Industrial robots are multi-mechanical-arm or multi-degree-of-freedom robots designed for industrial applications that can replace humans in performing simple and repetitive tasks in harsh environments [

1,

2,

3]. Over time, the repeatability of industrial robots can be affected by changes in the precision of the joint gear system and the resolution of the encoder. The accuracy of robots can also be influenced by geometric factors such as deviations in link parameters and coordinate frame definitions, as well as non-geometric factors like temperature and deformations. These factors can lead to deviations in the pose of the end effector of industrial robots, which can impact the quality of associated products. On one hand, industrial robots generally have high repeatability, often reaching the level of 0.1 mm, but their absolute positioning accuracy is usually in the millimeter range. On the other hand, the accuracy of industrial robots gradually deteriorates with increasing operating time, and the rate of deterioration determines their lifecycle. As industrial robots find broader applications, meeting the repeatability requirement alone is no longer sufficient, and the low absolute positioning accuracy becomes a bottleneck for further development. Therefore, improving absolute positioning accuracy has become an urgent problem for industrial robot manufacturers.

The calibration of Industrial robots [

4,

5] typically involves four steps: kinematic modeling, pose measurement, parameter identification, and error compensation. Kinematic modeling serves as the mathematical foundation in the field of industrial robot calibration. In the 1950s, Denavit and Hartenberg proposed the Denavit–Hartenberg model (DH) [

6], which expresses the spatial coordinate transformation between adjacent joints by defining four parameters: link length

, link offset

, link twist

, and joint angle

. The DH model has clear physical significance, is convenient to use, and satisfies the principle of minimization [

7]. However, a wealth of research studies have demonstrated that the DH model fails to meet the continuity requirement when the axes of adjacent joints are parallel or nearly parallel. To address this singularity issue while maintaining the model’s parameter minimization principle, a modified Denavit–Hartenberg model (MDH) [

8,

9] was proposed by adding a parameter

for rotation around the y-axis in parallel or nearly parallel singular joint coordinate frames. In [

10], Stone et al. redefined the rules for establishing the link coordinate frame and proposed the S model. In the S model, each link is described by six parameters, including three translation parameters and three rotation parameters, but it does not satisfy the principle of minimization and contains redundant parameters [

11]. Zhuang et al. proposed the complete and parametrically continuous model (CPC) based on the idea that a kinematic model for robot calibration needs to satisfy both “completeness” and “parameter continuity” [

12]. In [

13,

14], the kinematic model of industrial robots was described as a product of a series of exponential matrices, known as the product of the exponentials (POE) model, which does not have parameters that mutate in terms of phenomena. To address the issue of model discontinuity commonly encountered in the traditional DH model, Zhang et al. proposed a local product of the exponential model [

15]. To reduce the difficulty of kinematic modeling, many researchers have considered using neural networks to depict the relationship between the end effector error and the joint angles of industrial robots [

16,

17]. Maghami et al. proposed a two-step calibration method for a master-slave collaborative robot system based on artificial neural networks (ANNs), using joint angles and output pose errors as the training data [

18]. Ma et al. employed an incremental extreme learning machine (IELM) to predict the positioning error of an industrial robot and improve its positioning accuracy [

19]. To improve the tracking accuracy of joint angles, Tan et al. proposed a robot-tracking error prediction and compensation method based on time-convolutional networks (TCN) [

20]. In [

21], Bo et al. used a genetic particle swarm optimization algorithm to optimize a neural network for predicting the positioning error of an industrial robot, thus improving the positioning accuracy of a KUKA robot.

Among all the mathematical models mentioned above, the MDH model is the most widely used in the field of industrial robot calibration due to its features of parameter completeness, minimization, continuity, and clear physical significance. Guo et al. established a geometric parameter error model for SCARA robots based on the MDH model and identified the corresponding structural parameters [

22]. Song et al. derived geometric and deformation errors based on the MDH model, combined them into a complete model, and proposed a step-by-step compensation method [

23]. In [

24], a kinematic error model for FANUC robots was established based on the MDH model, and the Levenberg-Marquardt algorithm (LM) and differential evolution algorithm (DE) were used to identify and optimize the related parameters. Chen et al. analyzed the joint motion of KUKA robots according to the MDH model and proposed a kinematic calibration method based on an improved beetle swarm optimization algorithm [

25]. Selami et al. presented a 3DPP measurement device and kinematic parameter identification method based on the MDH model for the calibration of 6 degrees-of-freedom (DOF) industrial manipulators [

26].

