Study of the Relationship between Mode I Fracture Toughness and Rock Brittleness Indices

Abstract

1. Introduction

2. Materials and Methods

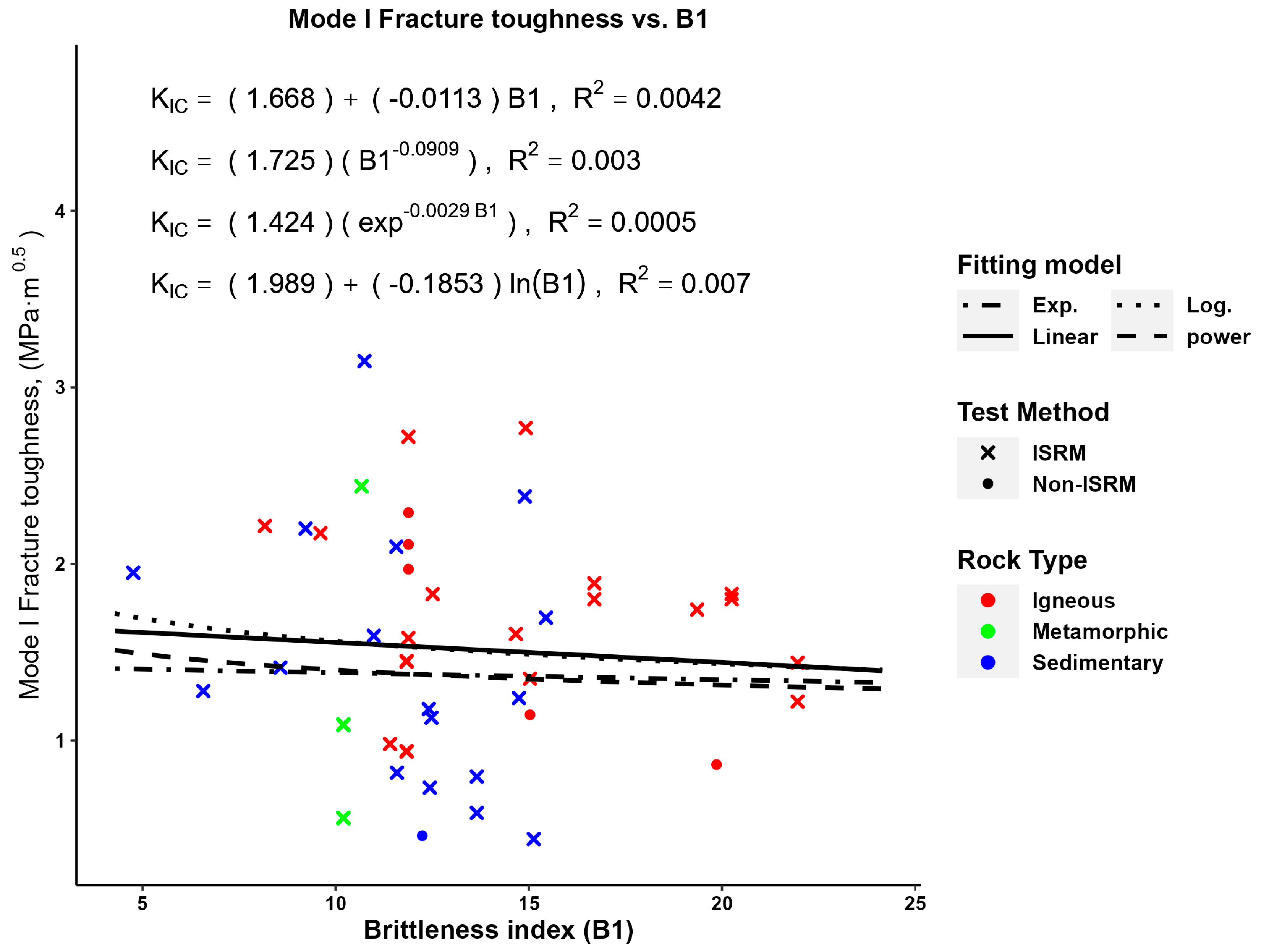

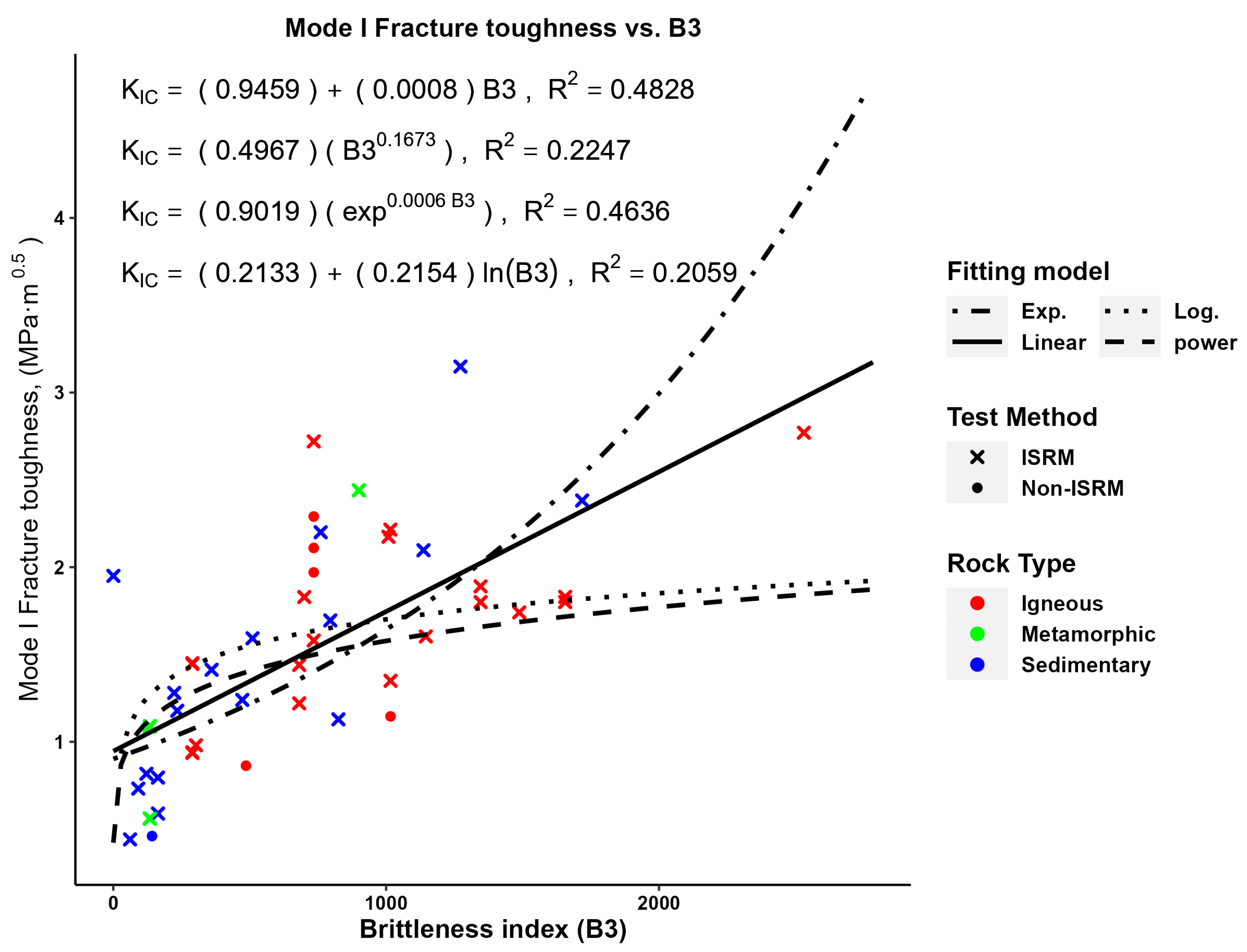

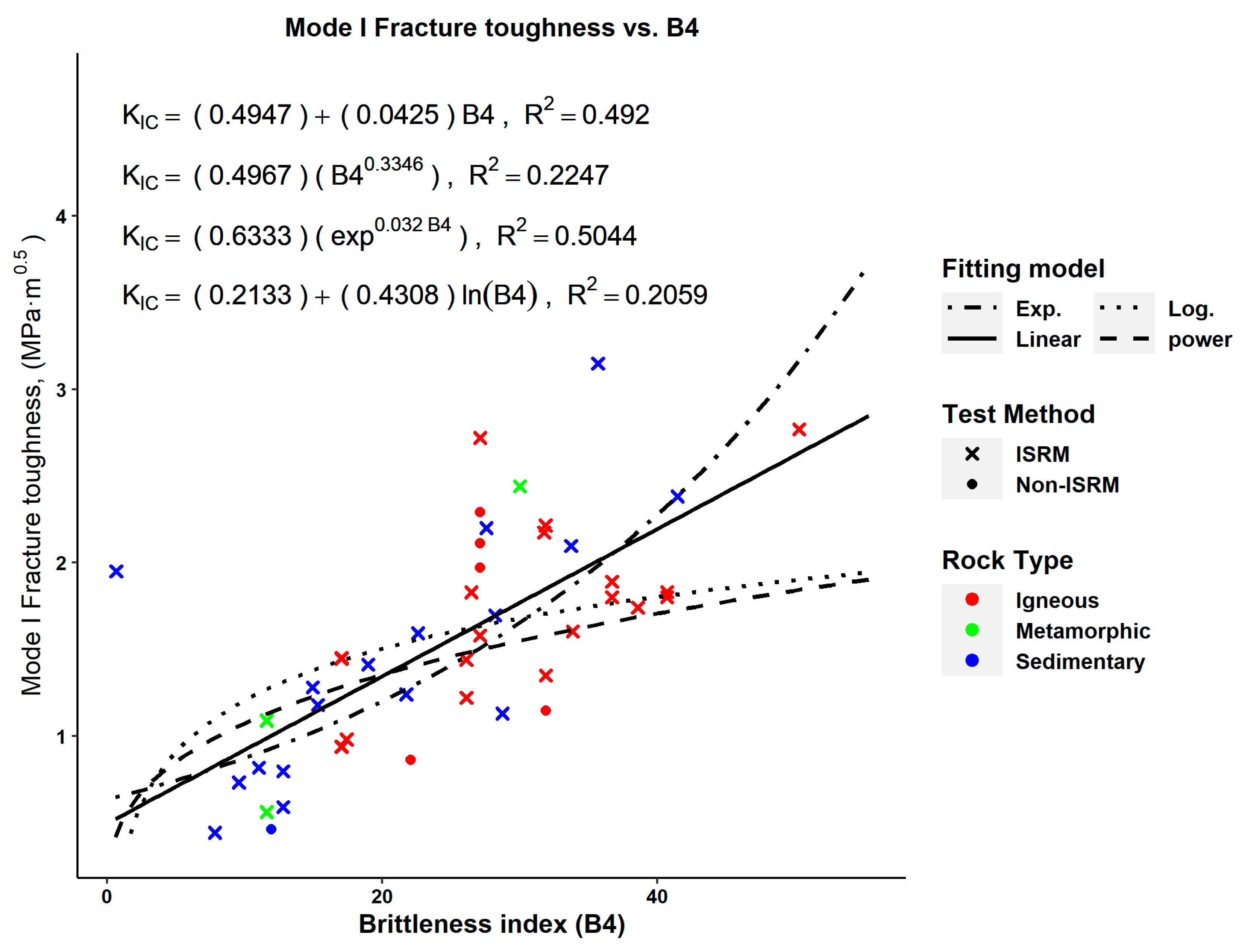

