Physical Modeling of the Process of Centrifugation of Crushed Bovine Bones to Separate Animal Fat and Meat–Bone Slurry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Objects

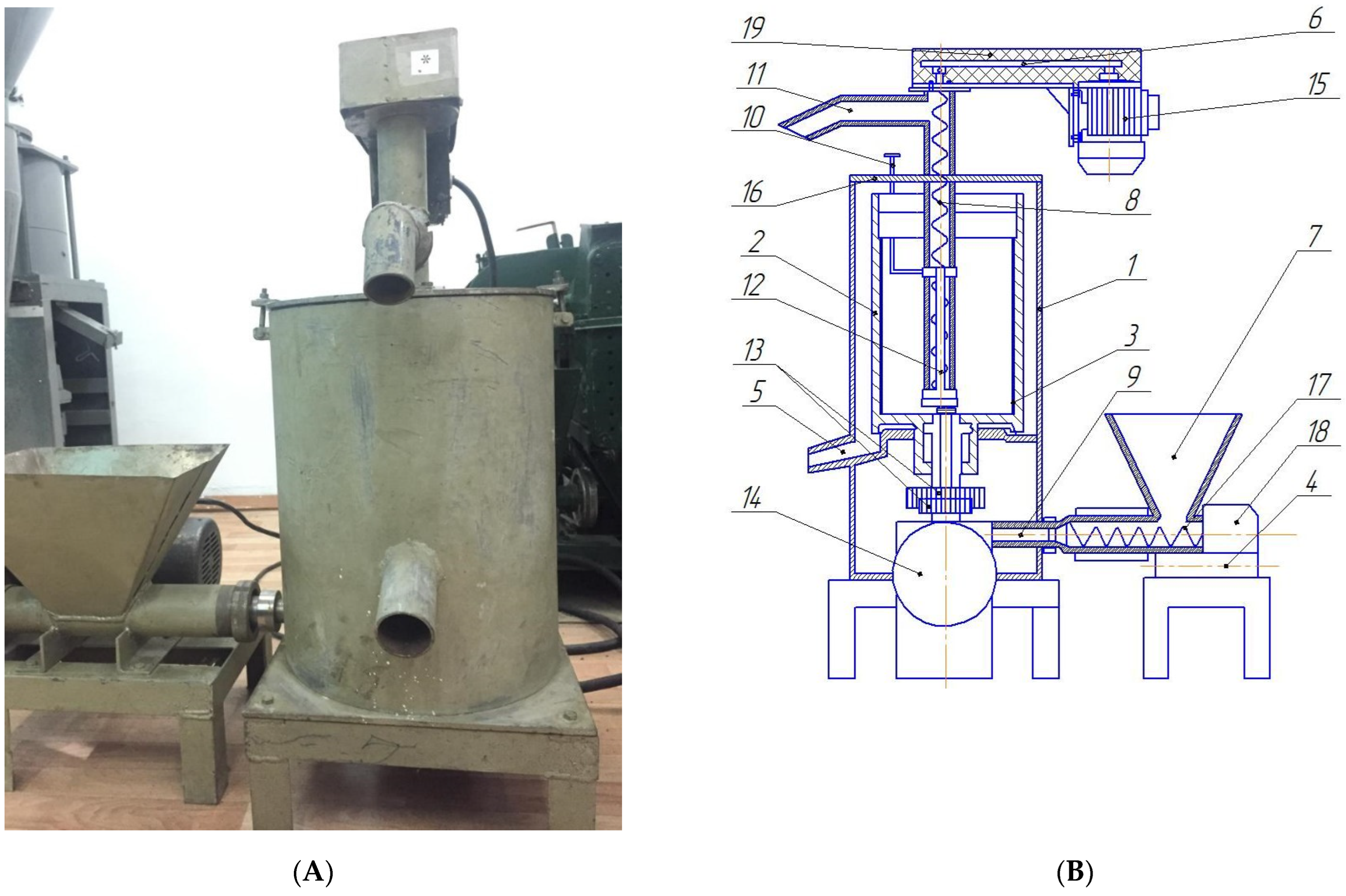

2.2. Description of the Design of the Pilot Installation—Centrifuge

2.3. Determining the Power Required for Pressing

- U—voltage indicated by the voltmeter, V;

- I—current intensity indicated by the ammeter, A;

- cosφ—power factor.

