CFD Assessment of Car Park Ventilation System in Case of Fire Event

Abstract

:1. Introduction

- What is the impact of adding an appropriate number of jet fan lines on the ventilation system’s capability to prevent back-layering and lateral smoke dispersion?

- How does the comparison of jet fan airflow rates between the high and low velocity jet fans affect the dispersion of smoke in underground car parks?

- What is the impact of the optimal positioning of supply and exhaust shafts on achieving efficient ventilation and smoke control in underground car parks?

- What is the significance of utilizing fire-resistant materials and components in jet fans to ensure their operational durability during fire events?

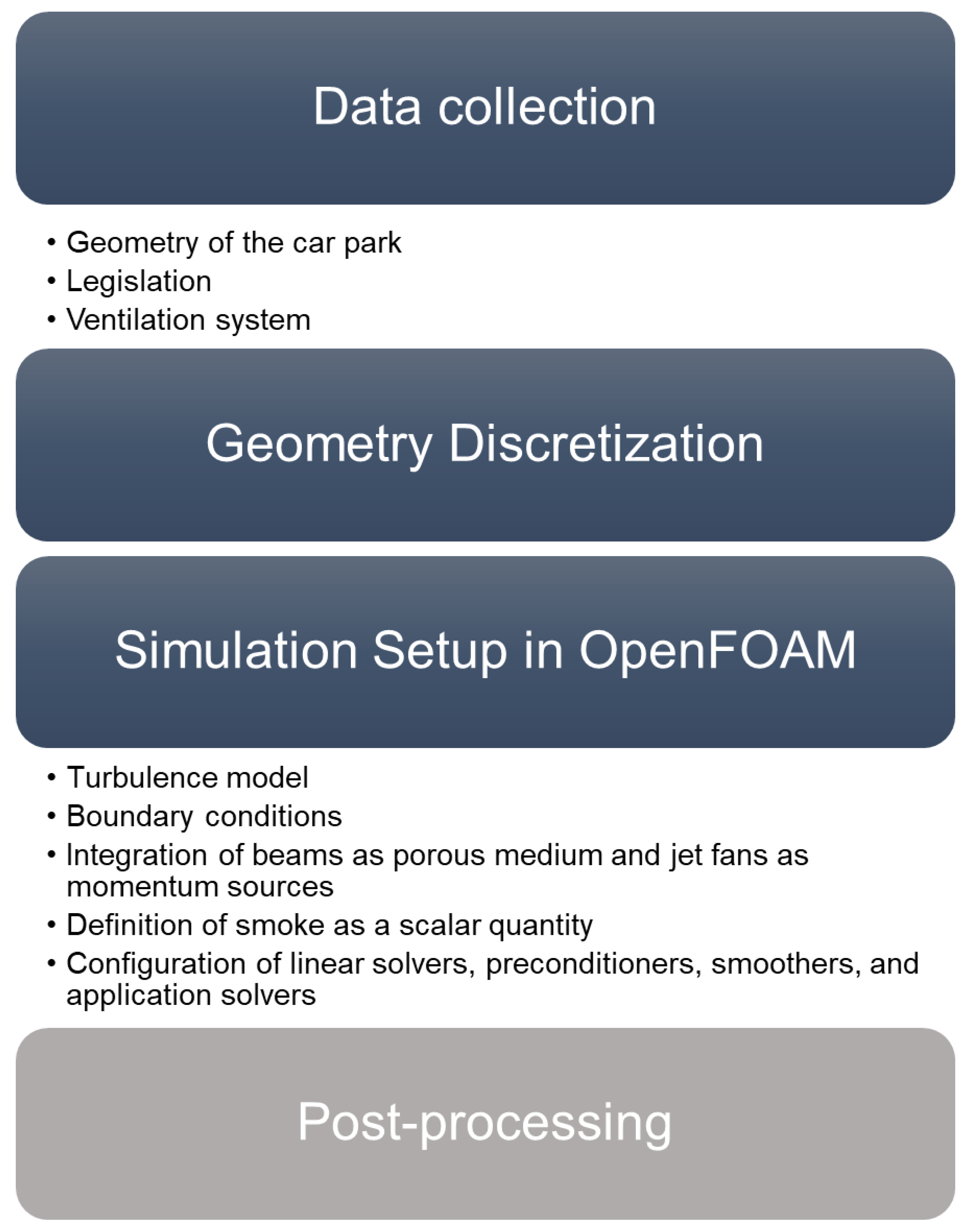

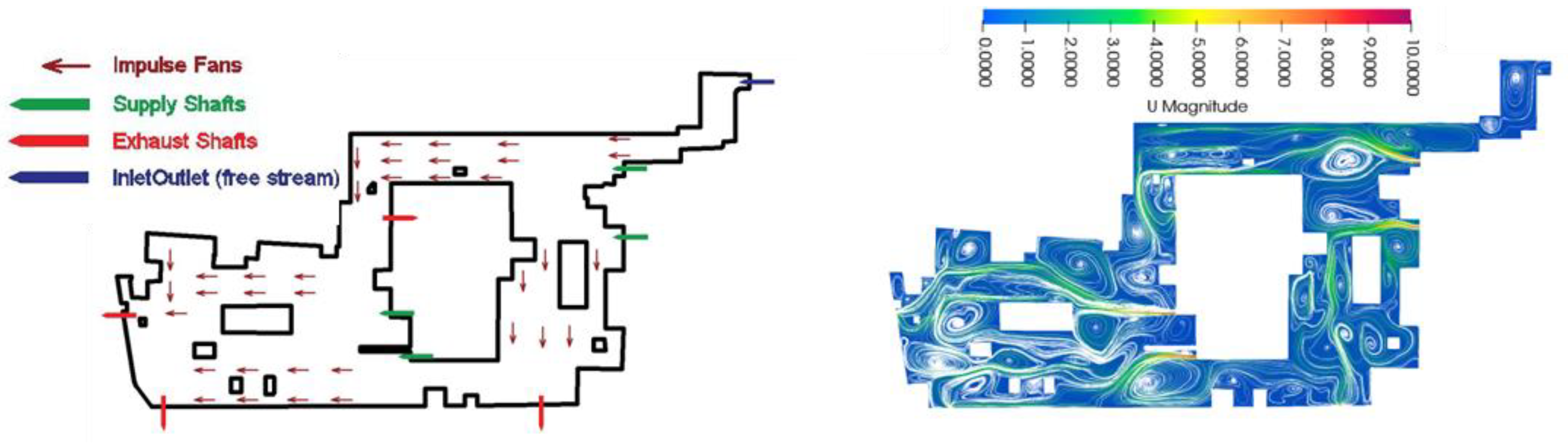

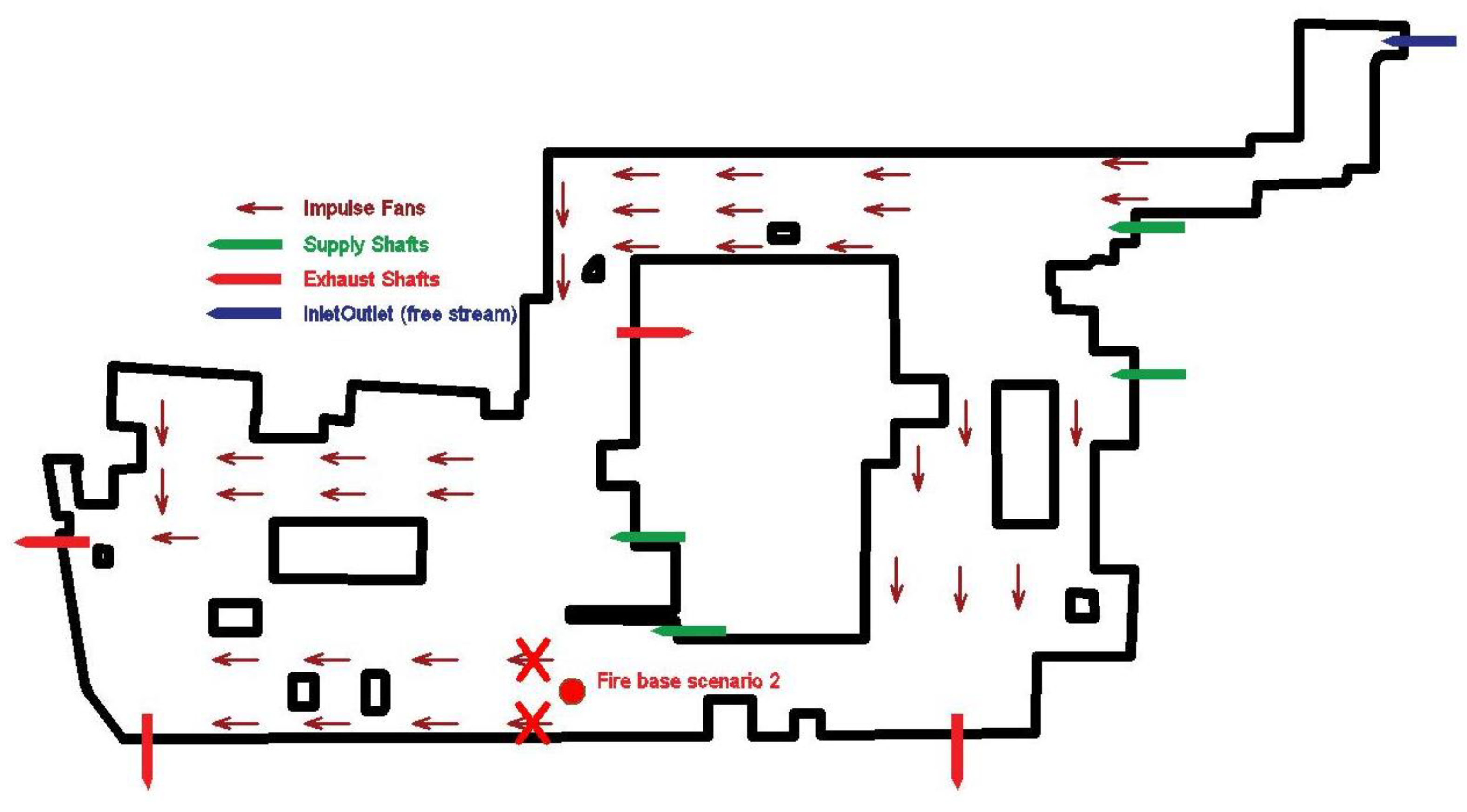

2. Materials and Methods

2.1. Data Collection

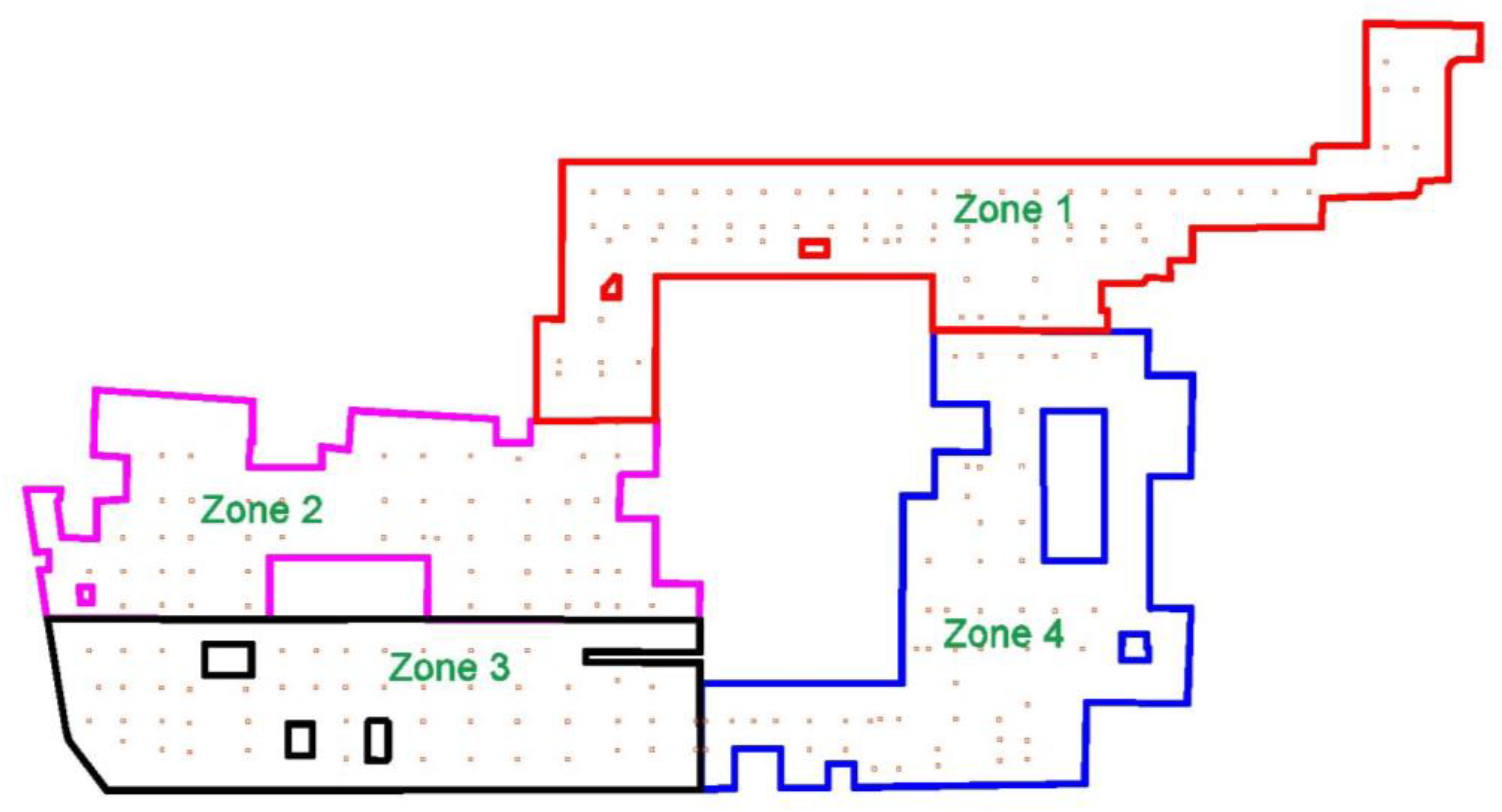

2.1.1. Geometry of the Car Park

- Zone 1: 5900 m2.

- Zone 2: 5120 m2.

- Zone 3: 5030 m2.

- Zone 4: 5620 m2.

