Abstract

Buttermilk and whey, despite their documented health and technological potential, are still not sufficiently utilized for the development of new products. In this research, the texture, color, gloss, cheese yield, and peptonization of fresh white cheeses made from buttermilk with the addition of whey proteins after heat treatment were analyzed. Additionally, the influence of the polymerization process on cheese yield and composition was examined. Four fresh white cheese samples were prepared: without a whey protein concentrate (FWC); with a whey protein concentrate (FWC/WPC); with single-heated polymerized whey proteins (FWC/SPWP); and with double-heated polymerized whey proteins (FWC/DPWP). The introduction of whey proteins in buttermilk cheese production increased the cheese yield by over 2-fold. There were no differences in color and gloss between the FWC/SPWP and FWC/DPWP samples. The cheese became glassy and transparent during melting. The content of uncrushed curd that remained white ranged from 27% in FWC/DPWP to 74% in FWC/SPWP.

1. Introduction

Buttermilk and skim milk are characterized by a similar composition in terms of their content of lactose, casein, whey proteins, and minerals [1,2]. However, they differ in phospholipid content. Buttermilk contains up to 10 times more phospholipids than skimmed milk [1]. The source of phospholipids in buttermilk is the milk fat globule membrane (MFGM), which surrounds and stabilizes the fat globules, which are released during the churning process [3]. Hence, buttermilk is classified as a functional food [4], and publications have cited the health benefits of the MFGM, e.g., infection prevention, cognitive improvement and brain system development, immunity and protection metabolism [5], reduction in cholesterol levels, and anticancer [2].

Due to its structure-forming, emulsifying, and water-binding properties, buttermilk is used in the production of yogurts [6,7,8]; ice cream [9,10]; as a component in mixtures for chocolate production [11]; meat marinating [12]; and to improve the flavor and texture of bakery products [13].

The cheesemaking sector is a large part of the dairy industry [14], where innovative concepts for the enhancement of cheese quality are of concern, e.g., the implementation of probiotic bacteria and non-fat cheese production, but also sensory properties. The sensory properties, texture, viscosity, and moisture retention of cheeses can be improved using buttermilk [15] and/or the introduction of whey proteins to its composition [16]. During the cheesemaking process, it is common to increase the protein content to increase cheese yield [14,17]. In the production of fresh and hard cheese, a high concentration of casein is recommended, while in the production of quark cheese, a high total protein concentration and a high degree of whey protein denaturation is also desirable. The protein’s composition can be modulated using membrane processes or the introduction of protein concentrates into the processed milk [18]. The texture of cheeses can be affected by moisture, fat content, pH, and, importantly, the structure of the protein matrix [14]. The structure of the protein’s matrix can be modified, e.g., by conducting the polymerization process of whey proteins induced by heat treatment [19,20,21]. The obtained whey protein aggregates are used as a thickening agent for the formulation of fermented milk [22]; for food texture design [23]; for the microencapsulation of Lactobacillus acidophilus, which improves their survivability in yogurts [24]; to increase the water holding capacity and reduce the syneresis of fermented milk [25]; as a fat replacement in the development of low-fat yogurts [26]; and in determining the behavior of water in cheese from buttermilk [16].

Buttermilk and whey are considered the main by-products in the dairy industry and, despite their documented health and technological potential, are still not sufficiently utilized for the development of new products [13]. In cheesemaking, milk is primarily employed as the basic raw material, and buttermilk is usually an additive aimed at improving rheological or sensory properties [27,28]. The replacement of milk with buttermilk in cheese production can successfully lead to a new product with improved functions and nutritional value [15].

The aim of our research was to directly use buttermilk as a by-product of butter production and indirectly use whey as a whey protein concentrate obtained from buttermilk, allowing for the development of an innovative dairy product: fresh white cheese from buttermilk with polymerized whey proteins. The effect of the heat treatment of whey proteins on the texture, color, and gloss of buttermilk cheese was analyzed for these parameters and its possible further use as a base, e.g., for the production of curd-ripened fried cheese. We also examined how the polymerization process impacted cheese yield and composition, which will provide the necessary knowledge for future cheesemaking.

2. Materials and Methods

2.1. Fresh White Cheese from Buttermilk Preparation

Buttermilk leftovers were obtained from the industrial production of butter from cream (Great Poland, Poland). The buttermilk contained 0.5% fat, 3.4% protein, and 3.7% lactose. The fresh white cheese from buttermilk was prepared with the addition of whey protein concentrate powder (WPC, 5.62%, w/v) and a whey protein concentrate after the polymerization process (PWP, 28%, w/v). The WPC contained 79.49% proteins, 6.31% fat, 5.15% lactose, 4.81% water, and 1.26% ash.

The WPC dispersion was adjusted to a pH of 7.0 using 0.1 M of sodium hydroxide at 21 °C. Single-heated polymerized whey proteins (SPWP, 28%, w/v) were heated at 85 °C for 30 min and then rapidly cooled to room temperature in ice water under agitation. The solutions were then heated again, keeping exactly the same conditions as used in the first heating process. Further heating at 85 °C for 30 min led to the formation of double-heated polymerized whey proteins (DPWP, 28%, w/v), which were then rapidly cooled to room temperature in ice water under agitation [21].

