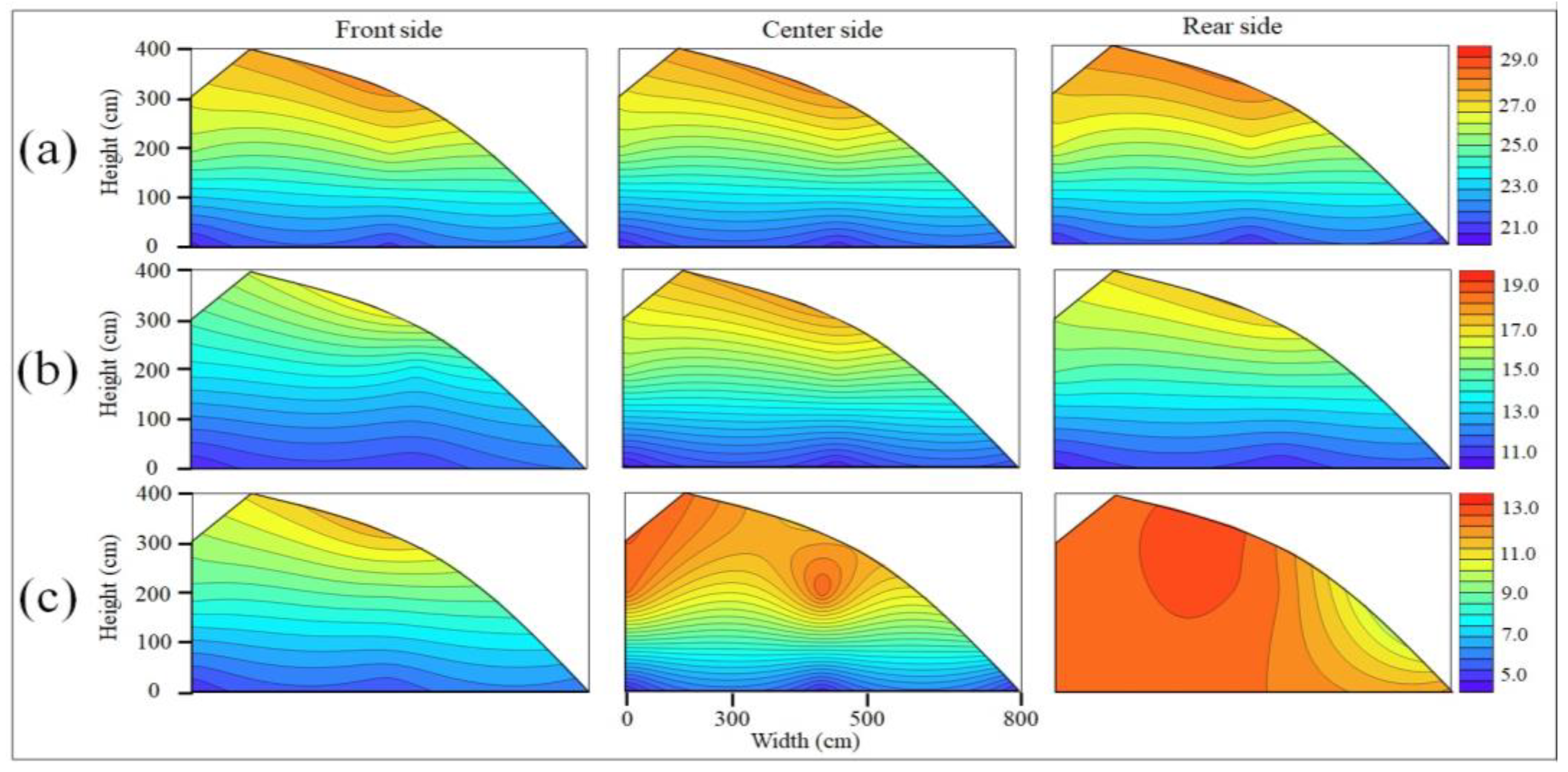

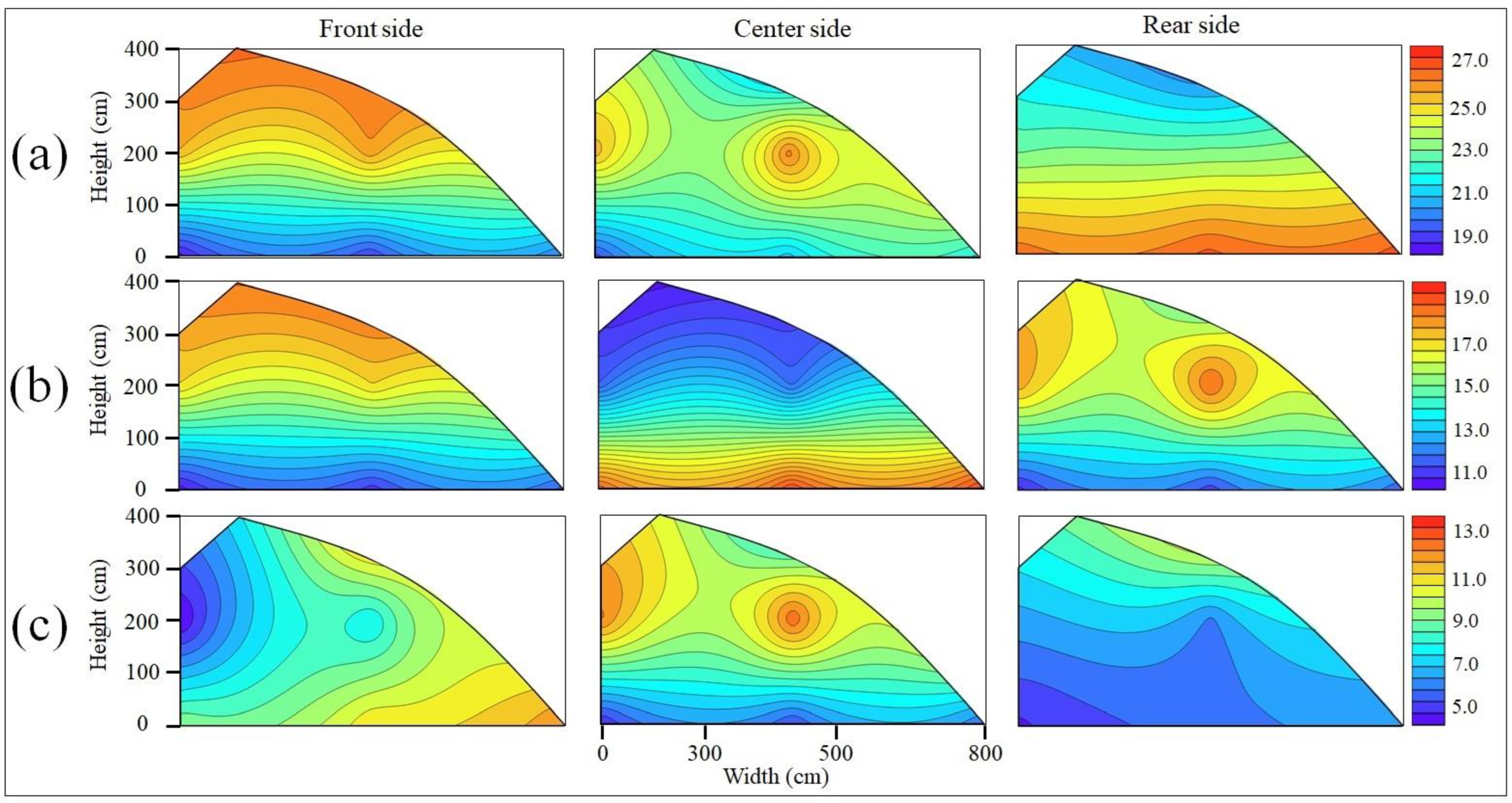

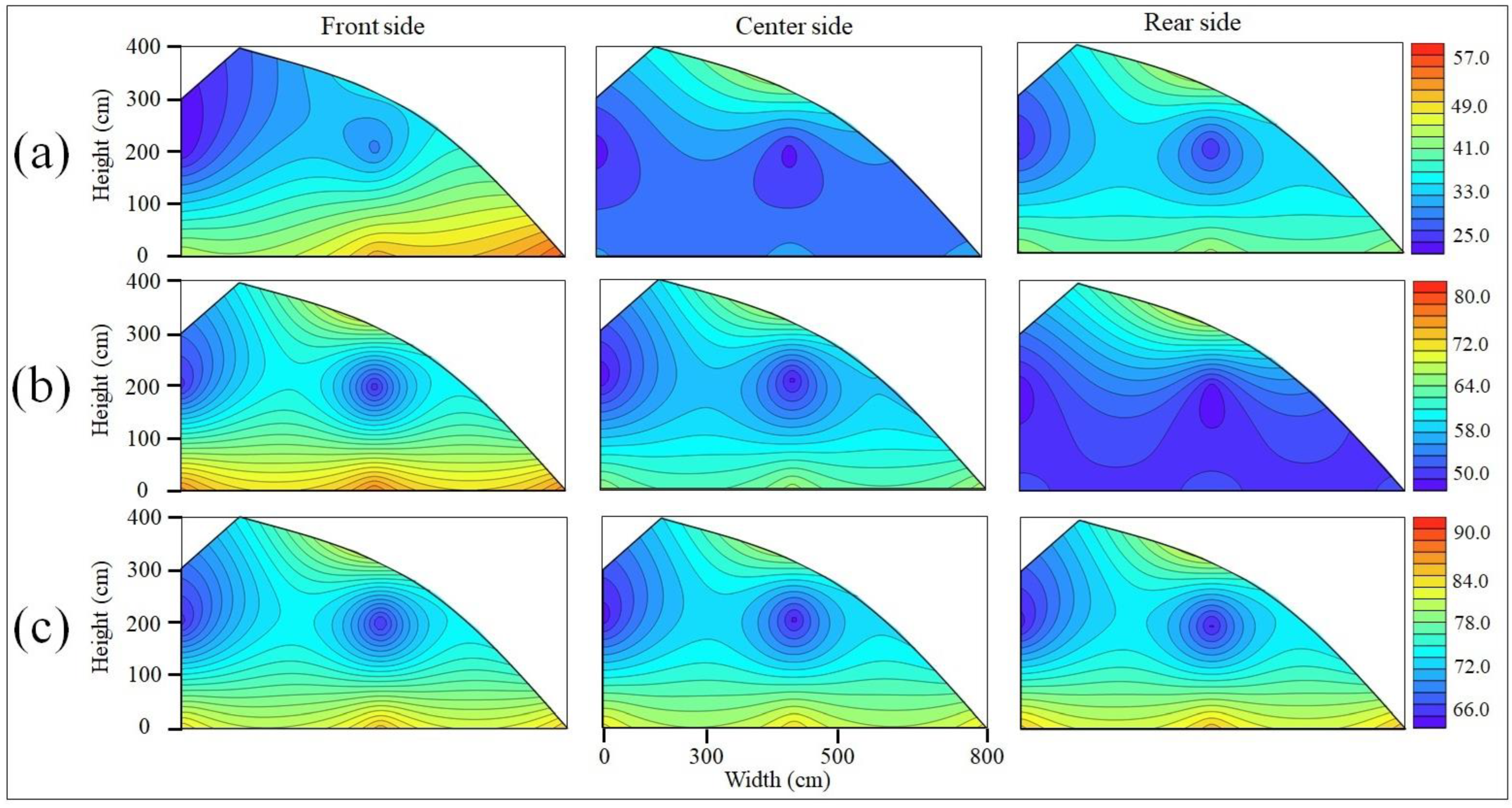

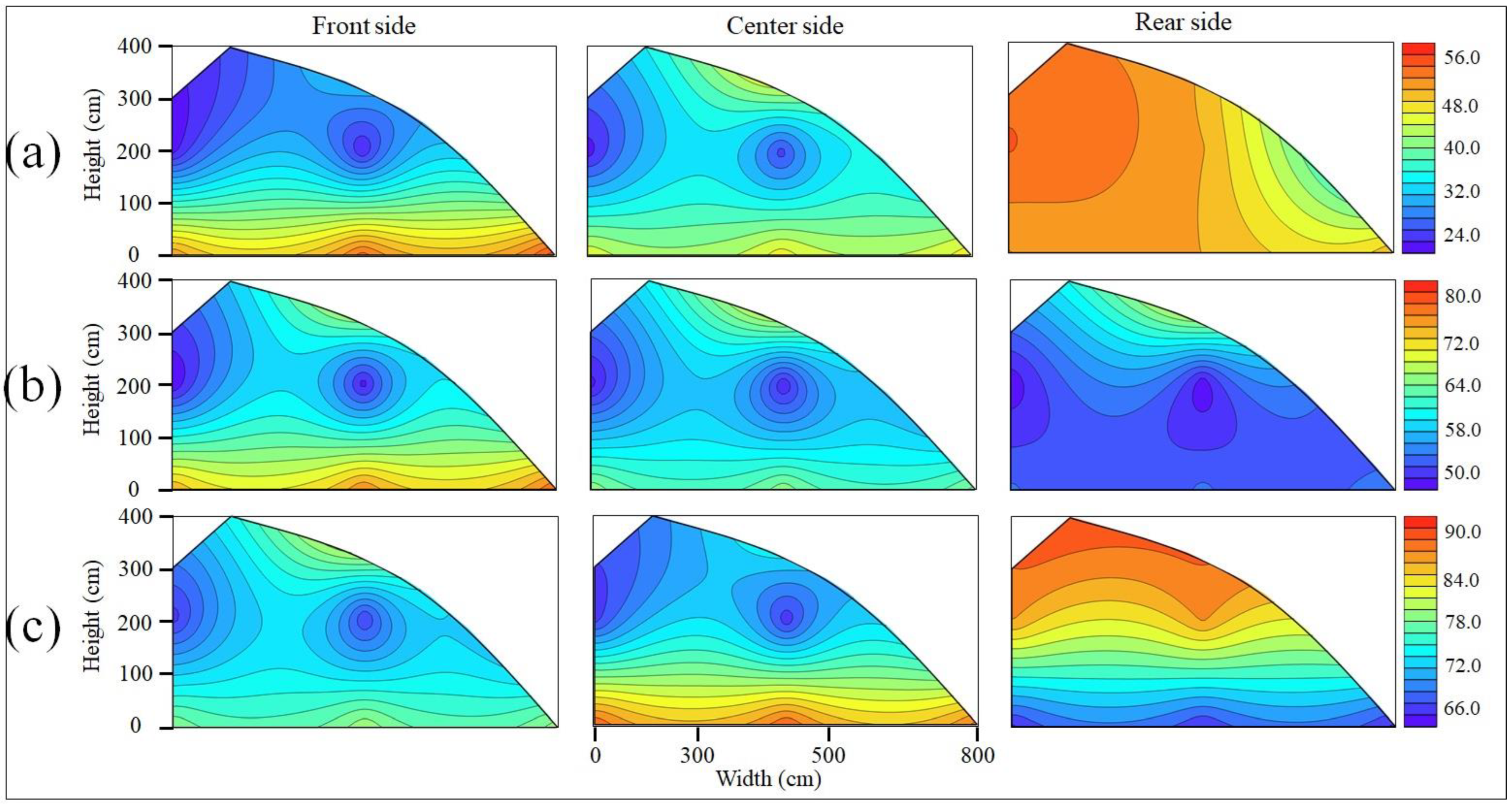

3.1. Variability in Temperature and Humidity

3.2. CO2 Variability

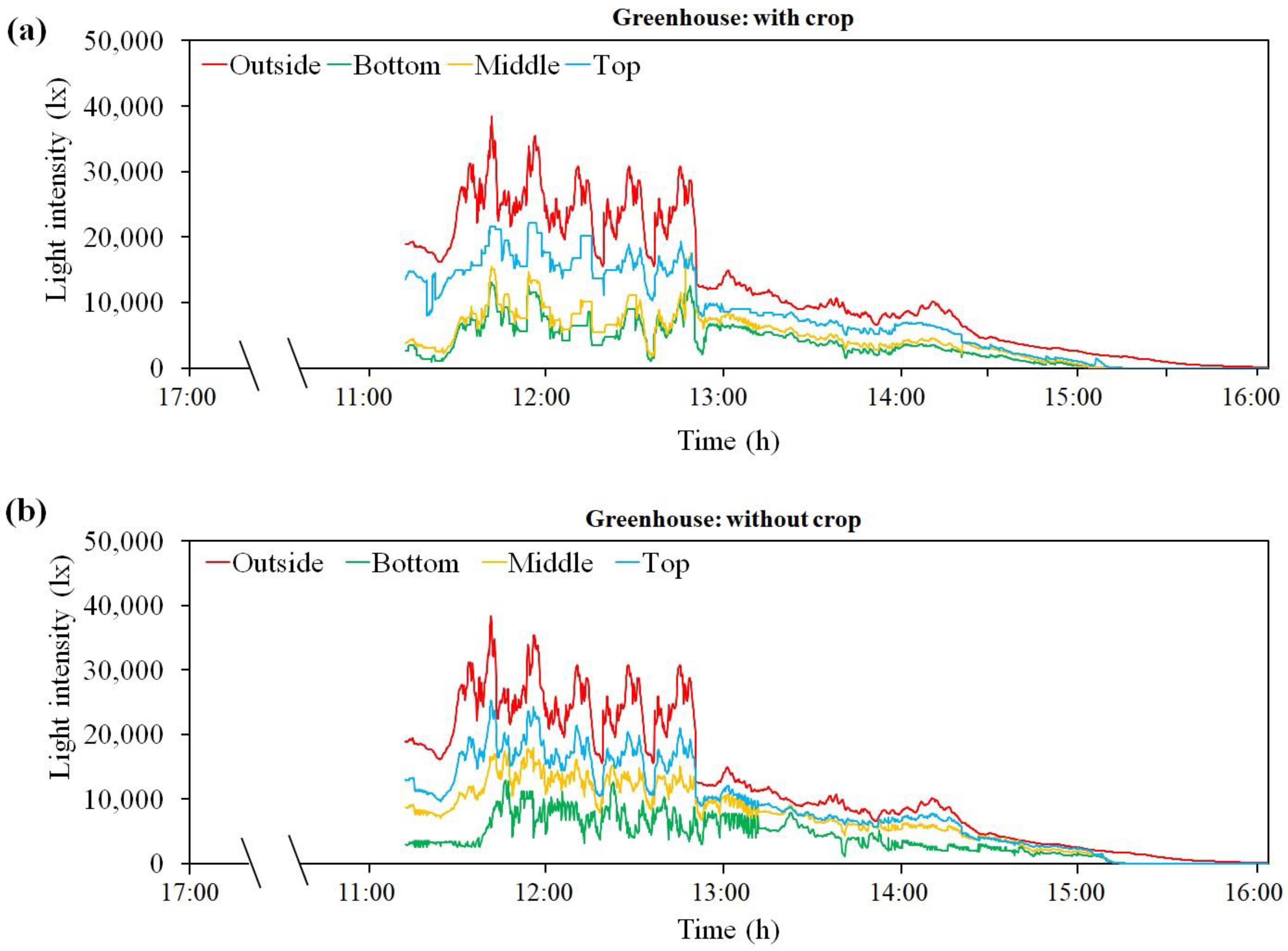

3.3. Solar Radiation and Light Intensity

3.4. The Scenario of Sensor Location for Optimum Monitoring and Control

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ray, D.K.; Mueller, N.D.; West, P.C.; Foley, J.A. Yield trends are insufficient to double global crop production by 2050. PLoS ONE 2018, 13, e0198604. [Google Scholar] [CrossRef] [PubMed]