2.1.2. Legislation

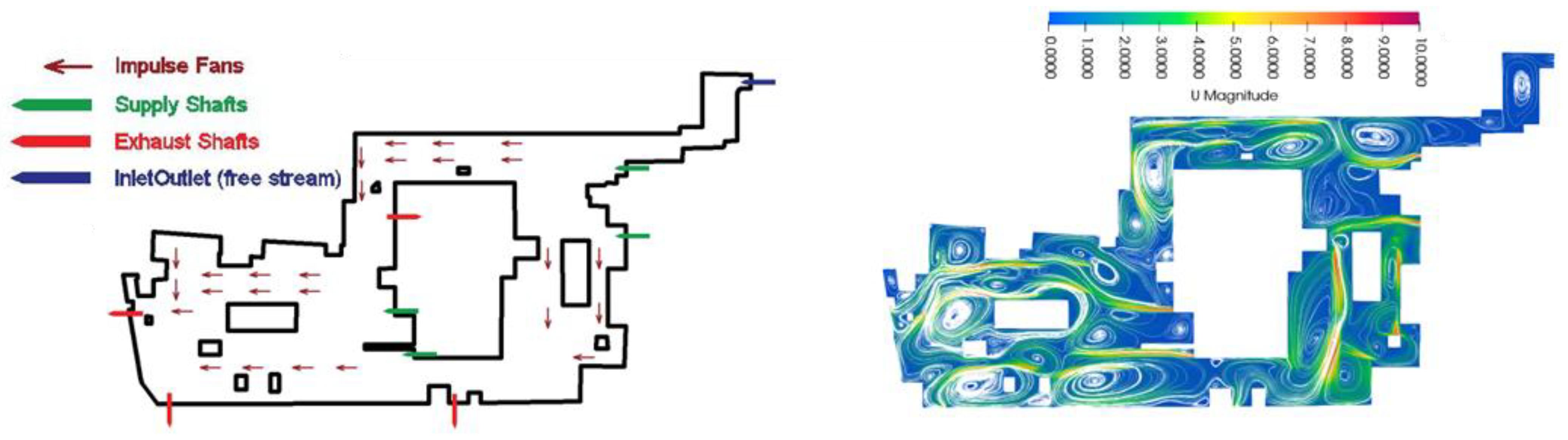

2.1.3. Ventilation System

2.2. Discretization Process

2.3. Simulation Setup in OpenFOAM

2.3.1. Turbulence Model

2.3.2. Boundary Conditions

2.3.3. Integration of Beams as Porous Medium and Jet Fans as Momentum Sources

2.3.4. Definition of Smoke as a Scalar Quantity

2.3.5. Configuration of Linear Solvers, Preconditioners, Smoothers, and Application Solvers

Linear Solvers

Preconditioners

Smoothers

Application Solvers

