Straight-Line Path Tracking Control of Agricultural Tractor-Trailer Based on Fuzzy Sliding Mode Control

Abstract

:1. Introduction

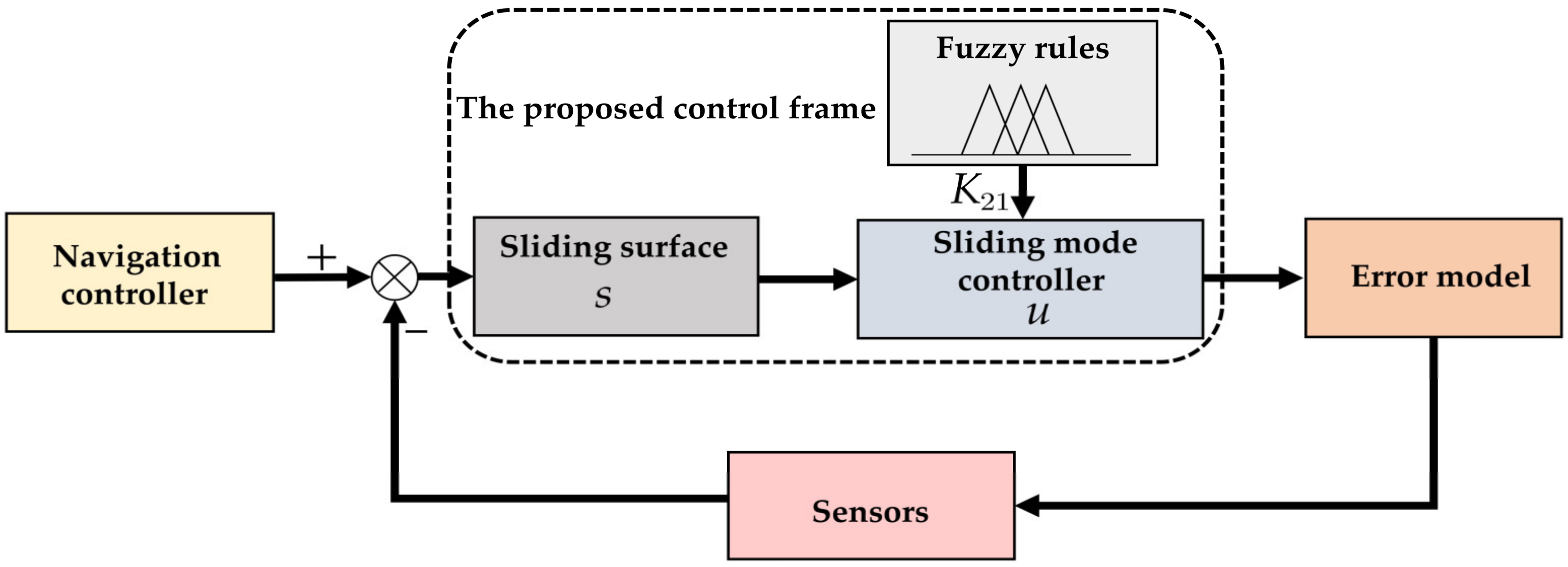

2. System Model

3. Sliding Mode Controller Design

3.1. Sliding Mode Controller Design

3.2. Fuzzy Sliding Mode Controller Design

3.2.1. Power Reaching Law Based Sliding Mode Controller Design

3.2.2. Fuzzy Rule Design

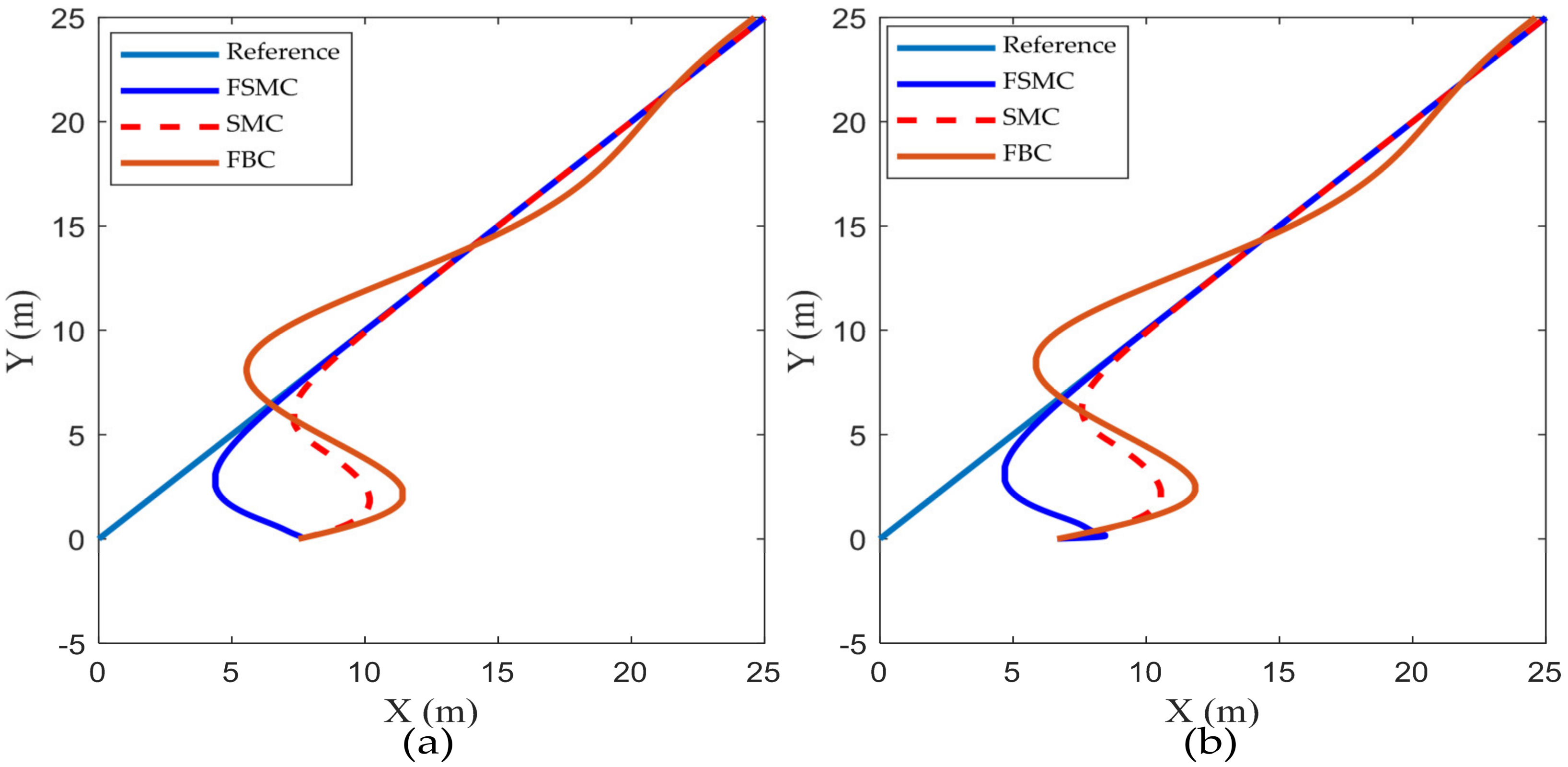

4. Simulation Results

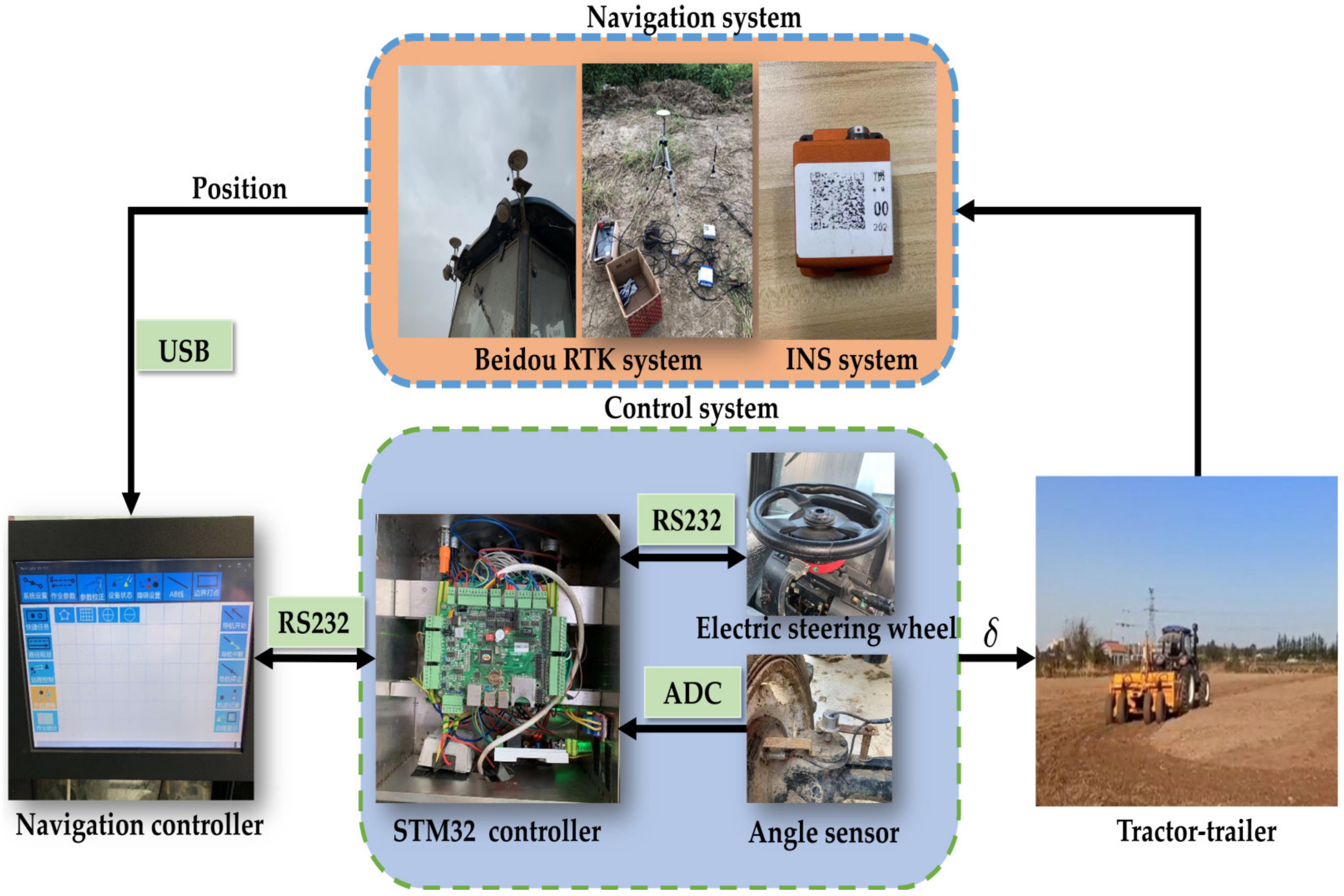

5. Experimental Results