- IPCC. Climate Change and Land: An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial Ecosystems; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019.

- Liu, J.; Hull, V.; Godfray, H.C.J.; Tilman, D.; Gleick, P.; Hoff, H.; Pahl-Wostl, C.; Xu, Z.; Chung, M.G.; Sun, J. Nexus approaches to global sustainable development. Nat. Sustain. 2018, 1, 466–476. [Google Scholar] [CrossRef]

- Li, T.; Li, H.; Li, Y.; Li, Y. Effects of environment control on tomato growth and fruit quality in greenhouses. J. Agric. Sci. 2018, 10, 197. [Google Scholar]

- Liu, X.; Yu, X.; Feng, B. Effects of environmental factors on tomato quality in greenhouses. Int. J. Agric. Biol. 2017, 19, 1235–1240. [Google Scholar]

- Hashemabadi, D.; Kashi, A.K.; Babaeian, E.; Hamidoghli, Y. Effects of greenhouse covering materials on the crop performance: A review. Renew. Sustain. Energy Rev. 2019, 103, 61–76. [Google Scholar]

- Migliaro, D.; Giuffrida, F.; Leonardi, C. Greenhouse tomato fruit quality. Sci. Hortic. 2015, 197, 601–611. [Google Scholar]

- Righini, H.; Rodriguez, J.P.; Arancibia, R.A.; Ortiz, R. Lettuce production in controlled environments. Acta Hortic. 2011, 918, 229–234. [Google Scholar]

