1. Introduction

Throughout its history, Turkey has been impacted by numerous damaging earthquakes because it is in a seismically active area. In the country, earthquakes have caused greater damage and fewer fatalities than other similar earthquakes elsewhere in the world. Further, each earthquake over the past 20 years has left behind a different kind of destruction. However, following the Erzincan earthquake in 1939, the lessons that can be learned from the earthquakes that have struck various parts of Turkey over the past 15 years are remarkably similar. It is clear from an analysis of the structural damage resulting from these earthquakes that the main contributing factors were mostly poor material and workmanship quality, inadequate detailing, and architectural errors [

1].

The most recent major earthquakes in Turkey were the 1999 Marmara and 1999 Düzce earthquakes on the North Anatolian Fault, and the 2003 Bingöl and 2011 Elazığ earthquakes on the East Anatolian Fault [

2,

3]. Research after these recent earthquakes has consistently shown that large losses are experienced due to similar problems. Earthquakes are one of the most common natural disasters experienced in Turkey. In the country, earthquakes have caused significant damage to various structures, with such structures often collapsing because of this damage. The following are some significant earthquakes that the country has experienced: the 1939 and 1992 Erzincan earthquakes, which had magnitudes of 7.9 and 6.8, respectively; the 1999 Kocaeli earthquake, magnitude 7.8; the 1999 Düzce earthquake, magnitude 7.5; the 2011 Van earthquake, magnitude 7.2; the 2020 Elazığ earthquake, magnitude 6.8; and, finally, the 30 October 2020 Aegean earthquake, magnitude 6.6. In the Aegean earthquake, unfortunately, thousands of people lost their lives, and many buildings collapsed in Turkey. The damage caused by this earthquake has been examined by various researchers, and it has been found that the necessary care was not taken in the design, construction, and usage stages of the damaged and/or collapsed structures [

4,

5]. Additionally, a study investigated the damage caused to reinforced concrete structures, masonry structures, and mosques in the earthquake region after the 2011 Van earthquake, as well as the factors causing this damage, with the cause of such damage being attributed to production errors [

6]. Further, after the 2020 Sivrice (Elazig) earthquake, researchers conducted a damage analysis, finding that no lessons had been learned from the earthquake. The researchers suggested that intact and slightly damaged structures should be improved to withstand possible future earthquakes [

7]. After the Aegean earthquake, researchers investigated the effects of the earthquake in Izmir (Turkey). To this end, they studied the influence of the seismological features of the region and the features of the recorded strong seismic ground motions. A total of 17 buildings were surveyed (7 partially destroyed and 10 collapsed buildings). Further, they investigated the kinds of structural damage and common non-structural damage that cause building malfunctions. Finally, a detailed site investigation of one structure stated that the structure was not designed according to established standards [

7].

Damage caused by low-strength concrete is often encountered during examinations conducted in earthquake zones. In construction projects, it is not always possible to achieve the concrete strength that has been stipulated. Turkey’s use of ready-mixed concrete in construction since the beginning of the 1990s has, at least, eliminated the earthquake damage caused by low-strength concrete. Globally, earthquakes still cause fatalities, along with structural and financial damage, despite the research that has been carried out on the subject by researchers across the world. During past earthquakes, Turkey was commonly characterized by buildings without concrete and reinforcement. Previous Turkish Earthquake Codes (TECs) defined the minimum concrete class to be used in buildings, such as 25 MPa in the 2018 TEC and 20 MPa in the 1998 and 2007 TECs. Further, the Turkish Ready Mixed Concrete Association prepared a report that provided observations about an earthquake area. The report found that the concrete strengths of the buildings in this area ranged from 6 to 12 MPa. Additionally, many earthquake investigations carried out by researchers have provided general observations about earthquake damage. In investigations carried out in the Elazığ and Malatya provinces, for instance, much of the building damage was attributed to a poor concrete mixture and concrete placement without a vibrator. Further, on 1 May 2003 in Bingöl and on 8 March 2010, after the Van earthquake, researchers reported similar problems. When other recent earthquake areas were examined, it was emphasized that TS 500 standards were not generally applied [

8]. Further, regarding another earthquake, it was observed that almost all buildings that were destroyed and severely damaged had concrete that did not meet the necessary standards and regulations. In particular, the concrete production for these buildings was found to have not met these standards. On construction sites, it was found that materials were produced with a low cement content using traditional methods. The researchers emphasized that such structures should have instead been built with materials that adhered to the defined requirements of various codes and qualified workmanship under strict supervision. They further suggested that, as the quality of construction materials is a fundamental factor contributing to earthquake damage, it needs to be scrutinized in more detail [

9,

10].

Comprehensive examinations of traditional reinforced concrete buildings have revealed that, most of the time, the concrete strength values predicted for construction projects cannot be achieved, and values around 50% of these predictions can be attained for some buildings. The impact of using low-quality concrete can be observed in a building’s structural system elements. In addition to such buildings not being able to achieve the bearing capacity aimed for in calculations, this causes a decrease in the rigidity of a building’s structure, the easy deterioration of its concrete in earthquakes, and brittle fractures in its concrete due to its low shear and bond strengths. In an examination carried out in the provinces affected by the earthquake in the Marmara region, it was found that quality control tests, such as tensile and bending tests, were not often performed for the reinforced concrete steels used in construction. As a consequence of this, the insufficient mechanical properties of the reinforced concrete steel produced from scrap steel in these regions adversely affected the behavior of the carrier system elements of buildings.

