Investigation into the Impact of Humidity on Early Age Cement Concrete Pavement Behavior in Hot and Humid Regions

Abstract

:1. Introduction

2. The 3D Moisture Simulation Program for Cement Concrete Pavement Panels

2.1. Principles and Equations

2.2. Conditions for the Fixed Solution of the Three-Dimensional Humidity Diffusion Differential Equation

2.3. The 3D Humidity Field Diffusion Difference Derivation

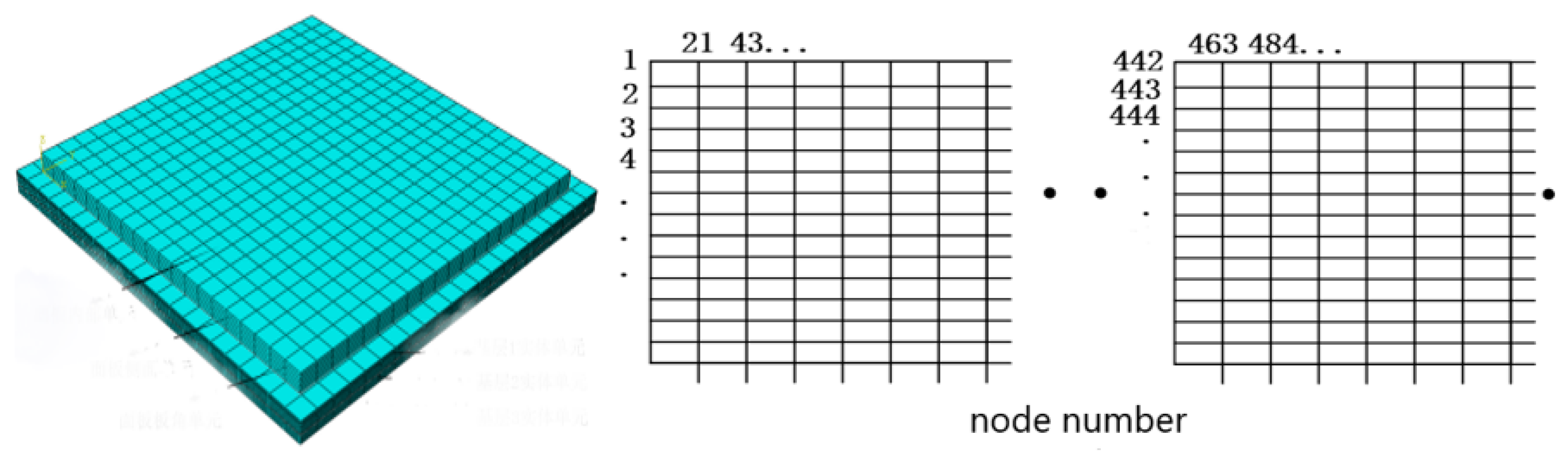

2.4. The 3D Meshing

3. Early Behavior of Cement Concrete Pavement Panels Moisture Field

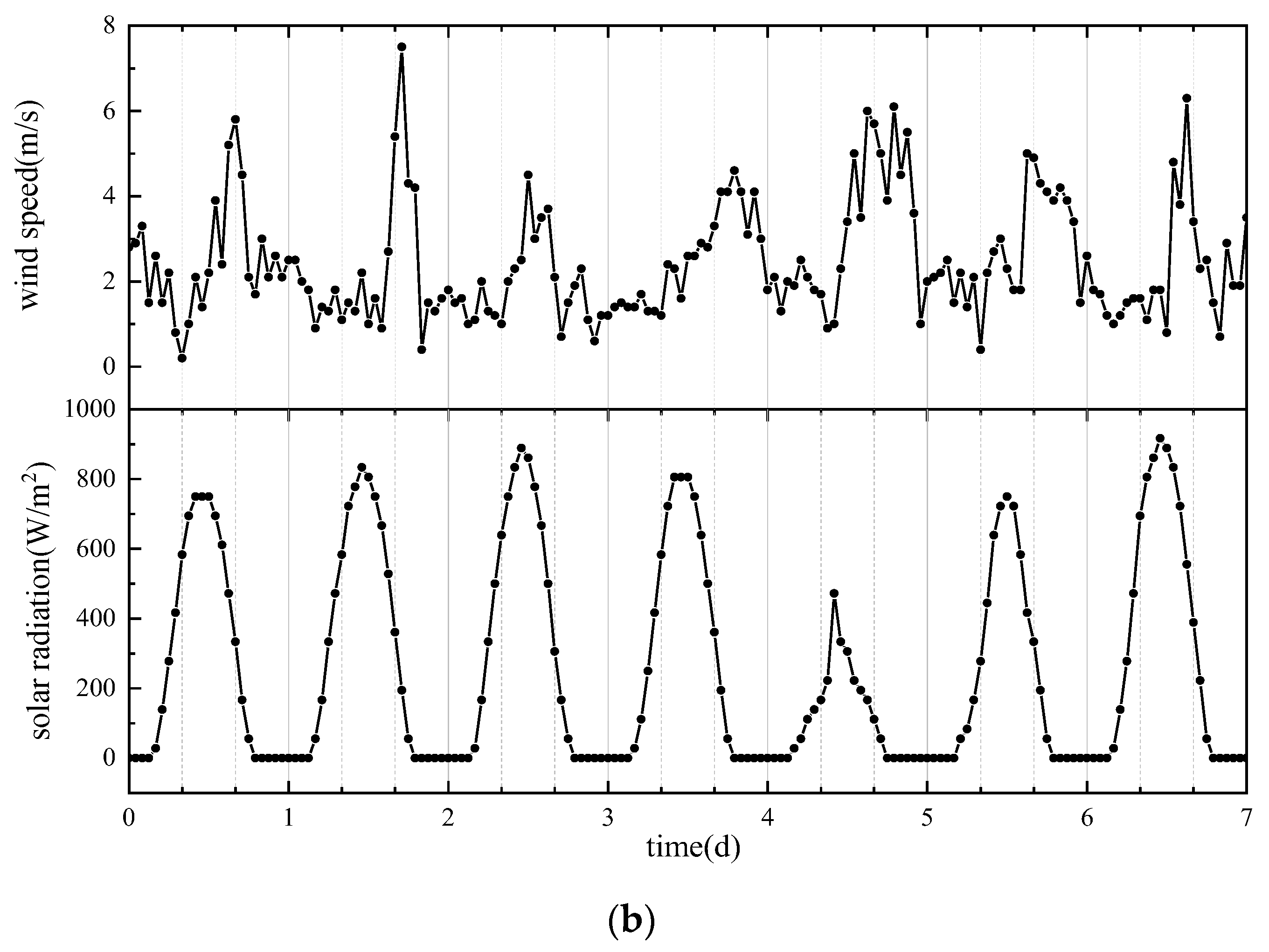

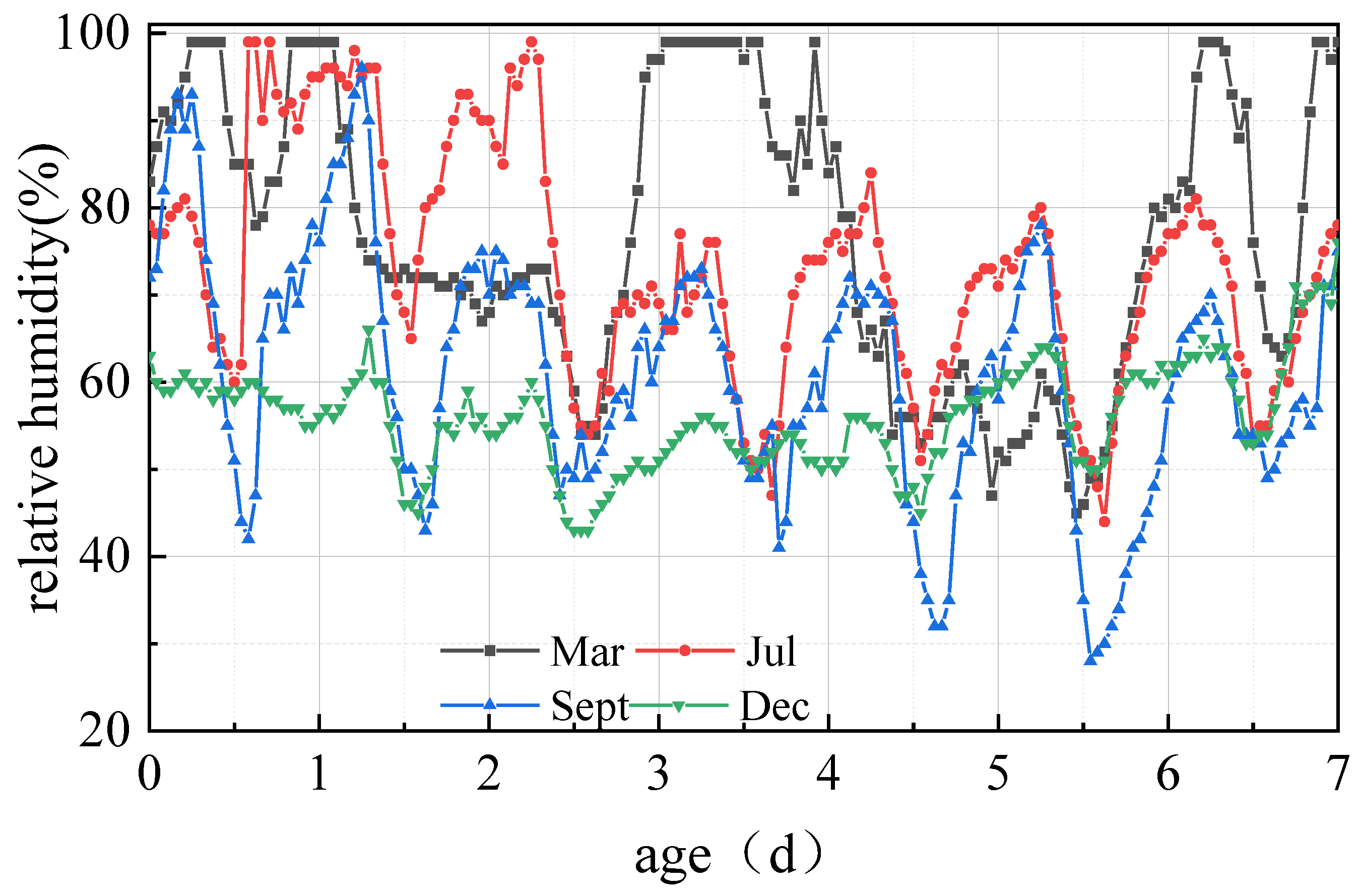

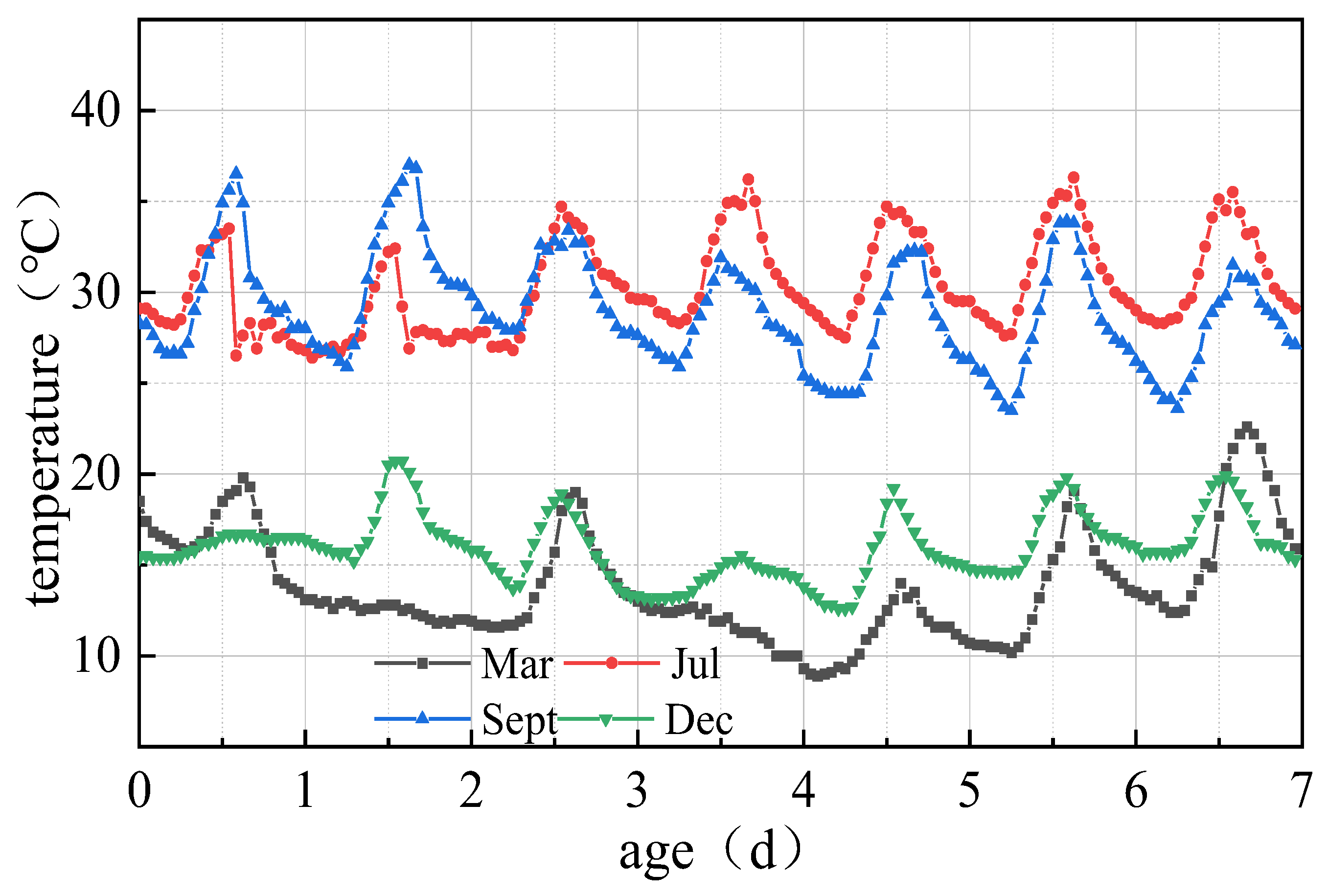

3.1. Design of Working Conditions

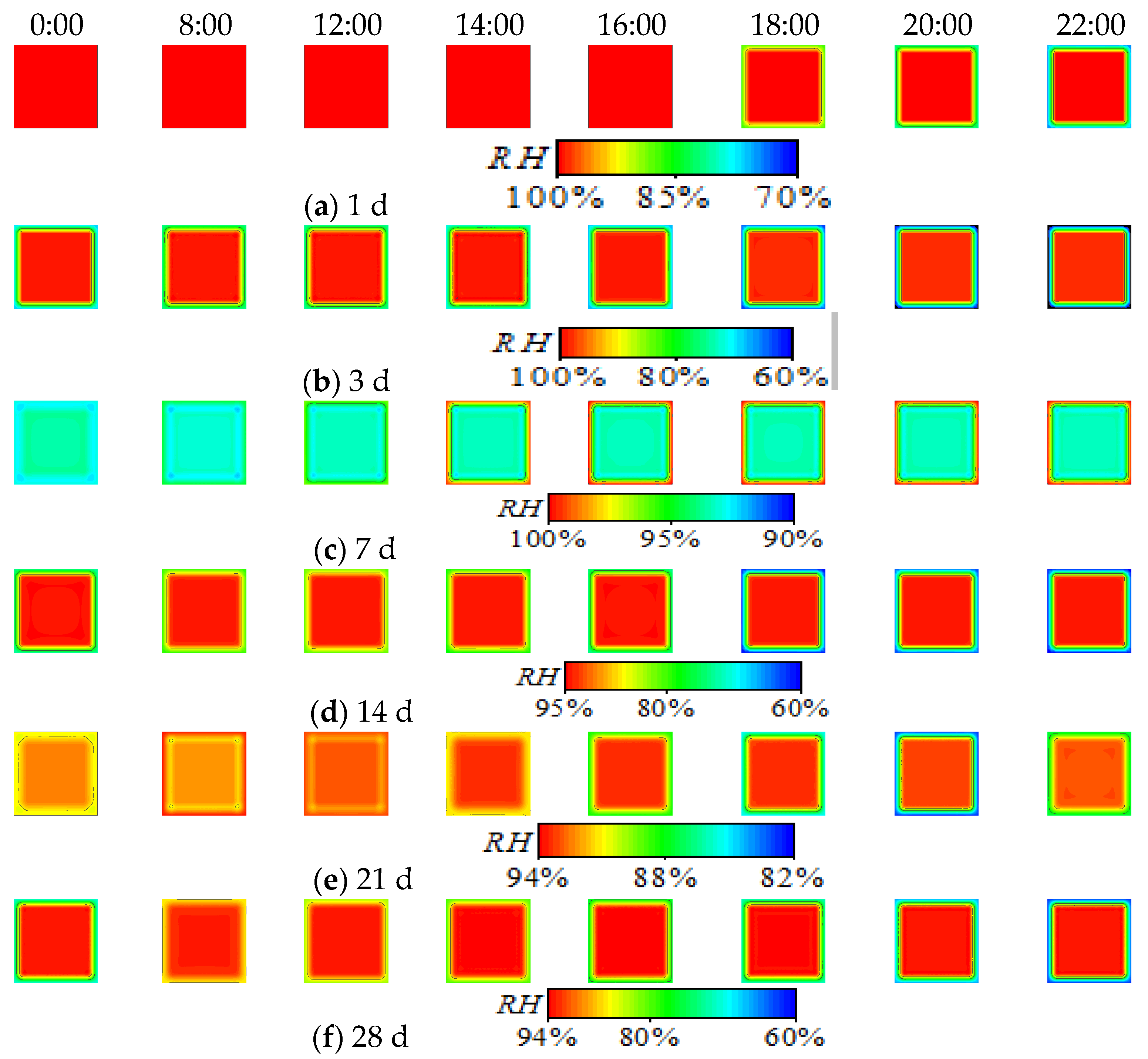

3.2. Three-Dimensional Moisture Field Trait Distribution of Road Panels at Early Ages

3.3. Influence of Different Factors on the Moisture Field of Pavement Panels at Early Ages

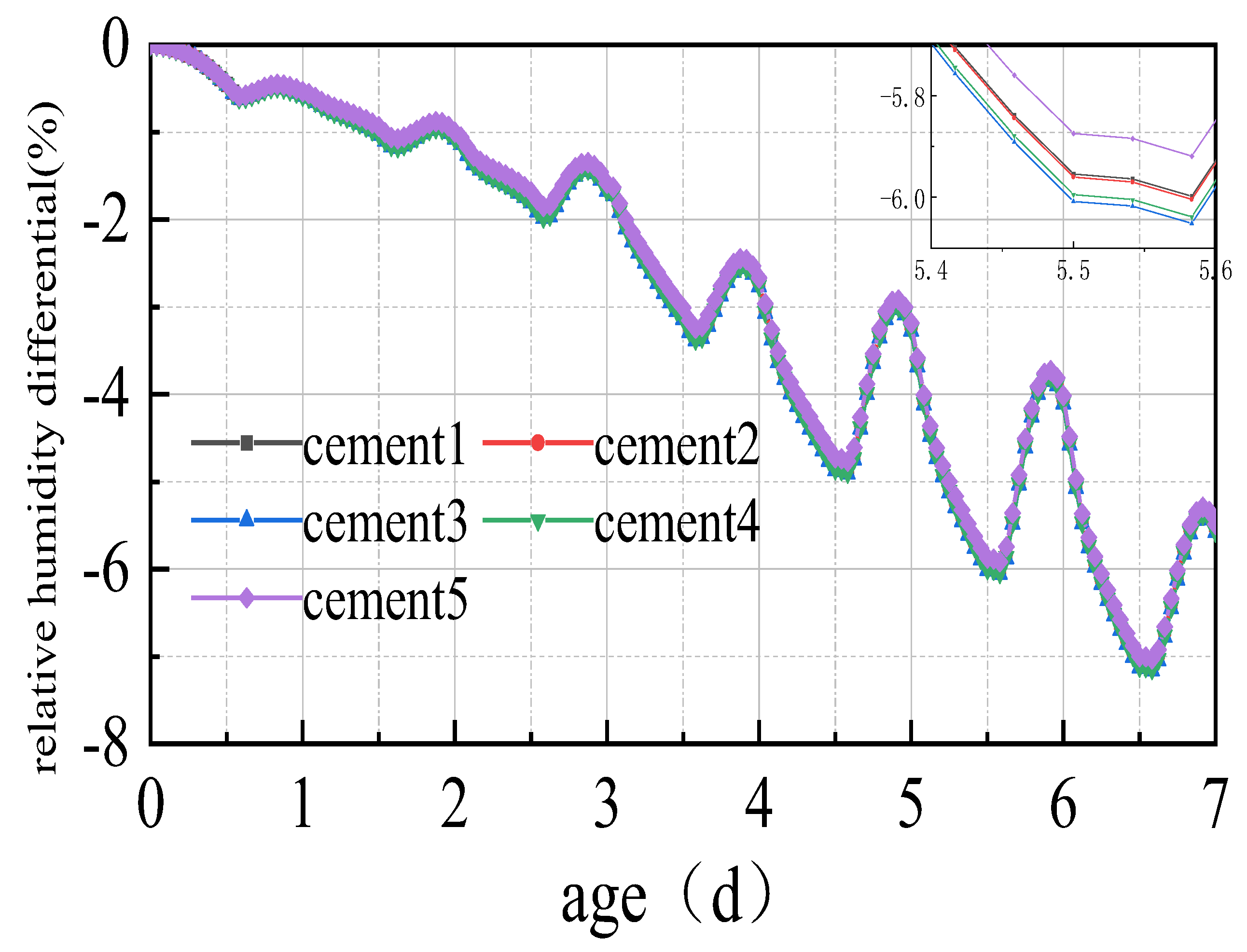

3.3.1. Effect of Cement Type

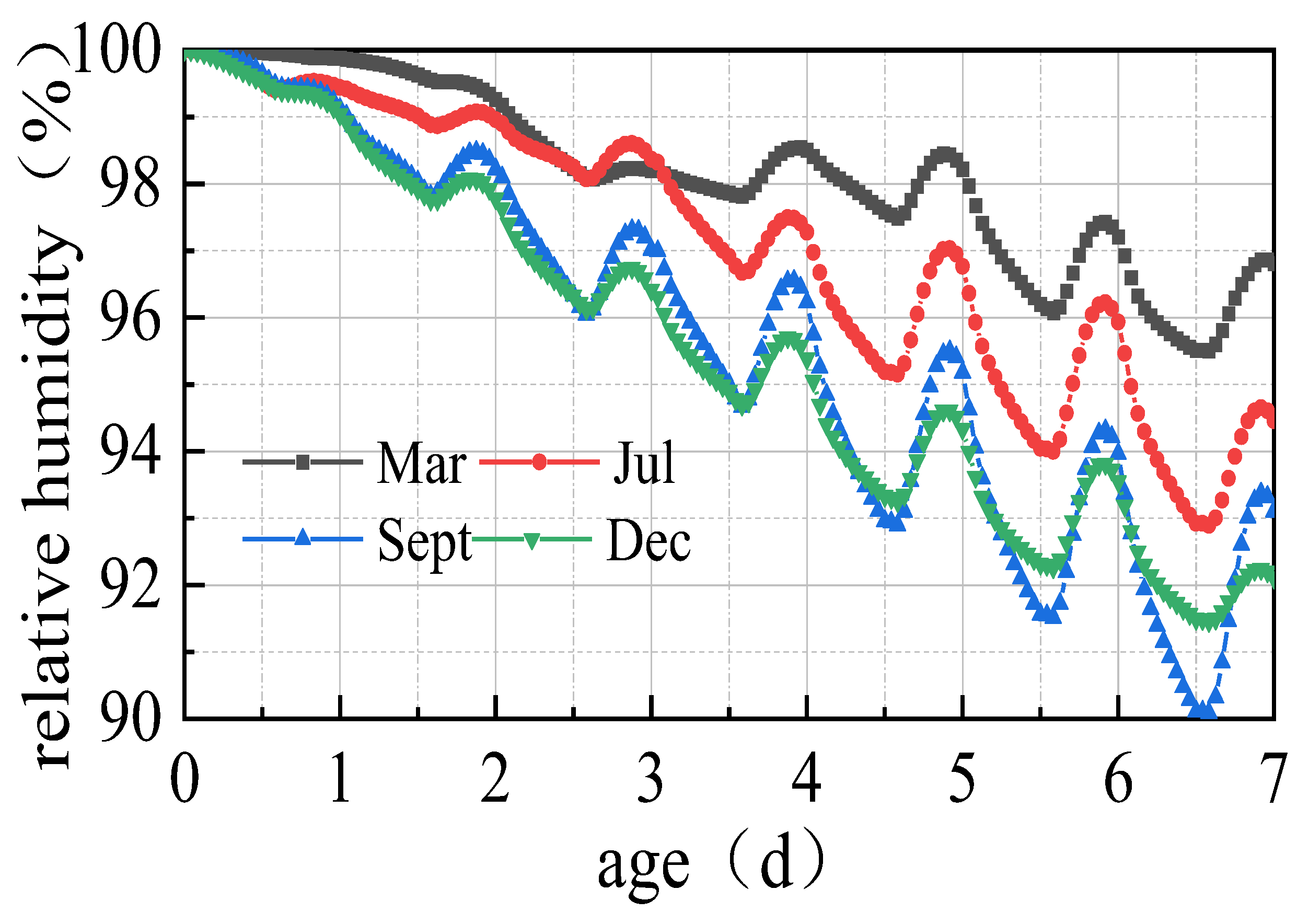

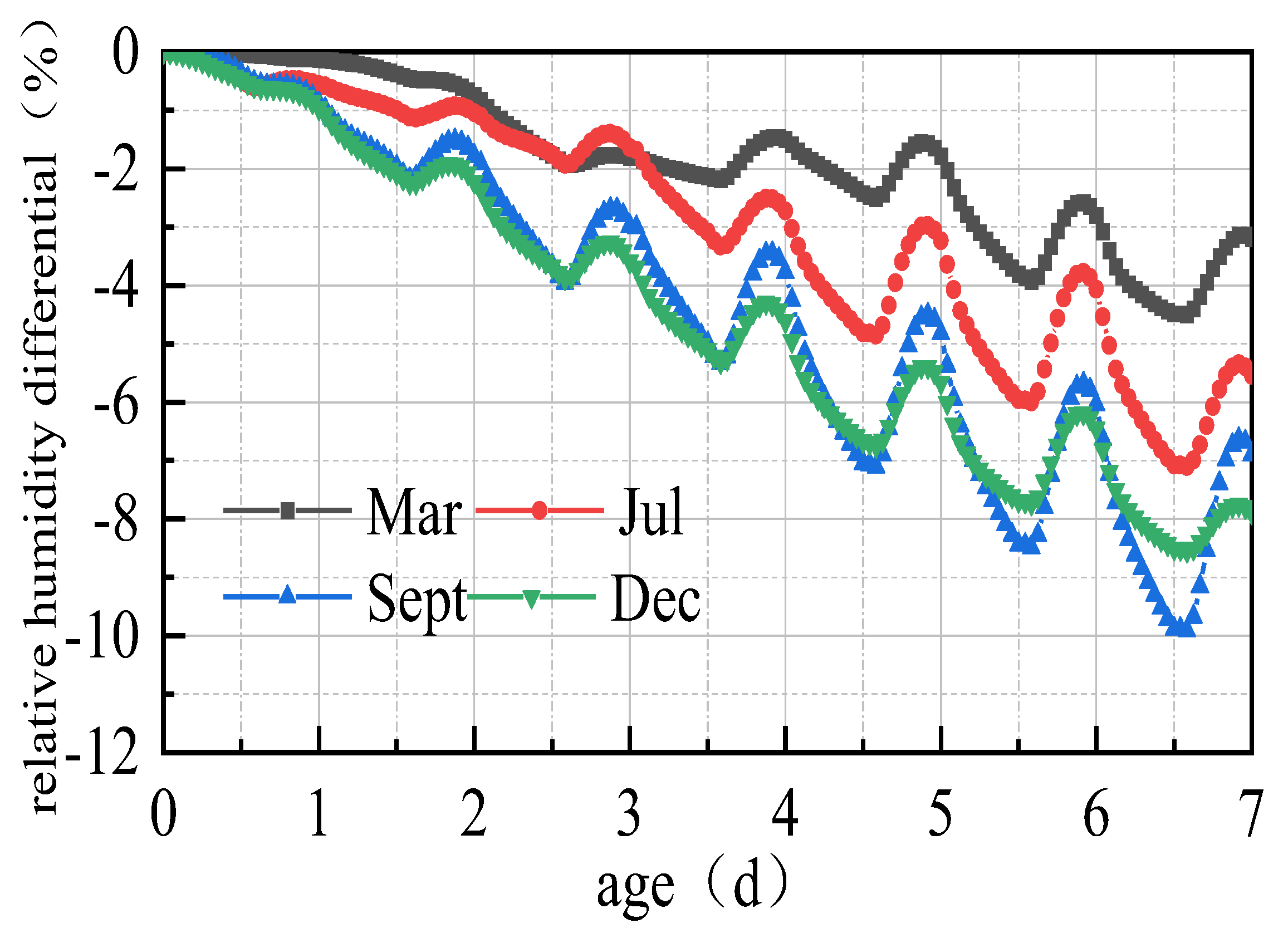

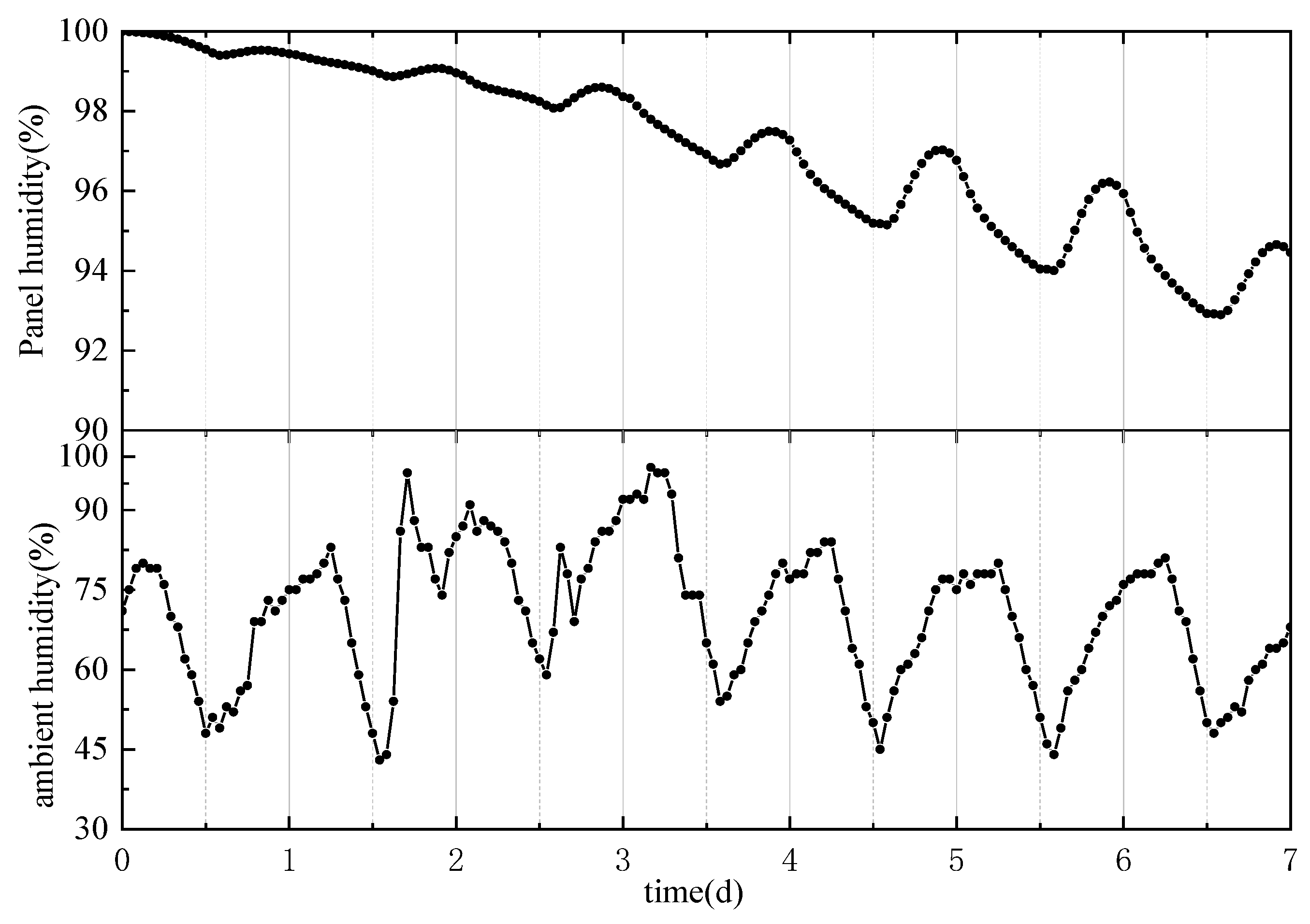

3.3.2. Influence of Construction Environmental Conditions

3.3.3. Influence of Structural and Construction Parameters

4. Parameter Sensitivity Analysis

5. Discussion and Conclusions

5.1. Analysis and Discussion

5.2. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Choi, P.; Poudyal, L.; Rouzmehr, F.; Won, M. Spalling in Continuously Reinforced Concrete Pavement in Texas. Transp. Res. Rec. 2020, 2674, 731–740. [Google Scholar] [CrossRef]

- Hu, C.; Sun, Z. Effects of a slab’s built-in curling on dynamic load and riding comfort of vehicles. J. Vib. Shock 2014, 33, 1–8. [Google Scholar] [CrossRef]