- Sanchez-Molina, J.A.; Ming, L.; Rodriguez, F.; Guzman, J.L.; Hui, W.; Xinting, Y. Development and test verification of air temperature model for Chinese solar and Spainish Almeria-type greenhouses. Int. J. Agric. Biol. Eng. 2017, 10, 66–76. [Google Scholar] [CrossRef]

- Fuller, R.; Zahnd, A. Solar greenhouse technology for food security: A case study from Humla District, NW Nepal. Mt. Res. Dev. 2012, 32, 411–419. [Google Scholar] [CrossRef]

- Qiu, R.; Du, T.; Kang, S.; Chen, R.; Wu, L. Assessing the SIMDualKc model for estimating evapotranspiration of hot pepper grown in a solar greenhouse in Northwest China. Agric. Syst. 2015, 138, 1–9. [Google Scholar] [CrossRef]

- Song, H.; Guo, J.; Ren, T.; Chen, Q.; Li, B.; Wang, J. Increase of soil pH in a solar greenhouse vegetable production system. Soil Sci. Soc. Am. J. 2012, 76, 2074–2082. [Google Scholar] [CrossRef]

- Xu, Q.; Hu, K.; Zhang, H.; Han, H.; Li, J. Organic vegetable cultivation reduces resource and environmental costs while increasing farmers’ income in the North China Plain. Agronomy 2020, 10, 361. [Google Scholar] [CrossRef]

- Al-Masri, M.R.; Al-Ghouti, M.A. Sustainable greenhouse production during the winter season. Int. J. Environ. Sci. Technol. 2021, 18, 593–604. [Google Scholar]

