Abstract

The Food Supply Chain (FSC) can be made more efficient, resilient, and transparent by implementing industry 4.0 technologies. In this context, blockchain and the Internet of Things (IoT) become a panacea for several FSC problems. As a result of FSC complexity and their specific needs, the adoption of Blockchain integrated IoT (B-IoT) in FSC is challenging, and further investigation is required. Therefore, this study aims to explore the Critical Success Factors (CSFs) for the adoption B-IoT in FSC. To achieve this objective, a literature review is conducted to identify the CSFs of B-IoT adoption and then a grey Delphi is conducted on finalised CSFs. Ten CSFs finalised that faceplate for the adoption of B-IoT in FSC. Further, these CSFs were analysed through a grey Decision-Making Trial and Evaluation Laboratory (DEMATEL) to determine the importance and causal relationships among them. A grey DEMATEL analysis also categorised these factors into influencing and influenced groups. The findings showed that “top management support”, “knowledge management”, “technology hardware readiness”, “skilled personnel”, and “high investment” were the influencing factors that needed to be addressed for the effective adoption of B-IoT. The FSC partners could benefit from the findings of this study by focusing on high-priority CSFs. The causal relationship among CSFs also helps the managers achieve optimal utilisation of resources. Further, this study encourages the FSC stakeholders to adopt the B-IoT in their supply chain to improve their performance.

1. Introduction

Many countries consider the food sector to be the most important element of several economic activities, as it facilitates feeding the entire population and generating employment. This is achieved with the management of the various flows (product, money and information) between the different stakeholders of the FSC to satisfy the consumers’ needs. These flows are efficiently managed through the adoption of emerging technologies in FSC [1,2]. These emerging technologies such as blockchain, IoT and remote sensing devices are used in FSC for enhancing the information flows, improving FSC functions and customer services [3]. This technology makes it possible for FSC stakeholders to track soil, crops, and weather conditions, and to manage animal grazing and FSC activities in real-time [4].

Industry 4.0 and digital technologies facilitate performance improvements for the FSC and ensure food safety and security. Among these technologies, IoT and blockchain are considered promising technologies that have the potential to solve the several challenges of FSC. The challenges include the safety and security of food, the traceability of food, disruptions, and the food wastage. The authentication of food enhances the consumers’ trust and willingness to purchase food. For instance, using IoT, specific information can be tracked and stored from the beginning to the end of the production, processing, distribution, and depletion process [5]. In addition, blockchain-based authenticating and tracking of the information throughout the entire FSC helps to identify and address sources of contamination. Furthermore, blockchain-based technology is being used to enhance traceability and trust by providing verified supply chain information that can be accessed by all stakeholders [6,7]. It has become popular to utilize blockchains in supply chains to provide transparency and authenticity, and their efficiency has been explored by Wu et al. [8]. They found that blockchain-based traceability is improved significantly in comparison to traditional traceability systems. Blockchain-based technologies seem to offer a relatively higher level of security and reliability as well as greater transparency and traceability [9,10]. Therefore, the integration of IoT and blockchain contributes to making the FSC more efficient and sustainable [4,11].

Food fraud continues to increase, resulting in huge financial losses and undermining consumer confidence [12]. Examples include the detection of horse meat in multiple ground beef products found in Europe [13] and the seizure of 100,000 tons of expired meat in China in 2015 [14]. These incidents make consumers more aware of food products; they become more interested in product origin, processing, and other characteristics [15]. Therefore, the FSC must provide transparency, traceability, and product information to guarantee food safety and quality [16]. Adoption of B-IoT in the FSC might solve this problem of economic loss and consumer confidence [17]. B-IoT is regarded as a promising technology that has potential to provide solutions to an extensive range of supply chain issues [18,19]. The adoption of B-IoT improves supply chain performance through enabling transparency, traceability, and operational efficiency [17,20]. In this context, the food industry has begun promoting the deployment of B-IoT. Food industry professionals are seeking to adopt the B-IoT in FSC to manage real-time information related to food origin and other handling-related information with stakeholders.

While B-IoT offers many benefits to the FSC, its effective implementation seems quite challenging for the numerous FSC partners. Most of the studies focus on a single technology’s adoption, either IoT or Blockchain. For example, Aamer et al. [19] found that there are few IoT implementation studies in FSCs. Similarly, Khan et al. [21] focus on the acquiring of blockchain adoption in the FSC under the circumstances in India. In cases like this of large countries such as India, studies related to the integration of the adoption of blockchain and IoT are limited. Although B-IoT in FSC in emerging marketplaces have received increased attention, many FSC partners have expressed their concerns about the adoption of B-IoT in their FSC. To address this issue, this study attempted to answer the following questions:

- What CSFs facilitate the successful adoption of B-IoT in the FSC of emerging countries?

- How are these CSFs interrelated in the case of the adoption of B-IoT in the FSC?

- What is the significance of each CSF in the adoption of B-IoT for FSC?

As a result of the above-mentioned research questions, the following objectives will be pursued as part of this study:

- To identify the significant CSFs of B-IoT in the FSC

- To investigate the causal relationships among the CSFs of B-IoT in the FSC

- To provide recommendations for the adoption of B-IoT in the FSC.

In order to fulfill the research objectives, the literature review is conducted for the identification of the CSFs of B-IoT in the FSC. Further, these CSFs are assessed in the context of developing countries with the help of the grey Delphi method. After finalizing the CSFs, the causal relationship among them is explored with the grey DEMATEL. By achieving the mentioned objectives, the major contributions of this study are as follows:

- The identification of CSFs that influence the adoption of B-IoT for FSCs in emerging economies helps the supply chain managers to adopt the B-IoT for achieving operational excellence.

- The causal relationships among the CSFs are helpful for the policy planner and supply chain managers in making the adoption decision of B-IoT.

- The proposed framework highlights the application of the Muti Criteria Decision Making (MCDM) method in the area of FSC that could easily be adopted by the practitioners.

The remainder of the paper is organized as follows: Section 2 is devoted to a literature review about the B-IoT and its application in FSC; Section 3 provides the proposed research framework for analysis; data analysis and results are reported in Section 4; Section 5 discusses the research findings for valuable insights; Section 6 highlights the implications of the study; Section 7 provides the conclusions, limitations, and future scope.

2. Literature Review

It has become difficult to identify the origin of the product and how it has been made as a result of the globalization of supply chains, which typically involve multiple countries and actors. Second and third-tier suppliers are generally less known to companies. There are several issues associated with this, particularly when it comes to sharing the facts with end users and evaluating the validity of a product. Despite the increasing complexity of the FSC, consumers have become more demanding concerning preserving the quality of food and sustainability [22]. There is a strong correlation between this and the food industry. Ninety-four percent of consumers believe that clarity regarding how their food is manufactured is significant [13]. It may be possible to increase traceability and trust by adopting digital technologies such as B-IoT in the supply chain to diminish the distance between producers and consumers. The IoT is concerned with data collection and blockchain established to split secure facts out of the supply chain partners.

2.1. Integration of IoT and Blockchain

Several years ago blockchain was invented as a diffused records technology that enabled a series of time-stamped, immutable data records to be stored in a decentralized network, and it has been used in a diversity of applications, including finance [23], design [24], and agriculture [25]. It has been proven that blockchain’s decentralised, verifiable, and immutable properties have facilitated its adoption as a tool for enhancing supply chain traceability and for ensuring product origin over the past few years [26,27,28]. Blockchain technology offers supply chain lucidity and ensures the consistency of all data recorded on a distributed record book. However, it is matter of the solicitude that blockchain does not possess the potential to verify the reliability of data exchanged by supply chain actors that is relevant to supply chain events in computer-to-human interactions, since it is incapable of verifying the integrity of data uploaded by supply chain actors [29]. For instance, Jiang et al. [30] proposed a blockchain-based healthcare information exchange platform for the storage and sharing of large amounts of healthcare data.

It has been observed that the B-IoT could be an infusion to secure data sources as well as rectitude [31,32,33]. In order to collect and transfer data, it is not necessary to have on-the-scene or remote human interference, and that is made possible through the use of IoT devices [34]. By storing data on the blockchain system from IoT devices rather than human input, one can significantly reduce the probability of malicious data manipulation. The authenticity of the data will be enhanced, as well as the level of trust within the network. The integration of blockchain in IoT systems in order to ensure the safety and security of data [35,36]. A number of studies have demonstrated the importance of blockchain technology and the Internet of Things in addressing the data-related issues of trust, security, privacy, and integrity [37,38,39]. In the digital world, the combination of blockchain and IoT would seem like an ideal match because they complement each other’s limitations, but there are a number of challenges that must be overcome [40]. There are various challenges associated with blockchain implementation in IoT applications, including the need to deal with computation, storage, communication latency, and energy incompatibility, as previously reported [41,42].