5.1. Experimental Platform

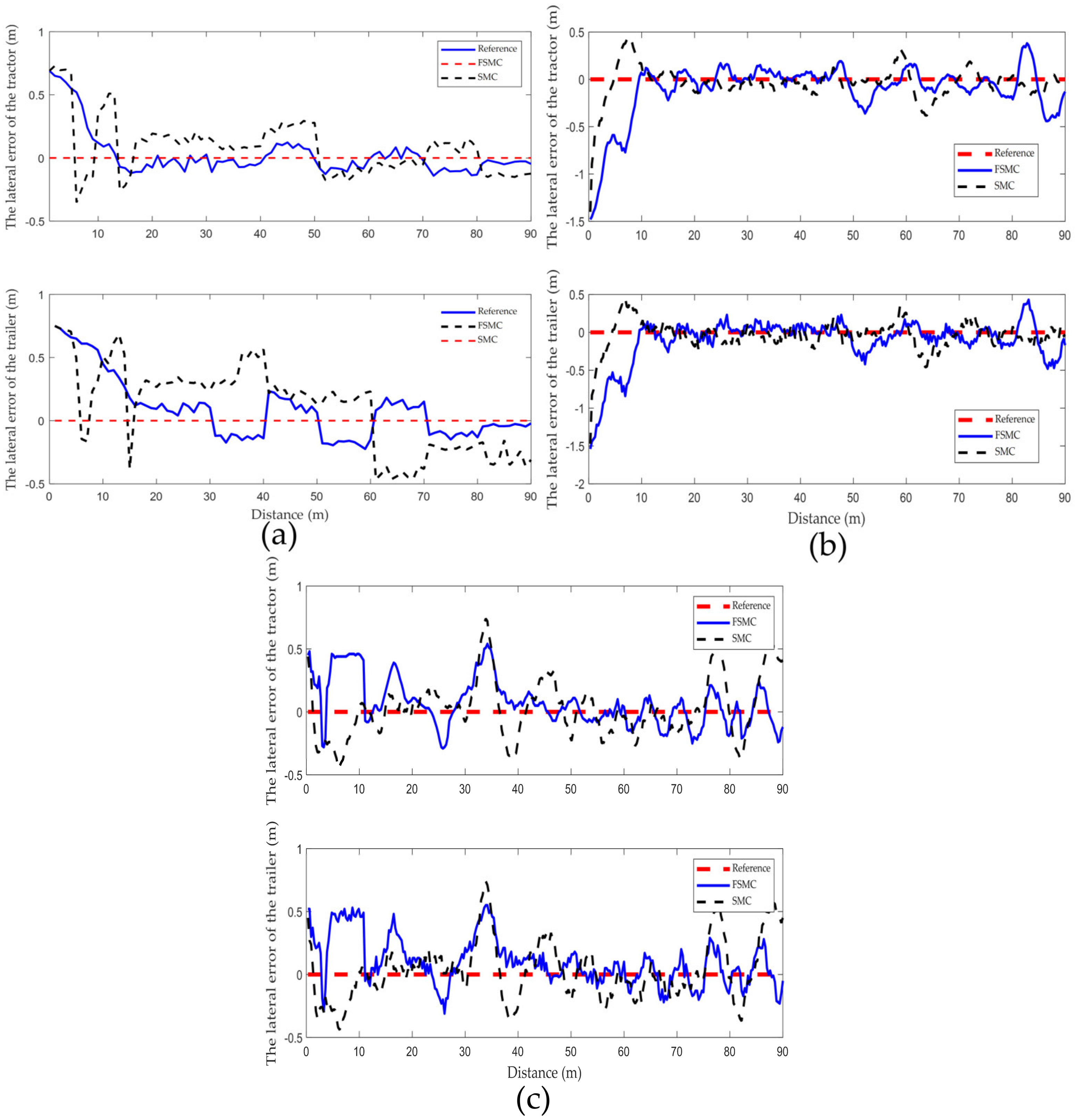

5.2. Field Tests

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, D.L.; Li, Z. System analysis and development prospect of unmanned farming. Trans. Chin. Soc. Agric. Mach. 2020, 51, 1–12. (In Chinese) [Google Scholar]

- Li, S.; Xu, H.; Ji, Y.; Cao, R.; Zhang, M.; Li, H. Development of a following agricultural machinery automatic navigation system. Comput. Electron. Agric. 2019, 158, 335–344. [Google Scholar] [CrossRef]

