Nucleation Mechanism and Rupture Dynamics of Laboratory Earthquakes at Different Loading Rates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fault Samples Acquisition

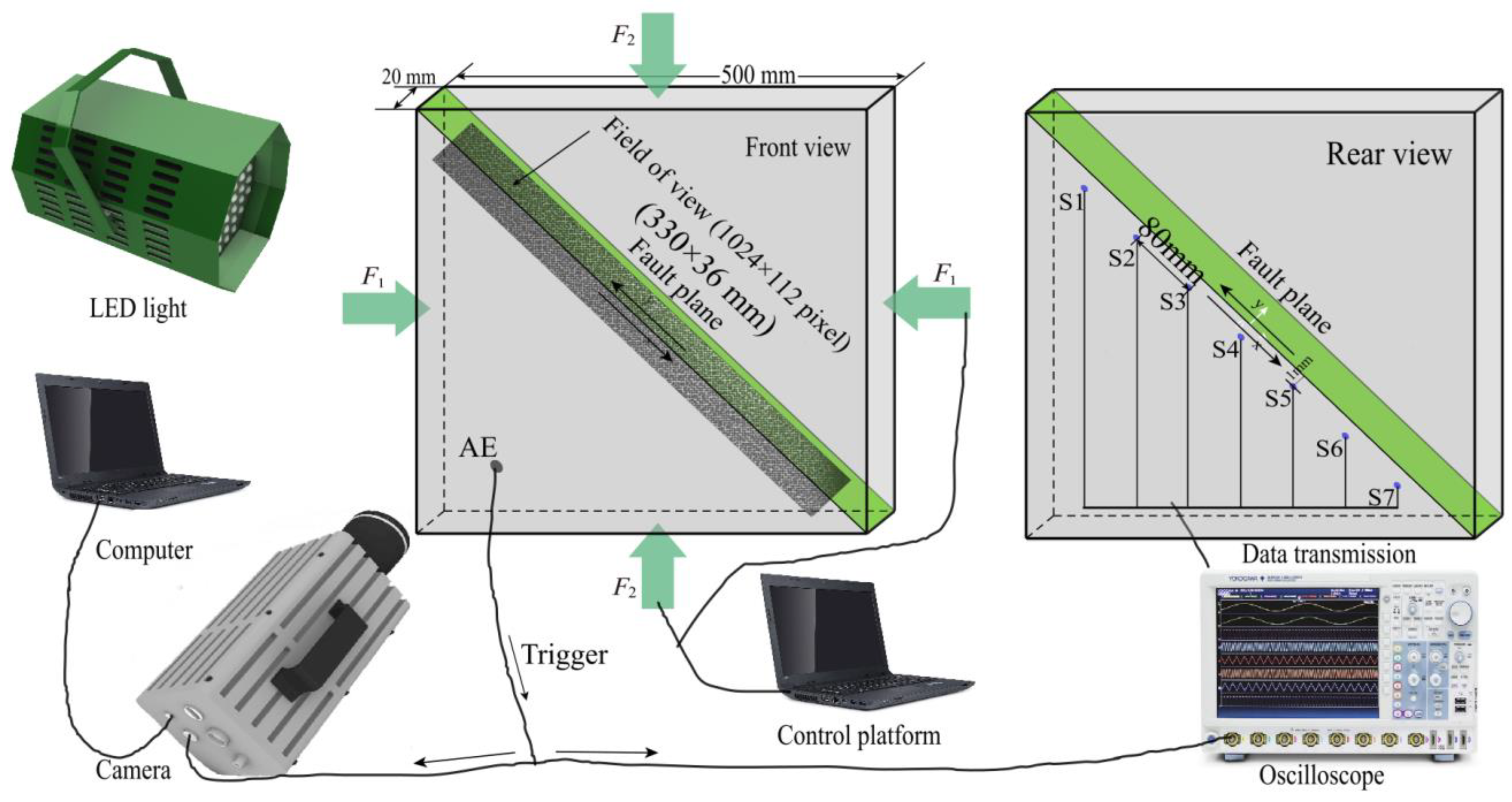

