Double Optimization Design of the Formula Racing Car Frame Based on the Variable Density Method and the Joint Variable Method

Abstract

:1. Introduction

2. Frame Model Design and Structural Analysis

2.1. Determine Geometric Modeling of Frame

- (1)

- Input the coordinates of suspension hard points in the CATIA V5 part design to create a suspension line diagram;

- (2)

- Determine the specific parameters of the main ring, front ring, and front partition;

- (3)

- Connect the bottom of the front partition, the bottom of the front ring, and the bottom of the main ring with lines in sequence;

- (4)

- Determine the slanted support structure for the main ring and its upper and lower slanted support structures;

- (5)

- Utilize the cockpit opening detection board and the cockpit internal cross-sectional detection board to verify whether the front cabin and cockpit of the frame meet the requirements of the competition rules.

2.2. Establishing Finite Element Model

2.2.1. Finite Element Theory

- (1)

- The structure is discretized, transforming the ductile continuous medium into a relatively limited number of simple basic elements. These elements are generated based on node connections, and the load is also transmitted through these nodes. Different types and numbers of elements can be selected during the entire process of discretization, which directly affects the accuracy and stability of the numerical values in the finite element analysis of the solid model;

- (2)

- After the discretization is constructed, to better represent the displacement, stress, and strain of the element with the nodal displacement, the displacement function formula can be used for description:

- (3)

- Solve, synthesize all bending stiffness equations, and obtain the equilibrium equations for all constructions, namely:

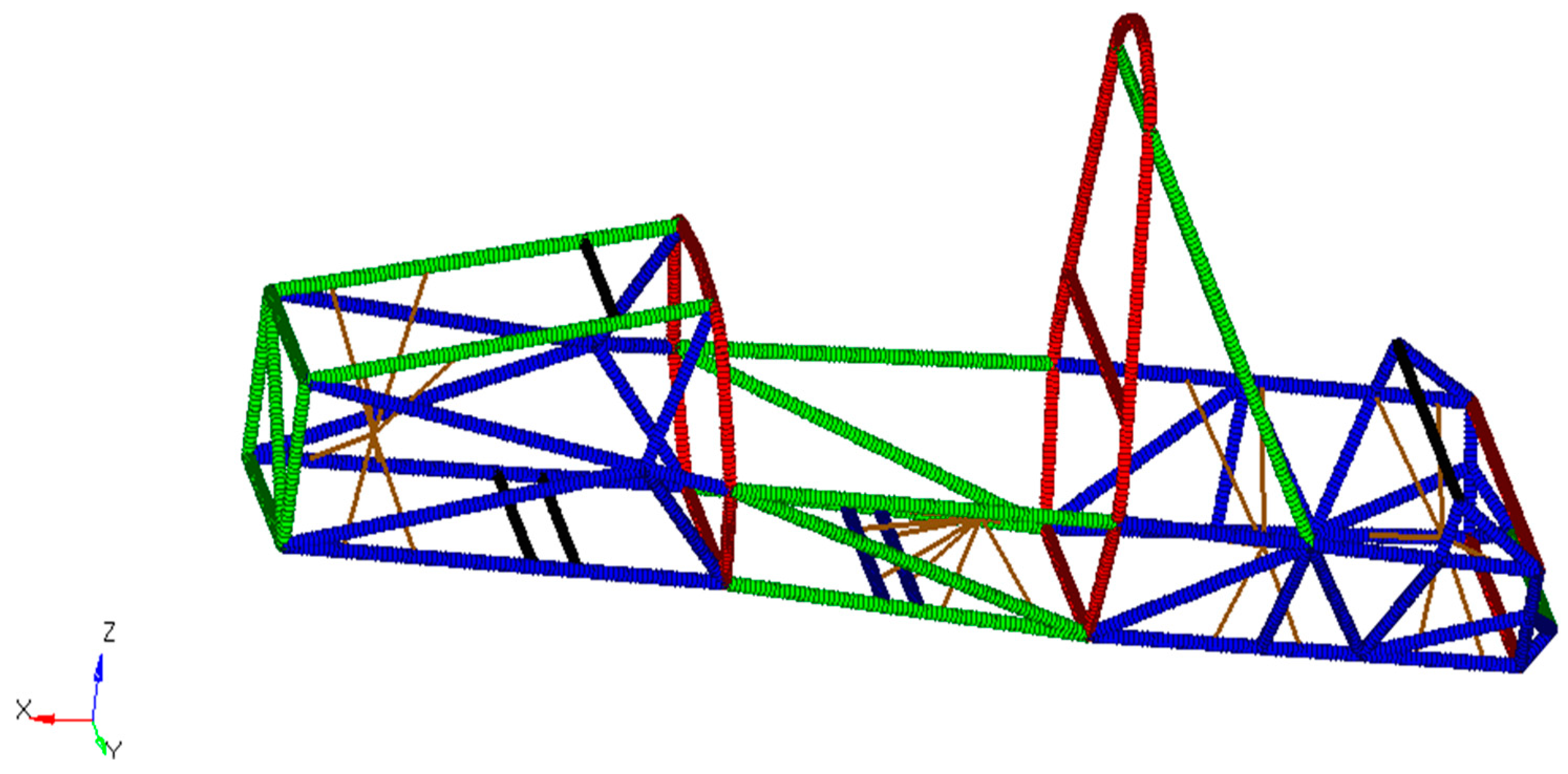

2.2.2. Establishment Process

- (1)

- Establishing materials: The frame is made of 4130 steel, also known as 30CrMo, with an elastic modulus of 2.0510 MPa, a Poisson’s ratio of 0.33, a density of 7.8510 g/cm3, and an allowable stress of approximately 390 MPa;

- (2)

- Unit selection: Using Hyperbeam, create a beam unit with a uniform outer diameter of 25.4 mm for pipes and individual pipes with an outer diameter of 20 mm. Following the rules of the competition frame design section, establish four different wall thicknesses for the steel pipes: 20 mm (outer diameter) × 2.2 mm (wall thickness), 25.4 mm × 2.4 mm, 25.4 mm × 1.65 mm, and 25.4 mm × 1.25 mm;

- (3)

- Establish attributes: Create four attributes with the same names as the previously established four beam elements (for easy matching). Ensure that they correspond one by one with the beam section;

- (4)

- Grid divisions: Divide the pipe fittings into grids and set the grid size to 10 mm for efficient calculation.