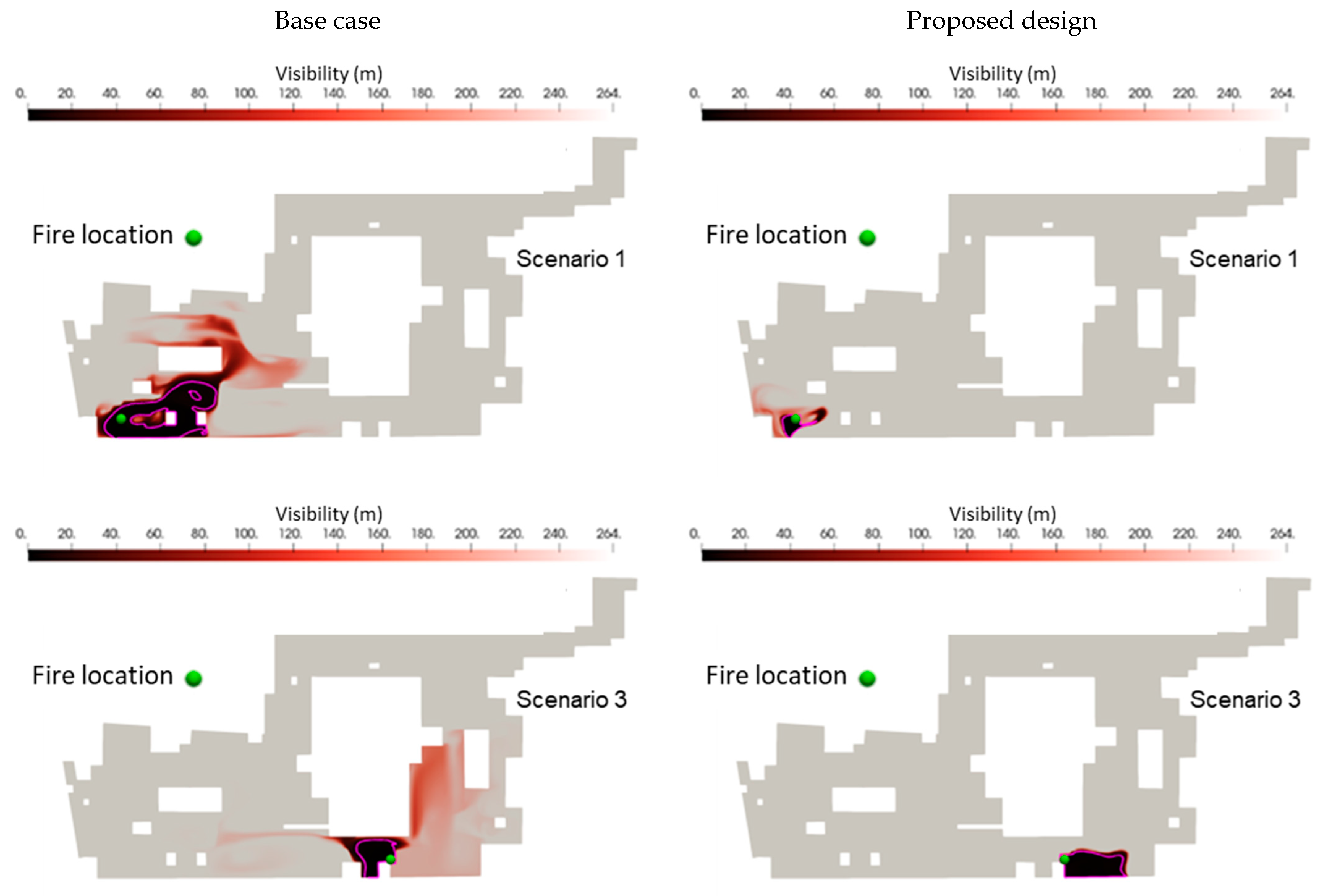

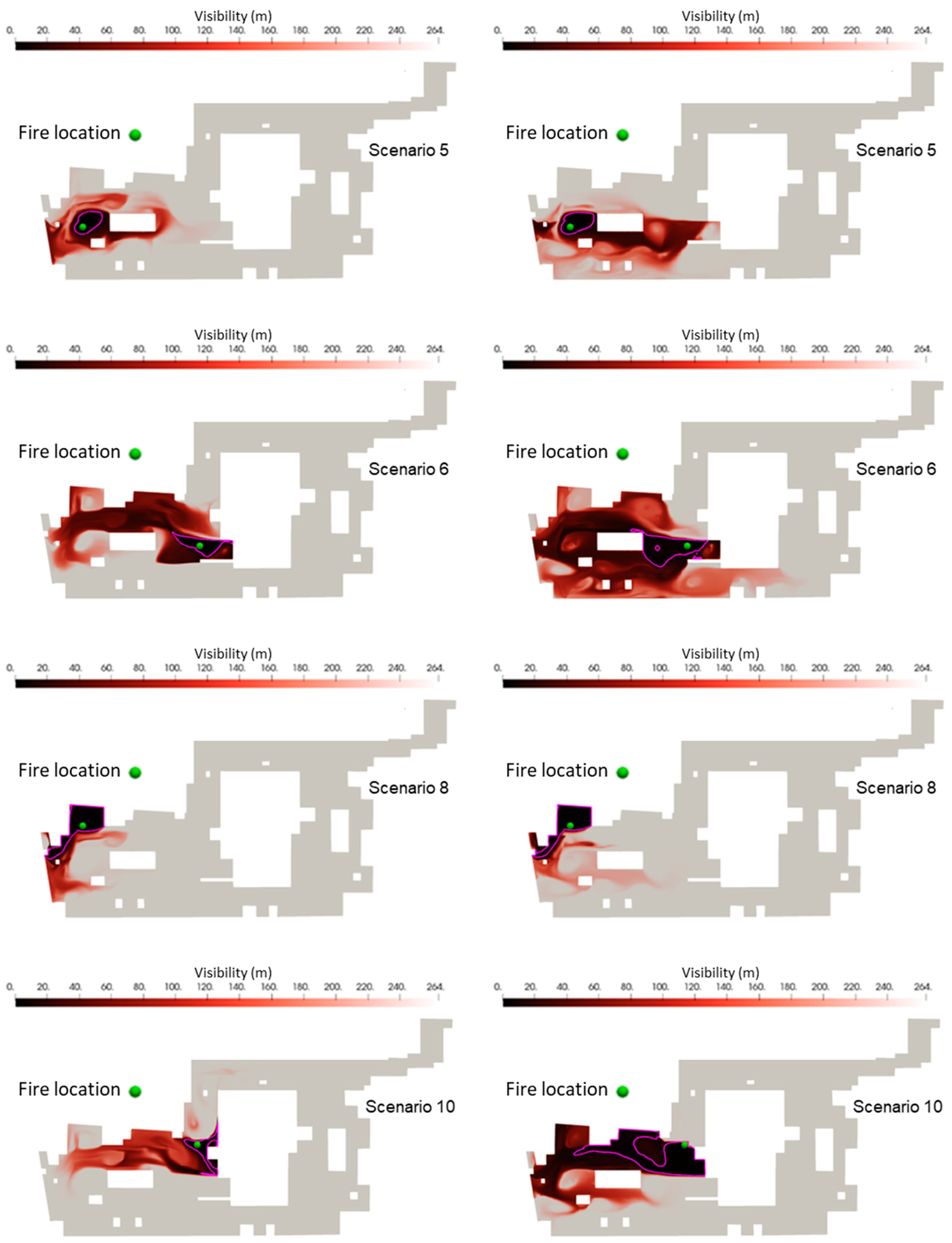

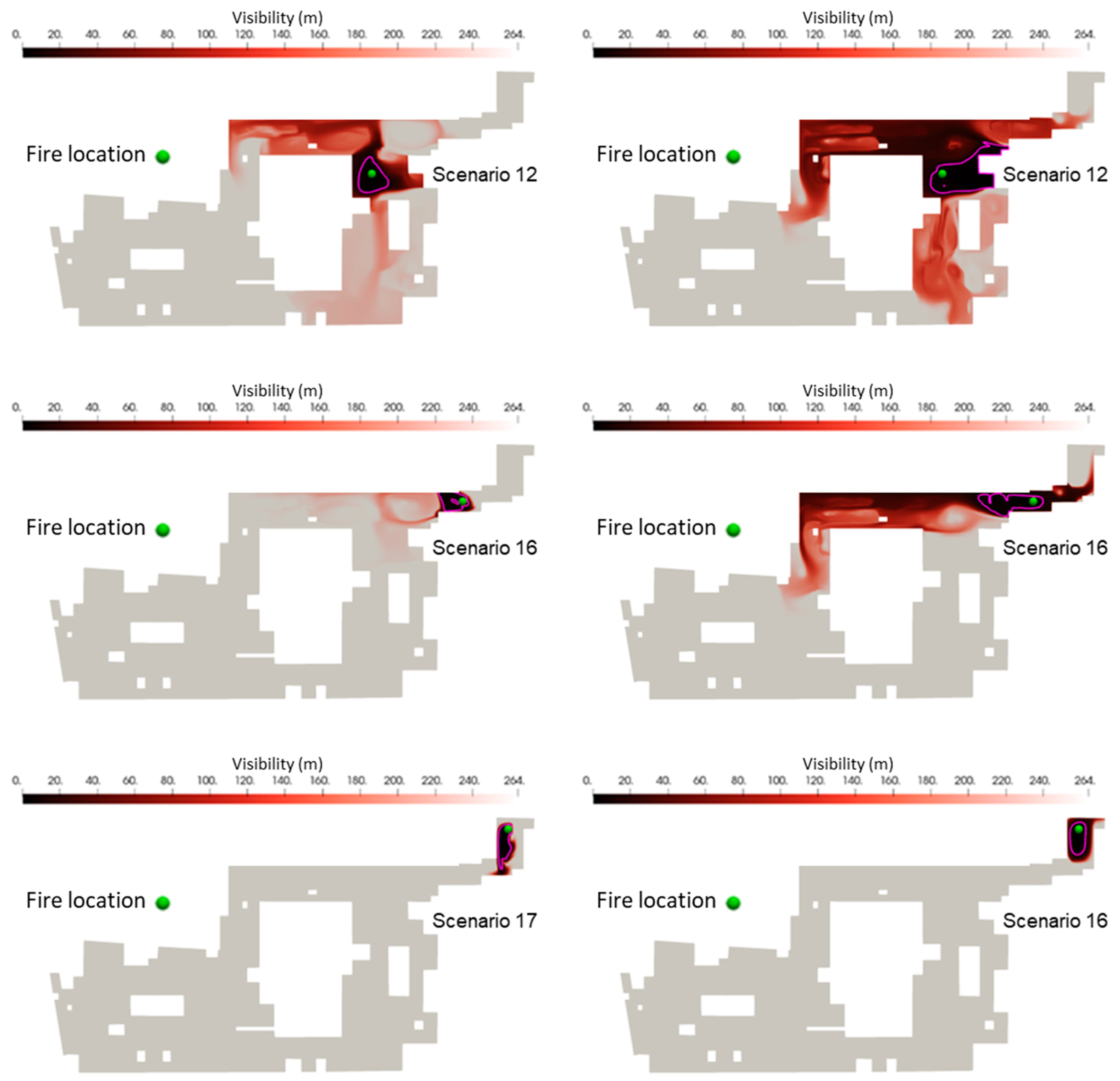

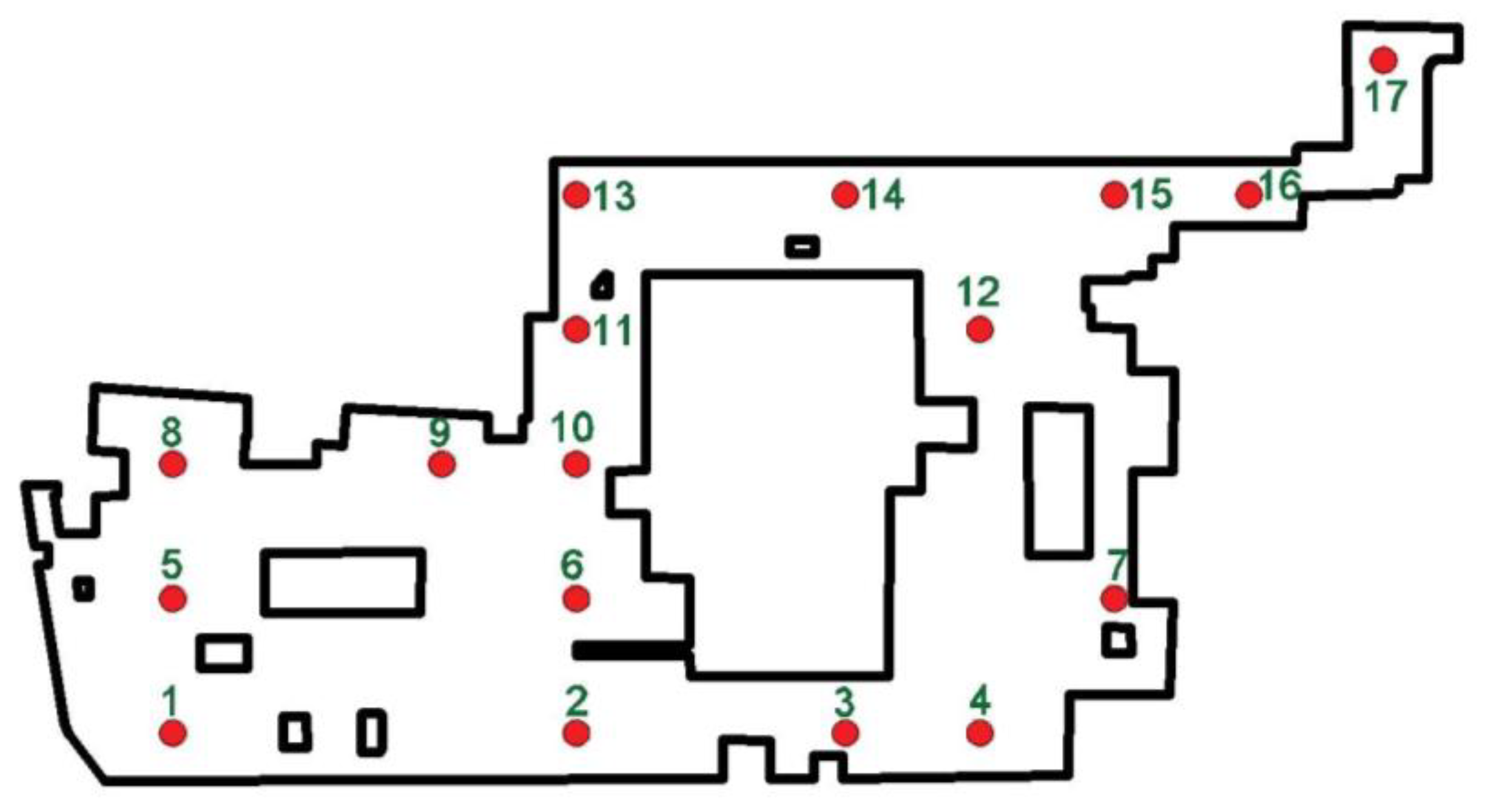

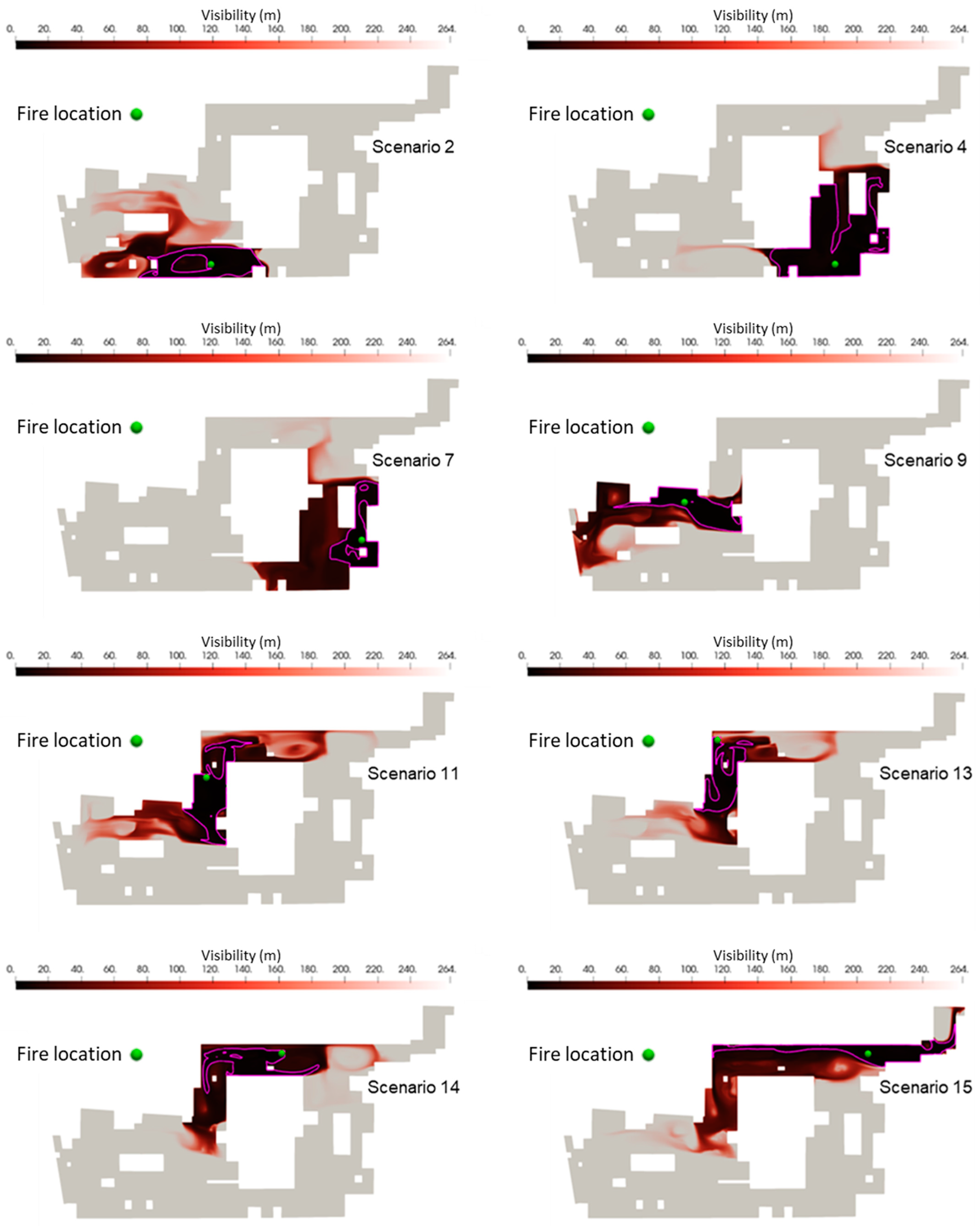

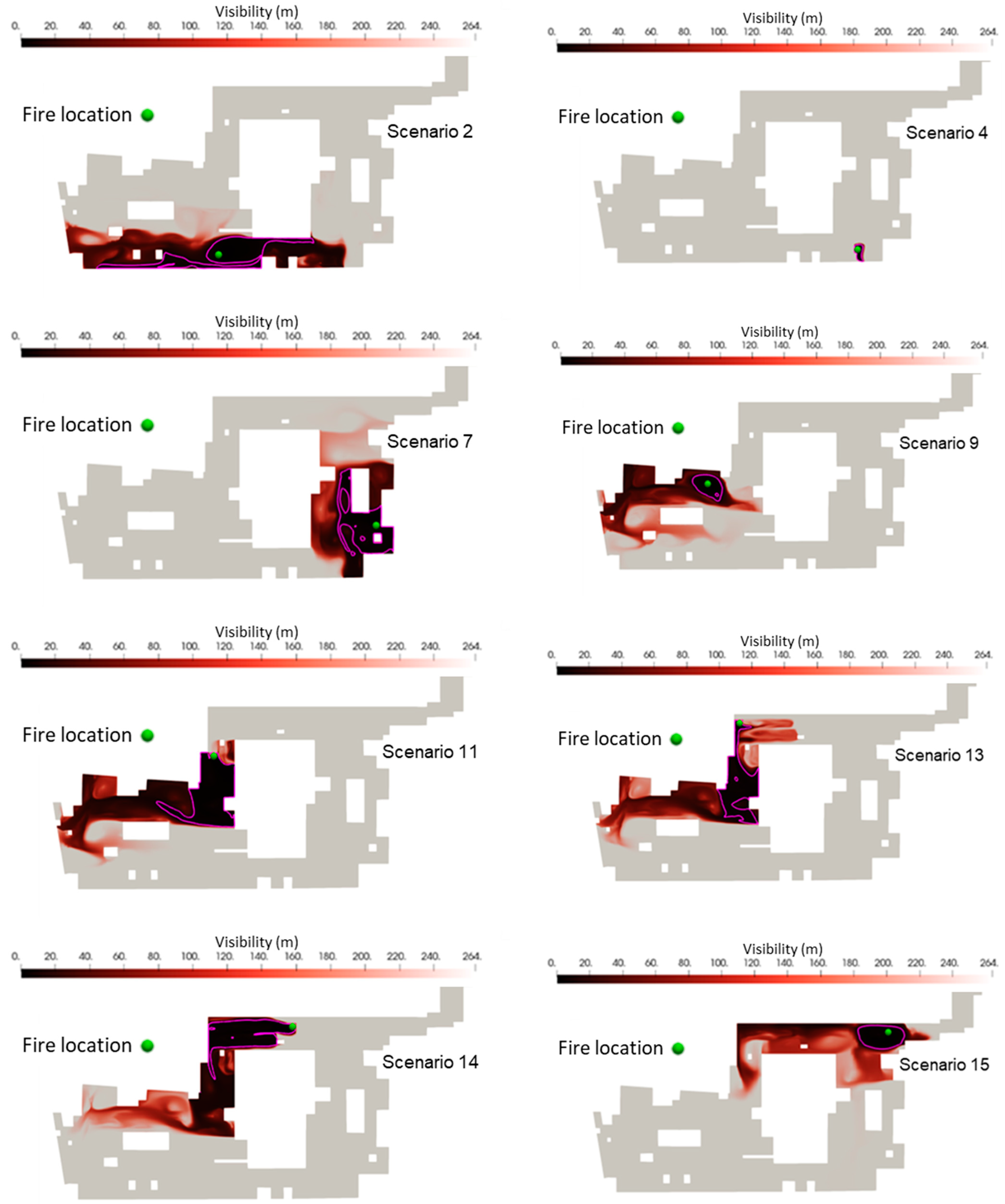

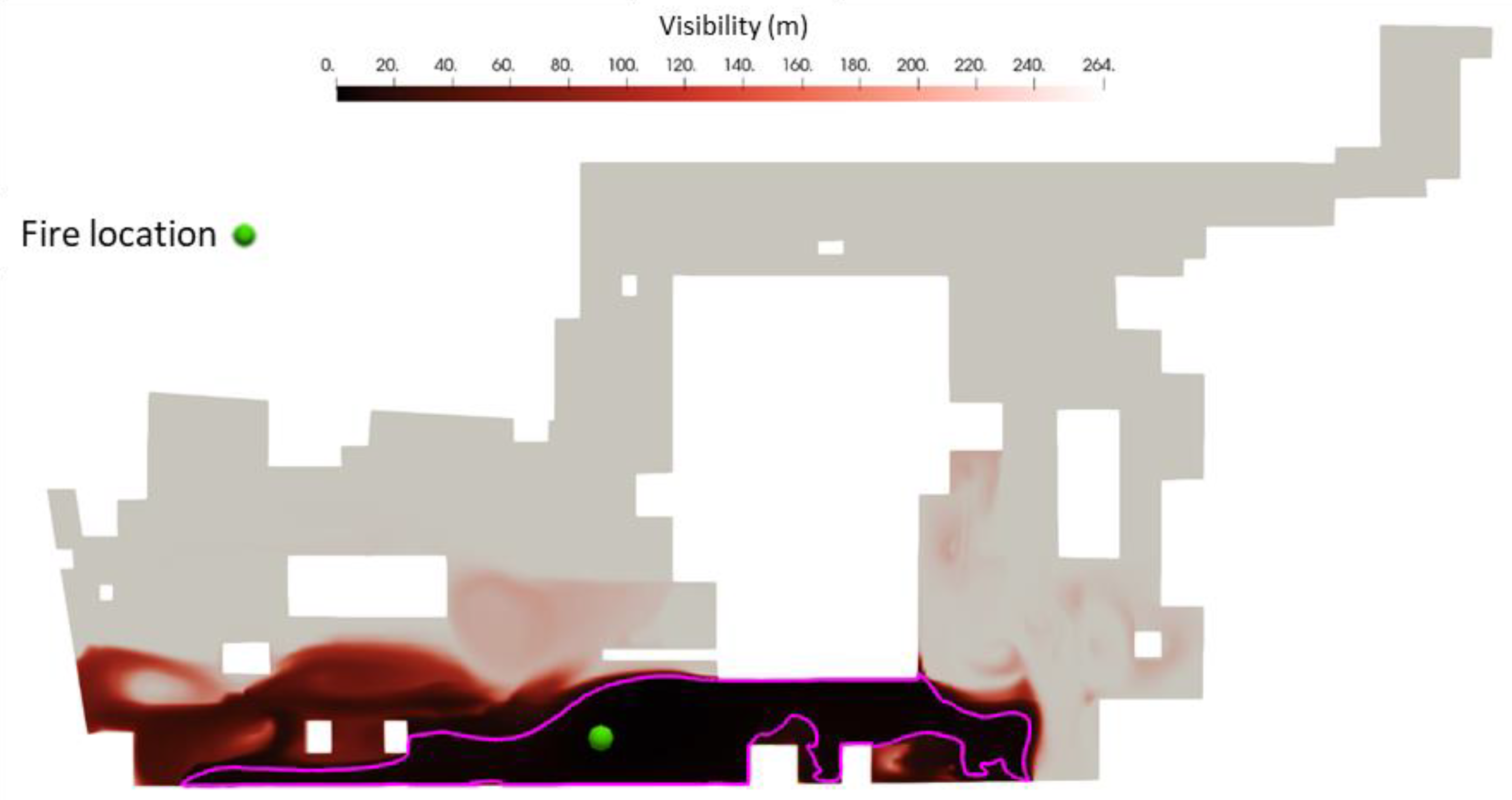

3. Results

4. Discussion and Conclusions

- Jet fan positioning and back-layering: The positioning of the jet fan system components significantly impacts its efficiency. Jet fans placed near the ceiling create a jet among themselves, necessitating the use of multiple lines of jet fans to prevent back-layering. Back-layering refers to “Movement of smoke and hot gasses counter to the direction of the ventilation airflow” according to National Fire Protection Association NFPA, which can reduce the ventilation efficiency. In the proposed design in this study, adding 10 extra jet fans to form additional lines in Zone 1 and Zone 3 enhances the capability of the ventilation system to prevent lateral smoke dispersion.

- Jet fan air flow rate: The analysis of air flow rates shows when jet fans direct an excessive airflow towards the exhaust shafts (which have a designated flow rate of 22.5 m3/s), recirculating flows occur, leading to the dispersion of smoke throughout the car park. Consequently, the utilization of low-velocity jet fans (11.2 m/s) proves to be more effective in clearing smoke compared to high-velocity jet fans (22.3 m/s).