Using blockchain as a transparent and transactional database, rapid and efficient generation and processing of information is possible. At the same time, IoT narrates the expansion of insert devices that can transmit data by way of a communication convention in order to provide data connectivity. There are many advantages that can be gained by integrating these two technologies [43]. It is difficult to integrate blockchain technology into IoT due to the constraints of limitations such as scalability, bandwidth, storage capacity, privacy, and legal permissions [44]. Tsang et al. [45] suggested that the FSC players should be able to obtain reliable and efficient tracing facts, goods and benchmarking data using B-IoT. Through B-IoT, privacy, security, data access control, and reporting issues can be identified [46,47]. In addition to increasing scalability, the integration of B-IoT will reduce third parties’ participation in the business operation [48,49]. Practitioners should develop plans for validating IoT data before processing it into the blockchain, because imprecise or invalid information can damage trust [46].

2.2. B-IoT in the Food Supply Chain

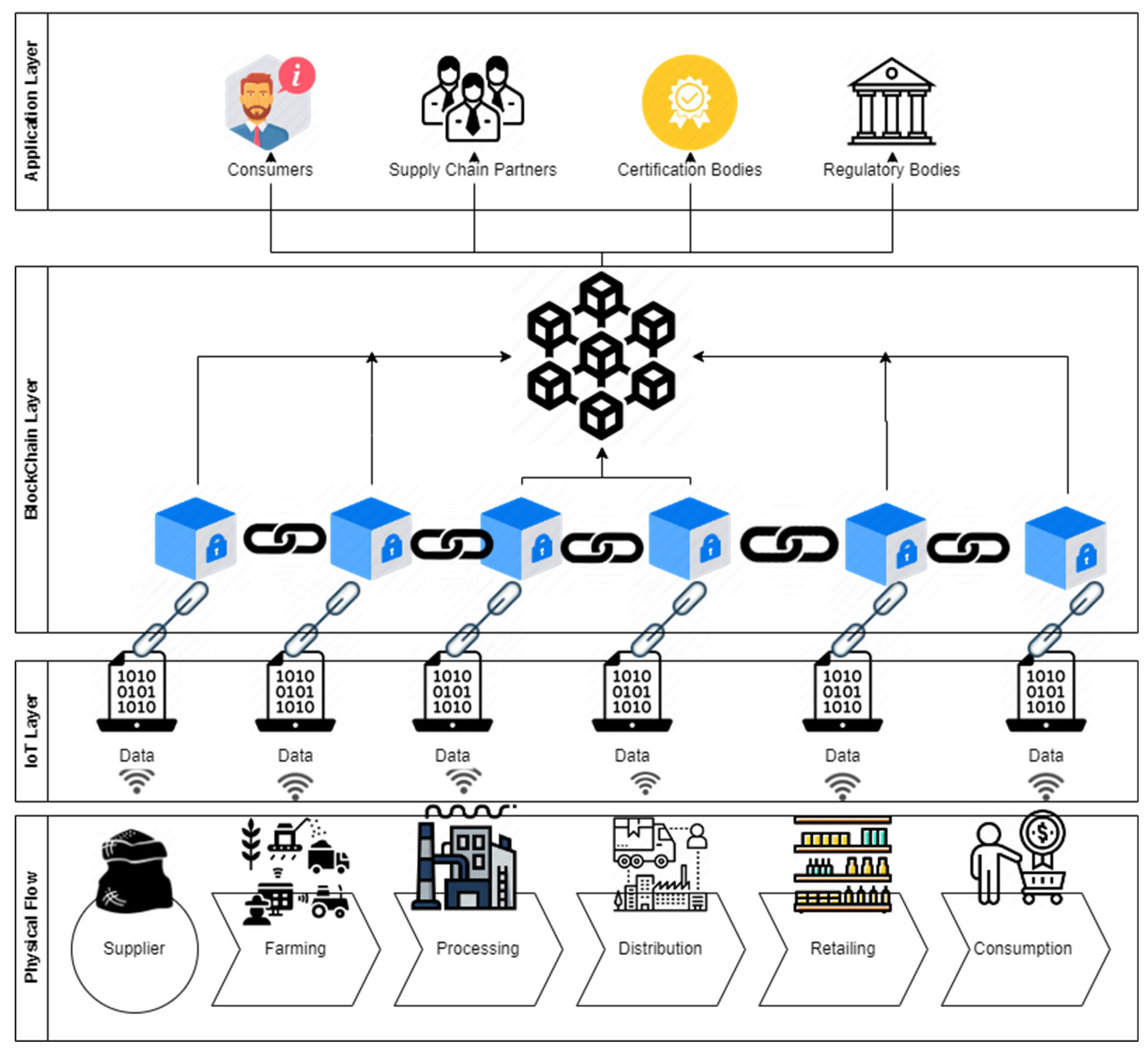

A multi-level distribution system is present in the food supply chain, which is composed of manufacturers, consigning companies, retailers, suppliers, and consumers [50]. Kamilaris et al. [51] have found that most of the business of food products between these competitors is driven by a negotiation mechanism, in which little value trade-off occurs in the process. In most countries, in local markets, there is a great deal of difficulty in tracing and tracking the origin, process, quality, and ecological footprint of goods that are purchased; therefore, there are concerns of food safety and security because it is difficult to trace goods. Kuokkanen et al. [52] have highlighted the lack of transparency relevant to the production and preparation of food, as well as the lack of footprints related to traceability, integrity, and food waste. The modern FSC poses a number of problems. It is essential that organizations embrace and manage modern technologies, including those that enable organizational, performance, scientific, and economic changes, in order to ensure food security and lucidity in the FSC [53]. A B-IoT-based food safety system that enhances food safety is one of the most important factors for enhancing e-governance and policy initiatives on improving food safety. The B-IoT enabled food supply chain is shown in Figure 1.

Figure 1.

B-IoT enabled FSC.

Based on a report by Astill et al. [13], B-IoT-enabled technical systems can be used to achieve accuracy in the FSC if the cost is not an obstacle. Devices that are used in FSC can be remotely controlled and monitored using the Internet of Things [54]. Further, the security concerns can be addressed by integrating these devices with distributed ledgers; IoT devices can be connected to the Internet of Things in order to ensure secure transactions of information. Kohler and Pizzol [55] investigated the benefits and disadvantages of implementing blockchain in the FSC as well as the trade-offs. They maintain that among the advantages are the elements of accountability, trust, traceability, and authenticity, while the disadvantages are the elements of permissions, stakeholder involvement, transaction time, and scalability issues. With the adoption of technologies such as B-IoT, food security and customer service will be improved through electronic culture. Wu et al. [56], address the issue of requirements, potential opportunities, and design principles for a blockchain in order to integrate with the supply chain. It also provides a better idea of how to handle the technical challenges while designing the blockchain enabled supply chain.

From the application perspective, Walmart is utilizing the IoT enabled by the B-IoT technology called Hyperledger fabric in order to track different kinds of foods (meats and poultry, dairy produce, multi-ingredient products, fruits, etc.) using an application that is based on the IoT [57]. In a recent announcement, the World Wildlife Fund-Australia has confirmed that it is currently developing an open-source web service called Open SC, which will help the B-IoT assist customers in preventing the consumption of illicit and unsafe food products. The B-IoT and its implementation, despite the limited disclosure of their practical advantages, still remain theoretical and under-developed, calling for further innovation and possible future applications [58,59].