2.3. Working Condition Analysis

2.3.1. Bending Conditions

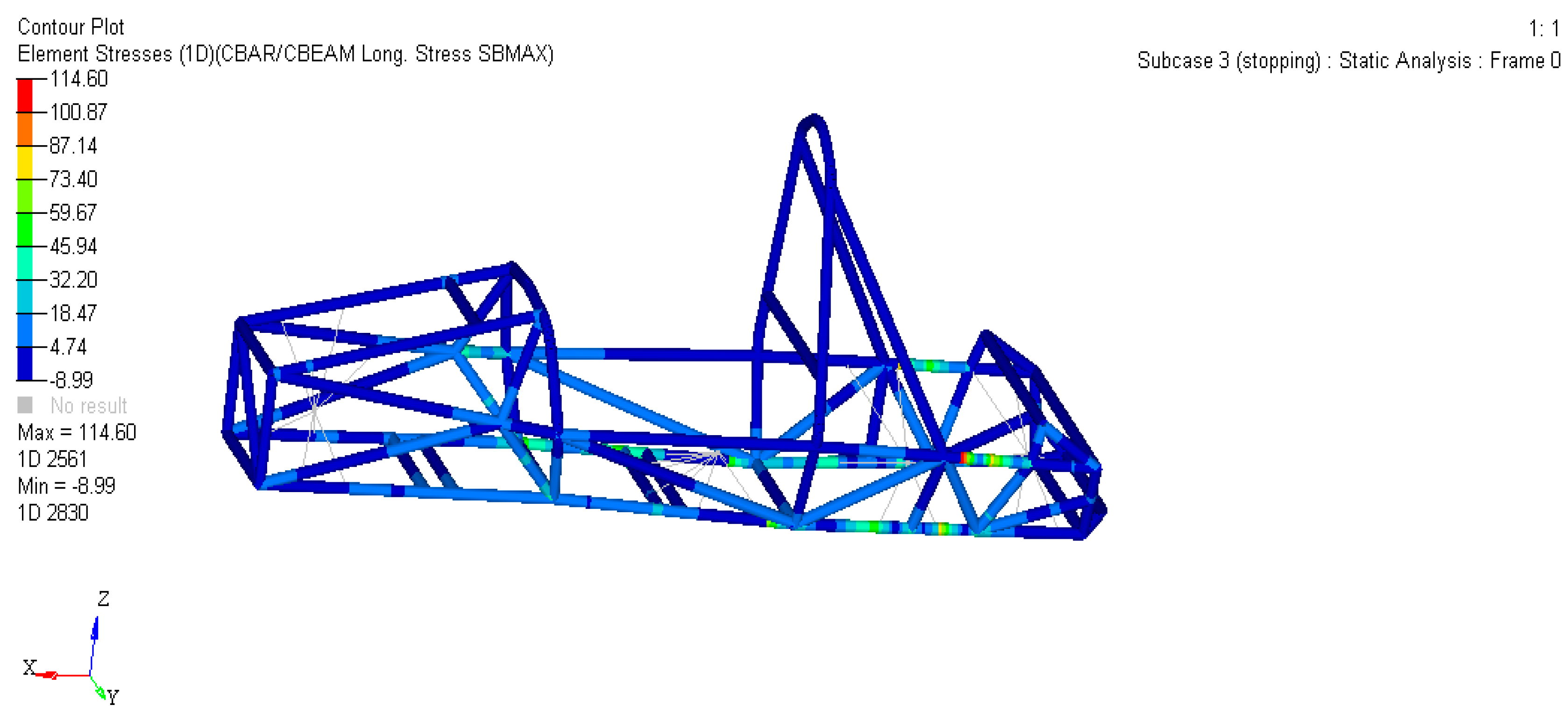

2.3.2. Emergency Braking Conditions

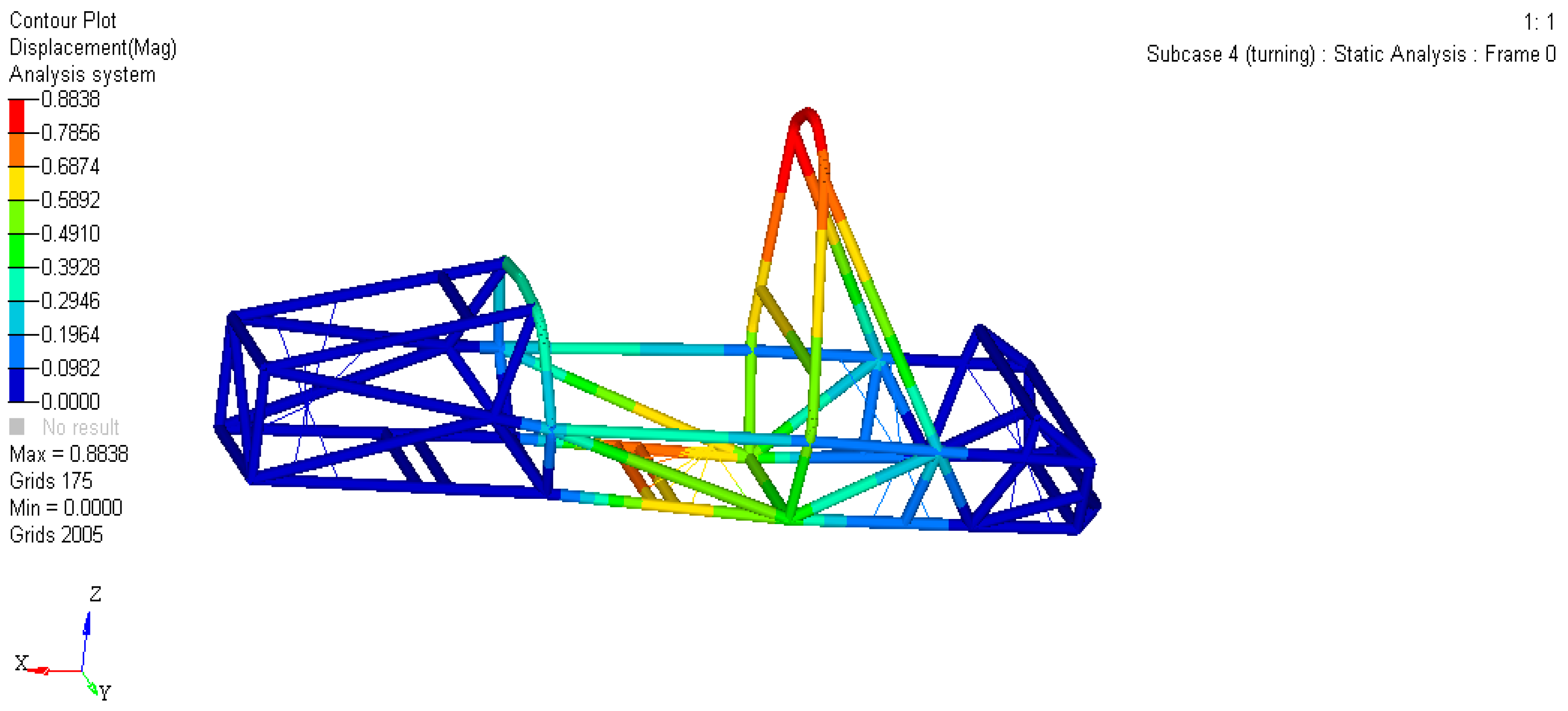

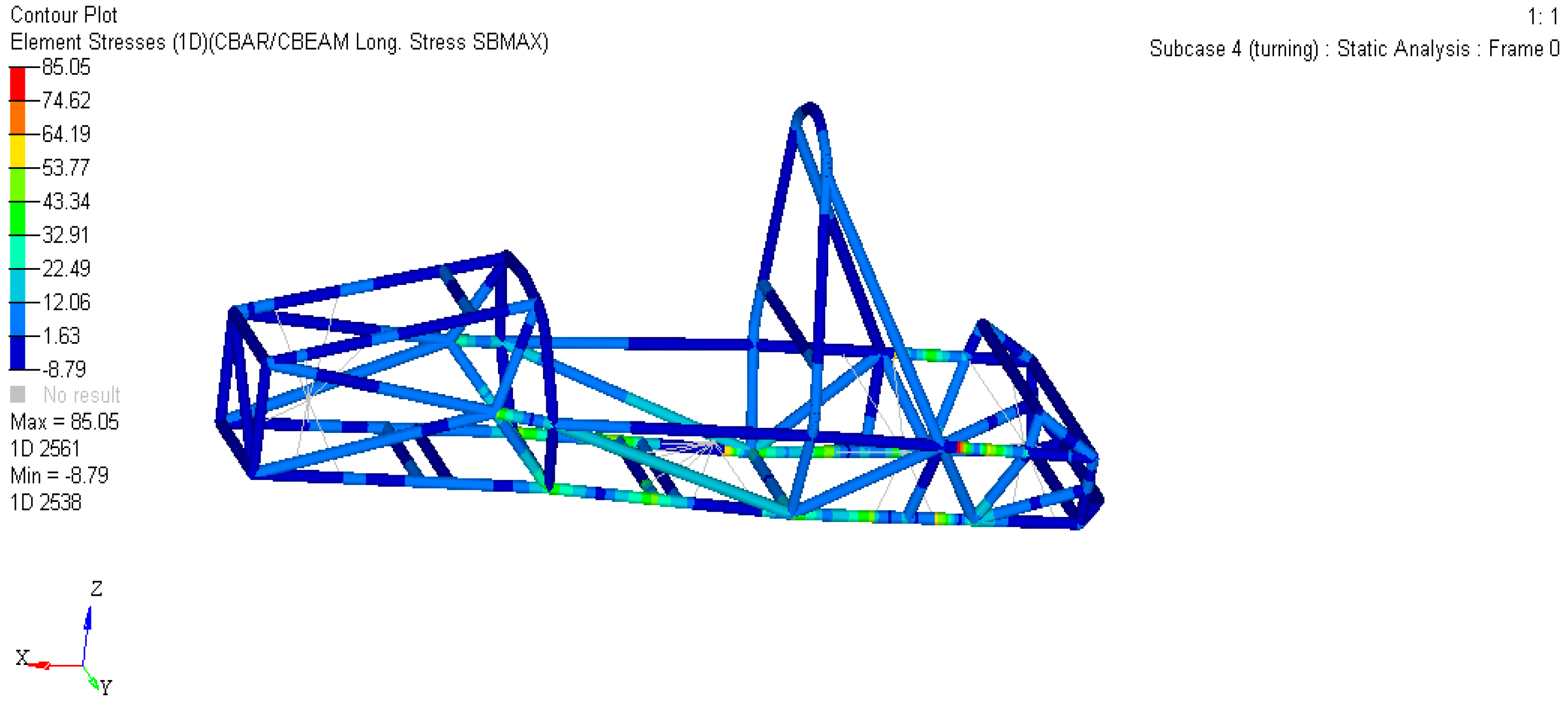

2.3.3. High-Speed Turning Conditions

2.4. Analysis of Frame Structure Stiffness

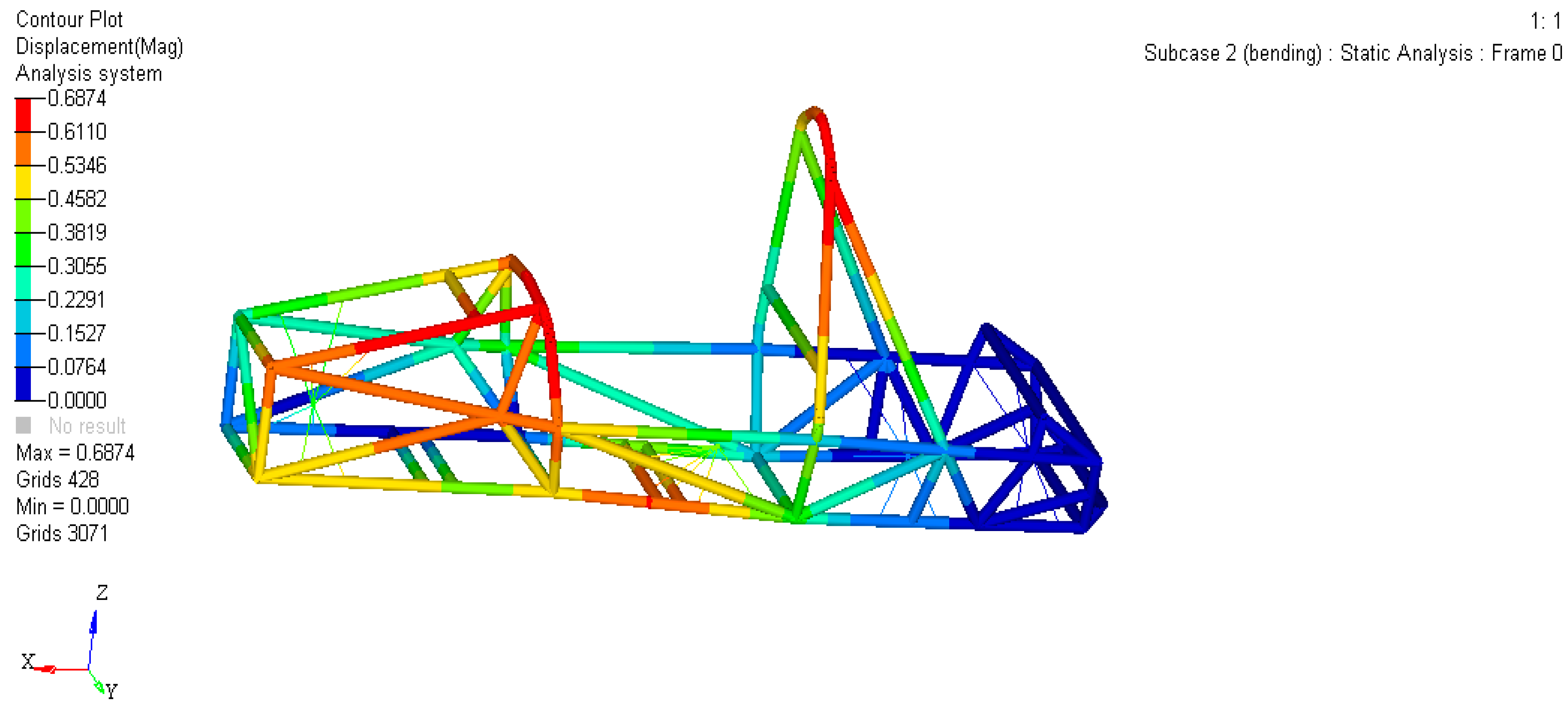

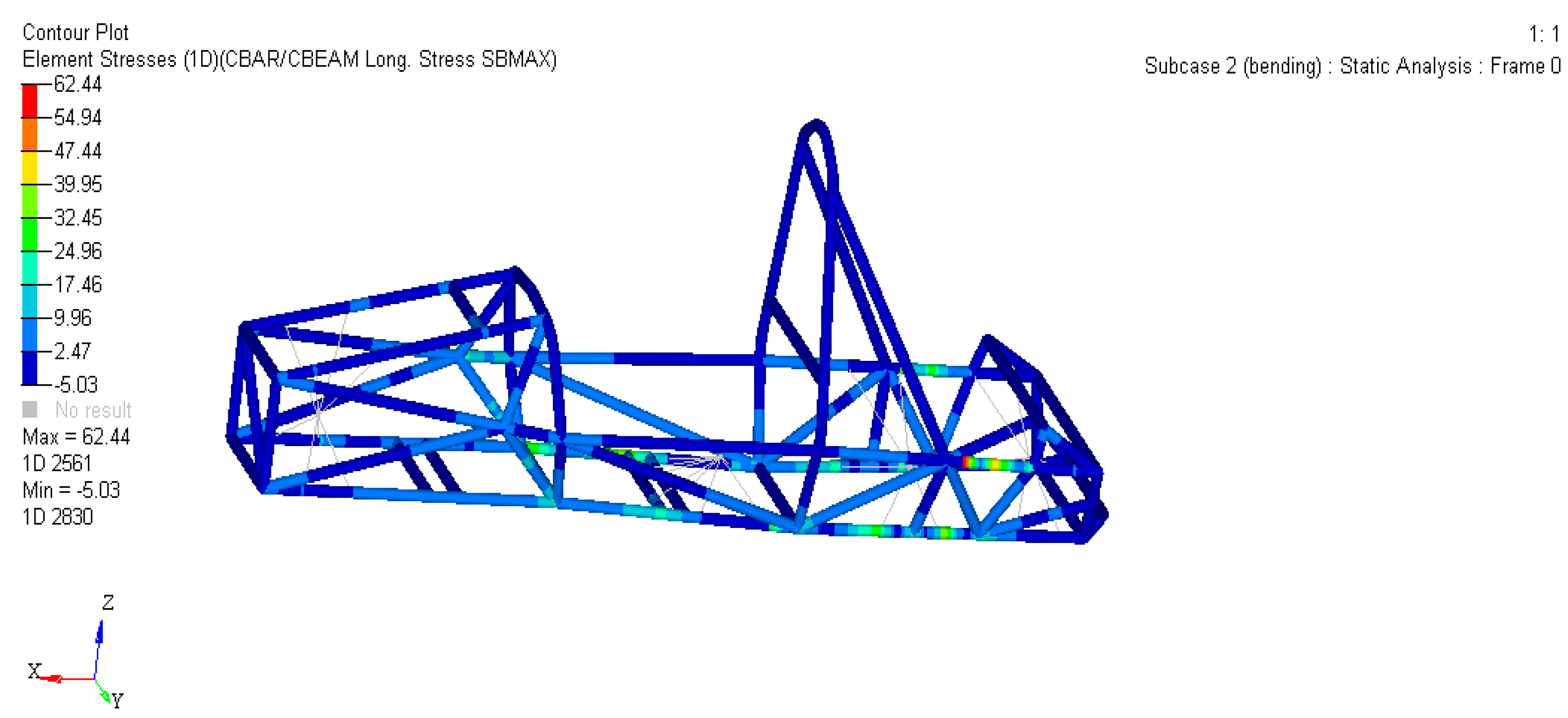

2.4.1. Bending Stiffness Analysis

2.4.2. Torsional Stiffness Analysis

2.5. Modal Analysis

2.5.1. Modal Analysis Theory

2.5.2. Calculation Process of Frame Mode

- (1)

- Establish a finite element model of the structure;

- (2)

- Set solution methods and control parameters;

- (3)

- Extracting modal results;

- (4)

- As shown in Table 2, the low-order modal frequency and modal shape of the frame are obtained through calculation. Among them, the frequencies before the first-order mode are all lower than 1 Hz, which corresponds to the six-degree-of-freedom rigid mode in free modal analysis. Therefore, considering the extraction from modes greater than 1 Hz as the first order, the result is that the lowest first-order frequency is approximately 36 Hz. The frame possesses a natural frequency, which refers to the frame’s elastic vibration frequency within a small range around its equilibrium state. When the frame experiences external excitation close to its natural frequency, resonance occurs, increasing the frame’s amplitude and consequently affecting the handling stability and driving safety of the vehicle. Generally, the frequency of road excitation is around 20 Hz, while the lowest first-order frequency of the frame is about 36 Hz. Thus, if the vehicle operates on a road with a frequency of around 20 Hz, it can avoid the frame’s natural frequency to a certain extent and prevent the occurrence of resonance effects.