- Optimal positioning of supply and exhaust shafts: Achieving optimal smoke control involves positioning the supply and exhaust shafts on opposite walls or minimizing the number of air flow turns between the supply and exhaust points. Ideally, all outlets should be placed directly opposite the inlets throughout the design, ensuring efficient ventilation and smoke control. In the proposed design, for instance, placing the exhaust shafts closer to the supply shaft in Zone 4 results in reduced back-layering compared to the same zone in the base case.

- Fire resistance of jet fans: It is crucial for the jet fans utilized in the system to possess fire resistance capabilities, enabling them to continue operating for a certain duration during fire events. The study underscores the significance of utilizing fire-resistant materials and components in jet fans, as their failure can result in severe conditions.

- Future research is recommended in the following directions:

- In order to further validate the findings of this study, it is recommended that future research incorporates experimental studies. By combining computational simulations with real-world experimentation, this approach will provide stronger evidence and enhance the credibility of the study’s findings.

- To gain a deeper understanding of the effectiveness of jet fan ventilation systems, future research should compare their performance with conventional systems, such as ventilation through ducts. This comparative analysis will offer insights into the advantages and limitations of each approach.

- Future research is recommended to conduct sensitivity analysis on key properties of jet fans and supply/exhaust shafts, such as air flow rate, air velocity, thrust, etc. By systematically varying these parameters, researchers can identify their impact on system performance and optimize their values accordingly.

- Future research should focus on investigating optimal jet fan positioning, aiming to provide practical guidelines that are solid and robust. This would enable engineers and practitioners to implement jet fan systems with confidence, knowing they are following the most effective and efficient layout.

- To enhance the operational efficiency of jet fan ventilation systems, future research should explore the integration of advanced control strategies, such as real-time feedback mechanisms or predictive modeling. Further investigations in this context can yield valuable insights into optimizing fan operation for improved smoke dispersion and evacuation efficiency.

- For future research, it is advisable to embark on a multi-physics analysis that combines simulations encompassing thermal dynamics, structural response, and fire propagation. This integration of distinct disciplines results in a thorough and all-encompassing safety assessment of subterranean parking facilities when confronted with fire incidents.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Sulaiman, R.; Din, N.B.C.; Ishak, N.H. Indoor air quality in selected underground car park in malaysia: Studies on ventilation system and the design layout. In Proceedings of the 6th International Conference on Indoor Air Quality, Ventilation and Energy Conservation in Buildings: Sustainable Built Environment, Sendai, Japan, 28–31 October 2007; pp. 28–31. [Google Scholar]

- Lu, S.; Wang, Y.H.; Zhang, R.F.; Zhang, H.P. Numerical Study on Impulse Ventilation for Smoke Control in an Underground Car Park. Procedia Eng. 2011, 11, 369–378. [Google Scholar] [CrossRef]

- Viegas, J.C. The use of impulse ventilation to control pollution in underground car parks. Int. J. Vent. 2009, 8, 57–74. [Google Scholar] [CrossRef]

- Kerber, S.; Walton, W.D. Characterizing Positive Pressure Ventilation using Computational Fluid Dynamics; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2003. [Google Scholar]

- Peeling, J.; Wayman, M.; Mocanu, I.; Nitsche, P.; Rands, J.; Potter, J. Energy Efficient Tunnel Solutions. Transp. Res. Procedia 2016, 14, 1472–1481. [Google Scholar] [CrossRef]

- Demirel, N. Energy-efficient mine ventilation practices. In Energy Efficiency in the Minerals Industry: Best Practices and Research Directions; Springer: Berlin/Heidelberg, Germany, 2018; pp. 287–299. [Google Scholar]

- Dai, B.; Wang, Q.; Liu, S.; Wang, D.; Yu, L.; Li, X.; Wang, Y. Novel configuration of dual-temperature condensation and dual-temperature evaporation high-temperature heat pump system: Carbon footprint, energy consumption, and financial assessment. Energy Convers. Manag. 2023, 292, 117360. [Google Scholar] [CrossRef]

- Dai, B.; Qi, H.; Liu, S.; Zhong, Z.; Li, H.; Song, M.; Ma, M.; Sun, Z. Environmental and economical analyses of transcritical CO2 heat pump combined with direct dedicated mechanical subcooling (DMS) for space heating in China. Energy Convers. Manag. 2019, 198, 111317. [Google Scholar] [CrossRef]

- Rahif, R.; Norouziasas, A.; Elnagar, E.; Doutreloup, S.; Pourkiaei, S.M.; Amaripadath, D.; Romain, A.C.; Fettweis, X.; Attia, S. Impact of climate change on nearly zero-energy dwelling in temperate climate: Time-integrated discomfort, HVAC energy performance, and GHG emissions. Build. Environ. 2022, 223, 109397. [Google Scholar] [CrossRef]

- Rahif, R.; Kazemi, M.; Attia, S. Overheating Analysis of Optimized Nearly Zero-Energy Dwelling During Current and Future Heatwaves Coincided with Cooling System Outage. Energy Build. 2023, 287, 112998. [Google Scholar] [CrossRef]

- Norouziasas, A.; Tabadkani, A.; Rahif, R.; Amer, M.; van Dijk, D.; Lamy, H.; Attia, S. Implementation of ISO/DIS 52016-3 for adaptive façades: A case study of an office building. Build. Environ. 2023, 235, 110195. [Google Scholar] [CrossRef]

- Piraei, F.; Matusiak, B.; Verso, V.R.L. Evaluation and Optimization of Daylighting in Heritage Buildings: A Case-Study at High Latitudes. Buildings 2022, 12, 2045. [Google Scholar] [CrossRef]

- Liu, E.; Wang, X.; Zhao, W.; Su, Z.; Chen, Q. Analysis and Research on Pipeline Vibration of a Natural Gas Compressor Station and Vibration Reduction Measures. Energy Fuels 2021, 35, 479–492. [Google Scholar] [CrossRef]

- Chow, W.K. Ventilation design: Use of computational fluid dynamics as a study tool. Build. Serv. Eng. Res. Technol. 1995, 16, 63–76. [Google Scholar] [CrossRef]

- Çakir, M.; Ün, Ç. CFD Analysis of Smoke and Temperature Control System of Car Park Area with Jet Fans. J. Eng. Res. Rep. 2020, 13, 27–40. [Google Scholar] [CrossRef]

- Sittisak, P.; Charinpanitkul, T.; Chalermsinsuwan, B. Enhancement of carbon monoxide removal in an underground car park using ventilation system with single and twin jet fans. Tunn. Undergr. Space Technol. 2020, 97, 103226. [Google Scholar] [CrossRef]

- Sultansu, S.; Ayhan, O. The Cfd Analysis of Ventilation and Smoke Control System with Jet Fan in a Parking Garage. Int. J. Adv. Eng. Pure Sci. 2020, 32, 89–95. [Google Scholar] [CrossRef]

- Nazari, A.; Jafari, M.; Rezaei, N.; Taghizadeh-Hesary, F.; Taghizadeh-Hesary, F. Jet fans in the underground car parking areas and virus transmission. Phys. Fluids 2021, 33, 013603. [Google Scholar] [CrossRef] [PubMed]

- Kmecová, M.; Krajčík, M.; Straková, Z. Designing jet fan ventilation for an underground car park by CFD simulations. Period. Polytech. Mech. Eng. 2019, 63, 39–43. [Google Scholar] [CrossRef]

- Immonen, E. CFD optimization of jet fan ventilation in a car park by fractional factorial designs and response surface methodology. Build. Simul. 2016, 9, 53–61. [Google Scholar] [CrossRef]

- Senveli, A.; Dizman, T.; Celen, A.; Bilge, D.; Dalkiliç, A.S.; Wongwises, S. CFD analysis of smoke and temperature control system of an indoor parking lot with jet fans. J. Therm. Eng. 2015, 1, 116–130. [Google Scholar] [CrossRef]

- Špiljar, Ž.; Drakulić, M.; Schneider, D.R. Analysis of Jet Fan Ventilation System installed in an Underground Car Park with Partition Walls. J. Sustain. Dev. Energy Water Environ. Syst. 2018, 6, 228–239. [Google Scholar] [CrossRef]

- Deckers, X.; Haga, S.; Tilley, N.; Merci, B. Smoke control in case of fire in a large car park: CFD simulations of full-scale configurations. Fire Saf. J. 2013, 57, 22–34. [Google Scholar] [CrossRef]

- UK Government. Statutory Guidance ‘Ventilation: Approved Document F’; Department for Levelling up, Housing and Communities and Ministry of Housing, Communities & Local Government: London, UK, 2010. Available online: https://www.gov.uk/government/publications/ventilation-approved-document-f (accessed on 6 July 2023).

