Mechanical Structural Design and Actuation Technologies of Powered Knee Exoskeletons: A Review

Abstract

:1. Introduction

2. Mechanical Structural Design of Knee Exoskeletons

2.1. Simplified Structure Design

2.2. Complex Design Based on Biological Geometries

3. Actuation Design

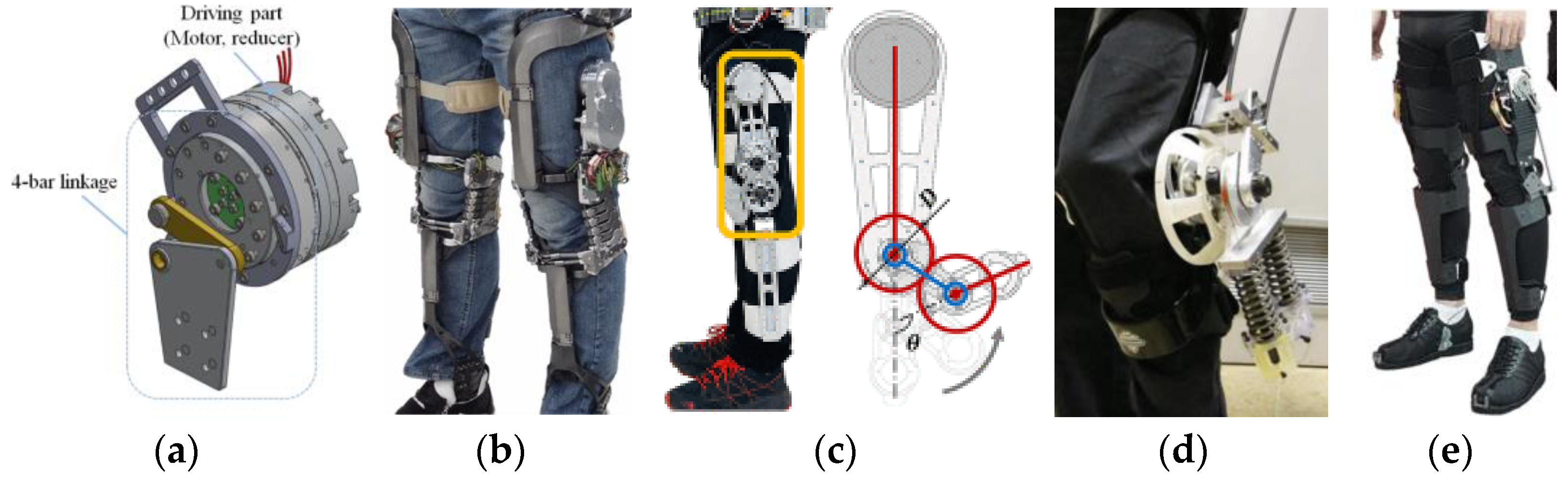

3.1. Conventional Driving Actuators

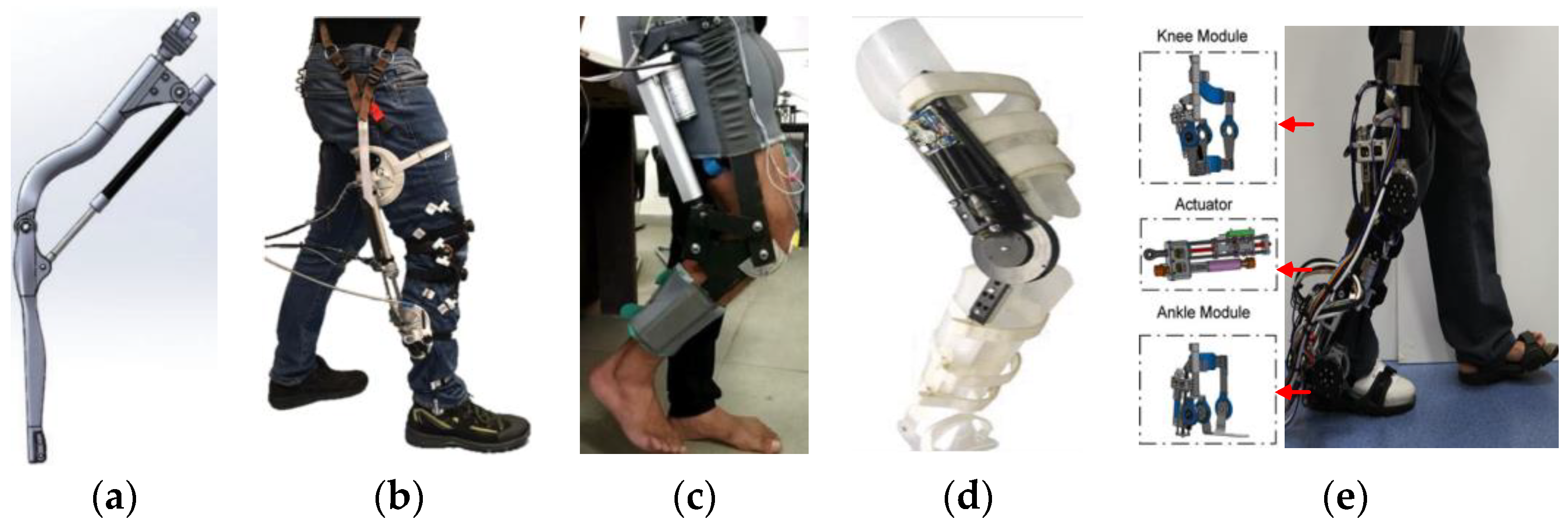

3.2. Pneumatic Muscle Actuators

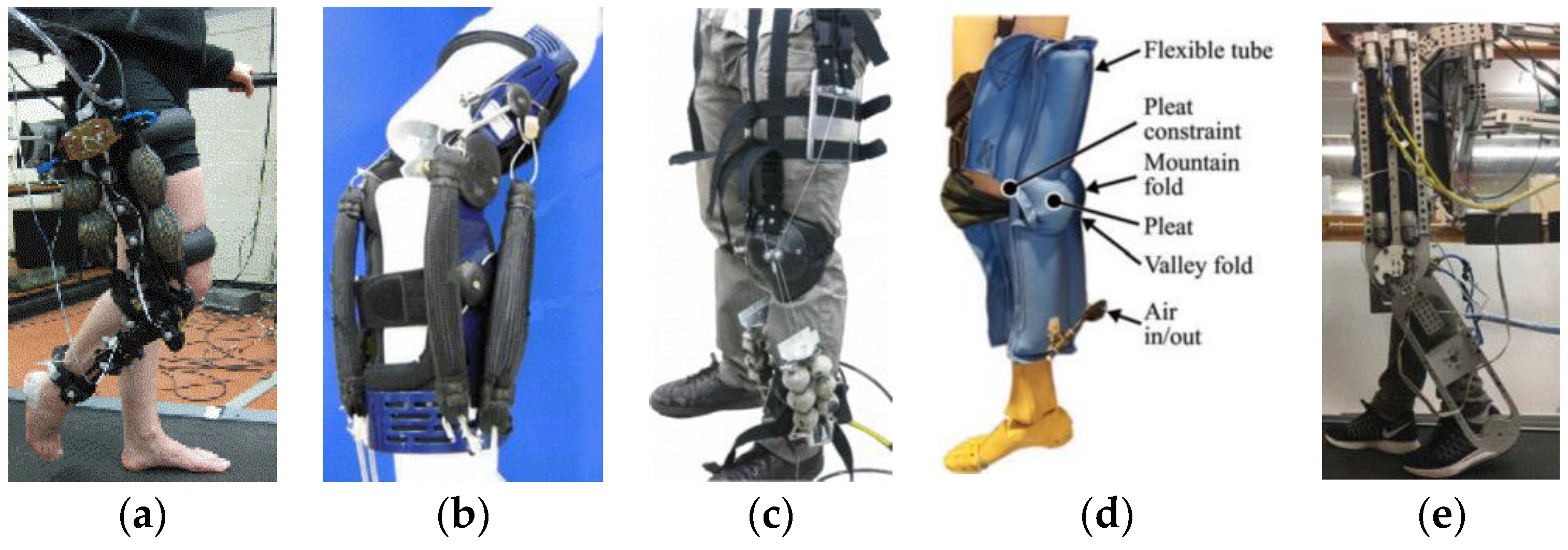

3.3. Variable Stiffness Actuators

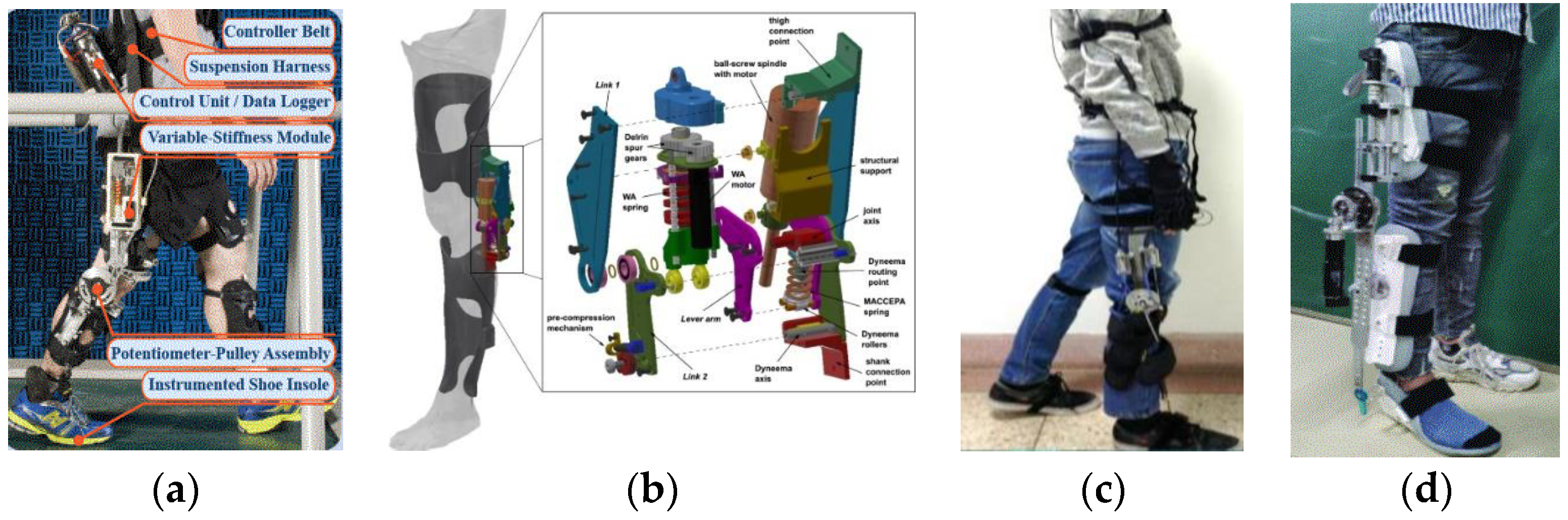

3.4. Other Actuators

4. Other Key Technologies

4.1. Motion Intention Recognition

4.2. Control Strategies

4.3. Performance Evaluation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, G.; Chan, C.K.; Guo, Z.; Yu, H. A review of lower extremity assistive robotic exoskeletons in rehabilitation therapy. Critical Review. Biomed. Eng. 2013, 41, 343–363. [Google Scholar]

- Chen, W.; Li, J.; Zhu, S.; Zhang, X.; Men, Y.; Wu, H. Gait recognition for lower limb exoskeletons based on interactive information fusion. Appl. Bionics Biomech. 2022, 9933018, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Attias, M.; Bonnefoy-Mazure, A.; De Coulon, G.; Cheze, L.; Armand, S. Feasibility and reliability of using an exoskeleton to emulate muscle contractures during walking. Gait Posture 2016, 50, 239–245. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, Q.; Wang, X.; Du, F.; Xi, R. Modeling and position control of a therapeutic exoskeleton targeting upper extremity rehabilitation. Proc. IMechE Part C J. Mech. Eng. Sci. 2017, 231, 4360–4373. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, S.; Xue, Q. Lower limb rehabilitation exoskeleton robot: A review. Adv. Mech. Eng. 2021, 13, 1–17. [Google Scholar] [CrossRef]

- Young, A.J.; Ferris, D.P. State of the art and future directions for lower limb robotic exoskeletons. IEEE T. Neur. Sys. Reh. 2017, 25, 171–182. [Google Scholar] [CrossRef]

- Babič, J.; Laffranchi, M.; Tessari, F.; Verstraten, T.; Novak, D.; Šarabon, N.; Ugurlu, B.; Peternel, L.; Torricelli, D.; Veneman, J.F. Challenges and solutions for application and wider adoption of wearable robots. Wearable Technol. 2021, 2, e14. [Google Scholar] [CrossRef]

- Asl, H.J.; Yamashita, M.; Narikiyo, T.; Kawanishi, M. Field-based assist-as-needed control schemes for rehabilitation robots. IEEE-ASME T. Mech. 2020, 25, 2100–2111. [Google Scholar] [CrossRef]

- Wang, D.; Lee, K.M.; Guo, J.; Yang, C.J. Adaptive knee joint exoskeleton based on biological geometries. IEEE-ASME T. Mech. 2014, 19, 1268–1278. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, G.; Zhang, L.; Gong, R.; Fu, P.; Han, B.; Li, H. Biomechanical effect of valgus knee braces on the treatment of medial gonarthrosis: A systematic review. Appl. Bionics Biomech. 2022, 4194472, 1–15. [Google Scholar] [CrossRef]

- Kim, J.H.; Shim, M.; Ahn, D.H.; Son, B.J.; Kim, S.-Y.; Kim, D.Y.; Baek, Y.S.; Cho, B.-K. Design of a knee exoskeleton using foot pressure and knee torque sensors. Int. J. Adv. Robot Syst. 2015, 12, 112. [Google Scholar] [CrossRef]

