Clayey Soil Improvement with Polyethylene Terephthalate (PET) Waste

Abstract

:1. Introduction

2. Literature Review

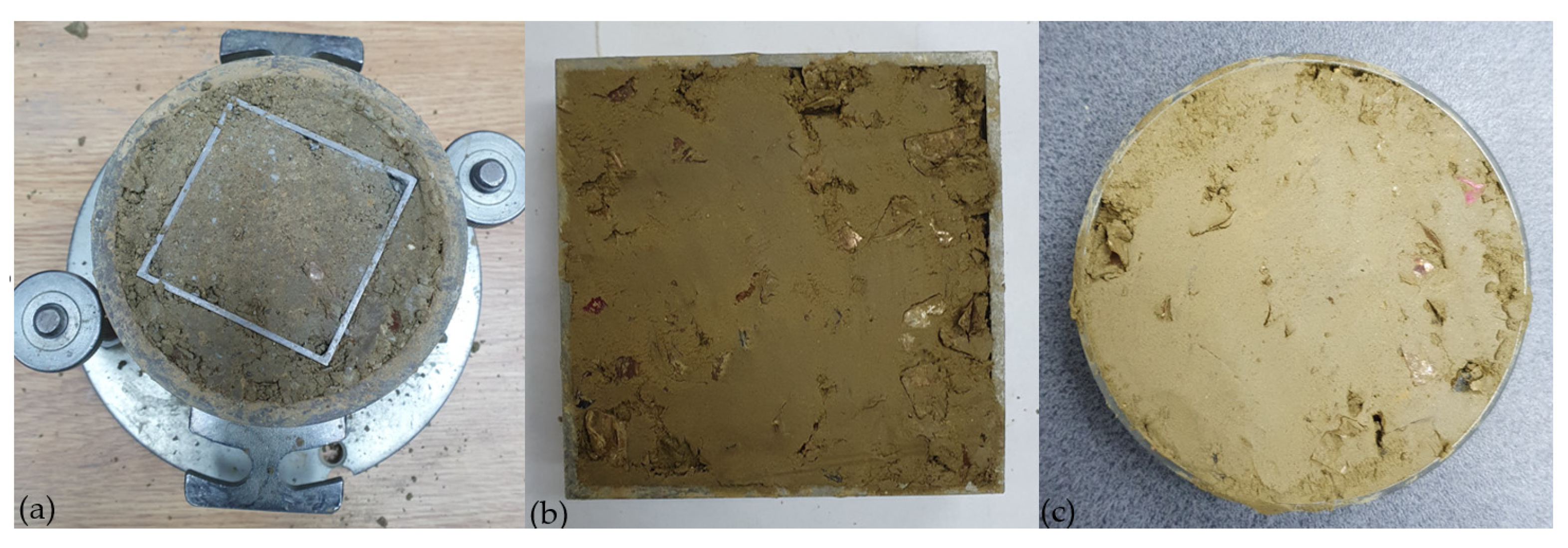

3. Materials and Methods

4. Results

