Effect of Simultaneous Changes in Asphalt Binder Bee Structure Components on Mechanical Properties during the Aging and Rejuvenation Process

Abstract

:1. Introduction

2. Objectives of the Study

3. Materials and Methods

3.1. AFM Test Materials and Methods

3.2. Finite Element Modeling of AFM Microforms

4. Analysis of Results

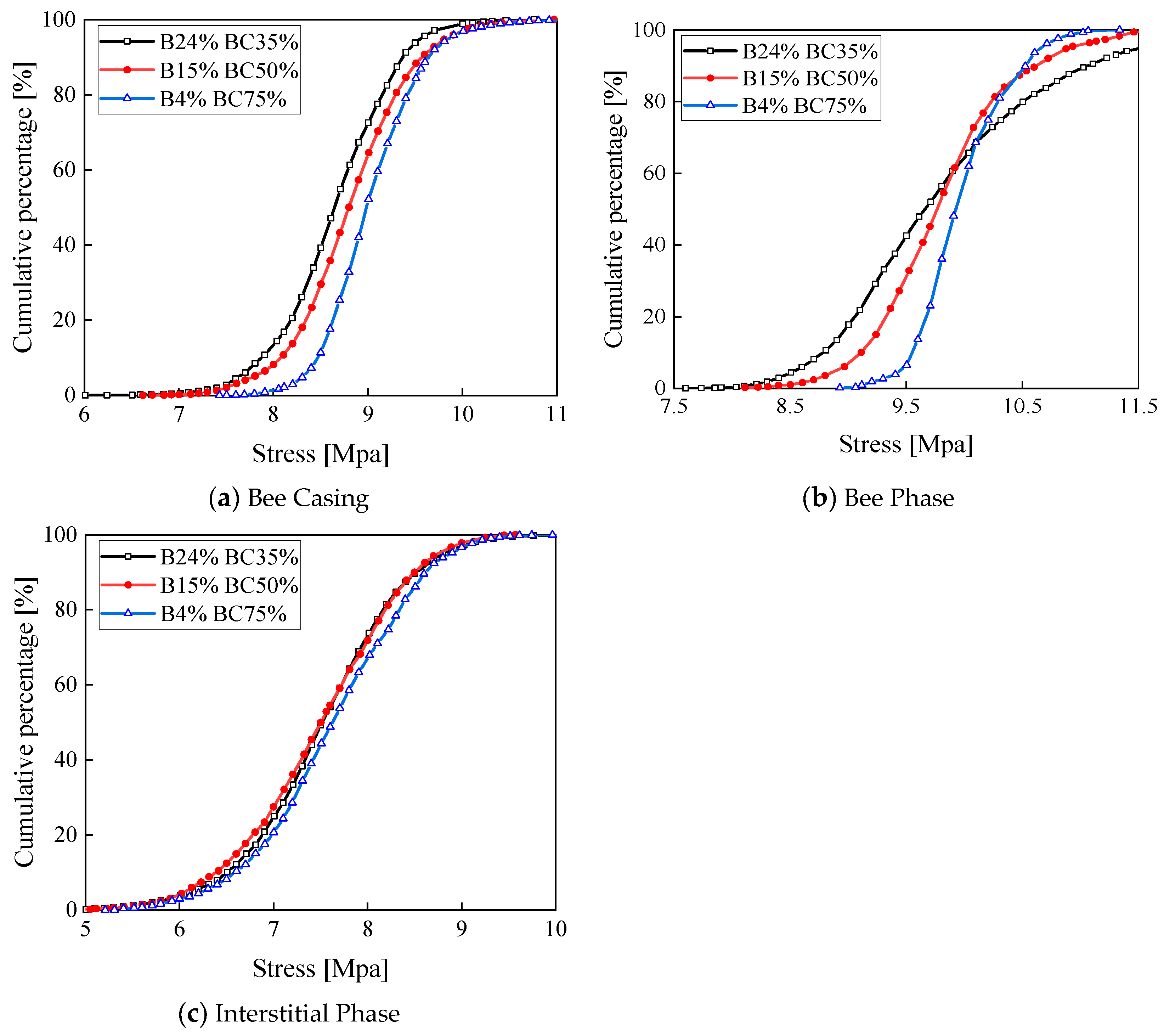

4.1. Analysis of Internal Stress Distribution Pattern

4.2. Analysis of the Internal Distribution Law of Tensile Strain

5. Conclusions

- (1)

- The stress in the bee phase is significantly greater than that in the bee casing, and the stress in the interstitial phase is minimal. When the asphalt binder is aged, the proportions of the bee phase and bee casing increase, which will produce greater internal stresses within the asphalt binder, which, in turn, is more prone to fatigue cracking and other problems.