- Edrisi, K. Designing a backstepping sliding mode controller for an assistant human knee exoskeleton based on nonlinear disturbance observer. Mechatronics 2018, 54, 121–132. [Google Scholar]

- Chen, B.; Zi, B.; Wang, Z.; Qin, L.; Liao, W.-H. Knee exoskeletons for gait rehabilitation and human performance augmentation: A state-of-the-art. Mech. Mach. Theory 2019, 134, 499–511. [Google Scholar] [CrossRef]

- Mikolajczyk, T.; Ciobanu, I.; Badea, D.I.; Iliescu, A.; Pizzamiglio, S.; Schauer, T.; Seel, T.; Seiciu, P.L.; Turner, D.L.; Berteanu, M. Advanced technology for gait rehabilitation: An overview. Adv. Mech. Eng. 2018, 10, 1–19. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Shi, D.; Geng, Y. Design and control of an adaptive knee joint exoskeleton mechanism with buffering function. Sensors 2021, 21, 8390. [Google Scholar] [CrossRef]

- Karavas, N.; Ajoudani, A.; Tsagarakis, N.; Saglia, J.; Bicchi, A.; Caldwell, D. Tele-impedance based assistive control for a compliant knee exoskeleton. Robot Auton. Syst. 2015, 73, 78–90. [Google Scholar] [CrossRef]

- Shi, D.; Zhang, W.; Zhang, W.; Ding, X. A review on lower limb rehabilitation exoskeleton robots. Chin. J. Mech. Eng-En. 2019, 32, 1–11. [Google Scholar] [CrossRef] [Green Version]

- de Andrade, R.M.; Ulhoa, P.H.F.; Dias, E.A.F.; Filho, A.B.; Vimieiro, C.B.S. Design and testing a highly backdrivable and kinematic compatible magneto-rheological knee exoskeleton. J. Intel. Mat. Syst. Str. 2022. [Google Scholar] [CrossRef]