2.4. Statistical Analysis

3. Results and Discussion

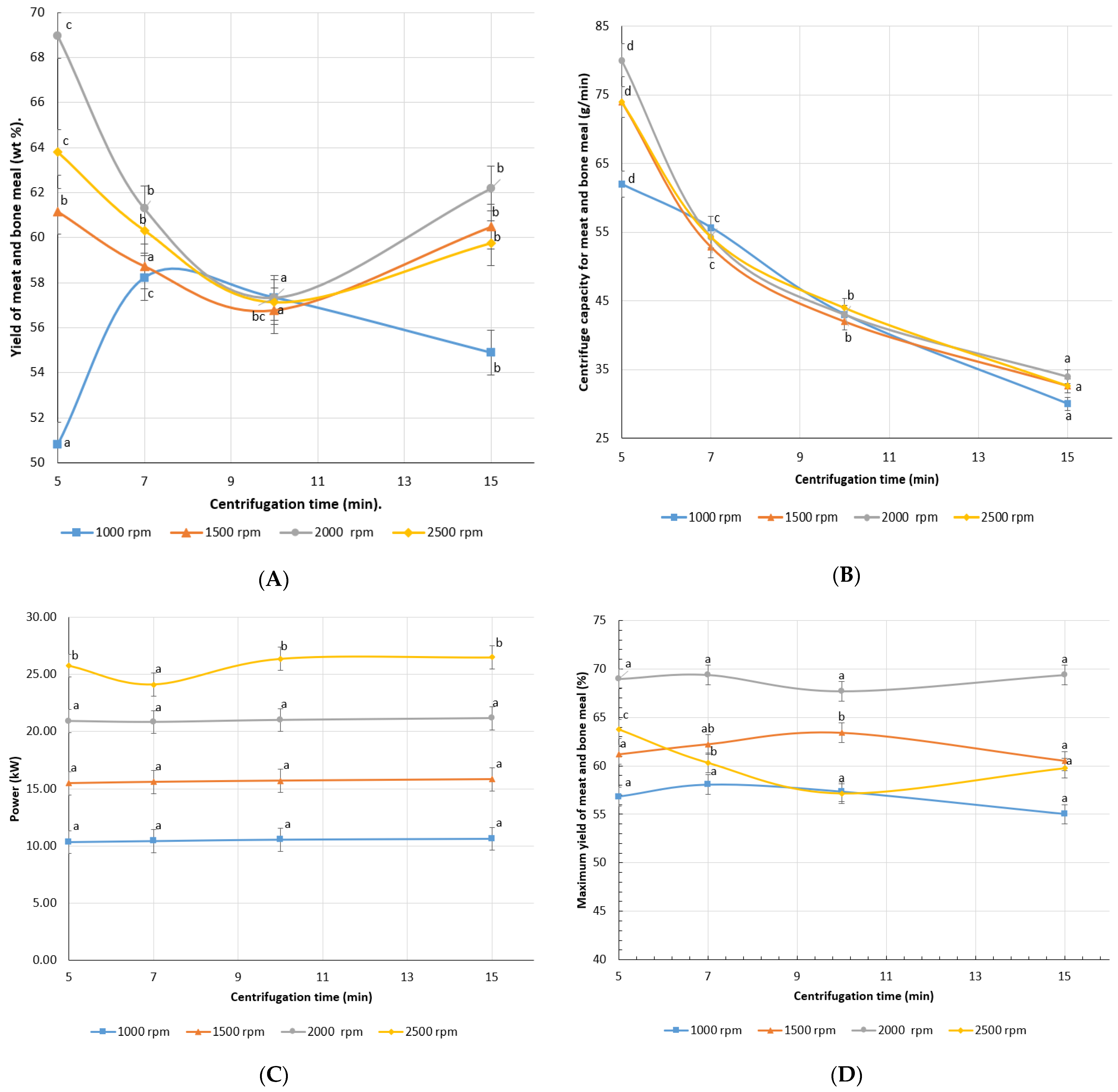

3.1. Determination of Centrifuge Capacity Depending on Centrifugation Duration and Rotation Speed

3.2. Physical Modeling of the Process of Centrifugation of Meat–Bone Cracklings

3.2.1. Derivation of the 1st Criterion Equation

- G—specific mass productivity of the centrifuge for meat–bone cracklings, kg/s m2.

