Digestate Quality Originating from Kitchen Waste

Abstract

:1. Introduction

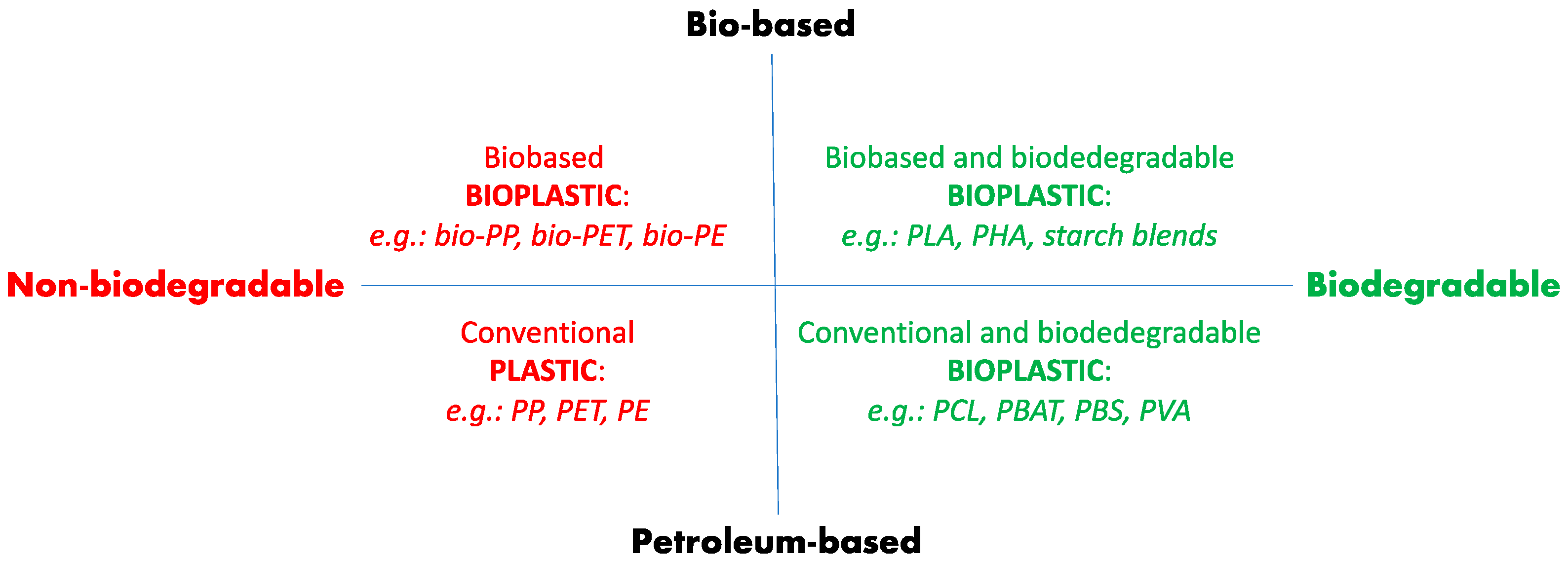

2. The Quality of Digestate

3. Conventional and Biodegradable Plastics

4. Susceptibility of Selected Bioplastics to Degradation

5. The Challenge of Microplastics’ Determination

6. Quality Concerns—Regulations

7. Digestate as Component Material Category

- 19 06 05 is a liquor from the anaerobic treatment of animal and vegetable waste;

- 19 06 04 is a digestate from the anaerobic treatment of municipal waste;

- 19 06 06 is a digestate from anaerobic treatment of animal and vegetable waste.

- PFC1—fertiliser: organic, organo-mineral, or inorganic and either solid or liquid;

- PFC3—soil improver: organic or inorganic;

- PFC4—growing medium;

- PFC7—fertilising product blend.

- for five tested samples, Salmonella spp. absence in 25 g or 25 mL;

- for five tested samples, Escherichia coli or Enterococcaceae limit 1000 in 1 g or 1 mL.

- sampling and sample preparation;

- test methods for the determination of elements (heavy metals and others);

- test methods for the detection of microorganisms.

