Experimental Study of the Self-Potential Response Characteristics of Anisotropic Bituminous Coal during Deformation and Fracturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental System

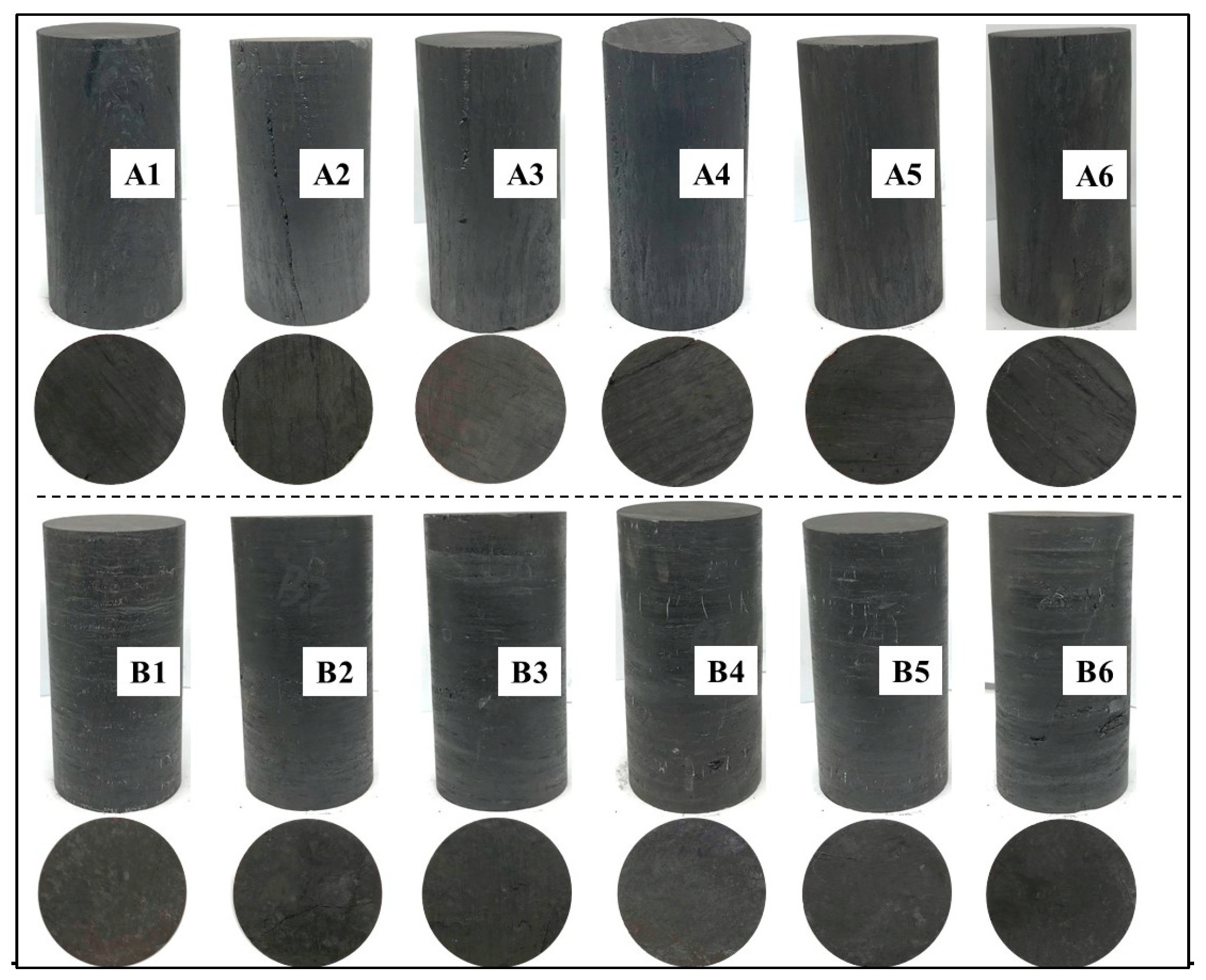

2.2. Coal Sample Preparation

2.3. Experimental Procedure

3. Results

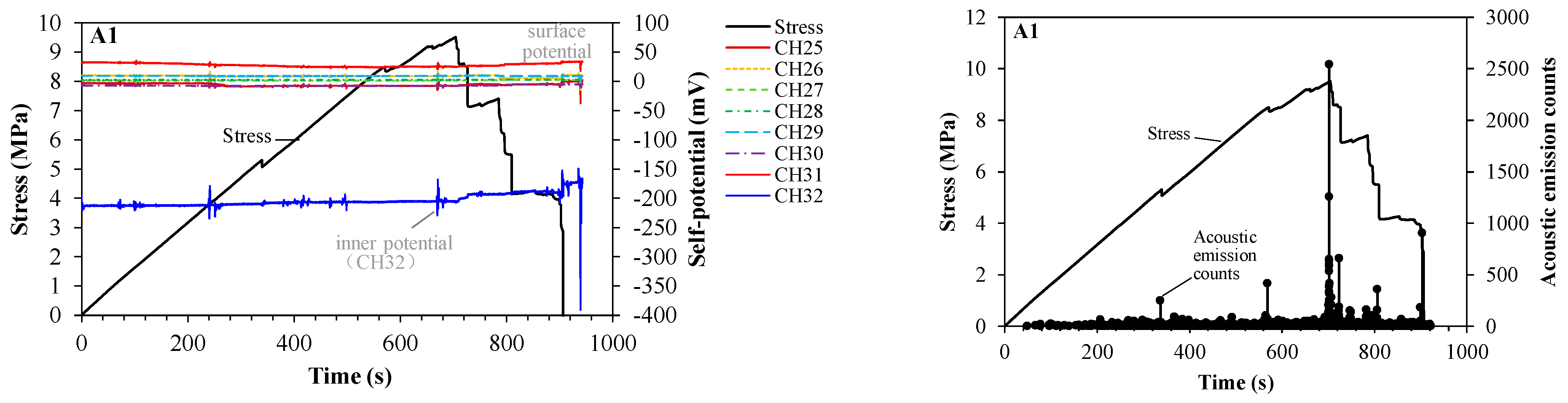

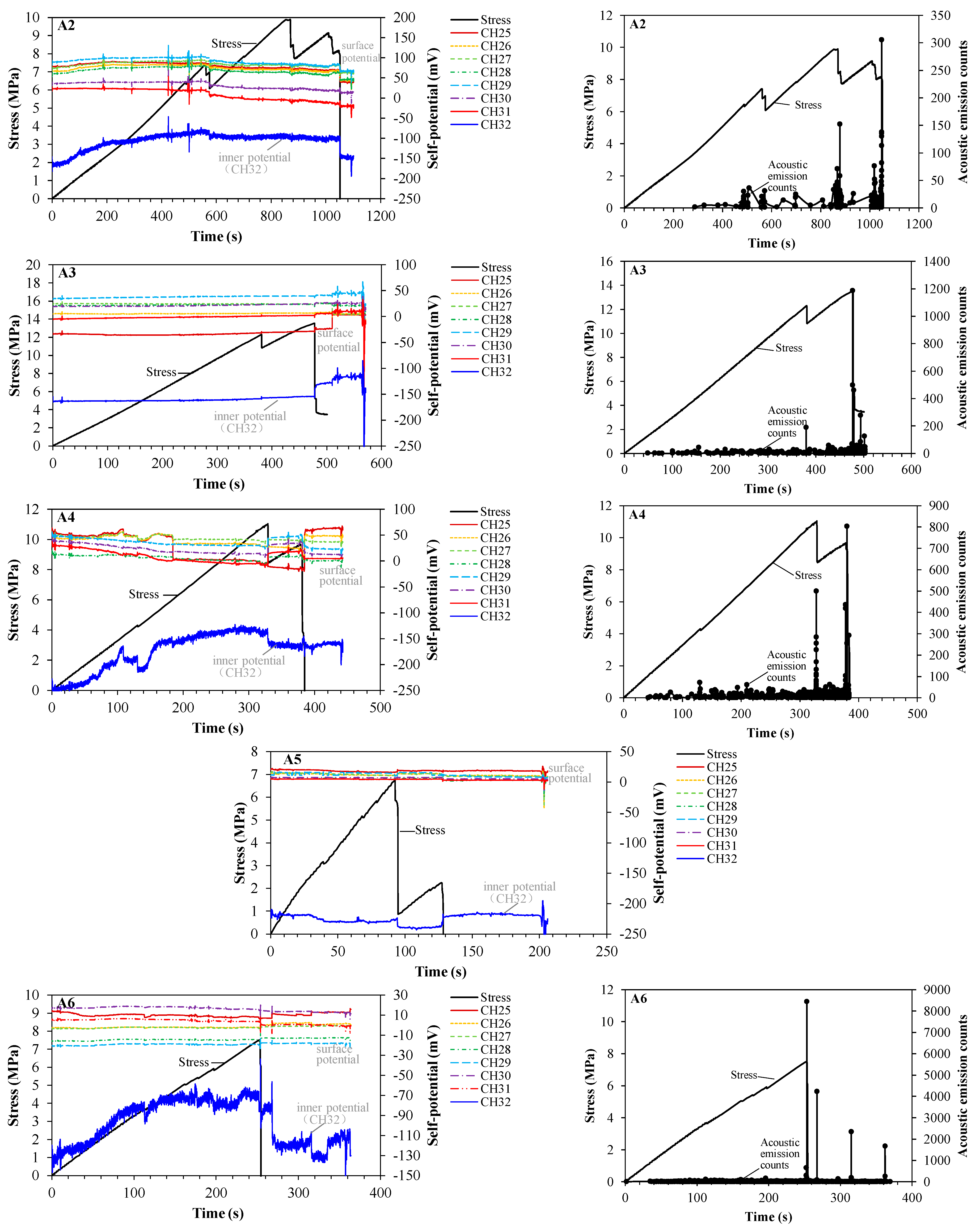

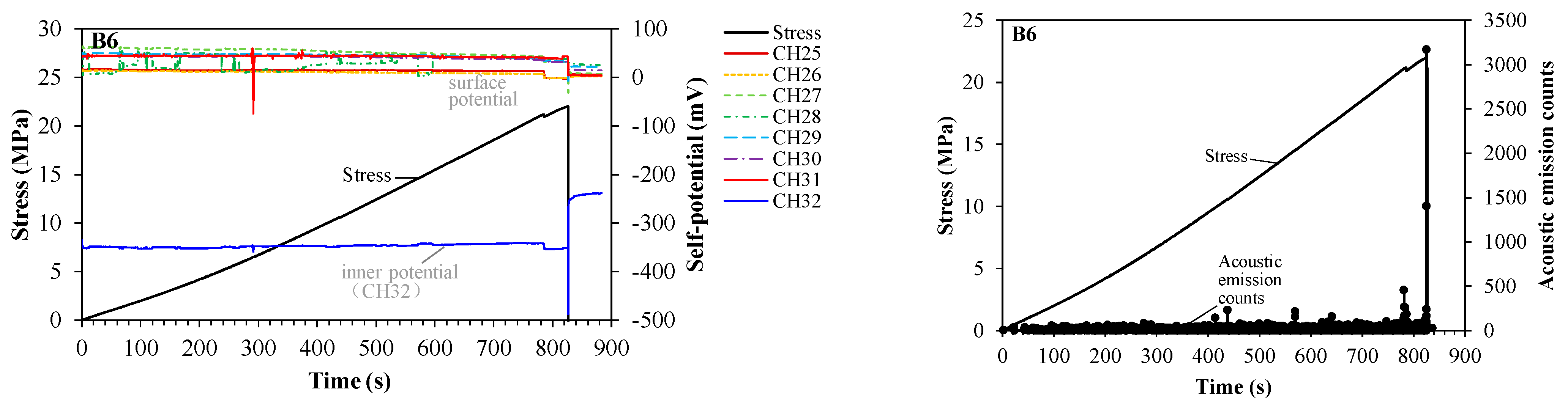

3.1. Response Characteristics of Self-Potential, Stress and Acoustic Emission

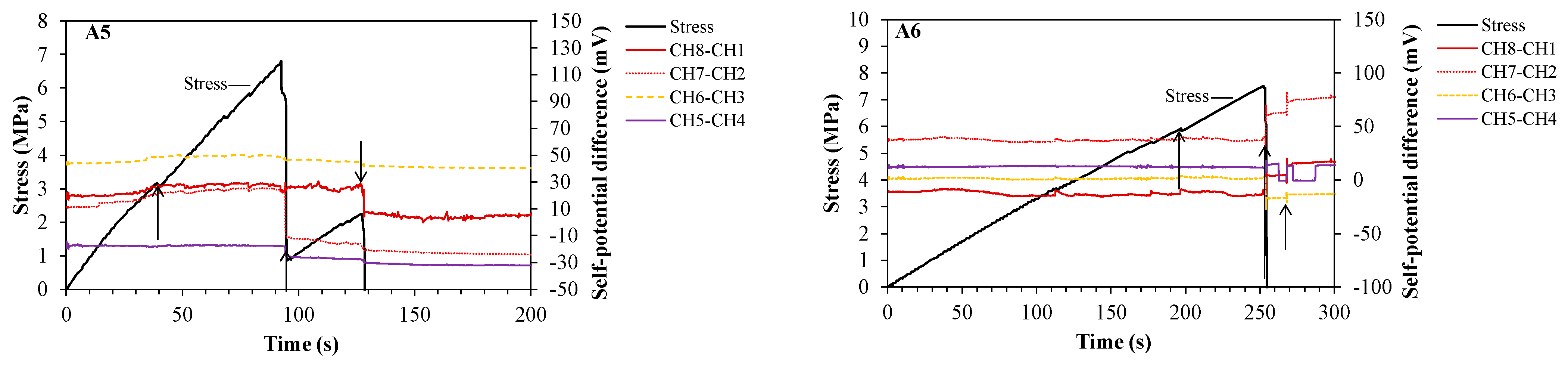

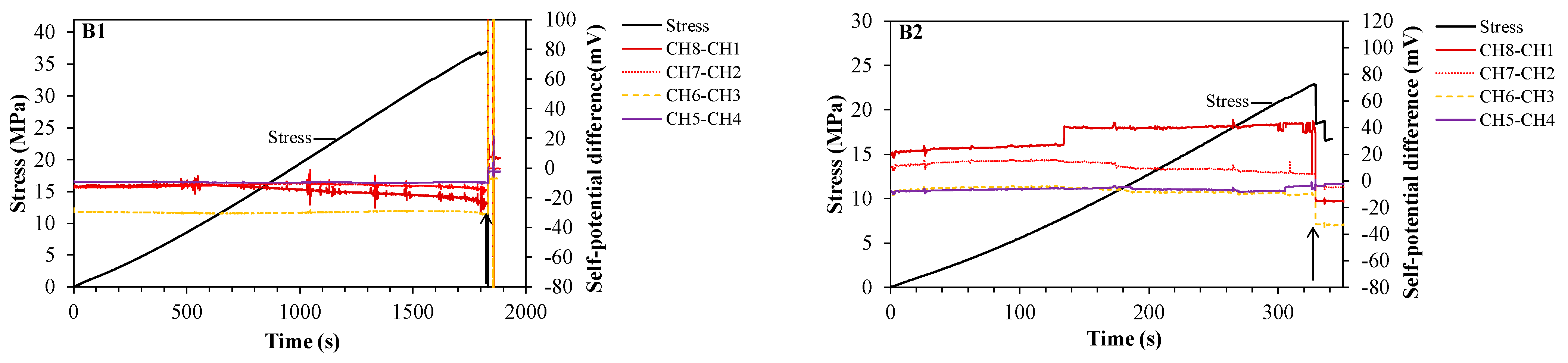

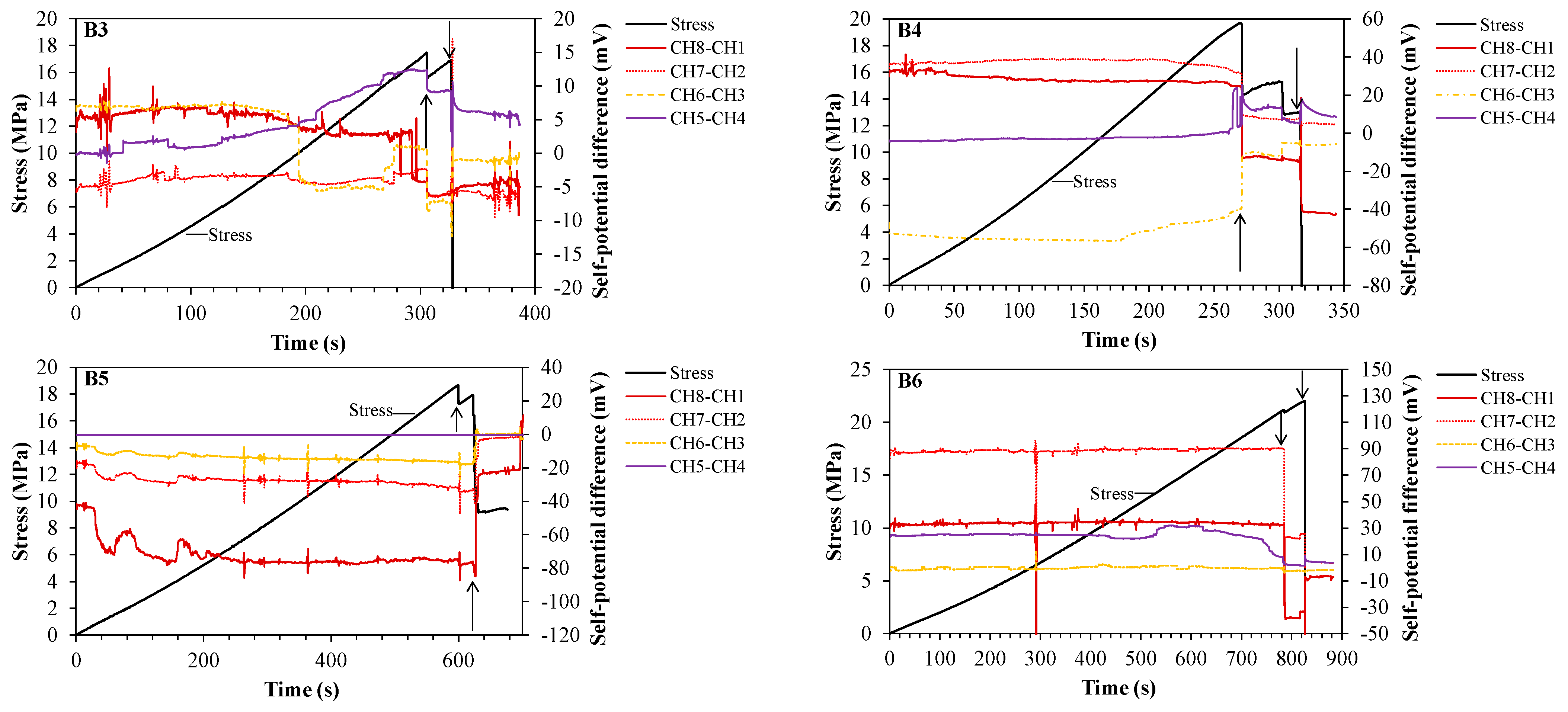