In the earthquakes featured in this study, the main issues were not only structural defects, design errors, and a lack of engineering services but also the earthquake accelerations that took place in Kahramanmaraş and the resulting displacement demands, which were well above the level that the structures in the region were able to respond to. However, most of these structures would have been able to withstand the earthquake if the established rules and regulations were applied, even at a minimum level. This point reveals the importance of earthquake-resistant building design. Because of this, some researchers have designed reinforced concrete structures resistant to earthquakes [

11,

12,

13,

14,

15,

16,

17,

18].

Further, the building stock in Turkey is currently being examined. It has been determined that the country’s buildings are generally not strong enough, and, therefore, possible future earthquakes pose great risks to them; additionally, many buildings have been found to be damaged in their current form. For this reason, it is necessary to strengthen those existing structures with insufficient strength and repair those with damaged structural elements. In recent years, many researchers have studied the local repair of reinforced concrete structural elements. Studies on building elements with low-quality concrete and inadequate reinforcement have emphasized the importance of reinforcing such structures. Existing reinforced concrete structures usually suffer from low concrete quality and inadequate confinement reinforcement. As these deficiencies lead to insufficient compressive strength and deformability, they, in turn, can cause structural damage and collapse during earthquakes. Concrete members with poor concrete quality or inadequate confinement can be wrapped in fiber-reinforced polymer (FRP) composites to overcome these problems. In addition to enhancing the compressive strength and deformability of concrete members, these wraps can also provide passive lateral pressure. In a previous study, researchers proposed compressive strength and ultimate axial strain values for FRP-wrapped normal-strength concrete that led to results that were in good agreement with experimental [

19] RC columns with poor-quality concrete that were repaired and retrofitted in the study. Further, a real building that was severely damaged by the 2009 L’Aquila earthquake and subsequently demolished was analyzed, along with the results of three tests conducted on two RC columns. Additionally, an innovative application of fiber-reinforced cement composites (FRCCs) for the repair and retrofit of damaged columns was proposed and validated experimentally. Their results revealed that this material is effective in recovering and improving the axial capacity of damaged RC members [

20]. Numerous studies have been carried out on damaged columns, beams, and brick walls. The issue of retrofitting is a topic that has come to the fore after several recent earthquakes, with interest in this subject increasing day by day. For example, the Sivrice (Elazig) earthquake, which occurred on 24 January 2020, affected two identical reinforced concrete residential buildings with the same material properties, structural configuration, and geometry and that were standing next to each other. Before the earthquake, however, only one of these two buildings had been strengthened through the addition of a wall. A field survey was conducted after the earthquake to investigate the differences in the seismic damage experienced by both buildings. The infill wall of the reinforced building was found to have a significantly lower deformation demand than the non-reinforced building. While there was no/slight damage to the infill walls in the reinforced building, serious damage was documented in the non-reinforced building due to the partial collapse of its infill walls [

21]. Further, Sukrawa [

22] studied reinforcement with steel braces in low-rise and mid-rise structures [

22]. Additionally, Perera et al. [

23] investigated the use of steel braces in frames instead of infill walls [

23].

Following the Kahramanmaraş earthquakes, a damage assessment was conducted by the ministry in 11 provinces in Turkey. This assessment provided new insights into the causes of the damage inflicted by the earthquake. During the period leading up to the earthquake, it was discovered that various regulations were not adhered to. The primary causes of building damage were identified as poor concrete quality, inadequate workmanship, incorrect reinforcement detailing, and unsuitable construction techniques for earthquakes. Further, an analysis of the earthquake records found that there were errors in project planning and application. Additionally, construction had an impact on building damage since the established regulations had predicted a much stronger earthquake. Newly restored buildings and places of worship suffered significant damage. Surface faulting caused displacements of up to 6.5 m, with surface ruptures spanning almost 290 and 130 km being documented. The affected areas exhibited distinct morpho-tectonic formations, such as stream offsets, ridge offsets, and depression lakes, commonly found in strike–slip fault systems. Furthermore, transportation lines, such as highways, railways, garden fences, and field boundaries, were significantly disrupted by surface ruptures in numerous regions. Following the earthquake, extensive secondary events occurred, including rock falls, landslides, and ground liquefaction.

In this study, a comprehensive analysis was carried out of the damage experienced by the regions affected by the Kahramanmaraş earthquakes on 6 February 2023. Since the earthquakes were felt in a wide area, the damage levels across various regions were compared. Further, the Elbistan region, which was impacted by two earthquakes, was selected for a situation evaluation of its buildings. The damage levels of the buildings in this region were assessed in correlation with the causes of the damage. Selected moderately and heavily damaged buildings in the Elbistan region were inspected, and concrete samples were collected. Additionally, non-destructive tests were conducted on-site at these buildings, and the data gathered from both destructive and non-destructive tests were compared. The quality of the concrete used in buildings characterized by various types of damage, as well as these buildings’ construction periods, were compared and analyzed. After this detailed analysis of the structures in the earthquake zone was conducted, both the material and damage conditions in the area were analyzed in order to propose designs that can withstand possible future earthquakes. To this end, several strengthening studies were carried out. Further, the effect of the material quality of a given building on its damage condition was studied. Although problems with load-bearing materials were found, it is suggested that moderately damaged structures can benefit from designs that strengthen them and make them reliable in the face of earthquakes.