- meet the requirements for a PFC;

- meet the requirements for a CMC;

- are labelled according to the requirements in FPR;

- pass the Conformity Assessment Procedure.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Paritosh, K.; Yadav, M.; Mathur, S.; Balan, V.; Liao, W.; Pareek, N.; Vivekanand, V. Organic Fraction of Municipal Solid Waste: Overview of Treatment Methodologies to Enhance Anaerobic Biodegradability. Front. Energy Res. 2018, 6, 75. [Google Scholar] [CrossRef]

- Yan, Y.-J.; Li, X.; Lu, C.-S.; Kobayashi, T.; Zhen, G.-Y.; Hu, Y. A Review on Start-Up Phase Optimization of Kitchen Waste Anaerobic Digestion. Fermentation 2023, 9, 603. [Google Scholar] [CrossRef]

- Tambone, F.; Scaglia, B.; D’Imporzano, G.; Schievano, A.; Orzi, V.; Salati, S.; Adani, F. Assessing amendment and fertilizing properties of digestates from anaerobic digestion through a comparative study with digested sludge and compost. Chemosphere 2010, 81, 577–583. [Google Scholar] [CrossRef] [PubMed]

- European Parliament, Council of the European Union. Official Journal of the European Union. 2019. Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019. Available online: https://eur-lex.europa.eu/eli/reg/2019/1009/oj (accessed on 26 June 2023).

- Logan, M.; Visvanathan, C. Management strategies for anaerobic digestate of organic fraction of municipal solid waste: Current status and future prospects. Waste Manag. Res. 2019, 37 (Suppl. S1), 27–39. [Google Scholar] [CrossRef]

- López-Gómez, J.P.; Latorre-Sánchez, M.; Unger, P.; Schneider, R.; Lozano, C.C.; Venus, J. Assessing the organic fraction of municipal solid wastes for the production of lactic acid. Biochem. Eng. J. 2019, 150, 107251. [Google Scholar] [CrossRef]

- Eurostat. Municipal Waste Statistics, 2021. Municipal Waste Generated 2006–2021. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics (accessed on 26 June 2023).

- European Parliament, Council of the European Union. Official Journal of the European Union. 2008. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32008L0098&qid=1694764606184 (accessed on 26 June 2023).

- Publications Office of the European Union. European Environmental Agency, Report No 4/2020. Bio-Waste in Europe—Turning Challenges into Opportunities. 2020. Available online: https://www.eea.europa.eu/publications/bio-waste-in-europe (accessed on 26 June 2023).

- Eurostat. Food Waste: 127 kg per Inhabitant in the EU in 2020. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/-/ddn-20220925-2 (accessed on 29 August 2023).

- European Commission, Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs; Blengini, G.; El Latunussa, C.; Eynard, U.; Torres De Matos, C.; Wittmer, D.; Georgitzikis, K.; Pavel, C.; Carrara, S.; Mancini, L.; et al. Study on the EU’s List of Critical Raw Materials—Final Report, Publications Office. 2020. Available online: https://data.europa.eu/doi/10.2873/11619 (accessed on 26 June 2023).

- Weithmann, N.; Möller, J.N.; Löder, M.G.J.; Piehl, S.; Laforsch, C.; Freitag, R. Organic fertilizer as a vehicle for the entry of microplastic into the environment. Sci. Adv. 2018, 4, eaap8060. [Google Scholar] [CrossRef]

- Malhotra, M.; Aboudi, K.; Pisharody, L.; Singh, A.; Banu, J.R.; Bhatia, S.K.; Varjani, S.; Kumar, S.; González-Fernández, C.; Kumar, S.; et al. Biorefinery of anaerobic digestate in a circular bioeconomy: Opportunities, challenges and perspectives. Renew. Sustain. Energy Rev. 2022, 166, 112642. [Google Scholar] [CrossRef]

- Beggio, G.; Schievano, A.; Bonato, T.; Hennebert, P.; Pivato, A. Statistical analysis for the quality assessment of digestates from separately collected organic fraction of municipal solid waste (OFMSW) and agro-industrial feedstock. Should input feedstock to anaerobic digestion determine the legal status of digestate? Waste Manag. 2019, 87, 546–558. [Google Scholar] [CrossRef]