- Shokatabad, M.B.; Sarkar, A. Temperature curling and gradient of roller-compacted concrete composite pavements. Constr. Build. Mater. 2022, 353, 129008. [Google Scholar] [CrossRef]

- Assogba, O.C.; Tan, Y.; Zhou, X.; Zhang, C.; Anato, J.N. Numerical investigation of the mechanical response of semi-rigid base asphalt pavement under traffic load and nonlinear temperature gradient effect. Constr. Build. Mater. 2020, 235, 117406. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, J.; Li, P. Prediction of Temperature Distribution for Previous Cement Concrete Pavement with Asphalt Overlay. Appl. Sci. 2020, 10, 3697. [Google Scholar] [CrossRef]

- Rouzmehr, F.; Choi, P.; Nam, J.H.; Won, M. Improvements of quality assurance testing program for subgrade and base layer construction. Constr. Build. Mater. 2021, 310, 125157. [Google Scholar] [CrossRef]

- Donnelly, C.A.; Sen, S.; Vandenbossche, J.M. Reduction of critical positive temperature gradients in jointed plain concrete pavements. Int. Pavement. Eng 2023, 24, 2197645. [Google Scholar] [CrossRef]

- Vedernikov, A.; Nasonov, Y.; Korotkov, R.; Gusev, S.; Akhatov, I.; Safonov, A. Effects of additives on the cure kinetics of vinyl ester pultrusion resins. J. Compos. Mater. 2021, 55, 2921–2937. [Google Scholar] [CrossRef]

- Vedernikov, A.; Gemi, L.; Madenci, E.; Onuralp Özkılıç, Y.; Yazman, Ş.; Gusev, S.; Sulimov, A.; Bondareva, J.; Evlashin, S.; Konev, S.; et al. Effects of high pulling speeds on mechanical properties and morphology of pultruded GFRP composite flat laminates. Compos. Struct. 2022, 301, 116216. [Google Scholar] [CrossRef]

