Method of Assessing the Logistics Process as Regards Information Flow Unreliability on the Example of a Container Terminal

Abstract

:1. Introduction

- Information flow;

- Assessment of information quality;

- Assessment of reliability.

2. Review of Literature

- Information flow;

- Assessment of information quality;

- Reliability of the technical systems.

2.1. Information Flow Issues

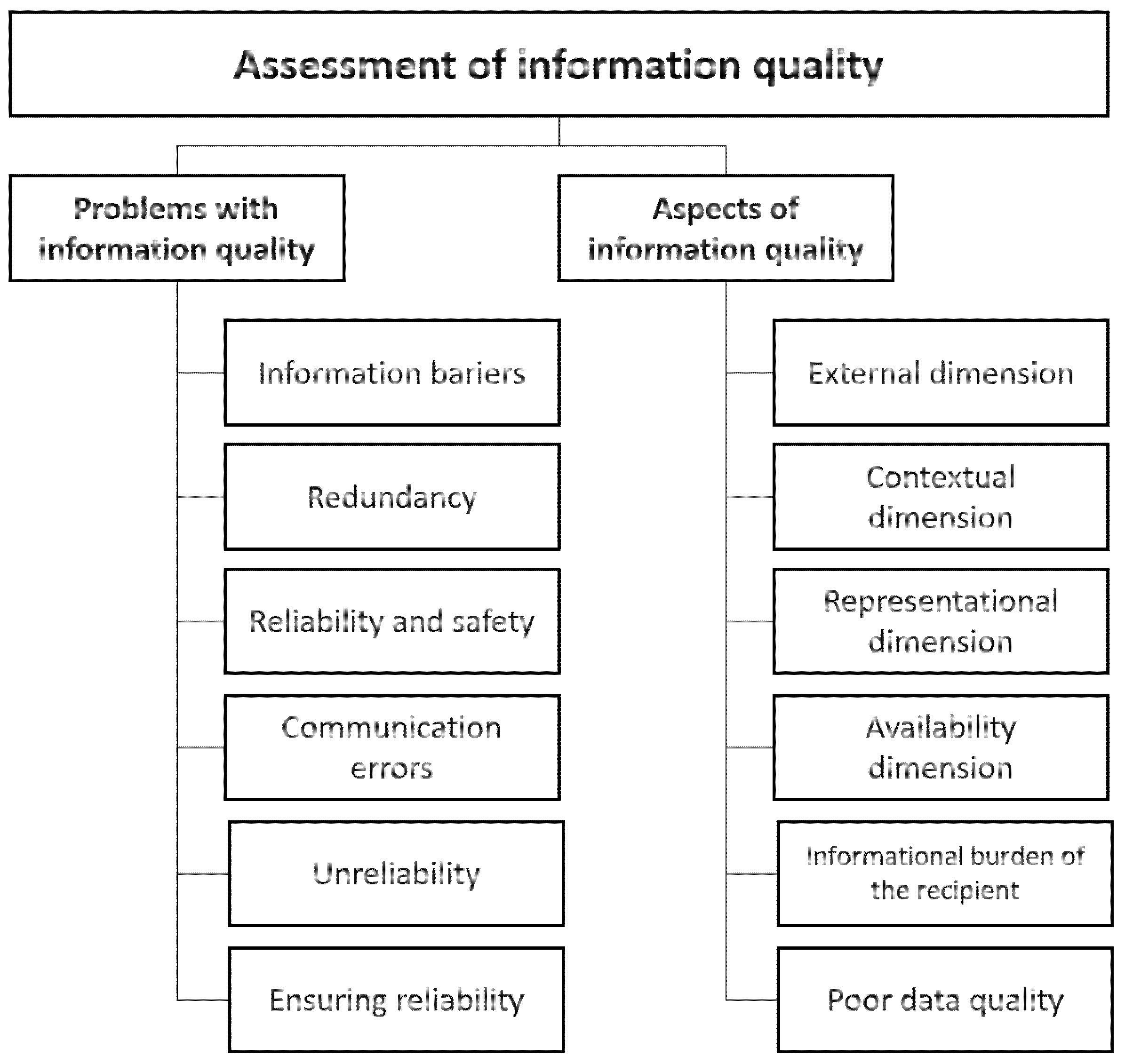

2.2. Assessment of Information Quality

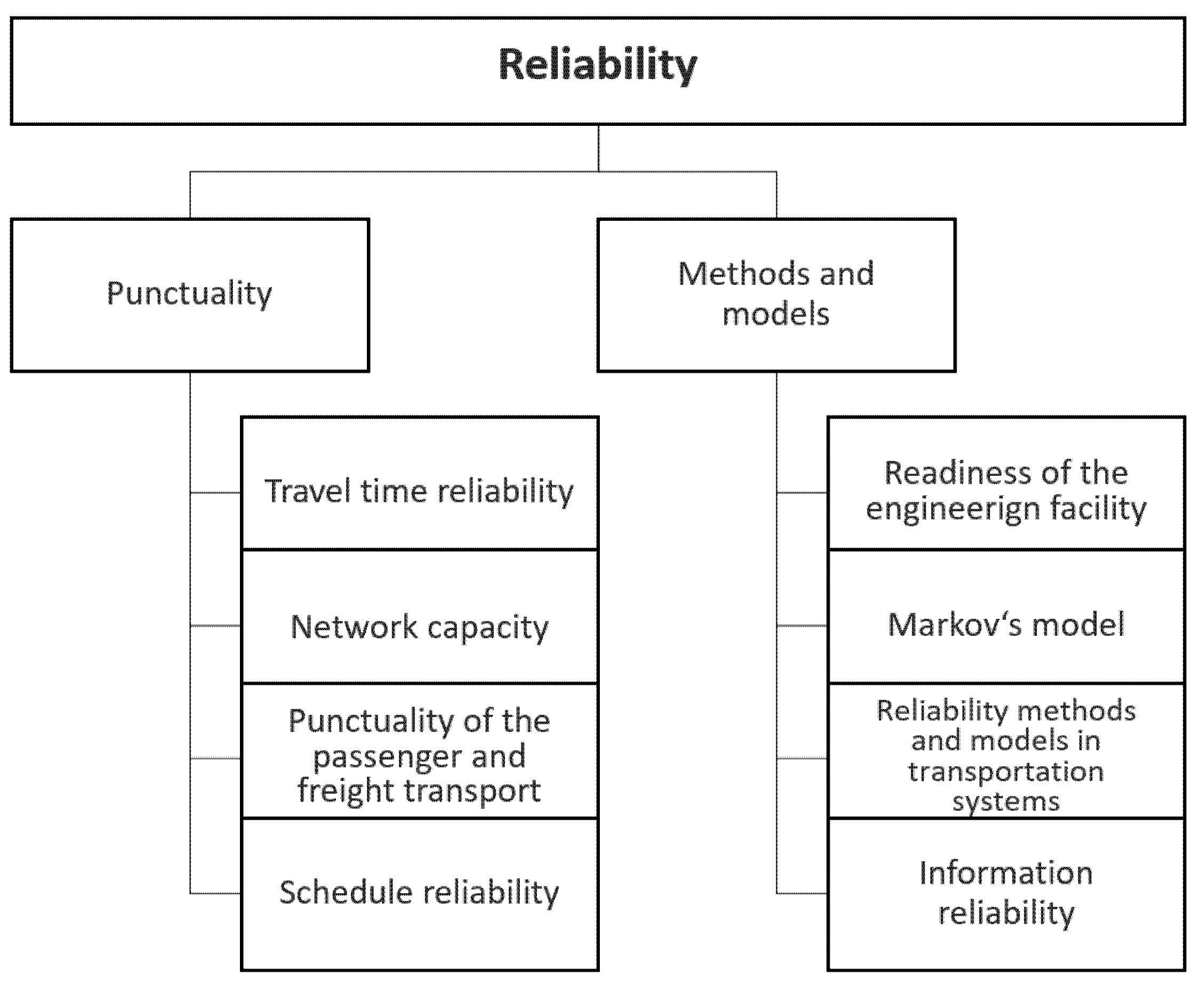

2.3. Logistics Process Reliability Assessment

3. The Proposed Method for Assessing the Logistics Process in Terms of Information Flow Unreliability

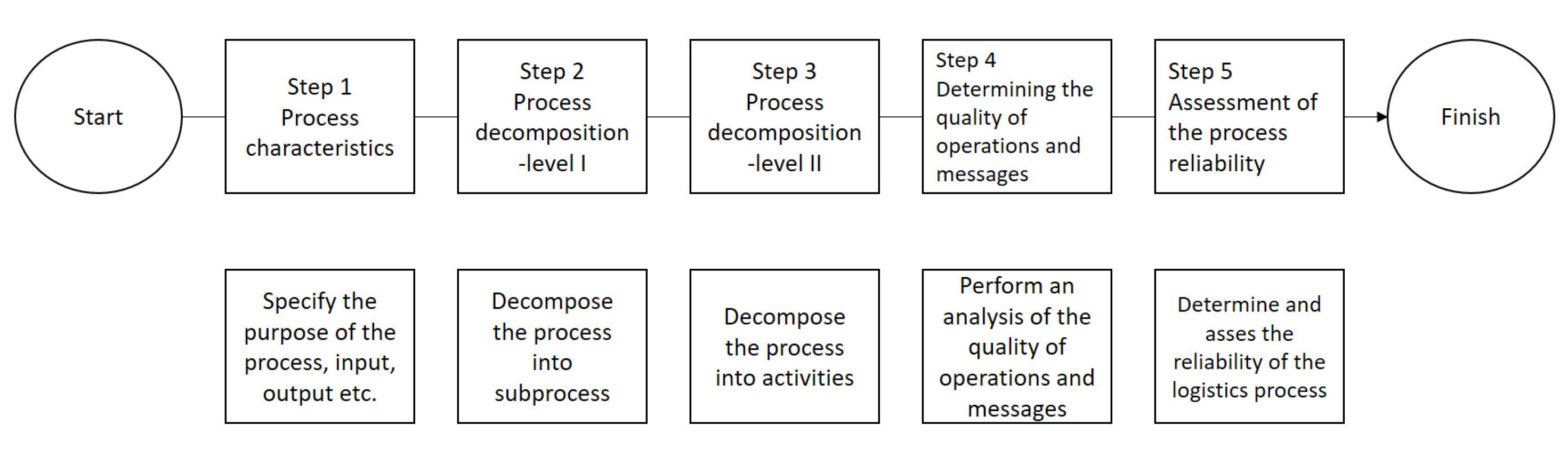

3.1. The Proposal to Assess the Logistics Process Based on Five Steps

- Step 1–Characterization of the process

- Step 2–Process decomposition—level I

- Step 3–Process decomposition—level II

- G = {A} process is a set of sub-processes, where A ={a1, … an};

- A = {D}, sub-processes are a set of activities, where D = {d1, …. dm};

- D = (I, B) activity is a set of messages and operations, where B = {b1, …, bm} and I = {I1, …, Im};

- W = {Y} set of relations of the G process.

