Development of a Conveyor Cart with Magnetic Levitation Mechanism Based on Multi Control Strategies

Abstract

:1. Introduction

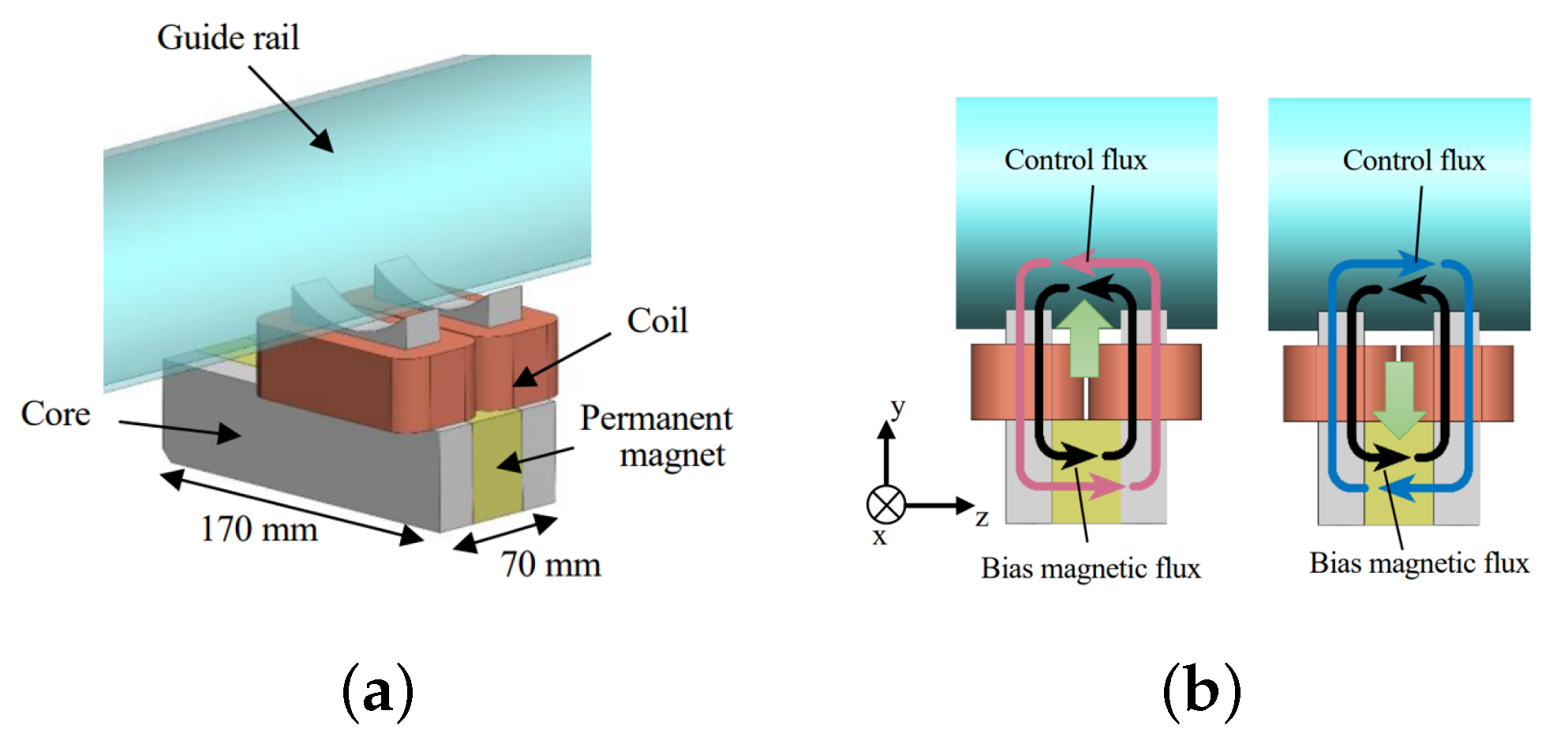

2. Mechanical Structure of Magnetic Levitation Conveyor

3. Magnetic Levitation Unit Support Force Analysis

Magnetic Levitation Transfer Equipment Position Measurement Circuit

4. Magnetic Levitation Unit Controller Strategies

4.1. Electrical Circuit of Four Magnetic Levitation Unit

4.2. Magnetic Levitation Math Model Analysis

- Magnetic flux leakage, edge effect and the reluctance between the rail and the electromagnet are ignored [10]

- The electromagnet unit is a homogeneous sphere, the magnetic force is concentrated on the center of it [10]

- There is a linear relationship between the output current and input voltage of the power amplifier, and there is no delay [10]

4.3. Experimental Test of Magnetic Levitation Unit with PID Controller

4.3.1. The Basic Principle of PID Controller

4.3.2. Performance of Magnetic Levitation Unit with PID Controller

4.4. Experiment Test of Magnetic Levitation Unit with State Feedback Controller

4.4.1. The Basic Principle of the State Feedback Controller

4.4.2. Performance of Magnetic Levitation Unit with State Feedback Controller

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

Abbreviations

| PM | Permanent Magnet |

| SFB | State Feedback Controller |

| Maglev | Magnetic Levitation |

References

- Qin, Y.; Yang, J.; Guo, H.; Wang, Y. Fuzzy Linear Active Disturbance Rejection Control Method for Permanent Magnet Electromagnetic Hybrid Suspension Platform. Appl. Sci. 2023, 13, 2631. [Google Scholar] [CrossRef]

