Damage Evolution in Quasi-Brittle Materials: Experimental Analysis by AE and Numerical Simulation

Abstract

:1. Introduction

- Research problem: to study the damage process of a prefissured basalt specimen through both simulation and experimental tests, collecting Acoustic Emission data to track damage development throughout the tests.

- Objectives: (i) to investigate the usefulness of a new parameter proposed originally by Dȩbski et al. [38] as a precursor for local and complete failure in the structure undergoing damage; (ii) to illustrate the possibilities of LDEM to aid in the interpretation of experimental results.

- Significance, Novelty, and Benefits: The index proposed by Dȩbski et al. [38], originally applied in numerical results only as a global failure precursor, is tested in our paper with an experimental approach, proposing an alternative measure of the elastic energy derivative during the test. Another novelty is related to the fact that this index is applied here not only to determine the global collapse but also to identify local failure regions with excellent performance. The behavior of this index as a failure precursor is compared with the b-value, which is a typical AE parameter. Moreover, in the present case, we observe that the benefit of proposing the index as a failure precursor could be another way to identify critical regions during the damage process to complement the analysis performed using AE signals.

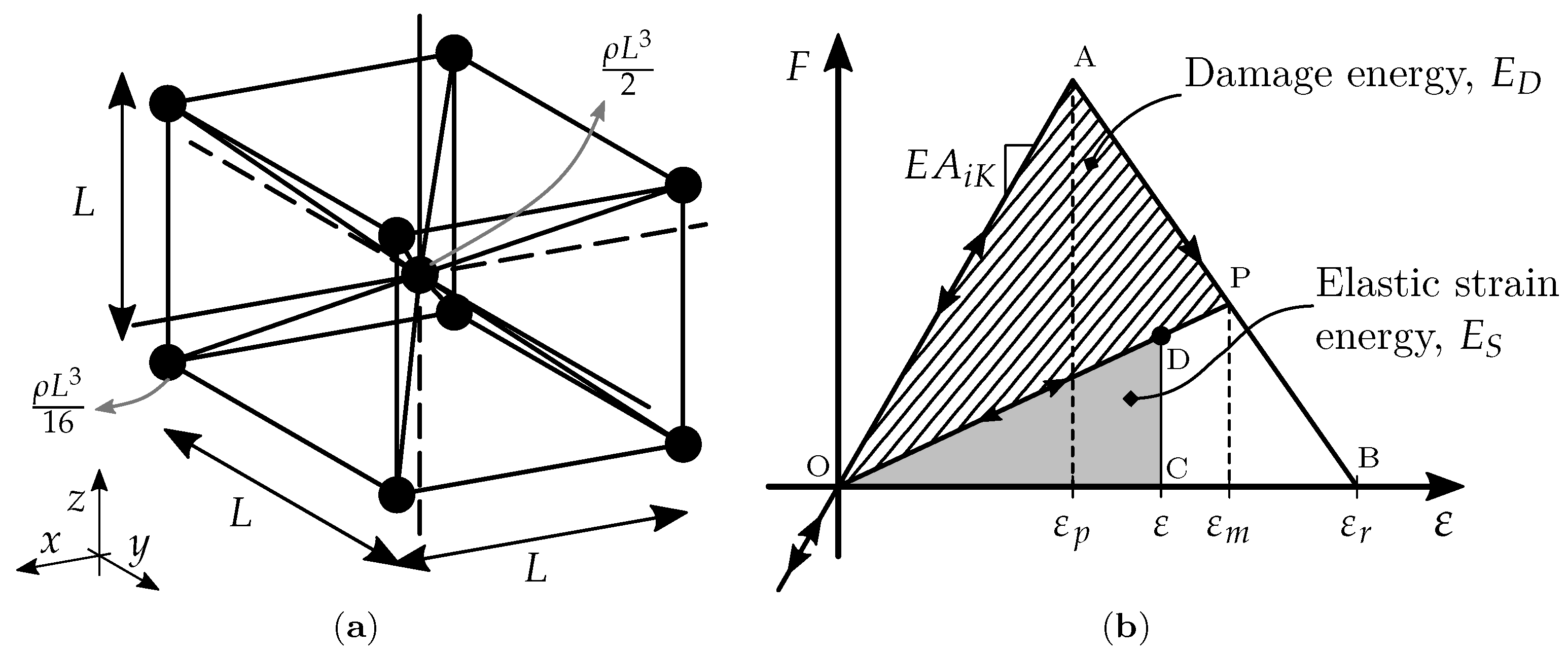

2. The Lattice Discrete Element Method (LDEM)

3. Acoustic Emission Technique

3.1. Global Parameters Computed from the AE Signal

- (a)