- Hong, S.Y.; Kim, S.H.; Kwon, Y.S. Performance of a semi-transparent photovoltaic greenhouse for winter crop production. J. Renew. Sustain. Energy 2018, 10, 013703. [Google Scholar]

- Wang, Y.; Zhen, Y. The low-temperature response of greenhouse crops: A review. Acta Hortic. 2017, 1164, 225–230. [Google Scholar]

- Liu, X.; Wu, X.; Xia, T.; Fan, Z.; Shi, W.; Li, Y.; Li, T. New insights of designing thermal insulation and heat storage of Chinese solar greenhouse in high latitudes and cold regions. Energy 2022, 242, 122953. [Google Scholar] [CrossRef]

- Huang, B.; Zhu, X.; Shi, Z.; Zhou, L.; Guo, X. Performance of a semi-underground solar greenhouse for vegetable production in Northwest China. Energy Build. 2022, 222, 110087. [Google Scholar]

- Singh, M.C.; Singh, J.; Singh, K. Development of a microclimate model for prediction of temperatures inside a naturally ventilated greenhouse under cucumber crop in soilless media. Comput. Electron. Agric. 2018, 154, 227–238. [Google Scholar] [CrossRef]

- Lee, C.K.; Chung, M.; Shin, K.Y.; Im, Y.H.; Yoon, S.W. A study of the effects of enhanced uniformity control of greenhouse environment variables on crop growth. Energies 2019, 12, 1749. [Google Scholar] [CrossRef]

- Saberian, A.; Sajadiye, S.M. The effect of dynamic solar heat load on the greenhouse microclimate using CFD simulation. Renew. Energy 2019, 138, 722–737. [Google Scholar] [CrossRef]

- Yang, L.; Liu, H.; Cohen, S.; Gao, Z. Microclimate and Plant Transpiration of Tomato (Solanum lycopersicum L.) in a Sunken Solar Greenhouse in North China. Agriculture 2022, 12, 260. [Google Scholar] [CrossRef]

- Hou, Y.; Li, A.; Li, Y.; Jin, D.; Tian, Y.; Zhang, D.; Wu, D.; Zhang, L.; Lei, W. Analysis of microclimate characteristics in solar greenhouses under natural ventilation. Build. Simul. 2021, 14, 1811–1821. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, X.; Chai, Y.; Yang, L.; Wei, W.; Gu, J.; Kang, H. Experimental study on indoor environmental factors of double film solar greenhouse and traditional Chinese greenhouse in cold region. Energy Explor. Exploit. 2022, 40, 1760–1787. [Google Scholar] [CrossRef]

- Dong, S.; Ahamed, M.S.; Ma, C.; Guo, H. A time-dependent model for predicting thermal environment of mono-slope solar greenhouses in cold regions. Energies 2021, 14, 5956. [Google Scholar] [CrossRef]

- Ryu, M.J.; Ryu, D.K.; Chung, S.O.; Hur, Y.K.; Hur, S.O.; Hong, S.J.; Sung, J.H.; Kim, H.H. Spatial, vertical, and temporal variability of ambient environments in strawberry and tomato greenhouses in winter. J. Biosyst. Eng. 2014, 39, 47–56. [Google Scholar] [CrossRef]

- Fan, X.; Chengwei, M.; Mei, Q.; Yang, L.; Binbin, G.; Jianyu, Z.; Yanfei, C.; Guotao, S.; Chenxia, L. Investigation and assessment on microclimate environment of solar greenhouse in North China. Chin. J. Agrometeorol. 2014, 35, 17–25. [Google Scholar]

- Ahamed, M.S.; Guo, H.; Tanino, K. Sensitivity analysis of CSGHEAT model for estimation of heating consumption in a Chinese-style solar greenhouse. Comput. Electron. Agric. 2018, 154, 99–111. [Google Scholar] [CrossRef]

- Tadj, N.; Bartzanas, T.; Fidaros, D.; Draoui, B.; Kittas, C. Influence of heating system on greenhouse microclimate distribution. Trans. ASABE 2010, 53, 225–238. [Google Scholar] [CrossRef]

- Wei, M.; Xing, Y.; Wang, X.; Ma, H. CO2 environment in solar greenhouse in Northern China and effects of CO2 enrichment on photosynthetic rate and dry matter production of cucumber. Acta Hortic. 2002, 633, 115–120. [Google Scholar] [CrossRef]

- Touhami, A.; Benahmed, K.; Parra, L.; Bounaama, F.; Lloret, J. An intelligent monitoring of greenhouse using wireless sensor networks. Smart Struct. Syst. 2020, 26, 117–134. [Google Scholar]