- G–process;

- dm–activity;

- Im–message in the consecutive action m;

- bm–operation in the consecutive activity m;

- e(m,v)–action in the consecutive activity m;

- i(m,u)–data in the message in the consecutive activity m;

- n–sub-process number, for n = {1, …, N};

- m–activity number, for m = {1, …, M};

- v–number of the consecutive activity in the execution of the operation bm, for v = {1, …, V};

- u–consecutive number of data in the message, Im, for u = {1, …, U}.

- Step 4–Determining the quality of operations and messages

- (a)

- operation quality analysis bm

- (b)

- analysis of the message quality Im

- Step 5—Process reliability assessment

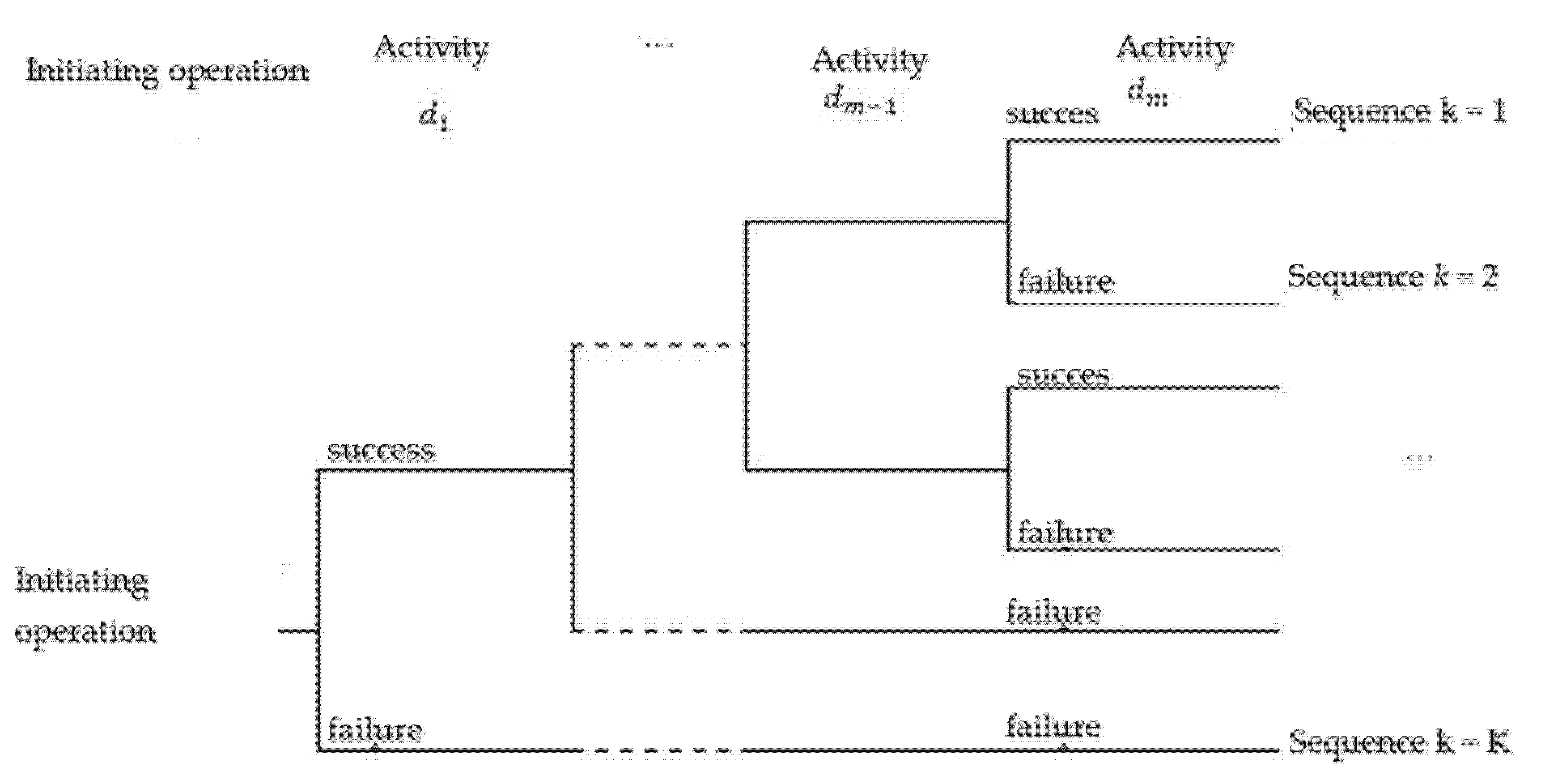

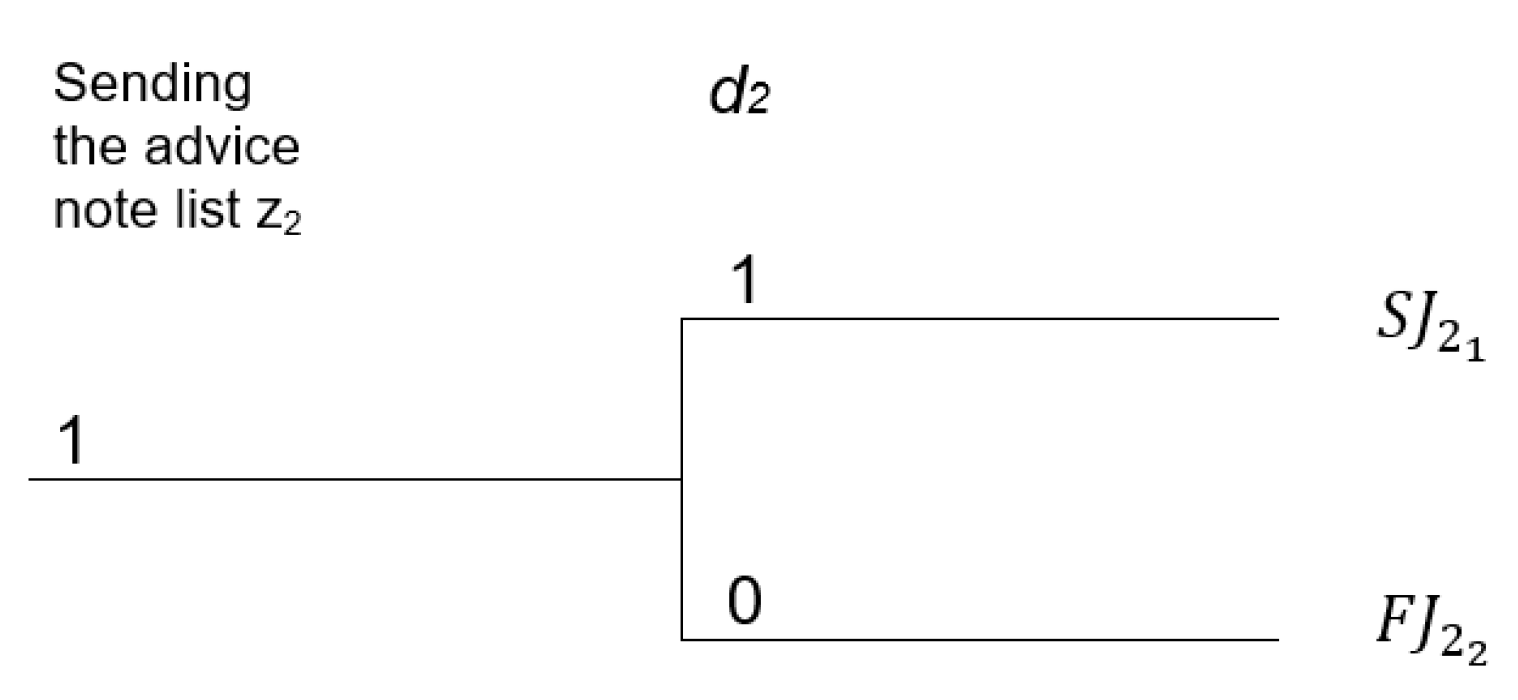

- Drawing up an event tree for each activity, assuming two states of activity execution: success and failure;

- Determining the probabilities or possibilities of two states occurring: success and failure for each activity;

- Determination of reliability;

- Analysis and evaluation of the results.

- is the probability of the success sequence for the activity dm, for m = 1, …, M;

- is the probability of the failure sequence for the activity dm, for m = 1, …, M;

- K is the subsequent binary branching of the sequence.