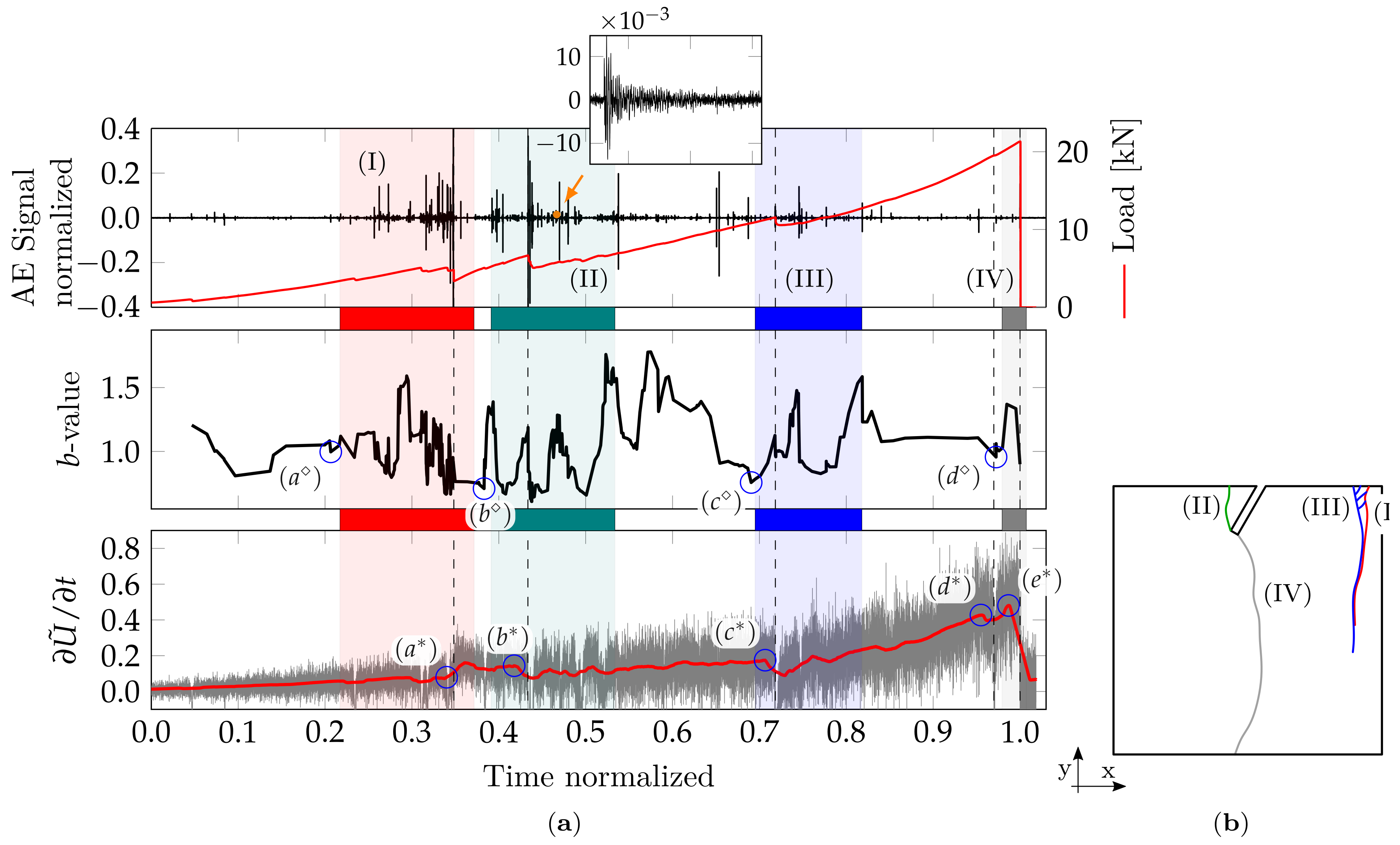

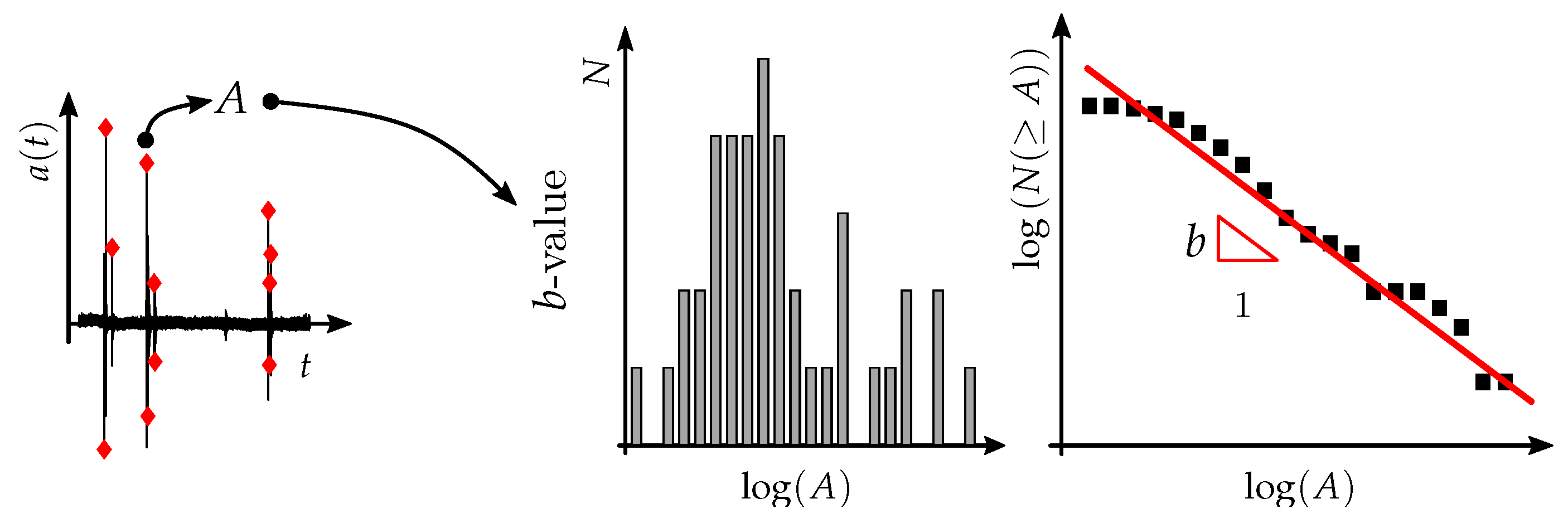

- Relation between the number of events and the signal amplitude (b-value): This relation is widely used in seismological applications, with the classic law by Gutenberg and Ritcher [50] being the primary example of its usefulness. It is mathematically expressed aswhere N is the cumulative number of signals and A is the signal amplitude. The physical meaning of b is discussed in refs. [21,56]; it is hypothetically related to the fractal dimension D of the domain from which the cracks emanate, according to the expression . At the beginning of a damage process within the structure, events originate from a micro-fissure of volumetric distribution, i.e., and , leading to small-amplitude signals. As damage progresses and localization effects occur, events emanate preferentially from the micro-fissure cloud, resulting in macro-crack nucleation.The procedure for computing b is explained in detail [57] and summarized schematically in Figure 2. The amplitudes due to each event are collected and organized in a histogram. Then, a bi-log diagram relating the cumulative number N of events with amplitudes is drawn. Finally, b is determined as the angular coefficient of the fitting line.

- (b)

- Temporal derivative of the system’s elastic energy: This criterion takes the local maxima of the system’s elastic energy variation rate (i.e., its time derivative) as a precursor. Given its original proposition by [38], it is referred to here as the Dȩbski–Pradhan–Hansen (DPH) parameter.

