Limit Equilibrium Analysis of Landfill Instability Based on Actual Failure Surface

Abstract

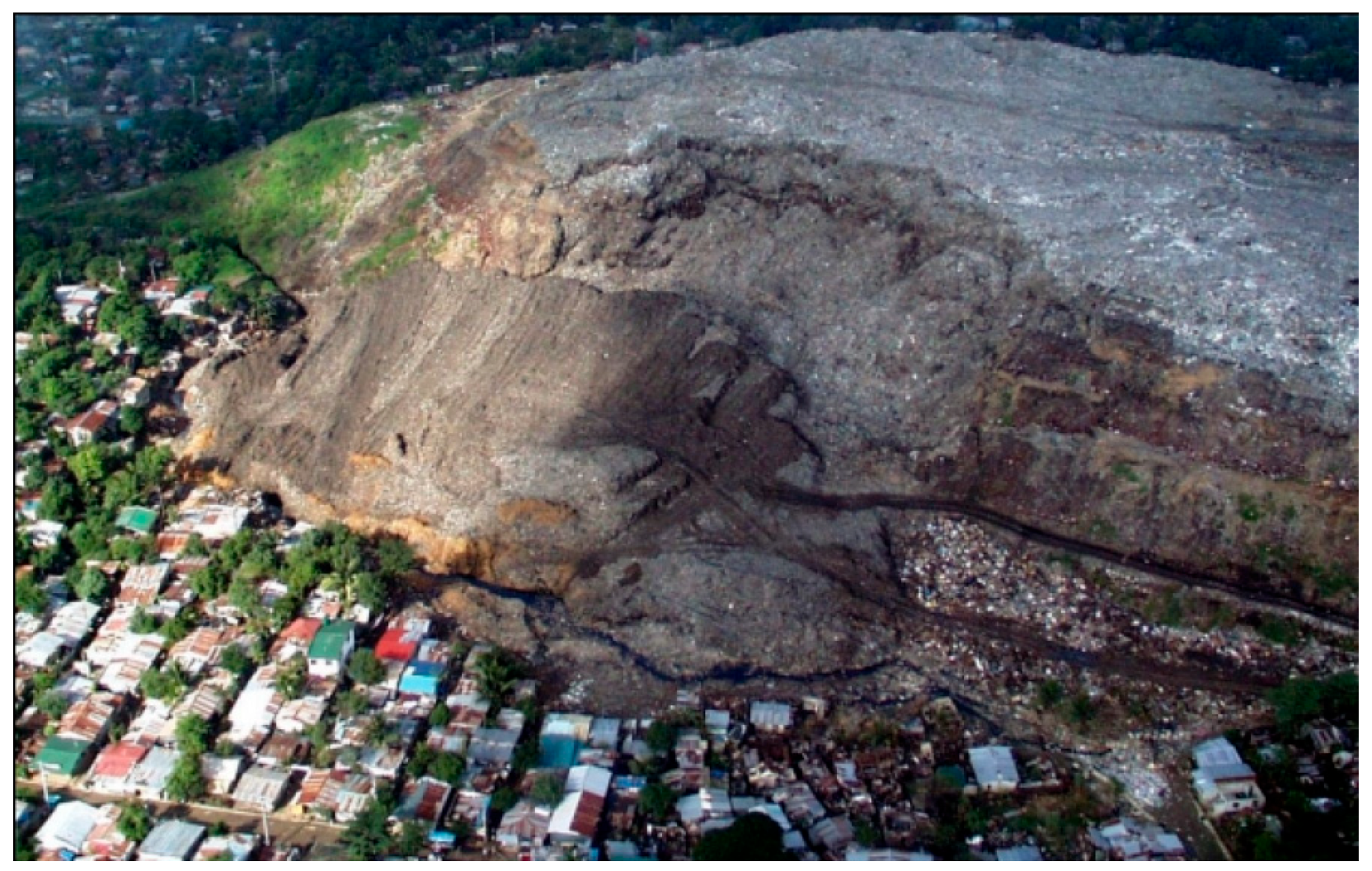

:1. Introduction

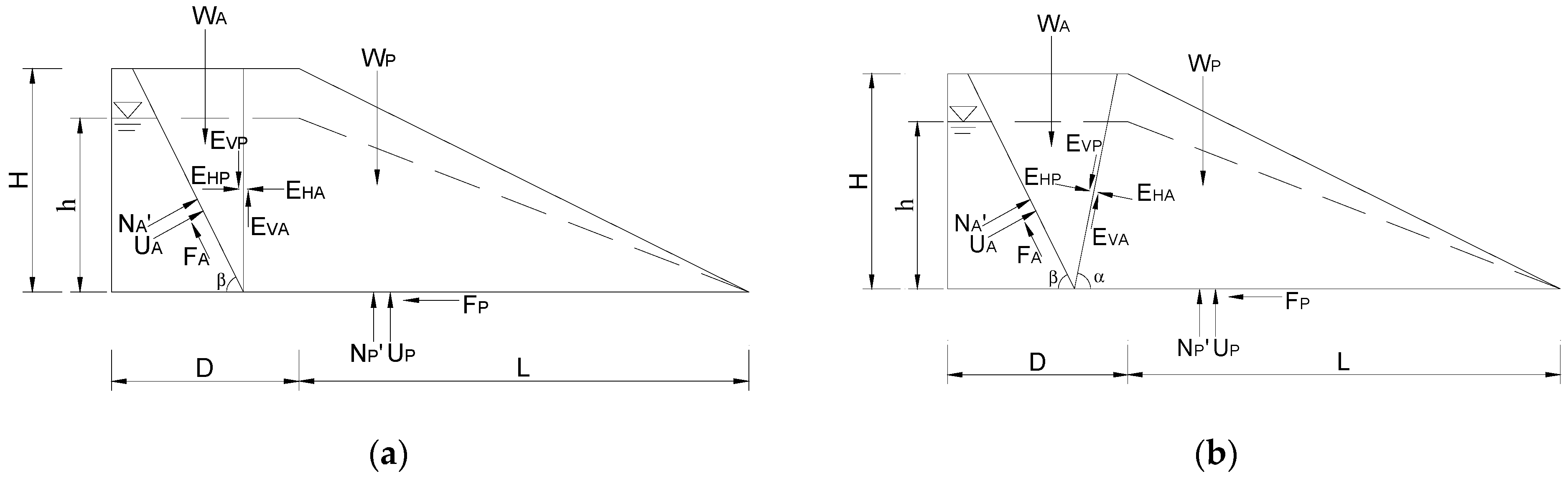

2. Theoretical Model and Analysis Method

2.1. Basic Theory

2.2. Assumptions

- (1)

- The factor of safety FS of the landfill is equal everywhere along the sliding surface;

- (2)

- The resultant force between the wedges forms an angle with the horizontal direction and acts at 1/3 of the height of the interface between the wedges and the horizontal and vertical components on the interface;

- (3)

- Meet the rationality requirements of the limit equilibrium method—that is, the factor of safety FSV of the interface between the wedges is greater than or equal to 1;

- (4)

- The factor of safety FSV of the interface between the wedges is not less than the FS of the landfill—that is, FSV ≥ FS;

- (5)

- The water level acts on each interface as a hydrostatic pressure, and the pore pressure and water pressure on the sliding surface act on the sliding body as a resultant force;

- (6)

- The frictional resistance between the bottom of the active wedge and the liner is ignored.