2. Kahramanmaraş Earthquakes

Turkey is located on the North Anatolian Fault (NAF), East Anatolian Fault (DAF), Northeast Anatolian Fault (NEAF), and West Anatolian Fault (WAF). The NAF and EAF have the shortest reversal times among all the most seismically active faults in the world. In recent years, these two faults have been responsible for many large and devastating earthquakes that have caused a significant loss of life and extensive structural damage [

24,

25,

26,

27].

Turkey, situated on the seismically active Anatolian Plate, has a history of major earthquakes. Over 20 major earthquakes have occurred in the country since 1900, making it the most earthquake-affected country in the world. Further, between 1900 and 2023, Turkey witnessed 269 earthquakes that resulted in the loss of life and economic damage. The most devastating earthquakes in terms of casualties and destruction were the 2023 Kahramanmaraş earthquakes, the 1939 Erzincan earthquake, and the 1999 Marmara earthquake, the epicenter of which was in Gölcük [

28].

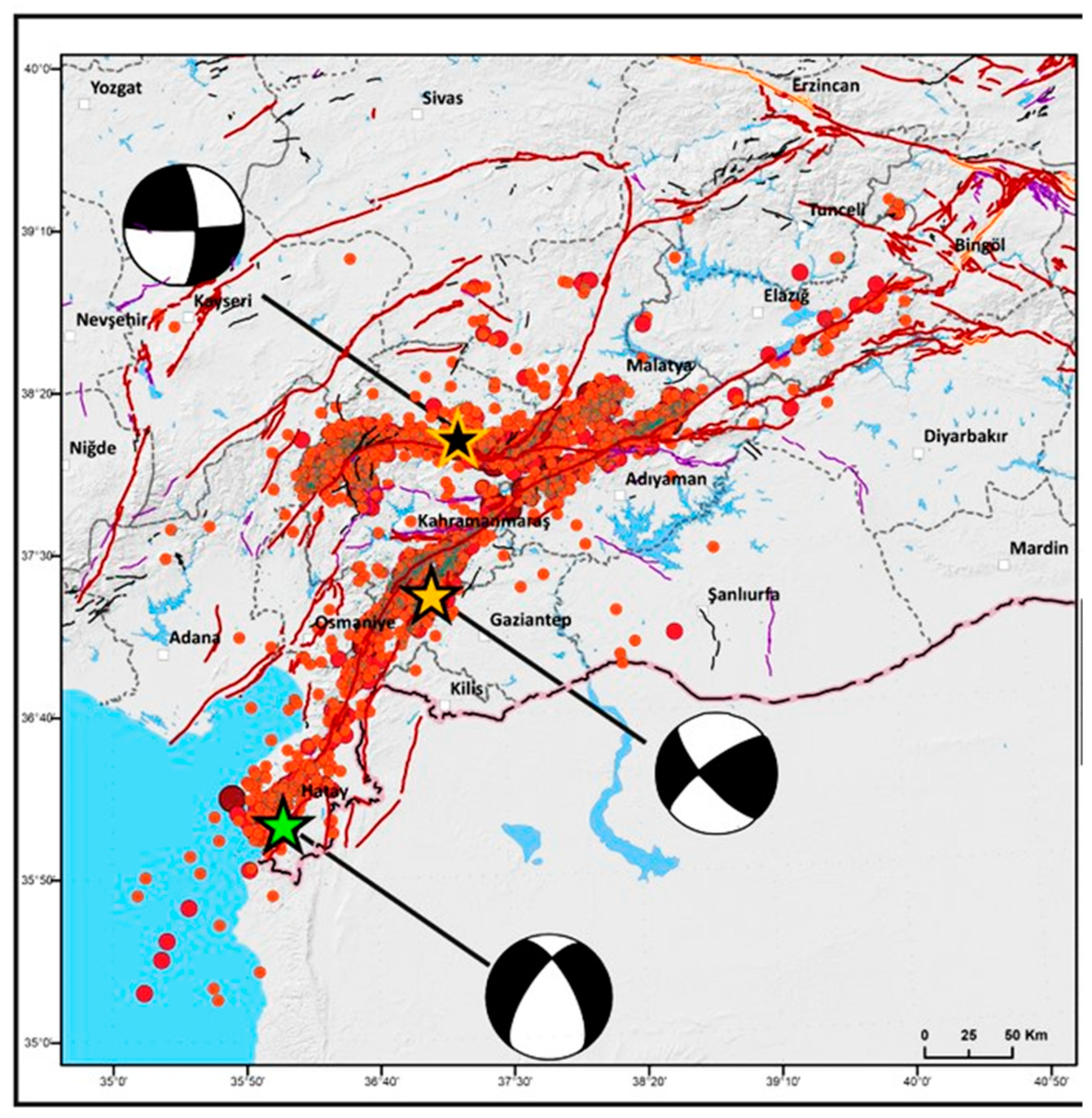

An earthquake with a magnitude of 7.8 Mw shook southern and central Turkey and northern and western Syria on 6 February 2023, 04:17 local time (01:17 UTC). The earthquake occurred in some parts of Hatay province, including Antakya, having a maximum intensity of XII (Extreme) according to the Mercalli scale. This earthquake was followed by an earthquake of magnitude Mw7.7 at 13:24. This second earthquake was centered 95 km (59 mi) north–northeast of the first. The size of the area affected by these earthquakes stands out as an exceptional feature of the incidents (Figure 15). The earthquakes left a huge number of landslides and destruction in their wake, especially since their ruptures and movements covered an area of 300 to 400 km [