- Wang, L.; Wang, B. Greenhouse microclimate environment adaptive control based on a wireless sensor network. Int. J. Agric. Biol. Eng. 2020, 13, 64–69. [Google Scholar] [CrossRef]

- Nicolosi, G.; Volpe, R.; Messineo, A. An innovative adaptive control system to regulate microclimatic conditions in a greenhouse. Energies 2017, 10, 722. [Google Scholar] [CrossRef]

- Azaza, M.; Tanougast, C.; Fabrizio, E.; Mami, A. Smart greenhouse fuzzy logic based control system enhanced with wireless data monitoring. ISA Trans. 2016, 61, 297–307. [Google Scholar] [CrossRef] [PubMed]

- Ferentinos, K.P.; Katsoulas, N.; Tzounis, A.; Bartzanas, T.; Kittas, C. Wireless sensor networks for greenhouse climate and plant condition assessment. Biosyst. Eng. 2017, 153, 70–81. [Google Scholar] [CrossRef]

- Balendonck, J.; Van Os, E.A.; Van Der Schoor, R.; Van Tuijl, B.A.J. Monitoring spatial and temporal distribution of temperature and relative humidity in greenhouses based on wireless sensor technology. Trials 2010, 52, 443–452. [Google Scholar]

- Liu, Z.; Zhang, J.; Li, S. Research into key techniques of the agricultural greenhouse monitoring system based on internet of things. Int. J. Smart Home 2016, 10, 1–10. [Google Scholar] [CrossRef]

- Iqbal, Z.; Islam, N.; Jang, B.E.; Ali, M.; Kabir, M.S.N.; Lee, D.H.; Na, K.D.; Park, S.B.; Chung, S.O. Monitoring the operating status of an automatic harmful fly collector for smart greenhouses. J. Biosyst. Eng. 2019, 44, 258–268. [Google Scholar] [CrossRef]

- Wang, Y.; Chi, Z. System of wireless temperature and humidity monitoring based on Arduino Uno platform. In Proceedings of the 2016 Sixth International Conference on Instrumentation & Measurement, Computer, Communication and Control (IMCCC), Harbin, China, 21–23 July 2016. [Google Scholar] [CrossRef]

- Wei, B.; Guo, S.; Wang, J.; Li, J.; Wang, J.; Zhang, J.; Qian, C.; Sun, J. Thermal performance of single span greenhouses with removable back walls. Biosyst. Eng. 2016, 141, 48–57. [Google Scholar] [CrossRef]

- Ruiz-Nieves, J.M.; Ayala-Garay, O.J.; Serra, V.; Dumont, D.; Vercambre, G.; Génard, M.; Gautier, H. The effects of diurnal temperature rise on tomato fruit quality. Can the management of the greenhouse climate mitigate such effects? Sci. Hortic. 2021, 278, 109836. [Google Scholar] [CrossRef]

- Tang, Y.; Ma, X.; Li, M.; Wang, Y. The effect of temperature and light on strawberry production in a solar greenhouse. Sol. Energy 2020, 195, 318–328. [Google Scholar] [CrossRef]

- Vadiee, A.; Martin, V. Energy management in horticultural applications through the closed greenhouse concept, state of the art. Renew. Sustain. Energy Rev. 2012, 16, 5087–5100. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Z.; Wang, W.; Li, J.; Cao, R. Spatial and temporal distribution test and analysis of tomato planting environment parameters in solar greenhouse. J. Shanxi Agric. Sci. 2019, 47, 2172–2176+2181. [Google Scholar]

- Zhang, C.; Liu, H.; Wang, C.; Zong, Z.; Wang, H.; Zhao, X.; Wang, S.; Li, Y. Testing and analysis on the spatial and temporal distribution of light intensity and co2 concentration in solar greenhouse. Sustainability 2023, 15, 7001. [Google Scholar] [CrossRef]

- Rangaswamy, T.C.; Sridhara, S.; Ramesh, N.; Gopakkali, P.; El-Ansary, D.O.; Mahmoud, E.A.; Abdelmohsen, S.A.; Abdelbacki, A.M.; Elansary, H.O.; Abdel-Hamid, A.M. Assessing the impact of higher levels of CO2 and temperature and their interactions on tomato (Solanum lycopersicum L.). Plants 2021, 10, 256. [Google Scholar] [CrossRef] [PubMed]

- Kellogg, W.W.; Schware, R. Climate Change and Society: Consequences of Increasing Atmospheric Carbon Dioxide; Routledge: London, UK, 2019. [Google Scholar]