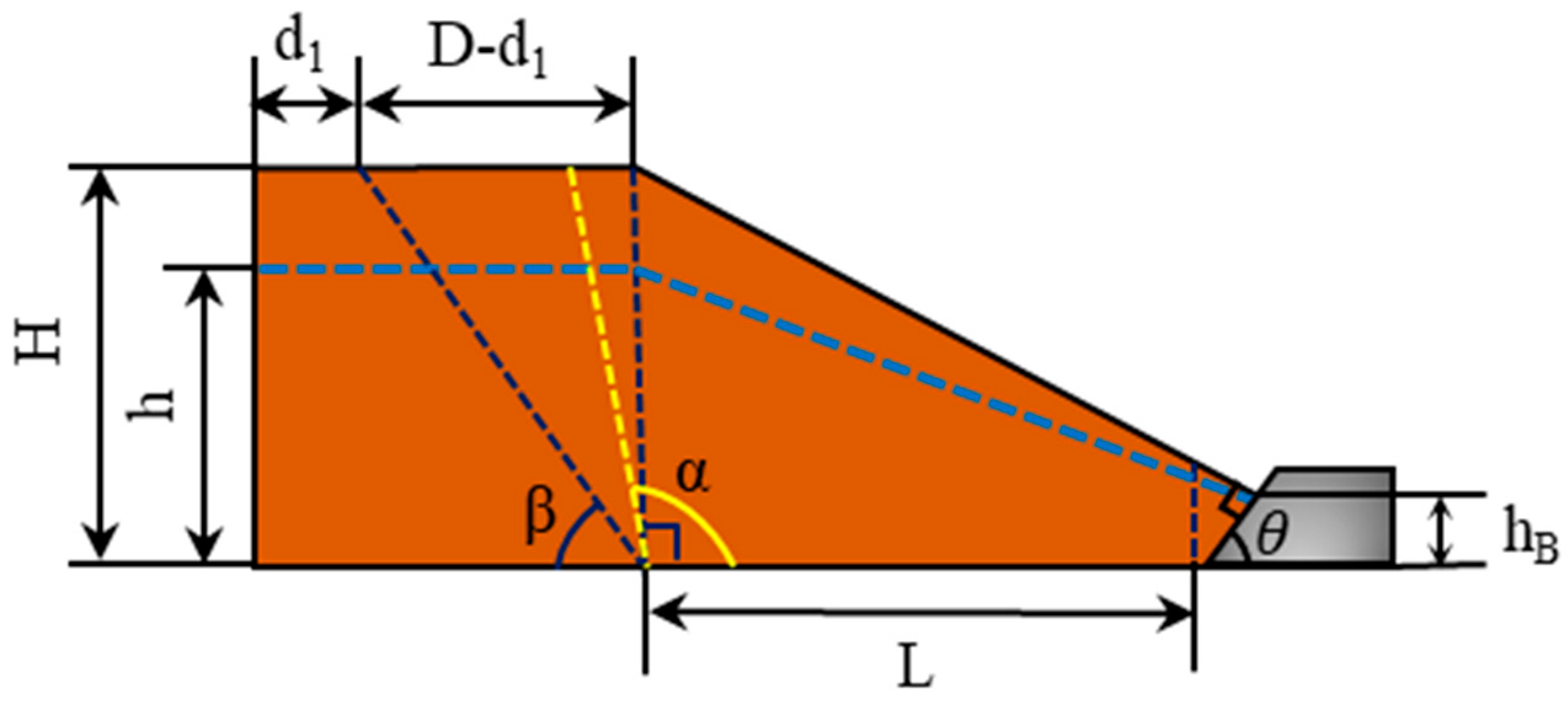

2.3. Parameters

2.4. Analysis Method

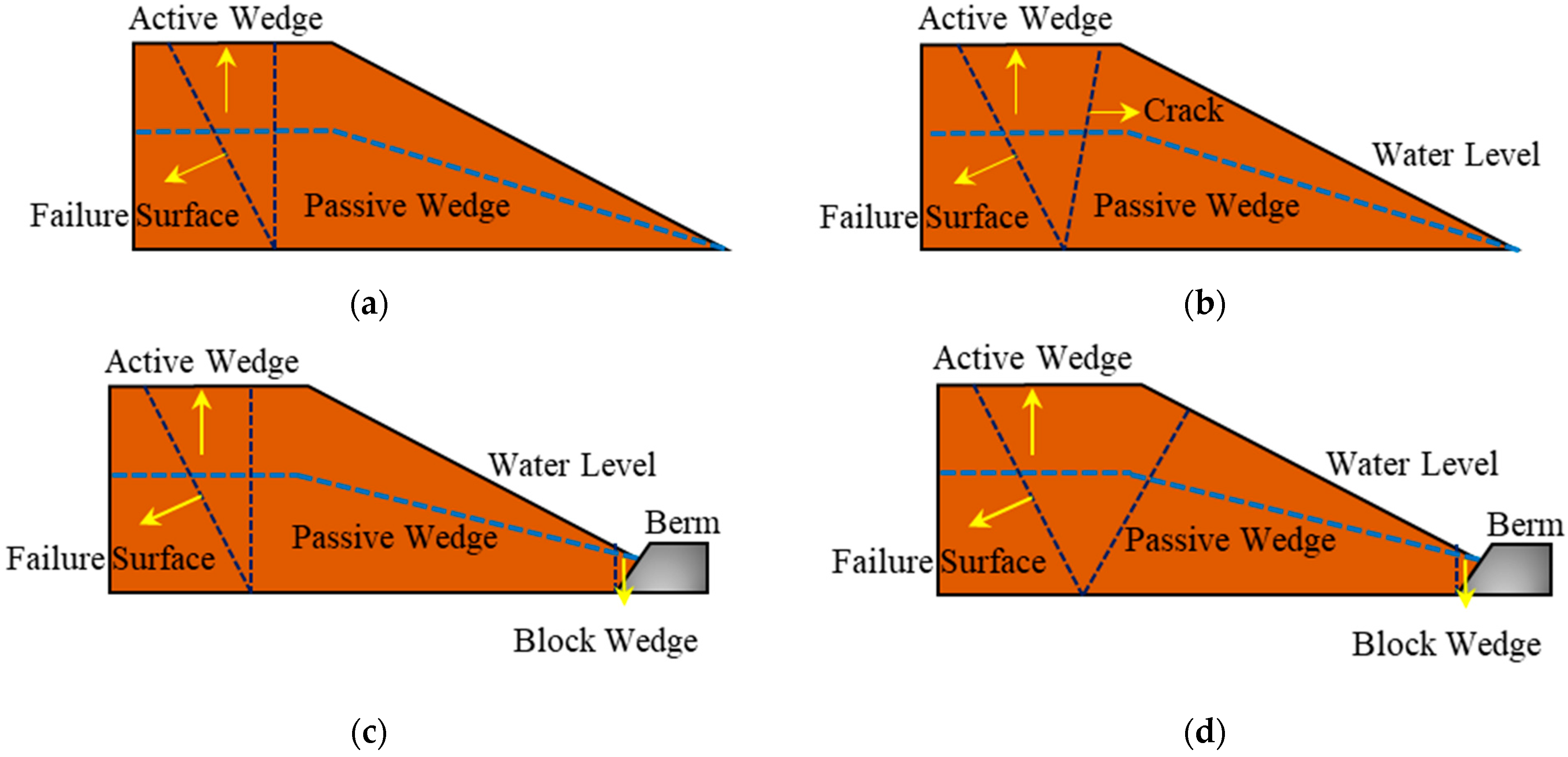

2.4.1. Two-Wedge Model without Berm

2.4.2. Two-Wedge Model without Berm Based on Actual Failure Surface

