Study of the Effect of Friction Time and Preheating on the Joint Mechanical Properties of Friction Welded SS 316-Pure Zn

Abstract

:1. Introduction

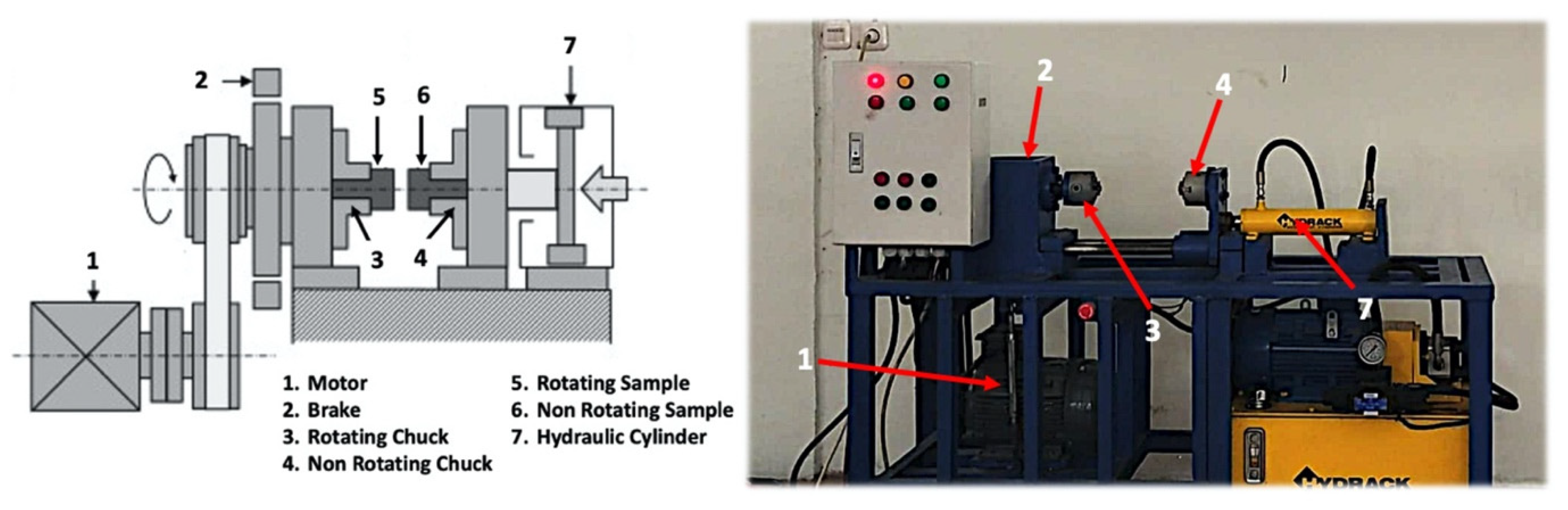

2. Experimental Procedure

2.1. Materials and Friction Welding Method

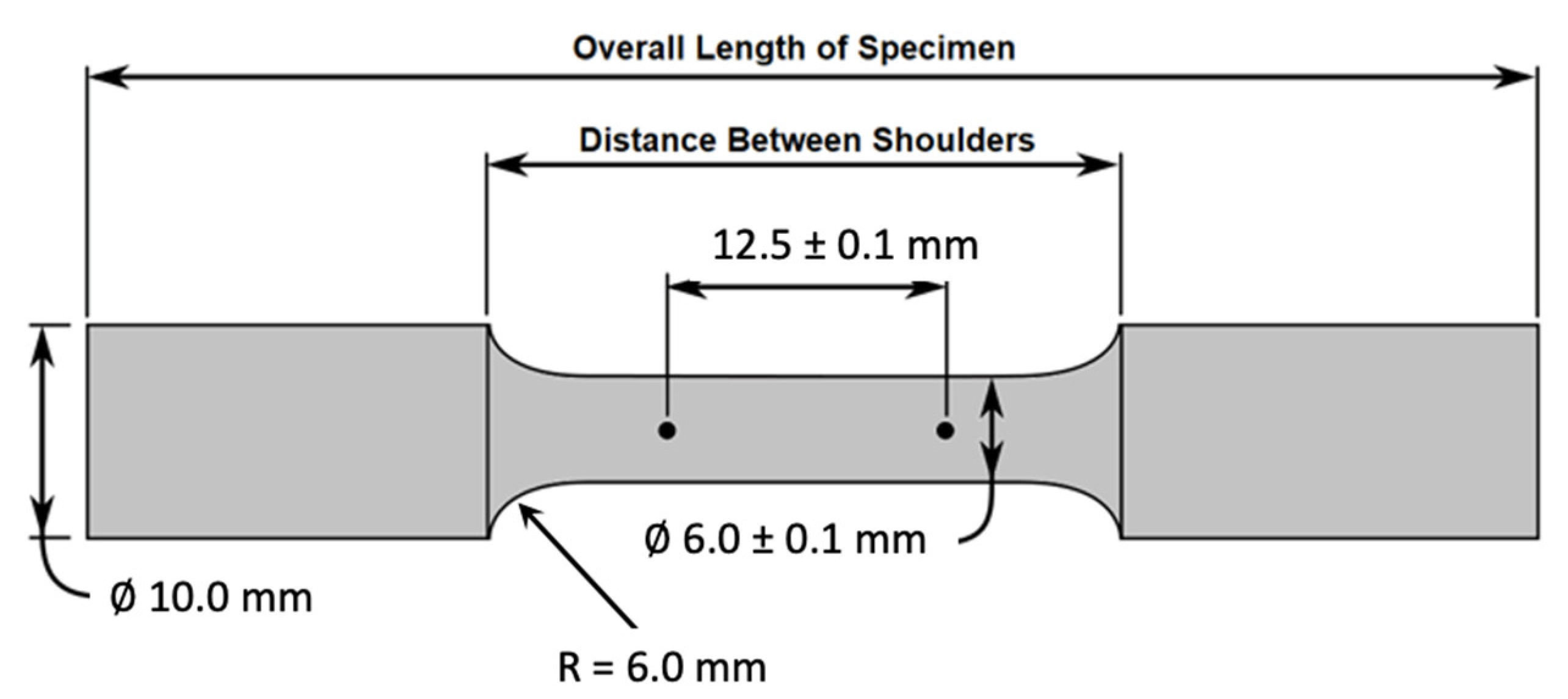

2.2. Mechanical Testing

2.3. Characterization Analyses