3.2. Assessment of Process Reliability, Taking into Consideration the Timeliness of Operations

- Identifying the initiating operation;

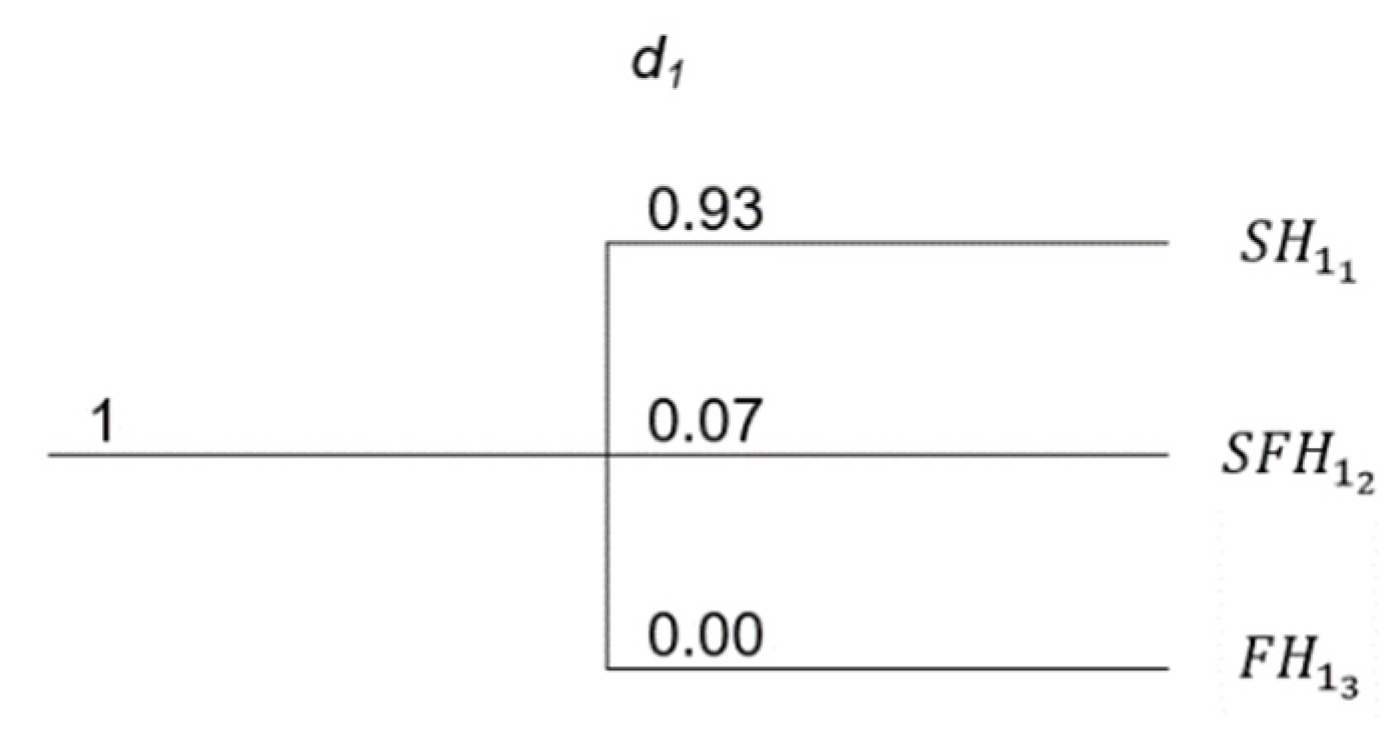

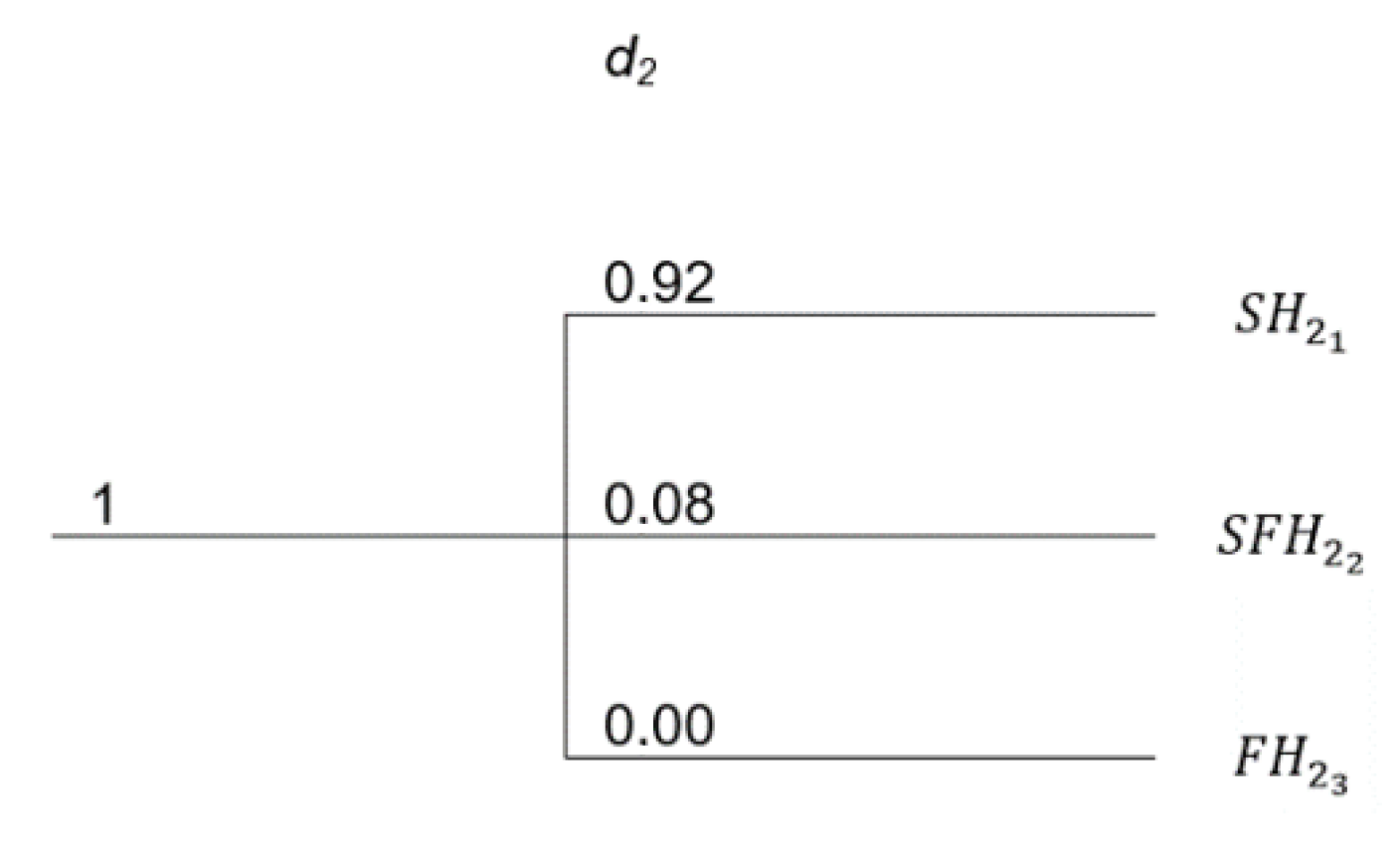

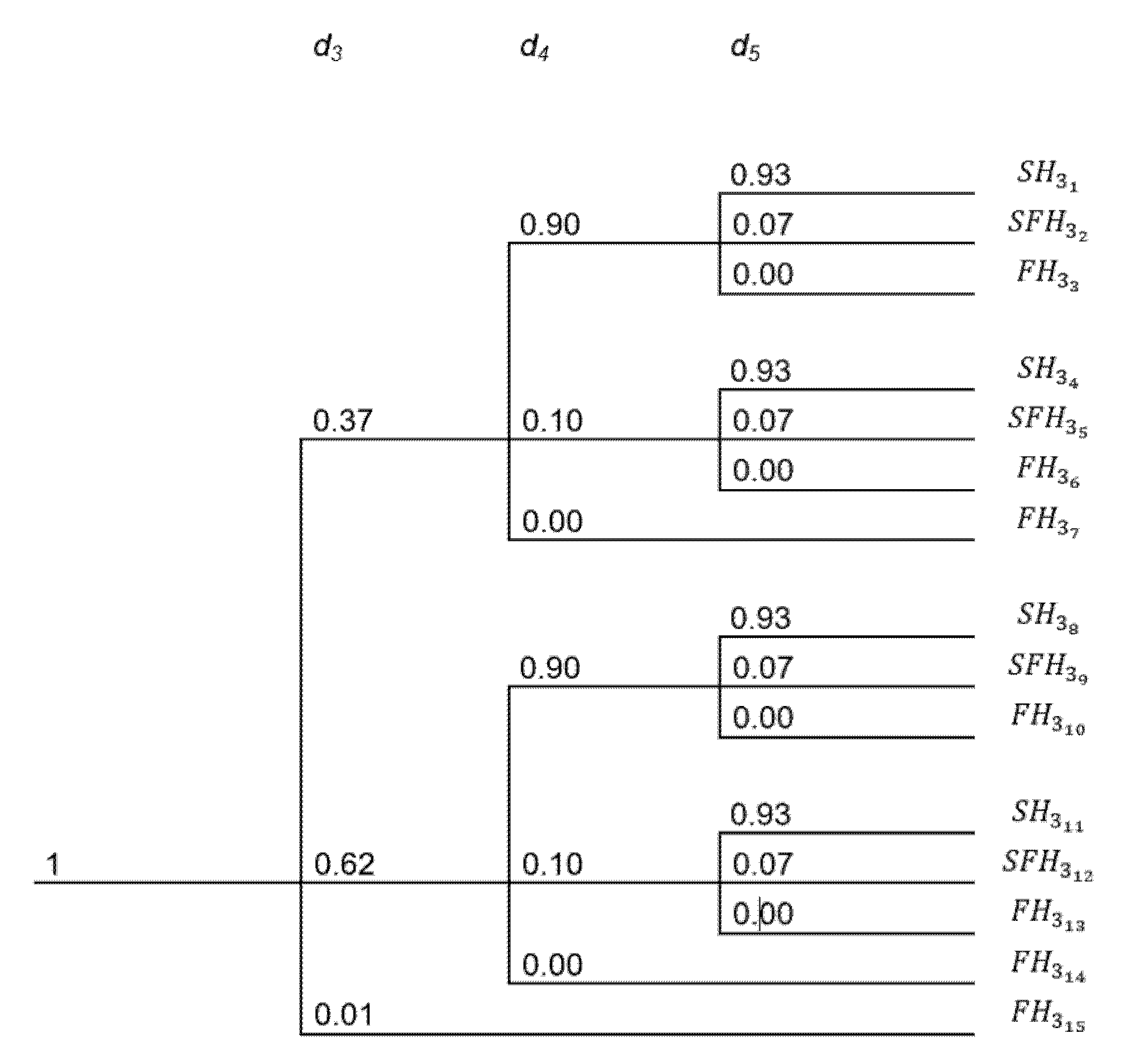

- Development of the event tree for each activity assuming three states for the event: success, partial success and failure;

- Designating the probabilities or possibilities of the occurrence of three states: success, partial success and failure for each activity;

- Determination of reliability;

- Analysis and evaluation of the results.