2.4.3. Three-Wedge Model with Berm

2.4.4. Three-Wedge Model with Berm Based on Actual Failure Surface

3. Results

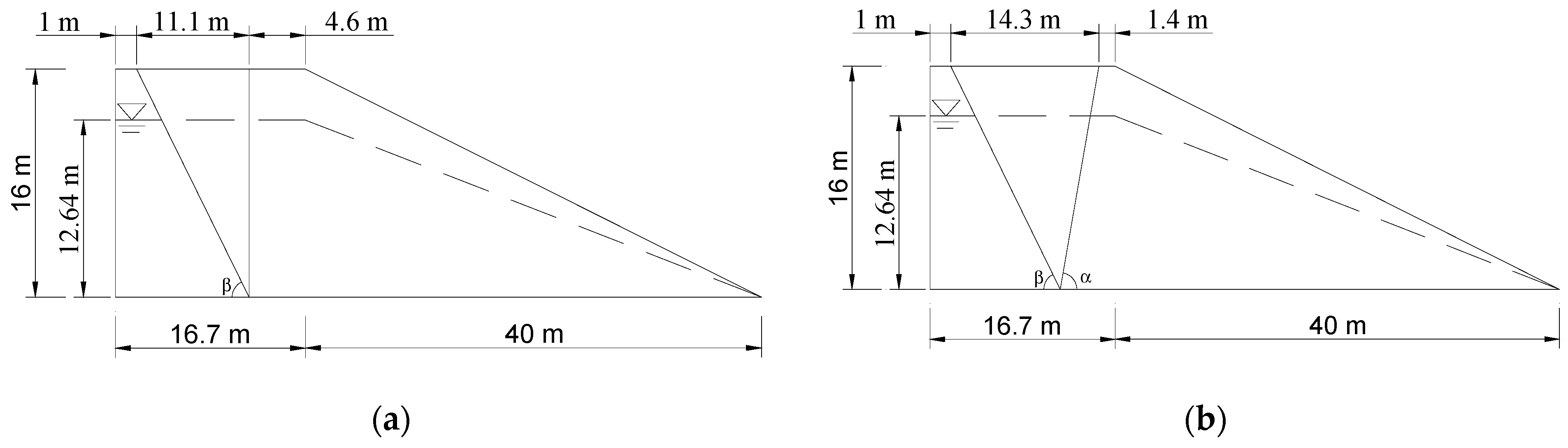

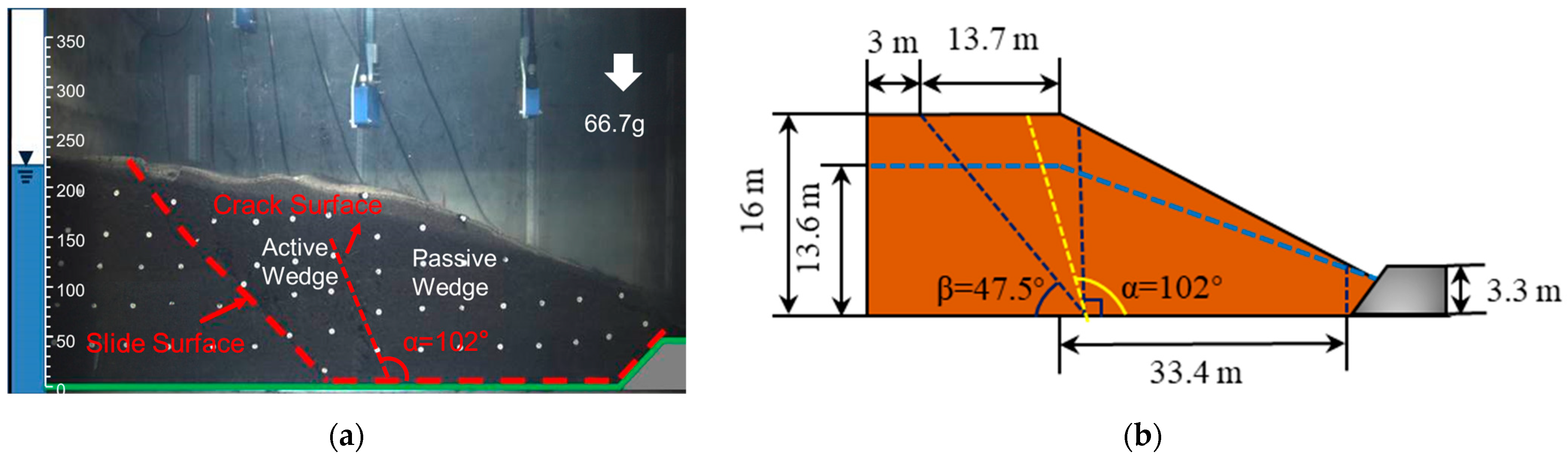

3.1. Centrifugal Test Case Analysis