- Kardan, I.; Akbarzadeh, A. Robust output feedback assistive control of a compliantly actuated knee exoskeleton. Robot Auton. Syst. 2017, 98, 15–29. [Google Scholar] [CrossRef]

- Li, F.; Wang, Q.; Xie, Y.; Xie, H. Admittance control of four-link bionic knee exoskeleton with inertia compensation. Tech. Gaz. 2019, 27, 891–897. [Google Scholar]

- Li, Z.; Ma, W.; Yin, Z.; Guo, H. Tracking control of time-varying knee exoskeleton disturbed by interaction torque. ISA Trans. 2017, 71, 458–466. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Villamañan, M.D.; Gonzalez-Vargas, J.; Torricelli, D.; Moreno, J.C.; Pons, J.L. Compliant lower limb exoskeletons: A comprehensive review on mechanical design principles. J. Neuroeng. Rehabil. 2019, 16, 55. [Google Scholar] [CrossRef]

- Tiboni, M.; Borboni, A.; Vérité, F.; Bregoli, C.; Amici, C. Sensors and actuation technologies in exoskeletons: A review. Sensors 2022, 22, 884. [Google Scholar] [CrossRef] [PubMed]

- Tucker, M.R.; Shirota, C.; Lambercy, O.; Sulzer, J.S.; Gassert, R. Design and characterization of an exoskeleton for perturbing the knee during gait. Trans. Biomed. Eng. 2017, 64, 2331–2343. [Google Scholar] [CrossRef]

- Lee, K.M.; Guo, J. Kinematic and dynamic analysis of an anatomically based knee joint. J. Biomech. 2010, 43, 1231–1236. [Google Scholar] [CrossRef]

- Zoss, A.B.; Kazerooni, H.; Chu, A. Biomechanical design of the Berkeley lower extremity exoskeleton (BLEEX). IEEE/ASME T. Mech. 2006, 11, 128–138. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, G.; Han, B.; Wang, Z.; Li, H.; Jiao, Y. Assistive devices of human knee joint: A review. Robot Auton. Syst. 2020, 125, 103394. [Google Scholar] [CrossRef]

- Mavroidis, C.; Nikitczuk, J.; Weinberg, B.; Arango, R.; Danaher, G.; Jensen, K.; Leahey, M.; Pavone, R.; Pelletier, P.; Provo, A.; et al. Smart portable rehabilitation devices. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Long Beach, CA, USA, 24–28 September 2005; pp. 501–510. [Google Scholar]

- Pratt, J.E.; Krupp, B.T.; Morse, C.J.; Collins, S.H. The RoboKnee: An exoskeleton for enhancing strength and endurance during walking. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), New Orleans, LA, USA, 26 April–01 May 2004; pp. 2430–2435. [Google Scholar]

- Rifaï, H.; Mohammed, S.; Hassani, W.; Amirat, Y. Nested saturation based control of an actuated knee joint orthosis. Mechatronics 2013, 23, 1141–1149. [Google Scholar] [CrossRef]

- Shamaei, K.; Napolitano, P.C.; Dollar, A.M. Design and functional evaluation of a quasi-passive compliant stance control knee–ankle–foot orthosis. IEEE T. Neur. Sys. Reh. 2014, 22, 258–268. [Google Scholar] [CrossRef]

- Long, Y.; Peng, Y. Design and Control of a Quasi-direct Drive Actuated Knee Exoskeleton. J. Bionic Eng. 2022, 19, 678–687. [Google Scholar] [CrossRef]

- Yan, L.; Fan, L.; Xiao, J.; Wang, F. Dynamics analysis and simulation verification of a novel knee joint exoskeleton. J. Vibroeng. 2017, 19, 3008–3018. [Google Scholar]

- Elliott, G.; Marecki, A.; Herr, H. Design of a clutch–spring knee exoskeleton for running. J. Med. Devices 2014, 8, 031002. [Google Scholar] [CrossRef] [Green Version]

- Fisher, S.; Lucas, L.; Thrasher, T.A. Robot-assisted gait training for patients with hemiparesis due to stroke Top. Stroke Rehabil. 2011, 18, 269–276. [Google Scholar] [CrossRef]

- Riener, R.; Lünenburger, L.; Colombo, G. Human-centered robotics applied to gait training and assessment. J. Rehabil. Res. Dev. 2006, 43, 679–694. [Google Scholar] [CrossRef] [PubMed]

- Veneman, J.F.; Kruidhof, R.; Hekman, E.E.; Ekkelenkamp, R.; Van Asseldonk, E.H.; Van Der Kooij, H. Design and evaluation of the LOPES exoskeleton robot for interactive gait rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2007, 15, 379–386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ayad, S.; Ayad, M.; Megueni, A.; Spaich, E.G.; Struijk, L.N.S.A. Toward standardizing the classification of robotic gait rehabilitation systems. IEEE Rev. Biomed. Eng. 2018, 12, 138–153. [Google Scholar] [CrossRef] [Green Version]

- Saccares, L.; Sarakoglou, I.; Tsagarakis, N.G. iT-Knee: An exoskeleton with ideal torque transmission interface for ergonomic power augmentation. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots & Systems, Daejeon, Republic of Korea, 9–14 October 2016; pp. 780–786. [Google Scholar]