4. Case Study

- The original DPH index is the time derivative of the body’s internal elastic energy, which cannot be accessed through direct measurement. Therefore, the original index applies only as a theoretical analysis tool based on simulation data. Here, we use the product between the prescribed displacement and the corresponding reaction force perceived in the test machine as a proxy for the body’s internal elastic energy. As these two variables are readily available for measurement, this procedure also allows the use of the DPH index with experimental data.

- The correspondence between the actual elastic within the structure and its proposed estimation counterpart is investigated through simulation results, confirming that the proposed proxy leads to equivalent conclusions.

- Instead of predicting total collapse only, the DPH index is investigated as a valid precursor also to local failures.

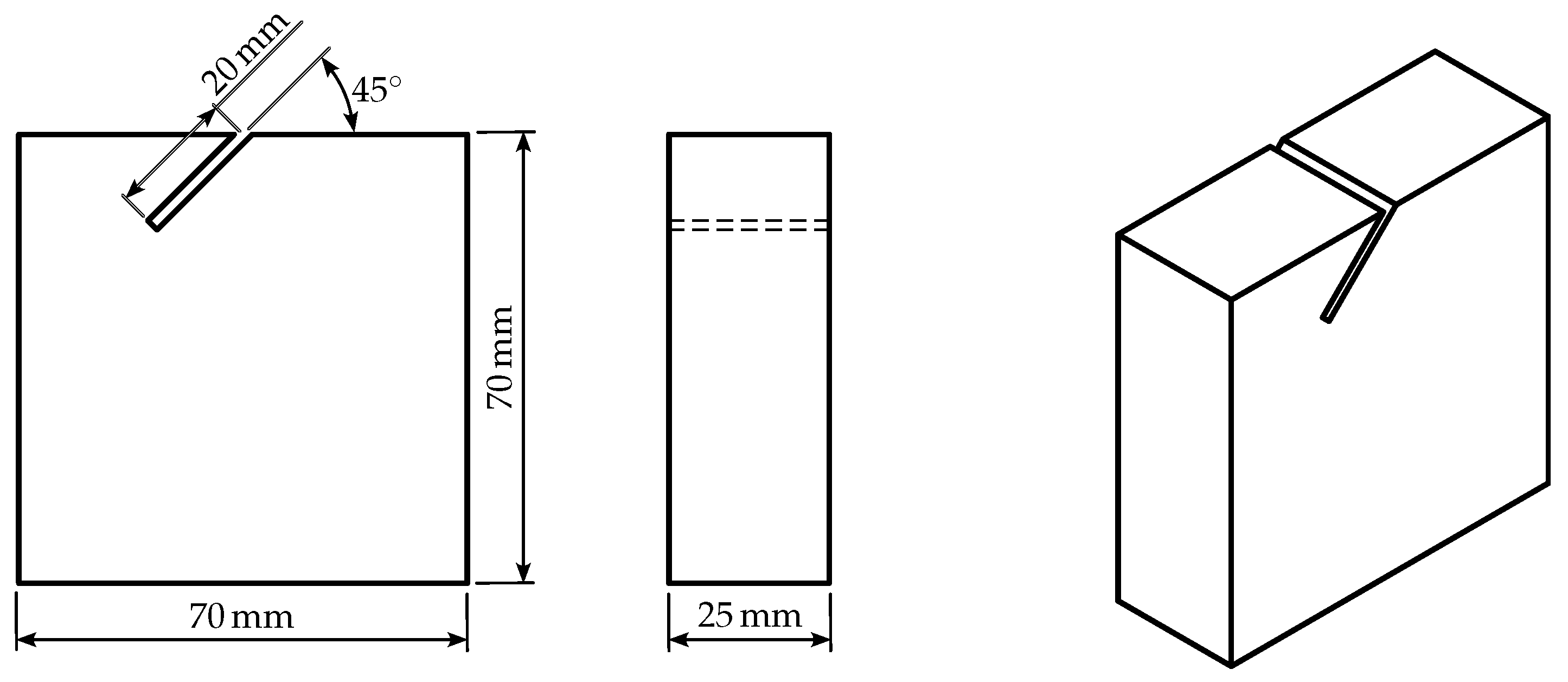