3. Frame Optimization Design

3.1. Introduction to Topology Optimization Method

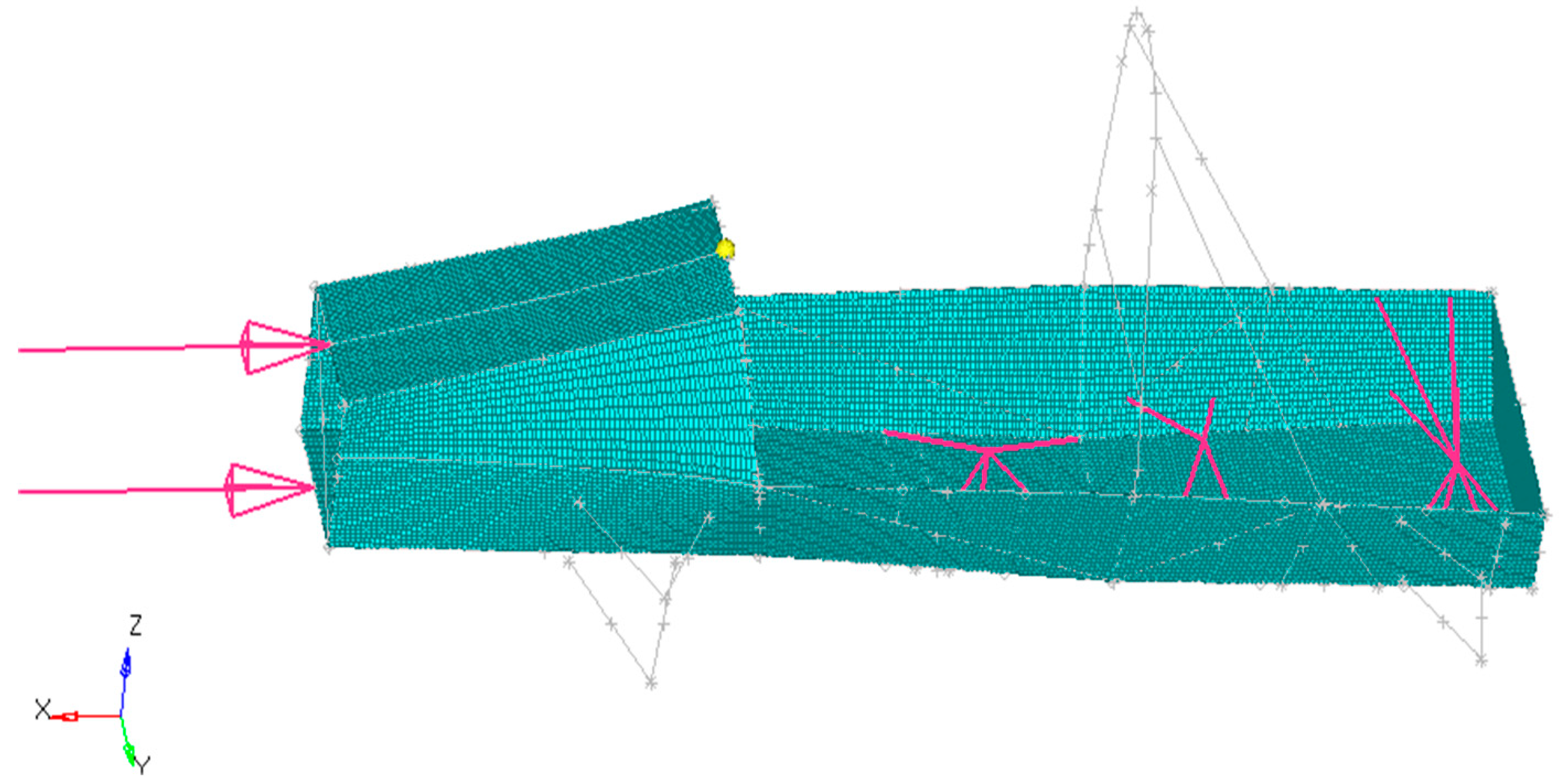

3.2. Topology Optimization of Frame

3.2.1. Topology Optimization Settings

- (1)

- Design variable: Unit density of the frame space;

- (2)

- Establish responses: Create responses such as weighted comp and mass, respectively;

- (3)

- Constraint condition: The mass of the frame design space is limited to 0.3–0.5, which means that the solved material mass accounts for 30–50% of the original mass (placement penalty factor);

- (4)

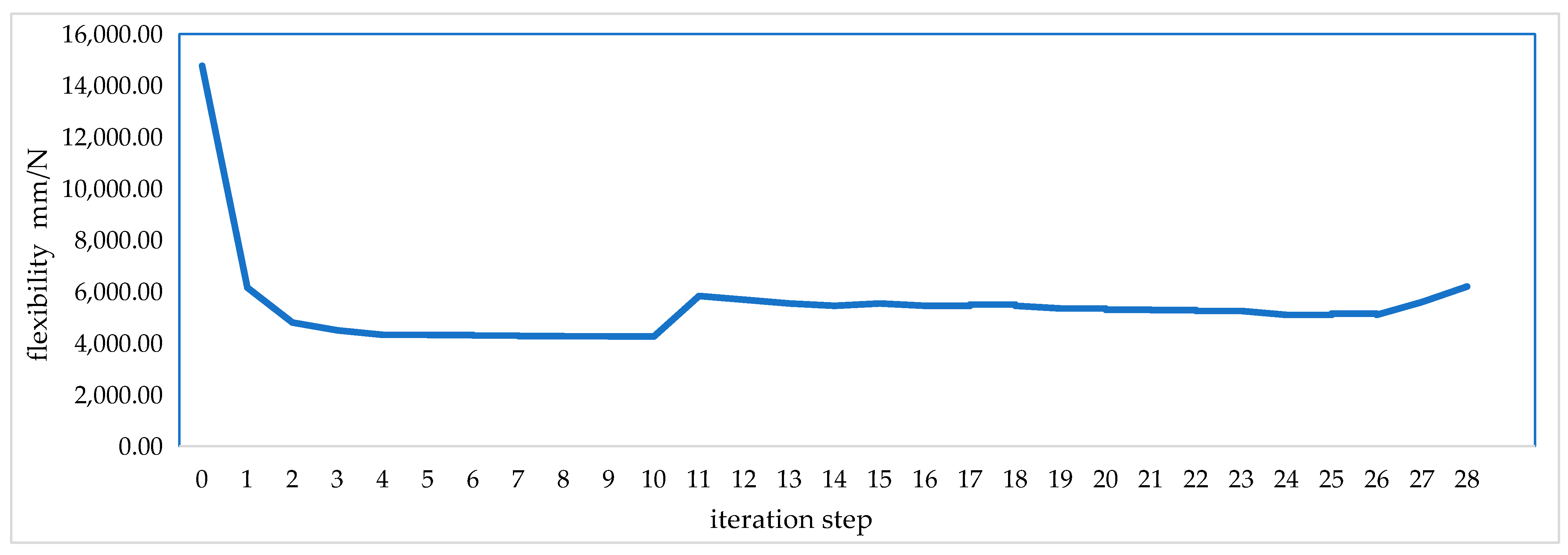

- Establish objective function: The optimization objective is flexibility, which is equivalent to the displacement formed by a unit force at that point in data, while stiffness is equivalent to the force required to cause a unit displacement at that point in data. Therefore, the objective function sets the minimum flexibility as the maximum stiffness;

- (5)

- Minimum and maximum member sizes: The minimum size needs to be greater than three times the size of the grid unit, and the maximum member size needs to be greater than two times the minimum member size. The measured unit distance is 13.15 mm, so the minimum size min-dim is set to 50 mm and the maximum size max-dim is set to 100 mm;

- (6)

- Symmetric constraint: The frame structure is symmetrical about the longitudinal plane. Since only the degrees of freedom of the left front suspension are fixed in the load step, a symmetric constraint about the xoz plane is applied in the design variables in order to simultaneously consider the right front suspension.