- μ—dynamic viscosity coefficient of liquid fat raw material, Pa·s.

- ρ—density of fat, kg/m3.

- n—centrifuge drum speed, s−1.

- D—inner diameter of the centrifuge drum, m.

- B—numerical coefficient;

- x, y, z, q—degree indices.

- [G] = kg/s·m2 = kg·s−1·m2

- [μ] = Pa·s = N·s/m2 = kg·m·s/s2·m2 = kg/s−1 m−1

- [ρ] = kg/m3 = kg·m−3

- [n] = s−1

- [D] = m

- kg: 1 = x + y

- s: −1 = −x − z

- m: −2 = −x − 3y + q

- y = 1 − x

- z = 1 − x

- −2 = −x − 3y + q

- q = x + 3y − 2 = x + 3·(1 − x) − 2 = x + 3 − 3x − 2 = 1 − 2x.

- At 1000 rpm: G = 1.73 × 2995 × (38,507)−1.155 = 5181.35 × (1/38,507)1.155 = 5181.35 × 5.055 × 10−6 = 0.02619 kg/s·m2

- At 1500 rpm: G = 1.73 × 4432.8 × (56,989)−1.155 = 7668.25 × (1/56,989)1.155 = 5181.35 × 5.055 × 10−6 = 0.02681 kg/s·m2

- At 2000 rpm: G = 1.73 × 5910 × (75,986)−1.155 = 10224.3 × (1/75,986)1.155 = 10224.3 × 1.316 × 10−5 = 0.135 kg/s·m2

3.2.2. Deriving the 2nd Criterion Equation

- dP—elementary centrifugal force, N;

- F—area of the inner side surface of the centrifuge drum, m2;

- M—mass of slurry in the drum, kg;

- ω—angular rotation speed, s−1;

- dr—elementary radius of the drum, m;

- D—inner diameter of drum, m;

- H—height of slurry level in the drum, m.

- du—elementary speed of filtered suspension, m3;

- R—total resistance of sludge and perforation holes, kg/s·m2; (the numerical value is selected from reference tables or calculated).

- P = M·ω2·R—centrifugal force, N.

- RΣ—is the total force of resistance to centrifugal filtration, N.

- RΣ = πDH·u·R

- Kcf—criterion for balanced centrifugal filtration.

3.2.3. Deriving the 3rd Criterion Equation

- dp—total centrifugal pressure, Pa;

- dp1—centrifugal pressure providing separation of fat from solid residue, Pa;

- dp2—centrifugal pressure ensuring sludge formation and capillary formation in it, Pa;

- dp3—centrifugal pressure ensuring sludge thickening and passage of cleared liquid (fugate) through the sludge layer, Pa.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A.S. Utilization of byproducts and waste materials from meat, poultry and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293. [Google Scholar] [CrossRef] [PubMed]

- Toldrá, F.; Mora, L.; Reig, M. New insights into meat by-product utilization. Meat Sci. 2016, 120, 54–59. [Google Scholar] [CrossRef]

- Yessimbekov, Z.; Kakimov, A.; Caporaso, N.; Suychinov, A.; Kabdylzhar, B.; Shariati, M.A.; Baikadamova, A.; Domínguez, R.; Lorenzo, J.M. Use of Meat-Bone Paste to Develop Calcium-Enriched Liver Pâté. Foods 2021, 10, 2042. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, S.; Wang, X.; Le, W.; Hu, G.; Liu, T.; Zhao, C.; Jin, Y.; Su, L. Preparation and Impact of Fermented Sheep Bone Powder on Sausage Quality. Fermentation 2023, 9, 842. [Google Scholar] [CrossRef]

- Piazza, G.; Garcia, R. Proteolysis of meat and bone meal to increase utilisation. Anim. Prod. Sci. 2014, 54, 200–206. [Google Scholar] [CrossRef]

- Kasenov, A.L.; Kakimov, M.M.; Tokhtarov, J.H.; Muratzhankyzy, N. Study of moisture content in fat separation from meat-bone residue under the influence of centrifugal force. In Modern Innovations in Science and Technology 2014; Universitetskaya Kniga: Kursk, Russia, 2014; pp. 233–235. [Google Scholar]

