1. Introduction

With the development of technology, mobile robots and UGVs (Unmanned Ground Vehicles) are gaining more and more widespread use in many areas of life [

1,

2]. Their main capability is to directly replace humans in hazardous work environments. To achieve the necessary functionality, they are required to have an adequate mobility level for the working conditions, effectiveness in task performance [

3], and sufficient energy reserve for the expected working time [

4].

In order to increase mobility, robots and UGVs are often equipped with tracked running gear [

5,

6]. Compared with wheeled traction systems, tracked systems are characterized by lower pressures, a higher ability to overcome terrain with low load capacity, the ability to develop higher traction forces with less slip, and a greater ability to overcome terrain obstacles [

7]. More and more often, instead of metal tracks, rubber tracks are used. They allow for driving on both paved roads and off-roads while ensuring quieter operation [

8], a longer service life, and lower operating costs [

9], as well as better traction characteristics and an advantageous distribution of ground pressure [

10,

11], typical for tracks. For these reasons, they can be increasingly used in low-speed transport vehicles and agricultural tractors of various sizes, where they replace wheeled chassis [

10,

11,

12,

13,

14].

Experimental and simulation studies in the field of rubber track applications focus mainly on the prediction of traction forces and rolling resistance on deformable soils, taking into account the principles of terramechanics [

15,

16,

17]. These studies show the high compatibility of heavy vehicle models; using them to model light robots and UGVs does not always bring satisfactory results [

18]. Similar problems occur when modeling the energy efficiency of driving. Experimental studies show that the resistance and energy consumption, especially of lightweight robots, can be relatively higher than in the case of classic heavy-tracked vehicles with metal tracks [

19,

20,

21]. The rolling resistance coefficient may be the main component of energy loss. Even on non-deformable surfaces, it may exceed 20% [

3,

22].

Research [

19,

23] indicates factors that have a significant impact on the internal motion resistance of rubber track running gear: track scrolling speed, diameters of driving, idler, and road wheels, as well as stiffness and damping of the track belt, depending on the type of rubber and structure of the track belt. These properties not only increase the track bending resistance but also cause the track belt to heat up and increase its temperature [

24,

25]. This may change its stiffness, lead to track elongation and shedding while driving, cause devulcanization, and accelerate the degradation of the track structure [

26]. In addition, the stiffness of the track belt (its susceptibility to deformation) and the track tension have a dominant effect on the contact with the ground. Increased track-terrain contact improves ground pressure, tractive forces, and the general ability to overcome obstacles [

17], which also depends on the applied running gear solutions [

27,

28,

29]. It is therefore advisable to take these factors into account in the track modeling process, especially in systems with complex kinematics, moving on rough surfaces, and overcoming obstacles.

2. Track Susceptibility in Simulation Models

In order to properly shape the running gear, simulation tests [

27,

30,

31,

32,

33,

34] are widely used. They make it possible to estimate the drive torques necessary to overcome the motion resistance, obstacle negotiation ability [

35], maneuver performance resistance [

33], and energy consumed by the robot [

20].

Despite the impact of rubber track susceptibility on many aspects of the robot’s functionality, it is not always taken into account. In fast real-time simulations, in order to shorten the calculation time, the structure of the track belt may be omitted or simplified [

36,

37]. Running gear is presented as a system consisting only of driving wheels. The belt adds to the hull weight. To increase the accuracy of the track-terrain contact surface, there are models where the shape of the tracked running gear is obtained by using an increased number of overlapping wheels to form an almost continuous contact surface with the ground [

33,

38]. An alternative solution is also to use the non-deformable track model [

35,

39]. It allows the track to perform on the ground, developing tractive force, but track deformation in reaction to the ground is impossible. This model allows for relatively quick determination of the parameters of driving straight, negotiating small, simple obstacles, and even turning with a fixed radius. The problem, however, may be situations of point contact with the ground, e.g., curb or stair climbing [

37]. This type of model is also used to predict the motion parameters of robots when performing maneuvers [

33].

The track model, taking into account its deformation ability, can be achieved by the coupled multibody dynamics-finite elements method model [

40] or the finite element method [

41,

42]. A model using a system of wheels and a track belt with a structure divided into a finite number of elements was used, e.g., in the research [

42] of the rubber-tracked running gear of a farm tractor. Considering the elasticity of the rubber belt, its deflection under its own weight was used to model parameter identification. By using finite elements, it is possible to give the elastomer material non-linear, hyperelastic properties. In this way, its deformations and stresses while driving can be reflected with high accuracy. The disadvantage of the method is its long simulation time. Therefore, despite the possibility of using the FEM method in dynamic simulations, it will not always be fully practical.

