Simulation and Experimental Study on Sealing Characteristics of Hydro-Pneumatic Spring GS Seal Rings

Abstract

:1. Introduction

2. Materials and Methods

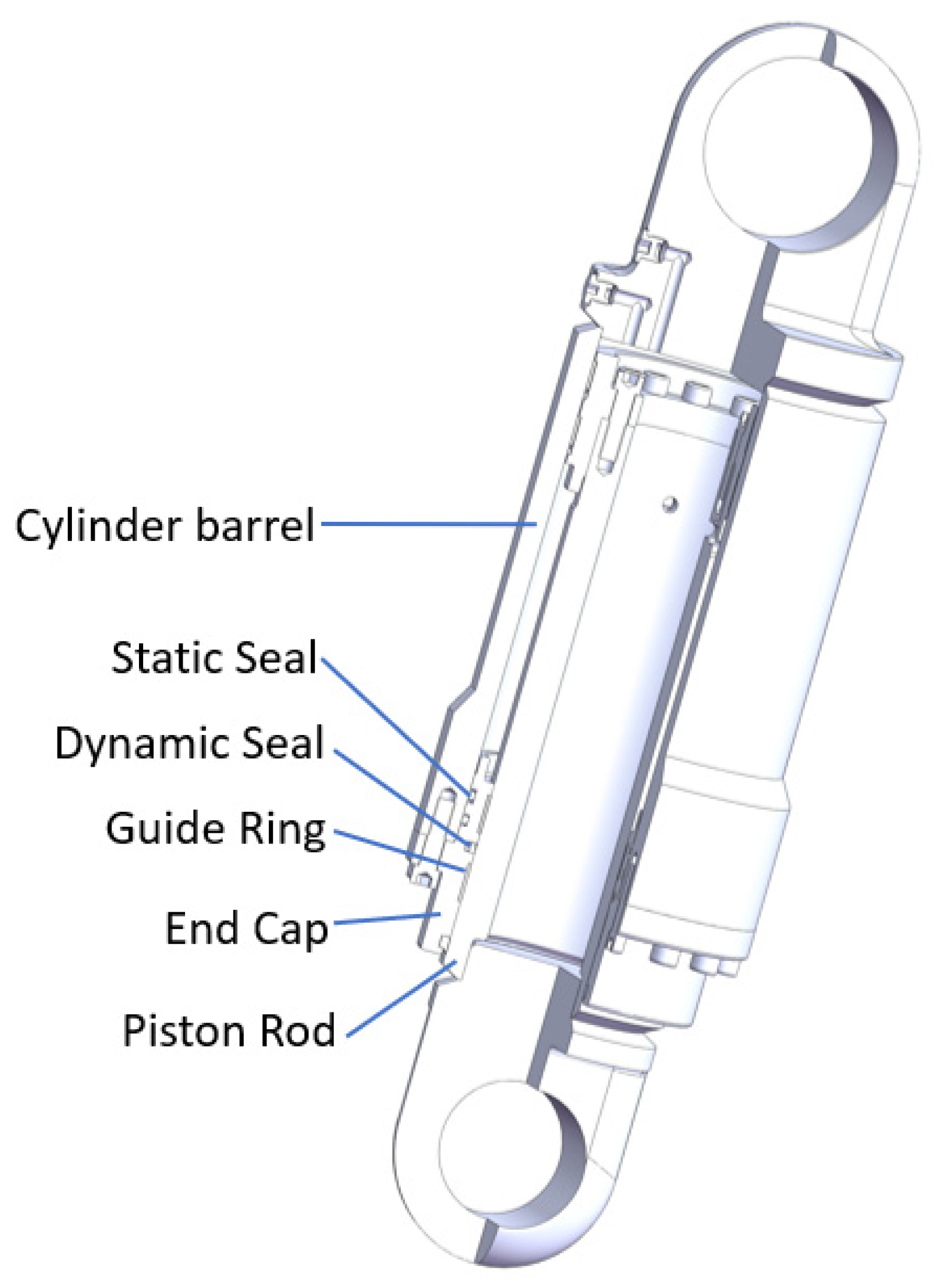

2.1. Hydro-Pneumatic Spring Sealing Structure

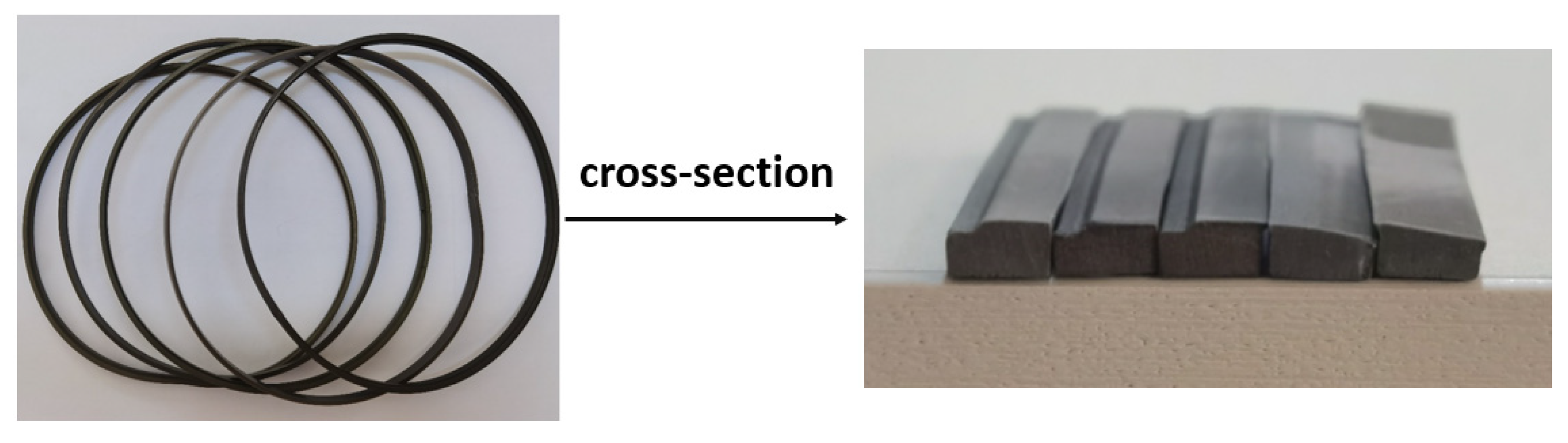

2.2. Sealing Ring Parameters