3. Results and Discussion

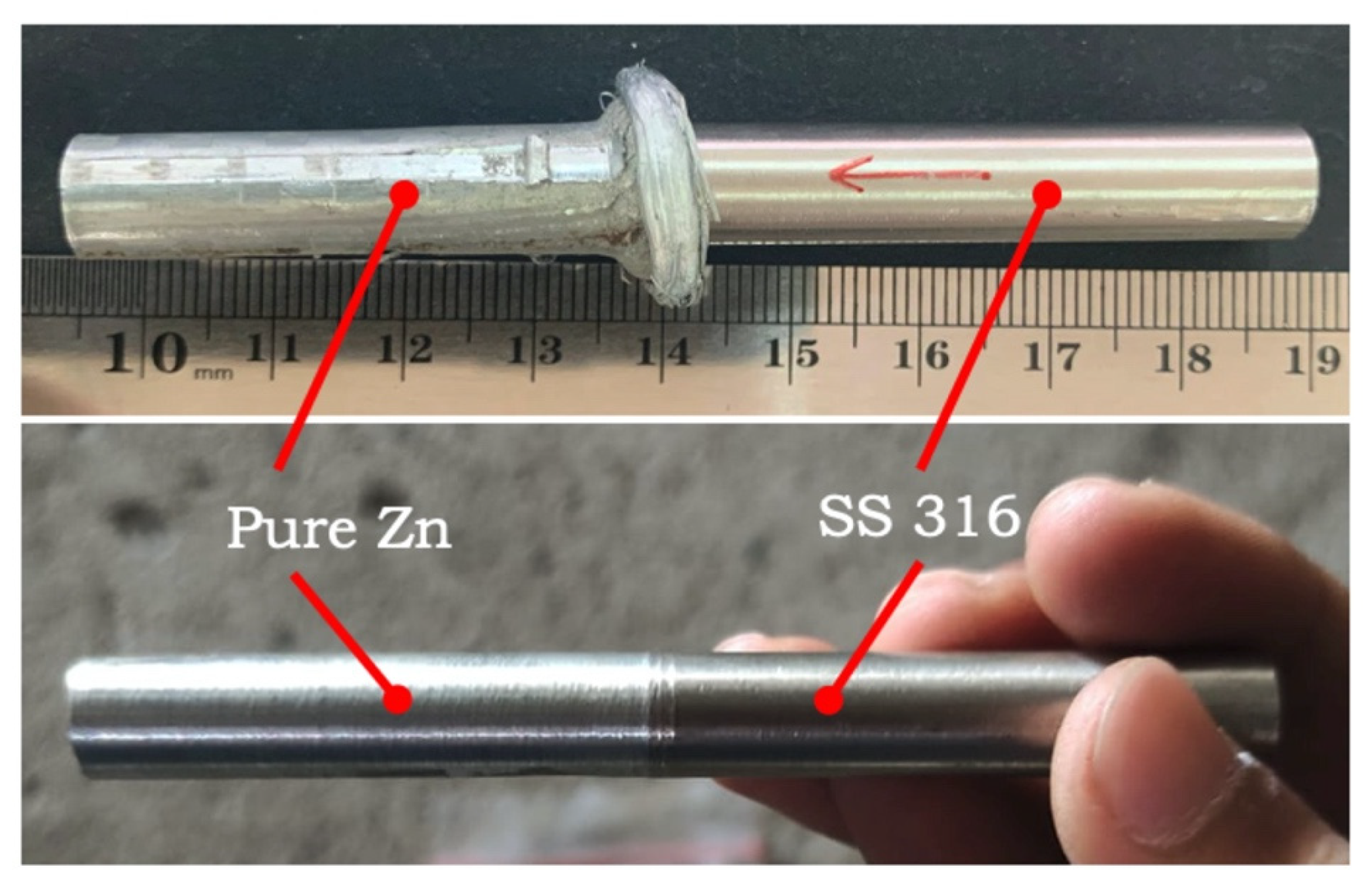

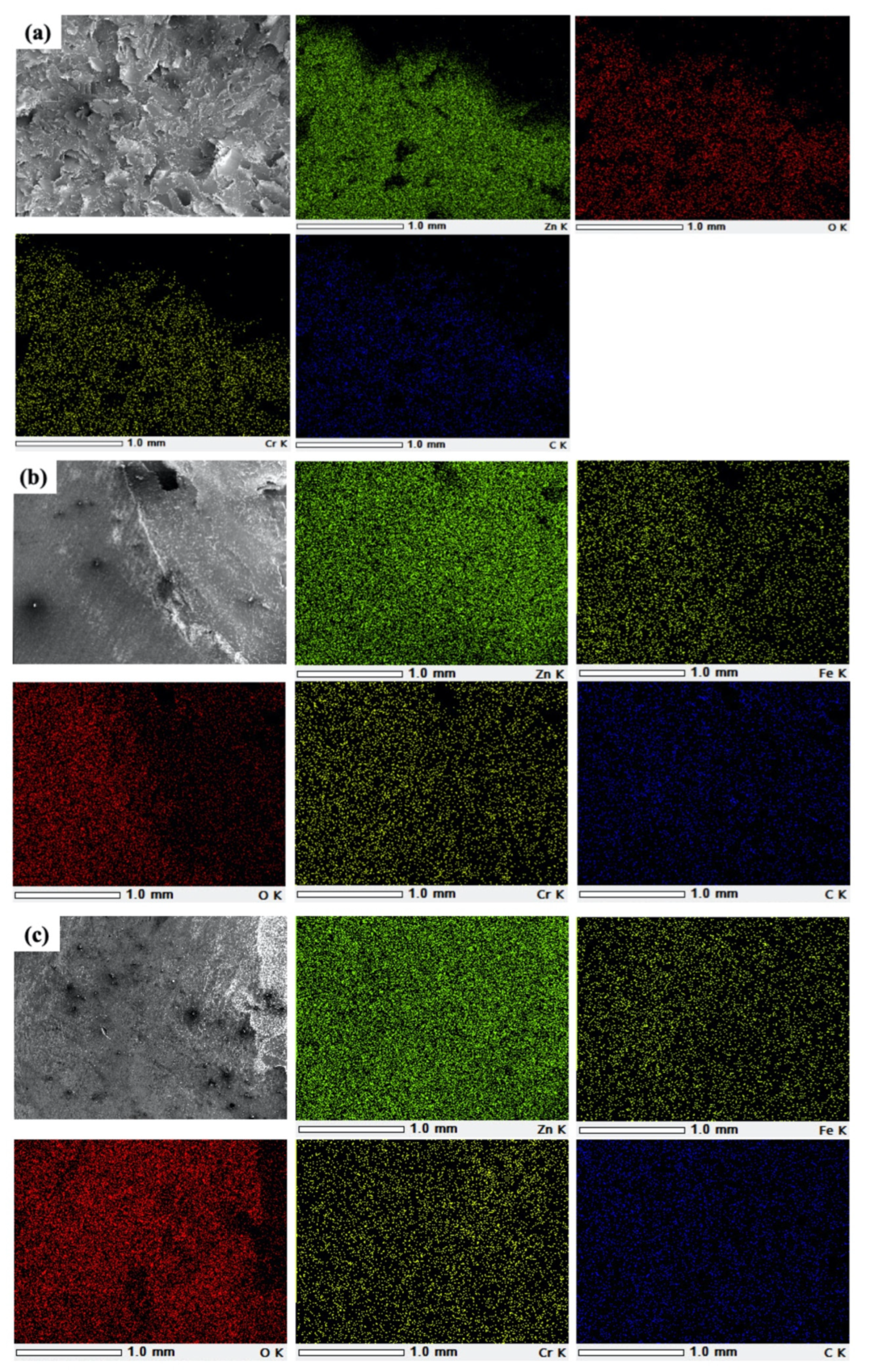

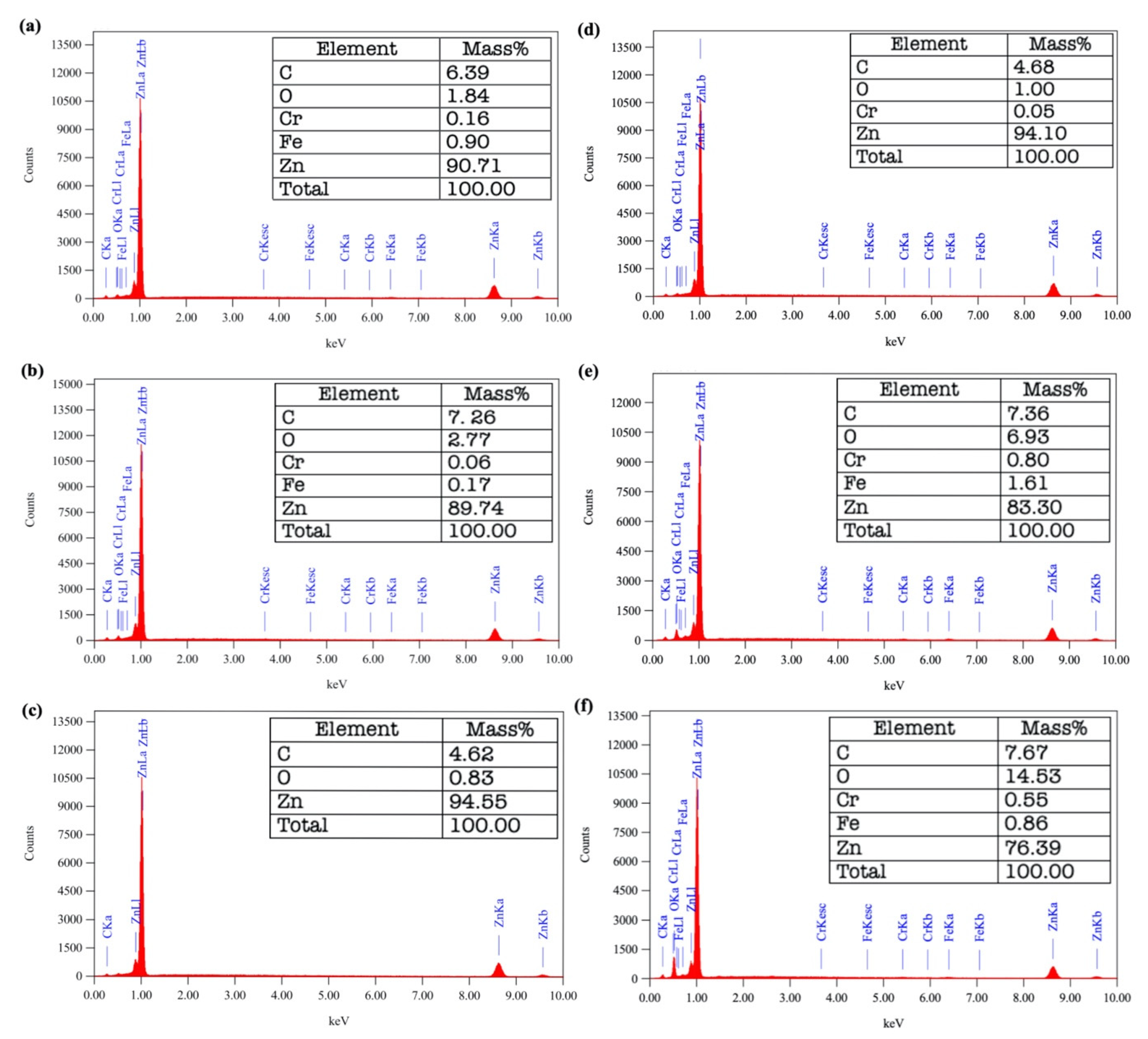

3.1. Morphology of Joint

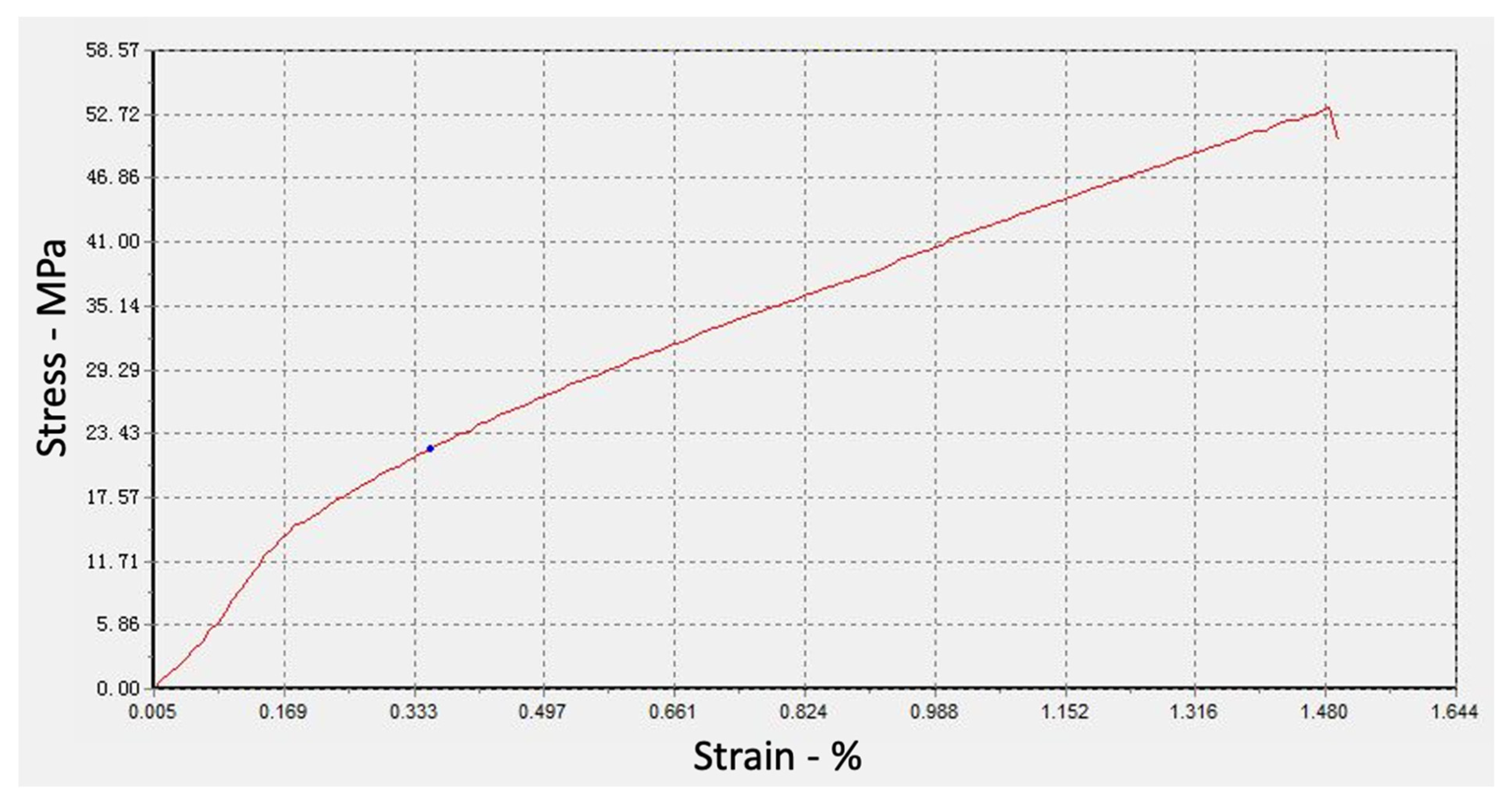

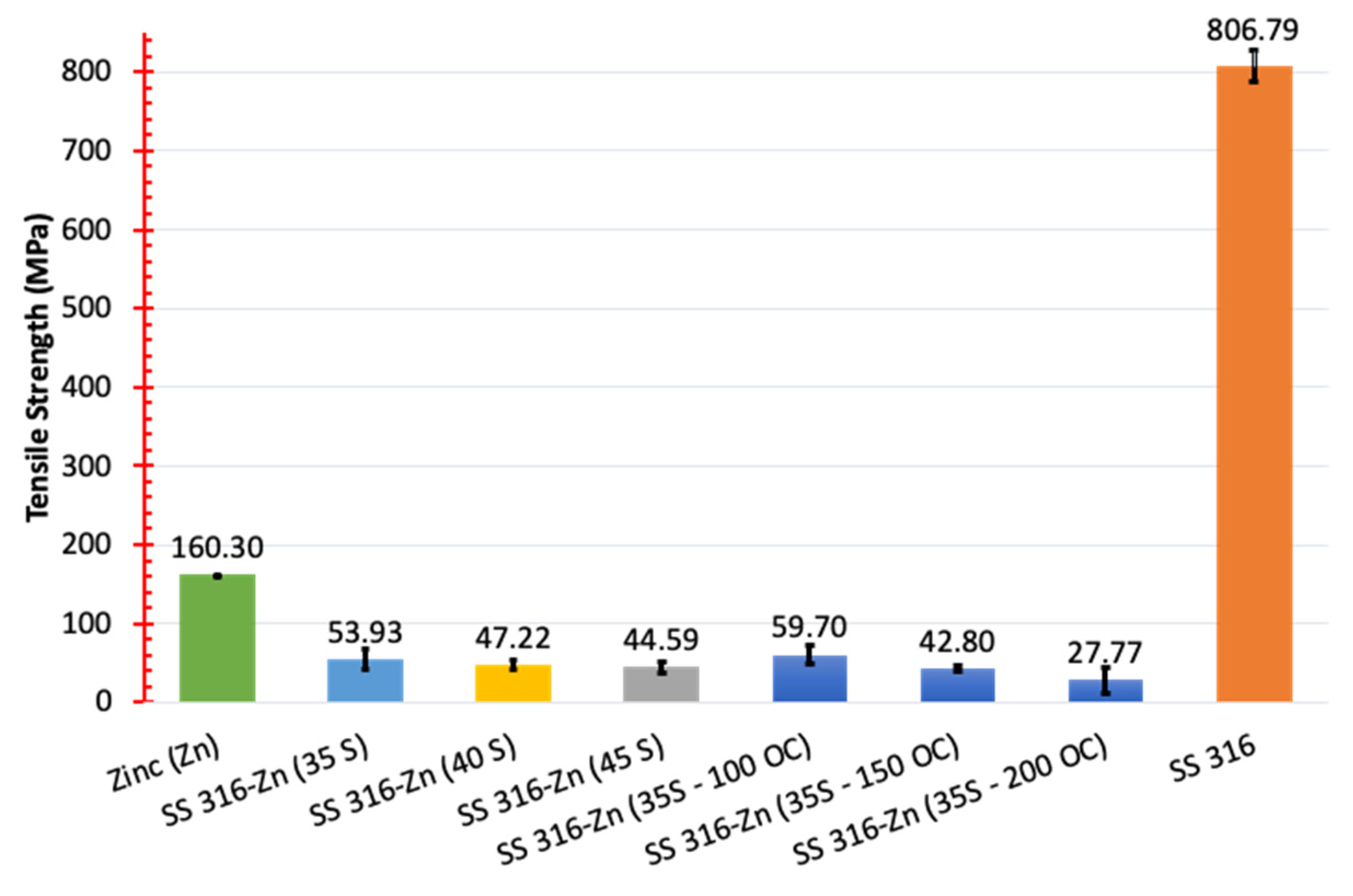

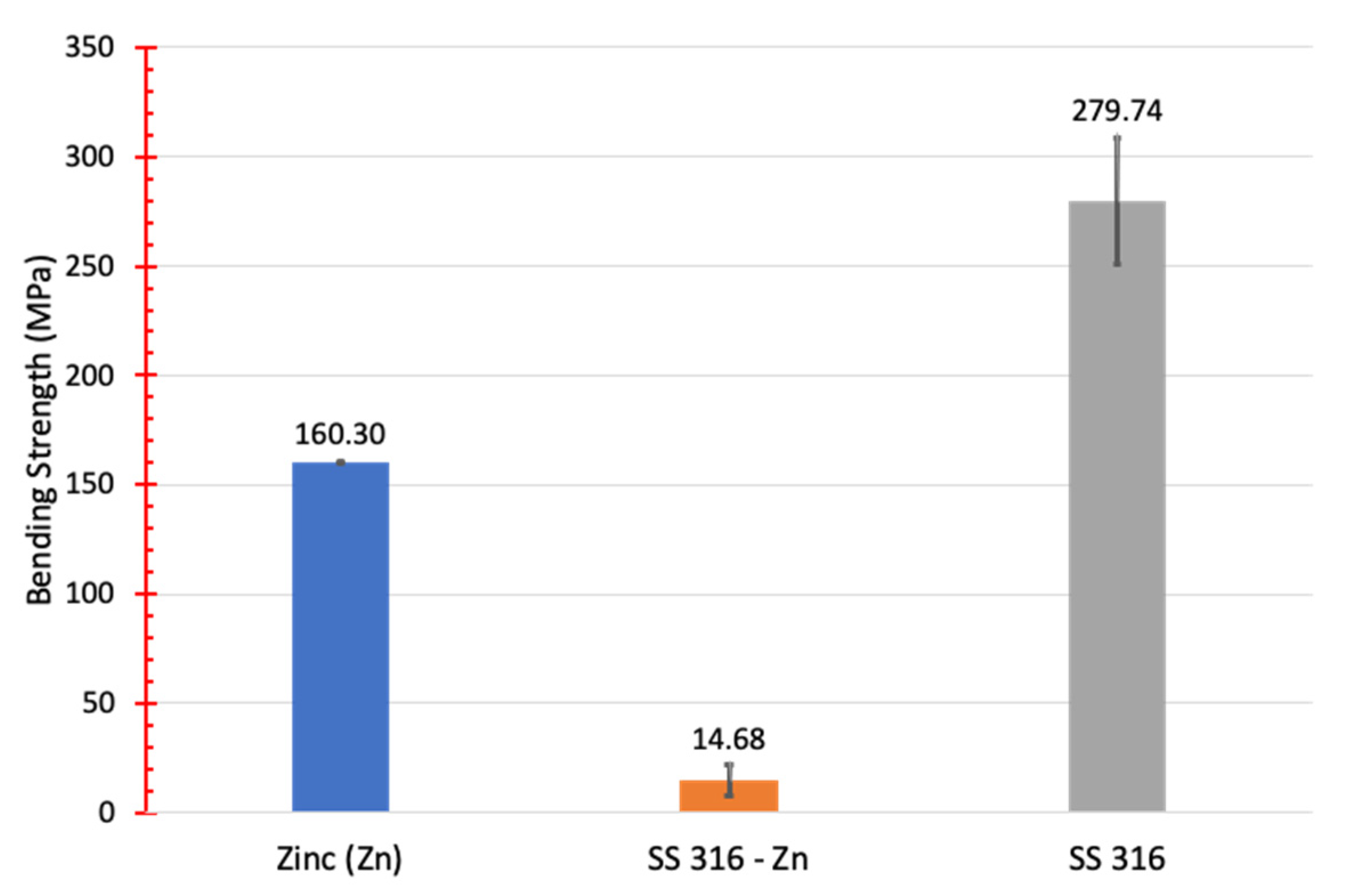

3.2. Mechanical Properties of Joint

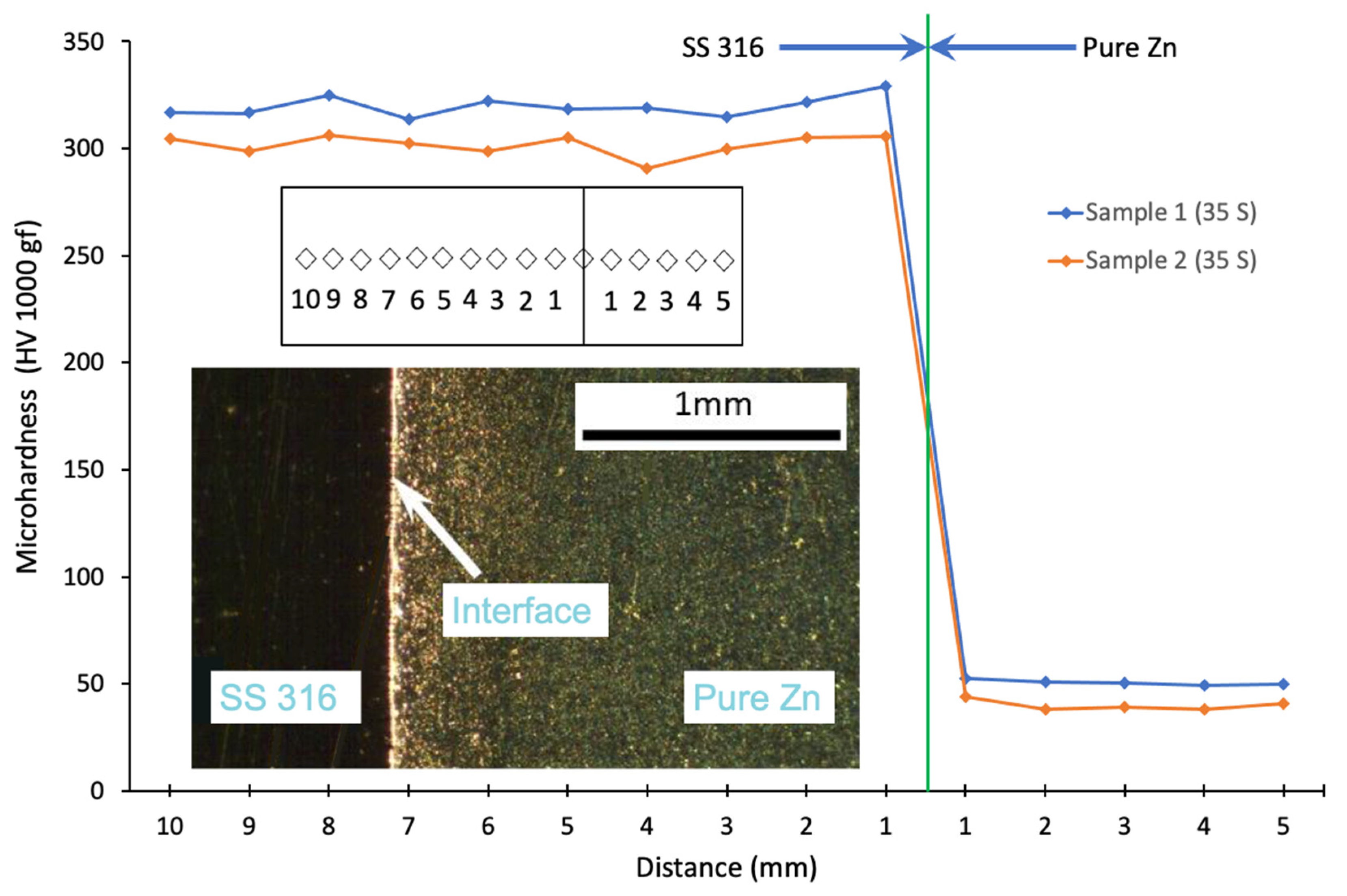