- Faivishevsky, M.L. Raw fat and its processing. Meat Ind. 2014, 8, 45–48. [Google Scholar]

- Gooding, C.; Meeker, D. Review: Comparison of 3 alternatives for large-scale processing of animal carcasses and meat by-products. Prof. Anim. Sci. 2016, 32, 259–270. [Google Scholar] [CrossRef]

- Ragasri, S.; Sabumon, P.C. A critical review on slaughterhouse waste management and framing sustainable practices in managing slaughterhouse waste in India. J. Environ. Manag. 2023, 327, 116823. [Google Scholar] [CrossRef]

- Neburchilova, N.F.; Volynskaya, I.P.; Petrunina, I.V.; Chernova, A.S. Problems of waste-free production in the meat industry. Meat Ind. 2014, 3, 7–11. [Google Scholar]

- Condé-Green, A.; Baptista, L.; Amorin, N.; Oliveira, E.; Silva, K.; Pedrosa, C.; Borojevic, R.; Pitanguy, I. Effects of centrifugation on cell composition and viability of aspirated adipose tissue processed for transplantation. Aesthetic Surg. J. 2010, 30, 249–255. [Google Scholar] [CrossRef]

- Tsoi, Y.A.; Turgenbaev, M.S.; Kozhevnikov, Y.A. Energy-saving technology of fat extraction from sheep wool. Tech. Support Agric. 2019, 1, 139–144. [Google Scholar]

- Schneider, S. Innovating the pusher centrifuge for bulk chemical separation. Filtr. Sep. 2003, 40, 38–39. [Google Scholar] [CrossRef]

- Ranade, V.V.; Bhandari, V.M. Industrial Wastewater Treatment, Recycling and Reuse; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Zeitsch, K. Centrifugal filtration. In Solid–Liquid Separation; Butterworth-Heinemann: Oxford, UK, 1990; pp. 476–532. [Google Scholar]

- Shinomiya, K.; Muto, M.; Kabasawa, Y.; Fales, H.; Ito, Y. Protein Separation by Improved Cross-Axis Coil Planet Centrifuge with Eccentric Coil Assemblies. J. Liq. Chromatogr. Relat. Technol. 1996, 19, 415–425. [Google Scholar] [CrossRef]

- Taulbee, D.N.; Furst, A. Centrifugation|Preparative. In Encyclopedia of Analytical Science, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2005; pp. 469–481. [Google Scholar]

- Dueik, V.; Sobukola, O.; Bouchon, P. Development of low-fat gluten and starch fried matrices with high fiber content. LWT Food Sci. Technol. 2014, 59, 6–11. [Google Scholar] [CrossRef]

- Najjar, Y.S.; Abu-Shamleh, A. Harvesting of microalgae by centrifugation for biodiesel production: A review. Algal Res. 2020, 51, 102046. [Google Scholar] [CrossRef]

- Kasenov, A.L. To the question of research of processes of grinding and pressing of meat-bone squash. Tech. Technol. Food Prod. 2009, 2, 13–15. [Google Scholar]

- Abdilova, G.; Sergibayeva, Z.; Orynbekov, D.; Shamenov, M.; Zhumadilova, G.; Bakiyeva, A.; Mukashev, N.; Bayadilova, A.; Dukenbayev, D. Influence of Grinding Degree and Screw Rotation Speed on Sunflower Oil Pressing Process. Appl. Sci. 2023, 13, 9958. [Google Scholar] [CrossRef]

- Pang, C.; Tan, W.; Sha, E.; Tao, Y.; Liu, L. Simulating multiphase flow in a two-stage pusher centrifuge using computational fluid dynamics. Front. Chem. Sci. Eng. 2012, 6, 329–338. [Google Scholar] [CrossRef]

- Prokop, W.H. Rendering systems for processing animal by-product materials. J. Am. Oil Chem. Soc. 1985, 62, 805–811. [Google Scholar] [CrossRef]

- Anlauf, H. Recent developments in centrifuge technology. Sep. Purif. Technol. 2007, 58, 242–246. [Google Scholar] [CrossRef]