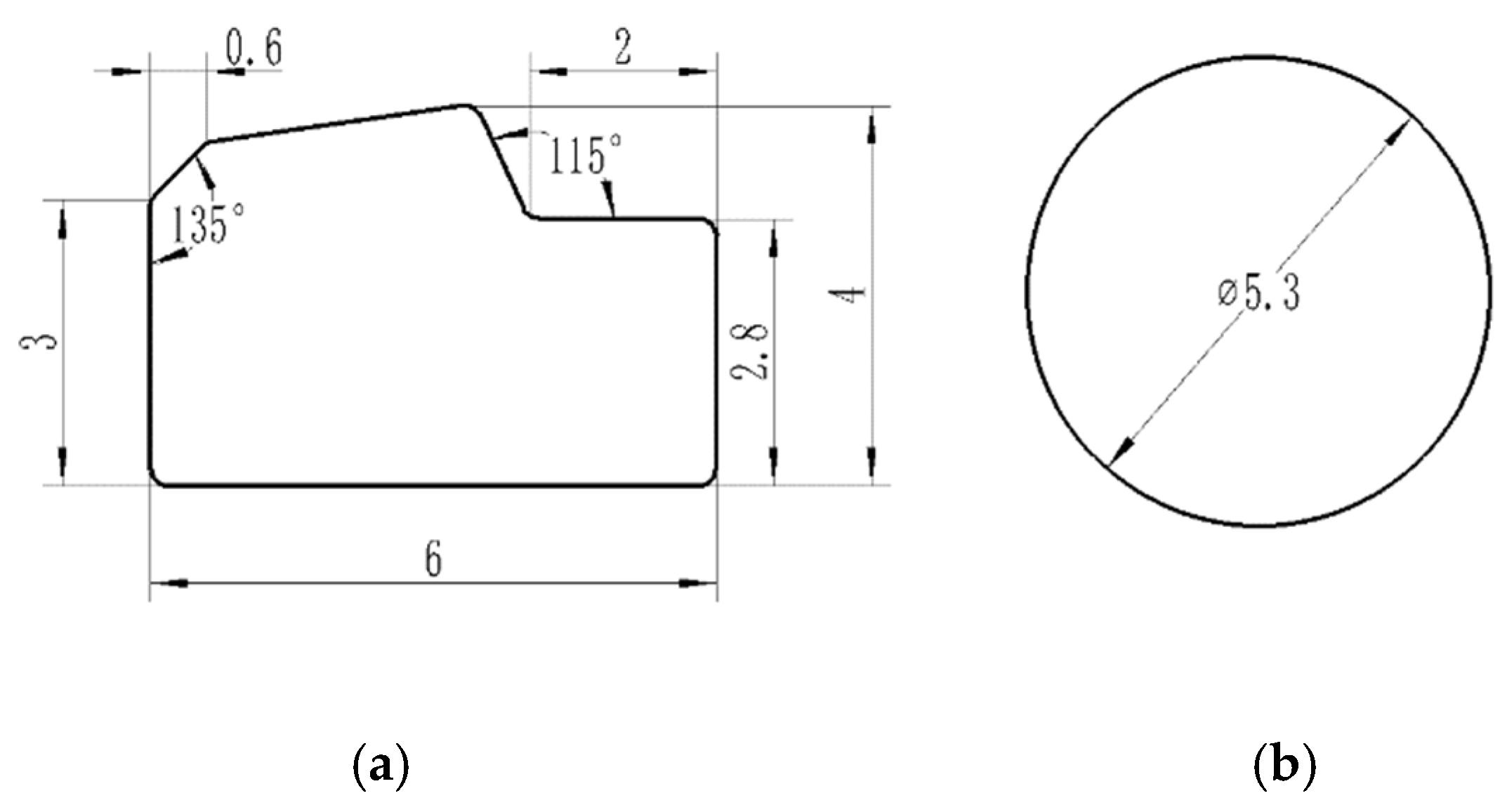

2.2.1. Geometric Parameters

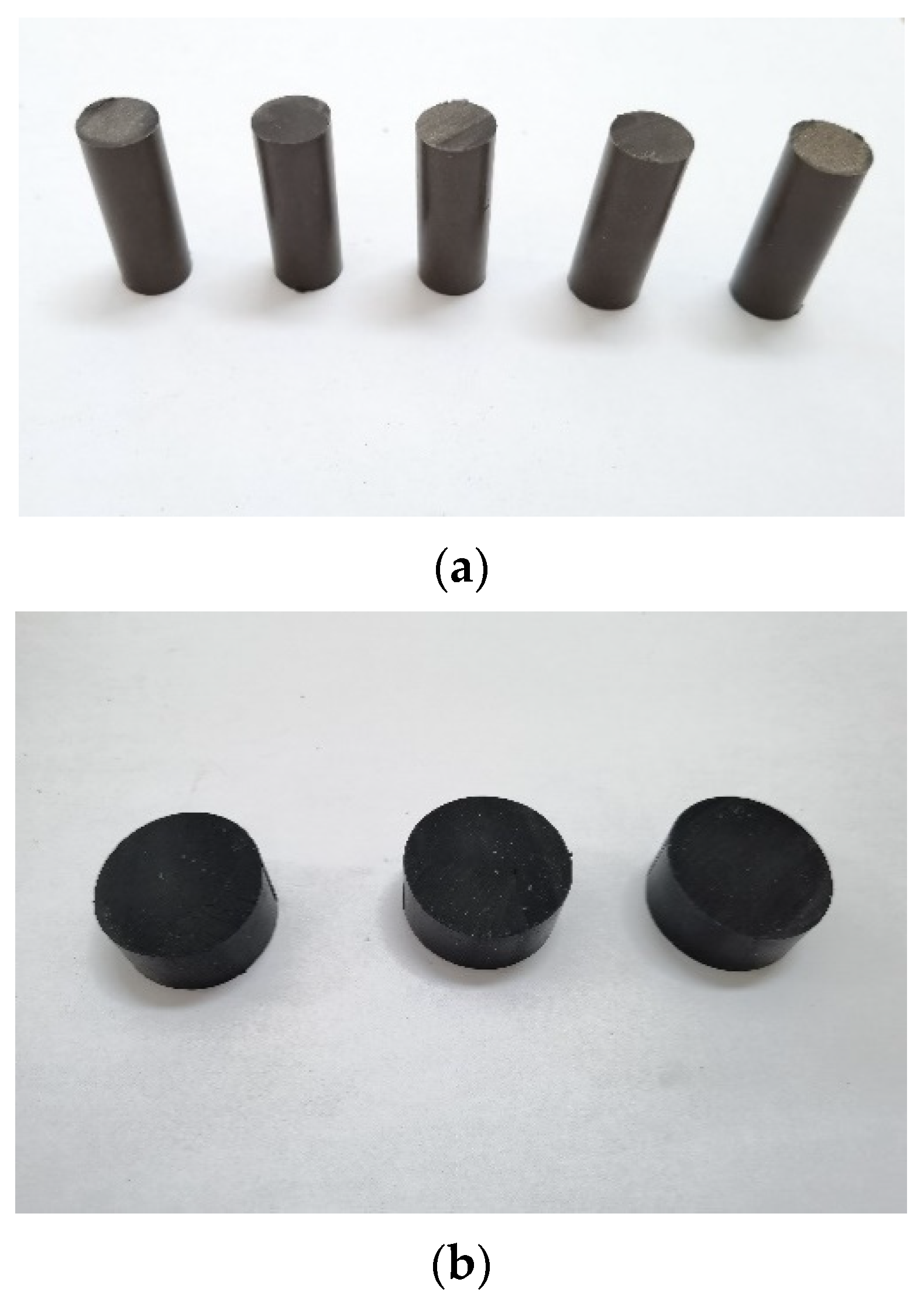

2.2.2. Determination of Material Parameters

2.3. Finite Element Simulation Model of Hydro-Pneumatic Spring Seal Based on ABAQUS

2.3.1. Model Establishment

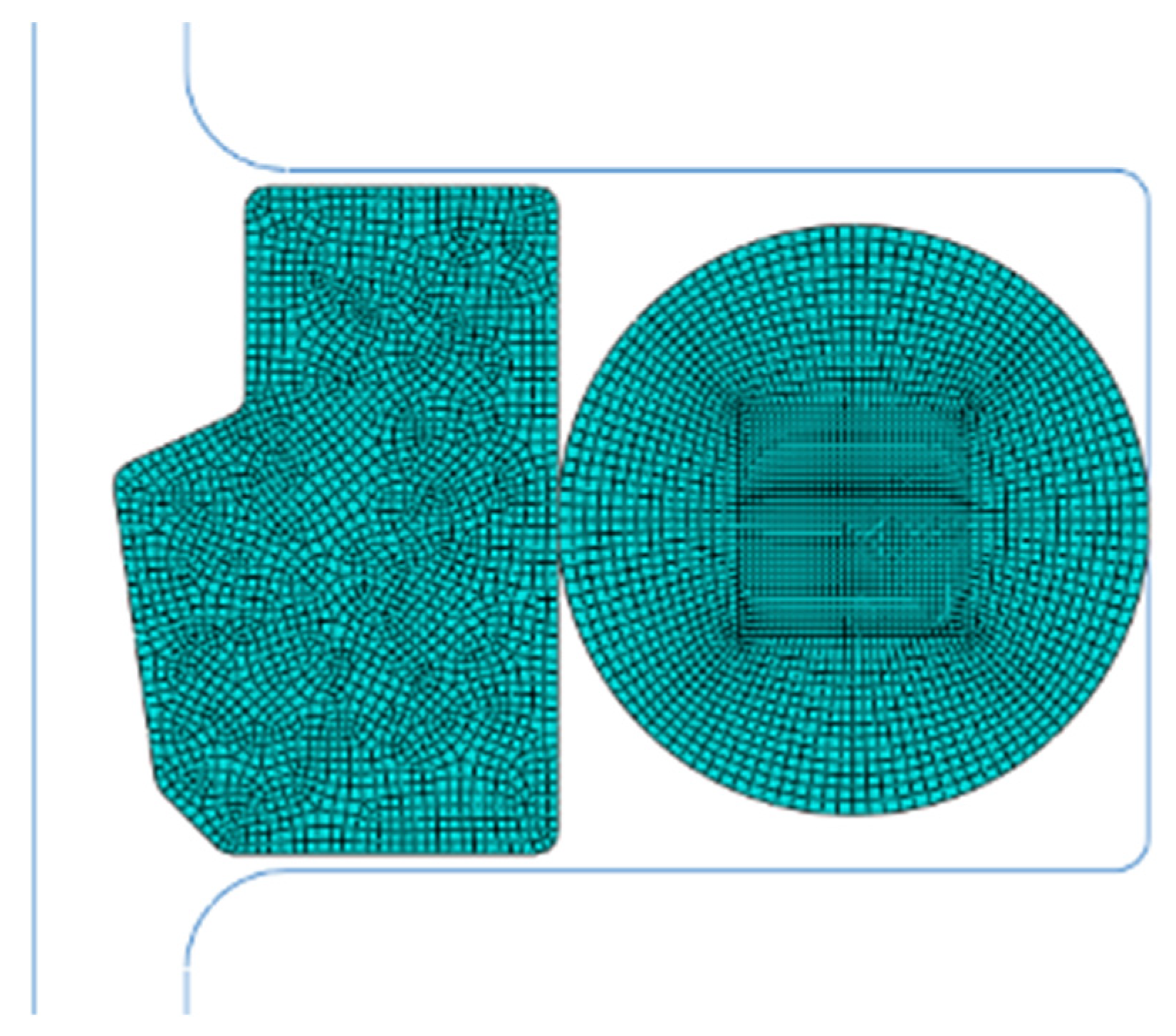

2.3.2. Meshing