- is the probability of the success sequence for activity dm for the three-state system, for m = 1, …, M;

- is the probability of the partial success sequence for the three-state system for activity dm, for m = 1, …, M;

- is the probability of failure sequence for the three-state system for activity dm, for m = 1, …, M;

- C is the consequent sequence branch for the three-state system.

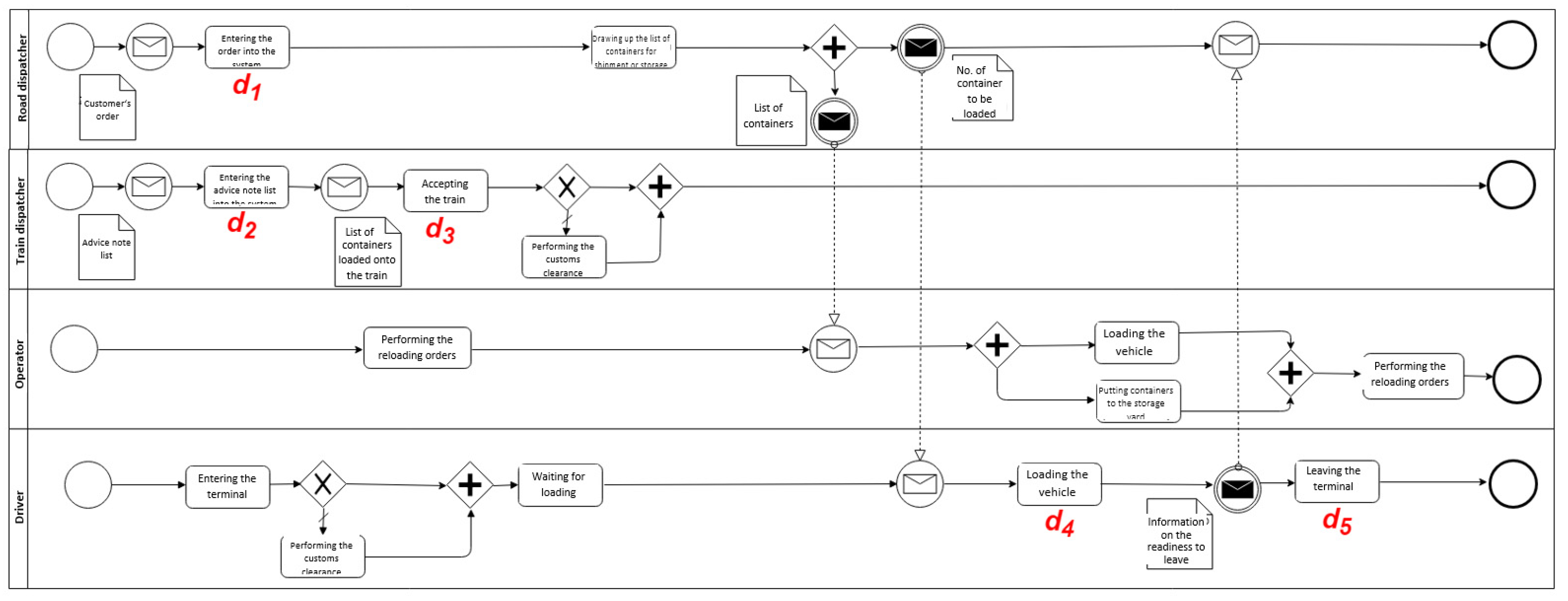

4. Verification of the Method

4.1. Stages of the Studies in the Real System in the Case of a Sample Container Terminal

4.2. Determining the Quality of Operations and Messages

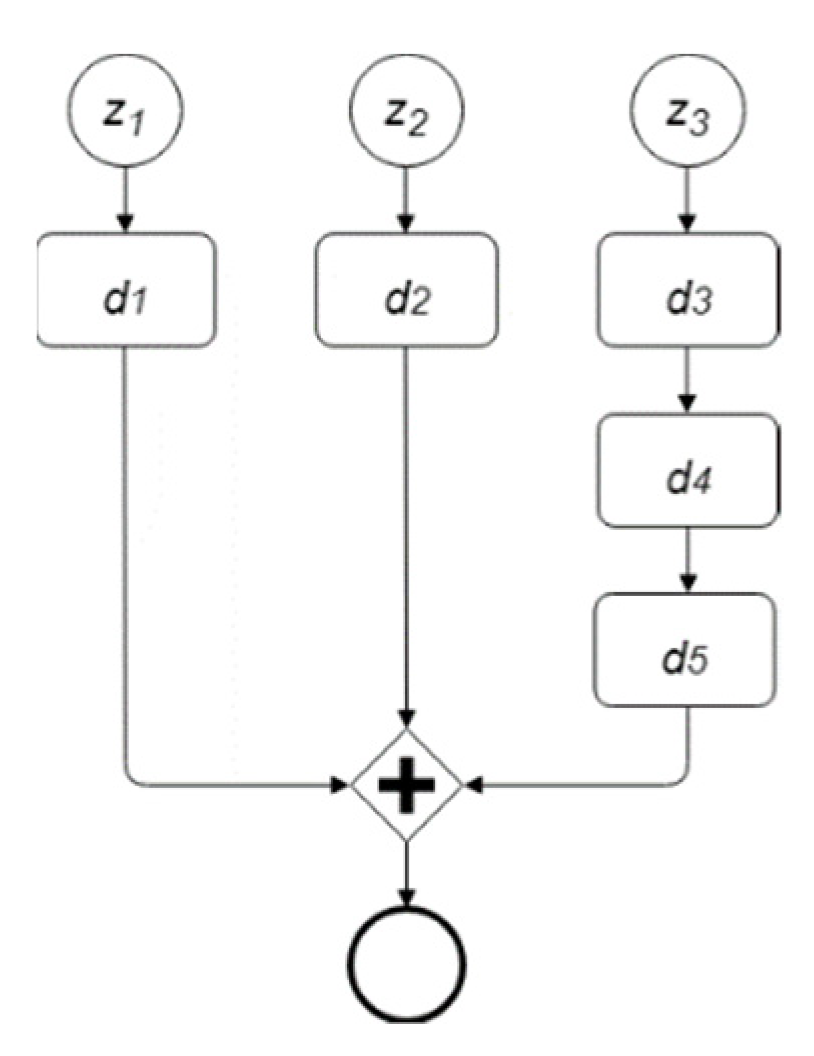

- G = {a1, a2}—a set of sub-processes;

- D = {d1, d2, d3, d4, d5}—a set of activities;

- B = {b1, b2, b3, b4, b5}—a set of operations;

- b1 = {e(1,1), e(1,2)}, b2 = {e(2,1), e(2,2)}, b3 = {e(3,1), e(3,2), e(3,3)}, b4 = { e(4,1)}, b5 = {e(5,1), e(5,2)},—a set of individual activities of the individual operations;

- I = {I1, I2, I3, I4, I5}—a set of messages;

- I1 = {i(1,1),…, i(1,34)}, I2 = {i(2,1),…, i(2,39)}, I3 = {i(3,1),…, i(3,10)}, I4 = {i(4,1),…, i(4,13)}, I5 = {i(5,1),…, i(5,27)},—a set of data in individual messages;

- —a set of process relationships.

4.3. Assessment of the Reliability of the Cargo Handling Process

4.4. Assessment of the Reliability of the Cargo Handling Process, Considering the Timely Execution of Operations

5. Conclusions

- Characterizing the examined logistics process;

- Determining the components of the process, including the information transferred within a complex engineering system;

- Formulating a definition of process reliability;

- Developing a method for assessing the reliability of a logistics process;

- Verifying a method for assessing the reliability of a logistics process using the sample cargo handling process;

- Performing analysis and evaluation of the results obtained;

- Formulation of summaries and conclusions.

- The developed method of assessing the reliability of the logistics process enables the following:

- Determination of reliability, taking into consideration the timeliness of operations performed within the framework of the analyzed process;

- Gaining knowledge on each component of the analyzed process and the determination of the necessary messages, as well as the data necessary for the execution of the operation;

- Collection of data on the causes of delays;

- Determination of the quality of the transmitted messages, in quantitative terms, as well as indicating which aspects are the most unreliable;

