Study on the Characteristics of Effective Internal Friction Angles of Silty Clay from the Yellow River Delta and the Inverse Method of CPTu Testing

Abstract

:1. Introduction

2. Inverse Method of Effective Internal Friction Angle Based on the CPTu Test

3. Yellow River Delta Silty Clay Effective Internal Friction Angle Test

3.1. Basic Parameters of Silty Clay

3.2. One-Dimension Consolidation Test

3.3. Triaxial Shear Test

4. CPTu Calibration Test

4.1. Test Device

4.2. Test Plan

5. Test Results and Analysis

5.1. CPTu Test Results

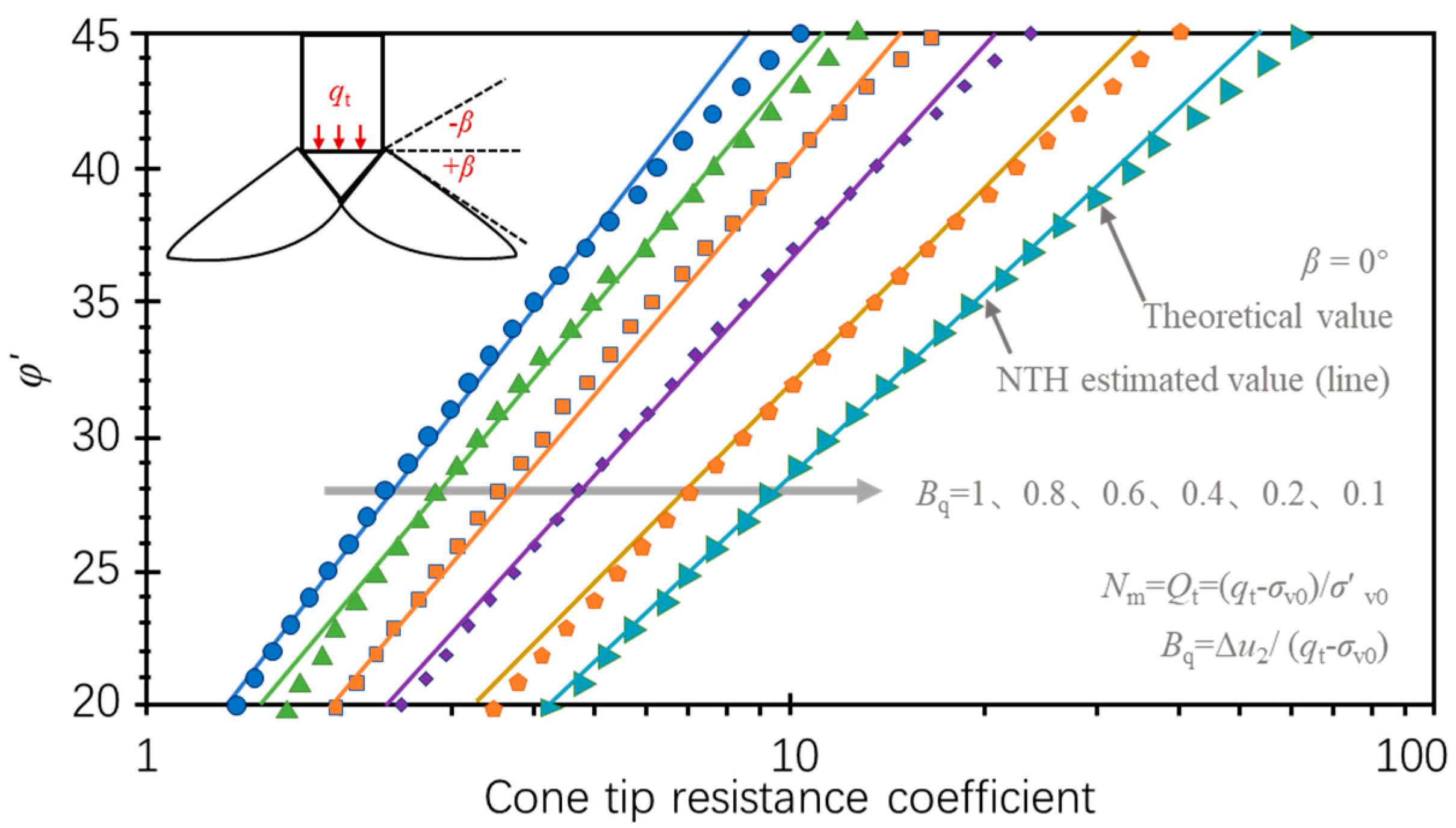

5.2. Inversion Results of NHT Method

5.3. Inversion of Undrained Shear Strength Based on CPTu

5.4. Limitations of NTH Method

6. Conclusions

- A series of indoor geological tests were conducted on samples of silty clay from the Yellow River Delta to determine their basic physical and mechanical properties.