3.2. Response Characteristics of Self-Potential Difference and Stress

3.3. Variation in Self-Potential with Time for Bituminous Coal Samples

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, L. Scientific conception of precision coal mining. J. China Coal Soc. 2017, 42, 1–7. [Google Scholar] [CrossRef]

- He, M.C.; Xie, H.P.; Peng, S.P.; Jiang, Y.D. Study on rock mechanics in deep mining engineering. Chin. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar] [CrossRef]

- Qian, Q.H. The characteristic scientific phenomena of engineering response to deep rock mass and the implication if deepness. J. East China Inst. Tech. 2004, 27, 1–5. [Google Scholar] [CrossRef]

- Zhang, B.; Guo, D.N.; Peng, S.P. Development Trends and Strategic Research for China’s Energy Engineering Science and Technology to 2035. Chin. Eng. Sci. 2017, 19, 64–72. [Google Scholar] [CrossRef]

- Wang, E.Y.; He, X.Q.; Dou, L.M.; Zhou, S.N.; Nie, B.S.; Liu, Z.T. Electromagnetic radiation characteristics of coal and rocks during excavation in coal mine and their application. Chin. J. Geophys. 2005, 48, 216–221. [Google Scholar] [CrossRef]

- Zhao, Y.F.; Pan, Y.S.; Liu, Y.S.; Luo, H. Experimental study of charge induction of coal samples under uniaxial compression. Chin. J. Rock Mech. Eng. 2011, 30, 306–312. [Google Scholar]