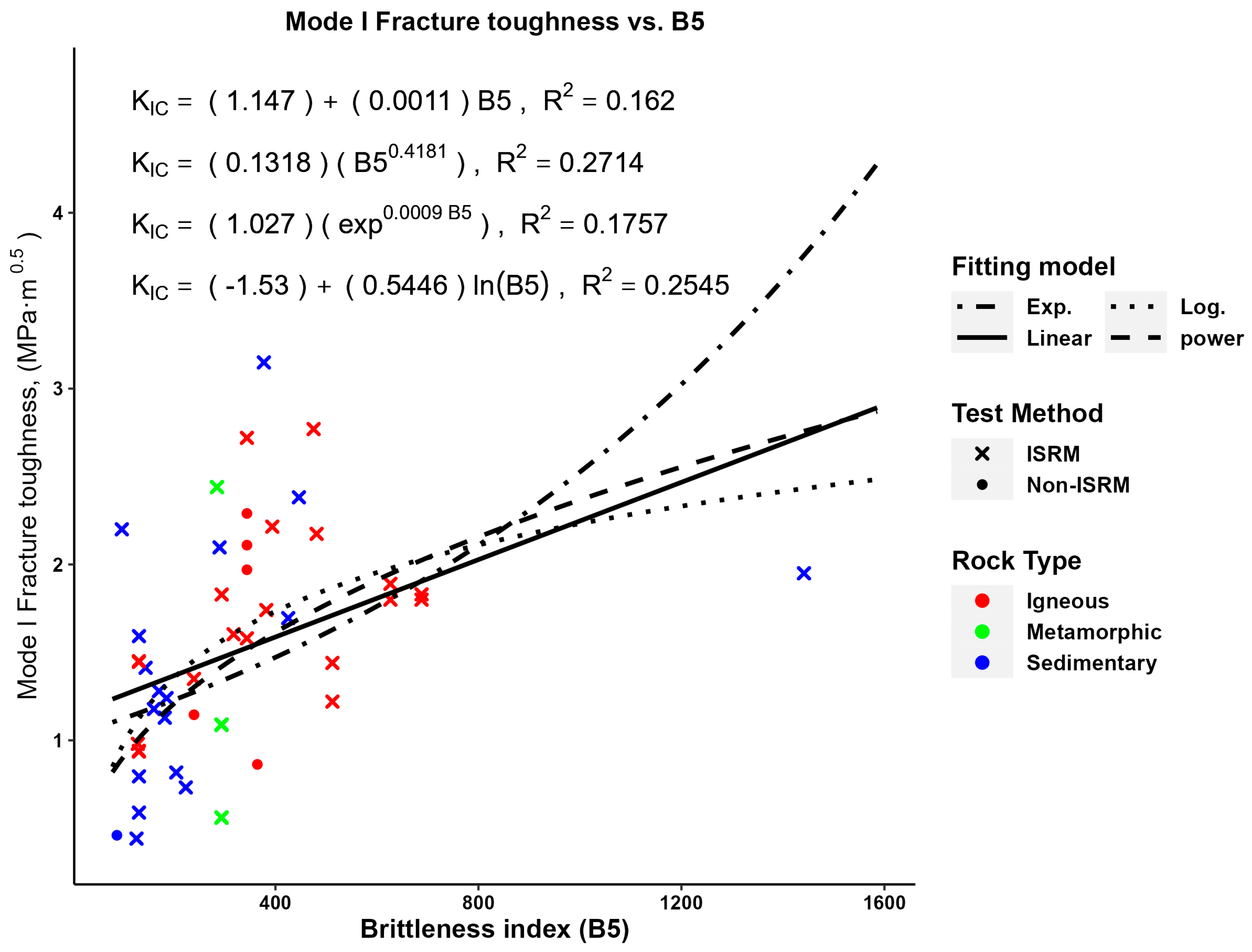

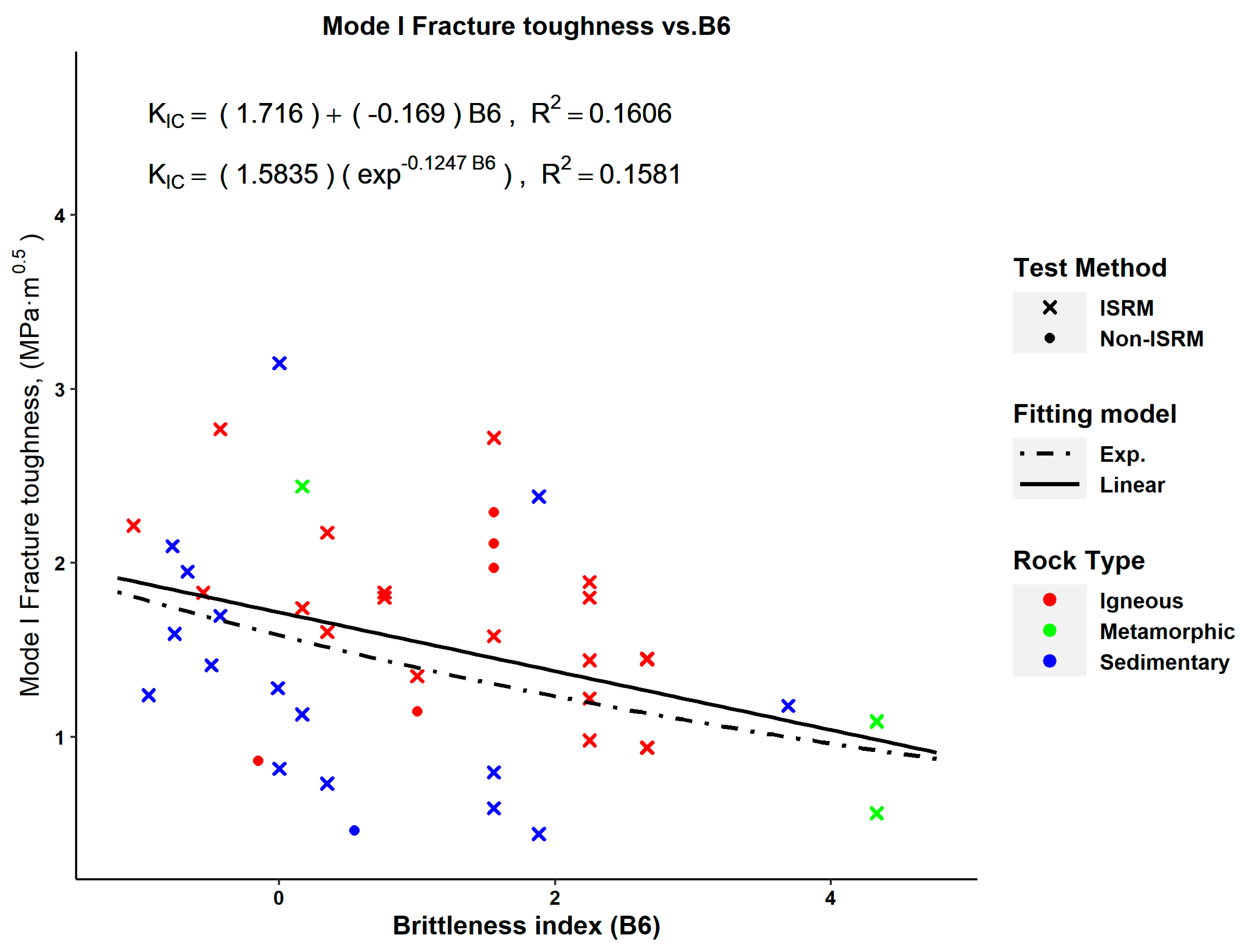

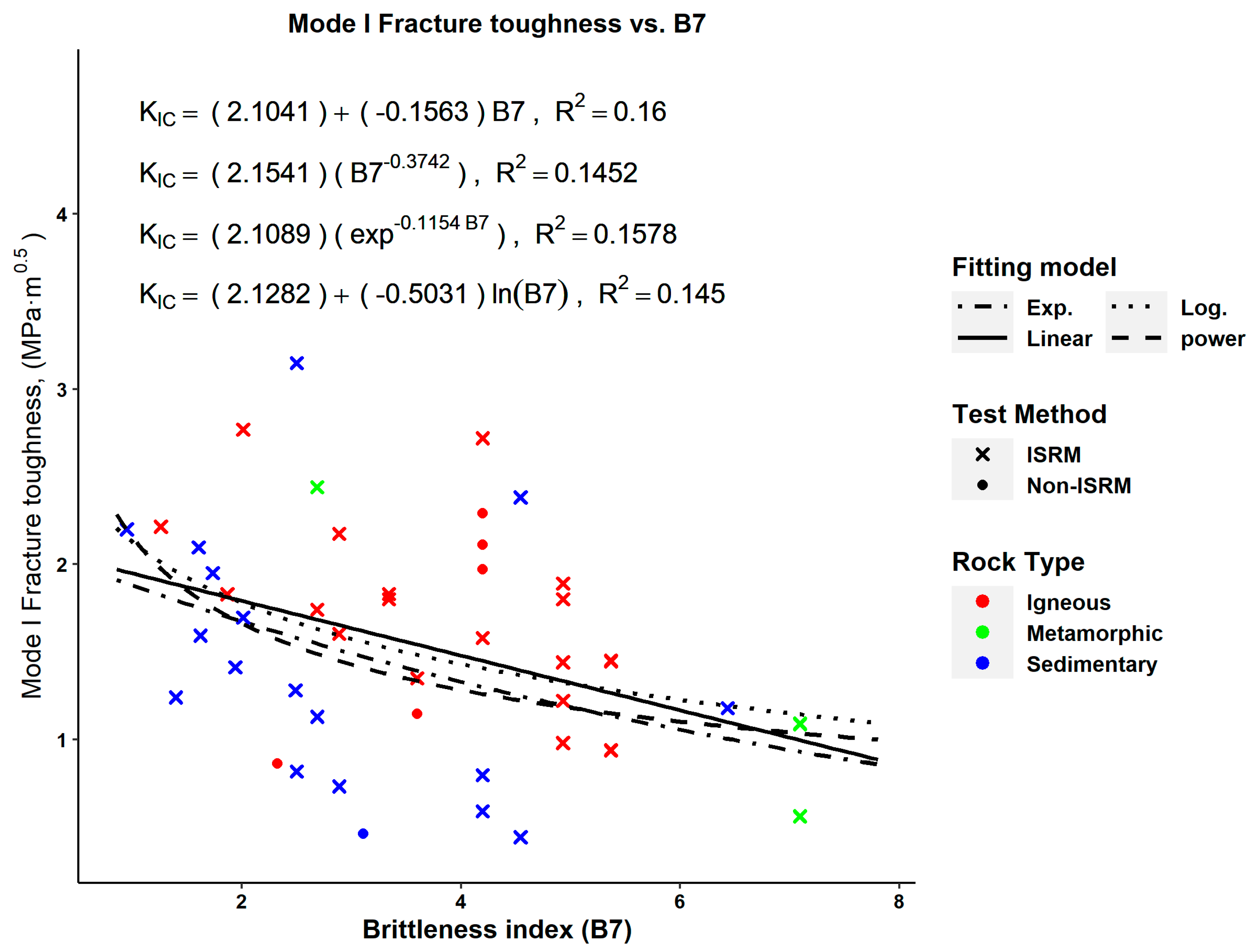

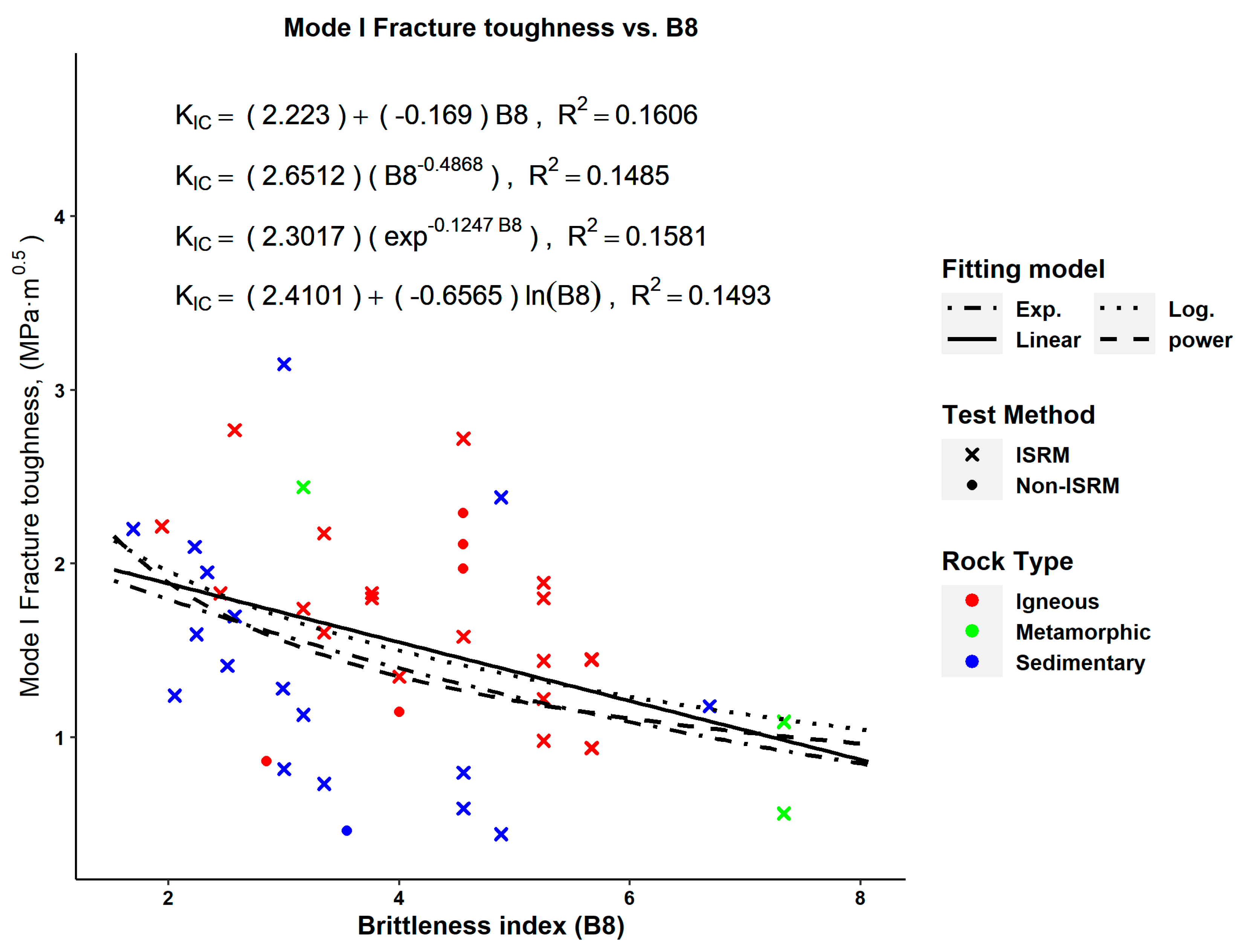

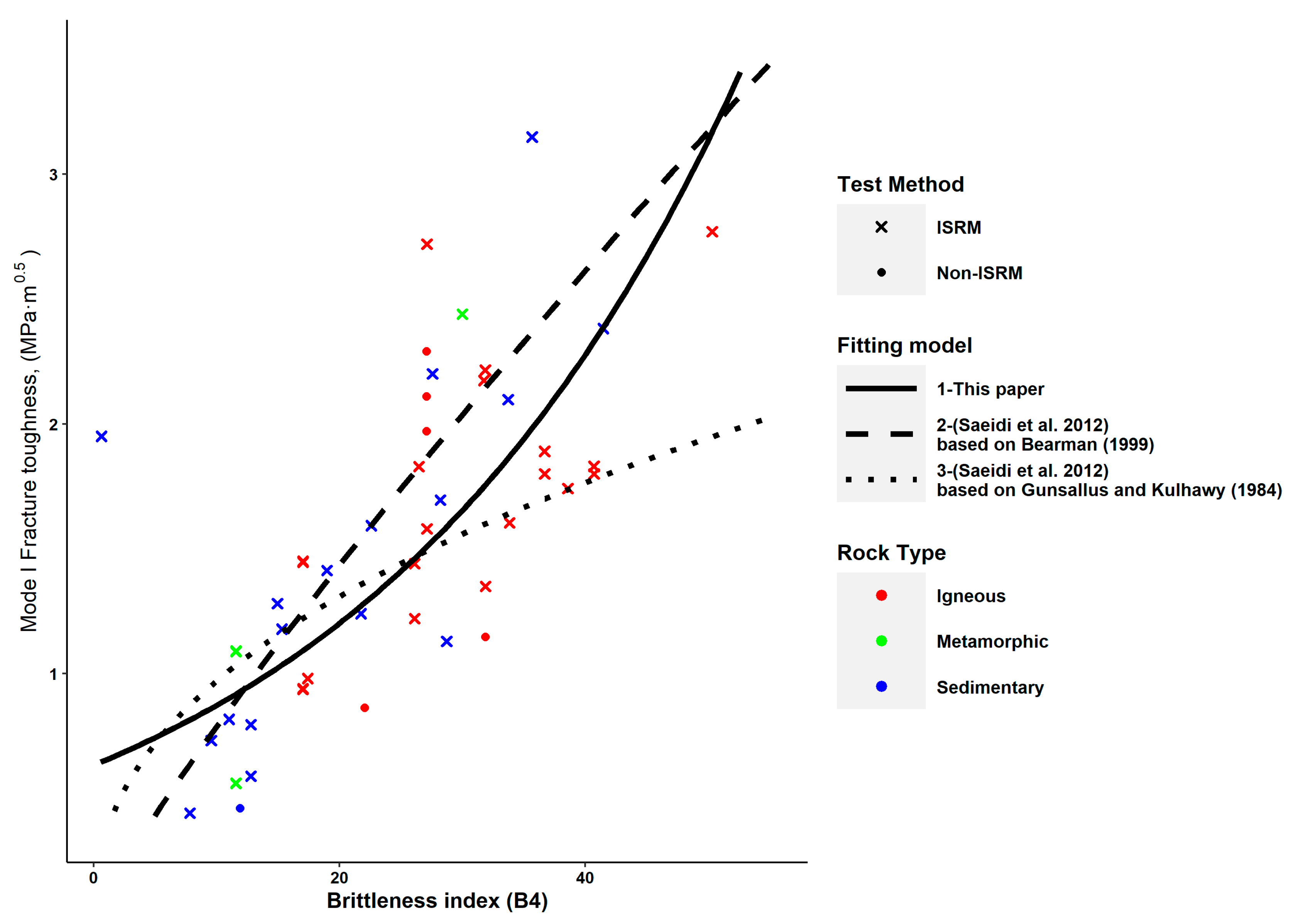

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Feng, G.; Wang, X.C.; Kang, Y.; Luo, S.G.; Hu, Y.Q. Effects of Temperature on the Relationship between Mode-I Fracture Toughness and Tensile Strength of Rock. Appl. Sci. 2019, 9, 1326. [Google Scholar] [CrossRef]