Another track modeling method is to digitize the belt into a finite number of elements (links) connected with each other by constraints (joints), defining its motions by restricting degrees of freedom [

43,

44,

45]. This method is widely used in metal track modeling [

28,

46]. It allows deformation of the track in accordance with the adopted constraints as well as a more accurate verification of which of its elements remain in contact with the ground. It is especially useful when simulating overcoming terrain roughness. Three connection methods are most often used between track links: kinematic joints, force constraints, and constraints with plastic deformation ability [

44].

The simplest type of track-link connection is one with kinematic constraints. They provide movement in an established angular range, but they do not reflect any forces occurring in the constraint. This method was used in research on heavy vehicle dynamics [

28,

45,

46,

47]. The simulations and experiment results for acceleration when driving over small obstacles were compared [

48]. The simulation data is compatible with experiments at low speeds. At higher speeds, the omission of the damping constraint properties resulted in too high simulated vertical vehicle body acceleration. This indicates the need to take into account the elastic-damping properties of the track belt constraints.

These properties may be described by general force constraints between track links. In the available research models, bushing connections (which define a six-degree-of-freedom force relationship between two parts) are used for this purpose [

49]. The forces in three axes and torques in three planes are often characterized by damping and stiffness coefficients (factors). Typically, similar proportions of stiffness and damping coefficients are maintained. The coefficients used to have fixed, constant values, but they are not always published [

27,

50].

Force connections were used, among others, in simulations of a light agricultural tractor [

49]. Due to track discretization, the individual ground reaction force for each link and the sinkage were calculated. The values of the parameters of damping and stiffness between the track elements were selected by comparing the simulation-obtained track belt shape to the real track belt set freely on the ground. The force connection was also successfully used in simulations of rubber-tracked running gears of light mobile robots when overcoming terrain unevenness [

27].

Stiffness and damping parameters between the track segments were usually selected on the basis of trial and error during simulations and observation of the static deflection of the track belt. However, the elastic-damping properties also vary with the deformation radius and the scrolling speed of the tracks [

23]. Statically determined parameters may therefore lead to significant errors during the track belt performance simulation. Reliable studies of tracked running gear dynamics require the development of a track belt model using experimentally determined stiffness and damping properties of track belts in dynamic tests.