3. Methodology

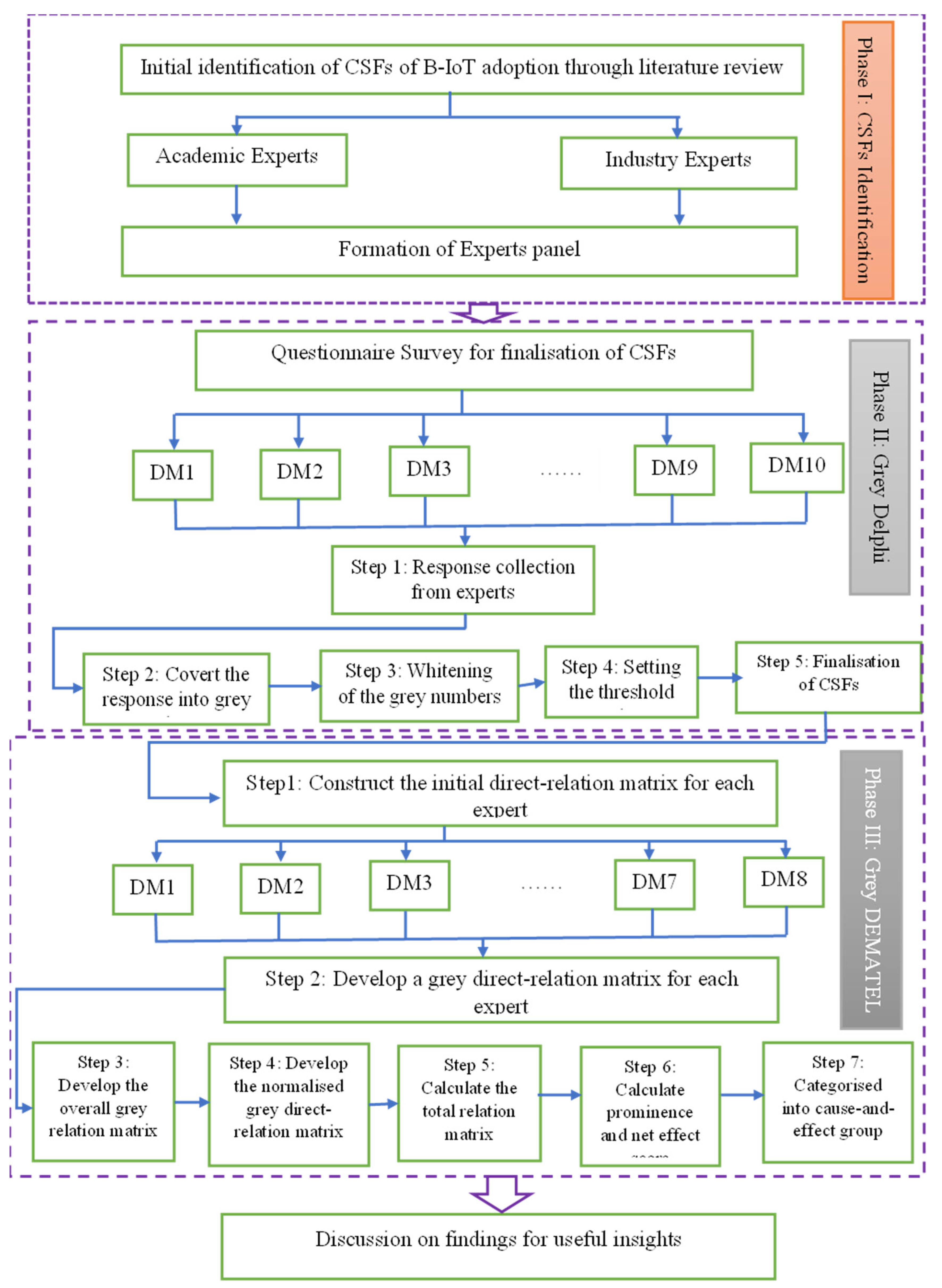

This study adopts a three-phase framework for achieving the mentioned research objectives. The first phase starts with the systematic literature review to identify the initial CSFs of B-IoT in FSC. A systematic literature review will be conducted using the Scopus database. The rationale behind the selection of the Scopus is that it is considered the largest database for peer review articles in the science and social science domain. Through the systematic review, initial CSFs are identified. The grey Delphi method is used for the finalization of the CSFs of B-IoT adoption in the FSC in the second phase. With the help of expert input, the relevant CSFs of B-IoT adoption are finalized using the grey Delphi method. After finalization of CSFs of B-IoT adoption, the grey DEMATEL is applied for the development of causal interrelationships among them. Numerous techniques, including Interpretive Structural Modelling (ISM), Total Interpretive Structural Modelling (TISM), Analytic Network Process (ANP), and DEMATEL are used in the literature to examine the causal relationships [60,61]. Despite the fact that ISM and TISM show the structural linkages between the CSFs, it does not show how strong the relationships are [62,63]. Using the DEMATEL approach, each relationship’s strength can be measured [63]. However, the subjectivity and vagueness of expert input are not efficiently addressed with the traditional DEMATEL technique. By combining grey theory with DEMATEL, these limitations can be improved [15,64]. Therefore, the grey DEMATEL appears suitable for the development of causal relationships among the CSFs. The purposed three-phase research framework is shown in Figure 2.

Figure 2.

Proposed framework for CSFs of B-IoT adoption in FSC.

3.1. Preliminaries

MCDM methods are based on the experts’ input, and these inputs have uncertainties. In order to address this issue, the theory of grey system [65] is selected and applied in various domains [66,67,68]. This study employs the grey systems theory with Delphi and DEMATEL dealing with the subjective data provided by the expert panel. The grey systems categorise the information into three categories: the fully certain information is categorised as white; inadequate information is categorised as grey; and absolute unknown information is shown as black [66,67]. In this study, the concept of interval grey numbers of the grey system theory is applied. Therefore, the essential definitions and operations of interval grey numbers are provided as follows:

Definition 1.

Suppose implies the interval grey number that could be expressed as:

where, shows the lower limit and depicts the upper limits of the information .

Definition 2.

The fundamental mathematical operations on the interval grey numbers are provided as follows:

Addition of two interval grey number is expressed as Equation (2):

Subtraction of interval grey number is expressed as Equation (3):

Multiplication of interval grey number is expressed as Equation (4):

Division of interval grey number is expressed as Equation (5):

Definition 3.

Usually, the whitenisation value (crisp value) of the interval grey number = [] is done withand could be done through Equation (6).

where,is the coefficient of whitenisation and the commonly used value foris 0.5, considering the equal weight mean whitenisation [68].

3.2. Grey Delphi

Dalkey and Helmer [69] proposed the Delphi approach. It is a popular survey methodology for synthesizing the opinion of experts on a specific issue to reach a mutual consensus [70,71]. The conventional Delphi method has some limitations such as multiple rounds to reach consciences, subjectivity, and expert biasness. These limitations could be overcome with the grey theory integration [72]. Therefore, Delphi and grey set theories are combined to create the grey Delphi approach. The following are the steps for the grey Delphi:

- Step 1: Identification of CSFs of B-IoT adoption in FSC

This step involves identifying the potential CSFs of B-IoT adoption in FSC through the literature review. Based on these CSFs, a questionnaire is developed to collect the data from the experts.

- Step 2: Response collection from experts

The developed questionnaire is being sent to experts, and they are required to provide their responses using the linguistic scale. The linguistic scales and grey numbers for each scale are listed in Table 1.

Table 1.

Linguistic scale and their associated grey number.

- Step 3: Overall evaluation using grey number

In accordance with Table 1, the responses have been converted into corresponding grey numbers. This grey number is used for integrating the responses of the experts. Consider the case of an expert panel consisting of k members. The evaluation of the factor is as follows:

where is the overall evaluation of CSF’s importance and denotes the hth expert’s evaluation of CSF ‘i’ of B-IoT adoption.

- Step 4: Whitening of the grey number

The grey number having the interval ( = [] = []) and their equivalent whitenisation value is . The whitenisation of grey numbers is obtained through Equation (6) as mentioned in preliminary section.

- Step 5: Setting threshold limit and CSFs selection

The final step of the grey Delphi method involves selecting and rejecting CSFs. In order to determine the significance of the factor, an overall score is calculated and compared to a threshold value (λ). If the value of ≥ λ, then the factor is selected; otherwise, it is rejected.

3.3. Grey DEMATEL

A grey DEMATEL approach combines grey theory and DEMATEL to address the incomplete information, subjectivities, and biases in expert input. Furthermore, this method can improve the accuracy of the observations [61,73]. Following is the stepwise procedure for grey DEMATEL [15,74]:

- Step 1: Construct the initial direct-relation matrix

Develop an initial direct relation matrix of CSFs (c = {ci|i = 1, 2,..., n}) of B-IoT adoption in FSC, utilizing the five-point grey linguistic scale (refer to Table 2), from “No Influence” to “Very High influence” by k experts through pair-wise comparisons.

Table 2.

Linguistics terms and their corresponding grey scales.

- Step 2: Develop a grey direct-relation matrix

The linguistic term is substituted with the corresponding grey number in order to convert the obtained initial direct relationship matrix into a grey initial direct relationship matrix. As K-number of experts provided their responses, the K grey direct relationship matrix ,…., is obtained. The direct-relation grey matrix is represented as follows by Equation (8):

The element of [X], = (, shows the influence of CSF ‘i’ on CSF ‘j’ by the kth expert. The represents the lower and the upper limit of grey values.

- Step 3: Develop the overall grey relation matrix

In order to formulate the overall grey relation matrix, we combine all grey direct-relation matrices by using Equation (9).

- Step 4: Express the normalised grey direct-relation matrix

In order to transform the grey relation matrix into a normalized grey direct-relation matrix N, Equations (4)–(6) are used.

- Step 5: Calculate the total relation matrix

The total relation matrix “T” is obtained from the normalized grey direct-relation matrix by using Equation (13).

where “I” is the grey identity matrix.

- Step 6: Compute the causal parameters

The Equations (14) and (15) are used to determine the causal parameter:

The Ri shows the influence of the CSF “i”, which infers the overall influence of CSFs, and the Cj represents the influence received by “j” by the other CSFs.

- Step 7: Calculate the prominence (Pi) and net effect (Ei)

The prominence (Pi) and net effect (Ei) score of the CSFs is determined using expressions (16) and (17):

The causal relationship graph is developed with the help of prominence (Pi) and the net effect (Ei) score. The net effect (cause) of CSF on the system is shown by the positive value of the Ei, whereas the net influence on the CSF is shown by the negative value of the Ei.

4. Data Analysis and Results

To finalise the CSFs of B-IoT adoption in FSC, a combination of a literature review and a grey Delphi approach is employed. Initially, a systematic literature review is done for the initial identification of CSFs for B-IoT in FSC. With the initial search of keywords in Scopus, the articles are identified for literature review. These keywords comprise “food supply chain”, “agri-food supply chain”, “agri-supply chain”, “blockchain”, “internet of things”, “IoT”, “factors”, “critical factors” and “critical success factors”. The search string is developed by combining these keywords through Boolean operators. After that, these strings are searched in the Scopus database that identifies the relevant articles. Furthermore, these articles are reviewed, and 14 CSFs of B-IoT are initially identified and shown in Table 3.

Table 3.

Initial CSFs of B-IoT adoption in FSC.