- Shojaei, K. Coordinated saturated output-feedback control of an autonomous tractor-trailer and a combine harvester in crop-harvesting operation. IEEE Trans. Veh. Technol. 2021, 71, 1224–1236. [Google Scholar] [CrossRef]

- Murillo, M.; Sánchez, G.; Deniz, N.; Genzelis, L. Improving path-tracking performance of an articulated tractor-trailer system using a non-linear kinematic model. Comput. Electron. Agric. 2022, 196, 106826. [Google Scholar] [CrossRef]

- Alipour, K.; Robat, A.B.; Tarvirdizadeh, B. Dynamics modeling and sliding mode control of tractor-trailer wheeled mobile robots subject to wheels slip. Mech. Mach. Theory. 2019, 138, 16–37. [Google Scholar] [CrossRef]

- Wang, H.; Wang, G.M.; Luo, X.W.; Zhang, Z.G.; Gao, Y.; He, J.; Yue, B.B. Path tracking control method of agricultural machine navigation based on aiming pursuit model. Trans. Chin. Soc. Agric. Eng. 2019, 35, 11–19. (In Chinese) [Google Scholar]

- Zhang, Y.; Li, Y.M.; Liu, X.P.; Tao, J.F.; Liu, C.L.; Li, R.C. Fuzzy adaptive control method for autonomous rice seeder. Trans. Chin. Soc. Agric. Mach. 2018, 49, 30–37. (In Chinese) [Google Scholar]