- Knoop, C.; Tietze, M.; Dornack, C.; Raab, T. Fate of nutrients and heavy metals during two-stage digestion and aerobic post-treatment of municipal organic waste. Bioresour. Technol. 2018, 251, 238–248. [Google Scholar] [CrossRef]

- Kupper, T.; Bürge, D.; Bachmann, H.J.; Güsewell, S.; Mayer, J. Heavy metals in source-separated compost and digestates. Waste Manag. 2014, 34, 867–874. [Google Scholar] [CrossRef]

- Lehmann, L.; Bloem, E. Antibiotic residues in substrates and output materials from biogas plants—Implications for agriculture. Chemosphere 2021, 278, 130425. [Google Scholar] [CrossRef] [PubMed]

- Carraturo, F.; Panico, A.; Giordano, A.; Libralato, G.; Aliberti, F.; Galdiero, E.; Guida, M. Hygienic assessment of digestate from a high solids anaerobic co-digestion of sewage sludge with biowaste by testing Salmonella Typhimurium, Escherichia coli and SARS-CoV-2. Environ. Res. 2022, 206, 112586. [Google Scholar] [CrossRef] [PubMed]

- DelRe, C.; Jiang, Y.; Kang, P.; Kwon, J.; Hall, A.; Jayapurna, I.; Ruan, Z.; Ma, L.; Zolkin, K.; Li, T.; et al. Near-complete depolymerization of polyesters with nano-dispersed enzymes. Nature 2021, 592, 558–563. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Delre, C.; Kwon, J. Bioactive Plastics with Programmable Degradation and Microplastic Elimination. Global Patent Index EP 4084830 A4, 28 June 2023. [Google Scholar]

- U.S. Environmental Protection Agency Office of Research and Development. Emerging Issues in Food Waste management, Plastic Contamination; 2019. Available online: https://www.epa.gov/system/files/documents/2021-08/emerging-issues-in-food-waste-management-plastic-contamination.pdf (accessed on 26 June 2023).

- Śniadecka, N. Investigation on Utilization of Organic Fraction of Municipal Solid Waste. Ph.D. Thesis, Gdansk University of Technology, Gdańsk, Poland, 2017. Available online: https://mostwiedzy.pl/pl/publication/download/1/badania-nad-zagospodarowaniem-organicznej-frakcji-odpadow-komunalnych_17700.pdf (accessed on 26 June 2023).

- Jędrczak, A. Properties of the Organic Fraction Directed to Biostabilization in Mbt Installations during the Heating Season. Civ. Environ. Eng. Rep. 2018, 28, 65–78. [Google Scholar] [CrossRef]

- Sewwandi, M.; Wijesekara, H.; Rajapaksha, A.U.; Soysa, S.; Vithanage, M. Microplastics and plastics-associated contaminants in food and beverages; Global trends, concentrations, and human exposure. Environ. Pollut. 2023, 317, 120747. [Google Scholar] [CrossRef]

- Yin, L.; Wen, X.; Huang, D.; Du, C.; Deng, R.; Zhou, Z.; Tao, J.; Li, R.; Zhou, W.; Wang, Z.; et al. Interactions between microplastics/nanoplastics and vascular plants. Environ. Pollut. 2021, 290, 117999. [Google Scholar] [CrossRef]

- Industrial Biotechnology Innovation Centre. A Review of Standards for Biodegradable Plastics. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/817684/review-standards-for-biodegradable-plastics-IBioIC.pdf (accessed on 26 June 2023).

- Hannover, H.; University of Applied Sciences and Arts, Institute for Bioplastics and Biocomposites. Biopolymers Facts and Statistics. 2021. Available online: https://www.ifbb-hannover.de/files/IfBB/downloads/faltblaetter_broschueren/f+s/Biopolymers-Facts-Statistics-einseitig-2021.pdf (accessed on 26 June 2023).