- Kim, J.; Ha, C.W.; King, G.B.; Kim, C.H. Experimental development of levitation control for a high-accuracy magnetic levitation transport system. ISA Trans. 2020, 101, 358–365. [Google Scholar] [CrossRef] [PubMed]

- Nobuyuki Kurita, Nobuya Hishinuma, K.E. Development of Magnetic Levitation Conveyor with Permanent Magnet. Dyn. Des. Conf. 2019, 2019, 521. [Google Scholar]

- Ogiwara, E.; Nobuyuki Kurita, B.W. Implementation and suspension force evaluation of a permanent magnet hybrid type magnetically levitated carrier system. Dyn. Des. Conf. 2021, 2021, 538. [Google Scholar]

- Ishino, Y.; Mizuno, T.; Takasaki, M. Control of Negative Stiffness by a Local Current Feedback in Magnetic Suspension Systems. Proc. Jpn. Jt. Autom. Control Conf. 2007, 50, 24. [Google Scholar]

- Swain, S.K.; Sain, D.; Mishra, S.K.; Ghosh, S. Real time implementation of fractional order PID controllers for a magnetic levitation plant. AEU-Int. J. Electron. Commun. 2017, 78, 141–156. [Google Scholar] [CrossRef]

- Sun, F.; Oka, K. Zero power non-contact suspension system with permanent magnet motion feedback. J. Syst. Des. Dyn. 2009, 3, 627–638. [Google Scholar] [CrossRef]

- About JMAG Products. Available online: https://www.jmag-international.com/products/ (accessed on 27 September 2023).

- dSPACE Introduction. [EB/OL]. Available online: https://www.dspace.com/en/pub/home.cfm (accessed on 4 March 2023).

- Wei, Z.; Huang, Z.; Zhu, J. Position control of magnetic levitation ball based on an improved adagrad algorithm and deep neural network feedforward compensation control. Math. Probl. Eng. 2020, 2020, 8935423. [Google Scholar] [CrossRef]

- Bleuler, H.; Cole, M.; Keogh, P.; Larsonneur, R.; Maslen, E.; Okada, Y.; Schweitzer, G.; Traxler, A. Magnetic Bearings: Theory, Design, and Application to Rotating Machinery; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Vinagre, B.M.; Monje, C.A.; Calderón, A.J.; Suárez, J.I. Fractional PID controllers for industry application. A brief introduction. J. Vib. Control 2007, 13, 1419–1429. [Google Scholar] [CrossRef]

- Wang, Q.G.; Lee, T.H.; Fung, H.W.; Bi, Q.; Zhang, Y. PID tuning for improved performance. IEEE Trans. Control Syst. Technol. 1999, 7, 457–465. [Google Scholar] [CrossRef]

- Malikov, A.I. State estimation and stabilization of continuous systems with uncertain nonlinearities and disturbances. Autom. Remote Control 2016, 77, 764–778. [Google Scholar] [CrossRef]

- Trentelman, H.L.; Stoorvogel, A.A.; Hautus, M. Control Theory for Linear Systems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Sazawa, M.; Ohishi, K.; Katsura, S. High speed positioning servo system using integrator correction of PI controller based on disturbance observer. In Proceedings of the 2008 34th Annual Conference of IEEE Industrial Electronics, Orlando, FL, USA, 10–13 November 2008; pp. 2539–2544. [Google Scholar]

| Parts | Material | Mesh Size |

|---|---|---|

| Permanent magnet | N48H | 1.0 mm |

| Core | SUY-1 | 1.0 mm |

| Coil | Copper | 1.0 mm |

| Guide rail | SUY-1 | 5.0 mm |

| Parameter | Description | Numerical Value |

|---|---|---|

| Target position | 0 mm | |

| x | Gap position | 4 mm |

| i | Control current | 0.05 A |

| Vacuum permeability | 4 × (H/m) | |

| A | Magnetic permeability area | × (m) |

| N | Coil turns | 670 |

| m | Suspend float | 70 kg |

| Gain of current and the force | 85 (N/A) | |

| Gain of position and the force | 1.5 × 10 (N/m) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, X.; Hashimoto, S.; Kurita, N.; Kawaguchi, T.; Ogiwara, E.; Hishinuma, N.; Egura, K. Development of a Conveyor Cart with Magnetic Levitation Mechanism Based on Multi Control Strategies. Appl. Sci. 2023, 13, 10846. https://doi.org/10.3390/app131910846

Tang X, Hashimoto S, Kurita N, Kawaguchi T, Ogiwara E, Hishinuma N, Egura K. Development of a Conveyor Cart with Magnetic Levitation Mechanism Based on Multi Control Strategies. Applied Sciences. 2023; 13(19):10846. https://doi.org/10.3390/app131910846

Chicago/Turabian StyleTang, Xiaowei, Seiji Hashimoto, Nobuyuki Kurita, Takahiro Kawaguchi, Eiji Ogiwara, Nobuya Hishinuma, and Keisuke Egura. 2023. "Development of a Conveyor Cart with Magnetic Levitation Mechanism Based on Multi Control Strategies" Applied Sciences 13, no. 19: 10846. https://doi.org/10.3390/app131910846

APA StyleTang, X., Hashimoto, S., Kurita, N., Kawaguchi, T., Ogiwara, E., Hishinuma, N., & Egura, K. (2023). Development of a Conveyor Cart with Magnetic Levitation Mechanism Based on Multi Control Strategies. Applied Sciences, 13(19), 10846. https://doi.org/10.3390/app131910846