3.1.1. Centrifugal Test without Berm

3.1.2. Centrifugal Test with Berm

3.2. Parameter Analysis

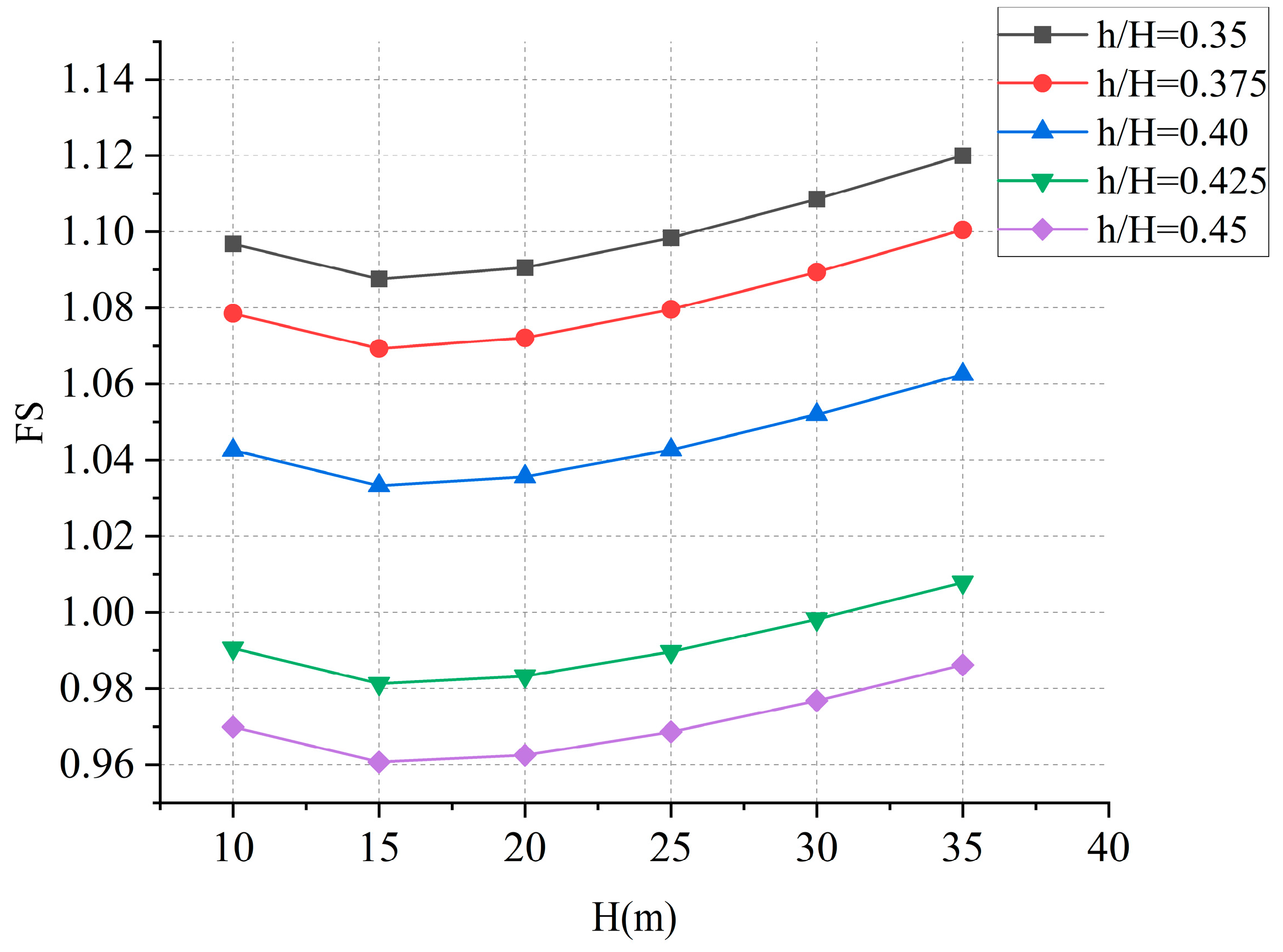

3.2.1. Two-Wedge Model

- Slope scale and water level

- 2.

- Failure surface angle

- 3.