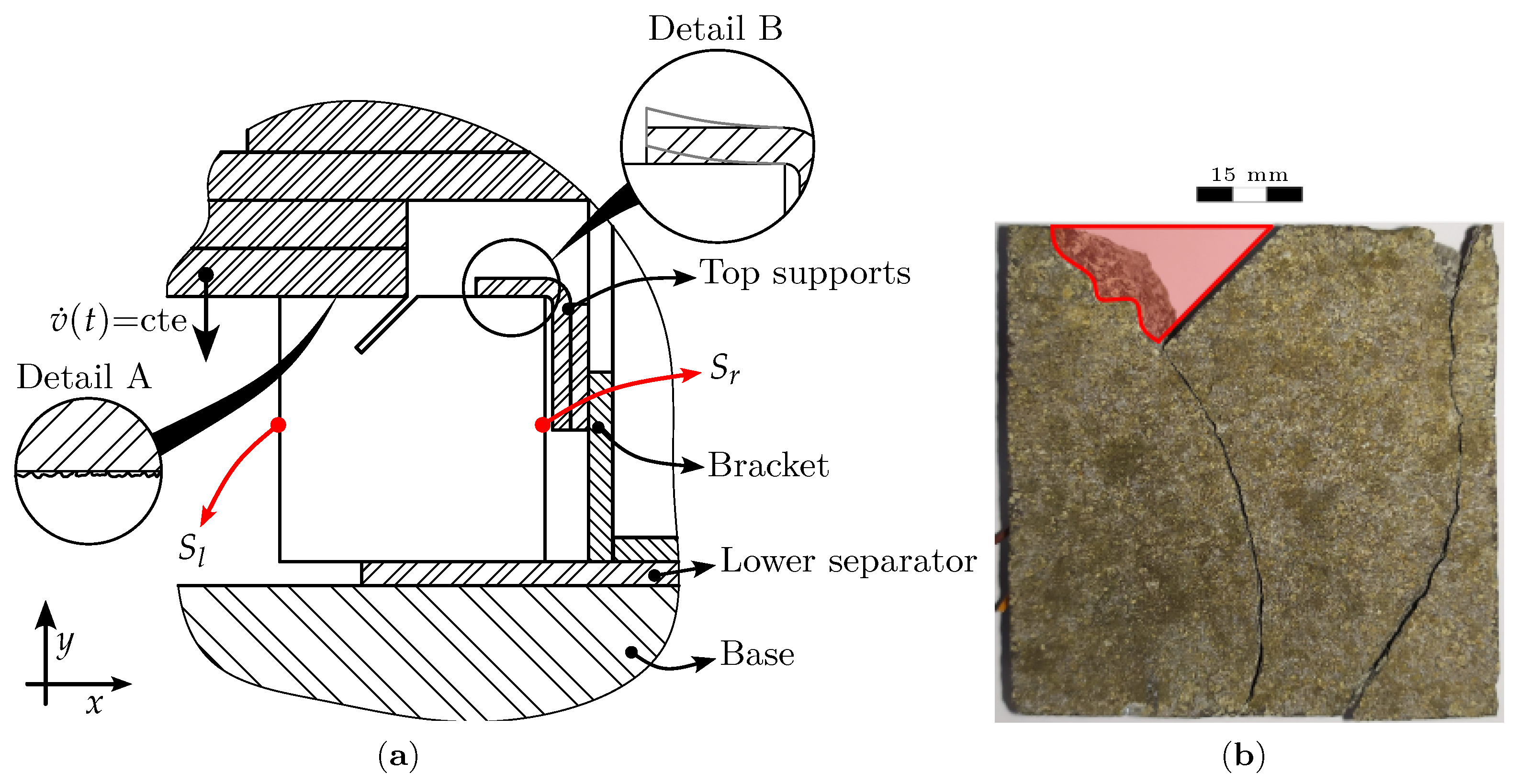

4.1. Experiment Description

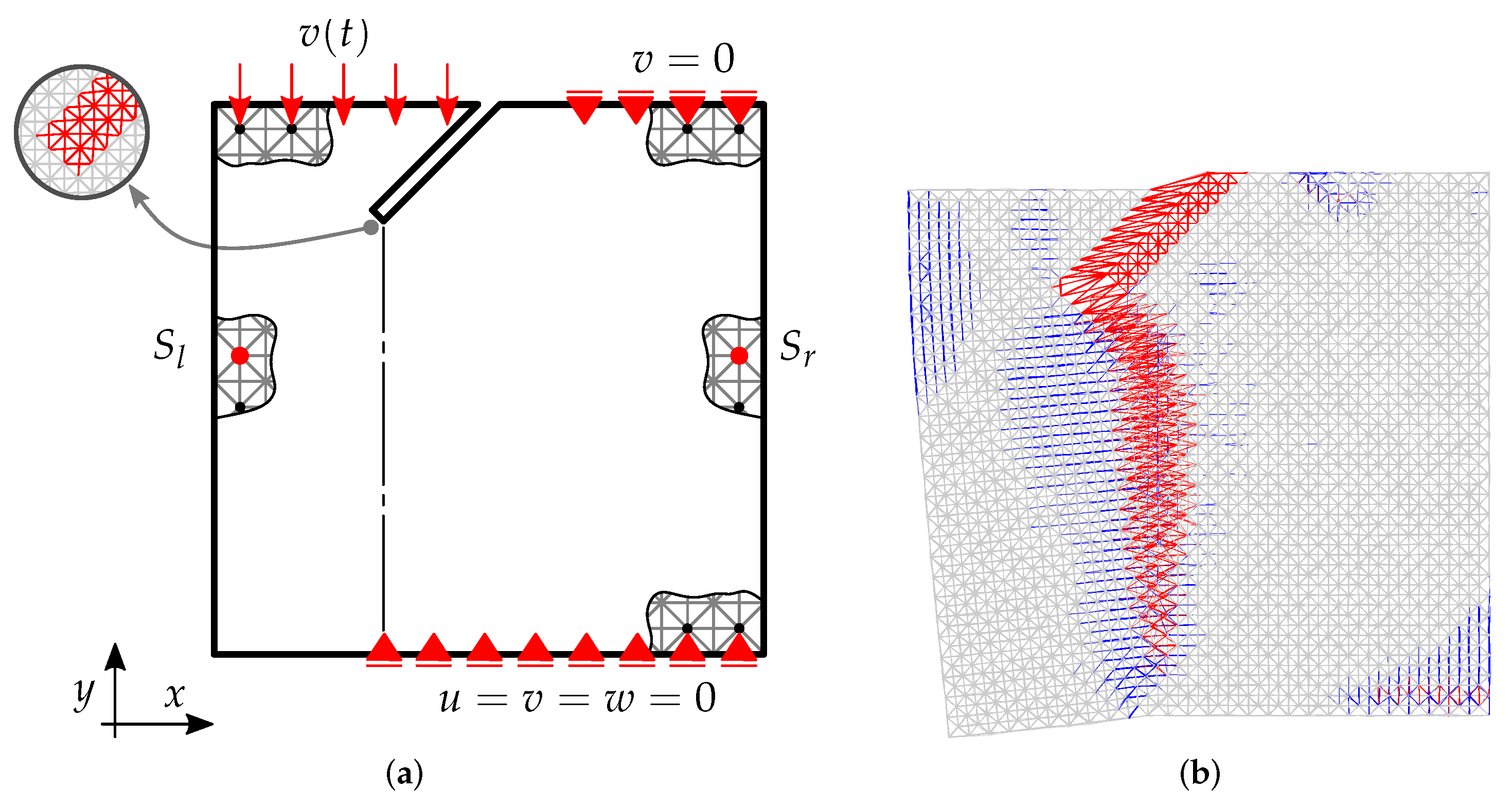

4.2. Numerical Simulation

4.3. Results

- I

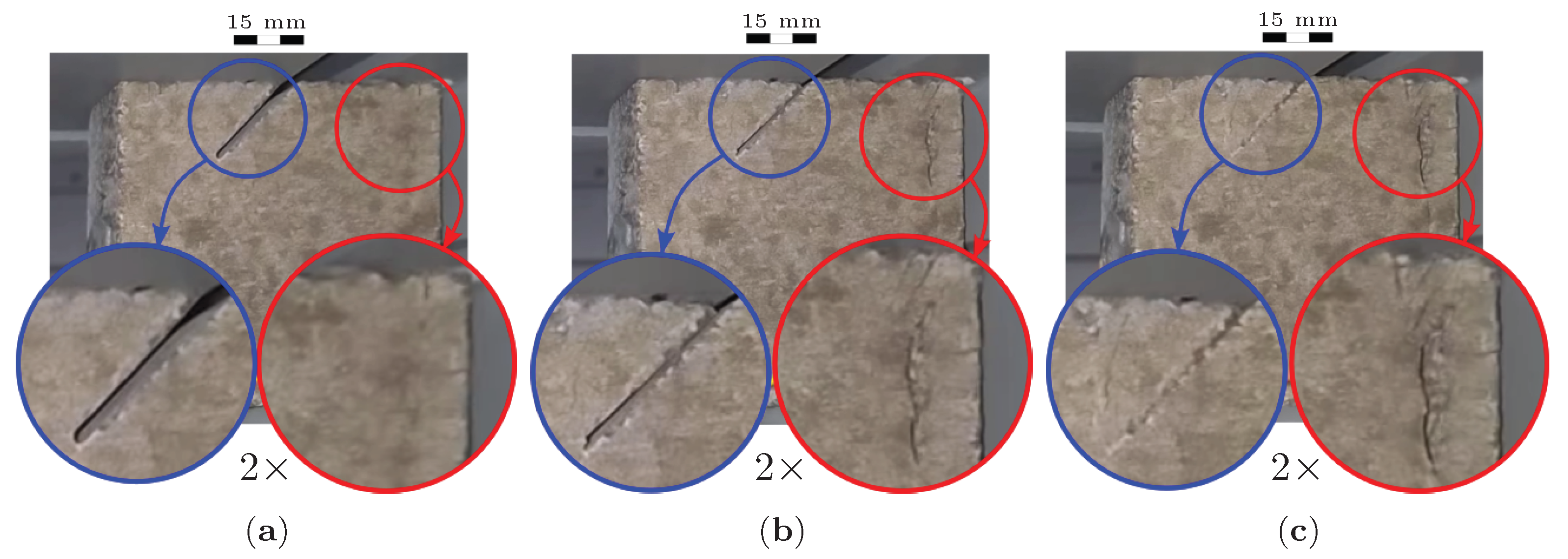

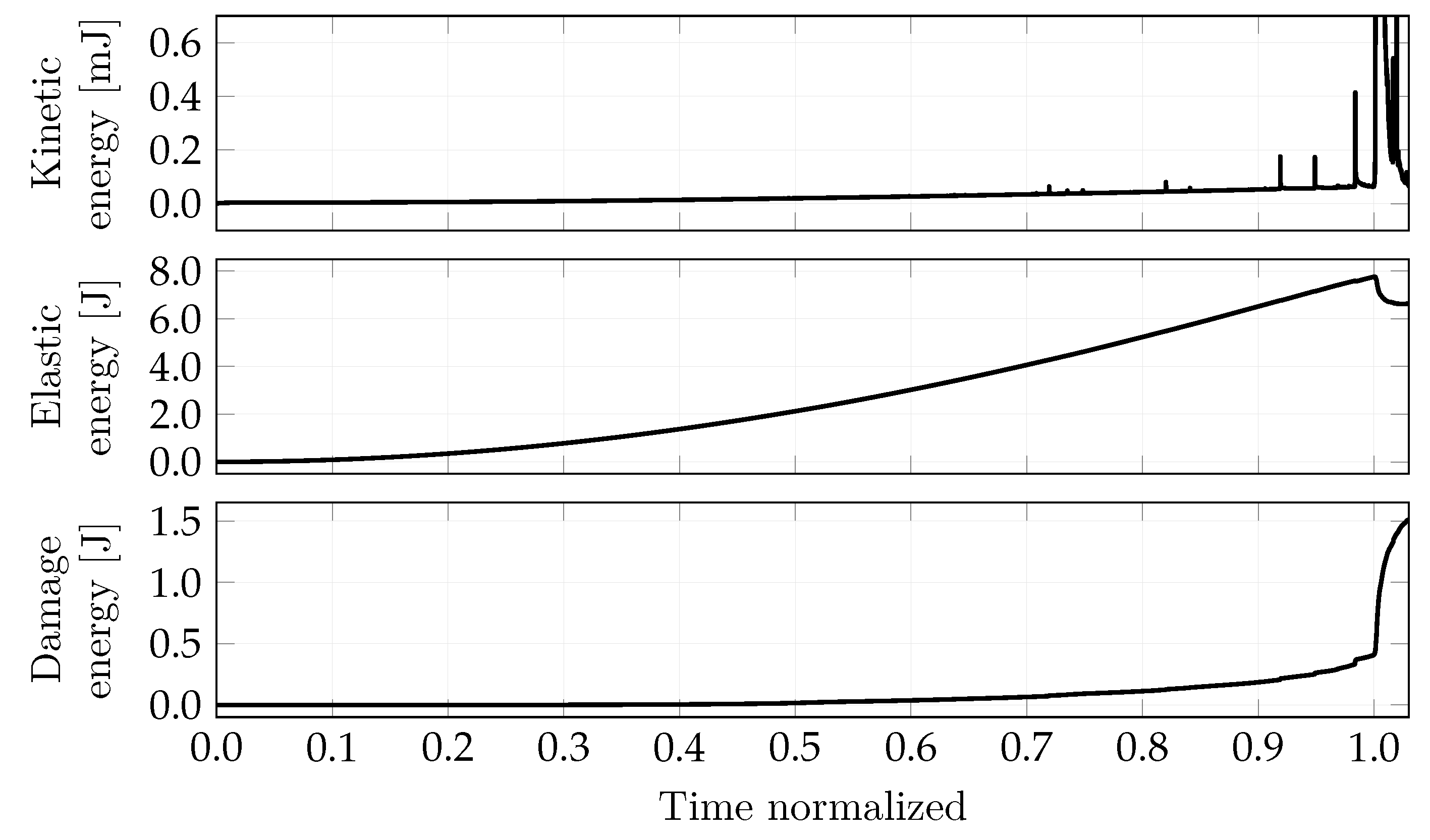

- A localized vertical fissure develops in the superior right corner. Notice that no prefissure is discernible in that region until the normalized time approaches 0.3 (Figure 7a) but its appearance is anticipated by significant AE activity since .