After the initial identification of CSFs of B-IoT adoption in FSC, the grey Delphi method is applied with the help of experts. To achieve a balanced view, experts from academia and industry are selected [61]. A group of industrial professionals from the FSC and technology development sectors has been identified to collect data, and each has at least eight years of experience in FSC management. These academic experts work in the areas of FSC and technology management or technology transfer in reputed academic institutes. Their selection was based on their expertise and knowledge in the field of FSC. A structured questionnaire was created to apply the grey Delphi approach, in order to get the data. The experts were given copies of this questionnaire and requested to respond. The experts have evaluated these CSFs and provided their responses. In this manner, 10 valid responses are collected and shown in Table 4.

Table 4.

Experts’ assessment for initial CSFs of B-IoT adoption in FSC.

Following the expert group’s responses, we transformed the linguistic value into grey numbers using Table 1. Table 5 shows the resulting grey value that is used for further process as grey Delphi steps.

Table 5.

Grey data as inputs to the grey Delphi method.

Further, Equation (7) is also used to calculate the overall grey weight. Whitening the grey weight (i.e., crisp number) is done using Equation (8). These crisp numbers are used to accept or reject the CSFs for analysis. Based on some studies such as [86,87], 3.5 is the threshold value () for crisp numbers. In other words, if the crisp value exceeds 3.5, then the CSF is considered relevant; otherwise, it is excluded. Table 6 shows the overall grey and crisp weights along with the decision.

Table 6.

Results of the grey Delphi method.

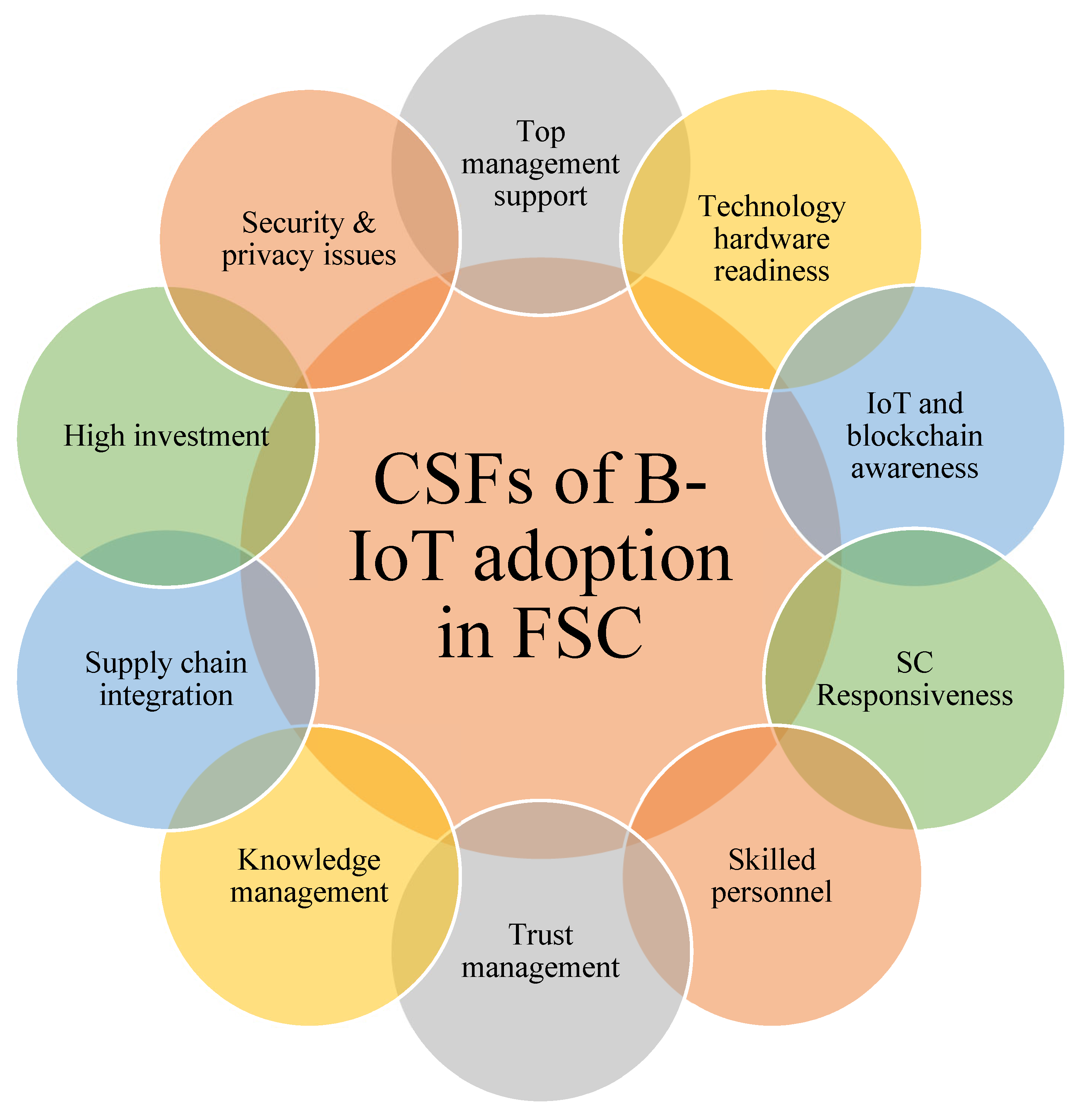

The results of the grey Delphi shows ten significant CSFs to B-IoT adoption in FSC, as shown in Table 6. These ten CSFs are important for FSC stakeholders in order to effectively adopt the B-IoT in the FSC. These CSFs range from policy to operational and are presented in Figure 3.

Figure 3.

CSFs of B-IoT adoption in FSC.

Grey DEMATEL Analysis

An analysis of the grey DEMATEL is conducted to determine the causal relationships between the CSFs of the B-IoT adoption in the CSFs. To help the experts know the research process, we first highlighted the objectives of this study and gave them a brief outline of the grey DEMATEL. Additionally, experts were asked to share their opinions related to the influence of one CSF on another, using the linguistic scale in the form of a direct-relationship matrix. Using the associated grey number, the obtained original direct relationship matrices are converted into grey relationship matrices. As eight experts provided their responses, eight grey relationship matrices are obtained. These matrices are combined to create a global grey relation matrix, which is displayed in Table 7.

Table 7.

Overall grey relation matrix of CSFs of B-IoT adoption in FSC (Z).

A normalized grey direct-relation matrix is then generated using Equations (10)–(12) from a grey direct-relation matrix. Further, Equation (1) is applied to transform this normalized grey relation matrix (see Table 8) into a total relationship matrix, as shown in Table 9.

Table 8.

Normalised grey direct-relation matrix (N) of CSFs of B-IoT adoption in FSC.

Table 9.

Total relation matrix of the enablers (T) of CSFs of B-IoT adoption in FSC.