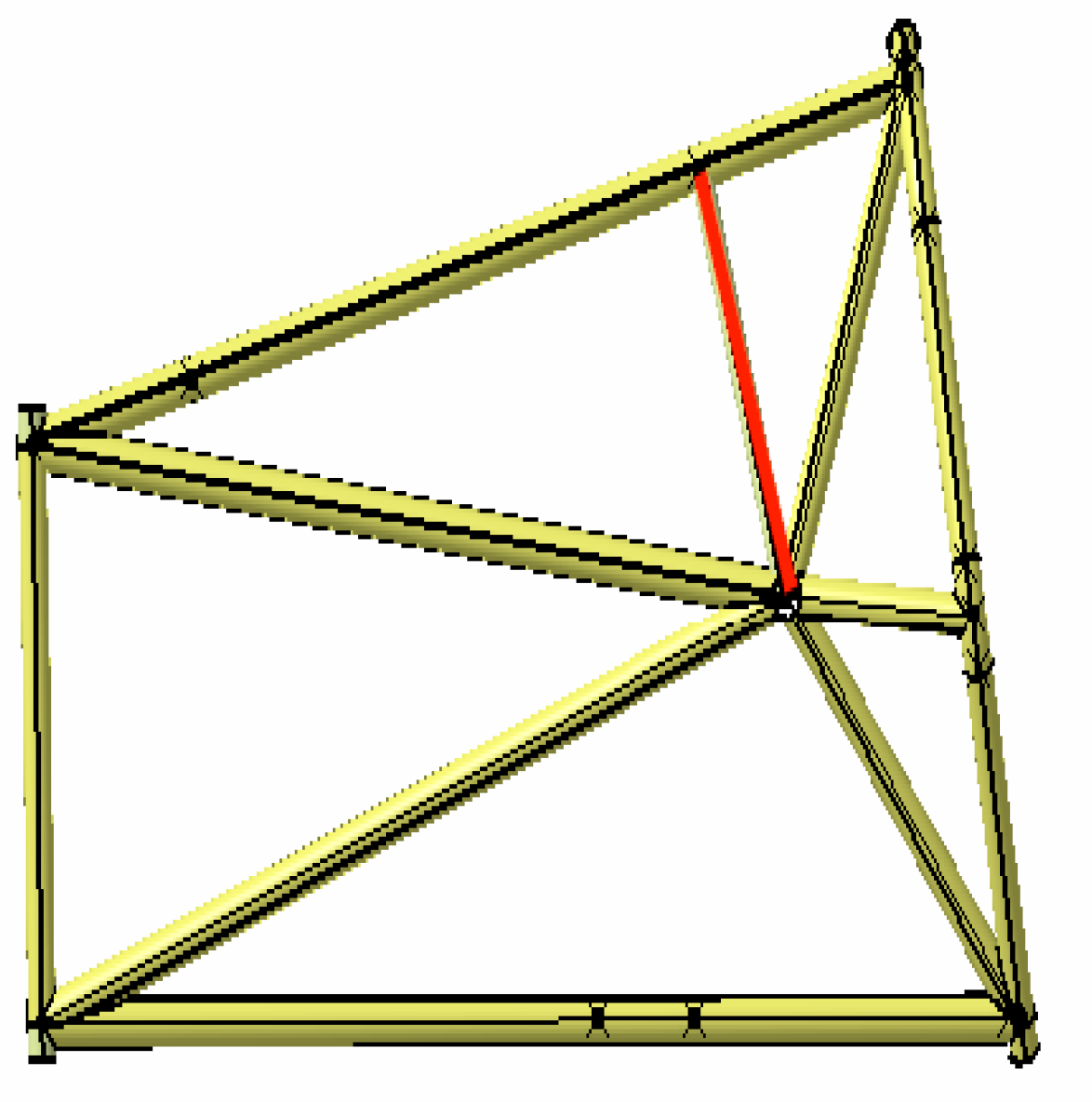

3.2.2. Topology Optimization Results

3.3. Size Optimization

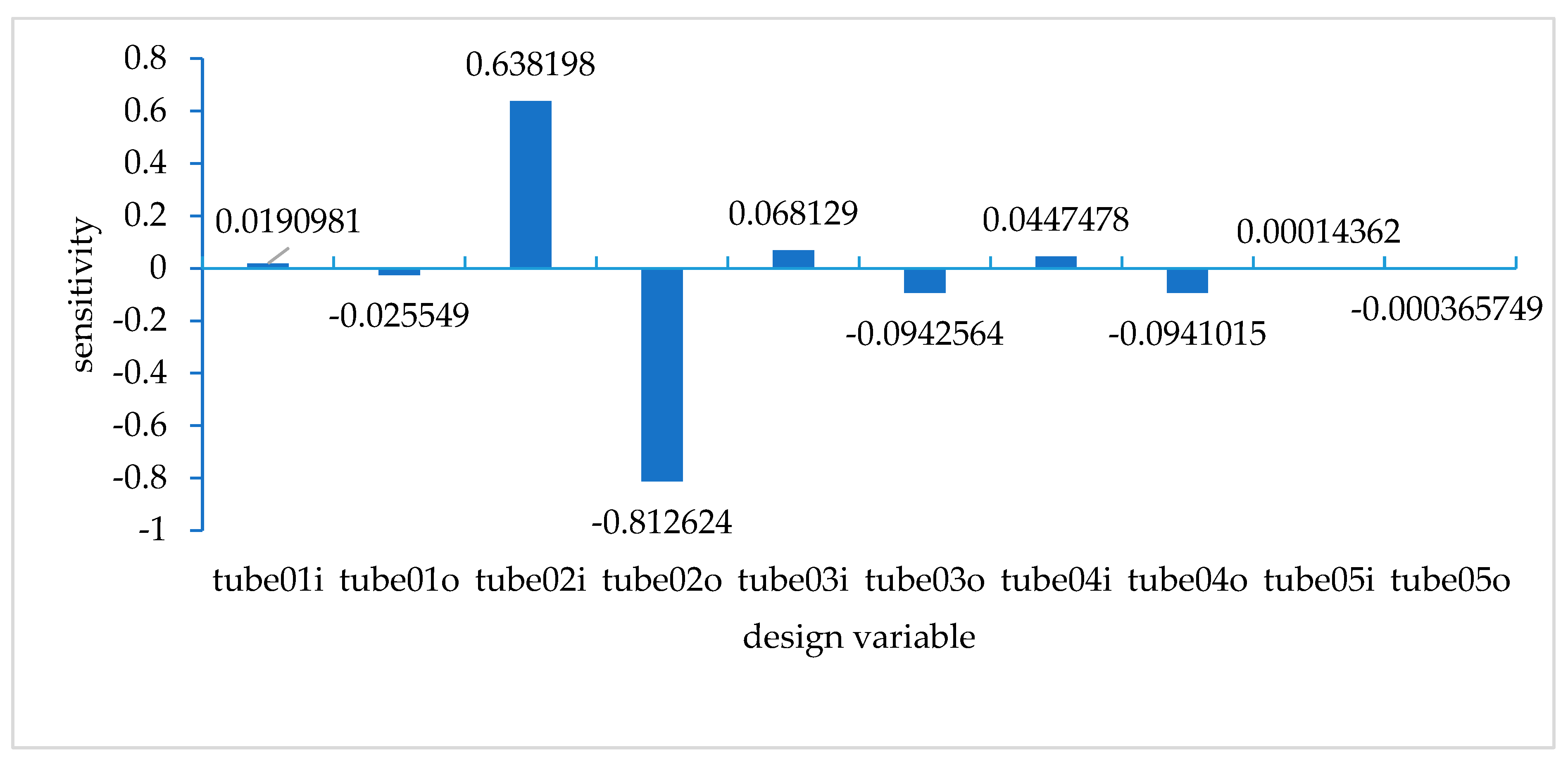

3.3.1. Sensitivity Analysis

- (1)

- Solving the original finite element model: According to the geometric parameters and material parameters of the original finite element model, the numerical solution of the target physical quantity represented by the displacement field is obtained by solving the static, dynamic, or steady-state analysis problems. This numerical solution is used to solve the following adjoint problem;

- (2)

- Establish the motion balance equation: There is a relationship between the structural performance parameter g and displacement as follows:where K represents the stiffness matrix and represents the load space vector of a unit node.

- (3)

- Lagrange equation: According to the Lagrange equation, the kinematic equation of the system is expressed as a differential equation of generalized coordinates and generalized velocities. The following formula is as follows:where is the Lagrange multiplier, the structural design variable , is the constraint function, and is the Lagrange function.

- (4)

- Solving the adjoint problem: Suppose there is the following relationship between the structural performance parameter g and the displacement:where represents the adjoint displacement vector and represents the vector of the element displacement node.

- (5)

- Calculation of generalized displacement gradient: For the optimization problem with many design variables and few design tube bundles, the adjoint variable a is introduced to make

3.3.2. Optimization of Frame Size

- (1)