- II

- The prefissure begins to close with visible damage in its supporting region, while the damage in the superior right corner continues to develop. At this interval’s end (normalized time = 0.52, displacement = 1 ), there is significant hardening in the load vs. global displacement response. The partial closing of the prefissure is confirmed by Figure 7b.

- III

- The diagonal prefissure is entirely closed while the damage continues to increase in the superior right corner (Figure 7c).

- IV

5. Conclusions

- While the original version of the DPH index was used only as a predictor of total structural failure, our proposed alternative could also identify intermediate local failure events. Its performance as a failure predictor was consistent in comparison with the widely used b-value during the experimental test. However, this could be a peculiar characteristic of the test carried out in the paper, and before generalizing its advantages, the persistence of this tendency must be verified by new tests to verify the index performance in other representative specimens of different materials and dimensions.

- Although the simulated results could not confirm the usefulness of the proposed DPH index conclusively, they showed that the behavior of the actual elastic energy within the system (which is necessary to calculate the original index) could be successfully approximated through the product between the applied displacement and the reaction from the structure. Since the direct measurement of such energy within the structure is unattainable, such an alternative method is of significant practical importance because it enables using a hitherto strictly theoretical tool in the experimental study of damage processes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AE | Acoustic Emission |

| CMOD | Crack mouth opening displacement |

| CP | Control parameter |

| FEM | Finite Element Methods |

| LDEM | Lattice Discrete Element Method |

| OP | Order parameters |

References

- Dhanasekar, S.; Ganesan, A.T.; Rani, T.L.; Vinjamuri, V.K.; Nageswara Rao, M.; Shankar, E.; Dharamvir; Kumar, P.S.; Misganaw Golie, W. A Comprehensive Study of Ceramic Matrix Composites for Space Applications. Adv. Mater. Sci. Eng. 2022, 2022, 6160591. [Google Scholar] [CrossRef]

- Kachanov, L.M. Introduction to Continuum Damage Mechanics. In Mechanics of Elastic Stability; Springer: Dordrecht, The Netherlands, 1986; Volume 10. [Google Scholar] [CrossRef]

- Krajcinovic, D. Damage Mechanics; Number 41 in North-Holland Series in Applied Mathematic and Mechanics; Elsevier: Amsterdam, The Netherlands; New York, NY, USA, 1996. [Google Scholar]

- Gross, D.; Seelig, T. Fracture Mechanics: With an Introduction to Micromechanics, 3rd ed.; Mechanical Engineering Series; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Ahmed, B.; Park, T. A review of continuum damage and plasticity in concrete: Part II—Numerical framework. Int. J. Damage Mech. 2022, 31, 762–794. [Google Scholar] [CrossRef]

- Park, T.; Ahmed, B.; Voyiadjis, G.Z. A review of continuum damage and plasticity in concrete: Part I—Theoretical framework. Int. J. Damage Mech. 2022, 31, 901–954. [Google Scholar] [CrossRef]

- Needleman, A. A Continuum Model for Void Nucleation by Inclusion Debonding. J. Appl. Mech. 1987, 54, 525–531. [Google Scholar] [CrossRef]

- Belytschko, T.; Chen, H.; Xu, J.; Zi, G. Dynamic crack propagation based on loss of hyperbolicity and a new discontinuous enrichment. Int. J. Numer. Methods Eng. 2003, 58, 1873–1905. [Google Scholar] [CrossRef]

- Rundle, J.B.; Turcotte, D.L.; Shcherbakov, R.; Klein, W.; Sammis, C. Statistical physics approach to understanding the multiscale dynamics of earthquake fault systems: Statistical physics of Earthquakes. Rev. Geophys. 2003, 41. [Google Scholar] [CrossRef]

- Kawamura, H.; Hatano, T.; Kato, N.; Biswas, S.; Chakrabarti, B.K. Statistical Physics of Fracture, Friction and Earthquake. Rev. Mod. Phys. 2012, 84, 839–884. [Google Scholar] [CrossRef]

- Hansen, A.; Hemmer, P.C.; Pradhan, S. The Fiber Bundle Model: Modeling Failure in Materials; Statistical Physics of Fracture and Breakdown; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2015. [Google Scholar]

- Biswas, S.; Ray, P.; Chakrabarti, B.K. Statistical Physics of Fracture, Breakdown, and Earthquake: Effects of Disorder and Heterogeneity; John Wiley & Sons: Weinheim, Germany, 2015. [Google Scholar]

- Wilson, K.G. Problems in Physics with many Scales of Length. Sci. Am. 1979, 241, 158–179. [Google Scholar] [CrossRef]

- Huang, K. Statistical Mechanics, 2nd ed.; Wiley: New York, NY, USA, 1987. [Google Scholar]

- Ohtsu, M. The history and development of acoustic emission in concrete engineering. Mag. Concr. Res. 1996, 48, 321–330. [Google Scholar] [CrossRef]

- Colombo, I.S.; Main, I.G.; Forde, M.C. Assessing Damage of Reinforced Concrete Beam Using “ B—Value” Analysis Acoustic Emission Signals. J. Mater. Civ. Eng. 2003, 15, 280–286. [Google Scholar] [CrossRef]

- Rao, M.V.M.S.; Lakshmi, K.J.P. Analysis of b-value and improved b-value of acoustic emissions accompanying rock fracture. Curr. Sci. 2005, 89, 1577–1582. [Google Scholar]

- Kurz, J.H.; Finck, F.; Grosse, C.U.; Reinhardt, H.W. Stress Drop and Stress Redistribution in Concrete Quantified Over Time by the b-value Analysis. Struct. Health Monit. 2006, 5, 69–81. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Niccolini, G. Critical Behaviour in Concrete Structures and Damage Localization by Acoustic Emission. Key Eng. Mater. 2006, 312, 305–310. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Niccolini, G.; Puzzi, S. Critical defect size distributions in concrete structures detected by the acoustic emission technique. Meccanica 2008, 43, 349–363. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Puzzi, S. From criticality to final collapse: Evolution of the “b-value” from 1.5 to 1.0. Chaos Solitons Fractals 2009, 41, 843–853. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Niccolini, G. Fractal analysis of damage detected in concrete structural elements under loading. Chaos Solitons Fractals 2009, 42, 2047–2056. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Niccolini, G.; Puzzi, S. Morphological Fractal Dimension Versus Power-Law Exponent in the Scaling of Damaged Media. Int. J. Damage Mech. 2009, 18, 259–282. [Google Scholar] [CrossRef]