- (2)

- With the simultaneous increase in the contents of the bee phase and the bee casing, the stress in each phase structure in the asphalt binder samples increase. The stress of the interstitial phase increases at the fastest rate, and the stresses of the bee phase and the bee casing increase at a similar rate. The rejuvenation level of the aged asphalt binder has not yet reached the upper limit, and with the increase in the dosage of the old material, its interfacial interaction capacity with the new asphalt binder also gradually increases, leading to an increase in the interfacial bee casing, and a gradual increase in the internal stress of the recycled asphalt binder.

- (3)

- Under the combined effect of the decrease in the proportion of bee phase and the increase in the proportion of the bee casing, there is a certain degree of increase in the internal stresses and strains in the asphalt binder, the effect of the bee casing on the internal stresses in the asphalt binder is more pronounced, and the bee phase and the bee casing play a better role in resisting external deformation due to the increase in the volume fraction. When the aged asphalt binder in the rejuvenation process gradually interacts with the unaged asphalt binder, part of the aged asphalt binder and the unaged asphalt binder are fused together to form an interfacial phase (bee casing), resulting in a decrease in the aged asphalt binder and an increase in the interfacial phase, and at this time, the internal stress of the regenerated asphalt binder becomes larger.

- (4)

- Under the action of a displacement load, the internal tensile strain of the asphalt binder increases, the magnitude of strain increases with the increase in old material mixing, and the interstitial phase is the most sensitive. For a recycled asphalt binder, whether it is used to improve the old material doping or to enhance the new and old asphalt binders’ interfacial diffusion fusion, it will, to a certain extent, increase the level of tensile strain within the recycled asphalt binder, which, in turn, puts forward higher requirements for its anti-cracking properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Cavalli, M.C.; Mazza, E.; Zaumanis, M.; Poulikakos, L.D. Surface nanomechanical properties of bio-modified reclaimed asphalt binder. Road Mater. Pavement Des. 2021, 22, 1407–1423. [Google Scholar] [CrossRef]

- Wu, L.; Zhao, K.-H.; Zhang, G.-H. Characterization of Reclaimed Asphalt Based on Microscopic Analysis. Bull. Chin. Ceram. Soc. 2018, 37, 3684–3689. [Google Scholar]

- Guo, M.; Yin, X.; Du, X.; Tan, Y. Effect of aging, testing temperature and relative humidity on adhesion between asphalt binder and mineral aggregate. Constr. Build. Mater. 2023, 363, 129775. [Google Scholar] [CrossRef]

- Guo, M.; Liang, M.; Du, X. Evaluation on Feasibility of Carbon Black and Hindered Amine Light Stabilizer as UV-Resistant Additives of Asphalt Binder. J. Test. Eval. 2023, 51. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Griffa, M.; Bressi, S.; Partl, M.N.; Tebaldi, G.; Poulikakos, L.D. Multiscale imaging and characterization of the effect of mixing temperature on asphalt concrete containing recycled components. J. Microsc. 2016, 264, 22–33. [Google Scholar] [CrossRef]

- Guo, M.; Liu, H.; Jiao, Y.; Mo, L.; Tan, Y.; Wang, D.; Liang, M. Effect of WMA-RAP technology on pavement performance of asphalt mixture: A state-of-the-art review. J. Clean. Prod. 2020, 266, 121704. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Zaumanis, M.; Mazza, E.; Partl, M.N.; Poulikakos, L.D. Effect of ageing on the mechanical and chemical properties of binder from RAP treated with bio-based rejuvenators. Compos. Part B Eng. 2018, 141, 174–181. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Spadafora, A.; Teltayev, B.; Izmailova, G.; Amerbayev, Y.; Bortolotti, V. Polymer modified bitumen: Rheological properties and structural characterization. Colloids Surf. A 2015, 480, 390–397. [Google Scholar] [CrossRef]

- Guo, M.; Liang, M.; Sreeram, A.; Bhasin, A.; Luo, D. Characterisation of rejuvenation of various modified asphalt binders based on simplified chromatographic techniques. Int. J. Pavement Eng. 2022, 23, 4333–4343. [Google Scholar] [CrossRef]

- Xing, C.; Jiang, W.; Li, M.; Wang, M.; Xiao, J.; Xu, Z. Application of atomic force microscopy in bitumen materials at the nanoscale: A review. Constr. Build. Mater. 2022, 342, 128059. [Google Scholar] [CrossRef]

- Loeber, L.; Sutton, O.; Morel, J.; Valleton, J.M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 1996, 182, 32–39. [Google Scholar] [CrossRef]

- Das, P.K.; Baaj, H.; Tighe, S.; Kringos, N. Atomic force microscopy to investigate asphalt binders: A state-of-the-art review. Road Mater. Pavement Des. 2016, 17, 693–718. [Google Scholar] [CrossRef]