- Anderson, T.L. FRACTURE MECHANICS: Fundamentals and Applications, 4th ed.; Taylor & Francis Group: Abingdon, UK, 2017; ISBN 9781420058215. [Google Scholar]

- Bearman, R.A.; Briggs, C.A.; Kojovic, T. The Application of Rock Mechanics Parameters to the Prediction of Comminution Behaviour. Miner. Eng. 1997, 10, 255–264. [Google Scholar] [CrossRef]

- Arshadnejad, S.; Goshtasbi, K.; Aghazadeh, J. A Model to Determine Hole Spacing in the Rock Fracture Process by Non-Explosive Expansion Material. Int. J. Miner. Metall. Mater. 2011, 18, 509–514. [Google Scholar] [CrossRef]

- Arshadnejad, S. Analysis of the First Cracks Generating Between Two Holes Under Incremental Static Loading with an Innovation Method by Numerical Modelling. Math. Comput. Sci. 2017, 2, 120. [Google Scholar] [CrossRef][Green Version]

- Feng, G.; Wang, X.; Wang, M.; Kang, Y. Experimental Investigation of Thermal Cycling Effect on Fracture Characteristics of Granite in a Geothermal-Energy Reservoir. Eng. Fract. Mech. 2020, 235, 107180. [Google Scholar] [CrossRef]

- Talukdar, M.; Guha Roy, D.; Singh, T.N. Correlating Mode-I Fracture Toughness and Mechanical Properties of Heat-Treated Crystalline Rocks. J. Rock Mech. Geotech. Eng. 2018, 10, 91–101. [Google Scholar] [CrossRef]

- Kang, P.; Hong, L.; Fazhi, Y.; Quanle, Z.; Xiao, S.; Zhaopeng, L. Effects of Temperature on Mechanical Properties of Granite under Different Fracture Modes. Eng. Fract. Mech. 2020, 226, 106838. [Google Scholar] [CrossRef]

- Xu, X.; Wu, S.; Jin, A.; Gao, Y. Review of the Relationships between Crack Initiation Stress, Mode I Fracture Toughness and Tensile Strength of Geo-Materials. Int. J. Geomech. 2018, 18, 04018136. [Google Scholar] [CrossRef]

- Tutluoglu, L.; Keles, C. Mode I Fracture Toughness Determination with Straight Notched Disk Bending Method. Int. J. Rock Mech. Min. Sci. 2011, 48, 1248–1261. [Google Scholar] [CrossRef]

- Ouchterlony, F. Suggested Methods for Determining the Fracture Toughness of Rock. Int. J. Rock Mech. Min. Sci. 1988, 25, 72–96. [Google Scholar] [CrossRef]

- Fowell, R.J.; Hudson, J.A.; Xu, C.; Chen, J.F.; Zhao, X. Suggested Method for Determining Mode I Fracture Toughness Using Cracked Chevron Notched Brazilian Disc (CCNBD) Specimens. Int. J. Rock Mech. Min. Sci. 1995, 32, 57–64. [Google Scholar] [CrossRef]

- Kuruppu, M.D.; Obara, Y.; Ayatollahi, M.R.; Chong, K.P.; Funatsu, T. ISRM-Suggested Method for Determining the Mode i Static Fracture Toughness Using Semi-Circular Bend Specimen. Rock Mech. Rock Eng. 2014, 47, 267–274. [Google Scholar] [CrossRef]

- Guha Roy, D.; Singh, T.N.; Kodikara, J.; Talukdar, M. Correlating the Mechanical and Physical Properties with Mode-I Fracture Toughness of Rocks. Rock Mech. Rock Eng. 2017, 50, 1941–1946. [Google Scholar] [CrossRef]

- Afrasiabiana, B.; Eftekharib, M. Prediction of Mode I Fracture Toughness of Rock Using Linear Multiple Regression and Gene Expression Programming. J. Rock Mech. Geotech. Eng. 2022, 14, 1421–1432. [Google Scholar] [CrossRef]

- Zhang, Z.X. An Empirical Relation between Mode I Fracture Toughness and the Tensile Strength of Rock. Int. J. Rock Mech. Min. Sci. 2002, 39, 401–406. [Google Scholar] [CrossRef]

- Chang, S.H.; Lee, C.I.; Jeon, S. Measurement of Rock Fracture Toughness under Modes I and II and Mixed-Mode Conditions by Using Disc-Type Specimens. Eng. Geol. 2002, 66, 79–97. [Google Scholar] [CrossRef]

- Bearman, R.A. The Use of the Point Load Test for the Rapid Estimation of Mode I Fracture Toughness. Int. J. Rock Mech. Min. Sci. 1999, 36, 257–263. [Google Scholar] [CrossRef]

- Shi, X.; Zhao, Y.; Danesh, N.N.; Zhang, X.; Tang, T. Role of Bedding Plane in the Relationship between Mode-I Fracture Toughness and Tensile Strength of Shale. Bull. Eng. Geol. Environ. 2022, 81, 81. [Google Scholar] [CrossRef]

- Hu, Y.; Hu, Y.; Zhao, G.; Jin, P.; Zhao, Z.; Li, C. Experimental Investigation of the Relationships Among P-Wave Velocity, Tensile Strength, and Mode-I Fracture Toughness of Granite After High-Temperature Treatment. Nat. Resour. Res. 2022, 31, 801–816. [Google Scholar] [CrossRef]

- Guha Roy, D.; Singh, T.N.; Kodikara, J. Predicting Mode-I Fracture Toughness of Rocks Using Soft Computing and Multiple Regression. Meas. J. Int. Meas. Confed. 2018, 126, 231–241. [Google Scholar] [CrossRef]

- Kahraman, S.; Altindag, R. A Brittleness Index to Estimate Fracture Toughness. Int. J. Rock Mech. Min. Sci. 2004, 41, 343–348. [Google Scholar] [CrossRef]

- Saeidi, O.; Torabi, S.R.; Ataei, M.; Hoseinie, S.H. Prediction of Rock Fracture Toughness Modes I and II Utilising Brittleness Indexes. Int. J. Min. Miner. Eng. 2012, 4, 163–173. [Google Scholar] [CrossRef]

- Nejati, H.R.; Moosavi, S.A. A New Brittleness Index for Estimation of Rock Fracture Toughness. J. Min. Environ. 2017, 8, 83–91. [Google Scholar] [CrossRef]

- Cai, M. Prediction and Prevention of Rockburst in Metal Mines—A Case Study of Sanshandao Gold Mine. J. Rock Mech. Geotech. Eng. 2016, 8, 204–211. [Google Scholar] [CrossRef]

- Wang, S.M.; Zhou, J.; Li, C.Q.; Armaghani, D.J.; Li, X.B.; Mitri, H.S. Rockburst Prediction in Hard Rock Mines Developing Bagging and Boosting Tree-Based Ensemble Techniques. J. Cent. South Univ. 2021, 28, 527–542. [Google Scholar] [CrossRef]

- Sepehri, M.; Apel, D.B.; Adeeb, S.; Leveille, P.; Hall, R.A. Evaluation of Mining-Induced Energy and Rockburst Prediction at a Diamond Mine in Canada Using a Full 3D Elastoplastic Finite Element Model. Eng. Geol. 2020, 266, 105457. [Google Scholar] [CrossRef]

- Mikaeil, R.; Ataei, M.; Yousefi, R. Correlation of Production Rate of Ornamental Stone with Rock Brittleness Indexes. Arab. J. Geosci. 2013, 6, 115–121. [Google Scholar] [CrossRef]

- Kahraman, S. Correlation of TBM and Drilling Machine Performances with Rock Brittleness. Eng. Geol. 2002, 65, 269–283. [Google Scholar] [CrossRef]

- Jamshidi, A. Prediction of TBM Penetration Rate from Brittleness Indexes Using Multiple Regression Analysis. Model. Earth Syst. Environ. 2018, 4, 383–394. [Google Scholar] [CrossRef]

- Wei, M.D.; Dai, F.; Xu, N.W.; Zhao, T. Experimental and Numerical Investigation of Cracked Chevron Notched Brazilian Disc Specimen for Fracture Toughness Testing of Rock. Fatigue Fract. Eng. Mater. Struct. 2017, 41, 197–211. [Google Scholar] [CrossRef]

- Vavro, L.; Malíková, L.; Frantík, P.; Kubeš, P.; Keršner, Z.; Vavro, M. An Advanced Assessment of Mechanical Fracture Parameters of Sandstones Depending on the Internal Rock Texture Features. Acta Geodyn. Geomater. 2019, 16, 157–168. [Google Scholar] [CrossRef]

- Pakdaman, A.M.; Moosavi, M.; Mohammadi, S. Experimental and Numerical Investigation into the Methods of Determination of Mode I Static Fracture Toughness of Rocks. Theor. Appl. Fract. Mech. 2019, 100, 154–170. [Google Scholar] [CrossRef]

- Chandler, M.R.; Meredith, P.G.; Brantut, N.; Crawford, B.R.; Sciences, E.; Urc, E. Fracture Toughness Anisotropy in Shale. J. Geophys. Res. Solid Earth 2016, 121, 1706–1729. [Google Scholar] [CrossRef]

- Ghamgosar, M.; Erarslan, N.; Tehrani, K. Laboratory Investigations of Fracture Toughness and Tensile Strength for Various Rock Types. In Proceedings of the ISRM International Symposium—EUROCK 2016, Ürgüp, Turkey, 29–31 August 2016; pp. 223–228. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Kazemi, M.T. Determination of Fracture Energy, Process Zone Length and Brittleness Number from Size Effecteffect, with Application to Rock and Concrete. Int. J. Fract. 1990, 44, 111–131. [Google Scholar] [CrossRef]