- Wei, X.-F.; Bohlén, M.; Lindblad, C.; Hedenqvist, M.; Hakonen, A. Microplastics generated from a biodegradable plastic in freshwater and seawater. Water Res. 2021, 198, 117123. [Google Scholar] [CrossRef]

- Su, Y.; Cheng, Z.; Hou, Y.; Lin, S.; Gao, L.; Wang, Z.; Bao, R.; Peng, L. Biodegradable and conventional microplastics posed similar toxicity to marine algae Chlorella vulgaris. Aquat. Toxicol. 2022, 244, 106097. [Google Scholar] [CrossRef]

- Weinstein, J.E.; Dekle, J.L.; Leads, R.R.; Hunter, R.A. Degradation of bio-based and biodegradable plastics in a salt marsh habitat: Another potential source of microplastics in coastal waters. Mar. Pollut. Bull. 2020, 160, 111518. [Google Scholar] [CrossRef]

- Qin, M.; Chen, C.; Song, B.; Shen, M.; Cao, W.; Yang, H.; Zeng, G.; Gong, J. A review of biodegradable plastics to biodegradable microplastics: Another ecological threat to soil environments? J. Clean. Prod. 2021, 312, 127816. [Google Scholar] [CrossRef]

- Wei, X.-F.; Capezza, A.J.; Cui, Y.; Li, L.; Hakonen, A.; Liu, B.; Hedenqvist, M.S. Millions of microplastics released from a biodegradable polymer during biodegradation/enzymatic hydrolysis. Water Res. 2022, 211, 118068. [Google Scholar] [CrossRef] [PubMed]

- Cucina, M.; Nisi, P.; Tambone, F.; Adani, F. The role of waste management in reducing bioplastics’ leakage into the environment: A review. Bioresour. Technol. 2021, 337, 125459. [Google Scholar] [CrossRef] [PubMed]

- Fojt, J.; David, J.; Přikryl, R.; Řezáčová, V.; Kučerík, J. A critical review of the overlooked challenge of determining micro-bioplastics in soil. Sci. Total Environ. 2020, 745, 140975. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.; Chen, Q. Biodegradable plastics in the air and soil environment: Low degradation rate and high microplastics formation, J. Hazard. Mater. 2021, 418, 126329. [Google Scholar] [CrossRef] [PubMed]

- Vasmara, C.; Marchetti, R. Biogas production from biodegradable bioplastics. Environ. Eng. Manag. J. 2016, 15, 2041–2048. [Google Scholar] [CrossRef]

- Ali, S.S.; Elsamahy, T.; Abdelkarim, E.A.; Al-Tohamy, R.; Kornaros, M.; Ruiz, H.A.; Zhao, T.; Li, F.; Sun, J. Biowastes for biodegradable bioplastics production and end-of-life scenarios in circular bioeconomy and biorefinery concept. Bioresour. Technol. 2022, 363, 127869. [Google Scholar] [CrossRef]

- Harrison, J.P.; Boardman, C.; O’Callaghan, K.; Delort, A.-M.; Song, J. Biodegradability standards for carrier bags and plastic films in aquatic environments: A critical review. R. Soc. Open Sci. 2018, 5, 171792. [Google Scholar] [CrossRef]

- Conn, R.E.; Kolstad, J.J.; Borzelleca, J.F.; Dixler, D.S.; Filer, L.J.; Ladu, B.N.; Pariza, M.W. Safety assessment of polylactide (PLA) for use as a food-contact polymer. Food Chem. Toxicol. 1995, 33, 273–283. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Fontana, L.; Minetola, P.; Iuliano, L.; Rifuggiato, S.; Khandpur, M.S.; Stiuso, V. An investigation of the influence of 3d printing parameters on the tensile strength of PLA material. Mater. Today Proc. 2022, 57, 657–663. [Google Scholar] [CrossRef]

- Oksiuta, Z.; Jalbrzykowski, M.; Mystkowska, J.; Romanczuk, E.; Osiecki, T. Mechanical and Thermal Properties of Polylactide (PLA) Composites Modified with Mg, Fe, and Polyethylene (PE) Additives. Polymers 2020, 12, 2939. [Google Scholar] [CrossRef]