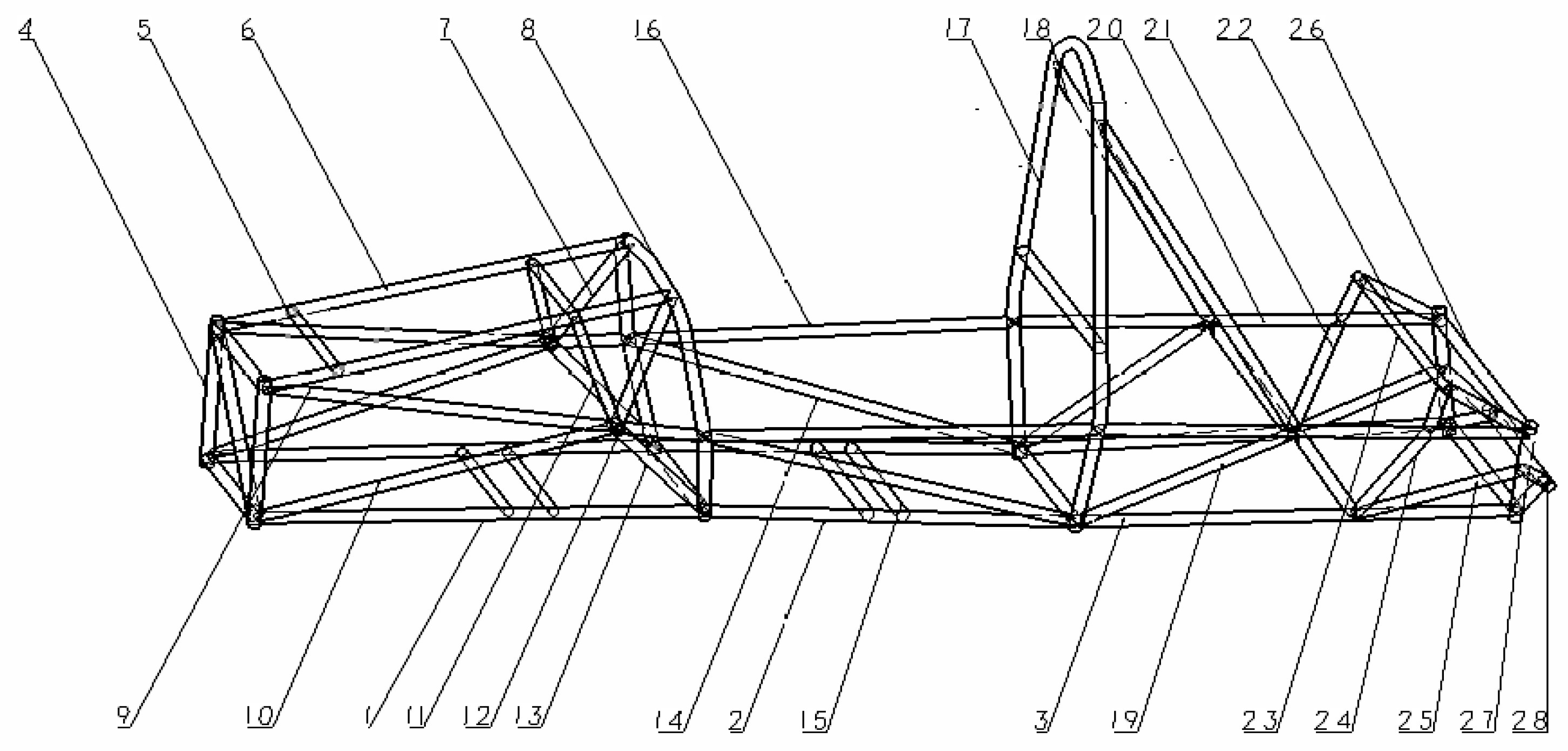

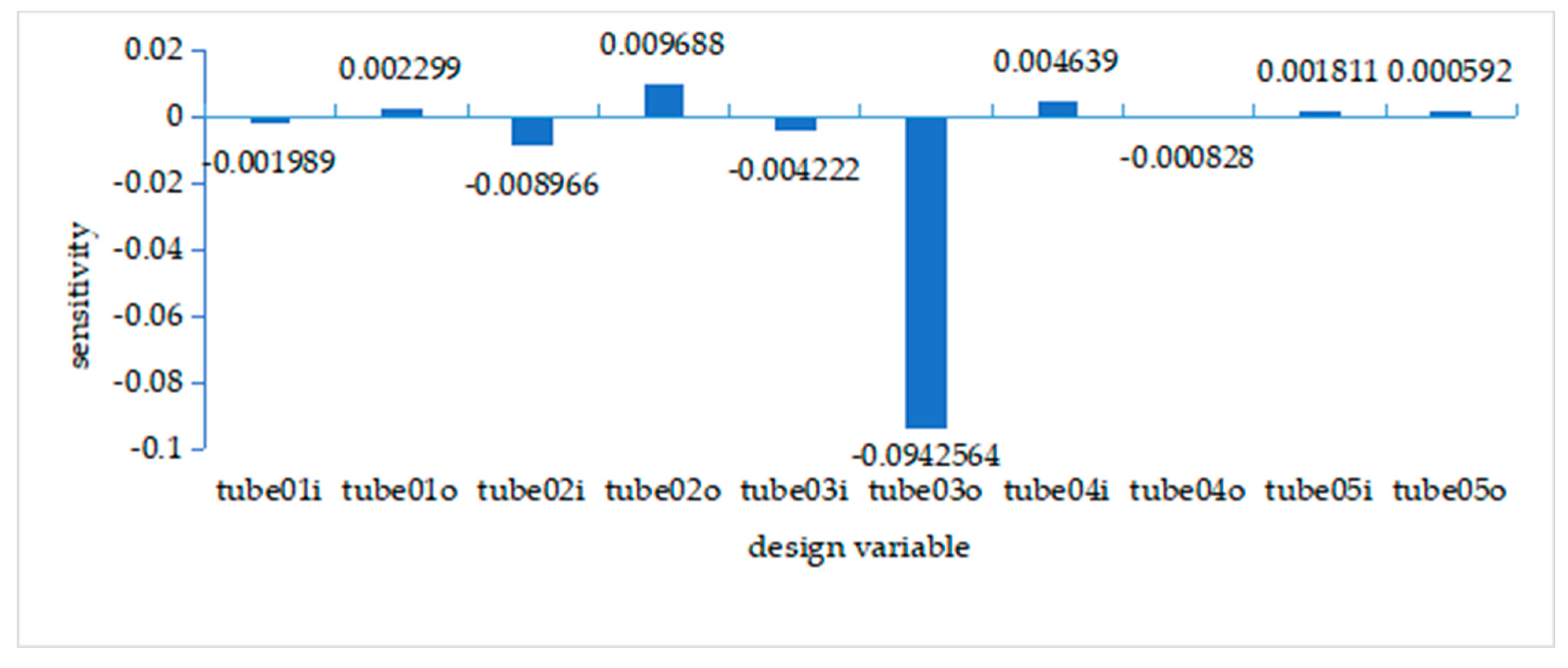

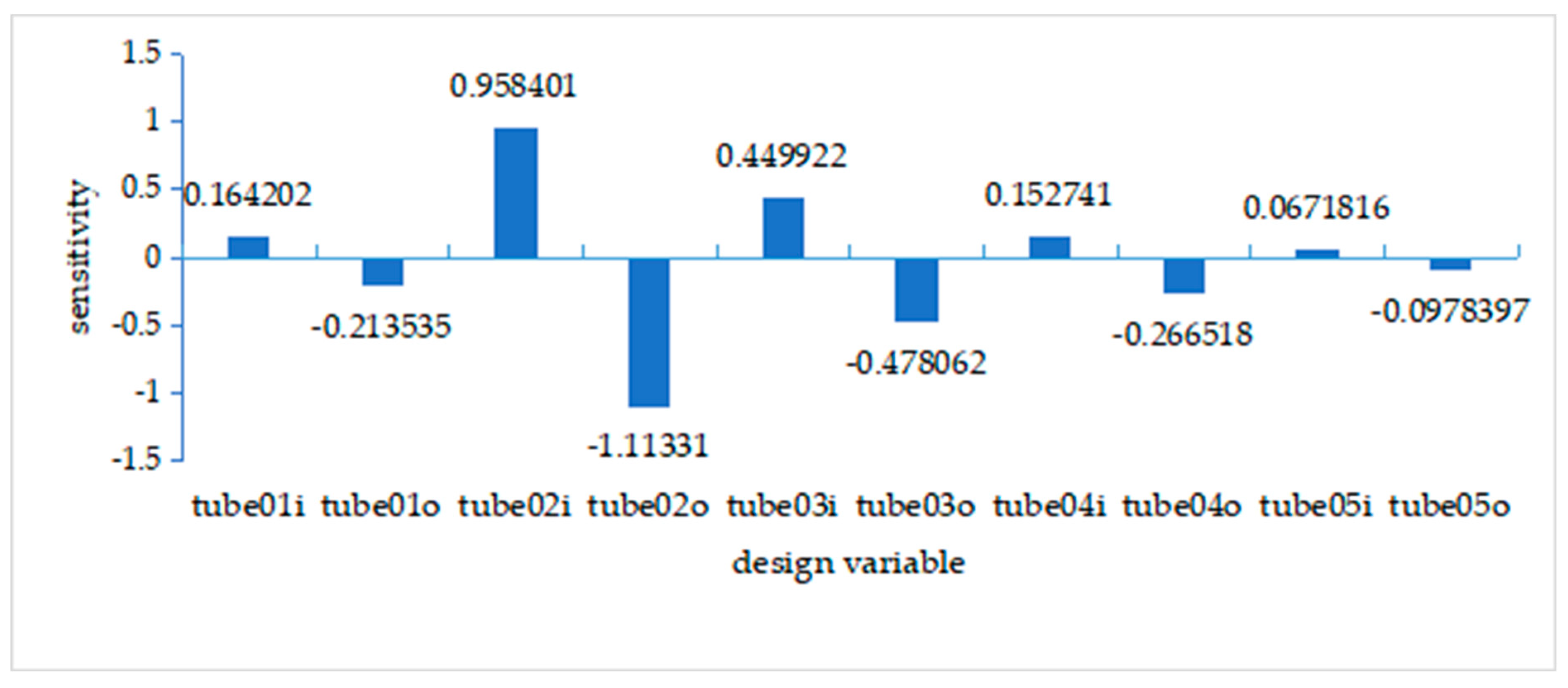

- Design variables: Use the inner and outer diameters of each pipe fitting on the frame as design variables. Because the frame is a symmetrical structure about the longitudinal plane, setting two symmetrical pipe fittings as a variable effectively improves computational efficiency. According to specific needs, the range of values for each variable should be clarified. The initial value of the inner circle radius for this racing frame is 10.3 mm, with a variation range of 1–14 mm. The initial value of the outer circle radius is 12.7 mm, with a variation range of 1–3 mm (as shown in Figure 16);