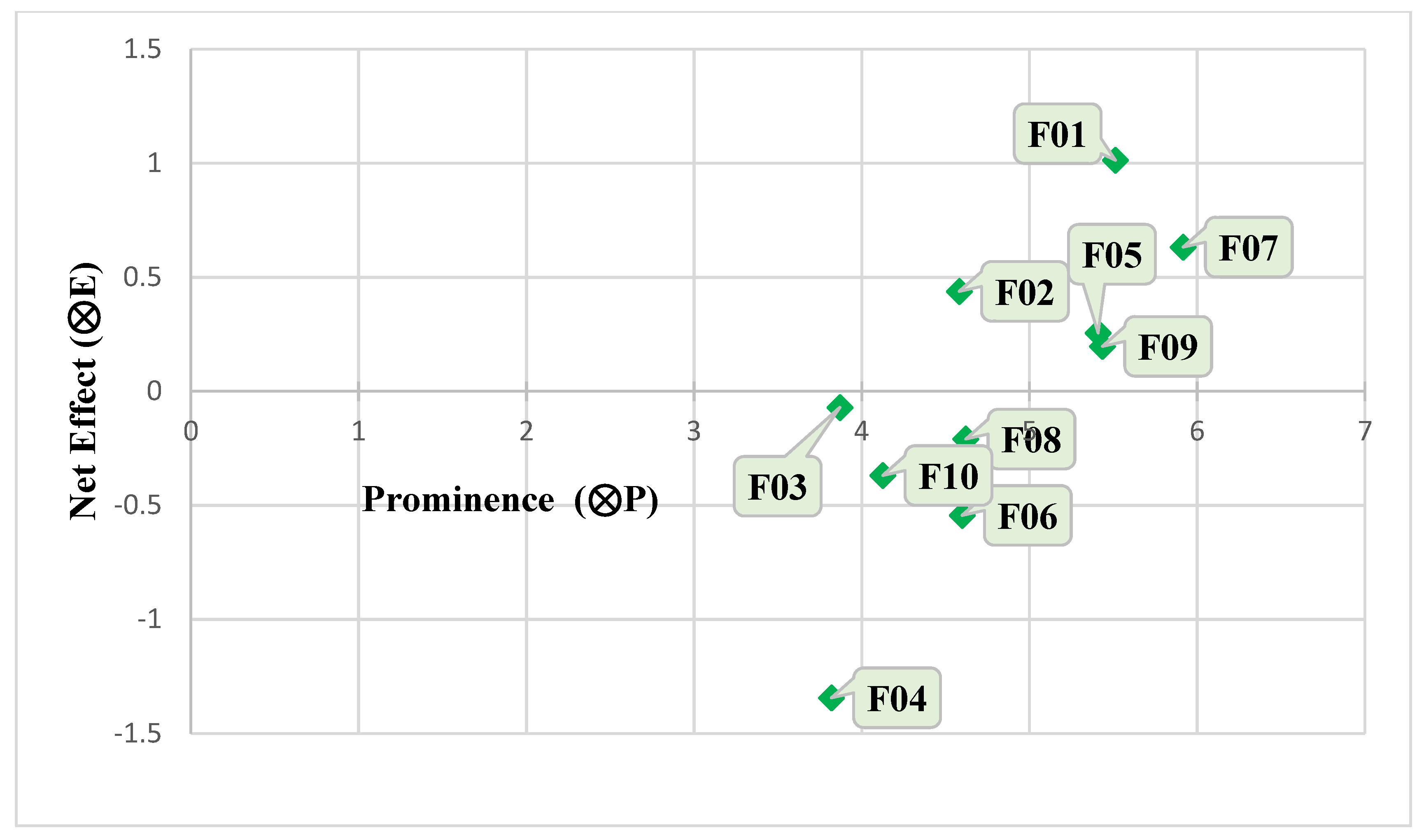

In order to estimate the causal parameters, the total relation matrix is used. The total relation matrix’s column-wise summation (using Equation (16)) is indicated by ⊗Ci, while its row-wise summation (using Equation (8)) is displayed as ⊗Ri. Using Equations (17) and (18), the prominence (⊗Pi) and net effect (⊗Ei) are calculated. Table 10 illustrates the prominence (⊗Pi) and net effect (⊗Ei) scores and their crisp values. Based on the value of the net effect score (Ei), the CSFs are classified into cause-and-effect categories.

Table 10.

Prominence and net effect score of CSFs of B-IoT adoption in FSC.

The ⊗Ri signifies the net effect of CSFs ‘i’ on other CSFs ‘j’, and ⊗Ci implies that CSF ‘j’ is influenced by other CSFs. In addition to this, the prominence (⊗Pi) score of each CSF may be used to assess its significance in adopting B-IoT in the FSC. Further, the ⊗Ei represents the net effect/cause of the CSF ‘i’ of B-IoT adoption in the FSC. Depending on the sign (positive/negative) of ⊗Ei, the CSFs are classified. The associated CSFs belong to the cause group if the value of ⊗Ei is positive; if not, it belongs to the effect group. The cause-and-effect group is determined for each CSF as per the sign ⊗Ei and presented in Table 6. In addition, the causal diagram is constructed by mapping the value of (⊗Pi)m and (⊗Ei)m, as shown in Figure 4.

Figure 4.

Causal relationship among the CSFs of B-IoT adoption FSC.

5. Discussion

The adoption of IoT and blockchain significantly improves the performance of the FSC. Therefore, the adoption of the B-IoT is beneficial for the FSC partner and improves traceability and transparency. The CSFs of the B-IoT are analysed with grey DEMATEL by determining the importance and causal relationship among them. The importance order is ‘knowledge management’, ‘top management support’, ‘high investment’, ‘skilled personnel’, ‘supply chain integration’, ‘trust management’, ‘technology hardware readiness’, ‘security & privacy issues’, ‘IoT and blockchain awareness’, and ‘SC responsiveness’. The result shows that knowledge management is an essential factor in the adoption of B-IoT. As B-IoT is a relatively new technology and FSC partners are less aware of its importance and impact, knowledge management is quite important. Without management support, any new technology cannot be possible and the same is true for the B-IoT. In order to implement the B-IoT, investment is required that could be facilitated through government funding to ensure food security. Further, the FSC stakeholder needs to develop a skilled human resource that could enable the adoption of B-IoT. These CSFs facilitate the adoption of B-IoT that leads towards SC integration and responsiveness, trust management, security, and privacy issue solutions.

5.1. Influencing CSFs

The DEMATEL analysis categorised the CSFs into influential and influenced groups. The influential group consisted of those CSFs that have a positive value of effect score. The influential CSFs include “top management support”, “knowledge management”, “technology hardware readiness”, “skilled personnel”, and “high investment”. Among these CSFs, top management support is the most influential CSF for the adoption of the B-IoT. Whenever an organisation decides to implement the latest technology, it is the top management that makes the decision. As B-IoT is a relatively new concept for the top management, they are not certain about their impact on the FSC. In that circumstance, top management needs to gain some knowledge regarding the impact of B-IoT on FSC to make a better decision. This top management support is required in terms of willingness to adopt the B-IoT and financial assistance. These CSFs have a high influence on the influenced CSFs, such as creating awareness about the blockchain and IoT.

Knowledge management is also an influencing CSF as it has a significant impact on the other CSFs. As architecture and planning of a B-IoT network for the FSC are difficult [88], knowledge management is considered a key to the successful adoption of B-IoT. FSC partners should be prepared for the practices regarding knowledge management for the successful adoption of B-IoT. Another major CSF is the “technology hardware readiness” that is the prerequisite for any technology adoption. Hardware includes sensors for data collection, geo-tag devices, secure data storage media, high-speed internet connection, a blockchain infrastructure, and other relevant accessories. An Internet connection is required in smart farming areas, as is ensuring that all supply chain partners can access it. It has been observed that a number of actors in the FSC are located in areas with varying Internet penetration rates that must be resolved before the adoption of B-IoT [18,89]. These infrastructures facilitate the successful adoption of B-IoT in FSC. In the context of emerging countries, the arrangement of such facilities/infrastructure is considered a major challenge. Therefore, the FSC partners need to push themselves to obtain this hardware infrastructure. In order to install, operate, and maintain this hardware, skilled human resources are required who have a good understanding of FSC operations. The skilled personnel also help to create an efficient design of the B-IoT architecture that is helpful to reduce operational and maintenance costs. Further, skilled personnel influence the creation of IoT and blockchain awareness among the FSC partners through training programs.

The next influencing CSF is the ‘high investment’ that is required for developing the hardware infrastructure and skill acquisition. During the implementation phase, technology costs, which are often associated with the viability of B-IoT adoption, are a significant CSF. Operational and maintenance costs hinder the implementation of B-IoT in the FSC [21]. A number of factors contribute to this situation, including the high cost of smart devices, the high cost of repair and maintenance, and the high cost of training employees to use IoT and blockchain technologies [90,91]. For the FSC partners, B-IoT is considered a costly affair and they are not certain about the return on investment. Therefore, the FSC managers needed to address the pros and cons of B-IoT so that they could make better decisions.

5.2. Influenced CSFs

The Grey DEMATEL analysis also identified the influenced CSFs for the adoption of B-IoT in FSC. It is necessary for FSC managers, government officials, and food authorities to focus on these CSFs to successfully implement the B-IoT. These influenced CSFs are affected by the other influencing CSFs; therefore, the performance of these CSFs could be improved by implementing influencing CSFs. The influencing factors include “IoT and blockchain awareness”, “supply chain integration”, “security & privacy issues”, “trust management”, and “SC responsiveness”. The IoT and blockchain awareness have a significant impact on the adoption of B-IoT in FSC. Blockchain-based IoT solutions may not be appreciated by end users in the agricultural sector. As a result, consumers should be educated and informed about the uses and benefits of IoT and blockchain in the food industry by providing them with training [92]. Experts also believed that, despite an influenced CSF, this CSF is playing an influential and vital role in the adoption of B-IoT. Further, the SC integration will improve through the adoption of B-IoT. Security and privacy are major concerns in the adoption of B-IoT in FSC [93,94], and they are also influenced by other CSFs. In order to share the information, trust management is the key, which is dependent on several influential CSFs, such as top management support, skilled personnel, and investment. With the adoption of B-IoT, the SC become more responsive, which will ultimately improve its performance.

6. Implications

The IoT and blockchain are still in the developmental stages and their integration is quite new [28]. Therefore, FSC partners focus on their technological needs and associated advantages. In order to gain a competitive edge and secure the FSC, B-IoT is considered a solution. In this regard, the present study contributes to the understanding of the cause-effect relationships among the CSFs and the ranking of these factors to assist decision-makers in making effective decisions for the efficient adoption of B-IoT. The causal relationship map among the CSFs is shown to help the policy planner formulate their policies as per their interaction. Additionally, this study guides managers of organisations, IoT solution providers, and governmental organizations in regard to the formulation and implementation of new policies and strategies or modifications to the existing ones, in order to achieve effective adoption of B-IoT in the FSC. The identified CSFs are beneficial for the management to adopt B-IoT by focusing on these factors

The most significant CSF is knowledge management and that needs to be addressed by all FSC partners. The management should focus on knowledge management to efficiently shift their process to a new platform. The results of this study may motivate the managers of FSC organizations to invest more in emerging technologies, such as blockchain and IoT. The cause-and-effect relationships help managers to effectively utilise their resources by focusing on the influential group CSFs. Among these factors, top management support is highly influential. Therefore, there is a need to develop awareness about the benefits of B-IoT among the FSC managers so they can invest in such technologies. The finding suggests that management knowledge is the most influential CSF, and this could be developed on the supply chain level. In addition to this, this study suggests developing the hardware infrastructure and recruiting skilled human resources for the effective adoption and management of B-IoT. This highlights issues of security and privacy, since information about the origin, transportation, and processing technique is required for the adoption of B-IoT.