- Carpinteri, A. Size-Scale Transition from Ductile to Brittle Failure: Structural Response vs. Crack Growth Resistance Curve. Int. J. Fract. 1991, 51, 175–186. [Google Scholar] [CrossRef]

- Bažant, Z.P. Size Effect in Blunt Fracture: Concrete, Rock, Metal. J. Eng. Mech. 1984, 110, 518–535. [Google Scholar] [CrossRef]

- Spagnoli, A.; Carpinteri, A.; Ferretti, D.; Vantadori, S. An Experimental Investigation on the Quasi-Brittle Fracture of Marble Rocks. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 956–968. [Google Scholar] [CrossRef]

- Gettu, R.; Bažant, Z.P.; Karr, M.E. Fracture Properties and Brittleness of High-Strength Concrete. ACI Mater. J. 1990, 87, 608–618. [Google Scholar] [CrossRef]

- Carpinteri, A. Size Effects in Material Strength Due to Crack Growth and Material Non-Linearity. Theor. Appl. Fract. Mech. 1984, 2, 39–45. [Google Scholar] [CrossRef]

- Xia, Y.; Zhou, H.; Zhang, C.; He, S.; Gao, Y.; Wang, P. The Evaluation of Rock Brittleness and Its Application: A Review Study. Eur. J. Environ. Civ. Eng. 2019, 26, 239–279. [Google Scholar] [CrossRef]

- Meng, F.; Wong, L.N.Y.; Zhou, H. Rock Brittleness Indices and Their Applications to Different Fields of Rock Engineering: A Review. J. Rock Mech. Geotech. Eng. 2021, 13, 221–247. [Google Scholar] [CrossRef]

- Carpinteri, A. Static and Energetic Fracture Parameters for Rocks and Concretes. Matér. Constr. 1981, 14, 151–162. [Google Scholar] [CrossRef]

- Sabri, M.; Ghazvinian, A.; Nejati, H.R. Effect of Particle Size Heterogeneity on Fracture Toughness and Failure Mechanism of Rocks. Int. J. Rock Mech. Min. Sci. 2016, 81, 79–85. [Google Scholar] [CrossRef]

- Team, R.C. R: A Language and Environment for Statistical Computing. 2022. Available online: https://www.scirp.org/(S(lz5mqp453ed%20snp55rrgjct55))/reference/referencespapers.aspx?referenceid=3456808 (accessed on 5 August 2023).

- Wickham, H.; Averick, M.; Bryan, J.; Chang, W.; McGowan, L.D.; François, R.; Grolemund, G.; Hayes, A.; Henry, L.; Hester, J.; et al. Welcome to the tidyverse. J. Open Source Softw. 2019, 4, 1686. [Google Scholar] [CrossRef]

- Kassambara, A. “Ggpubr: ‘Ggplot2” Based Publication Ready Plots", R Package Version 0.6.0. Available online: https://cran.rproject.org/web/packages/ggpubr/ (accessed on 5 August 2023).

- Wickham, H. “Modelr: Modelling Functions That Work with the Pipe”, R Package Version 0.1.10. Available online: https://CRAN.R-project.org/package=modelr/ (accessed on 5 August 2023).

- Li, X.; Zhang, Z.; Chen, W.; Yin, T.; Li, X. Mode I and Mode II Granite Fractures after Distinct Thermal Shock Treatments. J. Mater. Civ. Eng. 2019, 31, 06019001. [Google Scholar] [CrossRef]

- Xiao, P.; Li, D.; Zhao, G.; Liu, M. Experimental and Numerical Analysis of Mode i Fracture Process of Rock by Semi-Circular Bend Specimen. Mathematics 2021, 9, 1769. [Google Scholar] [CrossRef]

- Yin, T.; Wu, Y.; Wang, C.; Zhuang, D.; Wu, B. Mixed-Mode I + II Tensile Fracture Analysis of Thermally Treated Granite Using Straight-through Notch Brazilian Disc Specimens. Eng. Fract. Mech. 2020, 234, 107111. [Google Scholar] [CrossRef]

- Yin, T.; Wu, Y.; Li, Q.; Wang, C.; Wu, B. Determination of Double-K Fracture Toughness Parameters of Thermally Treated Granite Using Notched Semi-Circular Bending Specimen. Eng. Fract. Mech. 2020, 226, 106865. [Google Scholar] [CrossRef]

- Zuo, J.P.; Yao, M.H.; Li, Y.J.; Zhao, S.K.; Jiang, Y.Q.; Li, Z.D. Investigation on Fracture Toughness and Micro-Deformation Field of SCB Sandstone Including Different Inclination Angles Cracks. Eng. Fract. Mech. 2019, 208, 27–37. [Google Scholar] [CrossRef]

- Lim, I.L.; Johnston, I.W.; Choi, S.K.; Boland, J.N. Fracture Testing of a Soft Rock with Semi-Circular Specimens under Three-Point Bending. Part 1-Mode I. Int. J. Rock Mech. Min. Sci. 1994, 31, 185–197. [Google Scholar] [CrossRef]

- Erarslan, N.; Williams, D.J. The Damage Mechanism of Rock Fatigue and Its Relationship to the Fracture Toughness of Rocks. Int. J. Rock Mech. Min. Sci. 2012, 56, 15–26. [Google Scholar] [CrossRef]

- Funatsu, T.; Seto, M.; Shimada, H.; Matsui, K.; Kuruppu, M. Combined Effects of Increasing Temperature and Confining Pressure on the Fracture Toughness of Clay Bearing Rocks. Int. J. Rock Mech. Min. Sci. 2004, 41, 927–938. [Google Scholar] [CrossRef]

- Funatsu, T.; Shimizu, N.; Kuruppu, M.; Matsui, K. Evaluation of Mode I Fracture Toughness Assisted by the Numerical Determination of K-Resistance. Rock Mech. Rock Eng. 2015, 48, 143–157. [Google Scholar] [CrossRef]

- Iqbal, M.J.; Mohanty, B. Experimental Calibration of ISRM Suggested Fracture Toughness Measurement Techniques in Selected Brittle Rocks. Rock Mech. Rock Eng. 2007, 40, 453–475. [Google Scholar] [CrossRef]

- Alkiliçgil, Ç. Development of Specimen Geometries for Mode I Fracture Toughness Testing with Disc Type Rock Specimens; Middle East Technical University: Ankara, Turkey, 2010. [Google Scholar]

- Alpay, C. Investigation of Geometrical Factors for Determining Fracture Toughness with the Modified Ring Test; Middle East Technical University: Ankara, Turkey, 2008. [Google Scholar]

- Yarali, O.; Soyer, E. The Effect of Mechanical Rock Properties and Brittleness on Drillability. Sci. Res. Essays 2011, 6, 1077–1088. [Google Scholar] [CrossRef]

- Safari Farrokhad, S.; Lashkaripour, G.R.; Hafezi Moghaddas, N.; Aligholi, S.; Sabri, M.M.S. The Effect of the Petrography, Mineralogy, and Physical Properties of Limestone on Mode I Fracture Toughness under Dry and Saturated Conditions. Appl. Sci. 2022, 12, 9237. [Google Scholar] [CrossRef]

- Peck, R.; Olsen, C.; Devore, J. Introduction to Statistics and Data Analysis, 3rd ed.; Thomson Higher Education: Belmont, CA, USA, 2008; ISBN 9780495118732. [Google Scholar]

- Hauke, J.; Kossowski, T. Comparison of Values of Pearson’s and Spearman’s Correlation Coefficients on the Same Sets of Data. Quaest. Geogr. 2011, 30, 87–93. [Google Scholar] [CrossRef]

- Mishra, P.; Pandey, C.M.; Singh, U.; Gupta, A.; Sahu, C.; Keshri, A. Descriptive Statistics and Normality Tests for Statistical Data. Ann. Card. Anaesth. 2019, 22, 67–72. [Google Scholar] [CrossRef]

- Rani Das, K. A Brief Review of Tests for Normality. Am. J. Theor. Appl. Stat. 2016, 5, 5. [Google Scholar] [CrossRef]

- Ghasemi, A.; Zahediasl, S. Normality Tests for Statistical Analysis: A Guide for Non-Statisticians. Int. J. Endocrinol. Metab. 2012, 10, 486–489. [Google Scholar] [CrossRef]

- Gunsallus, K.L.; Kulhawy, F.H. A Comparative Evaluation of Rock Strength Measures. Int. J. Rock Mech. Min. Sci. 1984, 21, 233–248. [Google Scholar] [CrossRef]

- Wei, M.D.; Dai, F.; Xu, N.W.; Zhao, T.; Xia, K.W. Experimental and Numerical Study on the Fracture Process Zone and Fracture Toughness Determination for ISRM-Suggested Semi-Circular Bend Rock Specimen. Eng. Fract. Mech. 2016, 154, 43–56. [Google Scholar] [CrossRef]

- Guo, H.; Aziz, N.I.; Schmidt, L.C. Rock Fracture-Toughness Determination by the Brazilian Test. Eng. Geol. 1993, 33, 177–188. [Google Scholar] [CrossRef]

- Xu, S.; Malik, M.A.; Li, Q.; Wu, Y. Determination of Double-K Fracture Parameters Using Semi-Circular Bend Test Specimens. Eng. Fract. Mech. 2016, 152, 58–71. [Google Scholar] [CrossRef]

- Khan, K.; Al-Shayea, N.A. Effect of Specimen Geometry and Testing Method on Mixed Mode I-II Fracture Toughness of a Limestone Rock from Saudi Arabia. Rock Mech. Rock Eng. 2000, 33, 179–206. [Google Scholar] [CrossRef]

- Dutler, N.; Nejati, M.; Valley, B.; Amann, F.; Molinari, G. On the Link between Fracture Toughness, Tensile Strength, and Fracture Process Zone in Anisotropic Rocks. Eng. Fract. Mech. 2018, 201, 56–79. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Guo, T.Y. Microcracking Behavior of Two Semi-Circular Bend Specimens in Mode I Fracture Toughness Test of Granite. Eng. Fract. Mech. 2019, 221, 106565. [Google Scholar] [CrossRef]