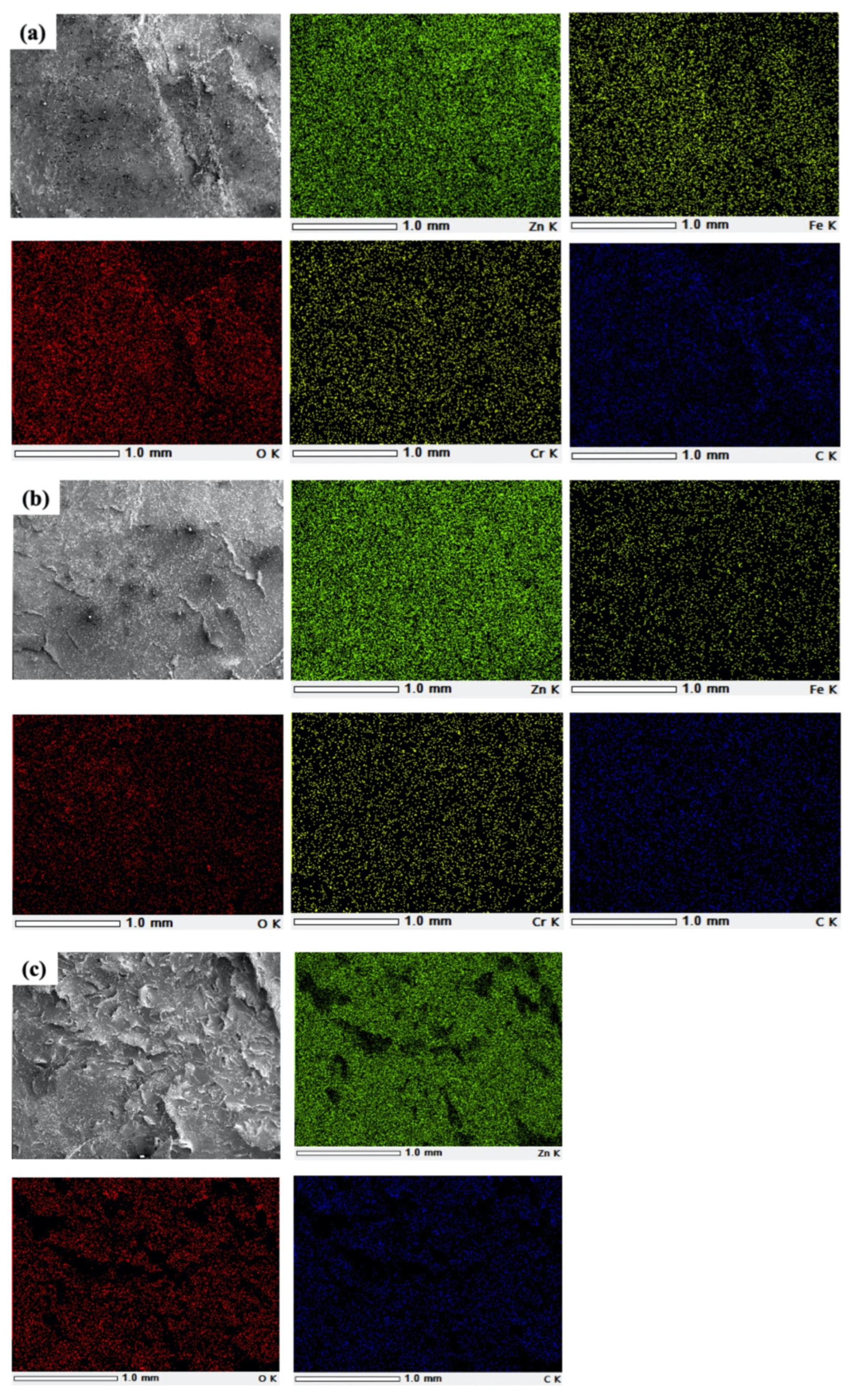

3.3. Microstructure of Joint

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kumar Rajak, D.; Pagar, D.D.; Menezes, P.L.; Eyvazian, A. Friction-based welding processes: Friction welding and friction stir welding. J. Adhes. Sci. Technol. 2020, 34, 2613–2637. [Google Scholar] [CrossRef]