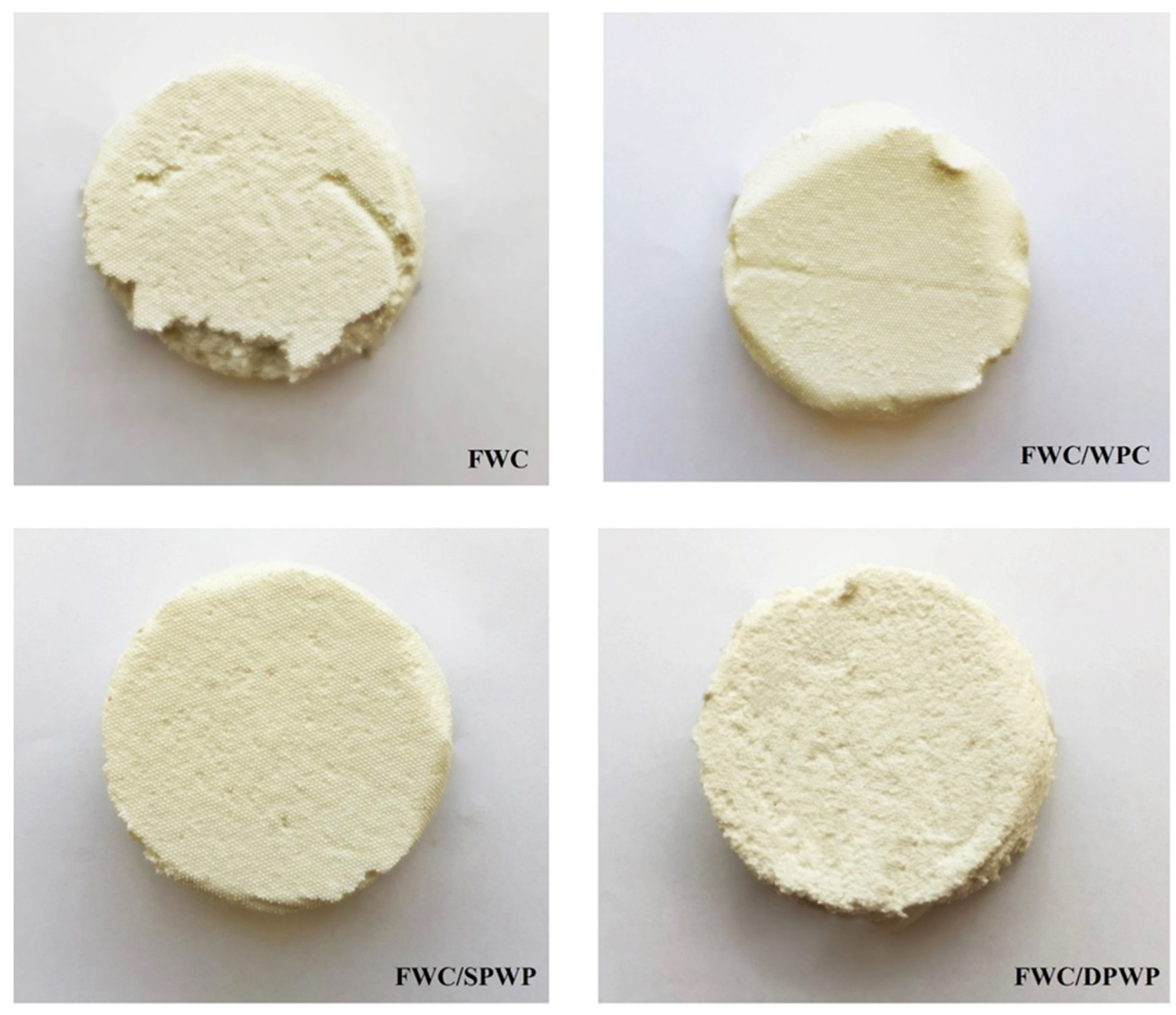

The buttermilk (20 L) with whey proteins (ratio of 0.23 L of PWP solution for every 1 L of buttermilk) was mixed in a double coat cheese kettle, type SKM50 (Plevnik, Dobrova, Slovenia), with an automatic processor, GPC 145, equipped with an automatic propeller stirrer at 36 rpm and 15 °C for 10 min,. Four fresh white cheese samples from buttermilk were prepared without the addition of the whey protein concentrate (FWC); with the addition of the whey protein concentrate (FWC/WPC); with the addition of single-heated polymerized whey proteins (FWC/SPWP); and with addition of double-heated polymerized whey proteins (FWC/DPWP) (Figure 1). The conditions for processing were selected so that coagulation occurred after 2 h at a temperature of 50–52 °C. The curd was sliced. Draining was performed in a layer on a special curd-finishing table. Pressing took 3.5 h at a maximum pressing force of 3 kg per 1 kg of cheese. Samples were packaged in paper foil [16]. The cheeses were stored under refrigerated conditions at 4 ± 0.3 °C and analyzed within the first 24 h after production.

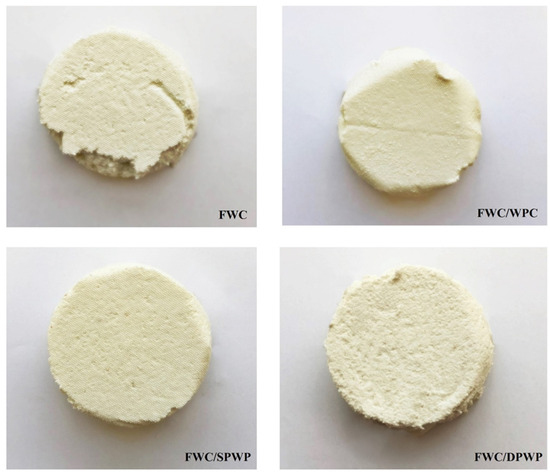

Figure 1.

Samples of fresh white cheeses from buttermilk with polymerized whey protein. FWC, fresh white cheese from buttermilk; FWC/WPC, fresh white cheese from buttermilk with whey protein concentrate; FWC/SPWP, fresh white cheese from buttermilk with single-heated polymerized whey proteins; FWC/DPWP, fresh white cheese from buttermilk with double-heated polymerized whey proteins.

2.2. Composition and Cheese Yield

The moisture in the prepared fresh white cheese from buttermilk was determined by standard methods, AOAC 926.08 [29]. Fat content was determined using standard methods, ISO 1735 [30]. The content of total nitrogen (TN), casein nitrogen (CN), non-casein nitrogen (NCN), and non-protein nitrogen (NPN) were determined according to methods described by Svanborg et al. [31]. The content of total protein (TP) and whey protein (WP) was calculated according to the following equations [32]:

where 6.38 represents the factor indicated for proteins derived from milk.

TP = (TN − NPN) · 6.38

WP = (NCN − NPN) · 6.38

Titratable acidity was determined by standard methods, AOAC 920.124 [33]. pH was measured using a CP-402 pH-meter (Elmetron, Zabrze, Poland) equipped with a IONODE IJ44A electrode (Ionode Pty. Ltd., Tennyson, Australia). The cheese yield (CY) was calculated according to Hanafy et al.’s [14] methods with modifications:

CY % = amount of cheese (kg)/amount of buttermilk (kg) · 100

2.3. Texture

Texture parameters were measured using a texturometer (Stable Micro Systems Ltd., Surrey, UK) equipped with an attachment: hardness and brittleness were measured using A/WEG attachment: pre-test speed 1.0 mm/s, test speed 2.0 mm/s, post-test speed 10.0 mm/s, and distance 10.0 mm; firmness and stickiness were measured using P/1S attachment: pre-test speed 1.5 mm/s, test speed 2.0 mm/s, post-test speed 10.0 mm/s, and distance 5 mm. Results were recorded using Texture Exponent E32 version 4.0.9.0 software (Godalming, Surrey, UK).

2.4. Color and Gloss

Measurements were made using an X-Rite SP-60 camera (X-Rite, Grandville, MI, USA). The whiteness index (WI), yellowness index (YI), chroma (C*), and browning index (BI) were calculated using the following equation:

where

WI = 100 − [(100 − L*)2 + a*2 + b*2]0.