- Huber, M.; Eschbach, M.; Kazerounian, K.; Ilies, H.T. Functional evaluation of a personalized orthosis for knee osteoarthritis: A motion capture analysis. J. Med. Devices 2021, 15, 041003. [Google Scholar] [CrossRef]

- Choi, B.; Lee, Y.; Kim, Y.J.; Lee, J.; Lee, M.; Roh, S.G.; Park, Y.J.; Kim, K.; Shim, Y. Development of adjustable knee joint for walking assistance devices. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 1790–1797. [Google Scholar]

- Zhu, Y.; Nakamura, M.; Ito, N.; Fujimoto, H.; Horikuchi, K.; Wakabayashi, S.; Takahashi, R.; Terada, H.; Haro, H. Study of wearable knee assistive instruments for walk rehabilitation. J. Adv. Mech. Des. Syst. 2012, 6, 260–273. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, J.; Choi, B.; Lee, M.; Roh, S.-G.; Kim, K.; Seo, K.; Kim, Y.-J.; Shim, Y. Flexible gait enhancing mechatronics system for lower limb assistance (GEMS L.-TYPE). IEEE/ASME T. Mech. 2019, 24, 1520–1531. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Huang, T.-H.; Yu, S.; Li, Y.; Chen, T.; Carriero, A.; Oh-Park, M.; Su, H. Comfort-centered design of a lightweight and backdrivable knee exoskeleton. IEEE Robotic Autom. Let. 2018, 3, 4265–4272. [Google Scholar] [CrossRef]

- Ergin, M.A.; Patoglu, V.A. self-adjusting knee exoskeleton for robot-assisted treatment of knee injuries. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; pp. 4917–4922. [Google Scholar]

- Celebi, B.; Yalcin, M.; Patoglu, V. AssistON-knee: A self-aligning knee exoskeleton. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 03–07 November 2013. [Google Scholar]

- Kim, T.; Jeong, M.; Kong, K. Bio-inspired knee joint of a lower-limb exoskeleton for misalignment reduction. IEEE/ASME T. Mech. 2022, 27, 1223–1232. [Google Scholar] [CrossRef]

- Moon, D.H.; Kim, D.; Hong, Y.D. Development of a single leg knee exoskeleton and sensing knee center of rotation change for intention detection. Sensors 2019, 19, 3960. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Sui, D.; Ju, H.; An, Y.; Zhao, J.; Zhu, Y. Mechanical compliance and dynamic load isolation design of lower limb exoskeleton for locomotion assistance. IEEE/ASME T. Mech. 2022, 27, 5392–5402. [Google Scholar] [CrossRef]

- Caulcrick, C.; Huo, W.; Hoult, W.; Vaidyanathan, R. Human joint torque modelling with MMG and EMG during lower limb human-exoskeleton interaction. IEEE Robot Automa. Let. 2021, 6, 7185–7192. [Google Scholar] [CrossRef]

- Lee, T.; Lee, D.; Song, B.; Baek, Y.S. Design and control of a polycentric knee exoskeleton using an electro-hydraulic actuator. Sensors 2019, 20, 211. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meng, Q.; Zeng, Q.; Xie, Q.; Fei, C.; Kong, B.; Lu, X.; Wang, H.; Yu, H. Flexible lower limb exoskeleton systems: A review. NeuroRehab. 2022, 50, 367–390. [Google Scholar] [CrossRef]

- Petsch, S.; Rix, R.; Khatri, B.; Schuhladen, S.; Müller, P.; Zentel, R.; Zappe, H. Smart artificial muscle actuators: Liquid crystal elastomers with integrated temperature feedback. Sens. Actuators A: Phys. 2015, 231, 44–51. [Google Scholar] [CrossRef]

- Lee, D.; Song, B.; Park, S.Y.; Baek, Y.S. Development and control of an electro-hydraulic actuator system for an exoskeleton robot. Appl. Sci. 2019, 9, 4295. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Wang, Y.; Jiang, J.; Sun, B.; Cao, H. Unidirectional variable stiffness hydraulic actuator for load-carrying knee exoskeleton. Int. J. Adv. Robot Syst. 2017, 14, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Kaminaga, H.; Amari, T.; Niwa, Y.; Nakamura, Y. Development of knee power assist using backdrivable electro-hydrostatic actuator. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 5517–5524. [Google Scholar]

- Klein Rot, J.E. Evaluation of a force controlled pneumatically actuated knee orthosis. Master’s Thesis, University of Twente, Enschede, The Netherlands, 2021. [Google Scholar]

- Aoyagi, D.; Ichinose, W.E.; Harkema, S.J.; Reinkensmeyer, D.J.; Bobrow, J.E. A robot and control algorithm that can synchronously assist in naturalistic motion during body-weight-supported gait training following neurologic injury. IEEE T. Neur. Sys. Reh. 2007, 15, 387–400. [Google Scholar] [CrossRef]

- Zhao, W.; Song, A. Active motion control of a knee exoskeleton driven by antagonistic pneumatic muscle actuators. Actuators 2020, 9, 134. [Google Scholar] [CrossRef]