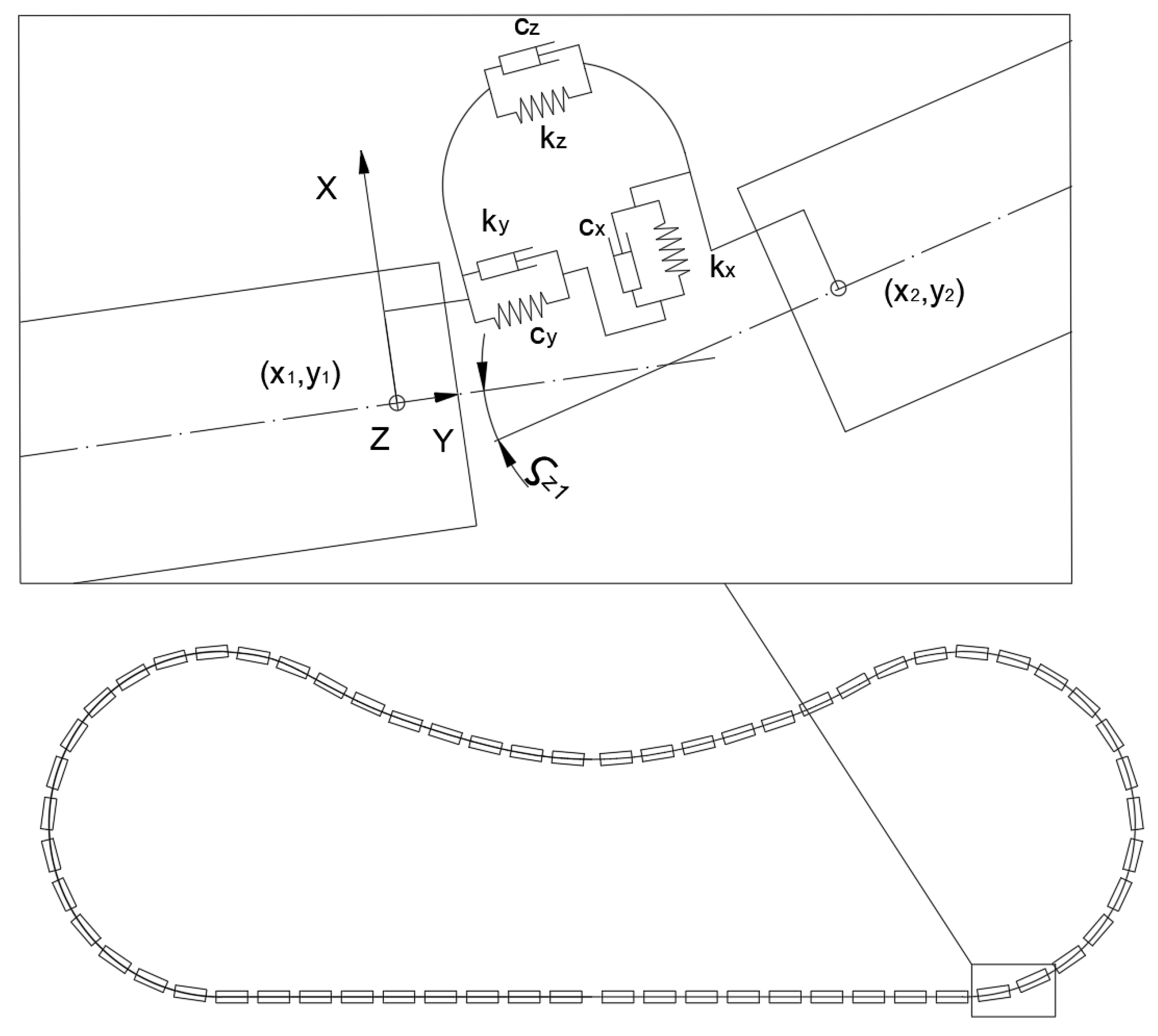

3. Track Belt Model

The elastomer track belt simulation model was made in the ADAMS MBD simulation program [

51]. The track belt was considered a flat system composed of link-type elements. Furthermore, links were joined by general force vector constraints, enabling rotation in the transverse axis Z (

Figure 1). The forces in the connection were characterized by the longitudinal, transverse, and angular stiffness and damping values (

Figure 1). Forces

and torque

occurring in the constraints were determined according to the equations:

where

is the rotation angle of the link axes,

are displacements of the connected elements,

are longitudinal and transverse stiffness,

is the angular stiffness,

are the damping values on the

X and

Y directions, and

is rotational damping in the transverse

Z axis.

The values of the stiffness and damping coefficients depend on the length and number of links representing the track belt; therefore, three track model variants were developed:

Variant where links and grouser quantities are equal (38-element variant—E38);

Variant with 1.5 times increased link quantity (56-element variant—E56);

Variant with twice the link quantity (76 element variant—E76).

Based on the rubber tracks modeling publication analysis, the coefficients of longitudinal and transverse stiffness and damping were determined as = 100,000 N/mm and = 1000 N/mm/s. High values of these coefficients significantly limited the possibility of longitudinal displacements of the track links. Therefore, the coefficients of angular stiffness and damping mainly affected the track’s susceptibility and its deformation ability. In order to determine the exact values of these parameters, experimental tests were carried out.

5. Model Validation

In order to determine the parameters of angular stiffness

and angular damping

, computer simulations were carried out. The track belt was formed into a circle and lowered onto a flat surface. After the track belt was formed by its own weight, the static test parameters were determined. Furthermore, the tracks were loaded with 1.3 kg of weight, and the oscillation parameters were determined. Comparing simulation parameters from static and dynamic tests with the experimental results, stiffness and damping in track belt constraints were set up (

Figure 6).

In order to match the simulation results with the experimental tests as precisely as possible, three methods of angular stiffness definition in the constraints (

Figure 6a) were compared:

Method I: constant stiffness value

regardless of the angle

(

Figure 6b);

Method II: bivalent stiffness—two different values

,

for bending track belt inwards and outwards (

Figure 6c);

Method III: variable stiffness value in the whole range of angles

. In this method, instead of the stiffness coefficient

, the torque—rotation angle characteristic is used in constraints as a nonlinear function

(

Figure 6d).

The constraint modeling methods were compared with each other on the basis of their relative errors. In addition, it was established whether the modeling method would affect the simulation-determined track belt bending resistance. For each method, the drive torque needed to scroll the track at a constant speed between a drive wheel and an idler without contact with the ground was determined.

5.1. Track Modeling Using Constant Stiffness Constraints

The angular stiffness coefficients

for three track variants (E38, E56, and E76) were selected by adjusting the achieved value of the height Hs with the static test results. With an increase in the stiffness coefficient, the values of the heights Hs and Hd also increased. The damping coefficient

was adjusted on the basis of the logarithmic decrement Λ so that its simulation-derived value was within the 10% accuracy range with the dynamic test experimental results. By changing the damping values, it was possible to adjust the oscillation amplitudes. A comparison of the oscillation plots obtained in the dynamic tests and simulations is shown in

Figure 7. The values of the stiffness and damping parameters for three variants of the track model and the obtained simulation results are presented in

Table 2.

Simulations indicated that regardless of the number of segments used for the track belt model, the obtained oscillation parameters remained similar. The use of constant stiffness resulted in an oscillation time period twice as long as the experimental one. In addition, the height Hd obtained in the simulations turned out to be almost two times lower than the experimental measurements. These differences may indicate that the constant value of the stiffness coefficient is insufficient to describe the susceptibility of the rubber belt.