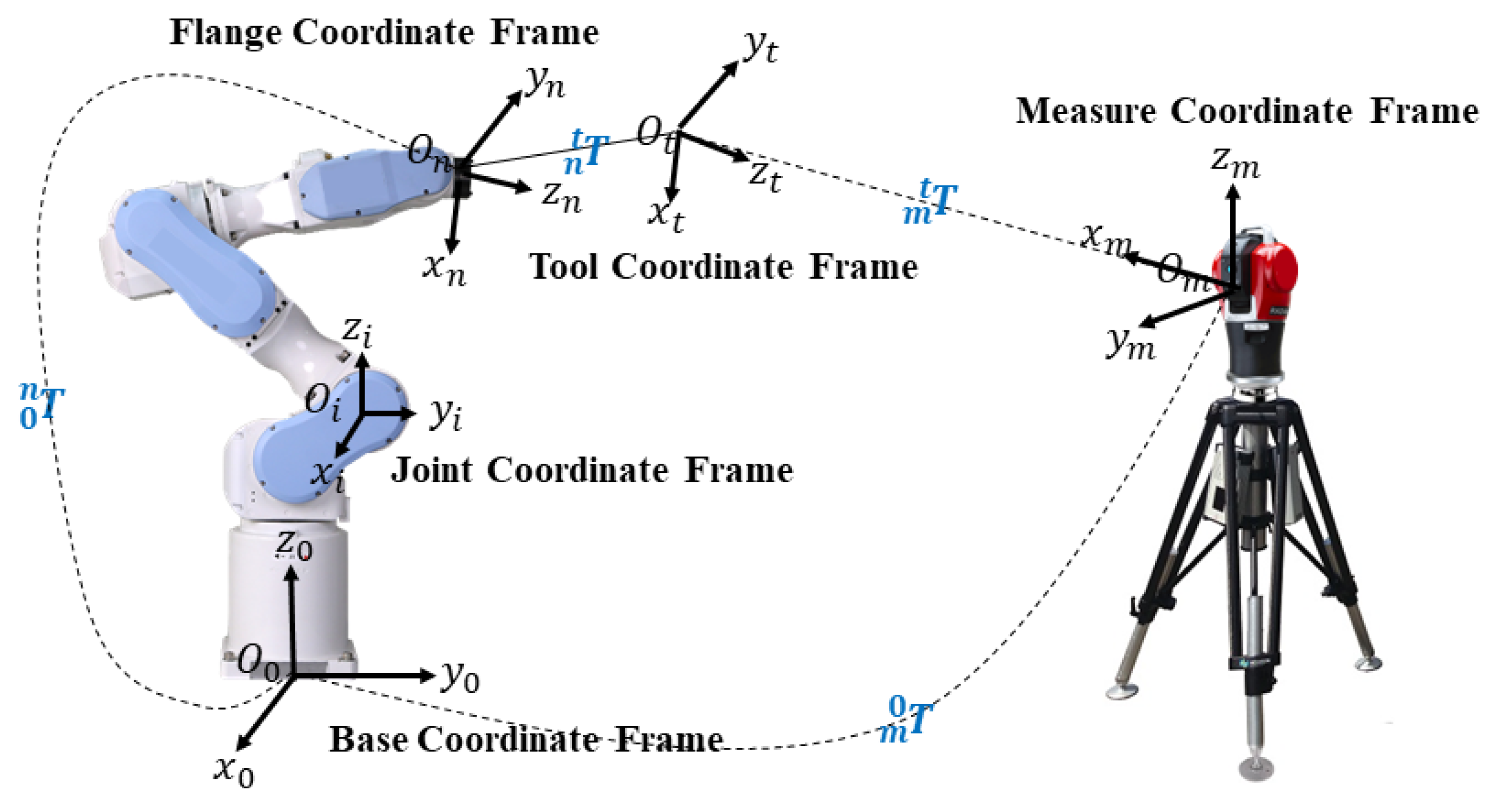

However, the majority of the aforementioned industrial robot calibration methods primarily focus on positional errors, neglecting the importance of orientation accuracy. Moreover, when the calibration of the tool coordinate frame and measurement coordinate frame is not sufficiently accurate (i.e., when there is a significant transformation error), the identification results based on the MDH error model often differ greatly from the actual structural parameters of the industrial robot [

27]. Additionally, industrial robot parameter identification is susceptible to falling into local optima due to the effects of transformation errors in the tool coordinate frame and measurement coordinate frame and other random noise. To address these issues, this paper presents a more accurate error model and parameter calibration method for industrial robots based on 6-DOF position and orientation to identify the actual structural parameters. The main contributions are as follows: (1) based on the modified Denavit–Hartenberg parameters, the transformation errors of tool coordinate system and measurement coordinate frame were introduced to establish a geometric parameter error model, which uses positional and orientation accuracy as optimization objectives; (2) to overcome the problem of easily falling into local optima when identifying geometric parameters simultaneously, a geometric parameter cross-identification method based on the Levenberg-Marquardt algorithm is proposed; (3) the linear relationships between the parameters of the proposed geometric error model are investigated, and a solution for not calibrating some geometric parameters under specific conditions is provided.