- Wei, M.D.; Dai, F.; Xu, N.W.; Zhao, T.; Liu, Y. An Experimental and Theoretical Assessment of Semi-Circular Bend Specimens with Chevron and Straight-through Notches for Mode I Fracture Toughness Testing of Rocks. Int. J. Rock Mech. Min. Sci. 2017, 99, 28–38. [Google Scholar] [CrossRef]

- Nasseri, M.H.B.; Mohanty, B. Fracture Toughness Anisotropy in Granitic Rocks. Int. J. Rock Mech. Min. Sci. 2008, 45, 167–193. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Ayatollahi, M.R. Rock Fracture Toughness Study Using Cracked Chevron Notched Brazilian Disc Specimen under Pure Modes I and II Loading—A Statistical Approach. Theor. Appl. Fract. Mech. 2014, 69, 17–25. [Google Scholar] [CrossRef]

- Ghasemi, S.; Khamehchiyan, M.; Taheri, A.; Nikudel, M.R.; Zalooli, A. Crack Evolution in Damage Stress Thresholds in Different Minerals of Granite Rock. Rock Mech. Rock Eng. 2020, 53, 1163–1178. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A.; Chanda, E.K. Fracture Energy-Based Brittleness Index Development and Brittleness Quantification by Pre-Peak Strength Parameters in Rock Uniaxial Compression. Rock Mech. Rock Eng. 2016, 49, 4587–4606. [Google Scholar] [CrossRef]