- Sharma, S.; Majumdar, A.; Butola, B.S. Tailoring the biodegradability of polylactic acid (PLA) based films and ramie- PLA green composites by using selective additives. Int. J. Biol. Macromol. 2021, 181, 1092–1103. [Google Scholar] [CrossRef] [PubMed]

- Hobbs, S.R.; Parameswaran, P.; Astmann, B.; Devkota, J.P.; Landis, A.E. Anaerobic Codigestion of Food Waste and Polylactic Acid: Effect of Pretreatment on Methane Yield and Solid Reduction. Adv. Mater. Sci. Eng. 2019, 2019, 4715904. [Google Scholar] [CrossRef]

- Cucina, M.; Nisi, P.; Trombino, L.; Tambone, F.; Adani, F. Degradation of bioplastics in organic waste by mesophilic anaerobic digestion, composting and soil incubation. Waste Manag. 2021, 134, 67–77. [Google Scholar] [CrossRef] [PubMed]

- Peng, W.; Wang, Z.; Shu, Y.; Lü, F.; Zhang, H.; Shao, L.; He, P. Fate of a biobased polymer via high-solid anaerobic co-digestion with food waste and following aerobic treatment: Insights on changes of polymer physicochemical properties and the role of microbial and fungal communities. Bioresour. Technol. 2022, 343, 126079. [Google Scholar] [CrossRef] [PubMed]

- Zaborowska, M.; Bernat, K.; Pszczółkowski, B.; Wojnowska-Baryła, I.; Kulikowska, D. Anaerobic Degradability of Commercially Available Bio-Based and Oxo-Degradable Packaging Materials in the Context of their End of Life in the Waste Management Strategy. Sustainability 2021, 13, 6818. [Google Scholar] [CrossRef]

- Pilarska, A.A.; Marzec-Grządziel, A.; Paluch, E.; Pilarski, K.; Wolna-Maruwka, A.; Kubiak, A.; Kałuża, T.; Kulupa, T. Biofilm Formation and Genetic Diversity of Microbial Communities in Anaerobic Batch Reactor with Polylactide (PLA) Addition. Int. J. Mol. Sci. 2023, 24, 10042. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Bary, A.I.; Hayes, D.G.; Wadsworth, L.C.; Anunciado, M.B.; English, M.E.; Bandopadhyay, S.; Schaeffer, S.M.; DeBruyn, J.M.; Miles, C.A.; et al. In situ degradation of biodegradable plastic mulch films in compost and agricultural soils. Sci. Total Environ. 2020, 727, 138668. [Google Scholar] [CrossRef]

- Kalita, N.K.; Sarmah, A.; Bhasney, S.M.; Kalamdhad, A.; Katiyar, V. Demonstrating an ideal compostable plastic using biodegradability kinetics of poly(lactic acid) (PLA) based green biocomposite films under aerobic composting conditions. Environ. Chall. 2021, 3, 100030. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Bary, A.I.; Hayes, D.G.; English, M.E.; Schaeffer, S.M.; Miles, C.A.; Zelenyuk, A.; Suski, K.; Flury, M. Release of micro- and nanoparticles from biodegradable plastic during in situ composting. Sci. Total Environ. 2019, 675, 686–693. [Google Scholar] [CrossRef]

- Al Hosni, A.S.; Pittman, J.K.; Robson, G.D. Microbial degradation of four biodegradable polymers in soil and compost demonstrating polycaprolactone as an ideal compostable plastic. Waste Manag. 2019, 97, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Fan, P.; Yu, H.; Xi, B.; Tan, W. A review on the occurrence and influence of biodegradable microplastics in soil ecosystems: Are biodegradable plastics substitute or threat? Environ. Int. 2022, 163, 107244. [Google Scholar] [CrossRef] [PubMed]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef]