- Li, Z.H. Study on Surface Potential Effect and Its Mechanism of Coal during Deformation and Fracture under Load. Ph.D. Thesis, China University of Mining & Technology, Xuzhou, China, 2007. [Google Scholar]

- Dou, L.M.; He, X.Q.; Ren, T.; He, J.; Wang, Z.Y. Mechanism of coal-gas dynamic disasters caused by the superposition of static and dynamic loads and its control technology. J. China Univ. Min. Tech. 2018, 47, 48–59. [Google Scholar]

- Hu, Q.T.; Zhou, S.N.; Zhou, X.Q. Mechanical mechanism of coal and gas outburst process. J. China Coal Soc. 2008, 33, 1368–1372. [Google Scholar] [CrossRef]

- Jiang, Y.D.; Pan, Y.S.; Jiang, F.X.; Dou, L.M.; Ju, Y. State of the art review on mechanism and prevention of coal bumps in China. J. China Coal Soc. 2014, 39, 205–213. [Google Scholar] [CrossRef]

- Khatiashvili, N.G.; Perel’man, M.E. On the mechanism of seismo-electromagnetic phenomena and their possible role in the electromagnetic radiation during periods of earthquakes, foreshocks and aftershocks. Phys. Earth Planet. Inter. 2014, 57, 169–177. [Google Scholar] [CrossRef]

- Chen, D.Y.; Zhang, D.H.; Sun, Z.J. Studies of natural potential changes in rock sample under stress. Chin. J. Geophys. 1981, 24, 242–244. [Google Scholar]