- (2)

- Establish responses: In the responses panel, establish three responses: mass, stress, and displacement;

- (3)

- Constraints: ① Because the maximum stress of the frame under three typical working conditions is 114.6 MPa, which is lower than the allowable stress and has a large optimization space, the maximum stress is set to not exceed 200 MPa. ② Respectively constrain the displacement to not exceed the original value under various working conditions; for example, the displacement does not exceed 0.3792 mm under bending conditions;

- (4)

- Set objective function: With the overall goal of minimizing the net weight of the vehicle frame, use the accuracy and output card provided in Hypermesh to define the accompanying variables and output sensitivity analysis results.

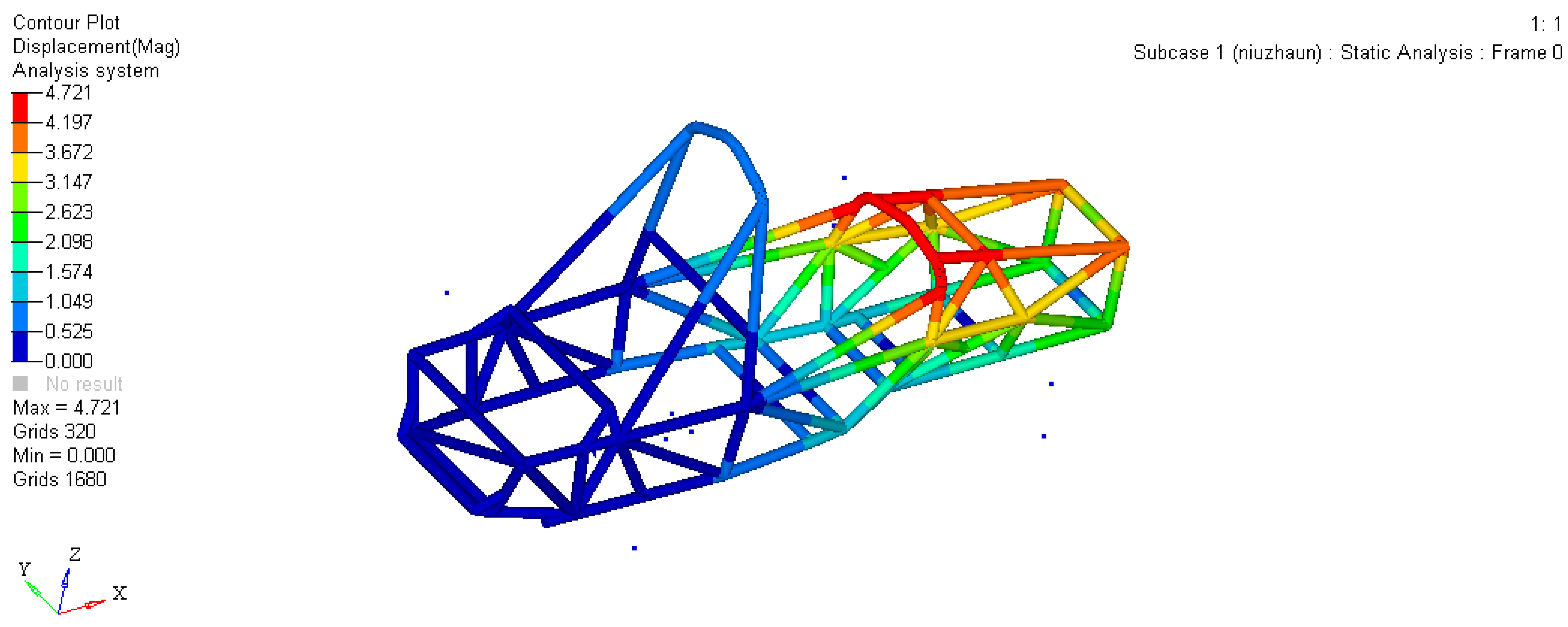

3.3.3. Analysis of Optimization Results

3.3.4. Comparison between the Optimized Frame and the Original Frame

- (1)

- Quality change: After size optimization, according to the results of sensitivity analysis, Table 2 shows that the diameter of No.2 and No.3 pipe fittings changes greatly; that is, the wall thickness of steel pipe decreases. In the solution report, the weight of the frame is reduced from 45.71 kg to 39.87 kg, which is reduced by 12.8%;

- (2)

- Strength change: As shown in Table 4, compared with the existing frame, the maximum displacement and maximum stress of the original frame have decreased to varying degrees under various working conditions, the strength performance has improved, and the modal has also been correspondingly improved;

- (3)

- Stiffness comparison: As shown in Figure 21, a force of 2000 N was applied to the optimized model under torsion conditions, resulting in a torsion angle of 0.592°. According to the formula K = T/θ, the calculated stiffness is 1718.3 Nm/°, which increases by 16.7% compared to the original torsional stiffness calculated in Section 2.4.2;

- (4)

- Modal comparison: The lowest-order modal of the frame increases by 0.75 Hz, which improves the handling stability and driving safety of the vehicle.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hetawal, S.; Gophane, M.; Ajayb, K. Aerodynamic study of formula FSAE car. Procedia Eng. 2016, 97, 1198–1207. [Google Scholar] [CrossRef]

- Song, S. Joint Study on Aerodynamics and Handling Stability of FSAE Racing Car under Unsteady Wind; Jilin University: Changchun, China, 2021. [Google Scholar]

- Ni, J.; Bin, X. Modeling and handling stability simulation of FSAE racing car based on ADAMS. Eng. Des. J. 2019, 18, 354–358. [Google Scholar]

- Vaidya, S.; Kulkarni, C. Aerodynamic development of a formula FSAE car: Initial Design Stage. Int. J. Eng. Res. Technol. 2017, 6, 14–18. [Google Scholar]

- Gui, C.; Bai, J.; Zuo, W. Simplified crash worthiness method of automotive frame for conceptual design. Thin-Walled Struct. 2018, 131, 324–335. [Google Scholar] [CrossRef]

- Yu, H.; Xu, H.; Zhou, C. Optimization of single shell body of composite material for Formula Student Racing. J. Tongji Univ. Nat. Sci. Ed. 2016, 44, 1729–1734. [Google Scholar]

- Hu, L.; Shi, Y.; Yang, Q. Optimization design of a certain type of college students’ formula racing car frame based on finite element method. J. Wuhan Univ. Sci. Technol. Nat. Sci. Ed. 2017, 38, 31–34. [Google Scholar]

- Kong, D.; Li, W.; Xiao, X. Lightweight design of Formula Racing Frame. Mech. Des. 2021, 26, 455–459. [Google Scholar]

- Abdi, M.; Ashcroft, I.; Wildman, R. Topology optimization of geometrically nonlinear structures using an evolutionary optimization method. Eng. Optim. 2018, 50, 1850–1870. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, L.; Xiao, M. Topology optimization design of heat dissipation structure based on variable density method. Comput. Integr. Manuf. Syst. 2018, 24, 117–126. [Google Scholar]

- Zhu, B.; Chen, Q.; Wang, R. Structural topology optimization using a moving morph able component-based method considering geometrical non-linearity. J. Mech. Des. 2018, 140, 081403. [Google Scholar] [CrossRef]

- Zang, J.; Peng, Y.; Liu, M. Topology optimization design of continuum structures based on multi-performance constraints. Comput. Integr. Manuf. Syst. 2022, 28, 1746. [Google Scholar]

- Jung, T.; Lee, J.; Nomura, T.; Dede, E. Inverse design of three-dimensional fiber reinforced composites with spatially-varying fiber size and orientation using multiscale topology optimization. Compos. Struct. 2022, 279, 114768. [Google Scholar] [CrossRef]

- Zhao, F. A nodal variable ESO (BESO) method for structural topology optimization. Finite Elem. Anal. Des. 2019, 86, 34–40. [Google Scholar] [CrossRef]