29]. The 7.7-magnitude earthquake occurred at a depth of 8.6 km, while the 7.6-magnitude earthquake occurred at a depth of 7 km. From the main shock to 2 September 2023 at 16:00, nearly 1300 additional earthquakes were recorded [

30,

31]. The first earthquake occurred in Kahramanmaraş Pazarcık, but while it had a major impact in 11 provinces, it also caused destruction in Syria. Since Pazarcık is close to Gazinatep, an earthquake was shown as such in that region. Later, devastating aftershocks occurred there. The second earthquake occurred in KAhramanmaraş-Elbistan. Earthquake tops were identified in yellow. The earthquake in Syria is indicated in green (

Figure 1).

In the analysis of the earthquakes, it was found that there were four to five bars in the area between the intersection of the East Anatolian Fault (EMF) and the Bitlis–Zagros Thrust Belt, as well as the Malatya Plain. Additionally, there were four to five bars on the Çelikhan–Erkenek segment of the EAF just southwest of the intersection. The tension, which initially started at five bars in Göksun (Kahramanmaraş), gradually decreased to one bar towards the west. Furthermore, it was observed that there was a voltage buildup ranging from one to four bars in Iskenderun. The impact of the earthquakes was felt all the way to the coasts of the Black Sea in Egypt and Turkey. Shallow faulting in a strike–slip manner caused the seismic activity. However, among earthquakes with such a “strike–slip” nature, these were exceptionally large and severe cases. Unfortunately, Turkey experienced these two major earthquakes within a 24 h period, and both of these were of significant magnitude, intensity, and type and occurred in densely populated regions. This combination of factors means that the earthquakes may have been among the 10 most devastating earthquakes in the world since 1900, especially when considering the destruction and potential damage that they caused in Syria.

3. Current Situation Post-Kahramanmaraş Earthquakes

On 6 February 2023, two major earthquakes occurred in Kahramanmaraş. The first earthquake, centered in Pazarcık, Kahramanmaraş, had a magnitude of Mw 7.7, and it was recorded at 04:17 (01:17 UTC) local time. The second earthquake, with a magnitude of Mw 7.5, occurred in Elbistan, Kahramanmaraş, on the same day at 13:24 (11:24 UTC) local time. In addition, an aftershock close to the first earthquake with a magnitude of Mw 6.7 occurred in Nurdağı, Gaziantep, at 04:28 (01:28 UTC). Aftershocks continued in the affected region for an extended period. The focal depths of the first and second earthquakes were 8.6 km and 7 km, respectively. Aftershocks with a magnitude as high as 6.5 occurred in both affected districts within 24 h of the initial earthquakes. Another earthquake, measuring Mw 6.4, took place in Yayladağı, Hatay, on 20 February 2023 at 20:04 local time. These earthquakes, unprecedented in recent history with respect to their size and impact, caused extensive destruction in 11 Turkish provinces (

Figure 2) [

29,

32].

In response to this incident, which has been termed the “disaster of the century”, the Ministry of Environment, Urbanization and Climate Change carried out damage assessment studies in the regions in Kahramanmaraş affected by the earthquakes, employing its own teams and university professors.

By 6 March 2023, the damage assessment of 1,712,182 buildings in the 11 affected provinces was completed. According to the findings, it was determined that 35,355 buildings were destroyed, 17,491 buildings needed urgent demolition, 179,786 buildings were severely damaged, 40,228 buildings were moderately damaged, and 431,421 buildings were slightly damaged. Not only residences but also historical and cultural structures, schools, administrative buildings, hospitals, and hotels were destroyed or severely damaged. The earthquakes resulted in the loss of over 48,000 lives, damage to over 500,000 buildings and communication and energy structures, and significant financial losses (

Figure 3).

Almost 280,000 buildings were destroyed or severely damaged, and the 11 affected provinces experienced substantial financial losses [

33]. The general population in these regions generally lived in highly sensitive structures that were seismically sensitive, but there were also some resilient structures. With each earthquake and the resulting aftershocks, the structures in these regions continued to be damaged. The damaged buildings were mainly masonry and poor-quality concrete structures without ductility. According to the 2021 Building and Housing Characteristics Survey, the percentage of households living in buildings constructed in 1980 and earlier was 10% in the affected regions, while it was 12.6% in Turkey as a whole. However, in Adana, Hatay, and Kilis, this percentage was higher than the national average. In contrast, the proportion of households living in buildings built between 1981 and 2000 was 30.9% in Turkey as a whole and 27.6% in the 11 provinces. In Adana and Hatay, the rate of households living in buildings constructed during this period was higher than that for the overall population of Turkey. In contrast, the rate of households living in buildings constructed since 2001 was 47.4% in Turkey as a whole, while in the earthquake zone, this was 51.1%. In Adana, Hatay, and Kilis, however, this percentage was lower than the national average. This indicates that the buildings in Adana, Hatay, and Kilis were relatively old [

33].