- Ananda Rao, G.; Ramanaiah, N. Dissimilar metals AISI 304 steel and AA 2219 aluminium alloy joining by friction welding method. Mater. Today Proc. 2019, 19, 902–907. [Google Scholar] [CrossRef]

- Rafi, H.K.; Ram, G.D.J.; Phanikumar, G.; Rao, K.P. Microstructure and tensile properties of friction welded aluminum alloy AA7075-T6. Mater. Des. (1980–2015) 2010, 31, 2375–2380. [Google Scholar] [CrossRef]

- Nasution, A.K.; Murni, N.S.; Sing, N.B.; Idris, M.H.; Hermawan, H. Partially degradable friction-welded pure iron–stainless steel 316L bone pin. J. Biomed. Mater. Res. Part B Appl. Biomater. 2015, 103, 31–38. [Google Scholar] [CrossRef] [PubMed]

- Sathishkumar, G.B.; Sethuraman, P.; Chanakyan, C.; Sundaraselvan, S.; Joseph Arockiam, A.; Alagarsamy, S.V.; Elmariung, A.; Meignanamoorthy, M.; Ravichandran, M.; Jayasathyakawin, S. Friction welding of similar and dissimilar materials: A review. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Basmaci, A.N.; Filiz, S.; Şahin, M. Experimental Analysis of Welded Rods with a Functionally Graded Material Approach. Appl. Sci. 2020, 10, 3908. [Google Scholar] [CrossRef]