- Yu, Y.; Griffin-LaHue, D.E.; Miles, C.A.; Hayes, D.G.; Flury, M. Are micro- and nanoplastics from soil-biodegradable plastic mulches an environmental concern? J. Hazard. Mater. Adv. 2021, 4, 100024. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I. Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly(ethylene terephthalate) (Bio-PET): Recent Developments in Bio-Based Polymers Analogous to Petroleum-Derived Ones for Packaging and Engineering Applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef]

- Sholokhova, A.; Denafas, G.; Mykhaylenko, V. The organic output from mechanical–biological treatment plants as a source of microplastics: Mini-review on current knowledge, research methodology and future study perspectives. Waste Manag. Res. 2021, 39, 652–663. [Google Scholar] [CrossRef]

- Steiner, T.; Möller, J.N.; Löder, M.G.J.; Hilbrig, F.; Laforsch, C.; Freitag, R. Microplastic Contamination of Composts and Liquid Fertilizers from Municipal Biowaste Treatment Plants: Effects of the Operating Conditions. Waste Biomass Valor 2022, 14, 873–887. [Google Scholar] [CrossRef]

- Edo, C.; Fernández-Piñas, F.; Rosal, R. Microplastics identification and quantification in the composted Organic Fraction of Municipal Solid Waste. Sci. Total Environ. 2022, 813, 151902. [Google Scholar] [CrossRef]

- Agilent Application Note Environment. Analysis of Microplastics Using FTIR Imaging, Identyfing and Quantifying Microplastics in Wastewater, Sediment and Fauna. 2017. Available online: https://www.agilent.com/cs/library/applications/5991-8271EN_microplastics_ftir_application.pdf (accessed on 26 June 2023).

- Dekiff, J.H.; Remy, D.; Klasmeier, J.; Fries, E. Occurrence and spatial distribution of microplastics in sediments from Norderney. Environ. Pollut. 2014, 186, 248–256. [Google Scholar] [CrossRef]

- Huertas de la Torre, S.H. Pyrolysis-GC/MS, A Powerful Analytical Tool for Additives and Polymers Characterization. In Recent Perspectives in Pyrolysis Research; Bartoli, M., Giorcelli, M., Eds.; IntechOpen: London, UK, 2022. [Google Scholar] [CrossRef]

- Käppler, A.; Fischer, M.; Scholz-Böttcher, B.M.; Oberbeckmann, S.; Labrenz, M.; Fischer, D.; Eichhorn, K.-J.; Voit, B. Comparison of μ-ATR-FTIR spectroscopy and py-GCMS as identification tools for microplastic particles and fibers isolated from river sediments. Anal. Bioanal. Chem. 2018, 410, 5313–5327. [Google Scholar] [CrossRef]

- Thermoscientific White Paper WP53077. Guide to the Identification of Microplastics by FTIR and Raman Spectroscopy. 2018. Available online: https://assets.thermofisher.com/TFS-Assets/MSD/Application-Notes/WP53077-microplastics-identification-ftir-raman-guide.pdf (accessed on 26 June 2023).

- Mariano, S.; Tacconi, S.; Fidaleo, M.; Rossi, M.; Dini, L. Micro and Nanoplastics Identification: Classic Methods and Innovative Detection Techniques. Front. Toxicol. 2021, 3, 636640. [Google Scholar] [CrossRef] [PubMed]

- Fontana, G.D.; Mossotti, R.; Montarsolo, A. Assessment of microplastics release from polyester fabrics: The impact of different washing conditions. Environ. Pollut. 2020, 264, 113960. [Google Scholar] [CrossRef] [PubMed]

- Barrows, A.P.W.; Christiansen, K.S.; Bode, E.T.; Hoellein, T.J. A watershed-scale, citizen science approach to quantifying microplastic concentration in a mixed land-use river. Water Res. 2018, 147, 382–392. [Google Scholar] [CrossRef] [PubMed]

- Biver, T.; Bianchi, S.; Carosi, M.R.; Ceccarini, A.; Corti, A.; Manco, E.; Castelvetro, V. Selective determination of poly(styrene) and polyolefin microplastics in sandy beach sediments by gel permeation chromatography coupled with fluorescence detection. Mar. Pollut. Bull. 2018, 136, 269–275. [Google Scholar] [CrossRef]