- Masson, J.-F.; Leblond, V.; Margeson, J. Bitumen morphologies by phase–detection atomic force microscopy. J. Microsc. 2006, 221, 17–29. [Google Scholar] [CrossRef] [PubMed]

- Blom, J.; Soenen, H.; Van den Brande, N.; Van den Bergh, W. New evidence on the origin of ‘bee structures’ on bitumen and oils, by atomic force microscopy (AFM) and confocal laser scanning microscopy (CLSM). Fuel 2021, 303, 121265. [Google Scholar] [CrossRef]

- Hofko, B.; Eberhardsteiner, L.; Füssl, J.; Grothe, H.; Handle, F.; Hospodka, M.; Grossegger, D.; Nahar, S.N.; Schmets, A.J.M.; Scarpas, A. Impact of maltene and asphaltene fraction on mechanical behavior and microstructure of bitumen. Mater. Struct. 2016, 49, 829–841. [Google Scholar] [CrossRef]

- Nahar, S.N.; Schmets, A.J.M.; Scarpas, A.; Schitter, G. Temperature and thermal history dependence of the microstructure in bituminous materials. Eur. Polym. J. 2013, 49, 1964–1974. [Google Scholar] [CrossRef]

- Hung, A.M.; Mousavi, M.; Pahlavan, F.; Fini, E.H. Intermolecular Interactions of Isolated Bio-Oil Compounds and Their Effect on Bitumen Interfaces. ACS Sustain. Chem. Eng. 2017, 5, 7920–7931. [Google Scholar] [CrossRef]

- Navarro, F.; Partal, P.; Garciamorales, M.; Martinezboza, F.; Gallegos, C. Bitumen modification with a low-molecular-weight reactive isocyanate-terminated polymer. Fuel 2007, 86, 2291–2299. [Google Scholar] [CrossRef]

- Xie, S.; Yi, J.; Zhao, H.; Feng, D.; Sun, Z. Micromorphology and Micromechanical Properties Evolution of Bitumen and Bitumen Fractions Using Atomic Force Microscopy Considering Temperature Effect. Energy Fuels 2021, 35, 17434–17445. [Google Scholar] [CrossRef]

- De Moraes, M.B.; Pereira, R.B.; Simão, R.A.; Leite, L.F.M. High temperature AFM study of CAP 30/45 pen grade bitumen. J. Microsc. 2010, 239, 46–53. [Google Scholar] [CrossRef]

- Chen, A.; Liu, G.; Zhao, Y.; Li, J.; Pan, Y.; Zhou, J. Research on the aging and rejuvenation mechanisms of asphalt using atomic force microscopy. Constr. Build. Mater. 2018, 167, 177–184. [Google Scholar] [CrossRef]

- Jahangir, R.; Little, D.; Bhasin, A. Evolution of asphalt binder microstructure due to tensile loading determined using AFM and image analysis techniques. Int. J. Pavement Eng. 2015, 16, 337–349. [Google Scholar] [CrossRef]

- Du, C.; Liu, P.; Ganchev, K.; Lu, G.; Oeser, M. Influence of microstructure evolution of bitumen on its micromechanical property by finite element simulation. Constr. Build. Mater. 2021, 293, 123522. [Google Scholar] [CrossRef]

- Li, X.; Wei, D.; Yao, Z.; Li, B. Effects of Rejuvenators on Rheological Properties and Microstructures of Aged Asphalt. J. Build. Mater. 2018, 21, 992–999. [Google Scholar]

- Hong, H.; Zhang, H.; Zhang, S. Effect of multi-dimensional nanomaterials on the aging behavior of asphalt by atomic force microscope. Constr. Build. Mater. 2020, 260, 120389. [Google Scholar] [CrossRef]

- Allen, R.G.; Little, D.N.; Bhasin, A.; Glover, C.J. The effects of chemical composition on asphalt microstructure and their association to pavement performance. Int. J. Pavement Eng. 2014, 15, 9–22. [Google Scholar] [CrossRef]

- Ganter, D.; Mielke, T.; Maier, M.; Lupascu, D.C. Bitumen rheology and the impact of rejuvenators. Constr. Build. Mater. 2019, 222, 414–423. [Google Scholar] [CrossRef]

- Fischer, H.R.; Dillingh, E.C.; Hermse, C. On the microstructure of bituminous binders. Road Mater. Pavement Des. 2014, 15, 1–15. [Google Scholar] [CrossRef]

- Cavalli, M.C.; Partl, M.N.; Poulikakos, L.D. Effect of ageing on the microstructure of reclaimed asphalt binder with bio-based rejuvenators. Road Mater. Pavement Des. 2019, 20, 1683–1694. [Google Scholar] [CrossRef]