- Wu, X.P.; Shi, X.J.; Guo, Z.Q. Study of the electrification of granite samples under compression. Chin. J. Geophys. 1990, 2, 208–211. [Google Scholar]

- Enomoto, Y.; Shimamoto, T.; Tsutumi, A. Rapid electric charge fluctuation prior to rock fracturing: Its potential use for an immediate earthquake precursor. In International Workshop on Electromagnetic Phenomena Related to Earthquake Prediction; Terra Scientific Publishing Company: Tokyo, Japan, 1993; pp. 64–65. [Google Scholar]

- Yoshida, S.; Clint, O.C.; Sammonds, P.R. Electric potential changes prior to shear fracture in dry and saturated rocks. Geophys. Res. Lett. 1998, 25, 1577–1580. [Google Scholar] [CrossRef] [Green Version]

- Hao, J.Q.; Liu, L.Q.; Long, H.L.; Ma, S.L.; Guo, Z.Q.; Qian, S.Q.; Zhou, J.G. New result of the experiment on self-potential change of rocks under biaxial compression. Chin. J. Geophys. 2004, 47, 475–482. [Google Scholar] [CrossRef]

- Eccles, D.; Sammonds, P.; Clint, O. Laboratory studies of electrical potential during rock failure. Int. J. Rock Mech. Min. 2005, 42, 933–949. [Google Scholar] [CrossRef]

- Takeuchi, A.; Bobby, W.S.L.; Friedemann, T.F. Current and surface potential induced by stress-activated positive holes in igneous rocks. Phys. Chem. Earth 2006, 31, 240–247. [Google Scholar] [CrossRef]

- Aydin, A.; Prance, R.J.; Prance, H.; Harland, C.J. Observation of pressure stimulated voltages in rocks using an electric potential sensor. Appl. Phys. Lett. 2009, 95, 12. [Google Scholar] [CrossRef]

- Triantis, D.; Stavrakas, I.; Kyriazopoulos, A.; Hloupis, G.; Agioutantis, Z. Pressure stimulated electrical emissions from cement mortar used as failure predictors. Int. J. Fract. 2012, 175, 53–61. [Google Scholar] [CrossRef]

- Li, Z.H.; Wang, E.Y.; Song, X.Y.; Hu, S.B. Study on strain localization and surface potential distribution law of coal samples fracturing. J. China Coal Soc. 2012, 37, 2043–2047. [Google Scholar]

- Archer, J.W.; Dobbs, M.R.; Aydin, A.; Reeves, H.J.; Prance, R.J. Measurement and correlation of acoustic emissions and pressure stimulated voltages in rock using an electric potential sensor. Int. J. Rock Mech. Min. 2016, 89, 26–33. [Google Scholar] [CrossRef] [Green Version]

- Yin, S.; Li, Z.H.; Niu, Y.; Qiu, L.M.; Sun, Y.H.; Cheng, F.Q.; Wei, Y. Experimental study on the characteristics of potential for coal rock evolution under loading. J. China Coal Soc. 2017, 42, 97–103. [Google Scholar]

- Liu, J.; Liu, S.D.; Cao, Y. Self-potential characteristics in deep rock mass damage based on point discharge mechanism. Chin. J. Geophys. 2018, 61, 323–330. [Google Scholar] [CrossRef]

- Yang, C. Study on the Time-Frequency Electrical Properties of Coal Rock Mass. Ph.D. Thesis, China University of Mining & Technology, Xuzhou, China, 2017. [Google Scholar]

- Wang, E.Y.; Li, Z.H.; Liu, Z.T.; Li, Y.N.; Song, X.Y. Experimental study on surface potential effect of coal under load. Chin. J. Geophys. 2009, 52, 1318–1325. [Google Scholar] [CrossRef]

- Yang, C.; Liu, S.D.; Liu, J.; Yang, H.P.; Xie, J.Y. Characteristics of self-potential of coal samples under uniaxial compression. J. Appl. Geophys. 2019, 168, 1–11. [Google Scholar] [CrossRef]

- Liu, B.X.; Huang, J.L.; Wang, Z.Y.; Liu, L. Study on damage evolution and acoustic emission character of coal-rock under uniaxial compression. Chin. J. Rock Mech. Eng. 2009, 28, 3234–3238. [Google Scholar]

- Wang, X.; Li, J.C.; Zhao, X.B.; Yue, L. Propagation characteristics and prediction of blast-induced vibration on closely spaced rock tunnels. Tunn. Undergr. Space Technol. 2022, 123, 104416. [Google Scholar] [CrossRef]