- Pratyusha, M.; Ramana, P.V.; Prasanthi, G. Evaluation of tensile strength of dissimilar metal pure aluminium and pure copper friction welds. Mater. Today Proc. 2021, 38, 2271–2274. [Google Scholar] [CrossRef]

- Nasution, A.K.; Gustami, H.; Suprastio, S.; Fadillah, M.A.; Octavia, J.; Saidin, S. Potential use of Friction Welding for Fabricating Semi-Biodegradable Bone Screws. Int. J. Automot. Mech. Eng. 2022, 19, 9660–9667. [Google Scholar] [CrossRef]

- Ramesh Kumar, R.; Babu, J.M.; Saleh, B.; Fayaz, H.; Chandrashekar, A.; Gera, T.; Nisar, K.S.; Saleel, C.A. Experimental and analytical investigation on friction welding dissimilar joints for aerospace applications. Ain Shams Eng. J. 2023, 14, 101853. [Google Scholar] [CrossRef]

- Li, W.; Vairis, A.; Preuss, M.; Ma, T. Linear and rotary friction welding review. Int. Mater. Rev. 2016, 61, 71–100. [Google Scholar] [CrossRef]

- Ahmad Mir, F.; Zaman Khan, N.; Noor Siddiquee, A.; Parvez, S. Friction based solid state welding—A review. Mater. Today Proc. 2022, 62, 55–62. [Google Scholar] [CrossRef]

- Tiley, J.S.; Mahaffey, D.W.; Alam, T.; Rojhirunsakool, T.; Senkov, O.; Parthasarthy, T.; Banerjee, R. Strengthening mechanisms in an inertia friction welded nickel-base superalloy. Mater. Sci. Eng. A 2016, 662, 26–35. [Google Scholar] [CrossRef]

- Guo, W.; You, G.; Yuan, G.; Zhang, X. Microstructure and mechanical properties of dissimilar inertia friction welding of 7A04 aluminum alloy to AZ31 magnesium alloy. J. Alloys Compd. 2017, 695, 3267–3277. [Google Scholar] [CrossRef]

- Mogami, H.; Matsuda, T.; Sano, T.; Yoshida, R.; Hori, H.; Hirose, A. High-frequency linear friction welding of aluminum alloys. Mater. Des. 2018, 139, 457–466. [Google Scholar] [CrossRef]

- Matsuda, T.; Adachi, H.; Sano, T.; Yoshida, R.; Hori, H.; Ono, S.; Hirose, A. High-frequency linear friction welding of aluminum alloys to stainless steel. J. Mater. Process. Technol. 2019, 269, 45–51. [Google Scholar] [CrossRef]

- Craine, R.E.; Francis, A. Frictional heat generated in the early stages of an orbital friction welding process. Wear 1987, 114, 355–365. [Google Scholar] [CrossRef]

- Raab, U.; Levin, S.; Wagner, L.; Heinze, C. Orbital friction welding as an alternative process for blisk manufacturing. J. Mater. Process. Technol. 2015, 215, 189–192. [Google Scholar] [CrossRef]

- Shanjeevi, C.; Arputhabalan, J.; Pavithran, E.; Raju, B. Prediction of Optimized Friction Welding Parameter for Joining of Dissimilar Material using Friction Welding. Mater. Today Proc. 2019, 16, 838–842. [Google Scholar] [CrossRef]

- Paventhan, R.; Lakshminarayanan, P.R.; Balasubramanian, V. Optimization of Friction Welding Process Parameters for Joining Carbon Steel and Stainless Steel. J. Iron Steel Res. Int. 2012, 19, 66–71. [Google Scholar] [CrossRef]

- Hiroshi, K. Application of Linear Friction Welding Technique to Aircraft Engine Parts. IHI Eng. Rev. 2014, 47, 40–43. [Google Scholar]

- Banerjee, A.; Ntovas, M.; Da Silva, L.; Rahimi, S. Microstructure and mechanical properties of dissimilar inertia friction welded 316L stainless steel to A516 ferritic steel for potential applications in nuclear reactors. Manuf. Lett. 2022, 33, 33–37. [Google Scholar] [CrossRef]

- Anant Sagar, D.B.; Pardhu, Y.; Rao, M.S.K.; Narasaiah, N. Strain hardening behavior of friction welded beta titanium alloy Titan 1023 used for aeronautical applications. Mater. Today Proc. 2022, 57, 687–692. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kishore Babu, N.; Talari, M.K.; Anwar, S.; Usmani, Y.; Al-Samhan, A.M. Dissimilar Rotary Friction Welding of Inconel 718 to F22 Using Inconel 625 Interlayer. Appl. Sci. 2021, 11, 10684. [Google Scholar] [CrossRef]

- Verma, G.; Kumar, S.; Bundel, B.R. A Research paper on the Comparison of Weld Strength of Friction Welding of Different Materials at two Different RPM. Int. J. Mech. Eng. Technol. 2016, 7, 123–127. [Google Scholar]

- Handa, A.; Chawla, V. Experimental study of mechanical properties of friction welded AISI 1021 steels. Sadhana 2013, 38, 1407–1419. [Google Scholar] [CrossRef] [Green Version]

- Zulu, M.C.; Mashinini, P.M. Process optimization of rotary friction welding of Ti-6Al-4V alloy rods. IOP Conf. Ser. Mater. Sci. Eng. 2018, 430, 012012. [Google Scholar] [CrossRef]

- Ramesh, A.P.; Subramaniyan, M.; Eswaran, P. Review on Friction Welding of Similar/Dissimilar Metals. J. Phys. Conf. Ser. 2019, 1362, 012032. [Google Scholar] [CrossRef]

- Skowrońska, B.; Bober, M.; Kołodziejczak, P.; Baranowski, M.; Kozłowski, M.; Chmielewski, T. Solid-State Rotary Friction-Welded Tungsten and Mild Steel Joints. Appl. Sci. 2022, 12, 9034. [Google Scholar] [CrossRef]

- Winiczenko, R.; Goroch, O.; Krzyńska, A.; Kaczorowski, M. Friction welding of tungsten heavy alloy with aluminium alloy. J. Mater. Process. Technol. 2017, 246, 42–55. [Google Scholar] [CrossRef]

- Nasution, A.K.; Nawangsari, P.; Junaidi, A.; Hermawan, H. Friction welding of AZ31-SS316L for partially-degradable orthopaedic pins. IOP Conf. Ser. Mater. Sci. Eng. 2019, 532, 012014. [Google Scholar] [CrossRef]