- Continuous improvement of the process by introducing changes and increasing the awareness of the users of the engineering system concerning errors in messages, as well as the untimeliness of the operations performed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Item No. | Information Exchange | Decision Making | Analysis of Information for Selected Parameters | Results of Information Sharing (Valorisation) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Information Sharing | Communication | Centralized | Decentralized | Lead Time | Demand | Inventory Level | Production Capacity | Total Cost | Costs of Penalties | Benefits | Service Level | Bullwhip Effect | Value of Information | Result of Tasks/Process Execution | |||||||

| Complete | Partial | Lack of | Sender—Recipient | Problems | Method (Conversation, Email, etc.) | Content of the Message | |||||||||||||||

| 1 | [53] | + | |||||||||||||||||||

| 2 | [54] | + | + | + | + | + | + | + | |||||||||||||

| 3 | [55] | + | + | + | + | + | + | G | |||||||||||||

| 4 | [17] | + | + | + | + | + | + | + | + | + | A | ||||||||||

| 5 | [56] | + | + | + | + | + | P | ||||||||||||||

| 6 | [57] | + | + | + | + | + | + | + | + | ||||||||||||

| 7 | [58] | + | + | + | + * | + | + | + | |||||||||||||

| 8 | [59] | + | + | + | + | + | G | ||||||||||||||

| 9 | [60] | + | + | + | + | + | + | + | A | ||||||||||||

| 10 | [61] | + | + | + | + * | + | + | + | + | + | P | ||||||||||

| 11 | [62] | + | + | ||||||||||||||||||

| 12 | [63] | + | + | + | + | + | + | + | + | + | + | + | + | + | |||||||

| 13 | [64] | + | + | + | + | G | |||||||||||||||

| 14 | [26] | + | + | + | + | A | |||||||||||||||

| 15 | [27] | + | + | P | |||||||||||||||||

| 16 | [28] | + | + | + | + | ||||||||||||||||

| 17 | [36] | + | |||||||||||||||||||

| 18 | [30] | + | + | + | + | + | + | + | + | + | + | + | + | + | G | ||||||

| 19 | [65] | + | + | + | + | + | + | + | + | + | + | + | A | ||||||||

| 20 | [66] | + | + | + | + | + | P | ||||||||||||||

| 21 | [67] | + | + | + | + | + | |||||||||||||||

| 22 | [68] | + | + | + | + | ||||||||||||||||

| 23 | [35] | + | + | + | + | + | |||||||||||||||

| 24 | [36] | + | + | + | + | ||||||||||||||||

| 25 | [69] | + | + | + | + | + | + | G | |||||||||||||

| 26 | [38] | + | + | + | + | A | |||||||||||||||

| 27 | [70] | + | + | + | + | + | P | ||||||||||||||

| 28 | [37] | + | + | + | + | ||||||||||||||||

| 29 | [41] | + | + | + | |||||||||||||||||

| 30 | [71] | + | + | + | G | ||||||||||||||||

| 31 | [43] | + | + | + | + | + | A | ||||||||||||||

| 32 | [44] | + | + | + | + | P | |||||||||||||||

| 33 | [72] | + | + | + | + | ||||||||||||||||

Appendix B

| Data Quality Dimension | Aspects | [44] | [73] | [74] | [75] | [76] | [77] | [78] | [79] | [80] | [81] | [82] | [83] | [84] | [85] | [86] | [87] | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Internal | Believability | + | + | + | + | + | 5 | |||||||||||

| Accuracy, no errors present | + | + | + | + | + | + | + | + | + | + | + | + | + | + | 14 | |||

| Reliability | + | + | + | + | + | + | + | + | + | 9 | ||||||||

| Objectivity | + | + | + | + | + | 5 | ||||||||||||

| Verifiability | + | 1 | ||||||||||||||||

| Contextual | Value added | + | + | + | + | + | + | 6 | ||||||||||

| Completeness | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | 15 | ||

| Timeliness (on-time) | + | + | + | + | + | + | + | + | + | + | + | 11 | ||||||

| Subject-matter relatedness, relevant | + | + | + | + | + | + | + | + | + | + | + | 11 | ||||||

| Amount of information | + | + | + | + | + | + | 6 | |||||||||||

| Actuality (in good standing) | + | + | + | + | + | 5 | ||||||||||||

| Representative | Concise representation | + | + | + | + | + | + | 6 | ||||||||||

| Adequacy (adequate) | + | + | + | + | 4 | |||||||||||||

| Interpretability | + | + | + | + | 4 | |||||||||||||

| Intelligibility (ease of understanding) | + | + | + | + | + | + | 6 | |||||||||||

| Usability (ease of use) | + | + | + | + | + | + | + | + | 8 | |||||||||

| Clarity, intelligibility (clear) | + | + | + | 3 | ||||||||||||||

| Availability dimension | Availability (access, availability) | + | + | + | + | + | + | + | + | + | + | 10 | ||||||

| Internal connectivity | + | 1 | ||||||||||||||||

| Security | + | + | + | + | + | 5 | ||||||||||||

| Internal dimension | Customer support | + | 1 | |||||||||||||||

| Price per request | + | 1 | ||||||||||||||||

| Response time | + | 1 | ||||||||||||||||

| External connectivity | + | 1 | ||||||||||||||||

| Right purpose | + | 1 | ||||||||||||||||

| Right location | + | 1 | ||||||||||||||||

| Opinion on the source of information (reputation) | + | + | + | + | + | 5 |

Appendix C

| [88] | [89] | [90] | [91] | [92] | [93] | [94] | [95] | [96] | [97] | [98] | [99] | [100] | [101] | [102] | [103] | [104] | [105] | [106] | [107] | [108] | [109] | [110] | [111] | [112] | [113] | [114] | [115] | [116] | [117] | TOTAL | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Information reliability | + | + | + | + | 4 | ||||||||||||||||||||||||||

| Travel time reliability | + | + | + | + | + | 5 | |||||||||||||||||||||||||

| Schedule/timetable reliability | + | + | + | + | + | + | 6 | ||||||||||||||||||||||||

| Reliability of IT network infrastructure | + | 1 | |||||||||||||||||||||||||||||

| Markov | + | + | + | + | + | + | 6 | ||||||||||||||||||||||||

| Semi-Markov | + | + | 2 | ||||||||||||||||||||||||||||

| Reliability structure with the unloaded reserve | + | + | 2 | ||||||||||||||||||||||||||||

| Monte Carlo simulation | + | + | + | 3 | |||||||||||||||||||||||||||

| Poisson distribution | + | + | + | 3 | |||||||||||||||||||||||||||

| Exponential distribution | + | + | + | + | + | + | + | + | 8 | ||||||||||||||||||||||

| Weibull distribution | + | 1 | |||||||||||||||||||||||||||||

| Normal distribution | + | 1 | |||||||||||||||||||||||||||||

| Log-normal distribution | + | 1 | |||||||||||||||||||||||||||||

| Readiness | + | + | + | + | + | + | + | + | + | + | + | 11 | |||||||||||||||||||

| Unreliability | + | + | 2 | ||||||||||||||||||||||||||||

| Network capacity | + | + | + | + | + | + | 6 | ||||||||||||||||||||||||

| Punctuality | + | + | + | + | + | + | + | + | + | + | + | + | 12 | ||||||||||||||||||

| Delay threshold | + | + | 2 | ||||||||||||||||||||||||||||

| Punctuality threshold | + | 1 | |||||||||||||||||||||||||||||

| Damage | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | + | 17 | |||||||||||||

| Repair/operation | + | + | + | + | + | + | + | + | + | + | + | + | + | + | 14 | ||||||||||||||||

| Surveys | + | + | 2 | ||||||||||||||||||||||||||||

| Task execution | + | + | + | + | + | + | + | + | + | + | + | 11 | |||||||||||||||||||

| Hierarchical task analysis (HTA) | + | 1 | |||||||||||||||||||||||||||||

| Costs | + | + | + | + | + | 5 | |||||||||||||||||||||||||

| Availability | + | + | + | + | + | 5 | |||||||||||||||||||||||||

| Dispatcher‘s decisions | + | + | 2 | ||||||||||||||||||||||||||||

| Schedule reliability | Readiness | Markov model | Transportation system reliability model | Information reliability | |||||||||||||||||||||||||||

Appendix D

References

- Zio, E. Reliability engineering: Old problems and new challenges. Reliab. Eng. Syst. Saf. 2009, 94, 125–141. [Google Scholar] [CrossRef] [Green Version]

- Cichosz, M.; Wallenburg, C.M.; Knemeyer, A.M. Digital transformation at logistics service providers: Barriers, success factors and leading practices. Int. J. Logist. Manag. 2020, 31, 209–238. [Google Scholar] [CrossRef]

- Meeker, W.Q.; Escobar, L.A.; Pascual, F.G. Statistical Methods for Reliability Data; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Levchenkov, A. Increasing the reliability of information management systems for complex objects. E3S Web Conf. 2020, 224, 01039. [Google Scholar] [CrossRef]

- Pomatto, L.; Strack, P.; Tamuz, O. The Cost of Information. arXiv 2018, arXiv:1812.04211. [Google Scholar]

- Cabrales, A.; Gossner, O.; Serrano, R. A normalized value for information purchases. J. Econ. Theory 2017, 170, 266–288. [Google Scholar] [CrossRef]

- Dean, M.; Neligh, N.L. Experimental Tests of Rational Attention; Columbia University Press: New York, NY, USA, 2017. [Google Scholar]

- Maćkowiak, B.; Matějka, F.; Wiederholt, M. Rational Inattention: A Review (June 1, 2021). ECB Working Paper No. 2021/2570. Available online: https://ssrn.com/abstract=3871534 (accessed on 15 December 2022).

- Chukurna, O.; Vaysman, V.; Kassien, O.; Dobrovoslkyi, V.; Strunnikova, N. Recycling of Municipal Sewage Sludge in Sustainable Logistics Systems in the Focus of Information Technology Management. J. Inf. Technol. Manag. 2022, 14, 157–178. [Google Scholar]

- Zha, X.; Zhang, X.; Liu, Y.; Dan, B. Bonded-warehouse or direct-mail? Logistics mode choice in a cross-border e-commerce supply chain with platform information sharing. Electron. Commer. Res. Appl. 2022, 54, 101181. [Google Scholar] [CrossRef]

- Antony, J.; Gupta, S. Top ten reasons for process improvement project failures. Int. J. Lean Six Sigma 2019, 10, 367–374. [Google Scholar] [CrossRef]

- Hebert, B.; Woodford, M. Rational Inattention and Sequential Information Sampling; NBER: Cambridge, MA, USA, 2017. [Google Scholar]

- Swieboda, J. Metoda Oceny Procesu Logistycznego w Aspekcie Zawodności Przepływu Informacji; Raporty Wydziału Mechanicznego Politechniki Wrocławskiej; Politechniki Wrocławskiej: Wrocław, Poland, 2019. [Google Scholar]

- Nowakowski, T.; Mlynczak, M.; Jodejko-Pietruczuk, A.; Werbinska-Wojciechowska, S. Safety and Reliability: Methodology and Applications; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Coyle, J.J.; Bardi, E.J.; Langley, C.J., Jr. Zarządzanie Logistyczne; Polskie Wydawnictwo Ekonomiczne: Warszawa, Poland, 2002. [Google Scholar]