Elbistan Region, Kahramanmaraş

The Elbistan region, which was the center of the second earthquake, was one of the regions most damaged by the earthquake. Elbistan is a district of Kahramanmaraş province. The population of all its districts, including the towns and villages, is 142 778 [

34]. Its area is 2547 km² (983 mi²). It is located at 38°12′1″ north, 37°11′35″ east, latitude: 38.2004, and longitude: 37.1931 (

Figure 4).

Elbistan, one of the biggest districts in Turkey, is heavily populated and characterized by significant industrialization and agricultural land. Since ancient times, Elbistan has experienced earthquakes, with the region needing to be re-established several times because of them. As already noted, the 2023 Elbistan earthquake saw a great loss of life in the region. Many earthquake investigations in the literature have provided general observations about the damage that this earthquake inflicted on the region. It has been suggested that the quality of construction materials was a fundamental factor contributing to damage in the region, and this therefore needs to be scrutinized in more detail.

Post-earthquake, the Ministry of Environment, Urbanization and Climate Change assigned technical teams consisting of municipal officials and university professors to the earthquake-affected regions in order to carry out damage assessment studies. In these examinations, buildings were categorized as ruined, heavily damaged, moderately damaged, slightly damaged, and undamaged.

Heavily Damaged Buildings: These were buildings in which there were wide and widespread shear breaks/separations in the load-bearing elements of the building due to the earthquake. “Heavily” damaged structures were defined as buildings with an irreparable loss of bearing capacity and irreversible (with respect to strength and economy) damage.

Moderately Damaged Buildings: These were buildings with cracks in their walls and thin cracks in their load-bearing elements due to the earthquake. The damage and defects in such buildings that occurred before the earthquake were not evaluated. In a “moderately” damaged building, the structure should not be used until its decrease in bearing capacity is addressed (the structure is repaired) or it is strengthened. Items from such buildings can be removed.

Less Damaged Buildings: These were buildings with thin cracks in their paint, plaster, and walls, as well as plaster falling from their walls, due to the earthquake. The damage and defects in such buildings that occurred before the earthquake were not evaluated. There is no harm in using these buildings.

Undamaged Buildings: These were buildings that had not suffered any damage due to the earthquake. The damage and defects in such buildings that occurred before the earthquake were not considered. There is no harm in using these buildings [

36].

After the carrier system of each building was determined, the information that characterized the building was processed into the system, and the observations made with photographs were documented. The processing was mainly observational. Adhering to the data gathered by the ministry, the current state of the buildings in the study region can be determined. In this study, we carried out damage mapping based on these data. The most damaged areas in Elbistan were determined according to their building damage status (

Table 1). Further, buildings from different regions were selected and re-examined. The damage situation is indicated in a circle to show more detail.

According to the data from the Ministry of Environment and Urban Planning, 26,747 buildings were examined, and 1045 buildings were found to have been destroyed. A total of 2640 heavily damaged, 463 moderately damaged, 5733 slightly damaged, 14,261 undamaged, and 2675 out-of-assessment buildings were documented. Buildings in the central neighborhood were found to be more heavily damaged than those in other areas. In the first earthquake, four buildings collapsed. Although these buildings were damaged, they were not destroyed. The real destruction occurred after the second earthquake. In addition to the various aftershocks that occurred along the fault line in the original earthquake, the frequency and intensity of the aftershocks caused by the 7.5-magnitude earthquake tended to decrease over time (

Figure 5).

The general population in this region lived in structures that were generally highly seismically sensitive, but some lived in resilient structures. The damaged buildings were mainly masonry and poor-quality concrete structures without ductility [

37]. In Turkey, studying local building codes is essential to establish planning, design, and construction standards. Likewise, it is essential to regulate the extent to which such regulations take seismic effects into account. If local building codes do not reflect the seismicity of a given area, the building codes of other countries that share relevant geological conditions and seismic hazard risks must be enforced and followed. In many countries, there are seismic hazards that are not considered in building codes, either because they are rare events or because the country’s seismic history is incomplete. However, it should be noted that infrequent events that can lead to major fatalities may occur during the lifetime of a building [

38].

Returning to the study region, as there had been no major earthquakes or any warnings of such incidents in Elbistan for two hundred years, the region’s level of preparedness for the 2023 earthquake was lower than that of other regions. There are two types of strategies for designing earthquake-resistant structures: traditional and advanced strategies. “The first are those that are mostly built”. These types of buildings are constructed to have the ability to distribute energy stably; in other words, the energy delivered to the ground during an earthquake survives, while the building can remove some of this energy. Such structures are designed to have the capacity to “plastically deform” in a ductile manner without breaking in areas of high seismicity. This type of deformation means that these buildings can dissipate the energy that they are exposed to during an earthquake. In turn, this means that the building can move laterally and continue to carry the vertical load to which it has been subjected. Further, with the right plasticization and correct projection, these buildings can undergo lateral deformation and experience significant damage, but not structural collapse.

4. Analysis of Heavily and Moderately Damaged Structure Materials in the Elbistan Region

In this study, the heavily and moderately damaged structures in Elbistan surveyed by the Ministry of Environment and Urbanization were analyzed. After the Kocaeli 1999 earthquake, changes in regulations and a greater inspection of buildings were instituted in the year 2000, with these factors therefore needing to be accounted for in the grouping and selection of such buildings.