- Mir, F.A.; Khan, N.Z.; Parvez, S. Recent advances and development in joining ceramics to metals. Mater. Today Proc. 2021, 46, 6570–6575. [Google Scholar] [CrossRef]

- Uday, M.B.; Ahmad-Fauzi, M.N.; Noor, A.M.; Rajoo, S. An insight into microstructural evolution during plastic deformation in AA6061 alloy after friction welding with alumina-YSZ composite. Mech. Mater. 2015, 91, 50–63. [Google Scholar] [CrossRef]

- Rombaut, P.; De Waele, W.; Faes, K. Friction welding of steel to ceramic. In Sustainable Construction and Design 2011 (SCAD); Ghent University, Laboratory Soete: Ghent, Belgium, 2011; Volume 2011. [Google Scholar]

- Li, P.; Li, J.; Dong, H.; Ji, C. Metallurgical and mechanical properties of continuous drive friction welded copper/alumina dissimilar joints. Mater. Des. 2017, 127, 311–319. [Google Scholar] [CrossRef]

- Goodwin, F.E. Zinc and Zinc Alloys. In Springer Handbook of Materials Data; Warlimont, H., Martienssen, W., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 431–442. [Google Scholar] [CrossRef]

- Liu, H.; Zuo, Y.; Ji, S.; Dong, J.; Zhao, H. Friction stir solid–liquid spot welding of Cu to Al assisted by Zn interlayer. J. Mater. Res. Technol. 2022, 18, 85–95. [Google Scholar] [CrossRef]

- Khajeh, R.; Jafarian, H.R.; Jabraeili, R.; Eivani, A.R.; Seyedein, S.H.; Park, N.; Heidarzadeh, A. Strength-ductility synergic enhancement in friction stir welded AA2024 alloy and copper joints: Unravelling the role of Zn interlayer's thickness. J. Mater. Res. Technol. 2022, 16, 251–262. [Google Scholar] [CrossRef]

- Delgado-Pamanes, M.; Alvarez-Montufar, J.; Reyes-Osorio, L.; Garza, C.; Suárez-Rosales, M.; Chávez-Alcalá, J. Evaluation of optimal processing parameters for a Zn-based eutectoid alloy processed by friction-stir welding. J. Mater. Res. Technol. 2022, 18, 3256–3265. [Google Scholar] [CrossRef]

- Zheng, Q.; Feng, X.; Shen, Y.; Huang, G.; Zhao, P. Dissimilar friction stir welding of 6061 Al to 316 stainless steel using Zn as a filler metal. J. Alloys Compd. 2016, 686, 693–701. [Google Scholar] [CrossRef]

- Triouleyre, J. Friction welding of zinc. Mater. Des. 1984, 5, 107–111. [Google Scholar] [CrossRef]

- ASTM E8; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM E290-14; Standard Test Methods for Bend Testing of Material for Ductility. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM E384; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Kimura, M.; Kusaka, M.; Kaizu, K.; Nakata, K.; Nagatsuka, K. Friction welding technique and joint properties of thin-walled pipe friction-welded joint between type 6063 aluminum alloy and AISI 304 austenitic stainless steel. Int. J. Adv. Manuf. Technol. 2016, 82, 489–499. [Google Scholar] [CrossRef]

- Senkov, O.N.; Mahaffey, D.W.; Semiatin, S.L. Effect of Preheating on the Inertia Friction Welding of the Dissimilar Superalloys Mar-M247 and LSHR. Metall. Mater. Trans. A 2016, 47, 6121–6137. [Google Scholar] [CrossRef]

- Ahmad Fauzi, M.N.; Uday, M.B.; Zuhailawati, H.; Ismail, A.B. Microstructure and mechanical properties of alumina-6061 aluminum alloy joined by friction welding. Mater. Des. 2010, 31, 670–676. [Google Scholar] [CrossRef]

- Sathiya, P.; Aravindan, S.; Noorul Haq, A. Effect of friction welding parameters on mechanical and metallurgical properties of ferritic stainless steel. Int. J. Adv. Manuf. Technol. 2007, 31, 1076–1082. [Google Scholar] [CrossRef]

- Çelikyürek, İ.; Torun, O.; Baksan, B. Microstructure and strength of friction-welded Fe–28Al and 316 L stainless steel. Mater. Sci. Eng. A 2011, 528, 8530–8536. [Google Scholar] [CrossRef]

- Kurt, A.; Uygur, I.; Paylasan, U. Effect of Friction Welding Parameters on Mechanical and Microstructural Properties of Dissimilar AISI 1010-ASTM B22 Joints. Weld. J. 2011, 90, 102–106. [Google Scholar]

- Fuji, A.; Kimura, M.; North, T.H.; Ameyama, K.; Aki, M. Mechanical properties of titanium-5083 aluminium alloy friction joints. Mater. Sci. Technol. 1997, 13, 673–678. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, H.; Peng, Y. Metallurgical reaction and joining phenomena in friction welded Al/Fe joints. Int. J. Adv. Manuf. Technol. 2020, 107, 1713–1723. [Google Scholar] [CrossRef]

- Liu, F.C.; Dong, P.; Zhang, J.; Lu, W.; Taub, A.; Sun, K. Alloy amorphization through nanoscale shear localization at Al-Fe interface. Mater. Today Phys. 2020, 15, 100252. [Google Scholar] [CrossRef]

| C. | Mn | P | S | Si | Cr | Ni | N | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.080 | 2.000 | 0.045 | 0.030 | 0.750 | 16.00–18.00 | 10.00–14.00 | 0.100 | 2.000–3.000 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dahlan, H.; Nasution, A.K.; Zuhdi, S.A.; Rusli, M. Study of the Effect of Friction Time and Preheating on the Joint Mechanical Properties of Friction Welded SS 316-Pure Zn. Appl. Sci. 2023, 13, 988. https://doi.org/10.3390/app13020988

Dahlan H, Nasution AK, Zuhdi SA, Rusli M. Study of the Effect of Friction Time and Preheating on the Joint Mechanical Properties of Friction Welded SS 316-Pure Zn. Applied Sciences. 2023; 13(2):988. https://doi.org/10.3390/app13020988

Chicago/Turabian StyleDahlan, Hendery, Ahmad Kafrawi Nasution, Sulthan Asyraf Zuhdi, and Meifal Rusli. 2023. "Study of the Effect of Friction Time and Preheating on the Joint Mechanical Properties of Friction Welded SS 316-Pure Zn" Applied Sciences 13, no. 2: 988. https://doi.org/10.3390/app13020988