- Sokolov, S. Optimization of greenhouse microclimate parameters considering the impact of CO2 and light. J. Eng. Sci. 2023, 10, G14–G21. [Google Scholar] [CrossRef]

- Zhang, X.; Lv, J.; Xie, J.; Yu, J.; Zhang, J.; Tang, C.; Li, J.; He, Z.; Wang, C. Solar Radiation allocation and spatial distribution in Chinese solar greenhouses: Model development and application. Energies 2020, 13, 1108. [Google Scholar] [CrossRef]

- Ryu, M.J.; Chung, S.O.; Kim, K.D.; Huh, Y.K.; Hur, S.O.; Ha, S.K.; Han, K.H.; Kim, H.H. Determination of sensor locations for monitoring of greenhouse ambient environment. In Proceedings of the 11th International Conference on Precision Agriculture, Indianapolis, IN, USA, 15–18 July 2012. [Google Scholar]

- Arnesano, M.; Revel, G.; Seri, F. A tool for the optimal sensor placement to optimize temperature monitoring in large sports spaces. Autom. Constr. 2016, 68, 223–234. [Google Scholar] [CrossRef]

- Feng, L.; Li, H.; Zhi, Y. Greenhouse CFD simulation for searching the sensors optimal placements. In Proceedings of the 2013 Second International Conference on Agro-Geoinformatics (Agro-Geoinformatics), Fairfax, VA, USA, 12–16 August 2013. [Google Scholar]

| Variable | Temperature | Humidity | CO2 | Light Intensity | Solar Radiation | Wind Speed | Wind Direction |

|---|---|---|---|---|---|---|---|

| Model | AM2315 | AM2315 | SH-300-ND | BH1750FVI | Watchdog 3670WS2 | Davis 7911 | Davis 7911 |

| Range | −20–80 °C | 0–100% | 0–3000 ppm | 0–65,535 lx | 0–1500 W m−2 | 0.5–89 m s−1 | 0°–360° |

| Resolution | 0.1 °C | 0.1% | 1 ppm | 0.1 lx | 0.1 W m−2 | 0.1 m s−1 | 1° |

| Accuracy | ±0.1 °C | 2% | 2% | ±5% | ±1% | ±5% | 7° |

| Treatment | CSG with Crops | CSG without Crops | ||

|---|---|---|---|---|

| Temperature (°C) | Humidity (%) | Temperature (°C) | Humidity (%) | |

| T1 | 11.950 c | 68.112 b | 18.783 a | 67.217 b |

| T2 | 13.274 b | 64.196 c | 16.821 b | 65.837 c |

| T3 | 14.002 a | 70.715 a | 15.483 c | 69.058 a |

| CV | 5.02 | 2.13 | 5.01 | 2.27 |

| LSD | 0.4587 | 1.0082 | 0.4752 | 1.0093 |

| Significance (%) | *** | *** | *** | *** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reza, M.N.; Islam, M.N.; Iqbal, M.Z.; Kabir, M.S.N.; Chowdhury, M.; Gulandaz, M.A.; Ali, M.; Jang, M.-K.; Chung, S.-O. Spatial, Temporal, and Vertical Variability of Ambient Environmental Conditions in Chinese Solar Greenhouses during Winter. Appl. Sci. 2023, 13, 9835. https://doi.org/10.3390/app13179835

Reza MN, Islam MN, Iqbal MZ, Kabir MSN, Chowdhury M, Gulandaz MA, Ali M, Jang M-K, Chung S-O. Spatial, Temporal, and Vertical Variability of Ambient Environmental Conditions in Chinese Solar Greenhouses during Winter. Applied Sciences. 2023; 13(17):9835. https://doi.org/10.3390/app13179835

Chicago/Turabian StyleReza, Md Nasim, Md Nafiul Islam, Md Zafar Iqbal, Md Shaha Nur Kabir, Milon Chowdhury, Md Ashrafuzzaman Gulandaz, Mohammod Ali, Moon-Ki Jang, and Sun-Ok Chung. 2023. "Spatial, Temporal, and Vertical Variability of Ambient Environmental Conditions in Chinese Solar Greenhouses during Winter" Applied Sciences 13, no. 17: 9835. https://doi.org/10.3390/app13179835

APA StyleReza, M. N., Islam, M. N., Iqbal, M. Z., Kabir, M. S. N., Chowdhury, M., Gulandaz, M. A., Ali, M., Jang, M.-K., & Chung, S.-O. (2023). Spatial, Temporal, and Vertical Variability of Ambient Environmental Conditions in Chinese Solar Greenhouses during Winter. Applied Sciences, 13(17), 9835. https://doi.org/10.3390/app13179835