YI = 142.86b* · L*−1

C* = (a*2 + b*2)0.5

BI = [100(x − 0.31)] · 5.88

x = (a* + 1.750 · L*) · (5.645 · L* + a* − 3.012 · b*)−1

The calculations assumed: L = 100, a* = 0, and b* = 0.

The gloss was measured using the gloss meter (DT 268, TestAn, Gdańsk, Poland), with a measurement geometry of 60°.

2.5. Peptonization

The cheese was fragmented to obtain a grain with a diameter of approximately 5 mm. Fragmented cheese in the form of a layer (h = 6 cm) was spread on perforated trays, which were transferred to the ripening room. The conditions during the process in the ripening room: time 3 days, temperature 25 ± 1 °C, and a relative humidity >75 RH. The cheese was turned over manually on the trays twice a day.

2.6. Statistical Evaluation

Verification of statistical hypotheses was achieved using a level of significance of α = 0.05 by a two-way analysis of variance followed by Tukey’s HSD post hoc test for multiple comparisons. Data were analyzed using Statistica data analysis software, version 13 (TIBCO Software Inc., Palo Alto, CA, USA).

3. Results and Discussion

3.1. Composition and Cheese Yield

The obtained results showed no differences in moisture, fat content, titratable acidity, and pH among all the analyzed samples (Table 1; p > 0.05). The introduction of whey proteins to buttermilk in the production of the FWC increased the TN in the analyzed samples by 7.4% in the FWC/WPC and by 10.6% in the FWC/SPWP compared to the fresh white cheese with no additive (p < 0.05). However, no TN differences were found between the samples of FWC/SPWP and FWC/DPWP (p > 0.05). The TP in the control sample was 167.4 g/kg and approx. 4% lower than in the other analyzed samples (p < 0.05). The TP content was the same among the samples with the addition of the whey protein concentrate and whey protein concentrate after the polymerization process (p > 0.05). No differences were observed between samples in terms of CN and NPN (p > 0.05), while the NCN concentration after the addition of whey proteins (regardless of the polymerization process) increased (p < 0.05). According to Masotti et al. [34], during cheese production, unused whey should be recycled; therefore, the introduction of whey proteins in cheese production is an innovative approach to responding to consumers’ expectations of a product with a new texture and functionality. Mileriene et al. [35] reported that curd cheese supplemented with thermo-coagulated whey proteins is a response to the global interest in sustainable dairy foods.

Table 1.

Composition and cheese yield of fresh white cheeses from buttermilk with polymerized whey proteins.

Studies have shown that the introduction of whey proteins in buttermilk cheese production increases CY over 2-fold (Table 1; p < 0.05). The CY can be increased by increasing the fat and protein content; stopping or re-adding whey proteins; and introducing other milk components (e.g., lactose; ash; moisture) [14]. Elbarbary and Saad [36] described the quality of buffalo’s milk soft cheese using the addition of camel’s whey protein concentrate and showed that the higher the amount of added WPC, the higher CY. The authors suggested that the increase in CY may be related to the addition of WPC powder and/or denatured WPs, which resulted from heat treatment. This enhanced the integration of whey proteins into cheese or the higher retention of serum in the cheese matrix while increasing the CY. As shown by Stankey et al. [37], a denatured whey protein has a better ability to bind water, thus increasing the moisture content in cheese and the CY. The same observations are made by Perreault et al. [38], where a denatured whey protein concentrate significantly increased CY (from 12.5% to 15% compared to the control) as a result of the higher cheese moisture. Giroux et al. [39] evaluated the cheesemaking properties of milk, where the denaturation of whey proteins resulted in a higher CY.