2.3.3. Boundary Condition Settings

2.3.4. Solver Settings

2.4. Experimental Setup and Testing

2.4.1. Static Loading Test

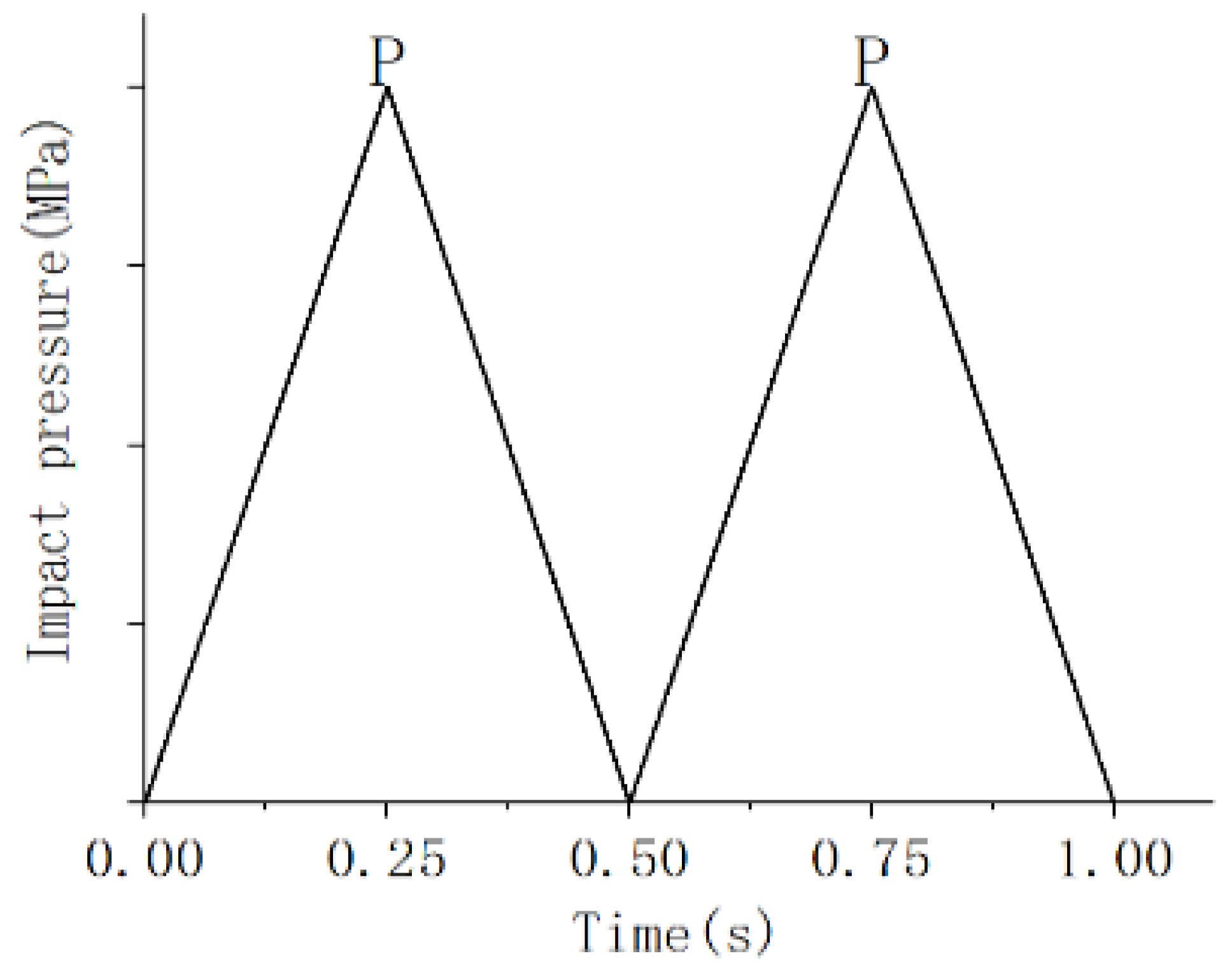

2.4.2. Dynamic Loading Test

3. Results

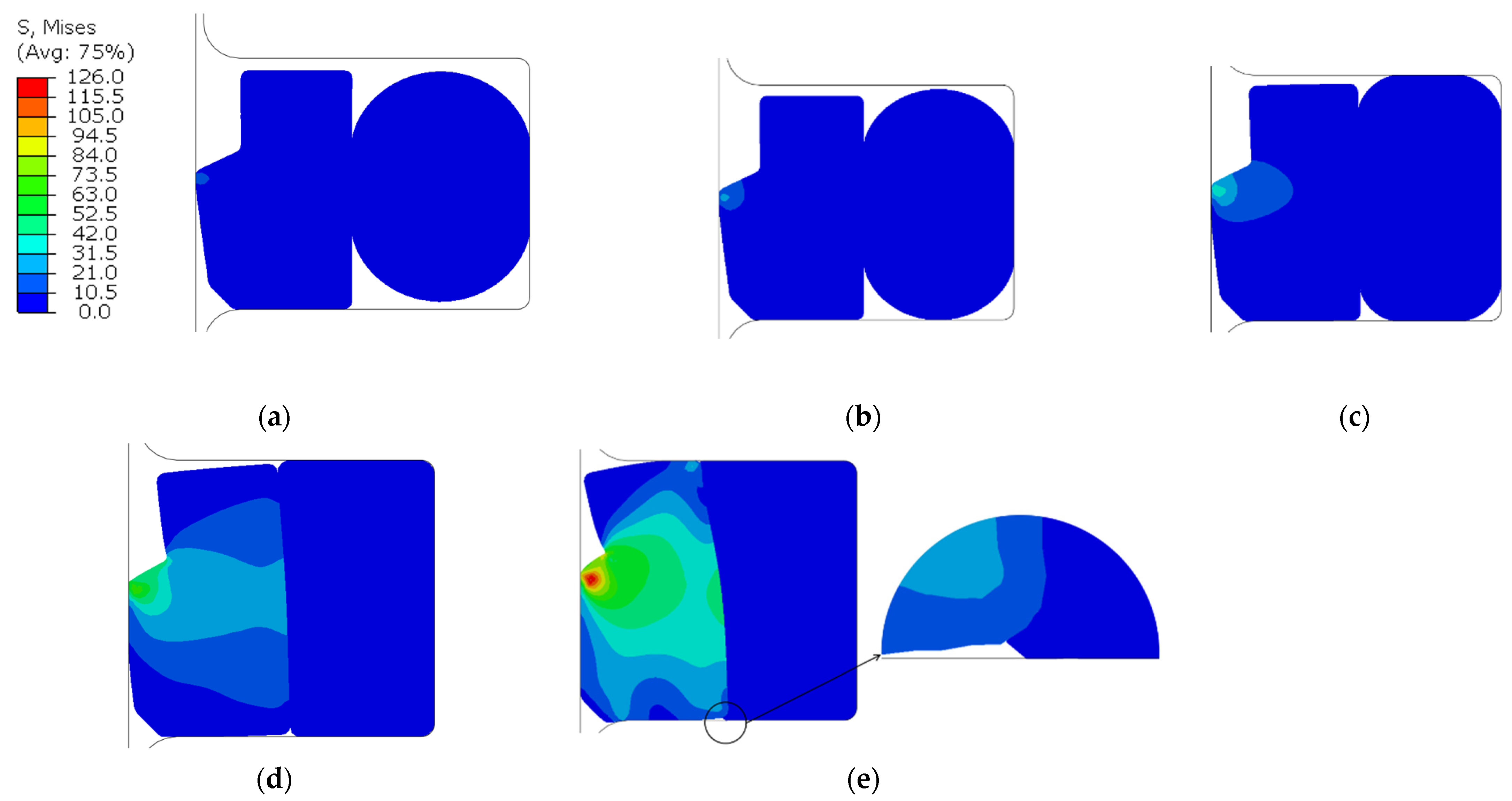

3.1. Analysis of the Sealing Ring Compression Process