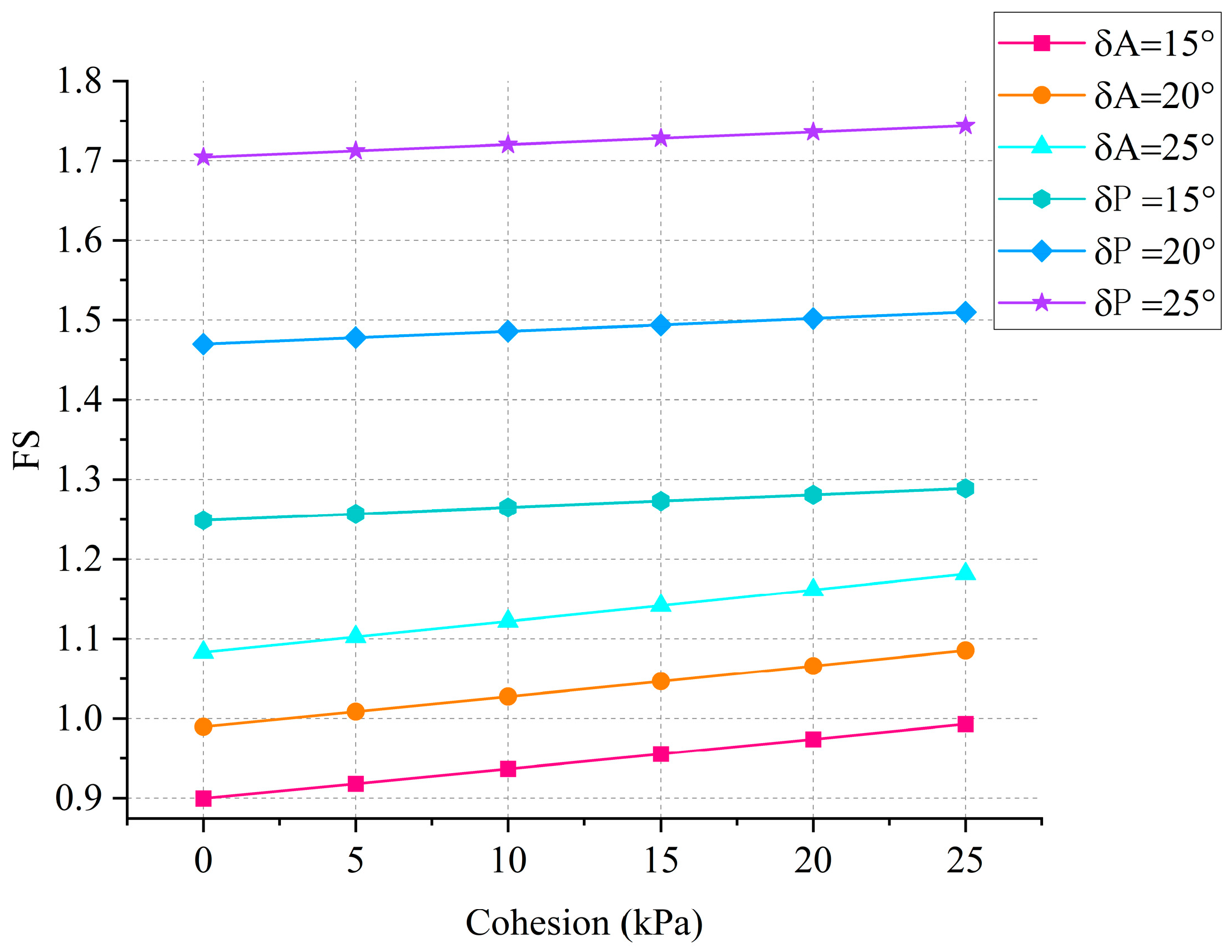

- Soil properties

3.2.2. Three-Wedge Model

- 4.

- Failure surface angle and water level

- 5.

- Soil properties

- 6.

- Berm parameters

4. Discussion

5. Conclusions

- (1)

- The phenomena of previous centrifugal model tests show that the penetrating crack of the instability failure of the landfill under a high water level is not vertical to the horizontal plane, as in the traditional wedge model; so, the limit equilibrium analysis method was improved based on the actual failure surface angle. The interface between the active wedge and the passive wedge was changed to the failure surface in the process of slope slip, and the results of the centrifugal experiment were verified, which has important implications for predicting the stability of the landfill slope;

- (2)

- The proposed model was checked according to the results of the previous centrifuge tests. The wedges were divided according to the failure surface in the process of model instability and slip, and the limit equilibrium analysis was carried out. The obtained FS is closer to 1.0, which means close to the unstable state;

- (3)

- In the two-wedge model, the factor of safety hardly changes under the condition of a particular value of water level ratio. As the failure surface angle of the slope continues to increase and the water level rises, the safety factor of the slope decreases significantly. The friction angle of the passive wedge in the wedge model significantly affects the stability of the entire slope;

- (4)