- Iturrioz, I.; Lacidogna, G.; Carpinteri, A. Experimental Analysis and Truss-Like Discrete Element Model Simulation of Concrete Specimens Under Uniaxial Compression. Eng. Fract. Mech. 2013, 110, 81–98. [Google Scholar] [CrossRef]

- Iturrioz, I.; Lacidogna, G.; Carpinteri, A. Acoustic emission detection in concrete specimens: Experimental analysis and lattice model simulations. Int. J. Damage Mech. 2014, 23, 327–358. [Google Scholar] [CrossRef]

- Birck, G.; Iturrioz, I.; Lacidogna, G.; Carpinteri, A. Damage process in heterogeneous materials analyzed by a lattice model simulation. Eng. Fail. Anal. 2016, 70, 157–176. [Google Scholar] [CrossRef]

- Rojo Tanzi, B.N.; Sobczyk, M.; Becker, T.; Segovia González, L.A.; Vantadori, S.; Iturrioz, I.; Lacidogna, G. Damage Evolution Analysis in a “Spaghetti” Bridge Model Using the Acoustic Emission Technique. Appl. Sci. 2021, 11, 2718. [Google Scholar] [CrossRef]

- Rojo Tanzi, B.N.; de Abreu Cáceres, G.; Echer, L.; Iturrioz, I.; Lacidogna, G. The damage evolution in specimens made with quasi-brittle materials: Experimental verification using Acoustic Emission technics. In Proceedings of the 26th International Acoustic Emission Symposium, Kawasaki, Japan, 31 October–2 November 2022; pp. 1–6. [Google Scholar]

- Rojo Tanzi, B.N.; Birck, G.; Sobczyk, M.; Iturrioz, I.; Lacidogna, G. Truss-like Discrete Element Method Applied to Damage Process Simulation in Quasi-Brittle Materials. Appl. Sci. 2023, 13, 5119. [Google Scholar] [CrossRef]

- Varotsos, P.A.; Sarlis, N.V.; Skordas, E.S. Natural Time Analysis: The New View of Time; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Potirakis, S.; Mastrogiannis, D. Critical features revealed in acoustic and electromagnetic emissions during fracture experiments on LiF. Phys. A Stat. Mech. Its Appl. 2017, 485, 11–22. [Google Scholar] [CrossRef]

- Niccolini, G.; Lacidogna, G.; Carpinteri, A. Fracture precursors in a working girder crane: AE natural-time and b-value time series analyses. Eng. Fract. Mech. 2019, 210, 393–399. [Google Scholar] [CrossRef]

- Niccolini, G.; Potirakis, S.M.; Lacidogna, G.; Borla, O. Criticality Hidden in Acoustic Emissions and in Changing Electrical Resistance during Fracture of Rocks and Cement-Based Materials. Materials 2020, 13, 5608. [Google Scholar] [CrossRef] [PubMed]

- Ferreira Friedrich, L.; Cezar, E.S.; Colpo, A.B.; Rojo Tanzi, B.N.; Sobczyk, M.; Lacidogna, G.; Niccolini, G.; Kosteski, L.E.; Iturrioz, I. Long-Range Correlations and Natural Time Series Analyses from Acoustic Emission Signals. Appl. Sci. 2022, 12, 1980. [Google Scholar] [CrossRef]

- Ferreira Friedrich, L.; Rojo Tanzi, B.N.; Colpo, A.B.; Sobczyk, M.; Lacidogna, G.; Niccolini, G.; Iturrioz, I. Analysis of Acoustic Emission Activity during Progressive Failure in Heterogeneous Materials: Experimental and Numerical Investigation. Appl. Sci. 2022, 12, 3918. [Google Scholar] [CrossRef]

- Mostafaei, H.; Ghamami, M.; Aghabozorgi, P. Modal identification of concrete arch dam by fully automated operational modal identification. Structures 2021, 32, 228–236. [Google Scholar] [CrossRef]

- Mostafaei, H.; Mostofinejad, D.; Ghamami, M.; Wu, C. A new approach of ensemble learning in fully automated identification of structural modal parameters of concrete gravity dams: A case study of the Koyna dam. Structures 2023, 50, 255–271. [Google Scholar] [CrossRef]

- Dȩbski, W.; Pradhan, S.; Hansen, A. Criterion for Imminent Failure During Loading—Discrete Element Method Analysis. Front. Phys. 2021, 9, 675309. [Google Scholar] [CrossRef]

- Nayfeh, A.H.; Hefzy, M.S. Continuum modeling of three-dimensional truss-like space structures. AIAA J. 1978, 16, 779–787. [Google Scholar] [CrossRef]

- Riera, J.D. Local effects in impact problems on concrete structures. In Proceedings of the Conference on Structural Analysis and Design of Nuclear Power Plants, Porto Alegre, RS, Brasil, 3–5 October 1984; pp. 57–79. [Google Scholar]

- Kosteski, L.; Barrios D’Ambra, R.; Iturrioz, I. Crack propagation in elastic solids using the truss-like discrete element method. Int. J. Fract. 2012, 174, 139–161. [Google Scholar] [CrossRef]

- Hillerborg, A. A Model for Fracture Analysis; Report TVBM; Division of Building Materials, LTH, Lund University: Lund, Sweden, 1978; Volume 3005. [Google Scholar]

- Carpinteri, A. Application of Fracture Mechanics to Concrete Structures. J. Struct. Div. 1982, 108, 833–848. [Google Scholar] [CrossRef]

- Kosteski, L.E.; Iturrioz, I.; Lacidogna, G.; Carpinteri, A. Size effect in heterogeneous materials analyzed through a lattice discrete element method approach. Eng. Fract. Mech. 2020, 232, 107041. [Google Scholar] [CrossRef]

- Puglia, V.B.; Kosteski, L.E.; Riera, J.D.; Iturrioz, I. Random field generation of the material properties in the lattice discrete element method. J. Strain Anal. Eng. Des. 2019, 54, 236–246. [Google Scholar] [CrossRef]