- Vivdenko, Y.N. Solution of experimental problems with the use of physical modeling. In National Priorities of Russia. Series 1: Science and Military Security; NVB: Omsk, Russia, 2015; pp. 43–47. [Google Scholar]

- Barford, J. A mathematical model for cell separation technique of centrifugal elutriation. Biotechnol. Bioeng. 1986, 28, 570–577. [Google Scholar] [CrossRef] [PubMed]

- Misic, T.; Najdanovic-Lukic, M.; Nešić, L. Dimensional analysis in physics and the Buckingham theorem. Eur. J. Phys. 2010, 31, 893–906. [Google Scholar] [CrossRef]

- Nemtin, V.G.; Aminov, L.A.; Kolbasiuk, K.Y.; Kishchenko, M.A. Similarity theorems, their description and application. In Innovative Technologies in Science and Education 2019; Nauka i Prosveshenie: Penza, Russia, 2019; pp. 27–30. [Google Scholar]

- Schaflinger, U. Centrifugal separation of a mixture. Fluid Dyn. Res. 1990, 6, 213–249. [Google Scholar] [CrossRef]

- Detloff, T.; Lerche, D. Centrifugal separation in tube and disc geometries: Experiments and theoretical models. Acta Mech. 2008, 201, 83–94. [Google Scholar] [CrossRef]

| Centrifuge Rotor Rotational Speed n, rpm | Optimal Centrifugation Time τ, min | Loading of Raw Materials into the Centrifuge Gr, g | Reynolds Number Recf | Parameter (kg/m2·s) ρ·n·D | Coefficient B | Degree Index, K = −x | Specific Calculated Yield of Meat–Bone Cracklings in kg/s·m2 Gy | Maximum Production Capacity of the Squash, g/min G |

|---|---|---|---|---|---|---|---|---|

| 1000 | 5 | 880 | 38,507 | 2995.0 | 1.73 | 1.155 | 0.0262 | 100.02 |

| 1500 | 5 | 870 | 56,989 | 4432.5 | 1.73 | 1.155 | 0.0278 | 106.02 |

| 2000 | 5 | 870 | 75,986 | 5910.0 | 1.73 | 1.155 | 0.1365 | 519.9 |

| 2500 | 5 | 580 | 94,982 | 7387.5 | 1.73 | 1.155 | 0.0970 | 369.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shayakhmetova, M.; Kassenov, A.; Zhumadilova, G.; Shayakhmetova, A.; Rebezov, M.; Bakiyeva, A.; Baikadamova, A.; Jumazhanova, M.; Mukhametov, Y.; Khayrullin, M.; et al. Physical Modeling of the Process of Centrifugation of Crushed Bovine Bones to Separate Animal Fat and Meat–Bone Slurry. Appl. Sci. 2023, 13, 11808. https://doi.org/10.3390/app132111808

Shayakhmetova M, Kassenov A, Zhumadilova G, Shayakhmetova A, Rebezov M, Bakiyeva A, Baikadamova A, Jumazhanova M, Mukhametov Y, Khayrullin M, et al. Physical Modeling of the Process of Centrifugation of Crushed Bovine Bones to Separate Animal Fat and Meat–Bone Slurry. Applied Sciences. 2023; 13(21):11808. https://doi.org/10.3390/app132111808

Chicago/Turabian StyleShayakhmetova, Madina, Amirzhan Kassenov, Gulmira Zhumadilova, Aigerim Shayakhmetova, Maksim Rebezov, Anara Bakiyeva, Assemgul Baikadamova, Madina Jumazhanova, Yeldos Mukhametov, Mars Khayrullin, and et al. 2023. "Physical Modeling of the Process of Centrifugation of Crushed Bovine Bones to Separate Animal Fat and Meat–Bone Slurry" Applied Sciences 13, no. 21: 11808. https://doi.org/10.3390/app132111808

APA StyleShayakhmetova, M., Kassenov, A., Zhumadilova, G., Shayakhmetova, A., Rebezov, M., Bakiyeva, A., Baikadamova, A., Jumazhanova, M., Mukhametov, Y., Khayrullin, M., & Ibragimov, N. (2023). Physical Modeling of the Process of Centrifugation of Crushed Bovine Bones to Separate Animal Fat and Meat–Bone Slurry. Applied Sciences, 13(21), 11808. https://doi.org/10.3390/app132111808