- Xie, L.; Zhang, Y.; Ge, M. Topology optimization of heat sink based on variable density method. Energy Rep. 2022, 8, 718–726. [Google Scholar] [CrossRef]

- Christensen, J.; Bastien, C. Introduction to structural optimization and its potential for development of vehicle safety structures. In Book: Nonlinear Optimization of Vehicle Safety Structures; Butterworth-Heinemann: Oxford, UK, 2019; pp. 169–207. [Google Scholar]

- Rodriguez, T.; Montemurro, M.; Texier, P.; Pailhès, J. Structural displacement requirement in a topology optimization algorithm based on isogeometric entities. J. Optim. Theory Appl. 2020, 184, 250–276. [Google Scholar] [CrossRef]

- Smith, H.; Norato, J. A MATLAB code for topology optimization using the geometry projection method. Struct. Multidiscip. Optim. 2020, 62, 1579–1594. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, Q.; Feng, W.; Youn, S.; Guo, X. Explicit structural topology optimization using boundary element method-based moving morphable void approach. Int. J. Numer. Methods Eng. 2021, 122, 6155–6179. [Google Scholar] [CrossRef]

- Lu, J.; Ding, J. Direct differential method for sensitivity analysis of multibody system dynamics design. J. Qingdao Univ. Eng. Technol. Ed. 2019, 19, 76–79. [Google Scholar]

- Blondel, M.; Berthet, Q.; Cuturi, M. Efficient and modular implicit differentiation. Adv. Neural Inf. Process. Syst. 2022, 35, 5230–5242. [Google Scholar]

- Wang, B.; Yuan, Z.; Hu, J.; Yao, W. Simulation Analysis and Experimental Study of Baja Racing Car Frame Based on Special Working Conditions. SAE Technical Paper 2023, 214–232. [Google Scholar]

- Lyduch, K.; Szymanski, S.; Nowak, M. The frame design of a three-wheeled vehicle for a student competition using topology optimization. Int. J. Interact. Des. Manuf. 2022, 16, 927–942. [Google Scholar] [CrossRef]

- Fu, S.; Li, Y.; Xiong, X.; Hu, L.; Jun, H.; Zhou, S. Optimal design of the frame of baja racing car for college students. In Proceedings of the China SAE Congress 2020: Selected Papers, Shanghai, China, 27–29 October 2022; pp. 293–310. [Google Scholar]

- Krzikalla, D.; Sliva, A.; Petru, J. On modelling of simulation model for racing car frame torsional stiffness analysis. Alex. Eng. J. 2020, 59, 5123–5133. [Google Scholar] [CrossRef]

- Napolitano, G.; Adiletta, G.; Farroni, F.; Sakhnevych, A.; Timpone, F. Tire wear sensitivity analysis and modeling based on a statistical multidisciplinary approach for high-performance vehicles. Lubricants 2023, 11, 269. [Google Scholar] [CrossRef]

- He, Y.; Pang, J. Optimization design of suspension geometric parameters of formula student race vehicle based on ADAMS. In Proceedings of the 2022 International Conference on Manufacturing, Industrial Automation and Electronics (ICMIAE), Rimini, Italy, 26–28 August 2022; pp. 164–169. [Google Scholar]

- Plante, E.; Bideaux, E.; Delhommais, M.; Gerard, M. Large size optimization problem for power management in a fuel cell electric race car using combinatorial approach. In Proceedings of the IECON 2022–48th Annual Conference of the IEEE Industrial Electronics Society, Brussels, Belgium, 17–20 October 2022; pp. 125–138. [Google Scholar]

- Jang, W. Optimal design for torsional stiffness of the tubular space frame of a low-cost single seat race Car. J. Korea Acad.-Ind. Coop. Soc. 2021, 15, 5955–5962. [Google Scholar]

- Yuan, S.; Lin, J. Design and lightweight of FSAE racing car frame. J. Zhengzhou Univ. (Eng. Ed.) 2018, 39, 18–24. [Google Scholar]

- Chen, H.; Lu, C.; Liu, Z. Structural modal analysis and optimization of SUV door based on response surface method. Shock Vib. 2020, 185–206. [Google Scholar] [CrossRef]

- Li, K.; Cheng, G. Structural topology optimization of elastoplastic continuous under shakedown theory. Int. J. Numer. Methods Eng. 2022, 123, 4459–4482. [Google Scholar] [CrossRef]

- Xu, S.; Liu, J.; Zou, B. Stress constrained multi-material topology optimization with the ordered SIMP method. Comput. Methods Appl. Mech. Eng. 2021, 373, 113453. [Google Scholar] [CrossRef]

- Kijanski, W.; Barthold, F. Two-scale shape optimisation based on numerical homogenisation techniques and variational sensitivity analysis. Comput. Mech. 2021, 67, 1021–1040. [Google Scholar] [CrossRef]

- Chun, J. Reliability-Based design optimization of structures using complex-step approximation with sensitivity analysis. Appl. Sci. 2021, 11, 4708. [Google Scholar] [CrossRef]

| Literature | Research Content |

|---|---|

| [22] | Local topology optimization, performance improvement, no weight reduction, and no sensitivity analysis. |

| [23] | Local topology optimization, performance improvement, and the mass were reduced by size optimization but without introducing sensitivity analysis. |

| [24] | Local topology optimization, reduced the quality but without introducing sensitivity analysis. |

| [25] | Sensitivity analysis was introduced to improve the torsional stiffness without lightweight design. |

| [26,27,28] | Sensitivity analysis was introduced into other fields of racing cars, and the lightweight design of the studied components was carried out. |

| This paper | Global topology optimization, performance improvement, accuracy improvement, sensitivity analysis is introduced into the field of racing car frame, and then lightweight design is carried out through size optimization. |

| Modal Order | First Order | Second Order | Third Order | Fourth Order | Fifth Order | Sixth Order |

|---|---|---|---|---|---|---|

| Natural frequency | 36 Hz | 45 Hz | 71 Hz | 79 Hz | 90 Hz | 118 Hz |

| Number | Before Optimization | After Optimization | Revised by | |||

|---|---|---|---|---|---|---|

| Inside Diameter/mm | Outside Diameter/mm | Inside Diameter/mm | Outside Diameter/mm | Inside Diameter/mm | Outside Diameter/mm | |

| 1 | 23.4 | 25.4 | 23.6 | 25.5 | 23.6 | 25.4 |

| 2 | 23.4 | 25.4 | 16 | 18.2 | 16 | 18 |

| 3 | 23.4 | 25.4 | 18.9 | 20.2 | 19 | 20 |

| 4 | 23.4 | 25.4 | 23.7 | 25.6 | 23.6 | 25.4 |

| 5 | 23.4 | 25.4 | 23.7 | 25.6 | 23.6 | 25.4 |

| Working Condition | Original Frame | Existing Frame | Relative Optimization Quantity | |||

|---|---|---|---|---|---|---|

| Maximum Displacement/mm | Maximum Stress/MPa | Maximum Displacement/mm | Maximum Stress/MPa | Maximum Displacement/mm | Maximum Stress/MPa | |

| Bending | 0.6847 | 62.44 | 0.4276 | 41.68 | 37.5% | 33.2% |

| Braking | 1.125 | 114.6 | 0.9835 | 98.79 | 12.5% | 13.7% |

| Turning | 0.8838 | 85.05 | 0.8454 | 83.66 | 4.34% | 1.63% |

| Reverse | 3.502 | 200.1 | 3.392 | 198.4 | 3.14% | 0.849% |

| Modal | 35.99 Hz | 36.74 Hz | / | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, W.; Lu, Y.; Wang, P.; Wang, Y.; Wang, J. Double Optimization Design of the Formula Racing Car Frame Based on the Variable Density Method and the Joint Variable Method. Appl. Sci. 2023, 13, 10155. https://doi.org/10.3390/app131810155

Ma W, Lu Y, Wang P, Wang Y, Wang J. Double Optimization Design of the Formula Racing Car Frame Based on the Variable Density Method and the Joint Variable Method. Applied Sciences. 2023; 13(18):10155. https://doi.org/10.3390/app131810155

Chicago/Turabian StyleMa, Weiyang, Yanhui Lu, Pengyu Wang, Yongjia Wang, and Jiahao Wang. 2023. "Double Optimization Design of the Formula Racing Car Frame Based on the Variable Density Method and the Joint Variable Method" Applied Sciences 13, no. 18: 10155. https://doi.org/10.3390/app131810155

APA StyleMa, W., Lu, Y., Wang, P., Wang, Y., & Wang, J. (2023). Double Optimization Design of the Formula Racing Car Frame Based on the Variable Density Method and the Joint Variable Method. Applied Sciences, 13(18), 10155. https://doi.org/10.3390/app131810155