- Li, J.C.; Yuan, W.; Li, H.B.; Zou, C.J. Study on dynamic shear deformation behaviors and test methodology of sawtooth-shaped rock joints under impact load. Int. J. Rock Mech. Min. 2022, 158, 105210. [Google Scholar] [CrossRef]

- Bi, S.K.; Zhang, H.W.; Zhang, Y.; Lu, L.; Ma, Y.S.; Gao, X.B. Experimental study on coal resistivity changing anisotropy during uniaxial compression. Saf. Coal Mines 2016, 47, 35–38. [Google Scholar] [CrossRef]

| Sample Name | Diameter (mm) | Height (mm) | Quality (g) | Loading Rate (mm/s) |

|---|---|---|---|---|

| A1 | 49.79 | 99.31 | 246.6 | 0.001 |

| A2 | 49.79 | 99.69 | 244.5 | 0.001 |

| A3 | 49.80 | 99.56 | 238.3 | 0.002 |

| A4 | 49.80 | 99.62 | 250.7 | 0.002 |

| A5 | 49.79 | 99.49 | 247.8 | 0.005 |

| A6 | 49.74 | 99.67 | 244.1 | 0.002 |

| B1 | 49.84 | 99.45 | 275.3 | 0.001 |

| B2 | 49.43 | 99.81 | 242.0 | 0.005 |

| B3 | 49.35 | 99.78 | 239.5 | 0.005 |

| B4 | 49.58 | 99.70 | 250.9 | 0.005 |

| B5 | 49.83 | 99.97 | 254.3 | 0.002 |

| B6 | 49.46 | 99.96 | 241.5 | 0.002 |

| R2 * | CH25 | CH26 | CH27 | CH28 | CH29 | CH30 | CH31 | CH32 | Loading Rate (mm/s) | Stress Interval (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|