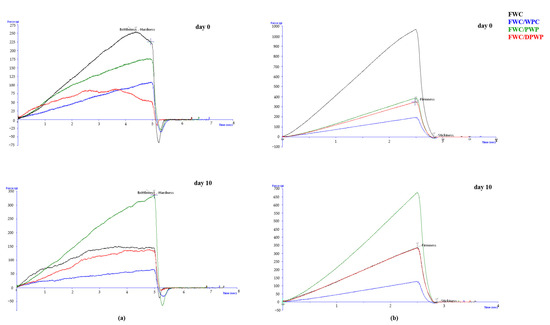

3.2. Texture

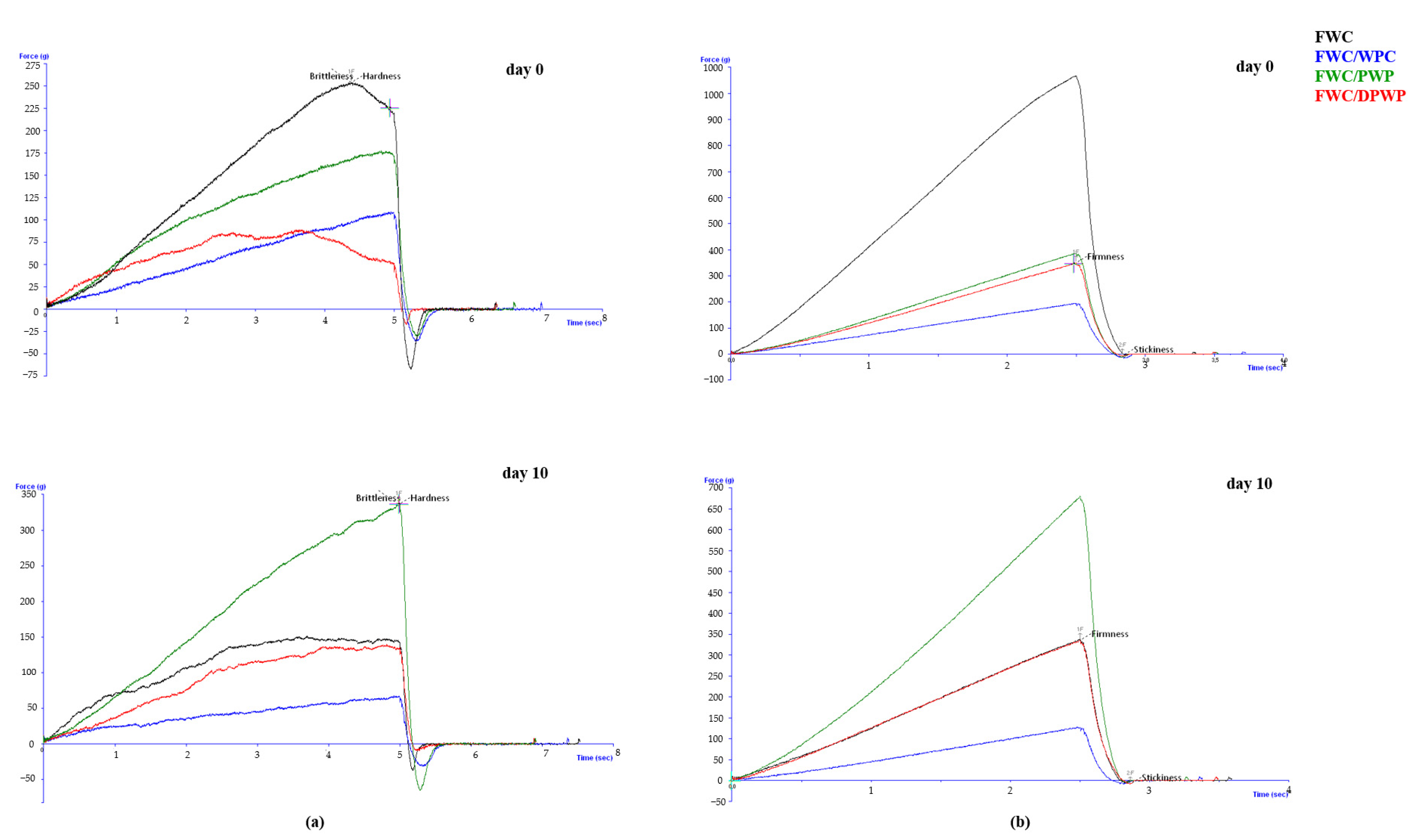

A 3.7-fold reduction in the hardness of the FWC/WPC (Table 2; Figure 2) was observed compared to the FWC (p < 0.05). According to Hanafy et al. [14], the introduction of 2% to 4% of a WPC in cheese production increased the hardness, but the addition of 6% significantly reduced the hardness. The same authors suggested that the characteristics that determine cheese texture were moisture, fat, pH, and the structure of the protein matrix. Similar results were presented by Mohamed [40], where the impact of the addition of 1% to 3% WPC in the production of Kariesh cheese was analyzed. The results showed that the hardness, cohesiveness, springiness, gumminess, and chewiness values decreased after the addition of inulin or a WPC. The addition of single-heated polymerized whey proteins to buttermilk reduced the cheese hardness by 40% (FWC/SPWP; p < 0.05) compared to the control sample but promoted a 2-fold increase in hardness compared to the FWC/WPC (p < 0.05). Sołowiej et al. [41] showed that the addition of polymerized whey proteins thickened the cheese mass due to their ability to emulsify fat and increase water absorption. Casein could crosslink with whey proteins in cheesemaking. This leads to the cheese possessing a higher hardness [42]. However, in our research, the further heating of the whey proteins and the addition of a double-heated polymerized whey protein significantly decreased the hardness. The addition of whey proteins (regardless of type) to buttermilk decreased firmness (compared to FWC; p < 0.05). Hence, in accordance with the results presented by Cais-Sokolińska et al. [16], the addition of whey protein concentrates in powder after the polymerization process to buttermilk in the production of buttermilk cheese caused a significant decrease in firmness (despite the use of other firmness measurement conditions). There were no differences observed in brittleness among all the cheese samples (p > 0.05), and the stickiness increased 3-fold only for the FWC/WPC compared to the control sample. The obtained results suggested that the texture of fresh white cheese from buttermilk could be modified via the modification of the composition of the main raw material with a simultaneous thermal modification of whey protein concentrates. This was previously confirmed by Domingos et al. [43], where the texture problem caused by fat reduction could be improved through the addition of a WPC. Tashakori et al. [44] found that the addition of 20% WPC improved the overall texture of spread cheese. However, Mohamed [40] reported that the ability of whey proteins to form gels that could hold water, lipids, and provide the appropriate texture was important for consumer acceptability. After 10 days of cold storage, significant changes were found in the hardness, firmness, and stickiness parameters, mainly for FWC/SPWP (Table 2; Figure 1). The hardness and firmness increased 2-fold, and stickiness showed a 2-fold decrease (FWC/SPWP; p < 0.05). Refrigerated storage had no effect on the brittleness of all the samples analyzed (p > 0.05). According to Gamlath et al. [17], denatured aggregates of whey proteins could avoid the impairment of rennet gelation caused by native whey proteins, and the combination of heat treatment with ultrasonication of whey proteins could potentially improve cheese texture.

Table 2.

Texture of fresh white cheeses from buttermilk with polymerized whey protein.

Figure 2.

Texture of fresh white cheeses from buttermilk with polymerized whey protein. (a) Hardness and brittleness measured using attachment A/WEG; (b) firmness and stickiness measured using attachment p/1S; FWC, fresh white cheese from buttermilk; FWC, fresh white cheese from buttermilk; FWC/WPC, fresh white cheese from buttermilk with whey protein concentrate; FWC/SPWP, fresh white cheese from buttermilk with single-heated polymerized whey proteins; FWC/DPWP, fresh white cheese from buttermilk with double-heated polymerized whey proteins.

3.3. Color

No differences in color were found between the samples of FWC/SPWP and FWC/DPWP (Table 3; p > 0.05). The least lightness was found in the cheese with a WPC, which was approx. 6% lower compared to the control sample (FWC; p < 0.05) and 5% lower compared to samples with polymerized whey proteins (p < 0.05). The cheese sample with a WPC was also characterized by the smallest whiteness index. This was consistent with the results reported by Cais-Sokolińska et al. [16], in which the buttermilk cheese with added WPC powder was darker than the samples of cheese with added polymerized whey proteins, and the calculated value of the total color difference (ΔE) was above 3.3. Such a result may negatively impact the consumer ratings of overall desirability. Brodziak et al. [45] also showed that the introduction of whey protein powder to yogurt caused the final product to be further from the ideal whiteness standard and thus less light.

Table 3.

Color of fresh white cheeses from buttermilk with polymerized whey proteins.

The addition of whey proteins after the polymerization process in the production of fresh white cheese from buttermilk resulted in an increased whiteness index and reduced yellowness index by 4.4% and 13.6%, respectively, compared to the FWC/WPC. The cheese with a WPC also had the highest browning index and chroma (Table 3; p < 0.05). The addition of whey proteins increased the gloss of the analyzed cheese samples compared to the control sample (p < 0.05). The gloss of the cheeses with a whey protein concentrate and polymerized whey proteins was the same (p > 0.05). According to Kampf and Nussinovitch [46] and Youssef et al. [47], gloss is an important parameter, assessed, e.g., in the selection of a cheese coating. After 10 days of cold storage, the lightness decreased in the FWC/WPC and increased in the FWC/SPWP, but the differences were less than 1% (p < 0.05). In the FWC/SPWP and FWC/DPWP cheeses, the whiteness index after 10 days of storage increased slightly above 1% (p < 0.05). In all the samples, after 10 days of refrigerated storage, the chroma parameter decreased (p < 0.05). Color is the first sense that registers with the consumer, who use it to accept or reject the product [48,49]. Whey proteins may undergo slight color changes when heated [50]. According to Ortega et al. [51], the color of whey proteins after heat treatment correlated with antioxidant activity due to the Maillard reaction.