During the simulations, the range of angles

between the modeled track links was also determined. Connections with the largest amplitudes of rotation angles are marked in

Figure 4 with the letters A and C. The angle

values obtained under these constraints are shown in

Table 3. As the number of links increases, the range of rotation angles decreases.

5.2. Track Modeling Using Bivalent Stiffness Constraints

Constraints with two stiffness coefficient values were applied in the rubber track model:

for positive rotation angles

and

for negative ones. Increasing the stiffness

in the positive range caused a significant oscillation period reduction. By limiting the possibility of track belt deflection, its upper part (point A) oscillated faster. In order to obtain oscillation period results similar to those from the experiment, the coefficient

needed to be increased almost 15 times (in relation to the value of the stiffness constant). This change in stiffness also caused an increase in the height of Hd and significantly reduced the oscillation amplitudes. As a result, it was necessary to modify the damping coefficient

, so that the logarithmic decrement values were consistent with the experimental test results. The

parameter remained at the same value as in the constant stiffness model. This parameter was responsible for the deflection of the side parts of the track (point C), so its stiffness was determined properly to obtain the height Hs. The determined values of stiffness and damping, as well as the parameters of the simulation tests, are presented in

Table 4. A comparison of the oscillation plots obtained in the dynamic tests and bivalent stiffness constraint simulations is shown in

Figure 8.

The use of a bivalent stiffness model resulted in a significant improvement in the consistency of the simulations and experiments, especially in terms of the time period.

Increased stiffness

caused a decrease in the point A (

Figure 4) rotation angle range (

Table 5). Such a powerful stiffening of the track belt was an adverse phenomenon. Visualizations did not agree with the experimental track’s dynamic deflection in terms of its overall shape. The simulation-obtained height Hd exceeded the height from the dynamic test. Furthermore, to obtain logarithmic decrement results consistent with the experimental results, the damping coefficient needed to be lowered at least two times.

5.3. Track Modeling Using Variable Stiffness Constraints

In the variable stiffness model, the torque occurring in each constraint was applied depending on the rotation angle value. The constraint torque-links rotation angle characteristic plot was assumed after many simulation attempts. They were able to shape the results of the simulation tests by changing the torque values in the different angle ranges. The determined function, divided into modified ranges, is presented in

Figure 9.

The negative part of the function plot was divided into three ranges: Z1, Z2, and Z3 (

Figure 9). The constraint torque in the Z1 range determined the maximum rotation angle that occurred in the simulation. Shaping the function plot in this range allowed to set the height Hd. In order to achieve the expected Hs value, it was necessary to modify the Z2 angle range (

Figure 9). By reducing the curve inclination, the difference between Hd and Hs values increased. At the same time, this procedure reduced the oscillation time period. In order to balance the phenomenon for the Z3 small angles, the torque function was shaped more inclined. Increased stiffness in the Z3 range allowed for the proper time period to occur and also maintained the correct overall geometric shape of the deflected track. The torque values in the positive angle range (

Figure 10) were determined to be more inclined than in the range of Z2 and Z3, but the difference between the positive and negative angle ranges of function inclination was not as high as in the bivalent stiffness simulation method (II).

Using these steps, stiffness characteristics and damping values for three variants of the track model were assumed. They are presented in

Figure 10. The oscillation plots for all three variants of simulations are presented in

Figure 11. Simulation static and dynamic test parameters and assumed damping coefficients are presented in

Table 6, and the obtained rotation angle ranges are described in

Table 7.

Using the variable stiffness model, the simulation results were compatible with the experiments. The maximum difference between the values obtained in simulations and the mean value of the experiment results does not exceed 10% of the experimental value in any of the parameters.

7. Conclusions

The method of testing the rubber track susceptibility proposed in the article allowed the determination of stiffness and damping parameters for three methods of link connection modeling. Comparing the relative errors of simulation results, modeling methods were assessed. The more developed the stiffness description, the more accurate the results were. In the future, it is also planned to extend the model with a non-linear damping description. It was also found that by increasing the link number even twice, no significant impact on the test result accuracy was achieved. A different number of model elements, however, determined higher stiffness and damping coefficients.

A significant impact of the modeling method on the drive torque spent on rubber belt bending was also noted. However, further research is needed to verify the belt bending resistance torque and evaluate the simulation models in terms of their actual values. Future experimental research will therefore be concerned with examining the energy consumption of running gear equipped with rubber tracks. Based on the results, it will be possible to extend the track model to account for the more complex damping characteristics of the track link constraints. The developed rubber track model will be used in simulations of lightweight tracked mobile robots in order to predict their energy consumption and ability to overcome obstacles.