- Xiloyannis, M.; Alicea, R.; Georgarakis, A.-M.; Haufe, F.L.; Wolf, P.; Masia, L.; Riener, R. Soft robotic suits: State of the art, core technologies, and open challenges. IEEE T. Robot 2022, 38, 1343–1362. [Google Scholar] [CrossRef]

- Veneman, J.F.; Ekkelenkamp, R.; Kruidhof, R.; van der Helm, F.C.; van der Kooij, H. A series elastic-and bowden-cable-based actuation system for use as torque actuator in exoskeleton-type robots. Int. J. Robot. Res. 2006, 25, 261–281. [Google Scholar] [CrossRef]

- Jain, P.; Bera, T.K.; Singla, A.; Isaksson, M. Linear actuator–based knee exoskeleton for stand–sit–stand motions: A bond graph approach. Simul-T Soc. Mod. Sim. 2022, 98, 627–644. [Google Scholar] [CrossRef]

- Horst, R.W.; Marcus, R.R. Flexcva: A continuously variable actuator for active orthotics. In Proceedings of the International Conference of the IEEE Engineering in Medicine and Biology Society, New York, NY, USA, 30 August–3 September 2006; pp. 2425–2428. [Google Scholar]

- Kong, K.; Bae, J.; Tomizuka, M. A compact rotary series elastic actuator for human assistive systems. IEEE/ASME T. Mech. 2011, 17, 288–297. [Google Scholar] [CrossRef]

- Chen, G.; Qi, P.; Guo, Z.; Yu, H. Mechanical design and evaluation of a compact portable knee–ankle–foot robot for gait rehabilitation. Mech. Mach. Theory 2016, 103, 51–64. [Google Scholar] [CrossRef]

- Zhou, C.; Li, C.; Song, Y.; Lei, Y.; Wang, J.; Wang, C.; Zeng, F. Optimal design and command filtered backstepping control of exoskeleton with series elastic actuator. J. Dyn. Syst. Meas. Control 2022, 144, 091002. [Google Scholar] [CrossRef]

- Zhu, L.; Shi, X.; Chen, Z.; Zhang, H.-T.; Xiong, C.-H. Adaptive servomechanism of pneumatic muscle actuators with uncertainties. IEEE Trans. Ind. Electron. 2016, 64, 3329–3337. [Google Scholar] [CrossRef]

- Beyl, P.; Knaepen, K.; Duerinck, S.; Van Damme, M.; Vanderborght, B.; Meeusen, R.; Lefeber, D. Safe and compliant guidance by a powered knee exoskeleton for robot-assisted rehabilitation of gait. Adv. Robot. 2011, 25, 513–535. [Google Scholar] [CrossRef]

- Maeda, D.; Tominaga, K.; Oku, T.; Pham, H.T.T.; Saeki, S.; Uemura, M.; Hirai, H.; Miyazaki, F. Muscle synergy analysis of human adaptation to a variable-stiffness exoskeleton: Human walk with a knee exoskeleton with pneumatic artificial muscles. In Proceedings of the IEEE-RAS International Conference on Humanoid Robots, Osaka, Japan, 29 November–1 December 2012; pp. 638–644. [Google Scholar]

- Mohri, S.; Inose, H.; Yokoyama, K.; Yamada, Y.; Kikutani, I.; Nakamura, T. Development of endoskeleton type knee auxiliary power assist suit using pneumatic artificial muscles. In Proceedings of the IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Banff, AB, Canada, 12–15 July 2016; pp. 107–112. [Google Scholar]

- Veale, A.J.; Staman, K.; Van Der Kooij, H. Soft, wearable, and pleated pneumatic interference actuator provides knee extension torque for sit-to-stand. Soft Robot. 2021, 8, 28–43. [Google Scholar] [CrossRef]

- Cao, J.; Xie, S.Q.; Das, R. MIMO sliding mode controller for gait exoskeleton driven by pneumatic muscles. IEEE Trans. Control. Syst. Technol. 2017, 26, 274–281. [Google Scholar] [CrossRef] [Green Version]

- Aguilar-Sierra, H.; Lopez, R.; Yu, W.; Salazar, S.; Lozano, R. A lower limb exoskeleton with hybrid actuation. In Proceedings of the IEEE RAS/EMBS International Conference on Biomedical Robotics and Biomechatronics, Sao Paulo, Brazil, 12–15 August 2014; pp. 695–700. [Google Scholar]

- Cao, Y.; Huang, J.; Huang, Z.; Tu, X.; Mohammed, S. Optimizing control of passive gait training exoskeleton driven by pneumatic muscles using switch-mode firefly algorithm. Robotica 2019, 37, 2087–2103. [Google Scholar] [CrossRef]

- Sawicki, G.S.; Ferris, D.P. A pneumatically powered knee-ankle-foot orthosis (KAFO) with myoelectric activation and inhibition. J. Neuroeng. Rehabil. 2009, 6, 1–16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, Y.; Wu, Q.; Chen, B.; Xu, D.; Shao, Z. Design and evaluation of a novel torque-controllable variable stiffness actuator with reconfigurability. IEEE/ASME T. Mech. 2021, 27, 292–303. [Google Scholar] [CrossRef]

- Shamaei, K.; Cenciarini, M.; Adams, A.A.; Gregorczyk, K.N.; Schiffman, J.M.; Dollar, A.M. Biomechanical effects of stiffness in parallel with the knee joint during walking. IEEE Trans. Biomed. Eng. 2015, 62, 2389–2401. [Google Scholar] [CrossRef] [PubMed]