- Graca, B.; Szewc, K.; Zakrzewska, D.; Dołęga, A.; Szczerbowska-Boruchowska, M. Sources and fate of microplastics in marine and beach sediments of the Southern Baltic Sea—A preliminary study. Environ. Sci. Pollut. Res. 2017, 24, 7650–7661. [Google Scholar] [CrossRef] [PubMed]

- Naidoo, T.; Sershen; Thompson, R.C.; Rajkaran, A. Quantification and characterisation of microplastics ingested by selected juvenile fish species associated with mangroves in KwaZulu-Natal, South Africa. Environ. Pollut. 2020, 257, 113635. [Google Scholar] [CrossRef]

- Battista, F.; Frison, N.; Bolzonella, D. Can bioplastics be treated in conventional anaerobic digesters for food waste treatment? Environ. Technol. Innov. 2021, 22, 101393. [Google Scholar] [CrossRef]

- European Commission. Official Journal of the European Union. 2021. Commission Delegated Regulation (EU) 2021/1768 of 23 June 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:32021R1768 (accessed on 26 June 2023).

- Scottish Environment Protection Agency; Aspray, T.J.; Dimambro, M.E.; Steiner, H.J. Investigation into Plastic in Food Waste Derived Digestate and Soil. 2017. Available online: https://www.sepa.org.uk/media/327640/investigation-into-plastic-in-food-waste-derived-digestate-and-soil.pdf (accessed on 6 September 2023).

- Yang, Z.; Lü, F.; Hu, T.; Xu, X.; Zhang, H.; Shao, L.; Ye, J.; He, P. Occurrence of macroplastics and microplastics in biogenic waste digestate: Effects of depackaging at source and dewatering process. Waste Manag. 2022, 154, 252–259. [Google Scholar] [CrossRef] [PubMed]

- Öling-Wärnå, V.; Åkerback, N.; Engblom, S. Digestate from Biowaste and Sewage Sludge as Carriers of Microplastic into the Environment: Case Study of a Thermophilic Biogas Plant in Ostrobothnia, Finland. Water Air Soil. Pollut. 2023, 234, 432. [Google Scholar] [CrossRef]

- Porterfield, K.K.; Hobson, S.A.; Neher, D.A.; Niles, M.T.; Roy, E.D. Microplastics in composts, digestates, and food wastes: A review. J. Environ. Qual. 2023, 52, 225–240. [Google Scholar] [CrossRef]

- Kawecki, D.; Goldberg, L.; Nowack, B. Material flow analysis of plastic in organic waste in Switzerland. Soil. Use Manag. 2021, 37, 277–288. [Google Scholar] [CrossRef]

- WRAP; Aponte, L.F.; Kabir, M.; Tompkins, D. Plastics in Composts and Digestates. Final report. 2022. Available online: https://wrap.org.uk/sites/default/files/2023-07/WRAP-Plastics-in-Composts-Digestates-final-report.pdf (accessed on 6 September 2023).

- Commission of the European Communities, Eurostat. Guidance on Classification of Waste According to EWC-Stat Categories, Supplement to the Manual for the Implementation of the Regulation (EC) No 2150/2002 on Waste Statistics. 2010. Available online: https://ec.europa.eu/eurostat/documents/342366/351806/Guidance-on-EWCStat-categories-2010.pdf/0e7cd3fc-c05c-47a7-818f-1c2421e55604 (accessed on 26 June 2023).

| No | Type of Material/ Environment | Observation | Ref. |

|---|---|---|---|

| 1 | Polylactic acid—(PLA) / Water solutions with adjusted pH (NaOH, HCl) | Influence of PLA pre-treatment on biogas yield and solid reduction. Alkaline treatment enhanced PLA solubilisation, up to 97–99% weight loss after a 15-day incubation period. Untreated PLA revealed only 54% weight loss. | [44] |

| 2 | Starch-based shopping bags (SBSB) and polylactic acid (PLA) tableware / Pilot-scale dry mesophilic anaerobic digestion (35 days), composting (58 °C, 90 days) | Degradation rate after:

| [45] |

| 3 | PBAT/PLA bags / Mesophilic and thermophilic AD, 44 days | Mesophilic AD:

| [46] |

| 4 | PLA bio-based foil / Mesophilic AD (37 °C, 1 year), OxiTop system |

| [47] |

| No | Type of Material/ Environment | Observation | Ref. |

|---|---|---|---|

| 1 | Plastic mulch / Compost and agricultural soils at warm and cool climate | 18-week experiments in compost gave surface area reduction between 85 and 99%. 36-month experiments in soil gave surface reduction results that ranged varying on area and climate type, between 26 and 83%. Faster degradation was observed in compost, while it was concluded that mulch fragments in soil may not degrade for many years. | [49] |

| 2 | PLA based green biocomposite:

Food waste compost–thermophilic conditions without external inoculum | Biodegradation tests were carried out per ASTM D5338–15 standard, concerning the amount of CO2 produced. The experiments revealed around 90% degradation within 37 days. 110 days exposure resulted in the following degradation trend: PLA/chitosan (around 95%) > NPLA (around 90%) > PLA/CNC (around 82%) > PLA/gum arabic (around 71%). | [50] |

| 3 | Plastic films: PBAT- polybutylene co-adipate co-terephthalate / PLA/PHA–polylactic acid/poly-hydroxy−alkanoate / Material placed in a mesh-bag and buried in the compost | 18-week composting resulted in 99% macroscopic degradation of PLA/PHA and 97% of PBAT. Simultaneously, the release of micro- and nanoparticles from biodegradable films was observed. | [51] |

| 4 | PCL—polycaprolactone, PHB—polyhydroxybutyrate (PHB), PLA, PBS—poly(1,4 butylene) succinate / Soil and compost, up to 21 months, varying temperatures, additionally soil with uncontrolled—environmental conditions | The temperature was recognised as a major factor influencing degradation rate and efficiency. Higher temperature contributed to greater weight loss. In compost: PCL: 100% degradation was observed within 91 days, at 50 °C. PLA: 275 days were needed for 100% degradation at 50 °C. At lower temperatures, no material weight loss was observed. PHB: similar degradation trend was observed at varying temperatures. ≈275 days resulted in degradation of around 96% at 50 °C, around 80% at 37 °C, and around 60% at 25 °C. PBS: ≈275 days resulted in degradation of around 60% at 50 °C, and at lower temperatures no higher than 10%. In soil: PCL: regardless of the temperature (25–37 °C), more than 50% weight loss was observed after around 275 days of the experiment. PLA: did not degrade in soil. PHB: after around 275 days, 30% weight loss was observed at 25 °C, and more than 60% at 37 °C. PBS: negligible weight loss was observed at 25 °C, and less than 50% at 37 °C. | [52] |

| No. | Element | PFC1—Organic | PFC3—Organic | PFC4 |

|---|---|---|---|---|

| (mg/Dry Matter) | ||||

| 1 | cadmium | 1.5 | 2 | 1.5 |

| 2 | hexavalent chromium | 2 | 2 | 2 |

| 3 | mercury | 1 | 1 | 1 |

| 4 | nickel | 50 | 50 | 50 |

| 5 | lead | 120 | 120 | 120 |

| 6 | arsenic | 40 | 40 | 40 |

| 7 | copper | <300 | <300 | <300 |

| 8 | zinc | <800 | <800 | <800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mioduska, J.; Grabowiec, A.; Hupka, J. Digestate Quality Originating from Kitchen Waste. Appl. Sci. 2023, 13, 10353. https://doi.org/10.3390/app131810353

Mioduska J, Grabowiec A, Hupka J. Digestate Quality Originating from Kitchen Waste. Applied Sciences. 2023; 13(18):10353. https://doi.org/10.3390/app131810353

Chicago/Turabian StyleMioduska, Joanna, Aleksandra Grabowiec, and Jan Hupka. 2023. "Digestate Quality Originating from Kitchen Waste" Applied Sciences 13, no. 18: 10353. https://doi.org/10.3390/app131810353