7. Conclusions

Conventionally, the FSC has continued to follow its traditional pattern of doing its operations and maintaining the coordination between different supply chain members. Currently, this sector is experiencing rapid growth and has started to adopt advanced technologies in farming, logistics, processing, and packaging of food products. Among these technologies, blockchain and IoT are considered a solution to several FSC challenges such as traceability, quality assessment, and coordination among supply chain partners. Therefore, this study is conducted to explore the adoption of the B-IoT in the FSC. As a result of the literature review, fourteen CSFs for the adoption of B-IoT have been identified. The CSFs are finalized using the grey Delphi method in combination with expert input. The findings indicate the presence of ten significant CSFs for the implementation of B-IoT in the FSC. These CSFs exist in relation to the operational and to the policy levels. Further, these identified CSFs have been examined to gain insight into them. After the identification of these CSFs, the causal relationships among these CSFs are explored with the help of the grey DEMATEL method. The grey DEMATEL method is utilised for the categorisation of the CSFs into influential and influence groups. The influential group consists of five CSFs including “top management support”, “knowledge management”, “technology hardware readiness”, “skilled personnel” and “high investment”. These CSFs are highly influential, so management needs to address these factors on a priority basis. The findings of this study motivate managers to adopt the B-IoT in their supply chain to improve their performance. Further, the causal relationships among the CSFs facilitates optimal utilisation of their resources.

The limitation of this study provides scope for its extension. The first limitation of this study is that the CSFs of B-IoT are identified through the literature review, and there is a possibility of overlooking some significant CSFs. In addition to this, the finalisation of CSFs is also influenced by the experts’ opinions and biases with respect to their working position and supply chain structure. Furthermore, the integration of blockchain and IoT is rarely studied, thus there is limited scope for the validation of the findings with existing literature. In addition to the modelling, this study could be extended by prioritisation of the CSFs using the Analytic Hierarchy Process (AHP), ANP, Best Worst Method (BWM), and Proximity Indexed Value (PIV) methods. The grey DEMATEL method develops the cause-and-effect relationships among the CSFs, which is based on the limited number of experts. In future studies, the sample size of experts could be increased to get more generalized findings. Further, the grey set theory is applied to deal with the subjectivity that could be addressed by using the type 2 fuzzy number or Z number in future studies. In addition to this, the findings could be validated with multiple case studies. Instead of the grey DEMATEL method, other modelling tools such as ISM, TISM, and the Weighted Influence Non-linear Gauge System (WINGS) could be used in future studies. This study could be extended to other supply chains, such as the Agri-food supply chain, electronic supply chain, and dairy supply chain. Qualitative studies based on these CSFs are also done with the help of advanced statistical tools such as Structural Equation Modeling (SEM), Partial Least Squares Structural Equation Modeling (PLS-SEM) and other multivariate analyses.

Author Contributions

R.S. and S.K. conceived the idea. J.D. surveyed the literature and found factors and collected the responses. S.K. contributed to the analysis, S.K. and R.S. wrote the paper, and P.C. edited the original draft and administered the project. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Symbol | Description |

| Co-efficient of whitenisation | |

| λ | Threshold value for acceptance of CSFs |

| Whitenisation value of grey number | |

| Ith Interval grey number | |

| ⊗ | Ith Interval grey number provided by hth expert |

| ⊗Ci | Column-wise summation of grey total relationship matrix |

| ⊗Ei | Net effect score |

| ⊗I | Grey identity matrix |

| ⊗Pi | Prominence score |

| ⊗Ri | Row-wise summation of grey total relationship matrix |

| ⊗T | Grey total relationship matrix |

| X | Grey direct relationship matrix |

| Influence of i on j by kth expert using grey number | |

| ⊗Z | Overall grey relation matrix |

| ANP | Analytic Network Process |

| B-IoT | Blockchain integrated Internet of Things |

| BWM | Best Worst Method |

| CSF | Critical Success Factor |

| DEMATEL | Decision-Making Trial and Evaluation Laboratory |

| DM | Decision Maker |

| FSC | Food Supply Chain |

| IoT | Internet of Things |

| ISM | Interpretive Structural Modelling |

| K | Number of experts |

| MCDM | Muti Criteria Decision Making |

| N | Normalized grey direct-relation matrix |

| PIV | Proximity Indexed Value |

| PLS-SEM | Partial Least Squares Structural Equation Modelling |

| SEM | Structural Equation Modelling |

| SC | Supply Chain |

| TISM | Total Interpretive Structural Modelling |

| WINGS | Weighted Influence Non-linear Gauge System |

| [X] | Direct relationship matrix |

References

- Nikkilä, R.; Seilonen, I.; Koskinen, K. Software architecture for farm management information systems in Precision Agriculture. Comput. Electron. Agric. 2010, 70, 328–336. [Google Scholar] [CrossRef]

- Kumar, S.; Raut, R.D.; Agrawal, N.; Cheikhrouhou, N.; Sharma, M.; Daim, T. Integrated blockchain and internet of things in the food supply chain: Adoption barriers. Technovation 2022, 118, 102589. [Google Scholar] [CrossRef]

- Krithika, L.B. Survey on the applications of Blockchain in Agriculture. Agriculture 2022, 12, 1333. [Google Scholar] [CrossRef]

- Feng, H.; Wang, X.; Duan, Y.; Zhang, J.; Zhang, X. Applying blockchain technology to improve agri-food traceability: A review of development methods, benefits and challenges. J. Clean. Prod. 2020, 260, 121031. [Google Scholar] [CrossRef]

- Yan, B.; Fan, J.; Cai, C.; Fang, J. Supply Chain Coordination of fresh agri-products based on value loss. Oper. Manag. Res. 2020, 13, 185–196. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Sarkis, J. Blockchain practices, potentials, and perspectives in greening supply chains. Sustainability 2018, 10, 3652. [Google Scholar] [CrossRef]

- Pearson, S.; May, D.; Leontidis, G.; Swainson, M.; Brewer, S.; Bidaut, L.; Frey, J.G.; Parr, G.; Maull, R.; Zisman, A. Are distributed ledger technologies the panacea for food traceability? Glob. Food Sec. 2019, 20, 145–149. [Google Scholar] [CrossRef]

- Wu, H.; Cao, J.; Jiang, S. High-efficiency Blockchain-based Supply ChainTraceability. IEEE Trans. Intell. Transp. Syst. 2022. [Google Scholar] [CrossRef]

- George, R.V.; Harsh, H.O.; Ray, P.; Babu, A.K. Food quality traceability prototype for restaurants using blockchain and food quality data index. J. Clean. Prod. 2019, 240, 118021. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Ren, S.; Yang, M.; Wang, Y.; Huisingh, D. How can smart technologies contribute to sustainable product lifecycle management? J. Clean. Prod. 2019, 248, 119423. [Google Scholar] [CrossRef]

- Olsen, P.; Borit, M. The components of a food traceability system. Trends Food Sci. Technol. 2018, 77, 143–149. [Google Scholar] [CrossRef]

- Galvez, J.; Mejuto, J.; Simal-Gandara, J. Future challenges on the use of blockchain for food traceability analysis. TrAC Trends Anal. Chem. 2018, 107, 222–232. [Google Scholar] [CrossRef]

- Astill, J.; Dara, R.; Campbell, M.; Farber, J.; Fraser, E.; Sharif, S.; Yada, R. Transparency in food supply chains: A review of enabling technology solutions. Trends Food Sci. Technol. 2019, 91, 240–247. [Google Scholar] [CrossRef]

- World Economic Forum. Innovation with a Purpose: Improving Traceability in Food Value Chains through Technology Innovations; World Economic Forum: Geneva, Switzerland, 2019. [Google Scholar]

- Haleem, A.; Khan, S.; Khan, M. Traceability implementation in food supply chain: A grey-DEMATEL approach. Inf. Process. Agric. 2019, 6, 335–348. [Google Scholar] [CrossRef]

- Nagarajan, S.M.; Deverajan, G.G.; Chatterjee, P.; Alnumay, W.; Muthukumaran, V. Integration of IoT based routing process for food supply chain management in sustainable smart cities. Sustain. Cities Soc. 2022, 76, 103448. [Google Scholar] [CrossRef]

- Visconti, P.; de Fazio, R.; Velázquez, R.; Del-Valle-Soto, C.; Giannoccaro, N. Development of Sensors-Based Agri-Food Traceability System Remotely Managed by a Software Platform for Optimized Farm Management. Sensors 2020, 20, 3632. [Google Scholar] [CrossRef]

- Narwane, V.; Gunasekaran, A.; Gardas, B. Unlocking adoption challenges of IoT in Indian Agricultural and Food Supply Chain. Smart Agric. Technol. 2022, 2, 100035. [Google Scholar] [CrossRef]