- Thomas, M.T.C.A.J.; Joy, A.T. Elements of Information Theory, Wiley-Interscience; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Lagorio, A.; Zenezini, G.; Mangano, G.; Pinto, R. A systematic literature review of innovative technologies adopted in logistics management. Int. J. Logist. Res. Appl. 2020, 25, 1043–1066. [Google Scholar] [CrossRef]

- Waters, D. Logistics An Introduction to Supply Chain Management; Palgrave Macmillan: London, UK, 2021. [Google Scholar]

- Pokrovskaya, O.; Reshetko, N.; Kirpicheva, M.; Lipatov, A.; Mustafin, D. The study of logistics risks in optimizing the company’s transportation process. IOP Conf. Ser. Mater. Sci. Eng. 2019, 698. [Google Scholar] [CrossRef]

- Stair, R.; Reynolds, G. Principles of Information Systems; Cengage Learning: Boston, MA, USA, 2020. [Google Scholar]

- van Goor, A.; van Amstel, M.P. European Distribution and Supply Chain Logistics; Routledge: London, UK, 2019. [Google Scholar]

- Cox, J.F.; Blackstone, J.H. The Educational Society for Resource Management, 9th ed.; APICS Dictionary (APICS): Chicago, IL, USA, 1998. [Google Scholar]

- Myerson, P. Lean Supply Chain and Logistics Management; McGraw-Hill Education: New York, NY, USA, 2012. [Google Scholar]

- Faheem, M.; Shah, S.; Butt, R.; Raza, B.; Anwar, M.; Ashraf, M.; Ngadi, M.; Gungor, V. Smart grid communication and information technologies in the perspective of Industry 4.0: Opportunities and challenges. Comput. Sci. Rev. 2018, 30, 1–30. [Google Scholar] [CrossRef]

- Anand, K.; Mendelson, H. Information organization for horizontal multimarket coordination. Manag. Sci. 1997, 43, 1609–1627. [Google Scholar] [CrossRef]

- Zhou, L.; Hu, D.L. The Beneficial Impact of Information Sharing on the Bullwhip Effect in Supply Chains. In Proceedings of the 2008 4th International Conference on Wireless Communications, Networking and Mobile Computing, Dalian, China, 12–14 October 2008; pp. 1–4. [Google Scholar]

- Moyaux, T.; Chaib-Draa, B.; D’Amours, S. Information Sharing as a Coordination Mechanism for Reducing the Bullwhip Effect in a Supply Chain. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2006, 37, 396–409. [Google Scholar] [CrossRef]

- Tan, G.W.; Wang, B. The Relationship between Product Nature, Demand Patterns and Information Sharing Strategies. In Proceedings of the 22nd ICIS, New Orleans, LA, USA, 16–19 December 2001; pp. 543–549. [Google Scholar]

- Wójcik, A.; Zabost, M. Symulacja jako narzędzie doskonalenia przepływu produkcji na przykładzie analizowanego przedsiębiorstwa–case study. J. Trans. Logist. 2016, 2, 145–163. [Google Scholar]

- Zhang, C. Design and simulation of demand information sharing in a supply chain. Simul. Model. Pract. Theory 2007, 15, 32–46. [Google Scholar] [CrossRef]

- Woźniak, W.; Sąsiadek, M.; Jachowicz, T.; Edl, M.; Zając, P. Studies on the Mechanical Properties of C45 Steel with Martensitic Structure after a High Tempering Process. Adv. Sci. Technol. Res. J. 2022, 16, 306–315. [Google Scholar] [CrossRef]

- Kochan, C.G.; Nowicki, D.R.; Sauser, B.; Randall, W.S. Impact of cloud-based information sharing on hospital supply chain performance: A system dynamics framework. Int. J. Prod. Econ. 2018, 195, 168–185. [Google Scholar] [CrossRef]

- Dejonckheere, J.; Disney, S.M.; Lambrecht, M.R.; Towill, D.R. The impact of information enrichment on the bullwhip effect in supply chains: A control engineering perspective. Eur. J. Oper. Res. 2004, 153, 727–750. [Google Scholar] [CrossRef]

- Agrawal, S.; Sengupta, R.N.; Shanker, K. Impact of information sharing and lead time on bullwhip effect and on-hand in-ventory. Eur. J. Oper. Res. 2009, 192, 576–593. [Google Scholar] [CrossRef]

- Sodhi, M.M.; Tang, S.; Christopher, S. The incremental bullwhip effect of operational deviations in an arborescent supply chain with requirements planning. Eur. J. Oper. Res. 2011, 215, 374–382. [Google Scholar] [CrossRef]

- Lee, H.L.; So, K.C.; Tang, C.S. The value of information sharing in a two-level supply chain. Manag. Sci. 2000, 46, 626–643. [Google Scholar] [CrossRef] [Green Version]

- Ojha, D.; Sahin, F.; Shockley, J.; Sridharan, S.V. Is there a performance tradeoff in managing order fulfillment and the bullwhip effect in supply chains? The role of information sharing and information type. Int. J. Prod. Econ. 2019, 208, 529–543. [Google Scholar] [CrossRef]

- Shanshan, W. The impact of information sharing and coordination in make-to-order supply chain. In Proceedings of the 2010 Second International Conference on Communication Systems, Networks and Applications, Hong Kong, China, 29 June–1 July 2010; pp. 325–328. [Google Scholar]

- Matharage, S.T.; Hewage, U.; Perera, H.N. Impact of sharing point of sales data and inventory information on bullwhip effect. In Proceedings of the 2020 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 14–17 December 2020; pp. 857–861. [Google Scholar]

- Chatfield, D.C.; Kim, J.G.; Harrison, T.P.; Hayya, J.C. The bullwhip effect—Impact of stochastic lead time, information quality, and information sharing: A simulation study. Prod. Oper. Manag. 2004, 13, 340–353. [Google Scholar] [CrossRef]

- Guo, C.; Li, X.; Wilck, J. Supply Chain Information Sharing Strategy on Inventory Systems; Institute of Industrial Engineers-Publisher: Peachtree Corners, GA, USA, 2011. [Google Scholar]

- Dimitriadis, N.I.; Koh, S.C.L. Information flow and supply chain management in local production networks: The role of people and information systems. Prod. Plan. Control. 2005, 16, 545–554. [Google Scholar] [CrossRef]

- Rached, M.; Bahroun, Z.; Campagne, J.P. Assessing the value of information sharing and its impact on the performance of the various partners in supply chains. Comput. Ind. Eng. 2015, 88, 237–253. [Google Scholar] [CrossRef]

- Choe, J.M. Inter-organizational relationships and the flow of information through value chains. Inf. Manag. 2008, 45, 444–450. [Google Scholar] [CrossRef]

- Nowakowski, T. Problems with analyzing operational data uncertainty. Arch. Civ. Mech. Eng. 2010, 10, 95–109. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Mohamed, M. RETRACTED: The role of single valued neutrosophic sets and rough sets in smart city: Imperfect and incomplete information systems. Measurement 2018, 124, 47–55. [Google Scholar] [CrossRef] [Green Version]

- Zając, M. The Analysis of Selected Factors Improving the Cargo Susceptibility to Modal Shift. Energies 2022, 15, 8811. [Google Scholar] [CrossRef]

- Nowakowski, T. Problemy Reprezentacji Niepewności Danych Niezawodnościowych; Zimowa Szkoła Niezawodności, Zimowa Szkoła Niezawodności: Warsaw, Poland, 1997; pp. 147–152. [Google Scholar]

- Ruiz-Palmero, J.; Colomo-Magaña, E.; Ríos-Ariza, J.M.; Gómez-García, M. Big Data in Education: Perception of Training Advisors on Its Use in the Educational. System. Soc. Sci. 2020, 9, 53. [Google Scholar] [CrossRef] [Green Version]

- Rožić, T.; Naletina, D.; Zając, M. Volatile Freight Rates in Maritime Container Industry in Times of Crises. Appl. Sci. 2022, 12, 8452. [Google Scholar] [CrossRef]

- Henley, E.J.; Kumamoto, H. Reliability Engineering and Risk Assessment; Englewood Cliffs (NJ); Prentice-Hall: Hoboken, NJ, USA, 1981. [Google Scholar]

- Kierzkowski, A.; Kisiel, T. An impact of the operators and passengers behavior on the airport’s security screening reliability. In Proceedings of the European Safety and Reliability Conference—ESREL 2015, Zurich, Switzeland, 7–10 September 2015; pp. 2345–2354. [Google Scholar]

- Abdulrahaman, M.; Faruk, N.; Oloyede, A.; Surajudeen-Bakinde, N.; Olawoyin, L.; Mejabi, O.; Imam-Fulani, Y.; Fahm, A.; Azeez, A. Multimedia tools in the teaching and learning processes: A systematic review. Heliyon 2020, 6, e05312. [Google Scholar] [CrossRef]

- Abramowicz, W. Filtrowanie Informacji; Wydawnictwo Akademii Ekonomicznej w Poznaniu: Poznań, Poland, 2008. [Google Scholar]

- Grudzień, Ł. Koncepcja Oceny Jakości Informacji o Procesach w Systemach Zarządzania; Oficyna Wydawnicza Polskiego Towarzystwa Zarządzania Produkcją: Opole, Poland, 2012. [Google Scholar]

- Rainer, R.K.; Prince, B. Introduction to Information Systems; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Adamczewski, P. Informatyczne wspomaganie łańcucha logistycznego- struktura funkcjonalna i uwarunkowania realizacji. Zesz. Nauk. Akad. Ekon. W Pozn. 2000, 3, 36–56. [Google Scholar]

- Abt, S. Systemy Logistyczne w Gospodarowaniu, Teoria i Praktyka Logistyki; Wydawnictwo Akademii Ekonomicznej Poznaniu: Poznań, Poland, 1996. [Google Scholar]