- Hu, C.; Sun, Z.; Wang, L. Experimental study on the early-age stress behavior of cement concrete pavement. Eng. Mech. 2021, 138, 163–174. [Google Scholar] [CrossRef]

- Mousa, M.R.; Hassan, M.; Carlson, P.; Davis, J.; Mousa, S.R. Development of Cost-Effective Restriping Strategies using Standard Width and Wide Waterborne Paints on Asphalt Pavements in Hot and Humid Climates. Transport. Res. Rec. 2021, 2675, 284–295. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Fa, C.; Zou, X.; Xie, H.; Chen, H.; He, R. Investigation on the Temperature Distribution of Asphalt Overlay on the Existing Cement Concrete Pavement in Hot-Humid Climate in Southern China. Adv. Civ. Eng. 2021, 2021, 2984650. [Google Scholar] [CrossRef]

- Ziari, H.; Fazaeli, H.; Olyaei, S.J.V.K.; Ziari, M.A. Evaluation of Effects of Temperature, Relative Humidity, and Wind Speed on Practical Characteristics of Plastic Shrinkage Cracking Distress in Concrete Pavement Using a Digital Monitoring Approach. Int. J. Pavement Res. Technol. 2022, 15, 138–158. [Google Scholar] [CrossRef]

- Li, X.; Shen, A. Internal Stress Simulation of Pavement Concrete under Coupling Action of Temperature and Humidity. Jianzhu Cailiao Xuebao/J. Build. Mater. 2018, 21, 78–84. [Google Scholar] [CrossRef]

- Mateos, A.; Harvey, J.; Feldman, D.R. Evaluation of the Moisture Dependence of Concrete Coefficient of Thermal Expansion and Its Impacts on Thermal Deformations and Stresses of Concrete Pavements. Transport. Res. Rec. 2020, 2674, 545–555. [Google Scholar] [CrossRef]