- The NTH (Normalized Tangent Hyperbolic) method was applied using data obtained during the penetration phase of the indoor calibration chamber test. Analysis indicated that while the NTH method might yield slightly lower effective internal friction angle results for the silty clay, the overall consistency is good. It suggests the reliability of the NTH method for inferring an effective internal friction angle (φ′) for normally consolidated silty clay in the Yellow River Delta. Additionally, this approach avoids the complex and extensive field testing required to establish patterns and, inversely, model detailed parameters of a specific stratum.

- The coefficient Nkt for the silty clay in the Yellow River Delta region was successfully determined through inverse analysis. The results show excellent agreement with theoretical values, providing recommended values for Nkt. This information is essential for deriving the undrained shear strength during the inverse process and offers crucial empirical coefficients for in situ geological testing in this region.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Robertson, P.K. Interpretation of cone penetration tests—A unified approach. Can. Geotech. J. 2009, 46, 1337–1355. [Google Scholar] [CrossRef]

- Zhang, J.R.; Meng, Q.S.; Zhang, Y.; Feng, X.L.; Wei, G.L.; Su, X.T.; Liu, T. Effect of Penetration Rates on the Piezocone Penetration Test in the Yellow River Delta Silt. J. Ocean. Univ. China 2022, 21, 361–374. [Google Scholar] [CrossRef]

- Zhang, J.R.; Meng, Q.S.; Guo, L.; Zhang, Y.; Wei, G.L.; Liu, T. A Case Study on the Soil Classification of the Yellow River Delta Based on Piezocone Penetration Test. Acta Oceanol. Sin. 2022, 41, 119–128. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Liu, T.; Liu, H.Y.; Deng, S.G. Interpretation of pore pressure dissipation of CPTu in intermediate soil considering partial drainage effect. Ocean. Eng. 2022, 266, 112956. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, X.L.; Ding, C.H.; Liu, Y.N.; Liu, T. Study of Cone Penetration Rate Effects in the Yellow River Delta Silty Soils with Different Clay Contents and State Parameters. Ocean. Eng. 2022, 250, 110982. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, L.; Chen, X.G. Study on the Liquefaction properties of silt at Yellow River Delta. J. Ocean. Univ. China 2018, 17, 1382–1390. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, X.L.; Deng, S.G.; Ding, C.H.; Liu, T. Pore Pressure Response and Dissipation of Piezocone Test in Shallow Silty Soil of Yellow River Delta. J. Mar. Sci. Eng. 2022, 10, 225. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, L.; Kou, H.L.; Zhang, M.X. Model test of stratum failure and pore pressure variation induced by THF hydrate dissociation. Mar. Georesources Geotechnol. 2019, 37, 539–546. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, Y.; Meng, Q.S. Numerical Investigation and Design of Suction Caisson for On-bottom Pipelines under Combined V-H-M-T Loading in Normal Consolidated Clay. Ocean. Eng. 2023, 274, 113997. [Google Scholar] [CrossRef]

- Liu, T.; Yang, X.; Zhang, Y. A Review of Gassy Sediments: Mechanical Property, Disaster Simulation and In-Situ Test. Front. Earth Sci. 2022, 10, 0606219. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, X.; Su, X.; Guo, L.; Cui, Y.; Jia, C.; LING, X. CPT-Based evaluation of sediment characteristics and effective internal friction angle in the yellow river estuary. Mar. Georesources Geotechnol. 2022, 40, 1108–1118. [Google Scholar]

- Janbu, N.; Senneset, K. Effective stress interpretation of in situ static penetration tests. In Proceedings of the 1st European Symposium on Penetration Testing, ESOPT, Stockholm Sweden, 5–7 June 1974. [Google Scholar]

- Senneset, K.; Janbu, N. Shear strength parameters obtained from static cone penetration tests. In Strength Testing of Marine Sediments: Laboratory and In-Situ Measurements; American Society for Testing and Materials: Philadelphia, PA, USA, 1985; pp. 41–54. [Google Scholar]

- Senneset, K.; Sandven, R.; Janbu, N. Evaluation of soil parameters from piezocone tests. Transp. Res. Rec. 1989, 1235, 24–37. [Google Scholar]

- Sandven, R. Strength and Deformation Properties Obtained from Piezocone Tests. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 1990. [Google Scholar]

- Sandven, R.; Watn, A. Theme lecture: Interpretation of test results. Soil classification and parameter evaluation from piezocone tests. Results from Oslo airport. In Proceedings of the International Symposium on Cone Penetration Testing, Linköping, Sweden, 4–5 October 1995. [Google Scholar]

- Xu, Y.-S.; Wu, H.-N.; Shen, J.S.; Zhang, N. Risk and impacts on the environment of free-phase biogas in quaternary deposits along the Coastal Region of Shanghai. Ocean Eng. 2017, 137, 129–137. [Google Scholar] [CrossRef]