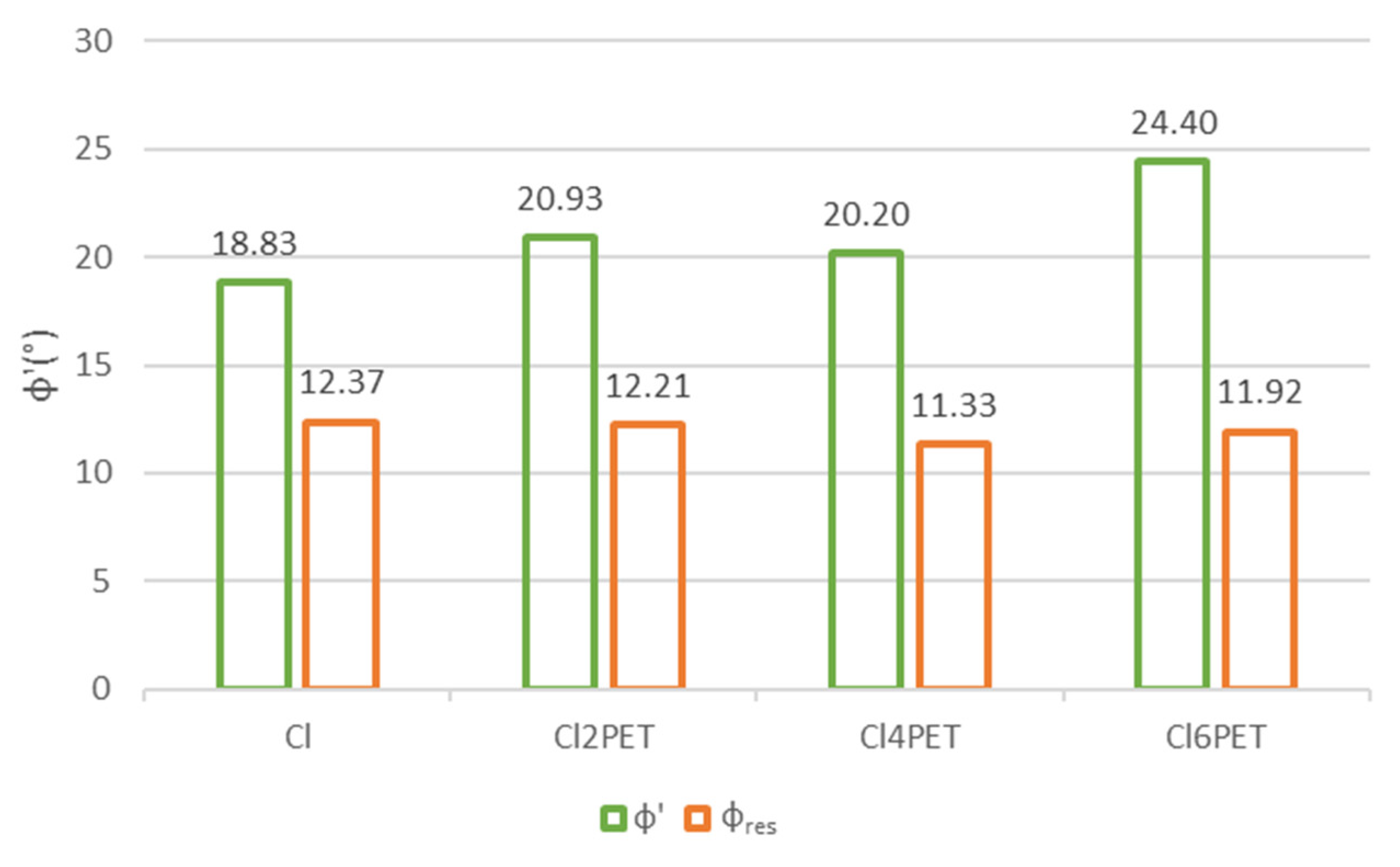

4.1. Direct Shearing Tests

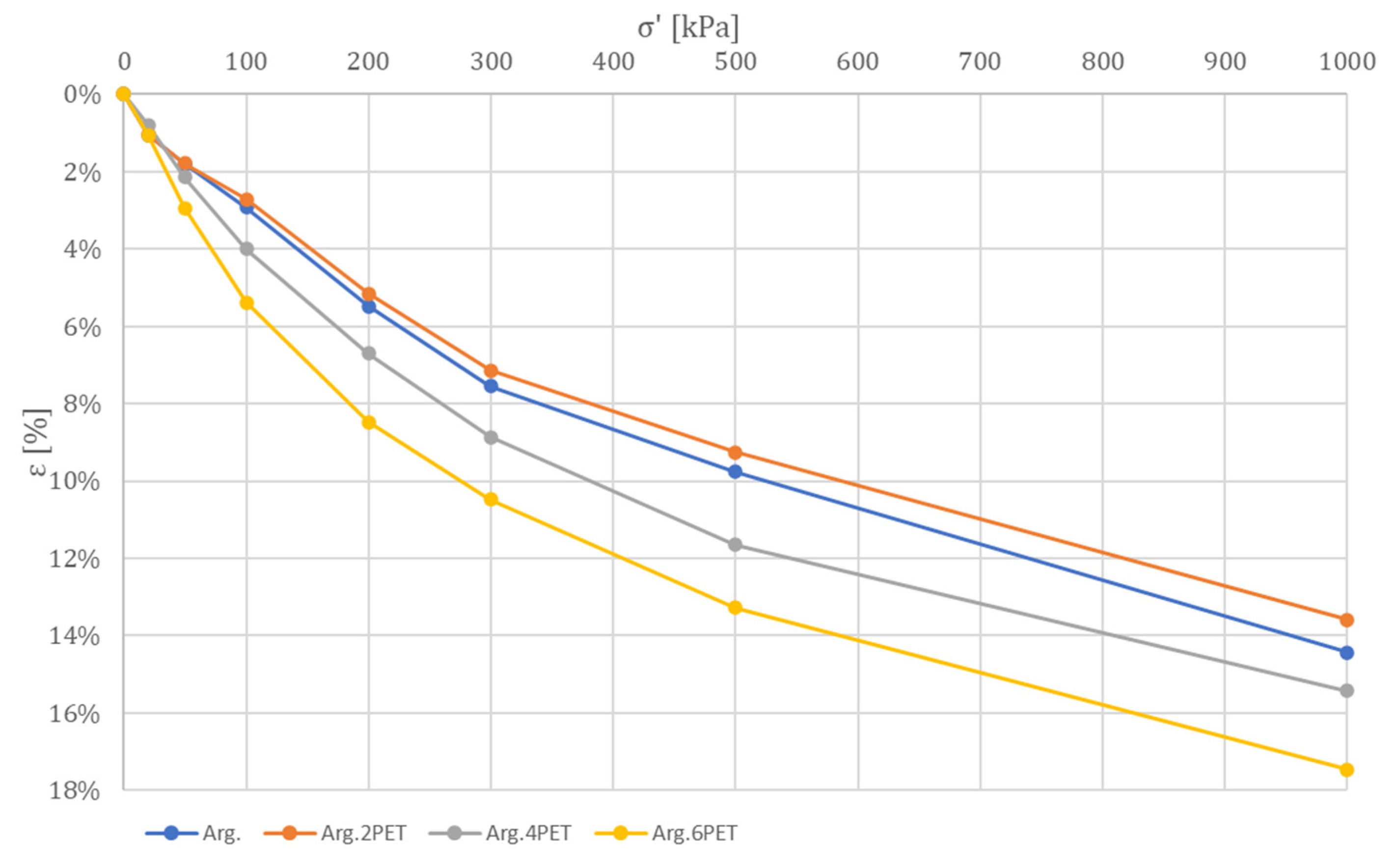

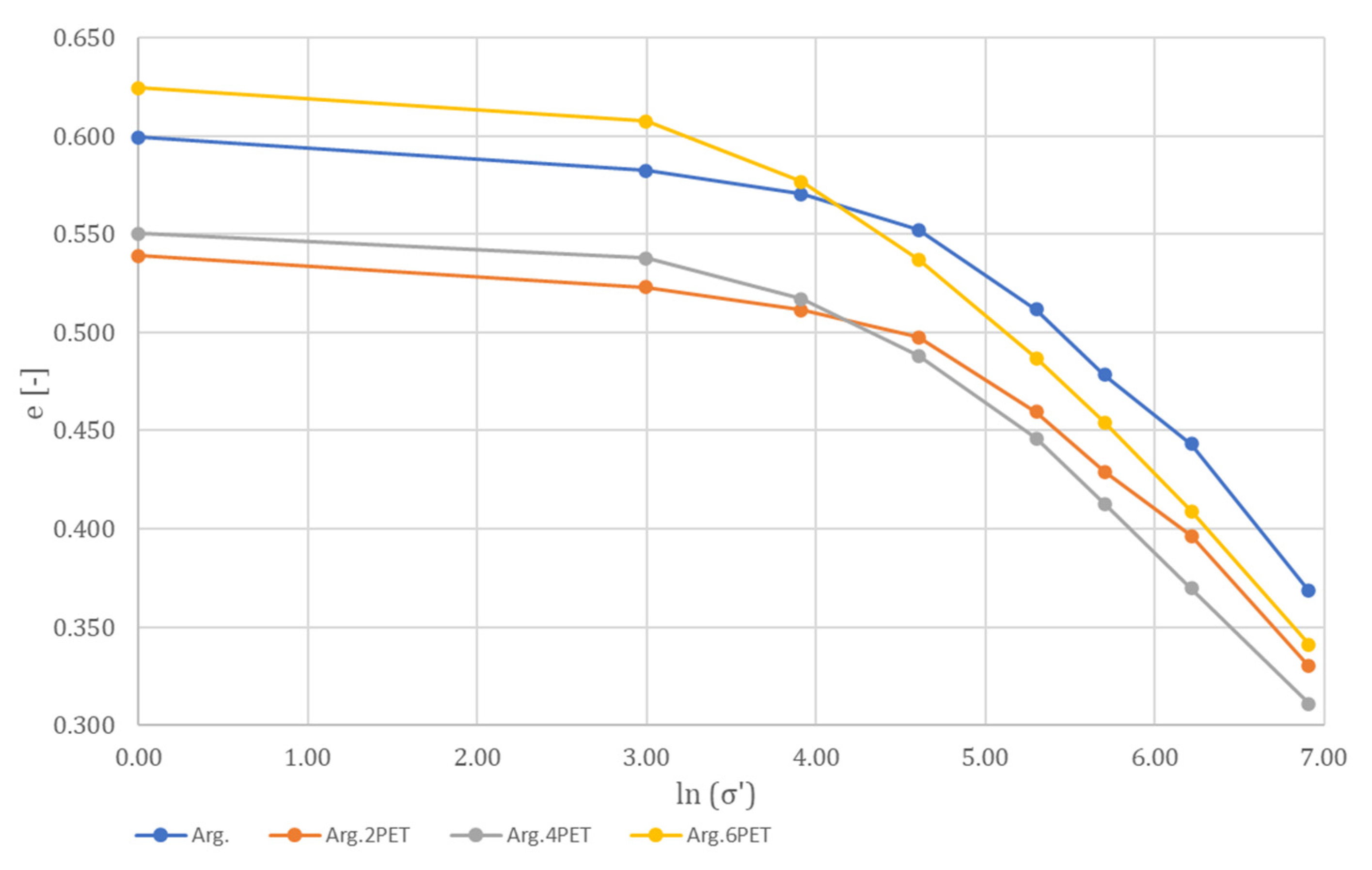

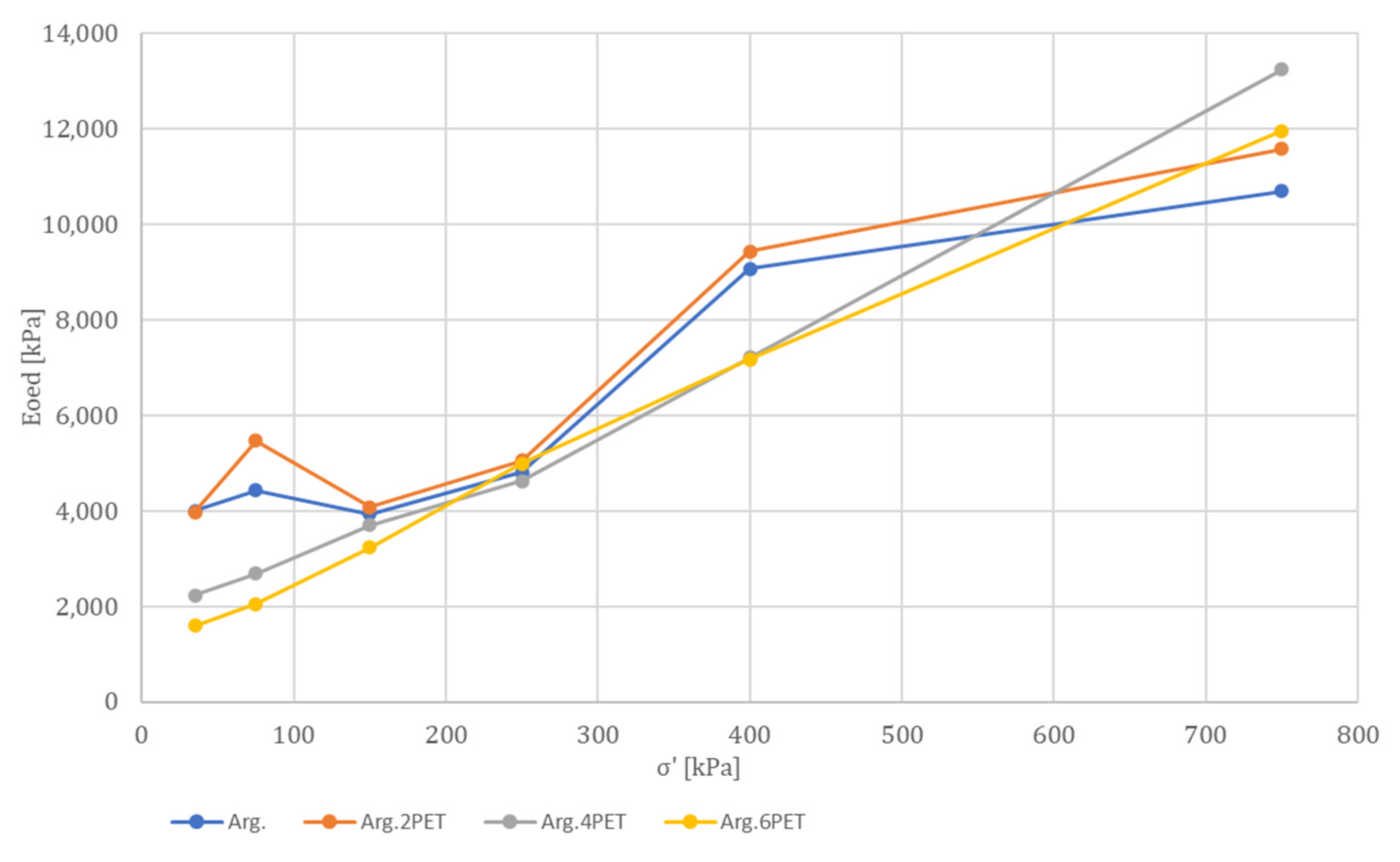

4.2. Oedometric Compression Tests

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bläsing, M.; Amelung, W. Plastics in soil: Analytical methods and possible sources. Sci. Total Environ. 2018, 612, 422–435. [Google Scholar] [CrossRef] [PubMed]

- The New Plastics Economy: Rethinking the Future of Plastics. Available online: https://www.weforum.org/reports/the-new-plastics-economy-rethinking-the-future-of-plastics/ (accessed on 30 June 2023).