- Tang, X.T.; Tao, J.F.; Li, Z.T.; Li, Y.M.; Liu, C.L. Fuzzy control optimization method for stability of path tracking system of automatic transplanter. Trans. Chin. Soc. Agric. Mach. 2018, 49, 29–34. (In Chinese) [Google Scholar]

- Agricultural machine path tracking method based on fuzzy adaptive pure pursuit model. Trans. Chin. Soc. Agric. Mach. 2018, 49, 29–34. (In Chinese)

- Lin, H.Z.; Li, Y.M.; Yuan, Z.H.; Wu, T.; Liu, C.L. Sliding mode anti-interference path tracking method for autonomous operation of paddy field plant protection machine. Trans. Chin. Soc. Agric. Mach. 2021, 59, 383–388. (In Chinese) [Google Scholar]

- Zhou, J.J.; Zhang, M.; Wang, M.H.; Liu, G.; Ji, C.F.; Zhang, Z.G. Path tracking for agricultural vehicle based on fuzzy control. Trans. Chin. Soc. Agric. Mach. 2009, 40, 151–156. (In Chinese) [Google Scholar]

- Jing, Y.P.; Liu, G.; Jin, Z.K. Adaptive guidance control method with sideslip estimation for land leveler pulling by tractor. Trans. Chin. Soc. Agric. Mach. 2020, 51, 26–33. (In Chinese) [Google Scholar]

- Yin, X.; Wang, Y.X.; Chen, Y.L.; Du, J. Development of autonomous navigation controller for agricultural vehicles. Int. J. Agric. Biol. Eng. 2020, 13, 70–76. [Google Scholar] [CrossRef]

- Li, T.C.; Hu, J.T.; Gao, L.; Liu, X.G.; Bai, X.P. Agricultural machine path tracking method irrelevant to travel speeds. Trans. Chin. Soc. Agric. Mach. 2014, 45, 59–65. (In Chinese) [Google Scholar]

- Zhang, H.Q.; Wang, G.D.; Lv, Y.F.; Qin, C.L.; Liu, L. Agricultural machinery automatic navigation control system based on improved pure tracking model. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2020, 51. (In Chinese) [Google Scholar]

- Ding, Y.C.; He, Z.B.; Xia, Z.Z.; Peng, J.Y.; Wu, T.H. Design of navigation immune controller of small crawler-type rape seeder. Trans. Chin. Soc. Agric. Eng. 2019, 35, 12–20. (In Chinese) [Google Scholar]

- Zhao, X.; Yang, Y.; Zhang, W.M.; Zeng, J. Sliding mode control algorithm for path tracking of articulated dump truck. Trans. Chin. Soc. Agric. Eng. 2015, 31, 198–203. (In Chinese) [Google Scholar]

- Ding, C.; Ding, S.H.; Wei, X.H.; Mei, K.Q. Composite SOSM controller for path tracking control of agricultural tractors subject to wheel slip. ISA Trans. 2022, 130, 389–398. [Google Scholar] [CrossRef]

- Utkin, V.I.; Poznyak, A.S. Adaptive sliding mode control with application to super-twist algorithm: Equivalent control method. Automatica 2013, 49, 39–47. [Google Scholar] [CrossRef]

- Ji, X.; Wei, X.H.; Wang, A.Z.; Song, Q. A novel composite adaptive terminal sliding mode controller for farm vehicles lateral path tracking control. Nonlinear Dyn. 2022, 110, 2415–2428. [Google Scholar] [CrossRef]

- Sun, H.; Li, S.; Sun, C. Finite time integral sliding mode control of hypersonic vehicles. Nonlinear Dyn. 2013, 73, 229–244. [Google Scholar] [CrossRef]

- Kavikumar, R.; Kwon, O.M.; Lee, S.H.; Sakthivel, R. Input-output finite-time IT2 fuzzy dynamic sliding mode control for fractional-order nonlinear systems. Nonlinear Dyn. 2022, 108, 3745–3760. [Google Scholar] [CrossRef]

- Ji, W.; Qiu, J.; Lam, H.K. Fuzzy-Affine-Model-Based Sliding-Mode Control for Discrete-Time Nonlinear 2-D Systems via Output Feedback. IEEE Trans. Cybern. 2021. [Google Scholar] [CrossRef] [PubMed]