- Vantadori, S.; Carpinteri, A.; Iturrioz, I. Effectiveness of a lattice discrete element model to simulate mechanical wave shielding by using barriers into the ground. Eng. Fail. Anal. 2020, 110, 104360. [Google Scholar] [CrossRef]

- Iturrioz, I.; Riera, J.D. Assessment of the Lattice Discrete Element Method in the simulation of wave propagation in inhomogeneous linearly elastic geologic materials. Soil Dyn. Earthq. Eng. 2021, 151, 106952. [Google Scholar] [CrossRef]

- Silling, S.; Askari, E. A meshfree method based on the peridynamic model of solid mechanics. Comput. Struct. 2005, 83, 1526–1535. [Google Scholar] [CrossRef]

- Colpo, A.; Vantadori, S.; Friedrich, L.; Zanichelli, A.; Ronchei, C.; Scorza, D.; Iturrioz, I. A novel LDEM formulation with crack frictional sliding to estimate fracture and flexural behaviour of the shot-earth 772. Compos. Struct. 2023, 305, 116514. [Google Scholar] [CrossRef]

- Richter, C.F. Elementary Seismology; W. H. Freeman and Company: New York, NY, USA; Bailey Bros. & Swinfen Ltd.: London, UK, 1958; Volume 2. [Google Scholar]

- Grosse, C.; Ohtsu, M. (Eds.) Acoustic Emission Testing; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar] [CrossRef]

- Ferreira Friedrich, L.; Colpo, A.; Maggi, A.; Becker, T.; Lacidogna, G.; Iturrioz, I. Damage process in glass fiber reinforced polymer specimens using acoustic emission technique with low frequency acquisition. Compos. Struct. 2021, 256, 113105. [Google Scholar] [CrossRef]

- Aggelis, D.G. Classification of cracking mode in concrete by acoustic emission parameters. Mech. Res. Commun. 2011, 38, 153–157. [Google Scholar] [CrossRef]

- Behnia, A.; Chai, H.K.; Shiotani, T. Advanced structural health monitoring of concrete structures with the aid of acoustic emission. Constr. Build. Mater. 2014, 65, 282–302. [Google Scholar] [CrossRef]

- Shetty, N.; Livitsanos, G.; Van Roy, N.; Aggelis, D.G.; Van Hemelrijck, D.; Wevers, M.; Verstrynge, E. Quantification of progressive structural integrity loss in masonry with Acoustic Emission-based damage classification. Constr. Build. Mater. 2019, 194, 192–204. [Google Scholar] [CrossRef]

- Aki, K. Scaling Law of Seismic Spectrum. J. Geophys. Res. 1967, 72, 1217–1231. [Google Scholar] [CrossRef]

- Han, Q.; Wang, L.; Xu, J.; Carpinteri, A.; Lacidogna, G. A robust method to estimate the b-value of the magnitude–frequency distribution of earthquakes. Chaos Solitons Fractals 2015, 81, 103–110. [Google Scholar] [CrossRef]

- Shimadzu. AGS-X Plus: Instruction Manual; Shimadzu Corporation: Kyoto, Japan, 2012. [Google Scholar]

- Aldeeky, H.; Al Hattamleh, O. Prediction of Engineering Properties of Basalt Rock in Jordan Using Ultrasonic Pulse Velocity Test. Geotech. Geol. Eng. 2018, 36, 3511–3525. [Google Scholar] [CrossRef]

- Zhang, C.; Shi, F.; Cao, P.; Liu, K. The fracture toughness analysis on the basalt fiber reinforced asphalt concrete with prenotched three-point bending beam test. Case Stud. Constr. Mater. 2022, 16, e01079. [Google Scholar] [CrossRef]

- Balme, M.R.; Rocchi, V.; Jones, C.; Sammonds, P.R.; Meredith, P.G.; Boon, S. Fracture toughness measurements on igneous rocks using a high-pressure, high-temperature rock fracture mechanics cell. J. Volcanol. Geotherm. Res. 2004, 132, 159–172. [Google Scholar] [CrossRef]

- Junges, B.M.B.; Ficher, N.M.; Kosteski, L.E.; Marangon, E. Hardness correlation length in a self-compacting concrete. Rev. Ibracon Estruturas E Mater. 2020, 13, e13401. [Google Scholar] [CrossRef]

| # mod. | L | E | ||

|---|---|---|---|---|

| 0.25 | ||||

| 2456 | 1000 | 20 | 160% | 3 |

| () | () | () | () | () | |

|---|---|---|---|---|---|

| 0.340 | 0.418 | 0.707 | 0.955 | 0.987 | |

| 0.348 | 0.434 | 0.718 | 0.970 | 1.000 | |

| [%] | 97.626 | 96.356 | 98.360 | 98.466 | 98.674 |

| () | () | |

|---|---|---|

| 0.937 | 0.983 | |

| 1.000 | 1.000 | |

| [%] | 93.782 | 98.315 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojo Tanzi, B.N.; Sobczyk, M.; Iturrioz, I.; Lacidogna, G. Damage Evolution in Quasi-Brittle Materials: Experimental Analysis by AE and Numerical Simulation. Appl. Sci. 2023, 13, 10947. https://doi.org/10.3390/app131910947

Rojo Tanzi BN, Sobczyk M, Iturrioz I, Lacidogna G. Damage Evolution in Quasi-Brittle Materials: Experimental Analysis by AE and Numerical Simulation. Applied Sciences. 2023; 13(19):10947. https://doi.org/10.3390/app131910947

Chicago/Turabian StyleRojo Tanzi, Boris Nahuel, Mario Sobczyk, Ignacio Iturrioz, and Giuseppe Lacidogna. 2023. "Damage Evolution in Quasi-Brittle Materials: Experimental Analysis by AE and Numerical Simulation" Applied Sciences 13, no. 19: 10947. https://doi.org/10.3390/app131910947

APA StyleRojo Tanzi, B. N., Sobczyk, M., Iturrioz, I., & Lacidogna, G. (2023). Damage Evolution in Quasi-Brittle Materials: Experimental Analysis by AE and Numerical Simulation. Applied Sciences, 13(19), 10947. https://doi.org/10.3390/app131910947