- Kumi-Larbi, A.; Yunana, D.; Kamsouloum, P.; Webster, M.; Wilson, D.C.; Cheeseman, C. Recycling waste plastics in developing countries: Use of low-density polyethylene water sachets to form plastic bonded sand blocks. Waste Manag. 2018, 80, 112–118. [Google Scholar] [CrossRef] [PubMed]

- Abu Jadayil, W.; Qureshi, M.R.N.M.; Ajaj, R.; Aqil, E.; Shawahin, G.; Anver, H.; Aljeawi, S. An Empirical Investigation on Plastic Waste Issues and Plastic Disposal Strategies to Protect the Environment: A UAE Perspective. Sustainability 2022, 14, 16719. [Google Scholar] [CrossRef]

- Dutta, S.; Nadaf, M.B.; Mandal, J.N. An Overview on the Use of Waste Plastic Bottles and Fly Ash in Civil Engineering Applications. Procedia Environ. Sci. 2016, 35, 681–691. [Google Scholar] [CrossRef]

- Mallikarjuna, V.; Mani, T.B. Soil Stabilization using plastic waste. Int. J. Res. Eng. Technol. 2016, 5, 391–394. [Google Scholar]

- Dhar, S.; Hussain, M. The strength behaviour of lime-stabilised plastic fibre-reinforced clayey soil. Road Mater. Pavement Des. 2019, 20, 1757–1778. [Google Scholar] [CrossRef]

- Vijayakumar, A.; Naveen Kumar, S.; Abhinayasai Tejareddy, P. Utilization of Waste Materials for the Strengthening of Pavement Subgrade-A Research. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 209–212. [Google Scholar] [CrossRef]

- Ilieş, N.-M.; Cîrcu, A.-P.; Nagy, A.-C.; Ciubotaru, V.-C.; Kisfaludi-Bak, Z. Comparative Study on Soil Stabilization with Polyethylene Waste Materials and Binders. Procedia Eng. 2017, 181, 444–451. [Google Scholar] [CrossRef]

- Trimbitas (Urian), A.-M.; Nemes, O.; Ilies, N.M.; Nagy, A.C. Geotechnical and environmental aspects in soil improvement using plastic waste materials. In Proceedings of the 17th Danube European Conference on Geotechnical Engineering (17DECGE), Bucharest, Romania, 7–9 June 2023; Volume 2, pp. 675–681. [Google Scholar]

- Modak, P.R.; Nangare, P.B.; Nagrale, S.D.; Nalawade, R.D.; Chavhan, V.S. Stabilisation of Black Cotton Soil Using Admixtures. Int. J. Eng. Innov. Technol. 2012, 1, 1–3. [Google Scholar]

- Rica, H.C.; Saussaye, L.; Boutouil, M.; Leleyter, L.; Baraud, F. Stabilization of a silty soil: Effects of disruptive salts. Eng. Geol. 2016, 208, 191–197. [Google Scholar] [CrossRef]

- Vidal, H. The Principle of Reinforced Earth. Highw. Res. Rec. 1969, 1, 1–16. [Google Scholar]

- Hegde, A.; Sitharam, T.G. Use of Bamboo in Soft-Ground Engineering and Its Performance Comparison with Geosynthetics: Experimental Studies. J. Mater. Civ. Eng. 2015, 27, 04014256. [Google Scholar] [CrossRef]

- Mustapha, M. Bamboo as Soil Reinforcement: A Laboratory Trial. Leonardo J. Sci. 2008, 13, 69–77. [Google Scholar]

- Ghosh, S.K.; Bhattacharyya, R.; Mondal, M.M. Potential Applications of Open Weave Jute Geotextile (Soil Saver) in Meeting Geotechnical Difficulties. Procedia Eng. 2017, 200, 200–205. [Google Scholar] [CrossRef]