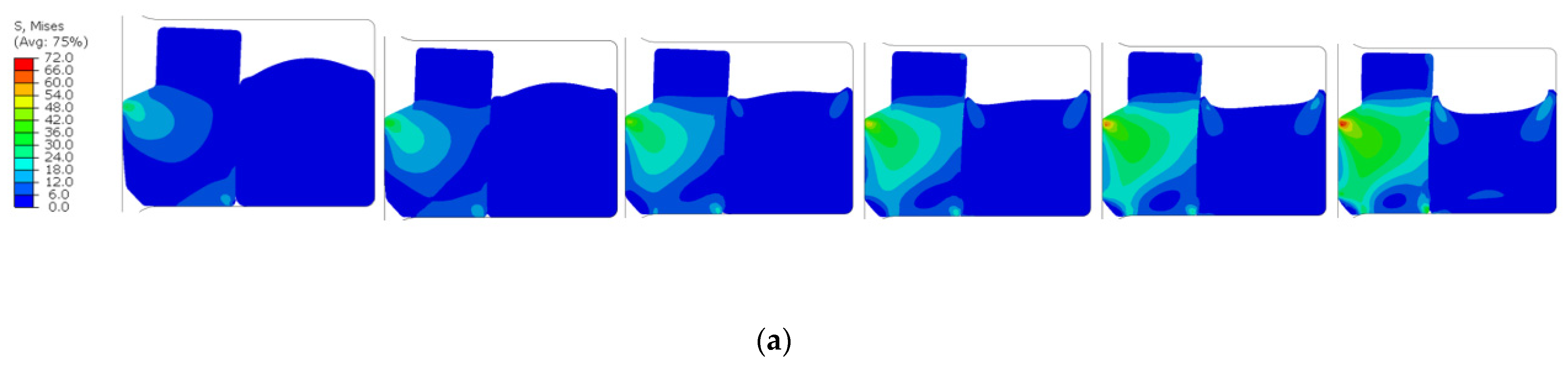

3.2. Analysis of the Pressure Shock Process

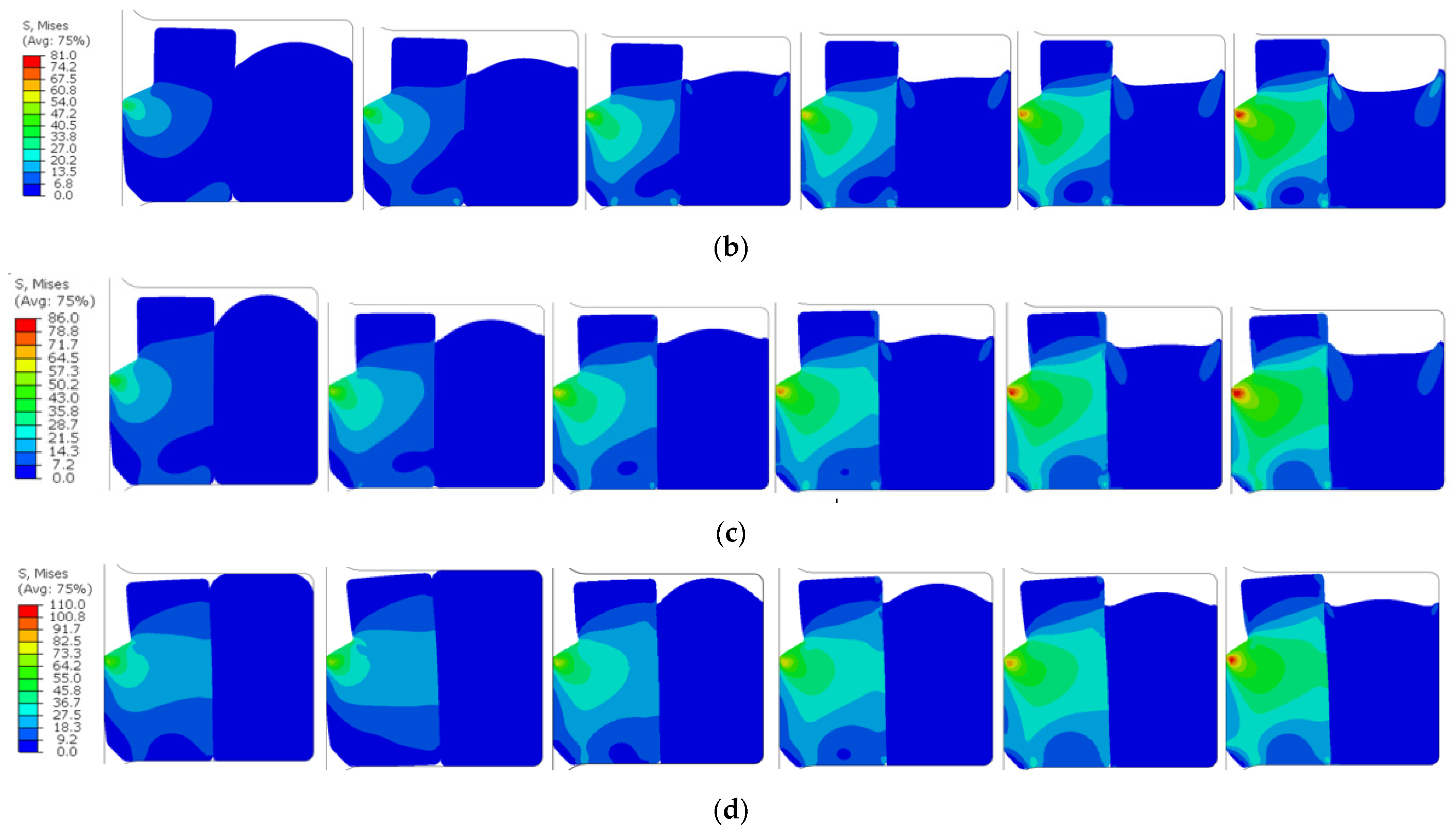

3.2.1. Stress Nephogram of Sealing Ring under Different Compression Rates and Different Pressure Impacts

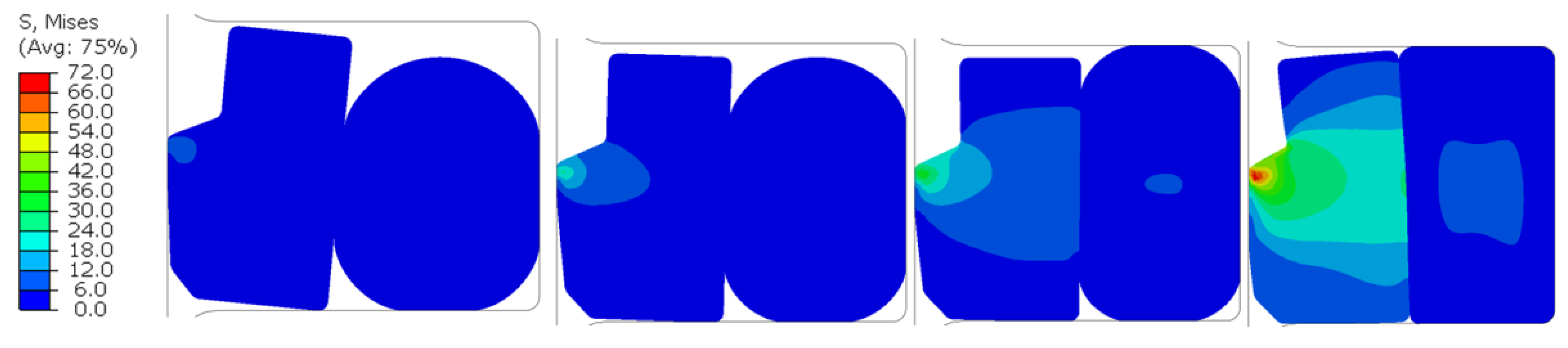

3.2.2. After the Stress Impact, Stress Nephogram of the Sealing Ring