- Bacek, T.; Moltedo, M.; Rodriguez-Guerrero, C.; Geeroms, J.; Vanderborght, B.; Lefeber, D. Design and evaluation of a torque-controllable knee joint actuator with adjustable series compliance and parallel elasticity. Mech. Mach. Theory 2018, 130, 71–85. [Google Scholar] [CrossRef]

- Tian, M.; Wang, X.; Wang, J.; Gan, Z. Design of a lower limb exoskeleton driven by tendon-sheath artificial muscle. In Proceedings of the IEEE International conference on robotics and biomimetics (ROBIO), Dali, China, 6–8 December 2019; pp. 2037–2042. [Google Scholar]

- Chen, B.; Wang, B.; Zheng, C.; Zi, B. Design and simulation of a robotic knee exoskeleton with a variable stiffness actuator for gait rehabilitation. In Proceedings of the IEEE International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Shanghai, China, 26–28 November 2021; pp. 24–29. [Google Scholar]

- Cestari, M.; Sanz-Merodio, D.; Garcia, E. A new and versatile adjustable rigidity actuator with add-on locking mechanism (ARES-XL). Actuators 2018, 7, 11–21. [Google Scholar] [CrossRef] [Green Version]

- Baček, T.; Moltedo, M.; Geeroms, J.; Vanderborght, B.; Rodriguez-Guerrero, C.; Lefeber, D. Varying mechanical compliance benefits energy efficiency of a knee joint actuator. Mechatronics 2020, 66, 102318. [Google Scholar] [CrossRef]

- Zhang, J.; Cong, M.; Liu, D.; Du, Y.; Ma, H. A lightweight variable stiffness knee exoskeleton driven by shape memory alloy. Ind. Robot. Int. J. Robot. Res. Appl. 2022, 49, 994–1007. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, Q.; Cai, K.; Wang, Z.; Wang, W.; Liu, J. A wearable soft knee exoskeleton using vacuum-actuated rotary actuator. IEEE Access 2020, 8, 61311–61326. [Google Scholar] [CrossRef]

- Li, Y.; Hashimoto, M. Design and prototyping of a novel lightweight walking assist wear using PVC gel soft actuators. Sensors Actuat. A Phys. 2016, 239, 26–44. [Google Scholar] [CrossRef]

- Pamungkas, D.S.; Caesarendra, W.; Soebakti, H.; Analia, R.; Susanto, S. Overview: Types of lower limb exoskeletons. Electronics 2019, 8, 1283. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Wu, Q.; Chen, B.; Zhao, Z. Design and voluntary control of variable stiffness exoskeleton based on sEMG driven mode. IEEE Robot Autom. Lett. 2022, 7, 5787–5794. [Google Scholar] [CrossRef]

- Gui, K.; Tan, U.-X.; Liu, H.; Zhang, D. Electromyography-driven progressive assist-as-needed control for lower limb exoskeleton. IEEE Trans. Med. Robo. Bionics 2020, 2, 50–58. [Google Scholar] [CrossRef]

- Pinto-Fernandez, D.; Torricelli, D.; Sanchez-Villamanan, M.D.C.; Aller, F.; Mombaur, K.; Conti, R.; Vitiello, N.; Moreno, J.C.; Pons, J.L. Performance evaluation of lower limb exoskeletons: A systematic review. IEEE T. Neur. Sys. Reh. 2020, 28, 1573–1583. [Google Scholar] [CrossRef]

- Li, W.-Z.; Cao, G.-Z.; Zhu, A.-B. Review on control strategies for lower limb rehabilitation exoskeletons. IEEE Access 2021, 9, 123040–123060. [Google Scholar] [CrossRef]

- Chang, Y.J.; Liang, J.N.; Hsu, M.J.; Lien, H.Y.; Fang, C.Y.; Lin, C.H. Effects of continuous passive motion on reversing the adapted spinal circuit in humans with chronic spinal cord injury. Arc. Phys. Med. and Rehab. 2013, 94, 822–828. [Google Scholar] [CrossRef]

- Aguirre-Ollinger, G.; Colgate, J.E.; Peshkin, M.A.; Goswami, A. Design of an active one-degree-of-freedom lower-limb exoskeleton with inertia compensation. Ind. Robot 2011, 30, 486–499. [Google Scholar] [CrossRef]

- Mohammed, S.; Huo, W.; Huang, J.; Rifaï, H.; Amirat, Y. Nonlinear disturbance observer based sliding mode control of a human-driven knee joint orthosis. Robot Auton. Syst. 2016, 75, 41–49. [Google Scholar] [CrossRef]

- Lee, D.; McLain, B.J.; Kang, I.; Young, A.J. Biomechanical comparison of assistance strategies using a bilateral robotic knee exoskeleton. IEEE T. Bio-Med. Eng. 2021, 68, 2870–2879. [Google Scholar] [CrossRef]

- Shan, H.; Jiang, C.; Mao, Y.; Wang, X. Design and control of a wearable active knee orthosis for walking assistance. In Proceedings of the IEEE International Workshop on Advanced Motion Control (AMC), Auckland, New Zealand, 22–24 April 2016; pp. 51–56. [Google Scholar]