- Aamer, A.M.; Al-Awlaqi, M.A.; Affia, I.; Arumsari, S.; Mandahawi, N. The internet of things in the food supply chain: Adoption challenges. Benchmarking Int. J. 2021, 28, 2521–2541. [Google Scholar] [CrossRef]

- Balamurugan, S.; Ayyasamy, A.; Joseph, K. IoT-Blockchain driven traceability techniques for improved safety measures in food supply chain. Int. J. Inf. Technol. 2021, 14, 1087–1098. [Google Scholar] [CrossRef]

- Khan, S.; Singh, R.; Haleem, A.; Dsilva, J.; Ali, S. Exploration of Critical Success Factors of Logistics 4.0: A DEMATEL Approach. Logistics 2022, 6, 13. [Google Scholar] [CrossRef]

- Behnke, K.; Janssen, M.F.W.H.A. Boundary conditions for traceability in food supply chains using blockchain technology. Int. J. Inf. Manag. 2019, 52, 1. [Google Scholar] [CrossRef]

- Hassani, H.; Huang, X.; Silva, E. Banking with blockchain-ed big data. J. Manag. Anal. 2018, 5, 256–275. [Google Scholar] [CrossRef]

- Foth, M. The promise of blockchain technology for interaction design. In Proceedings of the 29th Australian Conference on Computer-Human Interaction, Brisbane, QLD, Australia, 28 November–1 December 2017; ACM: New York, NY, USA, 2017; pp. 513–517. [Google Scholar] [CrossRef]

- Khan, S.; Kaushik, M.K.; Kumar, R.; Khan, W. Investigating the barriers of Blockchain Technology Integrated Food Supply Chain: A BWM approach. Benchmarking Int. J. 2022. [Google Scholar] [CrossRef]

- Kim, H.M.; Laskowski, M. Toward an ontology-driven blockchain design for supplychain provenance. Intell. Syst. Account. Finance Manag. 2018, 25, 18–27. [Google Scholar] [CrossRef]

- Salah, K.; Nizamuddin, N.; Jayaraman, R.; Omar, M. Blockchain-based soybean traceability in agricultural supply chain. IEEE Access 2019, 7, 73295–73305. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, S.; Lopez, C.; Lu, H.; Elgueta, S.; Chen, H.; Boshkoska, B.M. Blockchain technology in Agri-Food Value Chain Management: A synthesis of applications, challenges and future research directions. Comput. Ind. 2019, 109, 83–99. [Google Scholar] [CrossRef]

- Malik, S.; Dedeoglu, V.; Kanhere, S.S.; Jurdak, R. Trust Chain: Trust management in blockchain and iot supported supply chains. In Proceedings of the IEEE International Conference on Blockchain (Blockchain), Atlanta, GA, USA, 14–17 July 2019; pp. 184–193. [Google Scholar] [CrossRef]

- Jiang, S.; Cao, J.; Wu, H.; Yang, Y.; Ma, M.; He, J. BlocHIE: A BLOCkchain-Based Platform for Healthcare Information Exchange. In Proceedings of the 2018 IEEE International Conference on Smart Computing (SMARTCOMP), Taormina, Italy, 18–20 June 2018. [Google Scholar] [CrossRef]

- Malik, A.; Gautam, S.; Abidin, S.; Bhushan, B. Blockchain technology-future of IOT: Including structure, limitations and various possible attacks. In Proceedings of the 2019 2nd International Conference on Intelligent Computing, Instrumentation and Control Technologies (ICICICT), Kannur, India, 5–6 July 2019. [Google Scholar] [CrossRef]

- Li, Z.; Liu, G.; Liu, L.; Lai, X.; Xu, G. IoT-based tracking and tracing platform for prepackaged food supply chain. Ind. Manag. Data Syst. 2017, 117, 1906–1916. [Google Scholar] [CrossRef]

- Javaid, U.; Aman, M.N.; Sikdar, B. Block Pro: Blockchain based data provenance and integrity for secure IoT environments. In Proceedings of the 1st Workshop on Blockchain-Enabled Networked Sensor Systems, Shenzhen China, 4 November 2018; Association for Computing Machinery: New York, NY, USA, 2018; pp. 13–18. [Google Scholar] [CrossRef]

- Verdouw, C.N.; Wolfert, J.; Beulens, A.; Rialland, A. Virtualization of food supply chains with the internet of things. J. Food Eng. 2016, 176, 128–136. [Google Scholar] [CrossRef]

- Kosba, A.; Miller, A.; Shi, E.; Wen, Z.; Papamanthou, C. Hawk: The Blockchain Model of Cryptography and Privacy-Preserving Smart Contracts. In Proceedings of the 2016 IEEE Symposium on Security and Privacy (SP), San Jose, CA, USA, 22–26 May 2016. [Google Scholar] [CrossRef]

- Shen, M.; Tang, X.; Zhu, L.; Du, X.; Guizani, M. Guizani. Privacy-Preserving Support Vector Machine Training Over Blockchain-Based Encrypted IoT data in smart cities. IEEE Internet Things J. 2019, 6, 7702–7712. [Google Scholar] [CrossRef]

- Cao, B.; Li, Y.; Zhang, L.; Zhang, L.; Mumtaz, S.; Zhou, Z.; Peng, M. When Internet of Things Meets Blockchain: Challenges in Distributed Consensus. IEEE Netw. 2019, 33, 133–139. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M.; Singh, R.P.; Suman, R.; Khan, S. Management 4.0: Concept, applications and advancements. Sustain. Oper. Comput. 2023, 4, 10–21. [Google Scholar] [CrossRef]

- Minoli, D.; Occhiogrosso, B. Blockchain mechanisms for IoT security. Internet Things 2018, 1–2, 1–13. [Google Scholar] [CrossRef]

- Lu, Y. The Blockchain: State-of-the-art and research challenges. J. Ind. Inf. Integr. 2019, 15, 80–90. [Google Scholar] [CrossRef]

- Makhdoom, I.; Abolhasan, M.; Abbas, H.; Ni, W. Blockchain’s adoption in IoT: The challenges, and a way forward. J. Netw. Comput. Appl. 2019, 125, 251–279. [Google Scholar] [CrossRef]

- Wang, X.; Zha, X.; Ni, W.; Liu, R.P.; Guo, Y.J.; Niu, X.; Zheng, K. Survey on blockchain for Internet of Things. Comput. Commun. 2019, 136, 10–29. [Google Scholar] [CrossRef]

- Siegfried, N.; Rosenthal, T.; Benlian, A. Blockchain and the industrial internet of things fit analysis. J. Enterprise Inf. Manag. 2022, 35, 1454–1476. [Google Scholar] [CrossRef]

- Reyna, A.; Martín, C.; Chen, J.; Soler, E.; Díaz, M. On blockchain and its integration with IoT. Challenges and opportunities. Future Generat. Comput. Syst. 2018, 88, 173–190. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Choy, K.L.; Wu, C.H.; Ho, G.T.S.; Lam, H.Y. Blockchain-driven IoT for food traceability with an integrated consensus mechanism. IEEE Access 2019, 7, 129000–129017. [Google Scholar] [CrossRef]

- Alsuwaidan, L. Validating the adoption of heterogeneous internet of things with blockchain. Future Internet 2020, 12, 107. [Google Scholar] [CrossRef]

- Hong, H.; Hu, B.; Sun, Z. Toward secure and accountable data transmission in Narrow Band Internet of Things based on blockchain. Int. J. Distribut. Sens. Netw. 2019, 15. [Google Scholar] [CrossRef]

- Viriyasitavat, W.; Anuphaptrirong, T.; Hoonsopon, D. When blockchain meets Internet of Things: Characteristics, challenges, and business opportunities. J. Ind. Inf. Integr. 2019, 15, 21–28. [Google Scholar] [CrossRef]

- Badulescu, Y.; Cheikhrouhou, N. A Framework Integrating Internet of Things and Blockchain in Clinical Trials Reverse Supply Chain. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems; Springer: Cham, Switzerland, 2021; pp. 98–106. [Google Scholar] [CrossRef]

- Coppolino, L.; Romano, L.; Scaletti, A.; Sgaglione, L. Fuzzy set theory-based comparative evaluation of cloud service offerings: An agro-food supply chain case study. Technol. Anal. Strat. Manag. 2021, 33, 900–913. [Google Scholar] [CrossRef]

- Kamilaris, A.; Fonts, A.; Prenafeta-Boldύ, F.X. The rise of blockchain technology in agriculture and food supply chains. Trends Food Sci. Technol. 2019, 91, 640–652. [Google Scholar] [CrossRef]

- Kuokkanen, A.; Uusitalo, V.; Koistinen, K. A framework of disruptive sustainable innovation: An example of the Finnish food system. Technol. Anal. Strat. Manag. 2019, 31, 749–764. [Google Scholar] [CrossRef]

- Irani, Z.; Sharif, A.M.; Lee, H.; Aktas, E.; Topaloğlu, Z.; van’t Wout, T.; Huda, S. Managing food security through food waste and loss: Small data to big data. Comput. Oper. Res. 2018, 98, 367–383. [Google Scholar] [CrossRef]

- Osmanoglu, M.; Tugrul, B.; Dogantuna, T.; Bostanci, E. An effective yield estimation system based on blockchain technology. IEEE Trans. Eng. Manag. 2020, 67, 1157–1168. [Google Scholar] [CrossRef]

- Köhler, S.; Pizzol, M. Technology assessment of blockchain-based technologies in the food supply chain. J. Clean. Prod. 2020, 269, 122193. [Google Scholar] [CrossRef]

- Wu, H.; Cao, J.; Yang, Y.; Tung, C.L.; Jiang, S.; Tang, B.; Liu, Y.; Wang, X.; Deng, Y. Data Management in Supply Chain Using Blockchain: Challenges and a Case Study. In Proceedings of the 28th International Conference on Computer Communication and Networks (ICCCN), Valencia, Spain, 29 July–1 August 2019. [Google Scholar] [CrossRef]

- Hyperleadger. Case Study: How Walmart Brought Unprecedented Transparency to the Food Supply Chain with Hyperledger Fabric. 2019. Available online: https://www.hyperledger.org/learn/publications/walmart-case-study (accessed on 6 January 2023).