- Scheff, S.; Livngston, D.B. Computer Integrated Logistic: CIL Architecture in the Extended Enterprise; IBM Corporation, U.S. Transportation Industry Marketing: Southbury, CT, USA, 1991; p. 9. [Google Scholar]

- Birkel, H.; Müller, J.M. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. J. Clean. Prod. 2021, 289, 125612. [Google Scholar] [CrossRef]

- Parfenov, A.; Shamina, L.; Niu, J.; Yadykin, V. Transformation of distribution logistics management in the digitalization of the economy. J. Open Innov. Technol. Mark. Complex. 2021, 7, 58. [Google Scholar] [CrossRef]

- Barczak, A.; Dembińska, I.; Marzantowicz, Ł. Analysis of the Risk Impact of Implementing Digital Innovations for Logistics Management. Processes 2019, 7, 815. [Google Scholar] [CrossRef] [Green Version]

- Peña, J.D.; Bas, O.; Maldonado, N.R. Impact of Bullwhip Effect in Quality and Waste in Perishable Supply Chain. Processes 2021, 9, 1232. [Google Scholar] [CrossRef]

- Choi, J.; Chung, S.; Chang, Y.S. Is M&A Information Useful for Exploring Promising Industries and Technologies? Sustainability 2020, 12, 139. [Google Scholar]

- Fu, Y.H.; Piplani, R. Supply-side collaboration and its value in supply chains. Eur. J. Oper. Res. 2004, 152, 281–288. [Google Scholar] [CrossRef]

- Mostafa, N.; Hamdy, W.; Alawady, H. Impacts of Internet of Things on Supply Chains: A Framework for Warehousing. Soc. Sci. 2019, 8, 84. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Shi, L.; Zhuo, X.; Liu, Y. A Bullwhip Effect Weakening Approach Based on VMD-SVM Algorithm under the Background of Intelligent Manufacturing. Processes 2021, 9, 1957. [Google Scholar] [CrossRef]

- Lochan, S.A.; Rozanova, T.P.; Bezpalov, V.V.; Fedyunin, D.V. Supply Chain Management and Risk Management in an Environment of Stochastic Uncertainty (Retail). Risks 2021, 9, 197. [Google Scholar] [CrossRef]

- Merkuryev, Y.A.; Petuhova, J.J.; Van Landeghem, R.; Vansteenkiste, S. Simulation-based analysis of the bullwhip effect under different information sharing strategies. In Proceedings of the 14th European Simulation Symposium, Dresden, Germany, 23–26 October 2002. [Google Scholar]

- Yuan, Q.; Qiong, Z. Incentive Mechanism of Supply Chain Inventory Management Based on Information Sharing. In Proceedings of the Business and Information Management, Proceedings of the ISBIM International Seminar, Wuhan, China, 19 December 2008; Volume 2, pp. 373–377. [Google Scholar]

- Lanza, G.; Ferdows, K.; Kara, S.; Mourtzis, D.; Schuh, G.; Váncza, J.; Wang, L.; Wiendahl, H.-P. Global production networks: Design and operation. CIRP Ann. 2019, 68, 823–841. [Google Scholar] [CrossRef]

- Childerhouse, P.; Hermiz, R.; Mason-Jones, R.; Popp, A.; Towill, D.R. Information flow in automotive supply chains–present industrial practice. Ind. Manag. Data Syst. 2003, 103, 137–149. [Google Scholar] [CrossRef]

- Chileshe, N.; Jayasinghe, R.S.; Rameezdeen, R. Information flow-centric approach for reverse logistics supply chains. Autom. Constr. 2019, 106. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recycl. 2019, 153, 104559. [Google Scholar] [CrossRef]

- Li, J.; Shaw, M.J.; Sikora, R.T.; Tan, G.W.; Yang, R. The Effects of Information Sharing Strategies on Supply Chain Performance; College of Commerce and Business Administration, University of Illinois at Urbana: Champaign, IL, USA, 2001. [Google Scholar]

- Straub, D. Value of information analysis with structural reliability methods. Struct. Saf. 2014, 49, 75–85. [Google Scholar] [CrossRef]

- Helper, C.M.; Davis, L.B.; Wei, W. Impact of demand correlation and information sharing in a capacity constrained supply chain with multiple-retailers. Comput. Ind. Eng. 2010, 59, 552–560. [Google Scholar] [CrossRef]

- Davis, L.B.; King, R.E.; Hodgson, T.J.; Wenbin, W. Information sharing in capacity constrained supply chains under lost sales. Int. J. Prod. Res. 2011, 49, 7469–7491. [Google Scholar] [CrossRef]

- Wijayaratna, K.P.; Dixit, V.V. Impact of information on risk attitudes: Implications on valuation of reliability and information. J. Choice Model. 2016, 20, 16–34. [Google Scholar] [CrossRef]

- Billings, C.E. Misunderstanding of Communications between Pilots and Controllers; ASRS Third Quarterly Report, NASA TM X-3546; NASA: Washington, DC, USA, 1977.

- Araz, O.M.; Choi, T.; Olson, D.L.; Salman, F.S. Data Analytics for Operational Risk Management. Decis. Sci. 2020, 51, 1316–1319. [Google Scholar] [CrossRef]

- Lin, Y. Spoken Instruction Understanding in Air Traffic Control: Challenge, Technique, and Application. Aerospace 2021, 8, 65. [Google Scholar] [CrossRef]

- Knoblock, E.J.; Apaza, R.D.; Li, H.; Wang, Z.; Han, R.; Schimpf, N.; Rose, N.P. Investigation and Evaluation of Advanced Spectrum Management Concepts for Aeronautical Communications. In Proceedings of the 2021 Integrated Communications Navigation and Surveillance Conference (ICNS), Dulles, VA, USA, 19–23 April 2021. [Google Scholar]

- Stroeve, S.H.; van Doorn, B.A.; Everdij, M.H. Analysis of the roles of pilots and controllers in the resilience of air traffic management. Saf. Sci. 2015, 76, 215–227. [Google Scholar] [CrossRef]

- Skaltsas, G.; Rakas, J.; Karlaftis, M.G. An analysis of air traffic controller-pilot miscommunication in the NextGen environment. J. Air Transp. Manag. 2013, 27, 46–51. [Google Scholar] [CrossRef]

- Molesworth, B.R.; Estival, D. Miscommunication in general aviation: The influence of external factors on communication errors. Saf. Sci. 2015, 73, 73–79. [Google Scholar] [CrossRef]

- Telesetsky, A. The United States National Contingency Plan: Learning from Gaps in the System; Brill Nijhoff: Leiden, The Netherlands, 2017; pp. 201–222. [Google Scholar]

- Stedmon, A.W.; Sharples, S.; Littlewood, R.; Cox, G.; Patel, H.; Wilson, J.R. Datalink in air traffic management: Human factors issues in communications. Appl. Ergon. 2007, 38, 473–480. [Google Scholar] [CrossRef]

- Galotti, V.P. The Future Air Navigation System (FANS): Communications, Navigation, Surveillance–Air Traffic Management (CNS/ATM); Routledge: London, UK, 2019. [Google Scholar]

- International Civil Aviation Organization. Procedures for Air Navigation Services, Air Traffic Management, Fifth Edition—2007, International Civil Aviation Organization, Attachment to Guidelines No. 8 of the President of the Civil Aviation Authority of August 26, 2015; International Civil Aviation Organization: Montreal, QC, Canada. (In Polish)

- Loftus, G.R.; Dark, V.J.; Williams, D. Short-term memory factors in ground controller/pilot communication. Hum. Factors J. Hum. Factors Ergon. Soc. 1979, 21, 169–181. [Google Scholar] [CrossRef]

- Chen, J.Y.C.; Lakhmani, S.G.; Stowers, K.; Selkowitz, A.R.; Wright, J.L.; Barnes, M. Situation awareness-based agent transparency and human-autonomy teaming effectiveness. Theor. Issues Ergon. Sci. 2018, 19, 259–282. [Google Scholar] [CrossRef]

- Bullock, N. Evolving teacher training programmes through integrating contextual factors for language learning as part of aeronautical communication. In Proceedings of the Integrating Contextual Factors into Teaching of English for Aeronautical Communications, Daytona Beach, FL, USA, 10 May 2018. [Google Scholar]

- Available online: http://atccommunication.com (accessed on 15 December 2022).

- Cardosi, K.M. An Analysis of en Route Controller-Pilot Voice Communication; Final Report NASA ASRS; NASA: Washington, DC, USA, 1993.

- Ahlstrom, D.; Arregle, J.; Hitt, M.A.; Qian, G.; Ma, X.; Faems, D. Managing Technological, Sociopolitical, and Institutional Change in the New Normal. J. Manag. Stud. 2020, 57, 411–437. [Google Scholar] [CrossRef]

- Santalova, M.S.; Lesnikova, E.P.; Nechaeva, S.N.; Borshcheva, A.V.; Charykova, O.G. Information hindrances and communication barriers in project interactions. In The Future of the Global Financial System: Downfall of Harmony; Springer: Cham, Switzerland, 2018; pp. 273–281. [Google Scholar]

- Rodionov, D.; Zaytsev, A.; Konnikov, E.; Dmitriev, N.; Dubolazova, Y. Modeling changes in the enterprise information capital in the digital economy. J. Open Innov. Technol. Mark. Complex. 2021, 7, 166. [Google Scholar] [CrossRef]

- Wang, H.-W.; Lin, J.-R.; Zhang, J.-P. Work package-based information modeling for resource-constrained scheduling of construction projects. Autom. Constr. 2019, 109, 102958. [Google Scholar] [CrossRef]

- Urbinati, A.; Franzò, S.; Chiaroni, D. Enablers and Barriers for Circular Business Models: An empirical analysis in the Italian automotive industry. Sustain. Prod. Consum. 2021, 27, 551–566. [Google Scholar] [CrossRef]

- Liao, H.; Mi, X.; Xu, Z. A survey of decision-making methods with probabilistic linguistic information: Bibliometrics, preliminaries, methodologies, applications and future directions. Fuzzy Optim. Decis. Mak. 2019, 19, 81–134. [Google Scholar] [CrossRef]