- Arvind, L.; Bundela, A.K.; Singh, B.; Tiwari, A.; Kumar, A.; Dhemla, P. Identification of Weaker Subgrade Soil in Rajasthan and Increment of CBR by Jute Fiber as Additive. Int. J. Eng. Technol. Manag. Appl. Sci. 2015, 3, 109–113. [Google Scholar]

- Jairaj; Prathap Kumar, M.T. Long-term Performance Studies on Strength Characteristics of Black Cotton Soil Reinforced with Untreated and Treated Coir Fibre. Int. J. Geosynth. Ground Eng. 2018, 4, 25. [Google Scholar] [CrossRef]

- Sivakumar Babu, G.L.; Vasudevan, A.K.; Sayida, M.K. Use of Coir Fibers for Improving the Engineering Properties of Expansive Soils. J. Nat. Fibers 2008, 5, 61–75. [Google Scholar] [CrossRef]

- Ahmad, F.; Bateni, F.; Azmi, M. Performance evaluation of silty sand reinforced with fibres. Geotext. Geomembr. 2010, 28, 93–99. [Google Scholar] [CrossRef]

- Alhassani, A.M.J. Improvement of Sandy Soil Using Materials of Sustainable Consideration. Jordan J. Civ. Eng. 2021, 15, 623–632. [Google Scholar]

- Dang, L.C.; Fatahi, B.; Khabbaz, H. Behaviour of Expansive Soils Stabilized with Hydrated Lime and Bagasse Fibres. Procedia Eng. 2016, 143, 658–665. [Google Scholar] [CrossRef]

- Narani, S.S.; Abbaspour, M.; Mir Mohammad Hosseini, S.M.; Aflaki, E.; Moghadas Nejad, F. Sustainable reuse of Waste Tire Textile Fibers (WTTFs) as reinforcement materials for expansive soils: With a special focus on landfill liners/covers. J. Clean. Prod. 2020, 247, 119151. [Google Scholar] [CrossRef]

- Abbaspour, M.; Aflaki, E.; Moghadas Nejad, F. Reuse of waste tire textile fibers as soil reinforcement. J. Clean. Prod. 2019, 207, 1059–1071. [Google Scholar] [CrossRef]

- Kumar Rai, A.; Singh, G.; Kumar Tiwari, A. Comparative study of soil stabilization with glass powder, plastic and e-waste: A review. Mater. Today: Proc. 2020, 32, 771–776. [Google Scholar] [CrossRef]

- Meddah, A.; Goufi, A.E.; Pantelidis, L. Improving Very High Plastic Clays with the Combined Effect of Sand, Lime, and Polypropylene Fibers. Appl. Sci. 2022, 12, 9924. [Google Scholar] [CrossRef]

- Al-Haddad, S.A.; Al-Ani, F.H.; Fattah, M.Y. Effect of Using Plastic Waste Bottles on Soil Response above Buried Pipes under Static Loads. Appl. Sci. 2022, 12, 12304. [Google Scholar] [CrossRef]

- Mishra, B.; Kumar Gupta, M. Use of randomly oriented polyethylene terephthalate (PET) fiber in combination with fly ash in subgrade of flexible pavement. Constr. Build. Mater. 2018, 190, 95–107. [Google Scholar] [CrossRef]

- Poweth, M.J.; Haneef, F.M.; Krishnan, R.; Rajan, S. Effect of Plastic Granules on the Properties of Soil. Int. J. Eng. Res. Appl. 2014, 4, 160–164. [Google Scholar]

- Singh, J.; Sonthwal, V.K. Improvement of Engineering Properties of soil Using Waste Plastic Bottles Sttips (Polyethylene Tereohthalate). Int. J. Theor. Appl. Sci. 2017, 9, 21–27. [Google Scholar]

- Peddaiah, S.; Burman, A.; Sreedeep, S. Experimental Study on Effect of Waste Plastic Bottle Strips in Soil Improvement. Geotech. Geol. Eng. 2018, 36, 2907–2920. [Google Scholar] [CrossRef]

- Chebet, F.C.; Kalumba, D. Laboratory Investigation on Re-Using Polyethylene (Plastic) Bag Waste Material for Soil Reinforcement In Geotechnical Engineering. Civ. Eng. Urban Plan. 2014, 1, 67–82. [Google Scholar]

- Saha, A.; Maity, J.; Chattopadhyay, B.C. Characteristics of Clayey Soil Mixing with Randomly Distribute Plastic Waste Bags. Int. J. Eng. Adv. Res. Technol. 2017, 3, 42–44. [Google Scholar]

- Soltani-Jigheh, H. Compressibility and Shearing Behavior of Clayey Soil Reinforced by Plastic Waste. Int. J. Civ. Eng. 2016, 14, 479–489. [Google Scholar] [CrossRef]