- Lyu, Z.L.Z.; Guo, Y.G.Y.; Chen, Z.C.Z.; Shen, A.S.A.; Qin, X.Q.X.; Yang, J.Y.J.; Zhao, M.Z.M.; Wang, Z.W.Z. Research on shrinkage development and fracture properties of internal curing pavement concrete based on humidity compensation. Constr. Build. Mater. 2019, 203, 417–431. [Google Scholar] [CrossRef]

- Liang, S.; Wei, Y. Modelling of creep effect on moisture warping and stress developments in concrete pavement slabs. Int. J. Pavement Eng. 2018, 19, 429–438. [Google Scholar] [CrossRef]

- Tamrakar, P.; Nazarian, S. Moisture effects on moduli of pavement bases. Int. J. Pavement Eng. 2021, 22, 1410–1422. [Google Scholar] [CrossRef]

- Xing, X.; Zhu, Y.; Xu, W.; Peng, W.; Yuan, Z. Measuring Subsidence Over Soft Clay Highways Using a Novel Time-Series InSAR Deformation Model with an Emphasis on Rheological Properties and Environmental Factors (NREM). IEEE Trans. Geosci. Remote Sens. 2022, 60, 4601319. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, X.; Zhong, Y.; Li, X.; Hao, M.; Liu, J. Dynamic Inversion Analysis of Structural Layer Modulus of Semirigid Base Pavement considering the Influence of Temperature and Humidity. Adv. Civ. Eng. 2020, 2020, 8899888. [Google Scholar] [CrossRef]

- Asbahan, R.E.; Vandenbossche, J.M. Effects of Temperature and Moisture Gradients on Slab Deformation for Jointed Plain Concrete Pavements. J. Transp. Eng. 2011, 137, 563–570. [Google Scholar] [CrossRef]

- Wei, Y.; Liang, S.; Gao, X. Numerical Evaluation of Moisture Warping and Stress in Concrete Pavement Slabs with Different Water-to-Cement Ratio and Thickness. J. Eng. Mech. 2017, 143, 4016111. [Google Scholar] [CrossRef]

- Ya, W.; Liang, S.; Zhang, Q. Effect of bulit-in temperrature difference on curling and stresses in cement concrete slabs. J. Civ. Archit. Environ. Eng. 2015, 1, 81–87. [Google Scholar]