- Jagacinski, R.J.; Flach, J.M. Control Theory for Humans: Quantitative Approaches to Modeling Performance; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Lesca, H.; Lesca, E. Gestion de L’information; Litec: Paris, France, 1995. [Google Scholar]

- Zoltowski, B. Nadmiar Informacyjny w Diagnozowaniu Uszkodzeń; Zimowej Szkoły Niezawodności: Szczyrk, Poland, 2004; pp. 412–424. [Google Scholar]

- Nowakowski, T. Problemy Wykorzystania Nadmiaru Informacyjnego do Podwyższenia Niezawodności Maszyn; Zimowej Szkoły Niezawodności: Szczyrk, Poland, 1995; pp. 117–122. [Google Scholar]

- Salma, V.; Friedl, F.; Schmehl, R. Improving reliability and safety of airborne wind energy systems. Wind. Energy 2019, 23, 340–356. [Google Scholar] [CrossRef] [Green Version]

- Bukowski, L. Wpływ Nadmiaru Informacyjnego na Niezawodność Zautomatyzowanych Systemów Produkcyjnych; Zimowej Szkoły Niezawodności: Szczyrk, Poland, 2004; pp. 43–53. [Google Scholar]

- Moore, E.F.; Shannon, C.E. Reliable circuits using less reliable relays. J. Frankl. Inst. 1956, 262, 191–208. [Google Scholar] [CrossRef]

- Mao, H.; Schwarzkopf, M.; Venkatakrishnan, S.B.; Meng, Z.; Alizadeh, M. Learning scheduling algorithms for data processing clusters. In Proceedings of the ACM Special Interest Group on Data Communication, Beijing, China, 19 August 2019; pp. 270–288. [Google Scholar]

- Wawrzyński, W.; Dziula, P. Rola Nadmiaru Informacyjnego w Poprawie Bezpieczeństwa Systemu; Zimowej Szkoły Niezawodności: Szczyrk, Poland, 2004; pp. 379–388. [Google Scholar]

- Kołowrocki, K.; Soszyńska-Budny, J. Critical infrastructure safety indicators. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 1761–1764. [Google Scholar]

- Chen, W.; Xu, H.-L.; Peng, N.; Yang, F.-Q.; Lin, P. Linkage characteristics of deep-sea mining lifting system. Ocean Eng. 2021, 233, 109074. [Google Scholar] [CrossRef]

- Karolak, Z.; Olearczuk, E.; Zubko, W. Koncepcja Hybrydowego Modelu Odbioru Informacji w Systemach Człowiek—Obiekt Techniczny; Zimowej Szkoły Niezawodności: Szczyrk, Poland, 1979; pp. 133–148. [Google Scholar]

- Collin-Orellana, A.; Vásquez-Cassinelli, J.; Duque-Córdova, L.; Espinoza-Samaniego, C.; Arias-Ulloa, C.; Escobar-Segovia, K. Improvement in service quality by analyzing the relationship between psychosocial risks and labor engagement in a vertical transport equipment maintenance company. In Proceedings of the 18th LACCEI International Multi-Conference for Engineering, Education Caribbean Conference for Engineering and Technology, Bogota, Colombia, 27–31 July 2020. [Google Scholar]

- Ważyńska-Fiok, K. Model Bezpieczeństwa Systemu o Dwóch Stanach Intencjonalnych Wyposażonego w Układ Informacyjny; Zimowej Szkoły Niezawodności: Szczyrk, Poland, 1993; pp. 289–299. [Google Scholar]

- Barrows, C.; Bloom, A.; Ehlen, A.; Ikaheimo, J.; Jorgenson, J.; Krishnamurthy, D.; Lau, J.; McBennett, B.; O’Connell, M.; Preston, E. The IEEE reliability test system: A proposed 2019 Update. IEEE Trans. Power Syst. 2019, 99, 1. [Google Scholar] [CrossRef]

- Pawlak, E. Problemy Utrzymania W Stanie Zdatności Systemu Dystrybucji Drobnicowej W Aspekcie Niezawodności Przepływu Informacji; Zimowej Szkoły Niezawodności: Szczyrk, Poland, 2014; pp. 255–264. [Google Scholar]

| Data | User | Surroundings |

|---|---|---|

| Issue | Information Flow (Area I) | Information Quality (Area II) | Reliability (Area III) |

|---|---|---|---|

| System or process treated in its entirety | + | + | + |

| Information flow | + | + | + |

| Identification of the sender and recipient of the message | + | − | + |

| Determination of the data necessary for the task execution | − | − | − |

| Effects of making the information available, e.g., costs, benefits | + | − | + |

| Result of the execution of tasks | − | − | + |

| Impact of the correctness of the message on the task execution | − | − | − |

| The effects of delay in relation to the delay threshold | − | − | − |

| Surveys on the message quality | + | + | − |

| Reliability of devices in information flow | + | − | + |

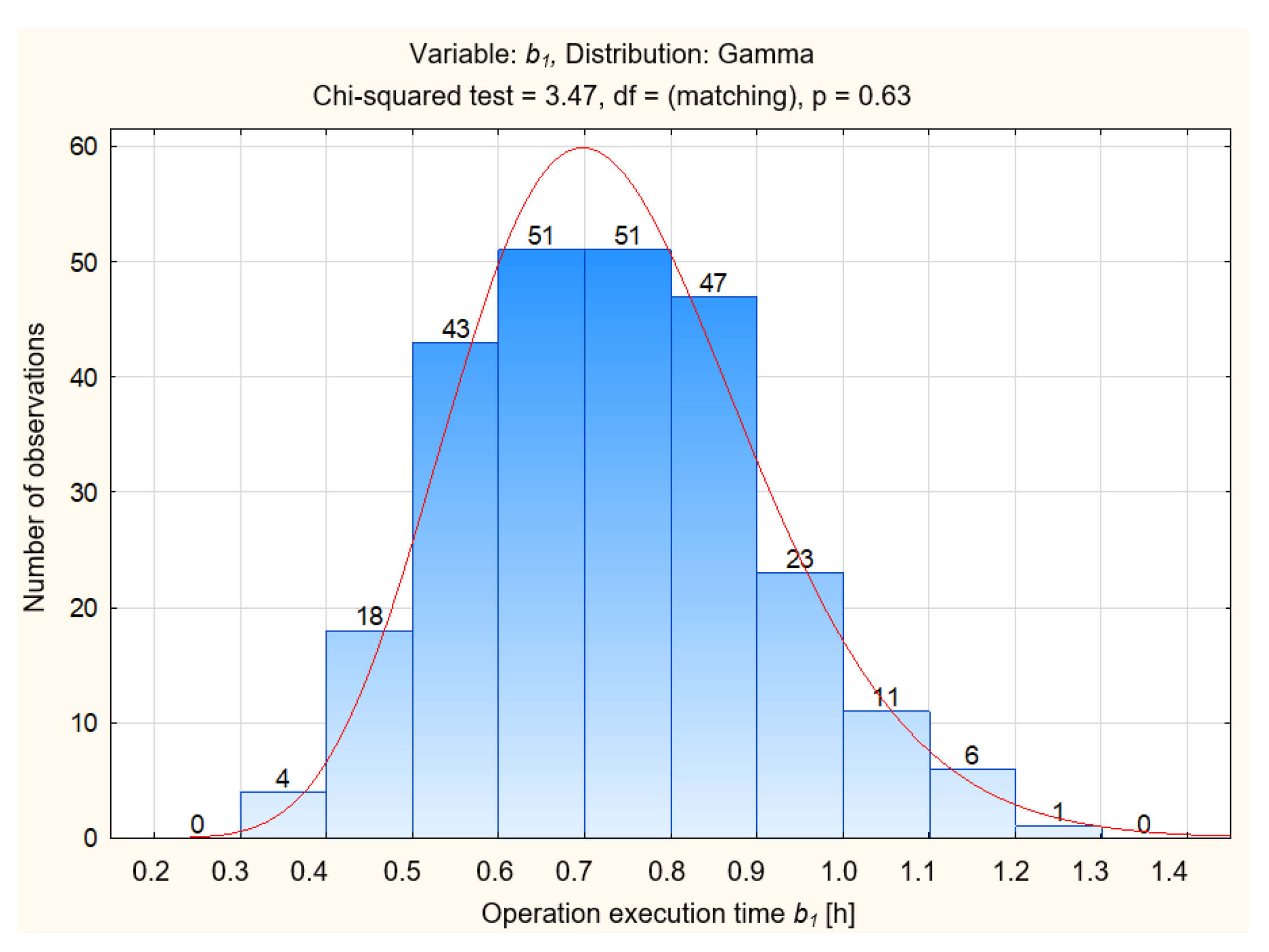

| The Operation of Supplementing the Data in the System | |

|---|---|

| Number of observations | 255 |

| Mean (h) | 0.74 |

| Confidence interval dg 95% (h) | 0.72 |

| Confidence interval gg 95% (h) | 0.76 |

| Min (h) | 0.35 |

| Max (h) | 1.22 |

| Standard deviation | 0.17 |

| Coefficient of variation (%) | 23.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zając, M.; Swieboda, J. Method of Assessing the Logistics Process as Regards Information Flow Unreliability on the Example of a Container Terminal. Appl. Sci. 2023, 13, 962. https://doi.org/10.3390/app13020962

Zając M, Swieboda J. Method of Assessing the Logistics Process as Regards Information Flow Unreliability on the Example of a Container Terminal. Applied Sciences. 2023; 13(2):962. https://doi.org/10.3390/app13020962

Chicago/Turabian StyleZając, Mateusz, and Justyna Swieboda. 2023. "Method of Assessing the Logistics Process as Regards Information Flow Unreliability on the Example of a Container Terminal" Applied Sciences 13, no. 2: 962. https://doi.org/10.3390/app13020962

APA StyleZając, M., & Swieboda, J. (2023). Method of Assessing the Logistics Process as Regards Information Flow Unreliability on the Example of a Container Terminal. Applied Sciences, 13(2), 962. https://doi.org/10.3390/app13020962