- Botero, E.; Ossa, A.; Sherwell, G.; Ovando-Shelley, E. Stress–strain behavior of a silty soil reinforced with polyethylene terephthalate (PET). Geotext. Geomembr. 2015, 43, 363–369. [Google Scholar] [CrossRef]

- Zukri, A.; Nazir, R.; Mender, F.N. An experimental study on stabilization of Pekan clay using polyethylene and polypropylene. In AIP Conference Proceedings; AIP Publishing: Long Island, NY, USA, 2017; p. 030002. [Google Scholar]

- NP 126 of 2010; Norm for the Foundation of Constructions on Soils with High Swelling and Shrinkage. Official Gazette of Romania: Bucharest, Romania, 2012.

- STAS 1913/13-83; Foundation Soil. Determination of Compaction Characteristics. Proctor Test. Romanian Institute for Standardization: Bucharest, Romania, 1983.

- STAS 8942/2-82; Foundation Soil. Determination of Earth Strength, by Direct Shearing. Romanian Institute for Standardization: Bucharest, Romania, 1982.

- STAS 8942/1-89; Foundation Soil. Earthes Compressibility Determination by Edometer. Romanian Institute for Standardization: Bucharest, Romania, 1989.

- SR EN ISO 17892; Geotechnical Investigation and Testing. Standardization Association of Romania: Bucharest, Romania, 2015.

- Ilies, N.M.; Farcas, V.; Muresan, O.; Chiorean, V.; Nagy, A.C. Improving clayey soils with polyethylene waste. In Proceedings of the the 13th National Conference on Geotechnics and Foundations, Cluj-Napoca, Romania, 7–10 September 2016. [Google Scholar]

- Urian, A.-M.; Gál, E.; Bizo, L.-A.; Nemes, O.; Ilies, N.M.; Nagy, A.C. Utilizing Plastic Waste Materials in Geotechnical Engineering: A Sustainable Solution for Environmental Challenges. Stud. Univ. Babes-Bolyai Chem. 2023, 68, 115–127. [Google Scholar] [CrossRef]

| Properties | Parameter | Value |

|---|---|---|

| Physical properties | Specific weight γs (kN/m3) | 26.70 |

| Dry unit weight γd (kN/m3) | 14.54 | |

| Natural unit weight γ (kN/m3) | 18.11 | |

| Natural water content w (%) | 21.05 | |

| Plastic limit, wP (%) | 15.95 | |

| Liquid limit, wL (%) | 47.65 | |

| Plasticity index, IP (%) | 31.70 | |

| Consistency index IC [-] | 0.83 |

| Soil Type | Grain Size d (mm) | Percentage (%) |

|---|---|---|

| Clay | d < 0.002 | 47.61 |

| Silt | 0.002 < d < 0.063 | 40.20 |

| Sand | 0.063 < d < 0.2 | 11.26 |

| Gravel | 0.2 < d < 6.3 | 0.93 |

| Samples Code | Composition | Nr. of Square Samples | Nr. of Round Samples |

|---|---|---|---|

| Cl | Clay + OWC | 3 | 3 |

| Cl2PET | Clay + OWC + 2% PET | 3 | 3 |

| Cl4PET | Clay + OWC + 4% PET | 3 | 3 |

| Cl6PET | Clay + OWC + 6% PET | 3 | 3 |

| τf (kPa) for Peak Shearing Parameters | |||||

|---|---|---|---|---|---|

| Cl | Cl2PET | Cl4PET | Cl6PET | ||

| σ (kPa) | 100 | 44.47 | 58.03 | 66.76 | 63.89 |

| 200 | 78.57 | 96.28 | 103.56 | 109.25 | |

| 300 | 112.67 | 134.52 | 140.36 | 154.61 | |

| τf (kPa) for Residual Shearing Parameters | |||||

| 100 | 22.43 | 31.34 | 35.54 | 34.26 | |

| 200 | 44.36 | 52.99 | 55.58 | 55.36 | |

| 300 | 66.29 | 74.63 | 75.63 | 76.47 | |

| Shearing Strength Parameters for | |||||

|---|---|---|---|---|---|

| Cl | Cl2PET | Cl4PET | Cl6PET | ||

| Peak Parameters | |||||

| Φ′ | (°) | 18.83 | 20.93 | 20.20 | 24.40 |

| c′ | (kPa) | 10.37 | 19.79 | 29.96 | 18.53 |

| Residual Parameters | |||||

| Φres | (°) | 12.37 | 12.21 | 11.33 | 11.92 |

| cres | (kPa) | 0.50 | 9.70 | 15.49 | 13.15 |

| Shearing Strength Parameters for | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cl 17 | Cl 23 | Cl2PET 17 | Cl2PET 23 | Cl2CEM 17 | Cl4PET 17 | Cl4PET 23 | Cl4CEM 17 | Cl6PET 17 | Cl6PET 23 | Cl6CEM 17 | ||