- Ozdemir, D.K.; Topal, A.; McNally, T. Relationship between microstructure and phase morphology of SBS modified bitumen with processing parameters studied using atomic force microscopy. Constr. Build. Mater. 2020, 268, 121061. [Google Scholar] [CrossRef]

- Ortega, F.J.; Roman, C.; Navarro, F.J.; García-Morales, M.; McNally, T. Physico-chemistry control of the linear viscoelastic behaviour of bitumen/montmorillonite/MDI ternary composites: Effect of the modification sequence. Fuel Process. Technol. 2016, 143, 195–203. [Google Scholar] [CrossRef]

- Soenen, H.; Besamusca, J.; Fischer, H.R.; Poulikakos, L.D.; Planche, J.; Das, P.K.; Kringos, N.; Grenfell, J.R.A.; Lu, X.; Chailleux, E. Laboratory investigation of bitumen based on round robin DSC and AFM tests. Mater. Struct. 2014, 47, 1205–1220. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, Z.; Shi, J.; Yang, X.; Li, X. Insights into permeability of rejuvenator in old asphalt based on permeation theory: Permeation behaviors and micro characteristics. Constr. Build. Mater. 2022, 325, 126765. [Google Scholar] [CrossRef]

- Aghazadeh Dokandari, P.; Topal, A.; Kaya Ozdemir, D. Rheological and Microstructural Investigation of the Effects of Rejuvenators on Reclaimed Asphalt Pavement Bitumen by DSR and AFM. Int. J. Civ. Eng. 2021, 19, 749–758. [Google Scholar] [CrossRef]

- Xing, C.; Liu, L.; Cui, Y.; Ding, D. Analysis of base bitumen chemical composition and aging behaviors via atomic force microscopy-based infrared spectroscopy. Fuel 2020, 264, 116845. [Google Scholar] [CrossRef]

- Guo, M.; Tan, Y.; Yu, J.; Hou, Y.; Wang, L. A direct characterization of interfacial interaction between asphalt binder and mineral fillers by atomic force microscopy. Mater. Struct. 2017, 50, 141. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communication Press: Beijing, China, 2011.

| Test Item | Unit | Test Result | Standard Value | Test Method | |

|---|---|---|---|---|---|

| Penetration (25 °C, 5 s, 100 g) | 0.1 mm | 81 | 80~100 | T0604 | |

| Penetration index (PI) | — | −1.48 | −1.5~+1.0 | T0604 | |

| Ductility (10 °C, 5 cm/min) | cm | >100 | ≥30 | T0605 | |

| Ductility (15 °C, 5 cm/min) | cm | >100 | ≥100 | T0605 | |

| Softening point (TR and B) | °C | 45.0 | ≥44 | T0606 | |

| Wax content (distillation method) | % | 0.3 | ≤2.2 | T0615 | |

| Flash point | °C | 301 | ≥245 | T0611 | |

| Solubility | % | 99.84 | ≥99.5 | T0607 | |

| Dynamic viscosity (60 °C) | Pa·s | 181 | ≥140 | T0620 | |

| Density (15 °C) | g/cm3 | 1.010 | measured result | T0603 | |

| Thin film heating (163 °C, 5 h) | Mass change | % | −0.122 | ≥−0.8, ≤0.8 | T0609 |

| Penetration ratio (25 °C) | % | 76 | ≥57 | T0604 | |

| Ductility (10 °C) | cm | 32 | ≥8 | T0605 | |

| Ductility (15 °C) | cm | >100 | ≥20 | T0605 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, D.; Yao, X.; Guo, M.; Luo, D. Effect of Simultaneous Changes in Asphalt Binder Bee Structure Components on Mechanical Properties during the Aging and Rejuvenation Process. Appl. Sci. 2023, 13, 10308. https://doi.org/10.3390/app131810308

Huo D, Yao X, Guo M, Luo D. Effect of Simultaneous Changes in Asphalt Binder Bee Structure Components on Mechanical Properties during the Aging and Rejuvenation Process. Applied Sciences. 2023; 13(18):10308. https://doi.org/10.3390/app131810308

Chicago/Turabian StyleHuo, Donghui, Xiupeng Yao, Meng Guo, and Daisong Luo. 2023. "Effect of Simultaneous Changes in Asphalt Binder Bee Structure Components on Mechanical Properties during the Aging and Rejuvenation Process" Applied Sciences 13, no. 18: 10308. https://doi.org/10.3390/app131810308

APA StyleHuo, D., Yao, X., Guo, M., & Luo, D. (2023). Effect of Simultaneous Changes in Asphalt Binder Bee Structure Components on Mechanical Properties during the Aging and Rejuvenation Process. Applied Sciences, 13(18), 10308. https://doi.org/10.3390/app131810308