- Zheng, E.H.; Xiong, J.J.; Luo, J.L. Second order sliding mode control for a quadrotor UAV. ISA Trans. 2014, 53, 1350–1356. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; Wang, M.; Xu, J. Robust adaptive sliding mode control of underactuated autonomous underwater vehicles with uncertain dynamics. Ocean Eng. 2019, 173, 802–809. [Google Scholar] [CrossRef]

- Zhang, L.; Ding, H.; Shi, J.; Huang, Y.; Chen, H.; Guo, K.; Li, Q. An adaptive backstepping sliding mode controller to improve vehicle maneuverability and stability via torque vectoring control. IEEE Trans. Veh. Technol. 2020, 69, 2598–2612. [Google Scholar] [CrossRef]

- Levant, A.; Yu, X. Sliding-mode-based differentiation and filtering. IEEE Trans. Autom. Control 2018, 63, 3061–3067. [Google Scholar] [CrossRef]

- Levant, A. Higher-order sliding modes, differentiation and output-feedback control. Int. J. Control 2003, 76, 924–941. [Google Scholar] [CrossRef]

- Zhang, S.C.; Wei, X.H.; Lu, Z.M.; Ji, X. Design and verification of electric steering system for wheeled farm machinery. J. Agric. Mech. 2023, 45, 233–238. (In Chinese) [Google Scholar]

- Cui, B.B.; Wei, X.H.; Wu, S.H.; Xiao, J.M.; Chen, J.X.; Liao, W.J. Development of agricultural machinery self-driving software system based on dynamic path research. J. Agric. Mech. 2022, 44, 228–232. (In Chinese) [Google Scholar]

| Parameters | Description |

|---|---|

| Position at the center of the rear axle of the trailer | |

| Velocity of tractor-trailer | |

| Angular velocity of trailer | |

| Articulated angle | |

| Vehicle lengths | |

| The front wheel steering angle |

| NB | NM | NS | ZO | PS | PM | PB | |

|---|---|---|---|---|---|---|---|

| NB | LA | ML | ML | MS | ML | ML | LA |

| NM | ML | ML | MS | Z | MS | ML | ML |

| NS | MS | MS | LE | Z | LE | MS | MS |

| ZO | LA | ML | LE | Z | LE | MS | LA |

| PS | MS | MS | LE | Z | LE | MS | MS |

| PM | ML | ML | MS | Z | MS | ML | ML |

| PB | LA | ML | ML | MS | ML | ML | LA |

| Controller | Tractor’s Lateral Error (m) | ||

|---|---|---|---|

| Max | Min | Ave | |

| SMC | 0.73 | −0.35 | 0.08 |

| 0.38 | −1.48 | 0.18 | |

| 0.74 | −0.9 | 0.18 | |

| FSMC | 0.39 | −0.17 | 0.04 |

| 0.42 | −0.6 | 0.11 | |

| 0.53 | −0.29 | 0.16 | |

| Controller | Trailer’s Lateral Error (m) | ||

|---|---|---|---|

| Max | Min | Ave | |

| SMC | 0.75 | −0.46 | 0.14 |

| 0.44 | −1.51 | 0.19 | |

| 0.75 | −0.45 | 0.19 | |

| FSMC | 0.35 | −0.23 | 0.09 |

| 0.45 | −1.35 | 0.12 | |

| 0.6 | −0.29 | 0.17 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, W.; Ji, X.; Wang, A.; Wang, Y.; Wei, X. Straight-Line Path Tracking Control of Agricultural Tractor-Trailer Based on Fuzzy Sliding Mode Control. Appl. Sci. 2023, 13, 872. https://doi.org/10.3390/app13020872

Huang W, Ji X, Wang A, Wang Y, Wei X. Straight-Line Path Tracking Control of Agricultural Tractor-Trailer Based on Fuzzy Sliding Mode Control. Applied Sciences. 2023; 13(2):872. https://doi.org/10.3390/app13020872

Chicago/Turabian StyleHuang, Wenyue, Xin Ji, Anzhe Wang, Yefei Wang, and Xinhua Wei. 2023. "Straight-Line Path Tracking Control of Agricultural Tractor-Trailer Based on Fuzzy Sliding Mode Control" Applied Sciences 13, no. 2: 872. https://doi.org/10.3390/app13020872