- Wei, Y.; Gao, X.; Wang, F.; Zhong, Y. Nonlinear strain distribution in a field-instrumented concrete pavement slab in response to environmental effects. Road Mater. Pavement 2019, 20, 367–380. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Najjar, L.J. Drying of concrete as a nonlinear diffusion problem. Cem. Concr. Res. 1971, 1, 461–473. [Google Scholar] [CrossRef]

- Xi, Y.; Bažant, Z.P.; Jennings, H.M. Moisture diffusion in cementitious materials Adsorption isotherms. Adv. Cem. Based Mater. 1994, 1, 248–257. [Google Scholar] [CrossRef]

- Hu, C.; Wang, L.; Lv, H. Numerical modeling of cement concrete pavements’ internal moisture fields at early ages. Eng. Mech. 2014, 31, 178–224. [Google Scholar] [CrossRef]

- Wang, L.-J.; Hu, C.; Sun, Z. Curling behavior mechanism of cement concrete pavement at early age. Eng. Mech. 2021, 38, 215–228. [Google Scholar] [CrossRef]

| Variable Type | Parameter Name | Range of Values | Base Value |

|---|---|---|---|

| Mixes | Cement Type/ASTM | Type I–V | Type I |

| Component Variables | Water to ash ratio | 0.33–0.45 | 0.39 |

| Environmental parameters | Average daily temperature/°C | Actual weather measurements in Fuzhou in March, July, September, and December | July |

| Average daily humidity/°C | |||

| Ambient humidity/% | |||

| Daily average wind speed/m/s | 0–6 | 2 | |

| Daily maximum solar radiation intensity/w/m2 | 0–1200 | 600 | |

| Sunshine time/h | 12 | ||

| Construction parameters | Pavement panel thickness/cm | 20–28 | 24 |

| Paving time/24 h | 0–24 | 16 | |

| Conservation status | Yes/No | None | |

| Number | C3S (%) | C3A (%) | C2S (%) | C4AF (%) | Specific Surface Area (m2/kg) |

|---|---|---|---|---|---|

| Type I | 51.36 | 9.59 | 23.82 | 9.70 | 404 |

| Type II | 53.28 | 9.31 | 21.80 | 10.59 | 408 |

| Type III | 55.94 | 11.94 | 16.91 | 10.18 | 377 |

| Type IV | 62.34 | 9.38 | 12.87 | 10.41 | 412 |

| Type V | 52.34 | 3.89 | 24.93 | 13.87 | 357 |

| Parameter Situation | Operating Conditions Take Values | Baseline Working Conditions | Panel Relative Humidity/% | Difference of Humidity at the Top and Bottom of the Board/% | ||||

|---|---|---|---|---|---|---|---|---|

| Peak/% | Difference from Base Value/% | Sensitivity Level | Peak/% | Difference from Base Value/% | Sensitivity Level | |||