| Reference | Rock Type | Test Method | (MPa⋅m0.5) | (MPa) | (MPa) | (GPa) | |

|---|---|---|---|---|---|---|---|

| [60] | Ankara andesite | SCB | 0.936 | 7.000 | 82.840 | 12.334 | 0.150 |

| Ankara andesite | CCNBD | 1.446 | 7.000 | 82.840 | 12.334 | 0.150 | |

| white Afyon marble | SCB | 0.561 | 5.130 | 52.320 | 34.294 | 0.120 | |

| white Afyon marble | CCNBD | 1.088 | 5.130 | 52.320 | 34.294 | 0.120 | |

| [61] | Pink Ankara andesite | SCB | 0.980 | 7.290 | 83.160 | 12.330 | 0.160 |

| [18] | Middleton limestone | CB | 0.732 | 3.840 | 47.760 | 27.520 | 0.230 |

| Harrycroft limestone | CB | 0.817 | 4.580 | 53.060 | 25.450 | 0.250 | |

| Montclie sandstone | CB | 1.178 | 6.150 | 76.310 | 15.920 | 0.130 | |

| Wredon limestone | CB | 1.695 | 10.150 | 156.730 | 57.170 | 0.280 | |

| Penryn granite | CB | 1.829 | 10.580 | 132.360 | 39.100 | 0.290 | |

| Pennant sandstone | CB | 2.097 | 14.020 | 162.190 | 39.070 | 0.310 | |

| Whitwick andesite | CB | 2.174 | 14.490 | 139.200 | 63.600 | 0.230 | |

| Bolton hill diorite | CB | 2.215 | 15.770 | 128.810 | 54.450 | 0.340 | |

| Ingleton greywacke | CB | 2.382 | 15.190 | 226.260 | 57.040 | 0.170 | |

| Nuneaton quartzite | CB | 2.440 | 12.990 | 138.580 | 36.400 | 0.240 | |

| Clie hill diorite | CB | 2.770 | 18.420 | 274.820 | 64.180 | 0.280 | |

| Cornish greywacke | CB | 3.149 | 15.390 | 165.360 | 49.620 | 0.250 | |

| [56] | Brisbane tuff | CCNBD | 1.129 | 11.500 | 143.500 | 22.000 | 0.240 |

| [6] | Suizhou Granite | SCB | 1.741 | 12.400 | 240.000 | 50.000 | 0.240 |

| [57] | Kimachi sandstone | SECRBB | 0.460 | 4.820 | 59.000 | 8.230 | 0.220 |

| [58] | Kimachi sandstone | SCB | 0.589 | 4.900 | 66.900 | 13.200 | 0.180 |

| Kimachi sandstone | CB | 0.795 | 4.900 | 66.900 | 13.200 | 0.180 | |

| [59] | Barre granite | CB | 1.890 | 12.700 | 212.000 | 82.000 | 0.160 |

| Barre granite | CCNBD | 1.800 | 12.700 | 212.000 | 82.000 | 0.160 | |

| Laurentian granite | CB | 1.800 | 12.790 | 259.000 | 92.000 | 0.210 | |

| Laurentian granite | CCNBD | 1.830 | 12.790 | 259.000 | 92.000 | 0.210 | |

| Stanstead granite | CB | 1.440 | 7.880 | 173.000 | 66.000 | 0.160 | |

| Stanstead granite | CCNBD | 1.220 | 7.880 | 173.000 | 66.000 | 0.160 | |

| [50] | Hunan Granite | CSTBD | 0.863 | 7.000 | 139.000 | 48.100 | 0.260 |

| [55] | Johnstone | SCB | 1.950 | 0.420 | 2.000 | 200.000 | 0.300 |

| [33] | Gabbro | SECRBB | 2.290 | 11.120 | 132.150 | 42.980 | 0.180 |

| Gabbro | CB | 2.720 | 11.120 | 132.150 | 42.980 | 0.180 | |

| Gabbro | SCB | 1.580 | 11.120 | 132.150 | 42.980 | 0.180 | |

| Gabbro | SNSRB | 1.970 | 11.120 | 132.150 | 42.980 | 0.180 | |

| Gabbro | BDT | 2.110 | 11.120 | 132.150 | 42.980 | 0.180 | |

| [19] | Shizhu Shale | CCNBD | 1.240 | 8.010 | 118.100 | 24.957 | 0.328 |

| Shizhu Shale | CCNBD | 1.280 | 8.243 | 54.200 | 20.687 | 0.251 | |

| Shizhu Shale | CCNBD | 1.413 | 9.170 | 78.600 | 17.977 | 0.285 | |

| Shizhu Shale | CCNBD | 1.593 | 9.638 | 105.900 | 16.803 | 0.309 | |

| Shizhu Shale | CCNBD | 2.200 | 12.840 | 118.400 | 13.827 | 0.371 | |

| [10] | Ankara andesite | SCB | 0.940 | 7.000 | 82.840 | 12.334 | 0.150 |

| Ankara andesite | CCNBD | 1.450 | 7.000 | 82.840 | 12.334 | 0.150 | |

| Afyon marble | SCB | 0.560 | 5.130 | 52.320 | 34.294 | 0.120 | |

| Afyon marble | CCNBD | 1.090 | 5.130 | 52.320 | 34.294 | 0.120 | |

| [51] | Fujian granite | SCB | 1.603 | 12.500 | 183.300 | 40.710 | 0.230 |

| [52] | Fujian granite | CSTBD | 1.145 | 11.630 | 174.780 | 28.940 | 0.200 |