In this study, the structures considered for analysis were all located close to one another. Further, buildings that allowed work within them were considered. Finally, 20 buildings were selected in the region. These buildings were distinguished as being either built pre-2000 or post-2000. Later, they were divided into moderately and heavily damaged groups. They were therefore divided into four different groups. This study aimed to compare the material quality of the buildings according to their periods of construction and types of damage. To this end, in situ non-destructive tests were carried out in the buildings. Further, experimental research was conducted afterwards in the laboratory environment with samples taken from the buildings. When classifying the structures, the study codes used were the following: heavily damaged structure (H), moderately damaged structure (M), pre-2000 (O), and post-2000 (N). Some samples’ cores had fragmented (

Figure 6b). The samples that were obtained intact were capped and pressure tested (

Figure 6c,d).

In building design in Turkey, the acceptable concrete strength specified by TS 500, /1969, B160, and TS 500/1984 [

39] is 14 MPa (provided by Turkish Standards). A correction factor of 0.85 for calculating the equivalent characteristic compressive strength is given by TS EN 13791/2010 [

40]. In this study, although it did not seem technically appropriate to make a statistical evaluation of the samples (due to the insufficient amount of data), when considering the aggregate maximums, it can be stated with great confidence that the concrete represented by the samples was not produced according to relevant standards. These standards state that aggregate sizes and grades, standard deviations (SDs), and coefficient of variation values should be around 0.10 to 0.25, with coefficients of variability exceeding this range indicating low and very low levels of quality control standards [

41,

42]. However, these standards have since been changed. New rules for concrete strength have been applied to all structures since 1975. The minimum concrete compressive strength of a structure was decreed to be C18 for first- and second-degree earthquake zones and C14 for other regions in TEC1975 [

43]. These values were increased to C20 MPa in TEC2007 [

44] and C25 MPa in TBEC2018 [

45]. Further, after the 1997 earthquakes [

46], the Turkish Ready Mixed Concrete Association stated in their evaluation meetings that the concrete class specified in the Regulation on Buildings to be Built in Disaster Areas and the Earthquake Map of Turkey would be insufficient for withstanding possible future earthquakes in terms of its strength and that the C 30 concrete class should therefore be used in buildings built in earthquake zones [

39].

In this study, the concrete quality of the buildings selected for analysis was evaluated. To this end, core samples were taken from the buildings (

Figure 3a). The effect of the core dimensions on the test results was important. According to TS 10465 [

47], coring was taken from the concrete, and its suitability was evaluated. Next, the compressive strength values of the cores were compared to those of the sample codes, as shown in

Figure 4. The concrete compressive strength values were around 4 MPa in the buildings with heavy and moderate damage that were built before 2000. For those built after 2000, their concrete strength values were around 14 MPa. Among the sampled buildings, the highest concrete strength was recorded for a building constructed in 2016. Although ready-mixed concrete was used in this newly built building, the concrete used was C20, and the building was heavily damaged. Its construction did not follow the concrete standard, and there were faults in its structural system. The average concrete strength of the pre-2000, heavily damaged structures was 2.6 MPa, while the average strength of the post-2000, heavily damaged structures was 13 MPa. The average strength of the pre-2000 structures with moderate damage was 4.4 MPa. Finally, the average strength of the post-2000 structures with moderate damage was around 15 MPa (

Figure 7).

The strength of the concrete used in the reinforced concrete structures was determined by obtaining concrete core samples from the columns and walls located on the outer surfaces of these buildings, as specified in the code TS EN 12504–1 (2019) [

48]. These concrete core samples were then tested in the laboratory environment according to the standards outlined in TS EN 12390–3 (2019) [

49] in order to determine the strength of the concrete. The results for the concrete core samples indicated that the concrete classes in these buildings ranged from C6 to C12. However, many of the samples had such poor concrete strength that they could not be evaluated under the relevant standards. Further investigations revealed that almost all the earthquake-damaged structures had been constructed using extremely low-quality concrete that was manually poured on the worksite using traditional methods. Various negative factors were identified in this concrete, including the use of aggregates with inadequate granulometry, tuvanan aggregate, and an insufficient cement dosage, as well as an uneven concrete mixture (

Figure 8). When examining the reinforced concrete columns of these buildings, it was observed that wooden waste materials and river aggregate with a diameter of 5–7 cm were present in the concrete. Aggregate size and segregation are shown in the figure circle. Additionally, it was discovered that the cement dosage used in the concrete was kept very low resulting in poor mixing and concrete fractures occurring at the cement–aggregate interface (

Figure 8).

4.1. Non-Destructive Experimental Tests

In order to conduct a thorough structural analysis of buildings and implement effective strengthening measures in them, it is necessary to obtain reliable information about their in situ compressive strength. This is particularly important when assessing the seismic capacity of existing buildings, which have often been designed to withstand only gravity loads or were constructed according to outdated seismic codes with low safety factors [

50]. Typically, this information is obtained by conducting compression tests on cores extracted from structural elements of the buildings under analysis [

51,

52].