| Cement type | Type II | Type I | 93 | 0 | Low | 7 | 0 | Low |

| Type III | 93 | 0 | 7 | 0 | ||||

| Type IV | 93 | 0 | 7 | 0 | ||||

| Type V | 93 | 0 | 7 | 0 | ||||

| Water to ash ratio | 0.33 | 0.38 | 92.6 | −0.4 | Low | 7.4 | 0.4 | Low |

| 0.41 | 93.1 | 0.1 | 6.9 | −0.1 | ||||

| 0.45 | 93.3 | 0.3 | 6.7 | −0.3 | ||||

| Ambient Humidity | 3 | 7 | 95.5 | 2.5 | High | 4.5 | −2.5 | High |

| 9 | 90 | −3 | 10 | 3 | ||||

| 12 | 91.5 | −1.5 | 8.5 | 1.5 | ||||

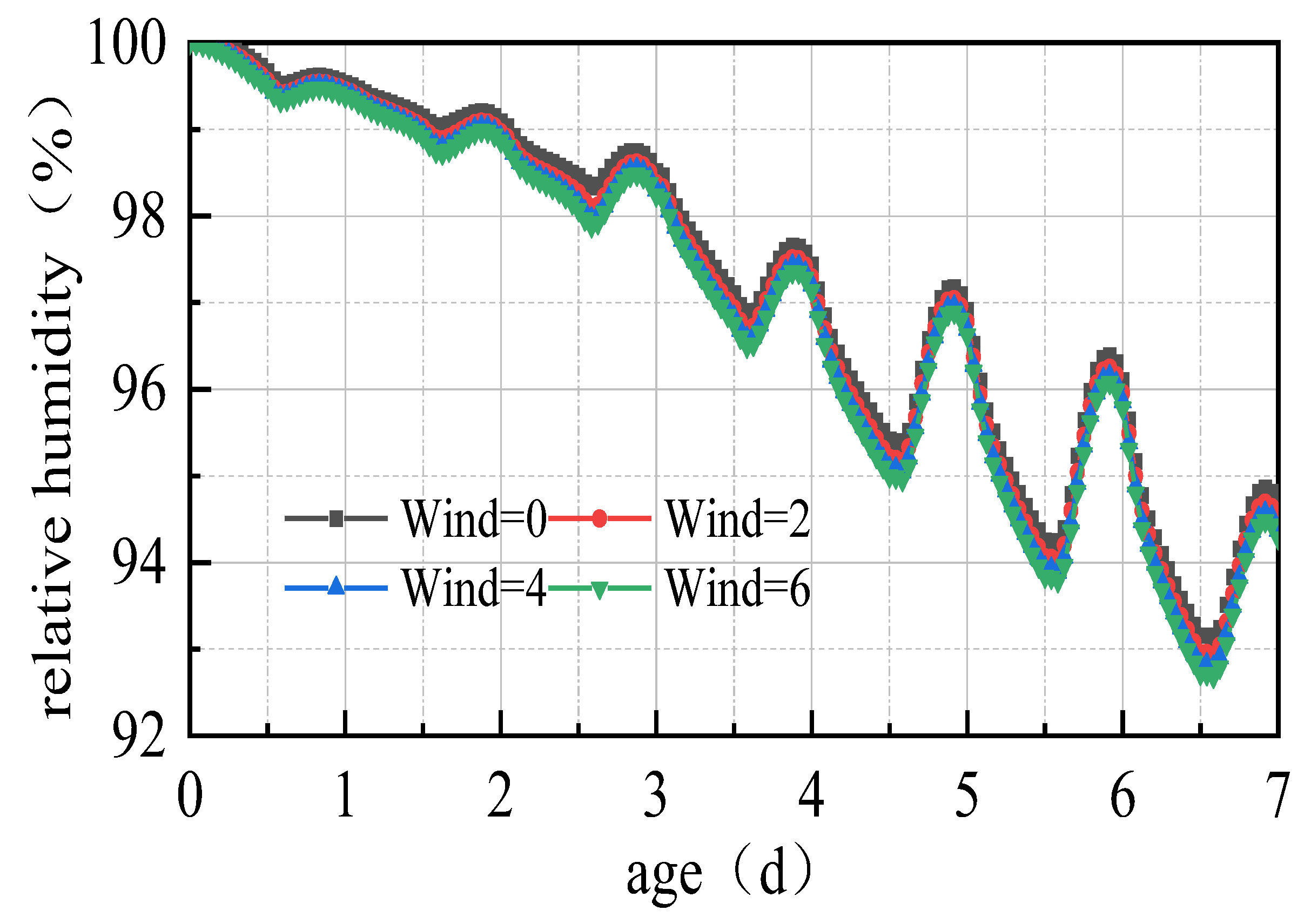

| Wind speed | 0 | 2 | 93.2 | 0.2 | Low | 6.8 | −0.2 | Low |

| 4 | 92.8 | −0.2 | 7.2 | 0.2 | ||||

| 6 | 92.7 | −0.3 | 7.3 | 0.3 | ||||