- After analyzing the parameter-sensitivity of the three-wedge model based on the actual failure surface, it was found that with the increase in failure surface angle, the FS of the slope gradually increases. The soil properties and the parameters of the retaining dam significantly affect the stability of the slope.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, S.J.; Chang, J.Y.; Shi, H.; Zheng, Q.T.; Guo, X.Y.; Zhang, X.L. Failure of an unfilled landfill cell due to an adjacent steep slope and a high groundwater level: A case study. Eng. Geol. 2019, 262, 105320. [Google Scholar] [CrossRef]

- Gao, W.; Bian, X.-C.; Xu, W.-J.; Chen, Y.-M. Storage Capacity and Slope Stability Analysis of Municipal Solid Waste Landfills. J. Perform. Constr. Facil. 2018, 32, 04018036. [Google Scholar] [CrossRef]

- Ering, P.; Sivakumar Babu, G.L. Slope Stability and Deformation Analysis of Bangalore MSW Landfills Using Constitutive Model. Int. J. Geomech. 2016, 16, 04015092. [Google Scholar] [CrossRef]

- Platis, A.; Eng, C.E.M.; Paraskevi, A. Reinforced Earth Used in Uncontrolled Landfill Final Closures—The Case of Syros Landfill. Int. J. Geoengin. Case Hist. 2016, 4, 1–13. [Google Scholar] [CrossRef]

- Stark, T.D.; Eid, H.T.; Evans, W.D.; Sherry, P.E. Municipal Solid Waste Slope Failure. II: Stability Analyses. J. Geotech. Geoenviron. Eng. 2000, 126, 408–419. [Google Scholar] [CrossRef]

- Seed, R.B.; Mitchell, J.K.; Seed, H.B. Kettleman hills waste landfill slope failure. II: Stability analyses. J. Geotech. Eng. 1990, 116, 669–690. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Seed, R.B.; Seed, H.B. Kettleman hills waste landfill slope failure. I: Liner-system properties. J. Geotech. Eng. 1990, 116, 647–668. [Google Scholar] [CrossRef]

- Qian, X.; Koerner, R.M.; Gray, D.H. Translational Failure Analysis of Landfills. J. Geotech. Geoenviron. Eng. 2003, 129, 506–519. [Google Scholar] [CrossRef]

- Qian, X.; Koerner, R.M. Effect of Apparent Cohesion on Translational Failure Analyses of Landfills. J. Geotech. Geoenviron. Eng. 2004, 130, 71–80. [Google Scholar] [CrossRef]

- Chen, Y.M.; Gao, D.; Zhu, B.; Chen, R.P. Seismic stability and permanent displacement of landfill along liners. Sci. China Ser. E Technol. Sci. 2008, 51, 407–423. [Google Scholar] [CrossRef]

- Qian, X.; Koerner, R.M. Stability Analysis When Using an Engineered Berm to Increase Landfill Space. J. Geotech. Geoenviron. Eng. 2009, 135, 1082–1091. [Google Scholar] [CrossRef]

- Feng, S.J.; Gao, L.Y. Seismic analysis for translational failure of landfills with retaining walls. Waste Manag. 2010, 30, 2065–2073. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.J.; Chen, Y.M.; Gao, L.Y.; Gao, G.Y. Translational failure analysis of landfill with retaining wall along the underlying liner system. Environ. Earth Sci. 2010, 60, 21–34. [Google Scholar] [CrossRef]

- Koerner, R.M.; Soong, T.Y. Leachate in landfills: The stability issues. Geotext. Geomembr. 2000, 18, 293–309. [Google Scholar] [CrossRef]

- Fellner, J.; Brunner, P.H. Modeling of leachate generation from MSW landfills by a 2-dimensional 2-domain approach. Waste Manag. 2010, 30, 2084–2095. [Google Scholar] [CrossRef]

- Aziz, H.A.; Adlan, M.N.; Amilin, K.; Yusoff, M.S.; Ramly, N.H.; Umar, M. Quantification of leachate generation rate from a semi-aerobic landfill in Malaysia. Environ. Eng. Manag. J. 2012, 11, 1581–1585. [Google Scholar] [CrossRef]

- Feng, S.J.; Chen, Z.W.; Chen, H.X.; Zheng, Q.T.; Liu, R. Slope stability of landfills considering leachate recirculation using vertical wells. Eng. Geol. 2018, 241, 76–85. [Google Scholar] [CrossRef]

- Kadambala, R.; Townsend, T.G.; Jain, P.; Singh, K. Temporal and spatial pore water pressure distribution surrounding a vertical landfill leachate recirculation well. Int. J. Environ. Res. Public Health 2011, 8, 1692–1706. [Google Scholar] [CrossRef]

- Feng, S.-J.; Chang, J.-Y.; Zhang, X.-L.; Shi, H.; Wu, S.-J. Stability Analysis and Control Measures of a Sanitary Landfill with High Leachate Level. J. Geotech. Geoenviron. Eng. 2021, 147, 05021009. [Google Scholar] [CrossRef]