- Mayne, P.W. Evaluating effective stress parameters and undrained shear strengths of soft-firm clays from CPT and DMT. Aust. Geomech. J. 2016, 51, 27–55. [Google Scholar]

- Ching, J.Y.; Phoon, K.K.; Wu, S.H. Impact of statistical uncertainty on geotechnical reliability estimation. J. Eng. Mech. 2016, 142, 40160276. [Google Scholar] [CrossRef]

- Mayne, P.W. In-situ test calibrations for evaluating soil parameters. In Characterization & Engineering Properties of Natural Soils; Taylor & Francis: London, UK, 2007; Volume 3. [Google Scholar]

- Mayne, P.W. Synthesis 368: Cone Penetration Testing; National Cooperative Highway Research Program (NCHRP): Washington, DC, USA, 2007. [Google Scholar]

- Ouyang, Z.; Mayne, P.W. Effective friction angle of clays and silts from cone piezocone penetration tests. Can. Geotech. J. 2018, 55, 1230–1247. [Google Scholar] [CrossRef]

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: Philadelphia, PA, USA, 2017.

- Gallikova, Z.; ur Rehman, Z. Appraisal of the hypoplastic model for the numerical prediction of high-rise building settlement in Neogene clay based on real-scale monitoring data. J. Build. Eng. 2022, 50, 104152. [Google Scholar] [CrossRef]

- Campanella, R.G.R.P. Current status of the piezocone test. In Proceedings of the First International Symposium on Penetration Testing, ISOPT-1, Orlando, FL, USA, 20–24 March 1988. [Google Scholar]

- Lunne, T.; Powell, J.J.; Robertson, P.K. Cone Penetration Testing in Geotechnical Practice; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Campanella, R.G.; Robertson, P.K.; Gillespie, D. Factors Affecting the Pore Water Pressure and Its Measurement around a Penetrating Cone; University of British Columbia, Department of Civil Engineering: Vancouver, BC, Canada, 1986. [Google Scholar]

- Lu, Q.; Randolph, M.F.; Hu, Y.; Bugarski, I.C. A numerical study of cone penetration in clay. Géotechnique 2004, 54, 257–267. [Google Scholar] [CrossRef]

- Liu, T.; Wei, G.L.; Kou, H.L.; Guo, L. Pore pressure observation: Pressure response of probe penetration and tides. Acta Oceanol. Sin. 2019, 38, 107–113. [Google Scholar] [CrossRef]

- Mayne, P.W.; Kulhawy, F.H.; Kay, J.N. Observations on developing pore-water stresses during piezocone penetration in clays. Can. Geotech. J. 1990, 27, 418–428. [Google Scholar] [CrossRef]

- Ijaz, N.; Ye, W.; ur Rehman, Z.; Dai, F.; Ijaz, Z. Numerical study on stability of lignosulphonate-based stabilized surficial layer of unsaturated expansive soil slope considering hydro-mechanical effect. Transp. Geotech. 2022, 32, 100697. [Google Scholar] [CrossRef]

| Soil Layer | Moisture Content (%) | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index | Initial Void Ratio |

|---|---|---|---|---|---|

| Silty clay | 23.00 | 33.50 | 19.00 | 14.50 | 0.67 |

| κ | λ | eN | M |

|---|---|---|---|

| 0.0306 | 0.0518 | 0.89 | 1.08 |

| OCR | Undrained Shear Strength su (kPa) | Coefficient of Consolidation cv (cm2/s) | Penetration Rate (mm/s) | Drainage Condition |

|---|---|---|---|---|

| 1 | 19.66 | 0.0053 | 5 | Completely undrained |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, H.; Wang, H.; Yan, C.; Zhan, Y.; Qiang, K. Study on the Characteristics of Effective Internal Friction Angles of Silty Clay from the Yellow River Delta and the Inverse Method of CPTu Testing. Appl. Sci. 2023, 13, 10724. https://doi.org/10.3390/app131910724

Qi H, Wang H, Yan C, Zhan Y, Qiang K. Study on the Characteristics of Effective Internal Friction Angles of Silty Clay from the Yellow River Delta and the Inverse Method of CPTu Testing. Applied Sciences. 2023; 13(19):10724. https://doi.org/10.3390/app131910724

Chicago/Turabian StyleQi, Huazhong, Han Wang, Chao Yan, Yuanzhe Zhan, and Keliang Qiang. 2023. "Study on the Characteristics of Effective Internal Friction Angles of Silty Clay from the Yellow River Delta and the Inverse Method of CPTu Testing" Applied Sciences 13, no. 19: 10724. https://doi.org/10.3390/app131910724

APA StyleQi, H., Wang, H., Yan, C., Zhan, Y., & Qiang, K. (2023). Study on the Characteristics of Effective Internal Friction Angles of Silty Clay from the Yellow River Delta and the Inverse Method of CPTu Testing. Applied Sciences, 13(19), 10724. https://doi.org/10.3390/app131910724