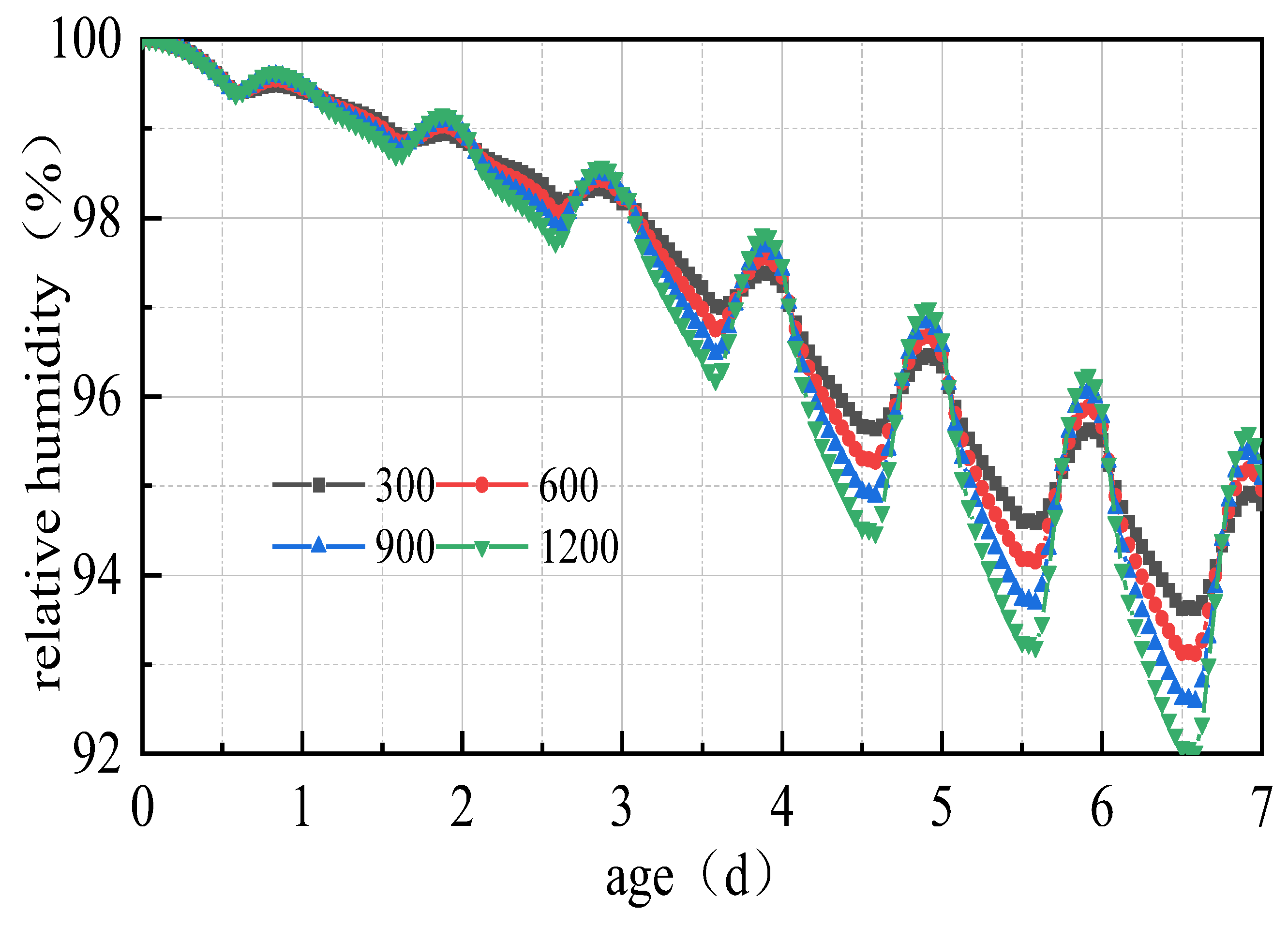

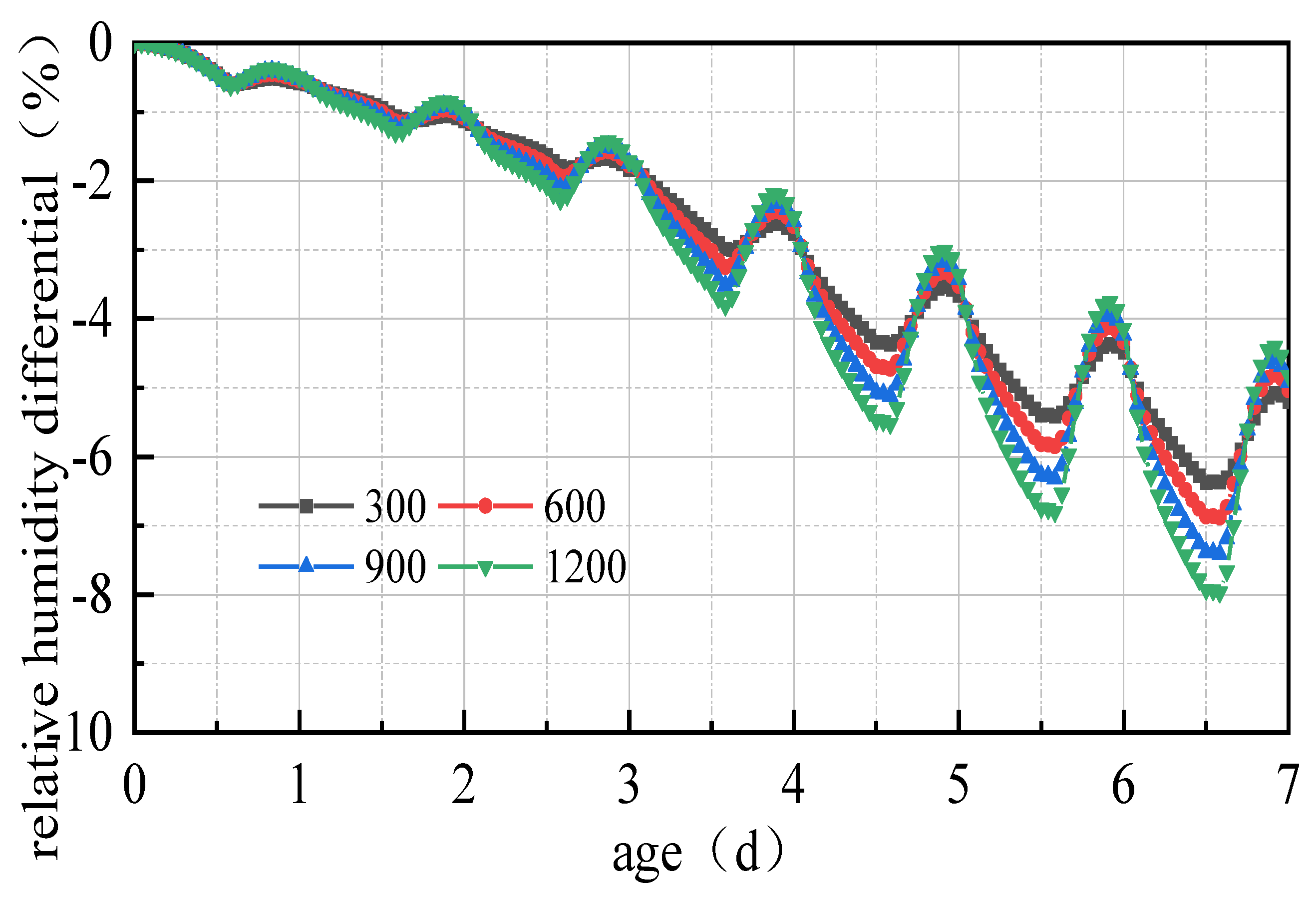

| Solar radiation | 300 | 600 | 93.7 | 0.7 | Medium | 6.3 | −0.7 | Medium |

| 900 | 92.5 | −0.5 | 7.5 | 0.5 | ||||

| 1200 | 92 | −1 | 8 | 1 | ||||

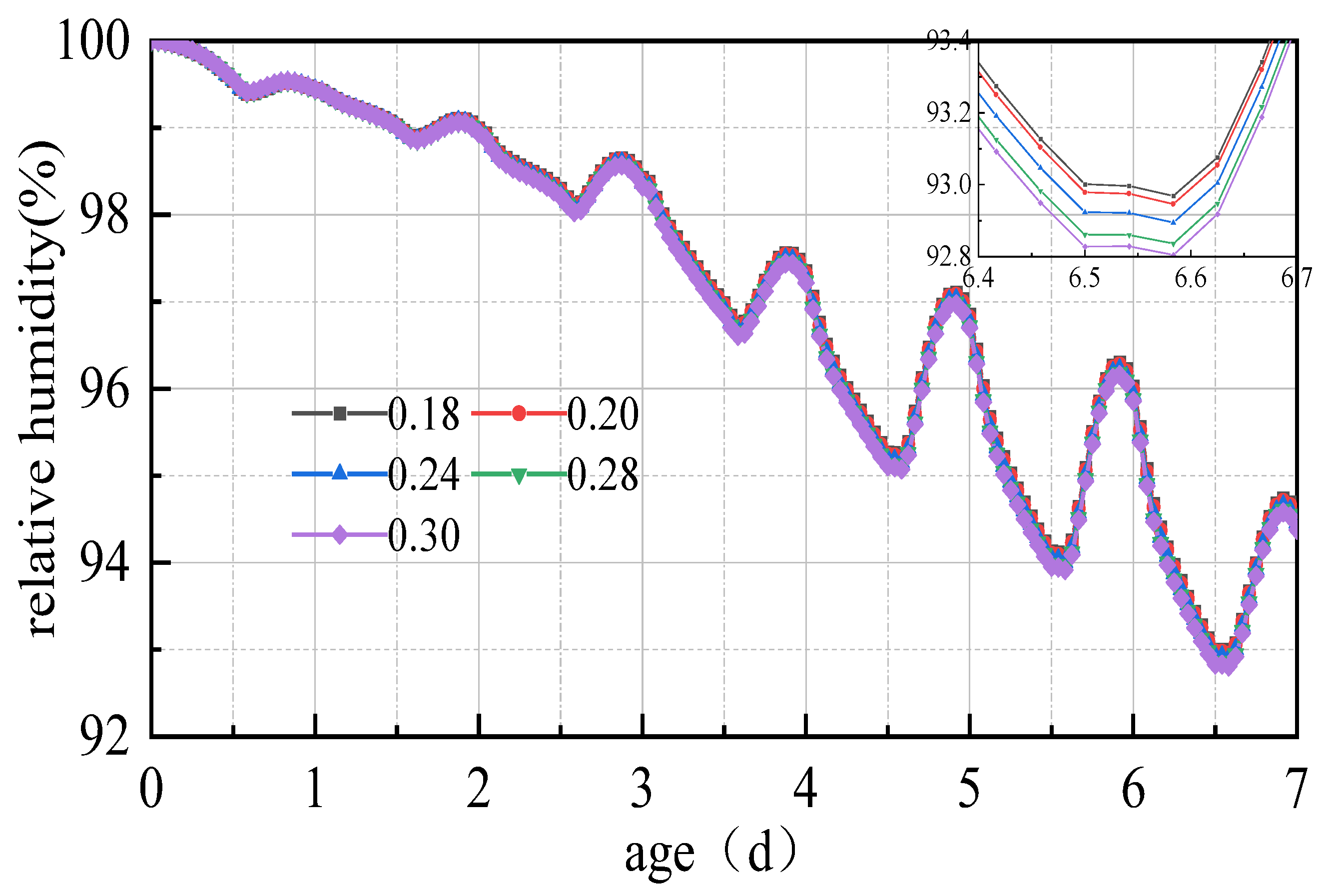

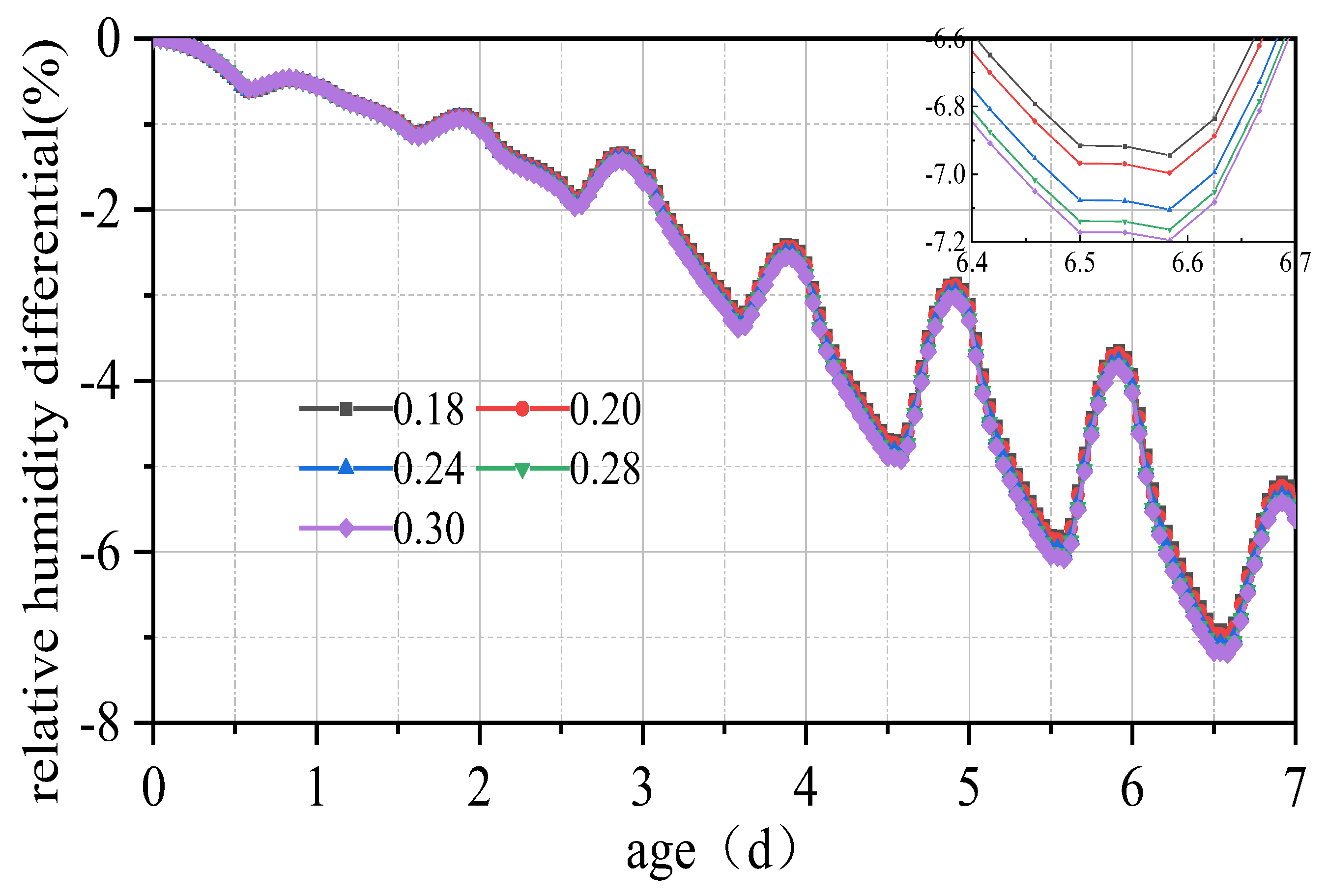

| Panel thickness | 0.18 | 0.24 | 93.1 | 0.1 | Low | 6.9 | −0.1 | Low |

| 0.2 | 93.1 | 0.1 | 6.9 | −0.1 | ||||

| 0.28 | 93.1 | 0.1 | 6.9 | −0.1 | ||||

| 0.30 | 93.1 | 0.1 | 6.9 | −0.1 | ||||

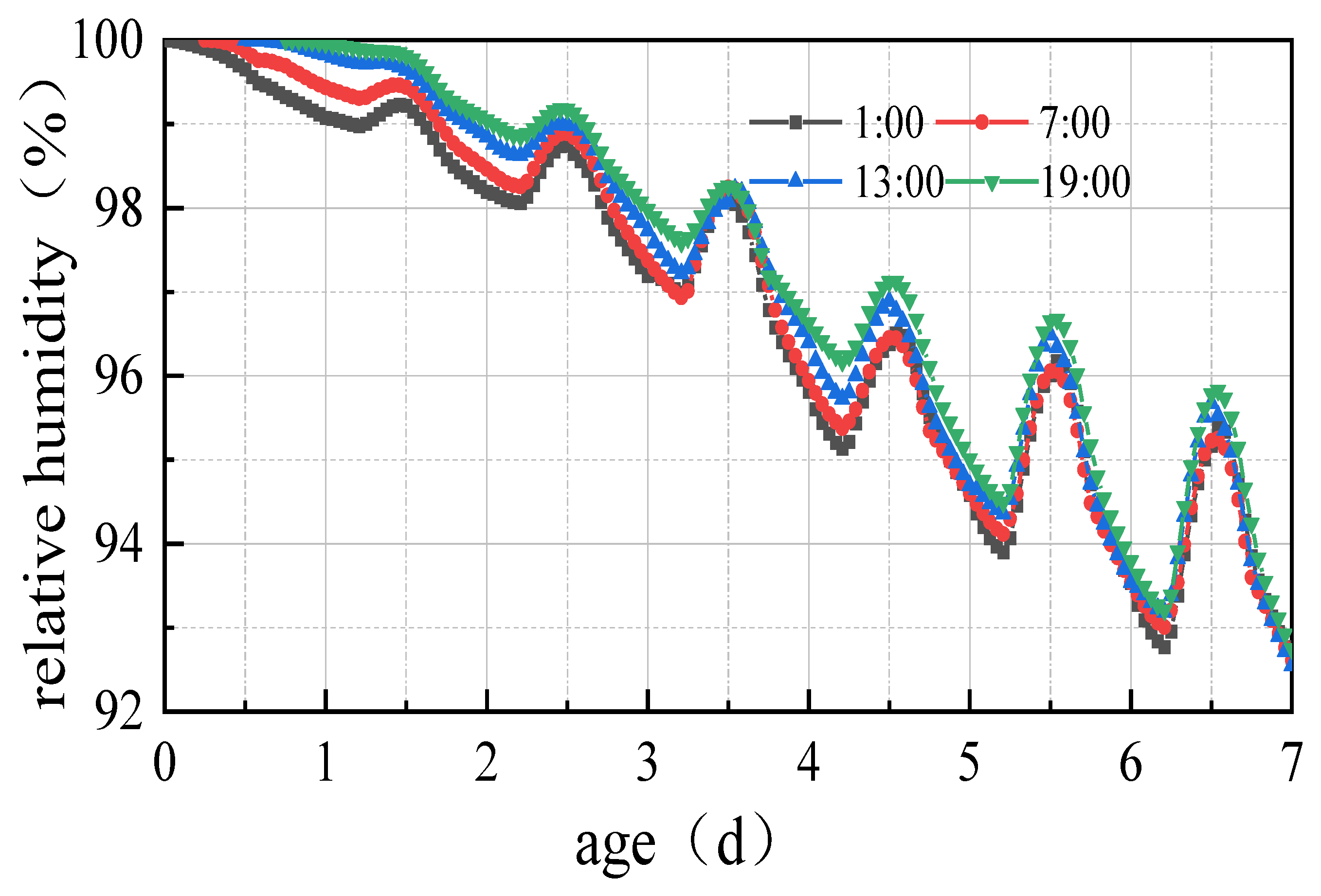

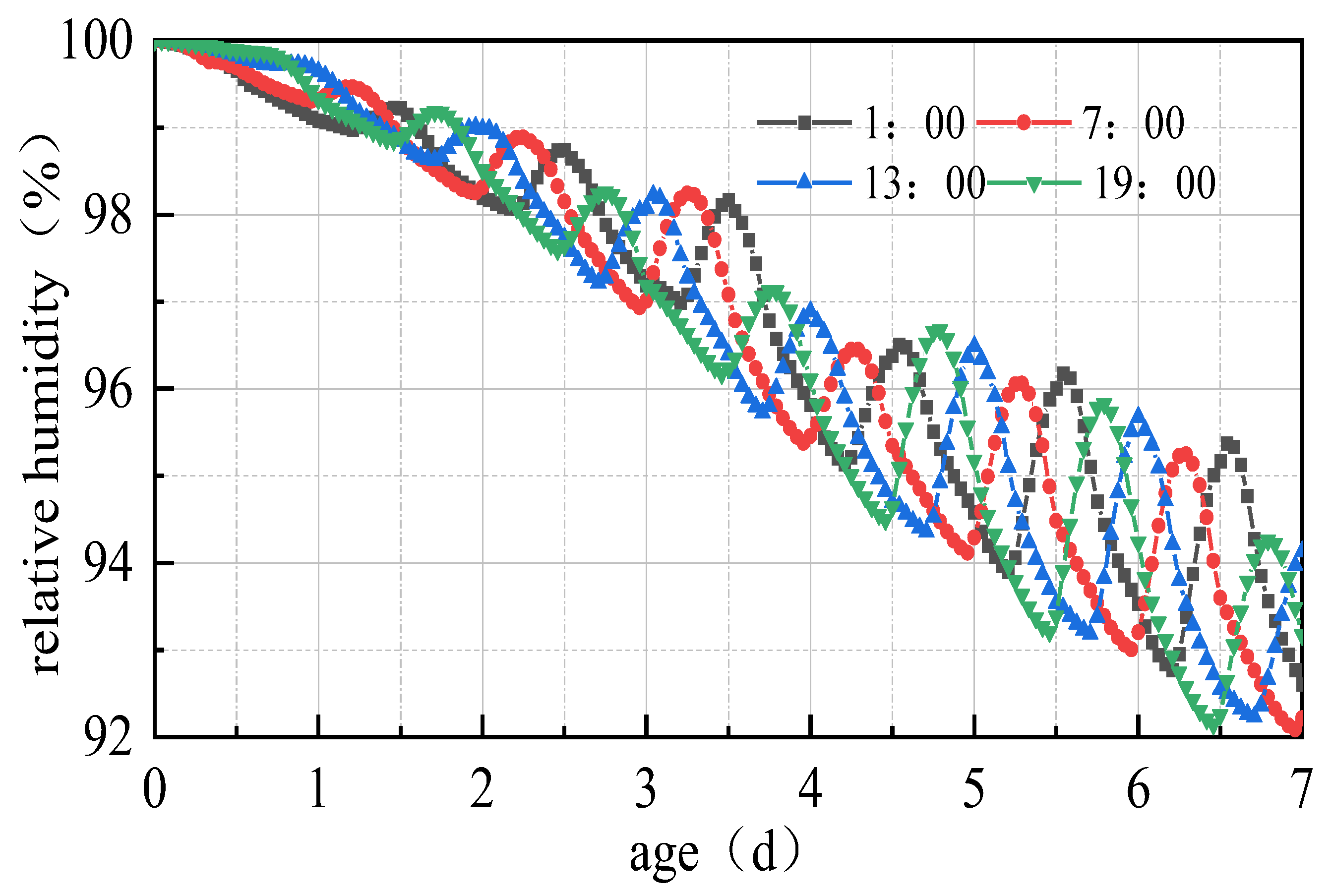

| Pavement construction moment | 1:00 | 13 | 92.8 | −0.2 | Low | 7.2 | 0.2 | Low |