- Merry, S.M.; Kavazanjian, E.; Fritz, W.U. Reconnaissance of the July 10, 2000, Payatas Landfill Failure. J. Perform. Constr. Facil. 2005, 19, 100–107. [Google Scholar] [CrossRef]

- Kavazanjian, E.; Beech, J.F.; Matasović, N.; Eid, H.T.; Stark, T.D.; Evans, W.D.; Sherry, P.E. Municipal Solid Waste Slope Failure. I: Waste and Foundation Soil Properties. J. Geotech. Geoenviron. Eng. 2001, 127, 812–815. [Google Scholar] [CrossRef]

- Blight, G.E. Interpretations of surface movements of a landfill built on steeply sloping ground. A cautionary case history. Waste Manag. Res. 2007, 25, 572–584. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Wang, Y.; Fang, Y.; Pan, X.; Zhang, J.; Xu, H. Global study on slope instability modes based on 62 municipal solid waste landfills. Waste Manag. Res. 2020, 38, 1389–1404. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Liu, Y.; Tang, H.; Kang, J.; Wang, L.; Li, C.; Wang, D.; Liu, Z. Experimental study of the influence of wetting and drying cycles on the strength of intact rock samples from a red stratum in the Three Gorges Reservoir area. Eng. Geol. 2023, 314, 107013. [Google Scholar] [CrossRef]

- Munwar Basha, B.; Raviteja, K.V.N.S. Meethotamulla Landfill Failure Analysis: A Probabilistic Approach. In Geotechnics for Natural and Engineered Sustainable Technologies: GeoNEst; Springer: Singapore, 2018; pp. 341–351. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, Y.; Yuan, H.; Liu, D.; Yan, Y.; Hua, S.; Ren, S. Study of an ancient landslide reactivation mechanism based on centrifuge model testing: An example of the Jiangdingya ancient landslide reactivation in 2018, Gansu Province, China. Landslides 2023, 20, 127–141. [Google Scholar] [CrossRef]

- Ling, H.; Ling, H.I. Centrifuge Model Simulations of Rainfall-Induced Slope Instability. J. Geotech. Geoenviron. Eng. 2012, 138, 1151–1157. [Google Scholar] [CrossRef]

- Xu, J.; Ueda, K.; Uzuoka, R. Evaluation of failure of slopes with shaking-induced cracks in response to rainfall. Landslides 2022, 19, 119–136. [Google Scholar] [CrossRef]

- Chen, Y.M.; Li, J.C.; Yang, C.B.; Zhu, B.; Zhan, L.T. Centrifuge modeling of municipal solid waste landfill failures induced by rising water levels. Can. Geotech. J. 2017, 54, 1739–1751. [Google Scholar] [CrossRef]

- Lü, X.; Xue, D.; Chen, Q.; Zhai, X.; Huang, M. Centrifuge model test and limit equilibrium analysis of the stability of municipal solid waste slopes. Bull. Eng. Geol. Environ. 2019, 78, 3011–3021. [Google Scholar] [CrossRef]

- Fang, K.; Zhang, J.; Tang, H.; Hu, X.; Yuan, H.; Wang, X.; An, P.; Ding, B. A quick and low-cost smartphone photogrammetry method for obtaining 3D particle size and shape. Eng. Geol. 2023, 322, 107170. [Google Scholar] [CrossRef]

- Zhan, T.L.T.; Chen, Y.M.; Ling, W.A. Shear strength characterization of municipal solid waste at the Suzhou landfill, China. Eng. Geol. 2008, 97, 97–111. [Google Scholar] [CrossRef]

- Xu, Q.; Tolaymat, T.; Townsend, T.G. Impact of Pressurized Liquids Addition on Landfill Slope Stability. J. Geotech. Geoenviron. Eng. 2012, 138, 472–480. [Google Scholar] [CrossRef]

- De Stefano, M.; Gharabaghi, B.; Clemmer, R.; Jahanfar, M.A. Berm design to reduce risks of catastrophic slope failures at solid waste disposal sites. Waste Manag. Res. 2016, 34, 1117–1125. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Chen, R.; Lin, H. Limit Equilibrium Analysis of Landfill Instability Based on Actual Failure Surface. Appl. Sci. 2023, 13, 10498. https://doi.org/10.3390/app131810498

Li J, Chen R, Lin H. Limit Equilibrium Analysis of Landfill Instability Based on Actual Failure Surface. Applied Sciences. 2023; 13(18):10498. https://doi.org/10.3390/app131810498

Chicago/Turabian StyleLi, Junchao, Ruiqi Chen, and Haoyu Lin. 2023. "Limit Equilibrium Analysis of Landfill Instability Based on Actual Failure Surface" Applied Sciences 13, no. 18: 10498. https://doi.org/10.3390/app131810498

APA StyleLi, J., Chen, R., & Lin, H. (2023). Limit Equilibrium Analysis of Landfill Instability Based on Actual Failure Surface. Applied Sciences, 13(18), 10498. https://doi.org/10.3390/app131810498