| R2 (A1) | 0.527 | 0.421 | 0.055 | 0.0006 | 0.087 | 0.606 | 0.931 | 0.124 | 0.001 | ≤4.899 |

| R2 (A2) | 0.465 | 0.658 | 0.817 | 0.778 | 0.707 | 0.320 | 0.249 | 0.882 | 0.001 | ≤5.523 |

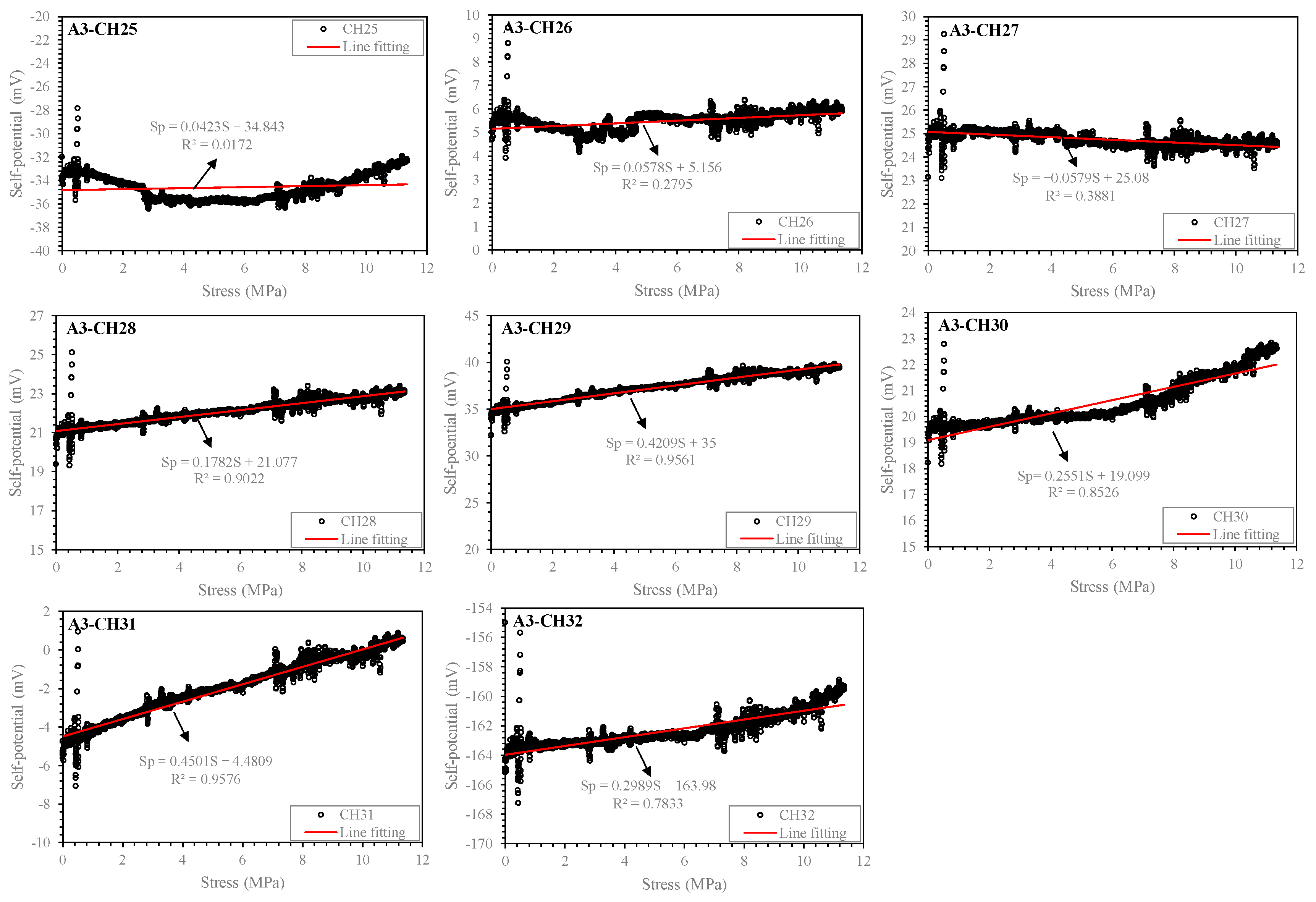

| R2 (A3) | 0.017 | 0.280 | 0.388 | 0.902 | 0.956 | 0.853 | 0.958 | 0.783 | 0.002 | ≤11.352 |

| R2 (A4) | 0.055 | 0.490 | 0.183 | 0.041 | 0.908 | 0.932 | 0.941 | 0.882 | 0.002 | ≤3.853 |

| R2 (A5) | 0.362 | 0.153 | 0.247 | 0.002 | 0.007 | 0.016 | 0.126 | 0.124 | 0.005 | ≤2.833 |

| R2 (A6) | 0.304 | 0.447 | 0.778 | 0.769 | 0.780 | 0.638 | 0.168 | 0.942 | 0.002 | ≤4.585 |

| R2 (B1) | 0.091 | 0.786 | 0.954 | 0.935 | 0.580 | 0.631 | 0.942 | 0.964 | 0.001 | ≤31.251 |

| R2 (B2) | 0.347 | 0.977 | 0.910 | 0.664 | 0.159 | 0.586 | 0.194 | 0.582 | 0.005 | ≤20.303 |

| R2 (B3) | 0.981 | 0.902 | 0.186 | 0.632 | 0.890 | 0.620 | 0.798 | 0.848 | 0.005 | ≤14.706 |

| R2 (B4) | 0.894 | 0.658 | 0.030 | 0.933 | 0.89 | 0.903 | 0.145 | 0.650 | 0.005 | ≤18.660 |

| R2 (B5) | 0.001 | 0.199 | 0.061 | 0.021 | 0.47 | 0.658 | 0.727 | 0.784 | 0.002 | ≤17.518 |

| R2 (B6) | 0.388 | 0.958 | 0.960 | 0.125 | 0.874 | 0.820 | 0.065 | 0.821 | 0.002 | ≤20.486 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Liu, S.; Yang, C.; Li, J. Experimental Study of the Self-Potential Response Characteristics of Anisotropic Bituminous Coal during Deformation and Fracturing. Appl. Sci. 2023, 13, 1095. https://doi.org/10.3390/app13021095

Zhang J, Liu S, Yang C, Li J. Experimental Study of the Self-Potential Response Characteristics of Anisotropic Bituminous Coal during Deformation and Fracturing. Applied Sciences. 2023; 13(2):1095. https://doi.org/10.3390/app13021095

Chicago/Turabian StyleZhang, Jun, Shengdong Liu, Cai Yang, and Juanjuan Li. 2023. "Experimental Study of the Self-Potential Response Characteristics of Anisotropic Bituminous Coal during Deformation and Fracturing" Applied Sciences 13, no. 2: 1095. https://doi.org/10.3390/app13021095

APA StyleZhang, J., Liu, S., Yang, C., & Li, J. (2023). Experimental Study of the Self-Potential Response Characteristics of Anisotropic Bituminous Coal during Deformation and Fracturing. Applied Sciences, 13(2), 1095. https://doi.org/10.3390/app13021095