| 7:00 | 93 | 0 | 7 | 0 | ||||

| 19:00 | 93.3 | 0.3 | 6.7 | −0.3 | ||||

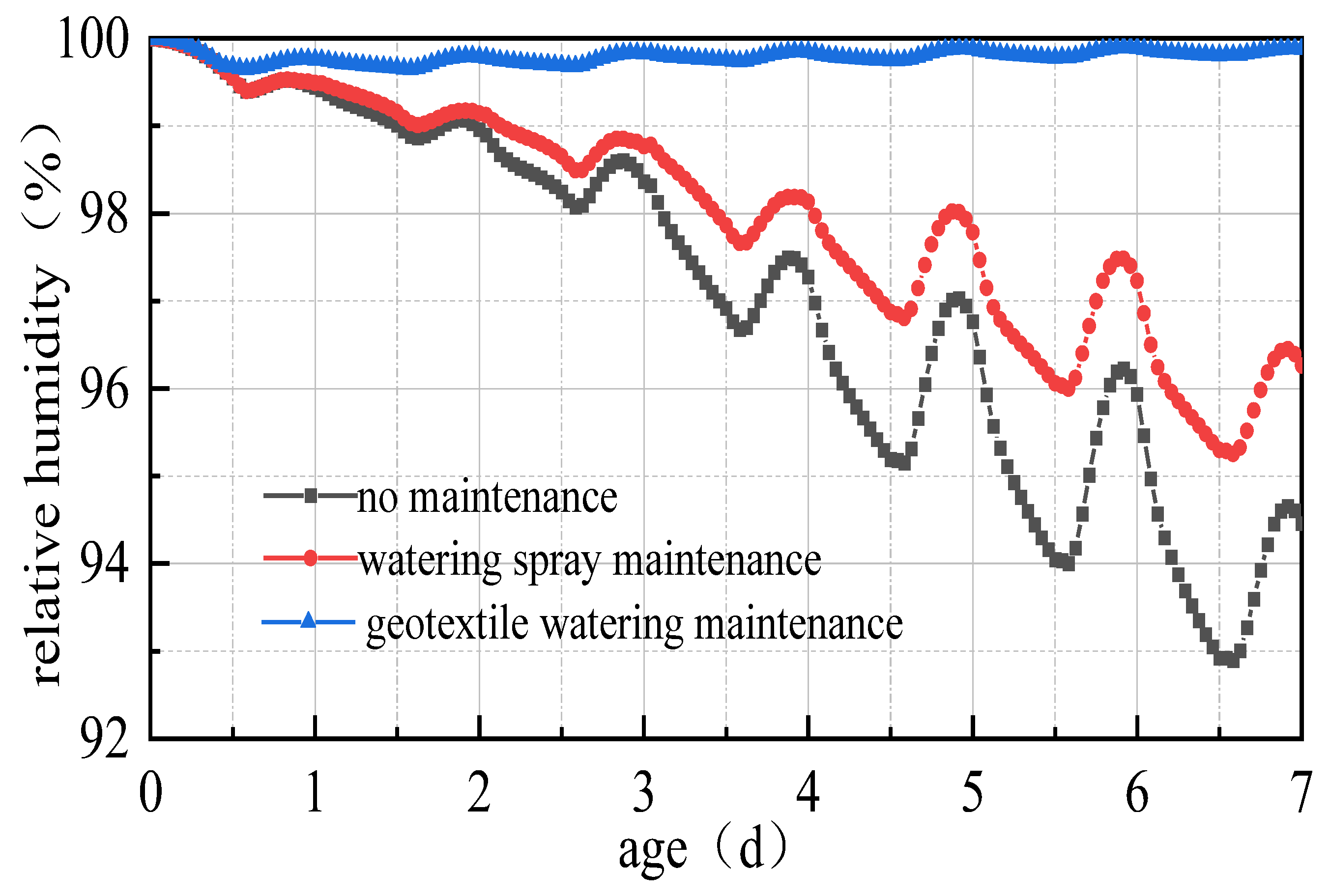

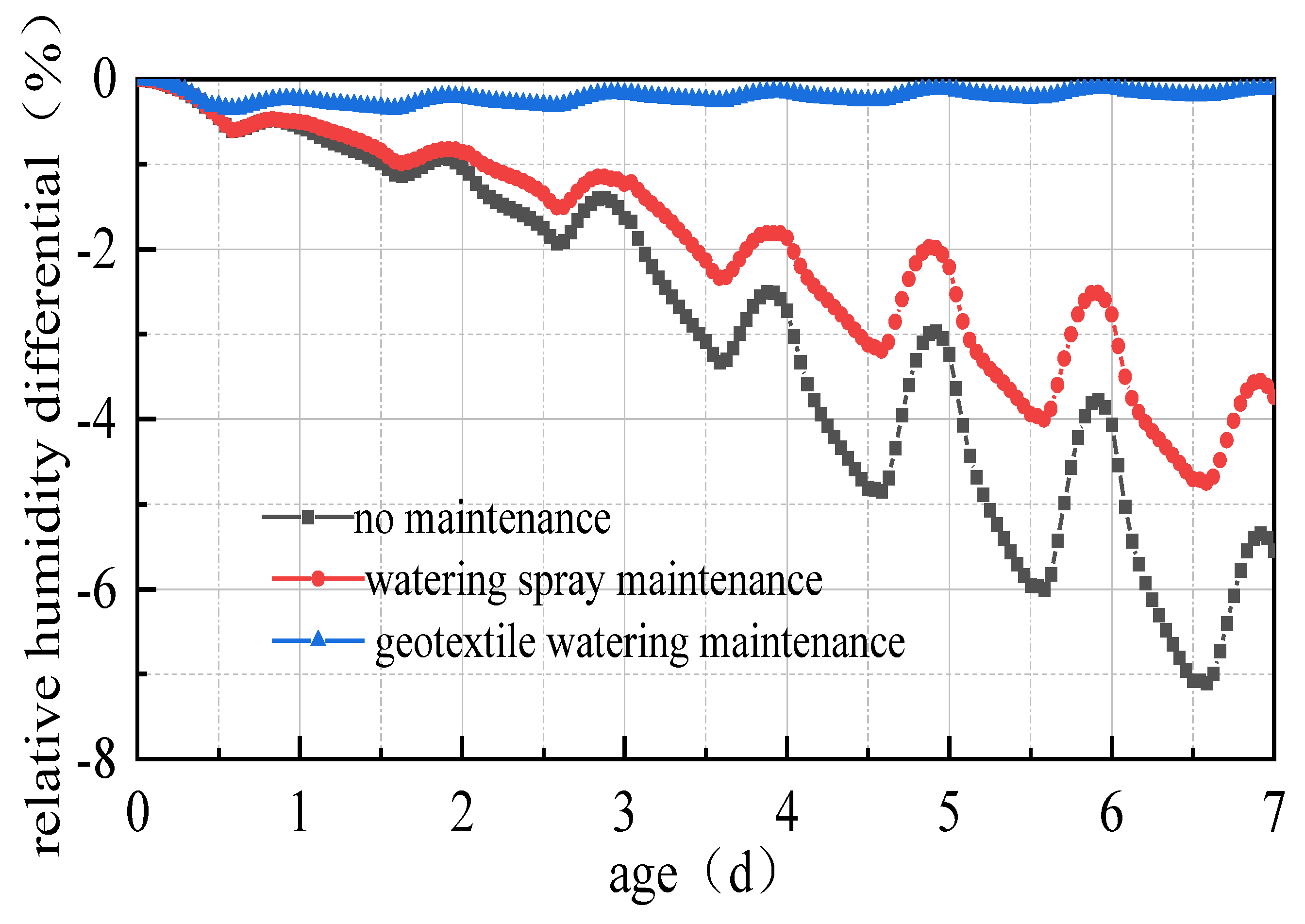

| Conservation methods | Sprinkler | None | 95.3 | 2.3 | High | 4.7 | −2.3 | High |

| Geotextile + Sprinkler | 93 | 0 | 7 | 0 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, M.; Wang, L.; Hu, C.; Chen, T. Investigation into the Impact of Humidity on Early Age Cement Concrete Pavement Behavior in Hot and Humid Regions. Appl. Sci. 2023, 13, 10180. https://doi.org/10.3390/app131810180

Chai M, Wang L, Hu C, Chen T. Investigation into the Impact of Humidity on Early Age Cement Concrete Pavement Behavior in Hot and Humid Regions. Applied Sciences. 2023; 13(18):10180. https://doi.org/10.3390/app131810180

Chicago/Turabian StyleChai, Min, Lijuan Wang, Changbin Hu, and Tao Chen. 2023. "Investigation into the Impact of Humidity on Early Age Cement Concrete Pavement Behavior in Hot and Humid Regions" Applied Sciences 13, no. 18: 10180. https://doi.org/10.3390/app131810180

APA StyleChai, M., Wang, L., Hu, C., & Chen, T. (2023). Investigation into the Impact of Humidity on Early Age Cement Concrete Pavement Behavior in Hot and Humid Regions. Applied Sciences, 13(18), 10180. https://doi.org/10.3390/app131810180