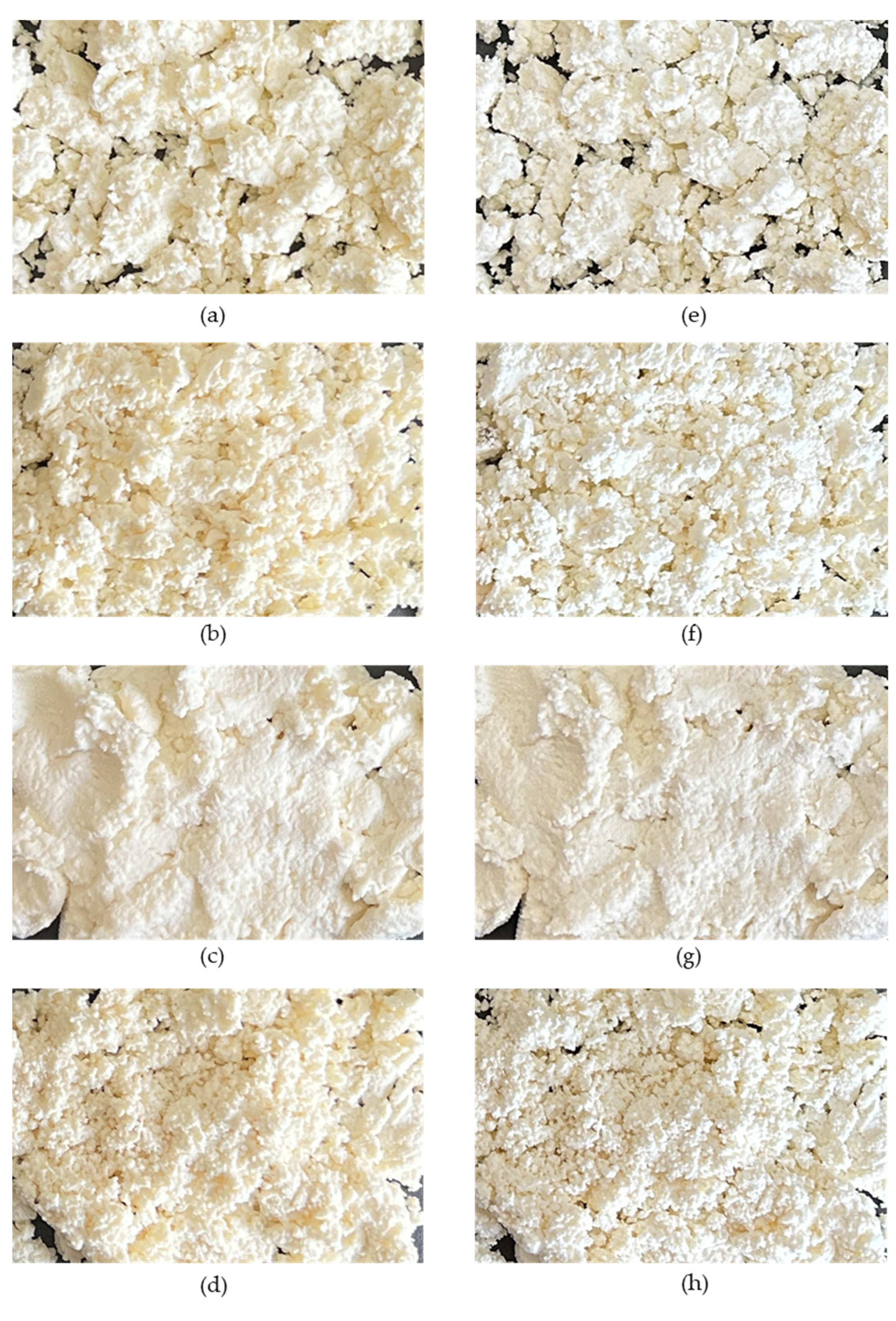

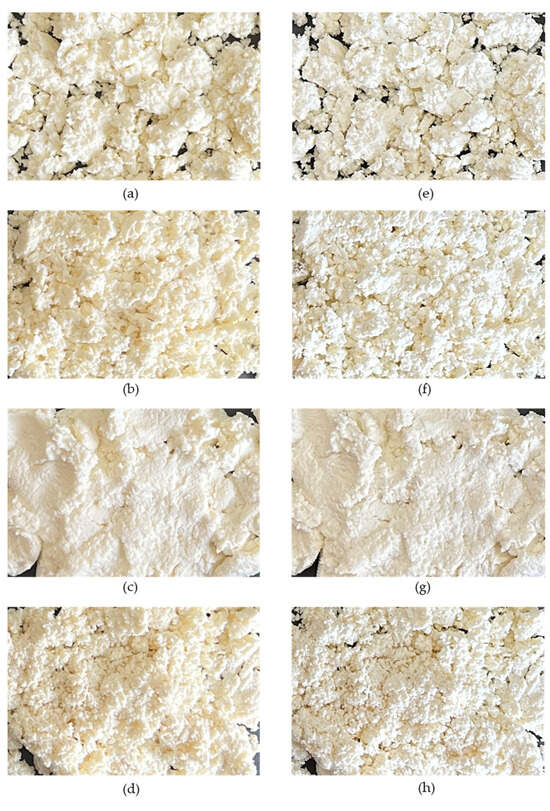

3.4. Peptonization

Water loss from cheese during the cheese curing ranged from 4.7 (FWC) to 5.1% (FWC/DPWP). The cheese became glassy/transparent during melting. The content of uncrushed curd that remained white ranged from 27% in FWC/DPWP to 74% in FWC/SPWP (Figure 3). There were no differences in the range of the casein peptonization of curd between the FWC and FWC/DPWP. A relationship was demonstrated between the scope of the casein peptonization of curd, expressed in the amount of grain glassiness, and the degree of cheese fragmentation. The FWC/SPWP cheese, which had the most clamminess and therefore was the least fragmentated, was characterized by the least casein peptonization of curd.

Figure 3.

Samples of cheeses from buttermilk with polymerized whey proteins before and during the casein peptonization of curd. (a) FWC before the casein peptonization of curd; (b) FWC/WPC before the casein peptonization of curd; (c) FWC/SPWP before the casein peptonization of curd; (d) FWC/DPWP before the casein peptonization of curd; (e) FWC during the casein peptonization of curd; (f) FWC/WPC during the casein peptonization of curd; (g) FWC/SPWP during the casein peptonization of curd; (h) FWC/DPWP during the casein peptonization of curd.