- UK Government. Statutory Guidance ‘Fire Safety: Approved Document B’; Department for Levelling up, Housing and Communities and Ministry of Housing, Communities & Local Government: London, UK, 2010. Available online: https://www.gov.uk/government/publications/fire-safety-approved-document-b (accessed on 6 July 2023).

- Briggs, W.L.; Henson, V.E.; McCormick, S.F. A Multigrid Tutorial; SIAM: Philadelphia, PA, USA, 2000. [Google Scholar]

- FlaktWoods. HTJM Aerofoil—Cased Axial Fans HTJM Aerofoil Performance and Electrical Data. 2013. Available online: https://www.flaktgroup.com/en/products/air-movement/fire-safety-fans/ht-axial-fans/ht-jm-aerofoil-axial-flow-fan/ (accessed on 6 July 2023).

- Fanchi, J.R. (Ed.) Chapter 9—Fluid Flow Equations. In Shared Earth Modeling; Butterworth-Heinemann: Woburn, UK, 2002; pp. 150–169. [Google Scholar] [CrossRef]

- Rohdin, P.; Moshfegh, B. Numerical modelling of industrial indoor environments: A comparison between different turbulence models and supply systems supported by field measurements. Build. Environ. 2011, 46, 2365–2374. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Pearson Education: London, UK, 2007. [Google Scholar]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Heinze, L. Mathematical Model for Darcy Forchheimer Flow with Applications to Well Performance Analysis; Texas Tech Univeristy: Lubbock, TX, USA, 2007. [Google Scholar]

- Darcy Fochheimer Explanation. 2018. Available online: https://openfoamwiki.net/index.php/DarcyForchheimer (accessed on 24 May 2019).

- Klote, J.H.; Milke, J.A. Principles of Smoke Management; ASHRAE: Peachtree Corners, GA, USA, 2002; Available online: http://fe.hkie.org.hk/FireDigest/Document/Images/20110601103834728/20110601103834728.pdf (accessed on 6 July 2023).

- Hopkin, C.; Spearpoint, M.; Hopkin, D. A review of design values adopted for heat release rate per unit area. Fire Technol. 2019, 55, 1599–1618. [Google Scholar] [CrossRef]

- BS 7346-7; Components for Smoke and Heat Control Systems. Code of Practice on Functional Recommendations and Calculation Methods for Smoke and Heat Control Systems for Covered Car Parks. British Standards Institution: London, UK, 2013.

- Behrens, T. OpenFOAM’s Basic Solvers for Linear Systems of Equations; Chalmers, Department of Applied Mechanics: Gothenburg, Sweden, 2009; Volume 18. [Google Scholar]

- Darwish, M.; Moukalled, F. The Finite Volume Method in Computational Fluid Dynamics: An Advanced Introduction with OpenFOAM® and Matlab®; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; Taylor & Francis: Oxfordshire, UK, 2018. [Google Scholar]

- Harlow, F.H.; Welch, J.E. Numerical calculation of time-dependent viscous incompressible flow of fluid with free surface. Phys. Fluids 1965, 8, 2182–2189. [Google Scholar] [CrossRef]

| Author(s) and Year of Publication | Ref. | Location | Building Type | Focus: Normal Conditions (N)/Fire Events (F) |

|---|---|---|---|---|

| Nazari et al., 2021 | [18] | Tabriz, Iran | Commercial | N |

| Çakir and Ün, 2020 | [15] | Isparta, Turkey | Hospital | F |

| Sittisak et al., 2020 | [16] | Bangkok, Thailand | Commercial and office | N |

| Sultansu and Onat, 2020 | [17] | Turkey | n/d | N and F |

| Kmecová et al., 2019 | [19] | Slovakia | Commercial | F |

| Špiljar et al., 2018 | [22] | Croatia | n/d | N |

| Immonen, 2016 | [20] | Finland | n/d | N |

| Senveli et al., 2015 | [21] | Istanbul, Turkey | Business center | N and F |

| Deckers et al., 2013 | [23] | Ghent, Belgium | Industrial | F |

| Performance Index | Air Flow [m3/s] | Air Speed [m/s] | Thrust [N] |

|---|---|---|---|

| Value | 2.88/1.44 | 22.3/11.2 | 78/20 |

| Boundary | p [Pa] | U [m/s] | K [m2s−2] | ε [m2s−3] |

|---|---|---|---|---|

| Inlet/outlet (supply/exhaust shafts) | Type: fanPressure—patchType: total Pressure—file: fanCurve—direction: in (supply) or out (exhaust)—p0: uniform 0 | pressureInletOutletVeloicity—value: uniform (0,0,0) | fixedValue—value: $internalField: uniform 0.375 | fixedValue—value: $internalField: uniform 14.855 |

| Parking entrance | fixedValue—value: uniform 0 | |||

| Walls | fixedValue—value: uniform (0,0,0) | kqRWallFunction—value: $internalField: uniform 0.375 | epsilonWallFunction—value: $internalField: uniform 14.855 |

| Static Pressure [Pa] | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 500 | 600 |

|---|---|---|---|---|---|---|---|---|---|---|

| Flux [m3/s] | 22.3 | 21.9 | 21.39 | 20.86 | 20.31 | 19.75 | 19.17 | 17.9 | 16.45 | 14.6 |

| Phase 01 | Phase 02 | |

|---|---|---|

| Linear solver | p: GAMG U, ε, and k: smoothSolver | T: PBiCGStab |

| Preconditioner | p: DIC U, ε, and k: DILU | T: DILU |

| Smoother | GaussSeidel | - |

| Application solver | porousSimpleFoam | scalarTransportFoam |

| Situation | K |

|---|---|

| Building components in reflected light | 3 |

| Illuminated signs | 8 |

| Reflecting signs | 3 |

| Mode of Combustion | |

|---|---|

| Flaming combustion | 7875.2 |

| Smoldering combustion | 4301.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahif, R.; Attia, S. CFD Assessment of Car Park Ventilation System in Case of Fire Event. Appl. Sci. 2023, 13, 10190. https://doi.org/10.3390/app131810190

Rahif R, Attia S. CFD Assessment of Car Park Ventilation System in Case of Fire Event. Applied Sciences. 2023; 13(18):10190. https://doi.org/10.3390/app131810190

Chicago/Turabian StyleRahif, Ramin, and Shady Attia. 2023. "CFD Assessment of Car Park Ventilation System in Case of Fire Event" Applied Sciences 13, no. 18: 10190. https://doi.org/10.3390/app131810190

APA StyleRahif, R., & Attia, S. (2023). CFD Assessment of Car Park Ventilation System in Case of Fire Event. Applied Sciences, 13(18), 10190. https://doi.org/10.3390/app131810190