| [53] | Fujian granite | SCB | 1.349 | 11.630 | 174.780 | 28.940 | 0.200 |

| [54] | Bayan Sandstone | SCB | 0.441 | 2.850 | 43.110 | 12.240 | 0.170 |

| Brittleness Index Equation | No. | Reference |

|---|---|---|

| (1) | [42,43] | |

| (2) | [42,43] | |

| (3) | [42,43] | |

| (4) | [42,43] | |

| (5) | [42] | |

| (6) | [42,43] | |

| (7) | [42,43] | |

| (8) | [42,43] | |

| (9) | [24] | |

| (10) | [24] |

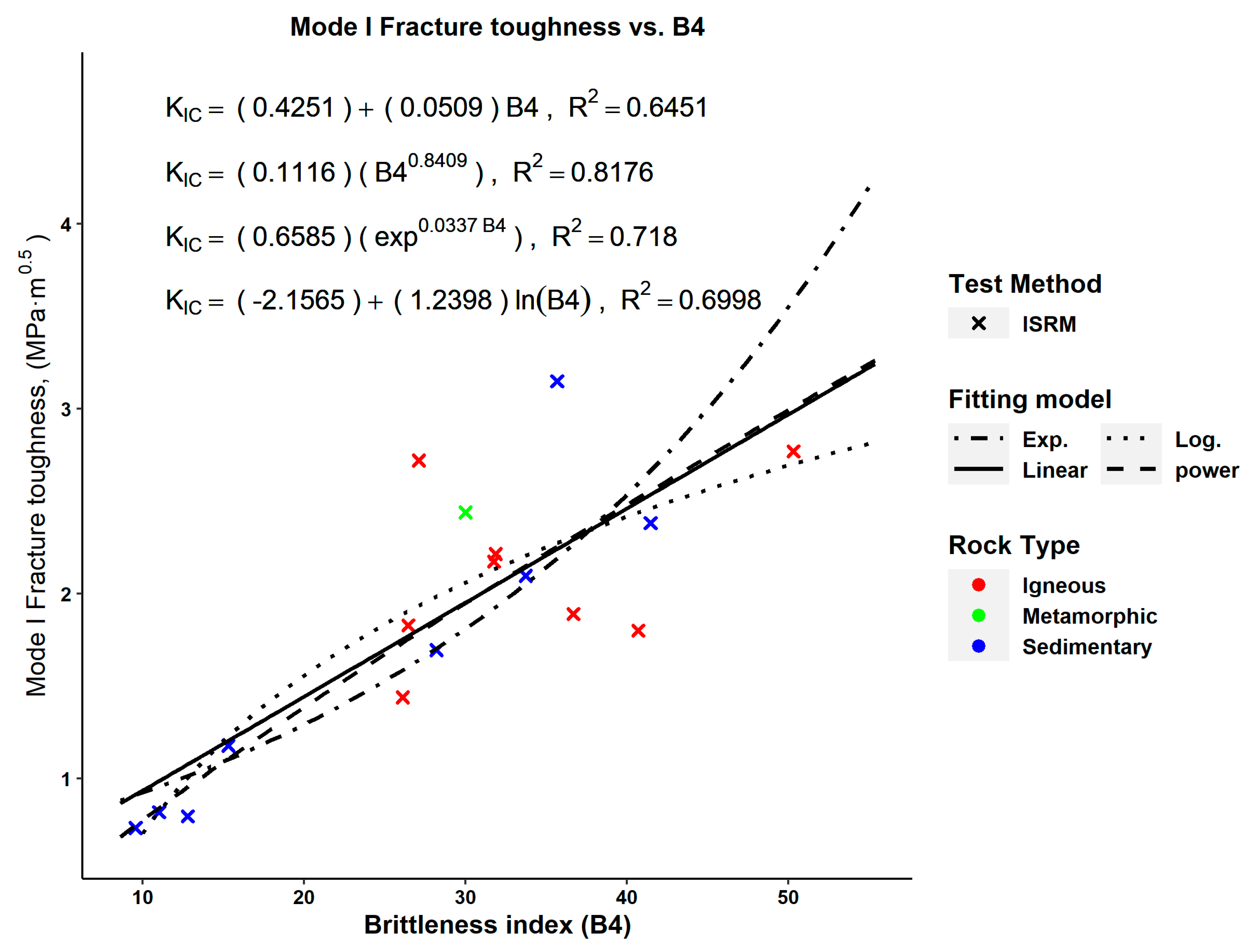

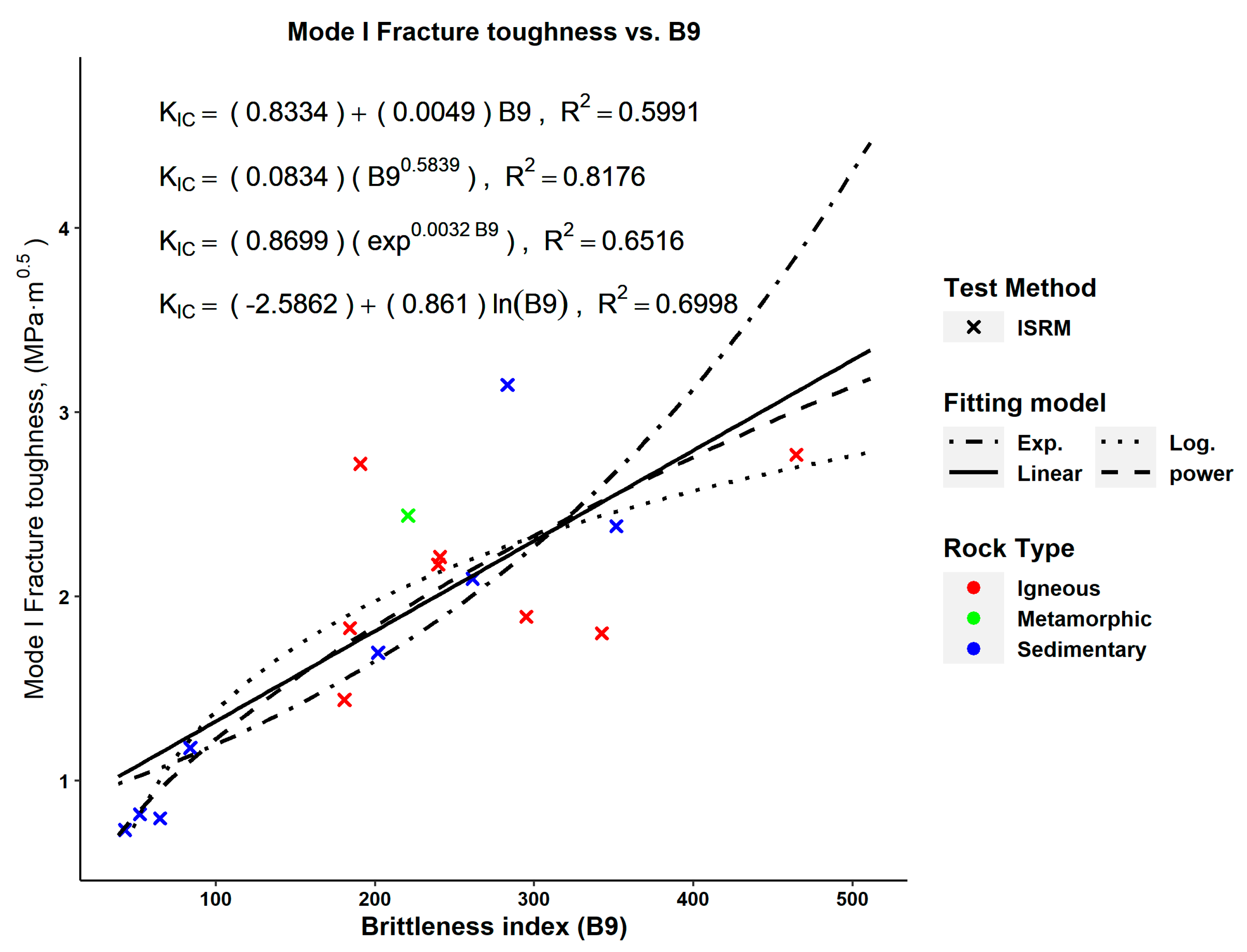

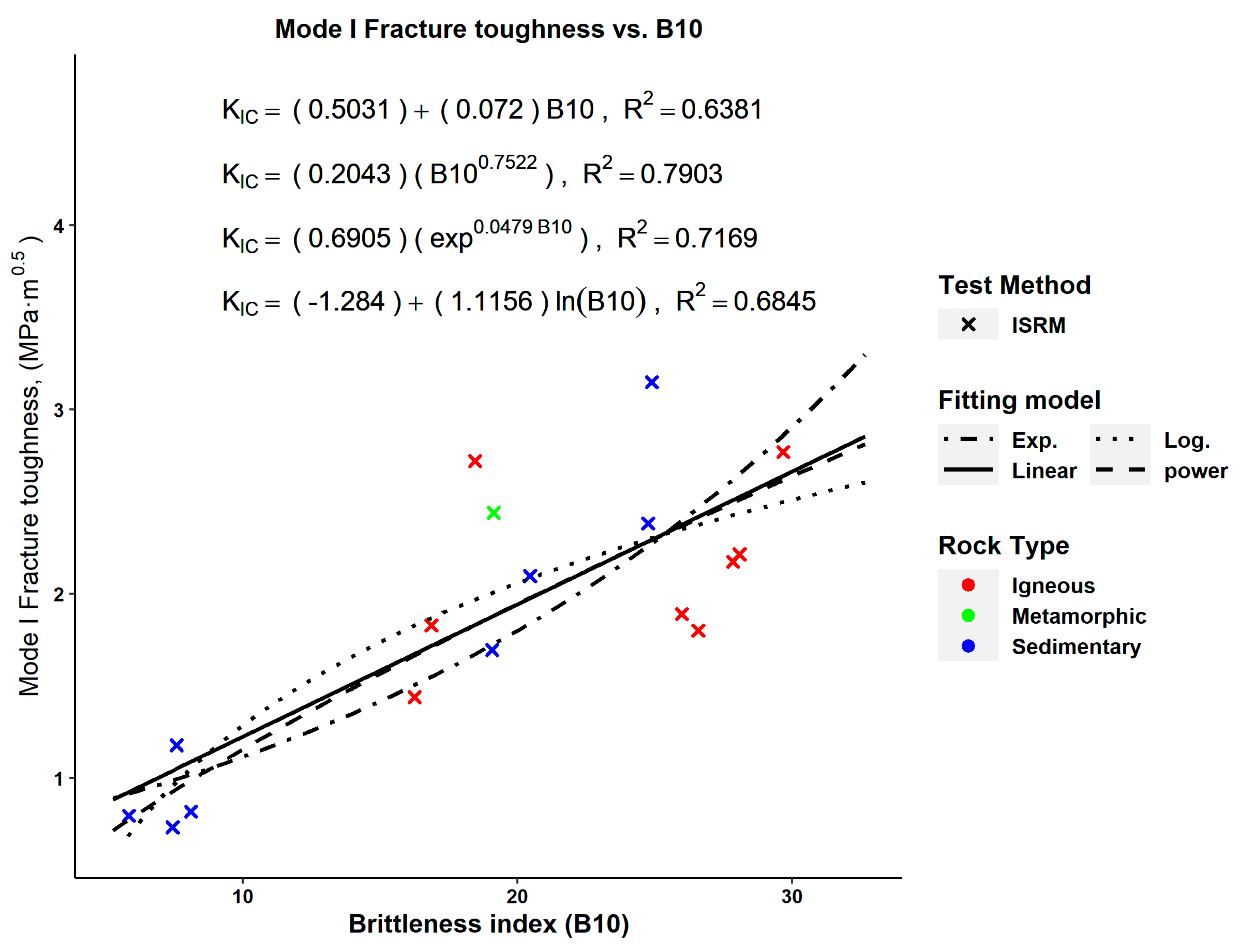

| Equation | No. | Figure No. | RMSE | p-Value (Pearson) | p-Value (Spearman) |

|---|---|---|---|---|---|

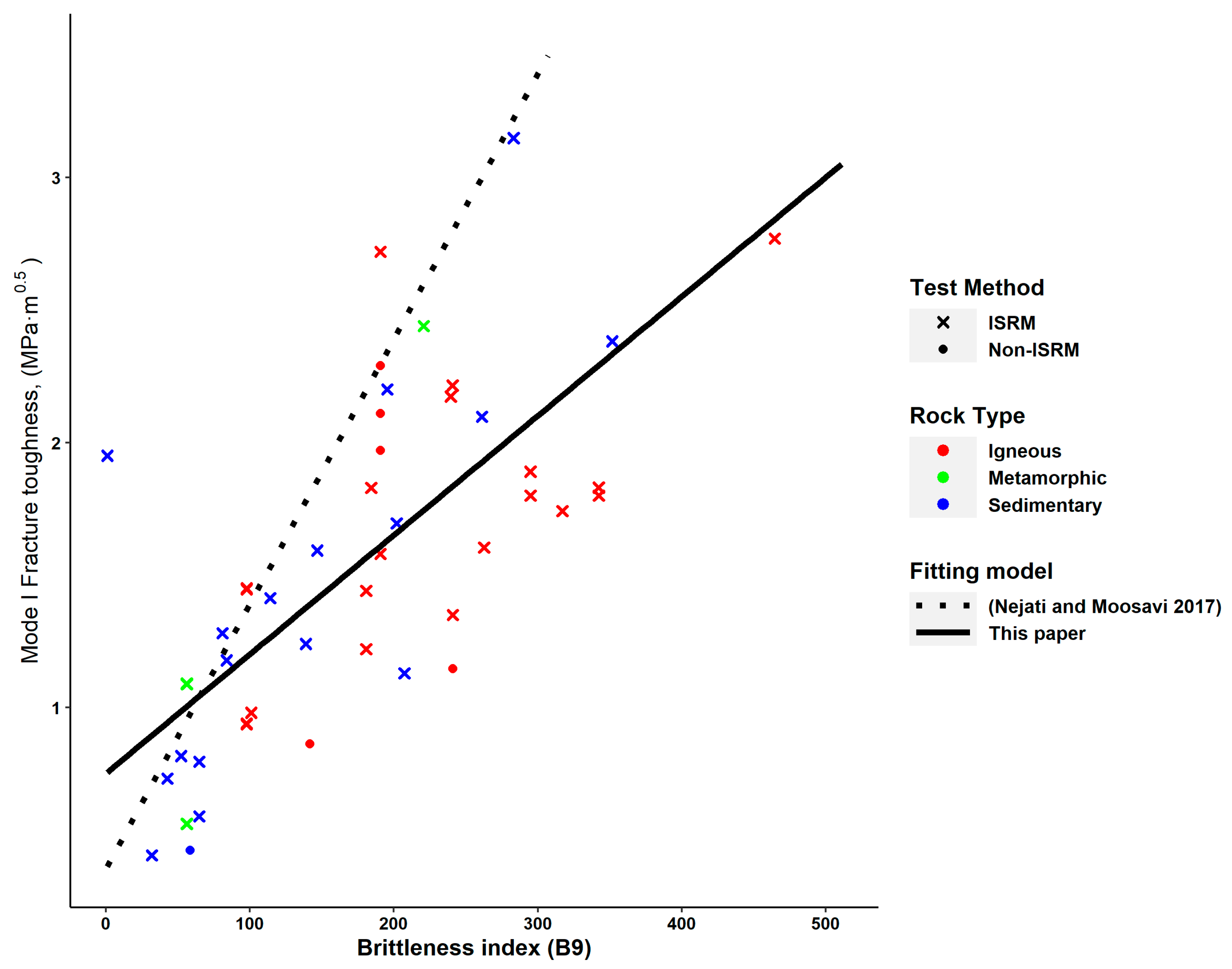

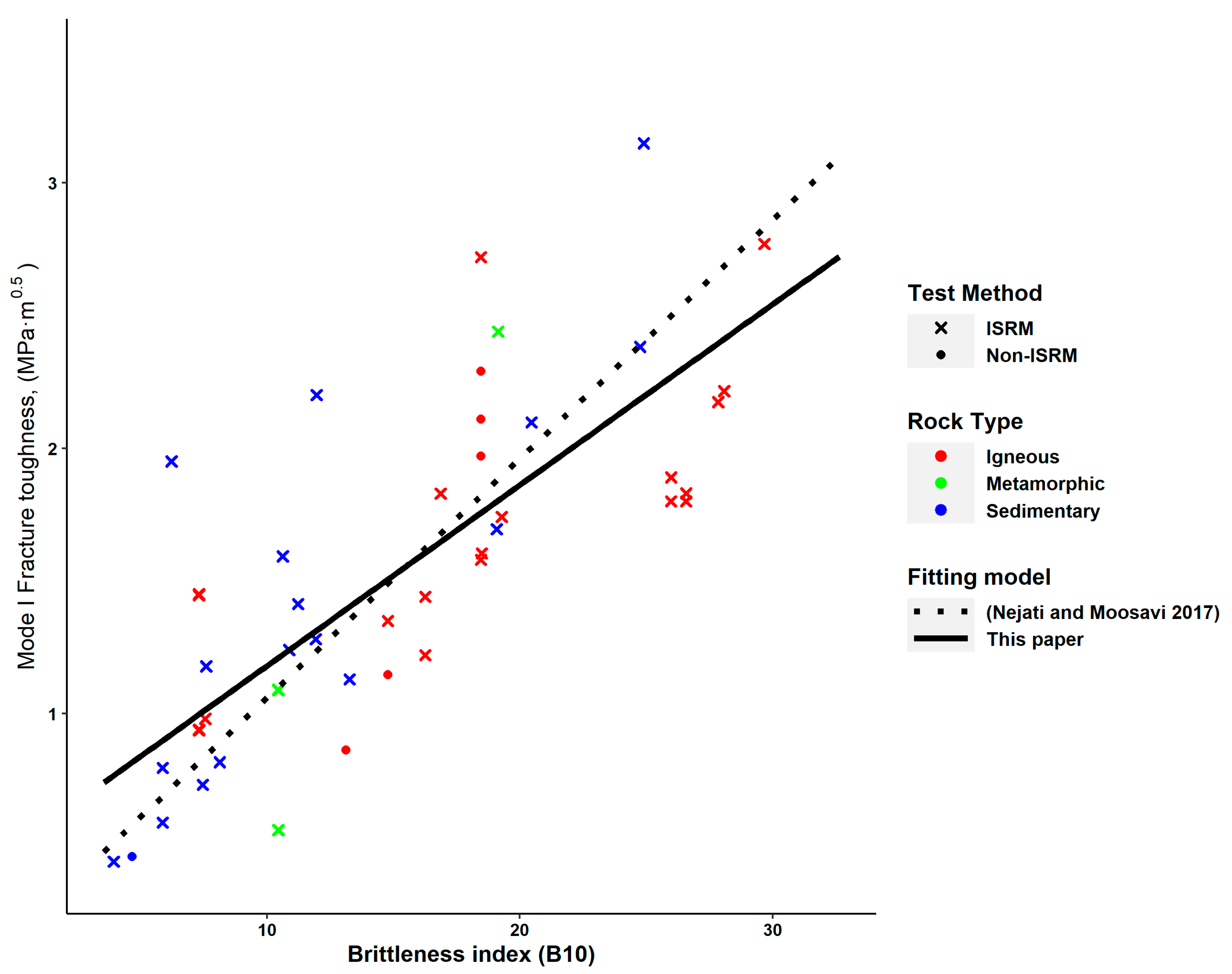

| (11) | Figure 4 | 0.3375 | 1.57 × 10−8 | N.A. | |

| (12) | Figure 9 | 0.3385 | 1.81 × 10−8 | N.A. | |

| (13) | 0.4543 | 1.64 × 10−8 | N.A. | ||

| (14) | Figure 10 | 0.3174 | N.A. | 9.86 × 10−11 | |

| (15) | 0.4209 | N.A. | 9.86 × 10−11 | ||

| (16) | 0.4173 | N.A. | 9.86 × 10−11 | ||

| (17) | 0.1307 | N.A. | 9.86 × 10−11 |

| B4 | B9 | B10 | ||||||

|---|---|---|---|---|---|---|---|---|

| Statistic | 0.9789 | 0.97599 | 0.9542 | 0.762 | 0.9497 | 0.9755 | 0.9544 | 0.9348 |

| p-value | 0.5351 | 0.4201 | 0.0589 | 1.98 × 10−7 | 0.0389 | 0.4071 | 0.06 | 0.0103 |

| Equation | No. | Reference |

|---|---|---|

| (18) | [24] | |

| (19) | ||

| (20) | [22] | |

| (21) | [23] | |

| (22) |

| Reference | Parameter | (MPa) | (MPa) | E (GPa) | |

|---|---|---|---|---|---|

| This paper | Mean | 9.42 | 125.88 | 41.31 | 0.21 |

| Range | 0.42 to 18.42 | 2 to 274.82 | 8.23 to 200.00 | 0.12 to 0.37 | |

| Standard deviation | 3.92 | 65.11 | 32.31 | 0.06 | |

| Skewness | −0.0230 | 0.4782 | 2.7206 | 0.5499 | |

| [18] | Mean | 11.8 | 141.79 | 44.13 | 0.25 |

| Range | 3.84 to 18.42 | 47.76 to 274.82 | 15.92 to 64.18 | 0.13 to 0.34 | |

| Standard deviation | 4.76 | 65.58 | 15.91 | 0.06 | |

| Skewness | −0.6026 | 0.452 | −0.3654 | −0.6731 | |

| [69] | Mean | 12.82 | 150.83 | ----- | ----- |

| Range | 5.9 to 17 | 57.2 to 264 | ----- | ----- | |

| Standard deviation | 3.61 | 58.84 | ----- | ----- | |

| Skewness | −0.8834 | 0.3376 | ----- | ----- | |

| [24] | Mean | 9.97 | 137.22 | 50.22 | ----- |

| Range | 2.3 to 17.6 | 32.3 to 224 | 9.9 to 78 | ----- | |

| Standard deviation | 4.61 | 56.26 | 20.21 | ----- | |

| Skewness | −0.1017 | −0.1939 | −0.6577 | ----- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ameen, M.; Elwageeh, M.; Abdelaziz, A.; Bonduà, S.; Elkarmoty, M. Study of the Relationship between Mode I Fracture Toughness and Rock Brittleness Indices. Appl. Sci. 2023, 13, 10378. https://doi.org/10.3390/app131810378

Ameen M, Elwageeh M, Abdelaziz A, Bonduà S, Elkarmoty M. Study of the Relationship between Mode I Fracture Toughness and Rock Brittleness Indices. Applied Sciences. 2023; 13(18):10378. https://doi.org/10.3390/app131810378

Chicago/Turabian StyleAmeen, Mostafa, Mohamed Elwageeh, Ahmed Abdelaziz, Stefano Bonduà, and Mohamed Elkarmoty. 2023. "Study of the Relationship between Mode I Fracture Toughness and Rock Brittleness Indices" Applied Sciences 13, no. 18: 10378. https://doi.org/10.3390/app131810378

APA StyleAmeen, M., Elwageeh, M., Abdelaziz, A., Bonduà, S., & Elkarmoty, M. (2023). Study of the Relationship between Mode I Fracture Toughness and Rock Brittleness Indices. Applied Sciences, 13(18), 10378. https://doi.org/10.3390/app131810378