According to El-Salam et al. [52], the ripening of cheese is a slow process due to its extended storage time. The occurring microbiological and biochemical changes lead to a change in taste and consistency. Ripening involves the natural decomposition of proteins (peptonization of casein) until the curd becomes glassy. The cheese then most often grows Galactomyces geotrichum, which is capable of biosynthesizing 2-phenylethanol and related rose-like aroma compounds from l-phenylalanine [53]. Next, bacteria with proteolytic and lipolytic abilities are important. The secreted hydrolytic enzymes cause proteolysis of casein proteins, and the products of proteolysis, i.e., peptones, peptides, amino acids, and ammonia, give the cheese its characteristic taste and smell. During the casein peptonization of curd, its active acidity is significantly reduced from a pH of 4.4 to a pH above 5.0, among others, due to the decomposition of lactic acid into carbon dioxide and water. The changes that occur during the casein peptonization of curd have been thoroughly described in the literature. Soltani et al. [54] showed that the proteolysis of cheese can be influenced by the salt concentration in its production.

In this research, the casein peptonization of curd is a process used to increase its utility value during the production of cheese based on ripened cheese and its greater culinary use. The use of the casein peptonization of curd is important, for example, in the production of fried ripened curd cheese. Fresh cheese used for the production of fried ripened curd cheese is crushed and stored in a ripening room, where an extensive proteolysis of casein takes place at a temperature of 16–27 degrees for about 3 days [55]. According to Rychlik et al. [56], fried ripened curd cheese is characterized by a specific aroma and taste that are closely related to the particular cheese manufacturing technology. This is important in the evaluation of cheeses used, for example, as fondue, for pizza, or in casseroles [57]. This is a stage of production that definitely influences the specificity and uniqueness of future cheeses, such as Brennkäse, Kochkäse, Cancoillotte, Glundner Käse, and Wielkopolski fried cheese.

4. Conclusions

In traditional cheesemaking, whey proteins are lost in the whey. Therefore, it is considered reasonable to increase the technological quality of buttermilk cheese through the introduction of whey protein concentrates to buttermilk. The use of buttermilk after the production of butter and whey proteins forms cheese whey, which is part of the global trend of sustainable food production and closed-loop food production. The obtained results can significantly influence the development of dairy products and teach technologists in the dairy industry how to use whey protein aggregates to modify the texture and color and improve the yield of fresh white cheese. The addition of whey proteins after heat treatment in the production of fresh white cheese from buttermilk increases its cheese yield and significantly affects the texture and color of the cheese. The cheese with a whey protein concentrate was darker, so there is a concern that it might not be accepted by consumers. This research also showed a relationship between the degree of cheese grinding and its ability to facilitate the casein peptonization of curd. The casein peptonization of curd is important in the assessment of the cheeses used, e.g., as fondue, for pizza, and in casseroles.

Author Contributions

Conceptualization, P.B. and D.C.-S.; methodology, P.B. and D.C.-S.; formal analysis, P.B. and D.C.-S.; investigation, D.C.-S.; writing—original draft preparation, P.B. and D.C.-S.; writing—review and editing, P.B. and D.C.-S.; visualization, P.B.; supervision, P.B. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Poznań University of Life Sciences (Poland) as the research program “First grant”, no. 11/2022, and by the Ministry of Education and Science (Poznań, Poland), MEN-UPP 506.784.03.00/KMIP.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets used during the current study available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Krebs, L.; Pouliot, Y.; Doyen, A.; Venema, K.; Brisson, G. Effect of reverse osmosis and ultra-high-pressure homogenization on the composition and microstructure of sweet buttermilk. J. Dairy Sci. 2023, 106, 1596–1610. [Google Scholar] [CrossRef] [PubMed]

- Sakkas, L.; Evageliou, V.; Igoumenidis, P.; Moatsou, G. Properties of sweet buttermilk released from the churning of cream separated from sheep or cow milk or sheep cheese whey: Effect of heat treatment and storage of cream. Foods 2022, 11, 465. [Google Scholar] [CrossRef] [PubMed]

- Iung, J.; Pouliot, Y.; Remondetto, G.; Jiménez-Flores, R.; Brisson, G. On the use on hydroxyapatite suspensions for the separation of milk fat globule membrane components from buttermilk. Food Chem. 2023, 404, 134535. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.H. Current knowledge of buttermilk: Composition, applications in the food industry, nutritional and beneficial health characteristics. Int. J. Dairy Technol. 2019, 72, 169–182. [Google Scholar] [CrossRef]

- Elkashef, H.; Mobdy, A.A.; Hassan, A. Texture, microstructure, and antioxidant characteristics of bio-fermented milk fortified with buttermilk nano-powder. Int. Dairy J. 2022, 126, 105248. [Google Scholar] [CrossRef]

- Yıldız, N.; Bakırcı, I. Investigation of the use of whey powder and buttermilk powder instead of skim milk powder in yogurt production. J. Food Sci. Technol. 2019, 56, 4429–4436. [Google Scholar] [CrossRef]

- Zhao, L.; Feng, R.; Mao, X. Addition of buttermilk powder improved the rheological and storage properties of low-fat yogurt. Food Sci. Nutr. 2020, 8, 3061–3069. [Google Scholar] [CrossRef]

- Garczewska-Murzyn, A.; Smoczyński, M.; Kotowska, N.; Kiełczewska, K. Effect of buttermilk and skimmed milk powder on the properties of low-fat yoghurt. J. Food Sci. Technol. 2022, 59, 2160–2167. [Google Scholar] [CrossRef]

- Szkolnicka, K.; Dmytrów, I.; Mituniewicz-Małek, A. Buttermilk ice cream—New method for buttermilk utilization. Food Sci. Nutr. 2020, 8, 1461–1470. [Google Scholar] [CrossRef]

- Ramos, I.; Silva, M.; Antunes, V.; Praxedes, C.; Oliveira, M. Development of ice cream with added buttermilk. Brazilian J. Food Technol. 2021, 24. [Google Scholar] [CrossRef]

- Rasouli Pirouzian, H.; Alakas, E.; Cayir, M.; Yakisik, E.; Toker, O.S.; Kaya, Ş.; Tanyeri, O. Buttermilk as milk powder and whey substitute in compound milk chocolate: Comparative study and optimisation. Int. J. Dairy Technol. 2021, 74, 246–257. [Google Scholar] [CrossRef]

- Latoch, A. Effect of meat marinating in kefir, yoghurt and buttermilk on the texture and color of pork steaks cooked sous-vide. Ann. Agric. Sci. 2020, 65, 129–136. [Google Scholar] [CrossRef]