| Peak Parameters | ||||||||||||

| Φ′ | (°) | 21.49 | 18.83 | 24.47 | 20.93 | 22.29 | 21.53 | 20.20 | 35.01 | 27.79 | 24.40 | 30.66 |

| c′ | (kPa) | 30.96 | 10.37 | 19.60 | 19.79 | 66.44 | 31.41 | 29.96 | 47.77 | 5.97 | 18.53 | 80.62 |

| Residual Parameters | ||||||||||||

| Φres | (°) | 10.61 | 12.37 | 14.19 | 12.21 | 11.83 | 9.62 | 11.33 | 34.14 | 19.94 | 11.92 | 20.48 |

| cres | (kPa) | 20.17 | 0.50 | 1.12 | 9.70 | 24.97 | 18.13 | 15.49 | 12.63 | 0.00 | 13.15 | 12.57 |

| ε (%) | |||||

|---|---|---|---|---|---|

| Cl | Cl2PET | Cl4PET | Cl6PET | ||

| σ′ (kPa) | 0 | 0.000 | 0.000 | 0.000 | 0.000 |

| 20 | 1.055 | 1.040 | 0.795 | 1.050 | |

| 50 | 1.805 | 1.795 | 2.140 | 2.940 | |

| 100 | 2.935 | 2.710 | 4.005 | 5.380 | |

| 200 | 5.475 | 5.165 | 6.710 | 8.480 | |

| 300 | 7.555 | 7.145 | 8.875 | 10.485 | |

| 500 | 9.760 | 9.265 | 11.650 | 13.275 | |

| 1000 | 14.435 | 13.580 | 15.425 | 17.455 | |

| e (-) | |||||

|---|---|---|---|---|---|

| Cl | Cl2PET | Cl4PET | Cl6PET | ||

| ln(σ′) | 0.00 | 0.599 | 0.539 | 0.550 | 0.625 |

| 3.00 | 0.582 | 0.523 | 0.538 | 0.607 | |

| 3.91 | 0.570 | 0.512 | 0.517 | 0.577 | |

| 4.61 | 0.552 | 0.497 | 0.488 | 0.537 | |

| 5.30 | 0.512 | 0.460 | 0.446 | 0.487 | |

| 5.70 | 0.478 | 0.429 | 0.413 | 0.454 | |

| 6.21 | 0.443 | 0.397 | 0.370 | 0.409 | |

| 6.91 | 0.368 | 0.330 | 0.311 | 0.341 | |

| Eoed (kPa) | |||||

|---|---|---|---|---|---|

| Cl | Cl2PET | Cl4PET | Cl6PET | ||

| σ′ (kPa) | 20 | 4000 | 3974 | 2230 | 1587 |

| 50 | |||||

| 50 | 4425 | 5464 | 2681 | 2049 | |

| 100 | |||||

| 100 | 3937 | 4073 | 3697 | 3226 | |

| 200 | |||||

| 200 | 4808 | 5051 | 4619 | 4988 | |

| 300 | |||||

| 300 | 9070 | 9434 | 7207 | 7168 | |

| 500 | |||||

| 500 | 10,695 | 11,587 | 13,245 | 11,962 | |

| 1000 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urian, A.-M.; Ilies, N.-M.; Nemes, O.; Nagy, A.-C. Clayey Soil Improvement with Polyethylene Terephthalate (PET) Waste. Appl. Sci. 2023, 13, 12081. https://doi.org/10.3390/app132112081

Urian A-M, Ilies N-M, Nemes O, Nagy A-C. Clayey Soil Improvement with Polyethylene Terephthalate (PET) Waste. Applied Sciences. 2023; 13(21):12081. https://doi.org/10.3390/app132112081

Chicago/Turabian StyleUrian, Ana-Maria, Nicoleta-Maria Ilies, Ovidiu Nemes, and Andor-Csongor Nagy. 2023. "Clayey Soil Improvement with Polyethylene Terephthalate (PET) Waste" Applied Sciences 13, no. 21: 12081. https://doi.org/10.3390/app132112081

APA StyleUrian, A.-M., Ilies, N.-M., Nemes, O., & Nagy, A.-C. (2023). Clayey Soil Improvement with Polyethylene Terephthalate (PET) Waste. Applied Sciences, 13(21), 12081. https://doi.org/10.3390/app132112081