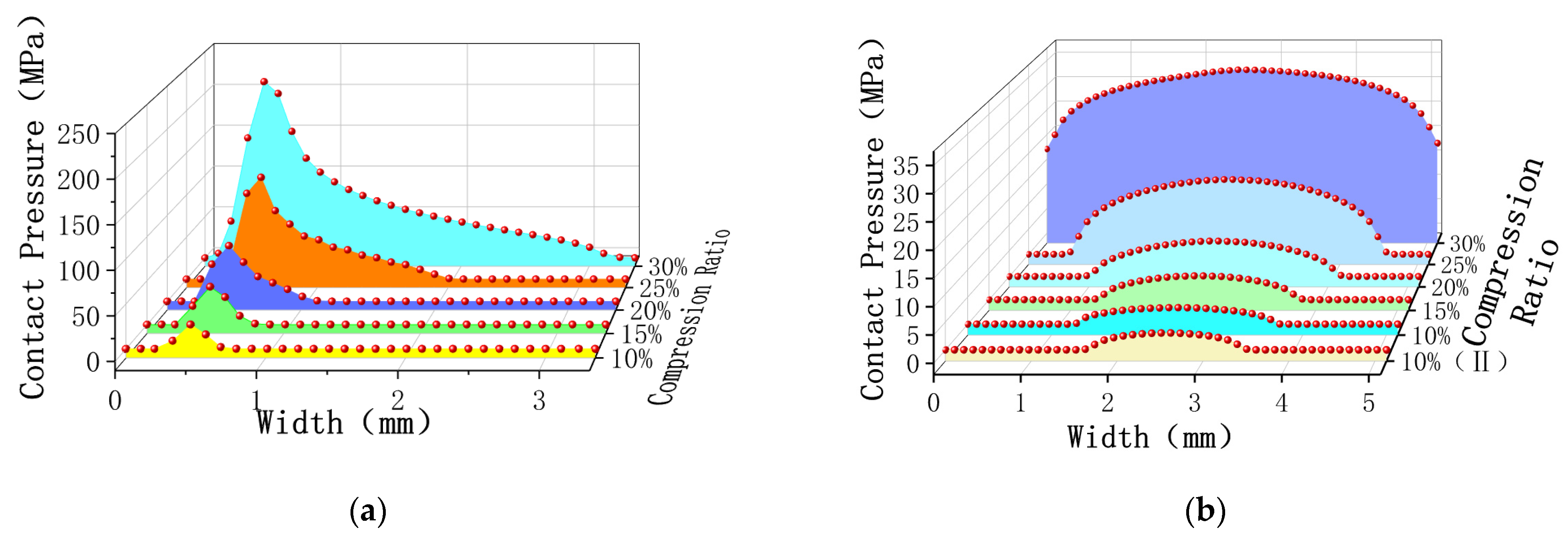

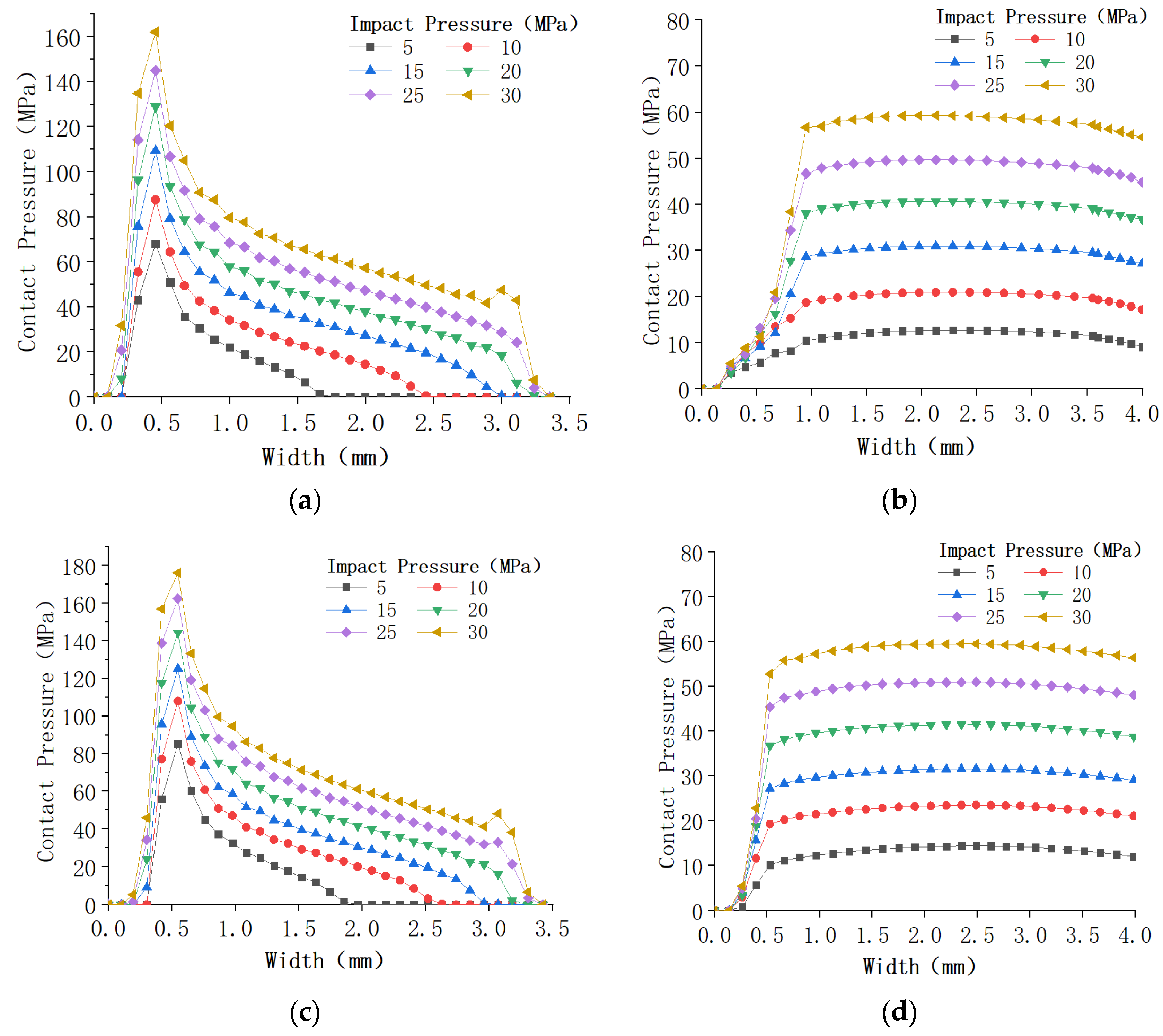

3.3. Contact Pressure on Sealing Surfaces under Impact Pressure

3.4. Experimental Results

4. Discussion

4.1. Compression Process of the Seal Ring

4.2. Pressure Impulse Process

4.3. Test Process Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, W.; Tang, H.; Zhang, S. High-precision Dynamics Characteristic Modeling Method Research Considering the Influence Factors of Hydropneumatic Suspension. Shock Vib. 2020, 8, 1–21. [Google Scholar] [CrossRef]

- Yang, L.; Wang, R.; Meng, X. Performance Analysis of a New Hydropneumatic Inerter-based Suspension System with Semi-active Control Effect. J. Automob. Eng. 2020, 234, 1883–1896. [Google Scholar] [CrossRef]

- Kucuk, K.; Yurt, H.K.; Arikan, K.B.; Mrek, H. Modelling and optimisation of an 8×8 heavy duty vehicle’s hydro-pneumatic suspension system. Int. J. Veh. Des. 2016, 71, 122–138. [Google Scholar] [CrossRef]