- Barukčić, I.; Jakopović, K.L.; Božanić, R. Whey and buttermilk—Neglected sources of valuable beverages. Nat. Beverages 2019, 13, 209–242. [Google Scholar] [CrossRef]

- Hanafy, N.M.; Ghanimah, M.A.; Hassanein, A.M.; Hashim, M.A. The effect of using whey protein concentrate on the quality of nonfat fresh cheese. J. Biol. Chem. Environ. Sci. 2016, 11, 455–469. [Google Scholar]

- Skryplonek, K.; Dmytrów, I.; Mituniewicz-Małek, A. The use of buttermilk as a raw material for cheese production. Int. J. Dairy Technol. 2019, 72, 610–616. [Google Scholar] [CrossRef]

- Cais-Sokolińska, D.; Bielska, P.; Baranowska, H.M.; Tomaszewska-Gras, J. Determining the behavior of water in buttermilk cheese with polymerized whey protein using differential scanning calorimetry and nuclear magnetic resonance. Appl. Sci. 2022, 22, 11528. [Google Scholar] [CrossRef]

- Gamlath, C.J.; Leong, T.S.; Ashokkumar, M.; Martin, G.J. Incorporating whey protein aggregates produced with heat and ultrasound treatment into rennet gels and model non-fat cheese systems. Food Hydrocoll. 2020, 109, 106103. [Google Scholar] [CrossRef]

- Warncke, M.; Kieferle, I.; Nguyen, T.M.; Kulozik, U. Impact of heat treatment, casein/whey protein ratio and protein concentration on rheological properties of milk protein concentrates used for cheese production. J. Food Eng. 2022, 312, 110745. [Google Scholar] [CrossRef]

- Jiang, S.; Altaf hussain, M.; Cheng, J.; Jiang, Z.; Geng, H.; Sun, Y.; Sun, C.; Hou, J. Effect of heat treatment on physicochemical and emulsifying properties of polymerized whey protein concentrate and polymerized whey protein isolate. LWT 2018, 98, 134–140. [Google Scholar] [CrossRef]

- Shi, H.; Kraft, J.; Guo, M. Physicochemical and microstructural properties and probiotic survivability of symbiotic almond yogurt alternative using polymerized whey protein as a gelation agent. J. Food Sci. 2020, 85, 3450–3458. [Google Scholar] [CrossRef]

- Bielska, P.; Cais-Sokolińska, D.; Dwiecki, K. Effects of heat treatment duration on the electrical properties, texture and color of polymerized whey protein. Molecules 2022, 27, 6395. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, C.; Wang, M.; Guo, M. Chemical, physiochemical, and microstructural properties, and probiotic survivability of fermented goat milk using polymerized whey protein and starter culture kefir Mild 01. J. Food Sci. 2017, 82, 2650–2658. [Google Scholar] [CrossRef] [PubMed]

- Andoyo, R.; Dianti Lestari, V.; Mardawati, E.; Nurhadi, B. Fractal dimension analysis of texture formation of whey protein-based foods. J. Food Sci. 2018, 2018, 7673259. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.; Gao, F.; Guo, M. Effects of polymerised whey protein-based microencapsulation on survivability of Lactobacillus Acidophilus LA-5 and physiochemical properties of yoghurt. J. Microencapsul. 2018, 35, 504–512. [Google Scholar] [CrossRef] [PubMed]

- Bierzuńska, P.; Cais-Sokolińska, D.; Yiğit, A. Storage stability of texture and sensory properties of yogurt with the addition of polymerized whey proteins. Foods 2019, 8, 548. [Google Scholar] [CrossRef]

- Fang, T.; Shen, X.; Hou, J.; Guo, M. Effects of polymerized whey protein prepared directly from cheese whey as fat replacer on physiochemical, texture, microstructure and sensory properties of low-fat set yogurt. LWT 2019, 115, 108268. [Google Scholar] [CrossRef]

- Bahrami, M.; Ahmadi, D.; Beigmohammadi, F.; Hosseini, F. Mixing sweet cream buttermilk with whole milk to produce cream cheese. Irish J. Agric. Food Res. 2015, 54, 73–78. [Google Scholar] [CrossRef][Green Version]

- Hickey, C.D.; O’Sullivan, M.G.; Davis, J.; Scholz, D.; Kilcawley, K.N.; Wilkinson, M.G.; Sheehan, J.J. The effect of buttermilk or buttermilk powder addition on functionality, textural, sensory and volatile characteristics of Cheddar-style cheese. Food Res. Int. 2018, 103, 468–477. [Google Scholar] [CrossRef]

- AOAC No. 33.7.03; Official Method 926.08. Loss on Drying (Moisture) in Cheese. Method I. Final Action. In Official Methods of Analysis of AOAC International, 16th ed.; Cunniff, P., Ed.; AOAC International: Arlington, TX, USA, 1995. [Google Scholar]

- ISO Standard No. 1735; Cheese and Processed Cheese Products—Determination of Fat Content—Gravimetric Method (Reference Method). International Organization for Standardization: Geneva, Switzerland, 2004.

- Svanborg, S.; Johansen, A.G.; Abrahamsen, R.K.; Skeie, S.B. The composition and functional properties of whey protein concentrates produced from buttermilk are comparable with those of whey protein concentrates produced from skimmed milk. J. Dairy Sci. 2015, 98, 5829–5840. [Google Scholar] [CrossRef]

- Bierzuńska, P.; Cais-Sokolińska, D.; Rudzińska, M.; Gramza-Michałowska, A. Evaluation of antioxidant activity of whey protein to improve cholesterol oxidation stability in fresh white cheese from buttermilk. J. Food Nutr. Res. 2017, 56, 101–108. [Google Scholar]

- AOAC No 33.7.14; Official Method 920.124. Acidity of Cheese. Titrimetric method. Final Action. In Official Methods of Analysis of AOAC International, 16th ed.; Cunniff, P., Ed.; AOAC International: Arlington, TX, USA, 1995. [Google Scholar]

- Masotti, F.; Cattaneo, S.; Stuknytė, M.; De Noni, I. Technological tools to include whey proteins in cheese: Current status and perspectives. Trends Food Sci. Technol. 2017, 64, 102–114. [Google Scholar] [CrossRef]

- Mileriene, J.; Serniene, L.; Kondrotiene, K.; Lauciene, L.; Kasetiene, N.; Sekmokiene, D.; Andruleviciute, V.; Malakauskas, M. Quality and nutritional characteristics of traditional curd cheese enriched with thermo-coagulated acid whey protein and indigenous Lactococcus Lactis strain. Int. J. Food Sci. Technol. 2021, 56, 2853–2863. [Google Scholar] [CrossRef]

- Elbarbary, H.A.; Saad, M.A. Improvement of the quality of buffalo’s milk soft cheese by camel’s whey protein concentrate. J. Adv. Vet. Anim. Res. 2019, 6, 528–535. [Google Scholar] [CrossRef] [PubMed]