The use of destructive coring testing is generally more accurate than non-destructive testing [

53,

54]. However, coring testing is expensive, invasive, time-consuming, and, in some cases, impossible to perform. To minimize the need for coring, non-destructive testing can be used in conjunction with coring testing to assess the strength of a structure, gather more information, and obtain a higher level of knowledge about the variability in the strength of the structure at a lower cost [

55,

56,

57]. Schmidt (SH) and Ultrasonic Pulse Velocity (UPV) tests are commonly used together in practice to provide a comprehensive evaluation of concrete strength [

58]. This paper aimed to introduce a new approach to predicting the concrete compressive strength of a given structure. This approach uses ultrasonic testing to non-destructively determine the dynamic and static moduli of the elasticity of concrete [

59]. Kouddane et al. (2023) also utilized a new multi-objective optimization method to evaluate the compressive strength and variability of concrete by combining several non-destructive techniques [

60].

In this study, only core samples were taken from the structures, and in situ non-destructive experiments were conducted. The UPV and Schmidt tests were carried out both in situ and in the laboratory environment on samples taken from the buildings (

Figure 9).

For the buildings produced post-2000, their UPV results were close to values that are considered good. Although the strength of their concrete was low, the age of the concrete and the use of ready-mixed concrete increased its quality. The lowest value obtained for these buildings was 3.57, while the highest was 4.9. Further, the UPV values of the moderately damaged structures were all close to one another. For the pre-2000 buildings, their concrete was of a low quality and porous, and its granulometry was not produced correctly. Although the pre-2000 buildings generally recorded a bad UPV value of 2, some structures recorded values close to or above 3, which were close to the average value. However, the Schmidt hammer strength values of the samples differed among the pre- and post-2000 buildings, as well as the UPV values. The granulometry of the aggregates used, segregation, and water–cement ratio all affects the strength of concrete. This study found that the concrete of the pre-2000 buildings performed poorly with regard to these factors. Values of around 14 were obtained for these pre-2000 buildings, while those for the post-2000 buildings varied between 25 and 40. Some of the values of the post-2000 buildings showed that their concrete was of a higher quality than that of the other buildings. In

Figure 10, the UPV and Schmidt test values are compared to each other.

4.2. Equipment Condition

Given the widespread use of lower-strength flat bars (i.e., those with 220 MPa instead of 420 MPa yield strength) as transverse reinforcement in the structures analyzed, the brittle failure modes of their RC vertical load-bearing members and joints further reduced their spherical ductility capacity. As a result, their ductility capacity implied by the default response modulation factor, typically taken as 4–8, may not have been available (

Figure 11a,b and in circle detailed). Further, this study found that mild steel reinforcement was used in most of the structures, while hooks were used for pressure reinforcement. However, the starter bars of the structures were not long enough at the lower ends of their columns. Reinforcement corrosion was also observed (

Figure 11c and in circle detailed).

Although lap joint flaws were recommended in the pre-2018 regulation, longitudinal reinforcement in the middle region of building columns is still allowed to be provided in their end regions. Overlapping longitudinal reinforcing bars are commonly used in construction in Turkey. This leads to earthquake forces causing extreme bending moments in structures that use such bars. Longitudinal reinforcements are exposed to high impacts due to tensile and compressive forces. For this reason, tensile continuity must be provided at the reinforcement ends of columns.

During earthquakes, force transmission is not fully realized. After the Kahramanmaraş earthquake, heavy damage was observed in many buildings in the impact zone. The inadequacy of these buildings’ reinforcement lap joints resulted in the buildings having a lack of uniform longitudinal bars and widely spaced transverse reinforcements due to there being a lack of sufficient expansion length. Overlap joints were also encountered in building lengths with insufficient stirrup spacing and development (

Figure 9). Further, transverse reinforcement details play a crucial role in the seismic performance of reinforced concrete buildings. Reinforced concrete members with an inadequate length and improper hook angles can lead to shear damage and instability in columns before they reach their bending capacity. The insufficient closure of stirrups in columns or a lack of confinement with 90° hooked reinforcement can cause explosions. Similar problems have been observed in buildings damaged by earthquakes in Turkey in recent years. However, the 1975 TEC, the 1997 TEC, and the 2007 TEC specify that side reinforcement spacing should not exceed 10 cm. For S420 and S220 stirrups with 135° hooks at both ends, their linear length should be at least 10 cm, leaving a minimum linear length of 8 cm. Nevertheless, most structures in Kahramanmaraş exhibited insufficient stirrup spacing and errors in their hook lengths and angles (

Figure 12).

6. Findings and Discussion

Through examining the damage status of buildings impacted by the Kahramanmaraş earthquakes, this study observed that similar damage occurred in previous earthquakes. The damage inflicted by the Kahramanmaraş earthquakes on post-2000 structures, in particular, was quite notable. When analyzing heavily and moderately damaged structures, the most apparent issues found were the subpar quality of the materials used and the incorrect design of their supports. In order to investigate the material quality of the analyzed buildings, both destructive and non-destructive experiments were conducted.

Through these methods, this study found a linear relationship between the compressive strength of the obtained concrete samples and the pressure test data (

Figure 17a–c).