- Shamaei, K.; Cenciarini, M.; Adams, A.A.; Gregorczyk, K.N.; Schiffman, J.M.; Dollar, A.M. Design and evaluation of a quasi-passive knee exoskeleton for investigation of motor adaptation in lower extremity joints. IEEE T. Bio-Med. Eng. 2014, 61, 1809–1821. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Liao, Y.; Wang, C.; Wang, Q. Preliminary evaluation of gait assistance during treadmill walking with a light-weight bionic knee exoskeleton. In Proceedings of the IEEE International Conference on Robotics and Biomimetics (ROBIO), Qingdao, China, 03–07 December 2016; pp. 1173–1178. [Google Scholar]

- Pagani, C.H.F.; Potthast, W.; Brüggemann, G.P. The effect of valgus bracing on the knee adduction moment during gait and running in male subjects with varus alignment. Clin. Biomech. 2010, 25, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Kamali, K.; Akbari, A.A.; Akbarzadeh, A. Trajectory generation and control of a knee exoskeleton based on dynamic movement primitives for sit-to-stand assistance. Adv. Robot 2016, 30, 846–860. [Google Scholar] [CrossRef]

- Pagani, C.H.F.; Willwacher, S.; Kleis, B.; Brüggemann, G.P. Influence of a valgus knee brace on muscle activation and co-contraction in patients with medial knee osteoarthritis. J. Electromyogr. and Kinesiol. 2013, 23, 490–500. [Google Scholar] [CrossRef]

- Galle, S.; Malcolm, P.; Derave, W.; De Clercq, D. Adaptation to walking with an exoskeleton that assists ankle extension. Gait Posture 2013, 38, 495–499. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Tang, Y.; Zheng, J.; Dong, D.; Chen, X.; Bai, L. From sensing to control of lower limb exoskeleton: A systematic review. Annu. Rev. Control 2022, 53, 83–96. [Google Scholar] [CrossRef]

| Simplified Structure | Complex Structure | |

|---|---|---|

| construction of knee components | (a) a hinge with single degree of freedom; | (a) multi-bar mechanism; |

| (b) modular actuator with rotary motion; | (b) a pulley and several rolling cams; | |

| (c) self-adapting joint with Schmidt coupling, guide rail, bearing, etc.; | ||

| advantages | (a) Easy to design and light in weight; | (a) little or no effect on kinematics; |

| (b) kinematic analysis is very simple; | (b) adapt to the knee joint motion; | |

| (c) high accuracy of mechanical motion; | (c) suitable for highly recovery patients; | |

| disadvantages | (a) alignment and adjustability are difficult; | (a) require complex mechanisms; |

| (b) usually alter normal walking kinematics; | (b) can be bulky and high inertia; | |

| (c) may cause discomfort due to undesired constraints and forces; | (c) kinematic analysis is difficult; |

| Type of Actuator | Driving Devices | Advantages | Disadvantages |

|---|---|---|---|

| Conventional driving model | (a) linear hydraulic actuators; | (a) fast response speed; | (a) with large stiffness; |

| (b) linear pneumatic cylinder; | (b) easy to control; | (b) poor human-machine interaction; | |

| (c) motor in combination with (d) other transmission mechanisms; | (c) large drive and auxiliary torque; | (c) defects in the weight and drive flexibility; | |

| Pneumatic muscles | (a) antagonistic pleated PAMs; | (a) simple structure; | (a) slow response time; |

| (b) McKibben style PAMs; | (b) compliant driving; | (b) fixed movement; | |

| (c) straight-fiber-type PAMs; | (c) small motion inertia; | (c) low control precision; | |

| Variable stiffness actuators | (a) adopted the combination of series and parallel springs; | (a) behaves similar to biological muscles; | (a) multiple components and complex structure; |

| (b) clutchable elastic device based on Hill muscle model; | (b) adaptable to multiple application; | (b) the drive system is relatively bulky; | |

| (c) multi-configuration elastic driving model; | (c) friendly to user; | (c) lack of robustness; | |

| Other novel actuators | (a) shape memory alloy; | (a) soft, light and flexible; | (a) geometries must be exact; |

| (b) plasticized polyvinyl chloride; | (b) biomimicry; | (b) difficult to control; | |

| (c) other novel function material; | (c) high force/weight ratio; | (c) nonlinear hysteresis effect |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Yang, M.; Xia, Y.; Wang, L. Mechanical Structural Design and Actuation Technologies of Powered Knee Exoskeletons: A Review. Appl. Sci. 2023, 13, 1064. https://doi.org/10.3390/app13021064

Wu Z, Yang M, Xia Y, Wang L. Mechanical Structural Design and Actuation Technologies of Powered Knee Exoskeletons: A Review. Applied Sciences. 2023; 13(2):1064. https://doi.org/10.3390/app13021064

Chicago/Turabian StyleWu, Zongpeng, Mingxing Yang, Yulei Xia, and Liwei Wang. 2023. "Mechanical Structural Design and Actuation Technologies of Powered Knee Exoskeletons: A Review" Applied Sciences 13, no. 2: 1064. https://doi.org/10.3390/app13021064

APA StyleWu, Z., Yang, M., Xia, Y., & Wang, L. (2023). Mechanical Structural Design and Actuation Technologies of Powered Knee Exoskeletons: A Review. Applied Sciences, 13(2), 1064. https://doi.org/10.3390/app13021064