- Stankey, J.A.; Lu, Y.; Abdalla, A.; Govindasamy-Lucey, S.; Jaeggi, J.J.; Mikkelsen, Ø.B.; Pedersen, K.T.; Andersen, C.B. Low-Fat Cheddar cheese made using microparticulated whey proteins: Effect on yield and cheese quality. Int. J. Dairy Technol. 2017, 70, 481–491. [Google Scholar] [CrossRef]

- Perreault, V.; Rémillard, N.; Chabot, D.; Morin, P.; Pouliot, Y.; Britten, M. Effect of denatured whey protein concentrate and its fractions on cheese composition and rheological properties. J. Dairy Sci. 2017, 100, 5139–5152. [Google Scholar] [CrossRef]

- Giroux, H.J.; Dupont, F.; Villeneuve, G.; Britten, M. Effect of heating milk on whey protein denaturation and cheese-making properties. Int. Dairy J. 2020, 111, 104831. [Google Scholar] [CrossRef]

- Mohamed, R.O. Improve microstructure and rheological properties of Kariesh cheese. J. Food and Dairy Sci. 2016, 7, 1–9. [Google Scholar] [CrossRef][Green Version]

- Sołowiej, B.G.; Nastaj, M.; Szafrańska, J.O.; Muszyński, S.; Gustaw, W.; Tomczyńska-Mleko, M.; Mleko, S. Effect of emulsifying salts replacement with polymerised whey protein isolate on textural, rheological and melting properties of acid casein model processed cheeses. Int. Dairy J. 2020, 105, 104694. [Google Scholar] [CrossRef]

- Li, H.; Qin, A.; Yu, H.; Han, Y.; Zheng, S.; Li, H.; Yu, J. Effects of pre-emulsification with heat-treated whey protein on texture and microstructure of processed cheese. LWT 2020, 124, 109185. [Google Scholar] [CrossRef]

- Domingos, L.D.; de Souza, H.A.L.; Mariutti, L.R.B.; de Toledo Benassi, M.; Bragagnolo, N.; Viotto, W.H. Fat reduction and whey protein concentrate addition alter the concentration of volatile compounds during prato cheese ripening. Food Res. Int. 2019, 119, 793–804. [Google Scholar] [CrossRef]

- Tashakori, A.; Ali, S.; Ardakani, Y.; Daneshi, M. Effect of whey protein concentrate and cornstarch on chemical, rheological and sensorial properties of white feta cheese. Am. J. Food Sci. Technol. 2013, 1, 25–29. [Google Scholar] [CrossRef]

- Brodziak, A.; Król, J.; Barłowska, J.; Teter, A.; Florek, M. Changes in the physicochemical parameters of yoghurts with added whey protein in relation to the starter bacteria strains and storage time. Animals 2020, 10, 1350. [Google Scholar] [CrossRef] [PubMed]

- Kampf, N.; Nussinovitch, A. Hydrocolloid coating of cheeses. Food Hydrocoll. 2020, 14, 531–537. [Google Scholar] [CrossRef]

- Youssef, A.M.; Assem, F.M.; El-Sayed, S.M.; Salama, H.; Abd El-Salam, M.H. Utilization of edible films and coatings as packaging materials for preservation of cheeses. J. Package Technol. Res. 2017, 1, 87–99. [Google Scholar] [CrossRef]

- Sakandar, H.A.; Ahmad, S.; Aslam, H.K.; Shakeel, A.; Shoaib, M. Polymerized whey protein isolates impact on organoleptic properties of camel milk stirred yoghurt. J. Glob. Innov. Agric. Sci. 2014, 2, 123–126. [Google Scholar] [CrossRef]

- de Sousa, P.B.; Guimarães, T.L.F.; da Silva, P.L.; Miranda, E.S.M.; de Andrade Castro , E.; da Costa Monção, É.; dos Santos, S.M.L.; Mendes, L.G.; Cavalcante, A.B.D.; Damaceno, M.N. Effect of inulin addition on the physicochemical, microbiological, and sensory characteristics from guava-flavored petit-suisse kefir cheese. Res. Soc. Dev. 2021, 10, e7010817139. [Google Scholar] [CrossRef]

- Khan, A.; Wang, C.; Sun, X.; Killpartrick, A.; Guo, M. Preparation and characterization of whey protein isolate–DIM nanoparticles. Int. J. Mol. Sci. 2019, 20, 3917. [Google Scholar] [CrossRef]

- Ortega, L.; Romero, A.; Muro, C.; Riera, F. Antioxidant activity and functional properties of polymerized whey products by glycation process. Int. J. Polym. Sci. 2015, 2015, 154262. [Google Scholar] [CrossRef]

- Abd El-Salam, B.A.E.Y.; Ahmed, M.S.; Yasser, M.M.; Taha, S.S.E.D. Soft white cheese ripening using bacterial protease enzyme. Acta Sci. Pol. Technol. Aliment. 2019, 18, 385–397. [Google Scholar] [CrossRef]

- Majcher, M.A.; Myszka, K.; Kubiak, J.; Jeleń, H.H. Identification of key odorants of fried cottage cheese and contribution of Galactomyces Geotrichum MK017 to the formation of 2-phenylethanol and related rose-like aroma compounds. Int. Dairy J. 2014, 39, 324–329. [Google Scholar] [CrossRef]

- Soltani, M.; Guzeler, N.; Hayaloglu, A.A. The Influence of salt concentration on the chemical, ripening and sensory characteristics of Iranian White Cheese manufactured by UF-Treated milk. J. Dairy Res. 2015, 82, 365–374. [Google Scholar] [CrossRef] [PubMed]

- Cais-Sokolińska, D.; Kaczyński, Ł.K.; Bierzuńska, P.; Skotarczak, E.; Dobek, A. Consumer acceptance in context: Texture, melting, and sensory properties of fried ripened curd cheese. Int. J. Dairy Technol. 2021, 74, 225–234. [Google Scholar] [CrossRef]

- Rychlik, T.; Szwengiel, A.; Bednarek, M.; Arcuri, E.; Montet, D.; Mayo, B.; Nowak, J.; Czarnecki, Z. Application of the PCR-DGGE technique to the fungal community of traditional Wielkopolska Fried Ripened Curd Cheese to determine Its PGI authenticity. Food Control 2017, 73, 1074–1081. [Google Scholar] [CrossRef]

- Cais-Sokolińska, D.; Pikul, J. Cheese meltability as assessed by the Tube Test and Schreiber Test depending on fat contents and storage time, based on curd-ripened fried cheese. Czech J. Food Sci. 2009, 27, 301–308. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).