The experimental data were compared with respect to the codes, damage conditions, and construction periods of the buildings analyzed. Unfortunately, no strength values were able to be obtained from the core samples taken from two pre-2000, heavily damaged structures, as the samples began to disintegrate while they were being obtained; their concrete had no adherence left. UPV and Schmidt values were obtained from a total of 20 buildings. For the pre-2000, heavily damaged structures, these values were in a similar range: their Schmidt values remained between 12 and 15, and their concrete strength remained around 4 MPa. For this first group of buildings, we can state that they were heavily damaged due to the material used for their construction; this material did not exhibit adequate strength properties. Conversely, the experimental results for the post-2000, heavily damaged buildings were very different. Here, it was determined that the damage that these structures experienced was not just caused by the quality of their construction material. Just like within the group of pre-2000, moderately damaged structures, the values obtained for the post-2000, moderately damaged structures were similar to one another. The strength of these post-2000, moderately damaged structures, however, was below the established standard. Their concrete strength values remained below 15 MPa, while their Schmidt values were around 30 to 35. These Schmidt and UPV results assisted us in determining the material quality of the studied buildings in a non-destructive way. The damage present made it difficult to obtain samples from the structures due to their large dimensions (

Figure 18).

In addition to the quality of the concrete, the reinforcements used in the analyzed reinforced concrete structures seemed to have been selected in accordance with the regulations for new buildings, but problems were observed in their fastening and frequency of placement.

The main reason for building collapse was found to be the wide spacing of stirrups, which caused shear fractures, as well as the buckling of longitudinal rebars and the poor containment of core concrete. The stirrups used in these cases were not effective due to the insufficient length of their embedded hooks. Additionally, the insufficient cross-sectional area of these buildings’ columns caused damage. Severe damage to or the collapse of buildings was also caused by inadequate longitudinal reinforcement (less than 1.0%), short lap joints, and incorrect end-hook angles in main bars. The use of low-quality concrete in the affected area further compromised the seismic performance of the reinforced concrete buildings. Existing damage was also observed in some buildings, which can be attributed to their poor quality and the fact that such structures were not affected by weak ground or earthquake amplification.

In this study, some of the problems documented were encountered during field observations. For instance, it was found that there were manufacturing problems in the strengthening of existing reinforced concrete buildings. In particular, it was observed that the shear walls used for strengthening these buildings were deboned from their connection anchors to the columns and beams of the buildings. This was caused by the fact that the columns were not jacketed at the column region of the strengthened shear walls. Further, although there is a subsection on strengthening in TBEC-2018, in general, the lack of comprehensive information with regard to strengthening applications causes some differences in building construction in practice. There is a need for a strengthening code with critical calculations and details affecting the behavior of reinforced buildings, such as CFRP applications and CFRP anchor, shear wall–column connection, and shear wall–foundation connection details.

Similar problems with regard to material quality and damage type have been found after other earthquakes in Turkey. For this reason, it is clear that many structures in the country have been produced in violation of the existing regulations. While damage to some structures in recent earthquakes has been classed as being at an acceptable level, damage to other structures has exceeded the established Life Safety (CG) limit. The damage that is at an acceptable level is fixed by simple repair and/or improvement processes. In these processes, there are two options: demolishing and rebuilding the CG border structures or reinforcing the desired performance of a given building. Cost structure determines which of these options is applied. In other words, through the concept of a cost–benefit analysis, the rough cost of the building in question is calculated depending on its maturity, and the obtained values are compared with the cost of the options.

From this, it can be seen that none of the three performance levels determined for reinforced concrete structures in TBEC-2018, namely, the (a) Limited Damage Level, (b) Controlled Damage Level, and (c) Anti-Collapse Level, can be met by most of these structures. Element reinforcement involves the strengthening of an element to which damage is detected through an evaluation of the existing structure. This involves the use of a material with strength properties much higher than those of the damaged element. One type of element reinforcement is jacketing, which is used for reinforced concrete column elements. In this process, the existing reinforced concrete column is surrounded by reinforcements and stirrups and is formed by the pouring of concrete. This causes an increase in the stiffness of the damaged element. Plastic strain limits increase under the effects of earthquakes. In addition, the axial bearing capacity of the element increases. According to TBDY 2018, the reinforced concrete wrapping thickness should be at least 100 mm. Such wrapping should also envelop a column throughout an entire floor.

Another strengthening method is system strengthening. After the performance of an existing structure is evaluated, new reinforced concrete carriers can be added under the existing carrier system of the structure. Reinforced concrete shears or reinforced concrete columns can then be added later so that the structure can withstand earthquake forces. Additional carrier elements increase the system rigidity of such structures. When this method is applied, the structure period will decrease as the system rigidity increases. If the structure then experiences further earthquake forces, the existing elements may need to be strengthened using the element reinforcement method.

For this purpose, some researchers have conducted studies on the repair and development of reinforced concrete structures, while others have carried out studies to determine the comprehensive performance of these processes, in turn demonstrating their development [

64,

65,

66,

67,

68,

69,

70,

71,

72].

In some cases, on-site and digital analyses can be performed, especially of damaged structures after an earthquake [

73]. In 2021, Liu [

74] suggested that the seismic performance of masonry walls can be greatly improved by their being wrapped in reinforced concrete or seismic tape; the use of such seismic tape in the reconstruction of typical houses in Nepal was found to effectively improve their seismic performance. In buildings, the areas around door and window openings are still the most vulnerable to damage. The reinforcements in these places should therefore be strengthened [

74]. The results of the present study suggest that the seismic performance of buildings located in active earthquake zones in Turkey is very low, as the moderate earthquake that was analyzed was found to have caused severe damage to the structures studied. To prevent possible future damage in rural areas, earthquake-resistant houses should be built in accordance with modern earthquake regulations and construction technology, and existing undamaged structures should be strengthened [

28]. Additionally, structures damaged by earthquakes should be examined in more detail in order to make them more sustainable and safer.