- Ali, D.; Frimpong, S. Artificial intelligence models for predicting the performance of hydro-pneumatic suspension struts in large capacity dump trucks. Nt. J. Ind. Ergonom. 2018, 67, 283–295. [Google Scholar] [CrossRef]

- Jiang, M.; Rui, X.T.; Yang, F.F. Design and dynamic performance research of MR Hydro-pneumatic spring based on multi-physics coupling model. Nonlinear Dyn. 2023, 111, 8191–8215. [Google Scholar] [CrossRef]

- Yi, T.; Ma, F.; Jin, C. A novel coupled hydro-pneumatic energy storage system for hybrid mining trucks. Energy 2018, 143, 704–718. [Google Scholar] [CrossRef]

- Ran, H.L.; Wang, S.P.; Liu, D. A multiscale wear model for reciprocating rod stepseal under mixed lubricating conditions based on linear elasticity. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 161–180. [Google Scholar] [CrossRef]

- Cheng, D.H.; Gu, L.C.; Sun, Y. Numerical Calculation Method of Multi-Lip Seal Wear under Mixed Thermal Elastohydrodynamic Lubrication. Lubricants 2023, 11, 248. [Google Scholar] [CrossRef]

- Malin, P. Derivation of Air Spring Model Parameters for Train Simulation; Lulea University of Technology: Lulea, Sverige, 2002. [Google Scholar]

- Gui, P.; Mao, M.; Chen, Y.J. Calculation and Simulation of Leakage of Stepseals in Main Piston of Hydro-pneumatic Springs. Acta Armamentarii 2017, 38, 1255–1262. [Google Scholar]

- Gui, P.; Mao, M.; Chen, Y.J. Failure Analysis of Seals in Hydro-Pneumatic Spring. In Proceedings of the 2016 SAE China Annual Conference, Shanghai, China, 26–28 October 2016; China Machine Press: Beijing, China, 2016; Volume 4. [Google Scholar]

- Yang, C.; Song, P.; Liu, X. Gas leakage fault recognition and prognostics of special vehicle Hydro-pneumatic spring. Chin. J. Sci. Instrum. 2016, 37, 2536–2544. [Google Scholar]

- Yang, C.; Song, P.; Liu, X. Failure prognostics of heavy vehicle Hydro-pneumatic spring based on novel degradation feature and support vector regression. Neural Comput. Appl. 2019, 31, 139–156. [Google Scholar] [CrossRef]

- Cheng, G.L.; Guo, F.; Zang, X.H. Failure analysis and improvement measures of airplane actuator seals. Eng. Fail. Anal. 2022, 133, 105949. [Google Scholar] [CrossRef]

- Ran, H.; Liu, D.; Wang, S. A Numerical Wear Simulation Method of Reciprocating Seals with a Textured Rod. Materials 2020, 13, 4458. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, X.P.; Xue, Z.Q.; Peng, C. Performance analysis on VL seal in aircraft cylinder. J. Zhejiang Univ. 2015, 49, 1755–1761. [Google Scholar]

- Qing, B.W.; Dong, X.P.; Kai, X.M. Simulation of the effects of non-Newtonian fluid on the behavior of a step hydraulic rod seal based on a power law fluid model. J. Zhejiang Univ.-Sci. A 2018, 19, 824–842. [Google Scholar]

- GB/T 1041-1992; Plastics—Determination of Compressive Properties. GBT: Ningbo, China, 1992.

- GB/T 7757-2009; Rubber, Vulcanized or Thermoplastic. Determination of Compression Stress-Strain Properties. GBT: Ningbo, China, 2009.

- Zhang, X.D.; Yang, L.; Zhang, Y. Finite Element Analysis of Tooth-shape Combined Seal Ring Based on Fluid Pressure Penetration. Lubr. Eng. 2019, 44, 12–17+95. [Google Scholar]

- Zhang, J.; Jin, G. Finite Element Analysis of Contact Pressure on O-ring. Lubr. Eng. 2010, 35, 65–69. [Google Scholar]

- Chang, K. Wear Simulation Method of O-ring Based on ANSYS. Chin. Hydraul. Pneum. 2018, 2, 98–103. [Google Scholar]

| Solution | ① | ② | ③ | ④ | ⑤ |

|---|---|---|---|---|---|

| Compression ratio | 10% | 15% | 20% | 25% | 30% |

| Displacement (mm) | 1.63 | 2.095 | 2.56 | 3.025 | 3.49 |

| Sealing groove depth (mm) | 8.17 | 7.705 | 7.24 | 6.775 | 6.31 |

| Compression Ratio | 10% | 15% | 20% | 25% | 30% |

|---|---|---|---|---|---|

| Sealing Surface I | 26.96 | 42.93 | 64.28 | 120.78 | 213.47 |

| Sealing Surface II | 3.03 | 4.49 | 6.88 | 14.96 | 34.46 |

| Sealing Surface III | 3.03 | 4.49 | 6.83 | 14.79 | 33.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Liu, P.; Li, D.; Dong, Z.; Li, G. Simulation and Experimental Study on Sealing Characteristics of Hydro-Pneumatic Spring GS Seal Rings. Appl. Sci. 2023, 13, 11703. https://doi.org/10.3390/app132111703

Wang S, Liu P, Li D, Dong Z, Li G. Simulation and Experimental Study on Sealing Characteristics of Hydro-Pneumatic Spring GS Seal Rings. Applied Sciences. 2023; 13(21):11703. https://doi.org/10.3390/app132111703

Chicago/Turabian StyleWang, Shuai, Pengyuan Liu, Donglin Li, Zhenle Dong, and Geqiang Li. 2023. "Simulation and Experimental Study on Sealing Characteristics of Hydro-Pneumatic Spring GS Seal Rings" Applied Sciences 13, no. 21: 11703. https://doi.org/10.3390/app132111703

APA StyleWang, S., Liu, P., Li, D., Dong, Z., & Li, G. (2023). Simulation and Experimental Study on Sealing Characteristics of Hydro-Pneumatic Spring GS Seal Rings. Applied Sciences, 13(21), 11703. https://doi.org/10.3390/app132111703