- Kaur, A.; Singh, G.; Kukreja, V.; Sharma, S.; Singh, S.; Yoon, B. Adaptation of IoT with blockchain in Food Supply Chain Management: An analysis-based review in development, benefits and potential applications. Sensors 2022, 22, 8174. [Google Scholar] [CrossRef]

- Ali, N.; Cai, H.; Hamou-Lhadj, A.; Hassine, J. Exploiting Parts-of-Speech for effective automated requirements traceability. Inf. Softw. Technol. 2019, 106, 126–141. [Google Scholar] [CrossRef]

- Katiyar, R.; Barua, M.; Meena, P. Analysing the Interactions Among the Barriers of Supply Chain Performance Measurement: An ISM with Fuzzy MICMAC Approach. Glob. Bus. Rev. 2017, 19, 48–68. [Google Scholar] [CrossRef]

- Khan, S.; Khan, M.; Haleem, A. Evaluation of barriers in the adoption of halal certification: A fuzzy DEMATEL approach. J. Model. Manag. 2019, 14, 153–174. [Google Scholar] [CrossRef]

- Khan, S.; Singh, R.; Kirti. Critical Factors for Blockchain Technology Implementation: A Supply Chain Perspective. J. Ind. Integr. Manag. 2021, 7, 2150011. [Google Scholar] [CrossRef]

- Sufiyan, M.; Haleem, A.; Khan, S.; Khan, M. Evaluating food supply chain performance using hybrid fuzzy MCDM technique. Sustain. Prod. Consum. 2019, 20, 40–57. [Google Scholar] [CrossRef]

- Khan, S.; Khan, M.I.; Haleem, A.; Jami, A.R. Prioritising the risks in Halal food supply chain: An MCDM approach. J. Islam. Mark. 2019, 13, 45–65. [Google Scholar] [CrossRef]

- Ju-Long, D. Control Problems of Grey Systems. Syst. Control Lett. 1982, 1, 288–294. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, X.; Sun, J.; Zhang, Y. Contextual and organisational factors in sustainable supply chain decision making grey relational analysis and interpretative structural modeling. Environ. Dev. Sustain. 2021, 23, 12056–12076. [Google Scholar] [CrossRef]

- Liu, S.; Fang, Z.; Yang, Y.; Forrest, J. General Grey numbers and their operations. Grey Syst. Theory Appl. 2012, 2, 341–349. [Google Scholar] [CrossRef]

- Liu, S.; Yang, Y.; Forrest, J. Grey numbers and their operations. In Computational Risk Management; Springer: Berlin/Heidelberg, Germany, 2016; pp. 29–43. [Google Scholar] [CrossRef]

- Singh, R.; Khan, S.; Dsilva, J. A framework for assessment of critical factor for Circular Economy Practice Implementation. J. Model. Manag. 2022. [Google Scholar] [CrossRef]

- Dalkey, N.; Helmer, O. An Experimental Application of the DELPHI Method to the Use of Experts. Manag. Sci. 1963, 9, 458–467. [Google Scholar] [CrossRef]

- Susanty, A.; Puspitasari, N.B.; Prastawa, H.; Renaldi, S.V. Exploring the best policy scenario plan for the dairy supply chain: A DEMATEL approach. J. Model. Manag. 2020, 16, 240–266. [Google Scholar] [CrossRef]

- Khan, S.; Haleem, A.; Khan, M. Risk management in Halal supply chain: An integrated fuzzy Delphi and DEMATEL approach. J. Model. Manag. 2020, 16, 172–214. [Google Scholar] [CrossRef]

- Liu, S.; Forrest, J.Y.L. Grey Systems: Theory and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Xia, X.; Govindan, K.; Zhu, Q. Analyzing internal barriers for automotive parts remanufacturers in China using grey-DEMATEL approach. J. Clean. Prod. 2015, 87, 811–825. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. A grey-based DEMATEL model for evaluating business process management critical success factors. Int. J. Prod. Econ. 2013, 146, 281–292. [Google Scholar] [CrossRef]

- Yadav, S.; Luthra, S.; Garg, D. Internet of things (IOT) based coordination system in Agri-Food Supply Chain: Development of an efficient framework using DEMATEL-ism. Oper. Manag. Res. 2020, 15, 1–27. [Google Scholar] [CrossRef]

- Benzidia, S.; Makaoui, N.; Subramanian, N. Impact of ambidexterity of blockchain technology and social factors on new product development: A supply chain and Industry 4.0 perspective. Technol. Forecast. Soc. Chang. 2021, 169, 120819. [Google Scholar] [CrossRef]

- Cole, R.; Stevenson, M.; Aitken, J. Blockchain technology: Implications for operations and supply chain management. Supply Chain. Manag. Int. J. 2019, 24, 469–483. [Google Scholar] [CrossRef]

- Yan, B.; Wu, X.; Ye, B.; Zhang, Y. Three-level supply chain coordination of fresh agricultural products in the Internet of Things. Ind. Manag. Data Syst. 2017, 117, 1842–1865. [Google Scholar] [CrossRef]

- Ferrández-Pastor, F.J.; Mora-Pascual, J.; Díaz-Lajara, D. gricultural traceability model based on IoT and Blockchain: Application in industrial hemp production. J. Ind. Inf. Integr. 2022, 29, 100381. [Google Scholar] [CrossRef]

- Tsang, Y.; Choy, K.; Wu, C.; Ho, G.; Lam, C.; Koo, P. An Internet of Things (IoT)-based risk monitoring system for managing cold supply chain risks. Ind. Manag. Data Syst. 2018, 118, 1432–1462. [Google Scholar] [CrossRef]

- Desingh, V.R.B. Internet of Things adoption barriers in the Indian healthcare supply chain: An ISM-fuzzy MICMAC approach. Int. J. Health Plan. Manag. 2021, 37, 318–351. [Google Scholar] [CrossRef]

- Annosi, M.; Brunetta, F.; Bimbo, F.; Kostoula, M. Digitalization within food supply chains to prevent food waste. Drivers, barriers and collaboration practices. Ind. Mark. Manag. 2021, 93, 208–220. [Google Scholar] [CrossRef]

- Talavera, J.; Tobón, L.; Gómez, J.; Culman, M.; Aranda, J.; Parra, D.T.; Quirozb, L.A.; Hoyosb, A.; Garreta, L.E. Review of IoT applications in agro-industrial and environmental fields. Comput. Electron. Agric. 2017, 142, 283–297. [Google Scholar] [CrossRef]

- Wamba, S.; Queiroz, M. Blockchain in the operations and supply chain management: Benefits, challenges and future research opportunities. Int. J. Inf. Manag. 2020, 52, 102064. [Google Scholar] [CrossRef]

- Vuran, M.; Salam, A.; Wong, R.; Irmak, S. Internet of underground things in precision agriculture: Architecture and technology aspects. Ad Hoc Netw. 2018, 81, 160–173. [Google Scholar] [CrossRef]

- Chen, Z.; Pak, M. A Delphi analysis on green performance evaluation indices for ports in China. Marit. Policy Manag. 2017, 44, 537–550. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Joshi, S. Modeling the internet of things adoption barriers in food retail supply chains. J. Retail. Consum. Serv. 2019, 48, 154–168. [Google Scholar] [CrossRef]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Manickam, S.; Kooy, A. Internet of Things for Smart Cities: Challenges, Security and Privacy Issues. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Pratap Singh, R.; Khan, S.; Suman, R. Blockchain technology applications for Industry 4.0: A literature-based review. Blockchain Res. Appl. 2021, 2, 100027. [Google Scholar] [CrossRef]

- Haleem, A.; Khan, M.; Khan, S. Conceptualising a framework linking halal supply chain management with sustainability: An India centric study. J. Islam. Mark. 2020, 12, 1535–1552. [Google Scholar] [CrossRef]

- Guruprakash, J.; Koppu, S. EC-ElGamal and genetic algorithm-based enhancement for lightweight scalable blockchain in iot domain. IEEE Access 2020, 8, 141269–141281. [Google Scholar] [CrossRef]

- Jayabalasamy, G.; Koppu, S. High-performance Edwards curve aggregate signature (HECAS) for nonrepudiation in IOT-based applications built on the blockchain ecosystem. J. King Saud Univ.-Comput. Inf. Sci. 2022, 34, 9677–9687. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).