2.2. Experimental Setup

2.3. Diagnostic Method

2.3.1. Full Field Displacement

2.3.2. Shear Strain

2.4. System Stiffness

2.4.1. Loading Stiffness

2.4.2. Unloading Stiffness

3. Results

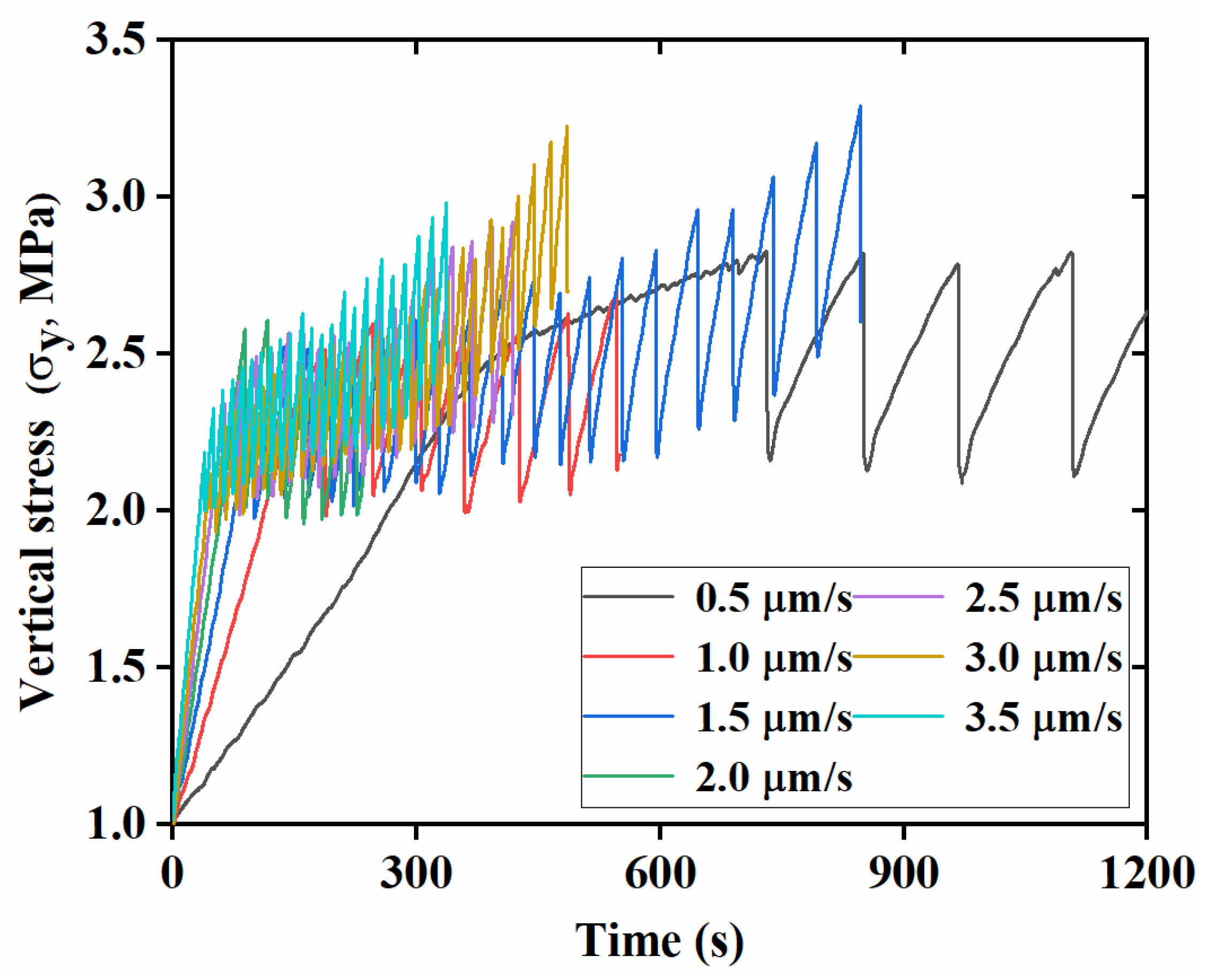

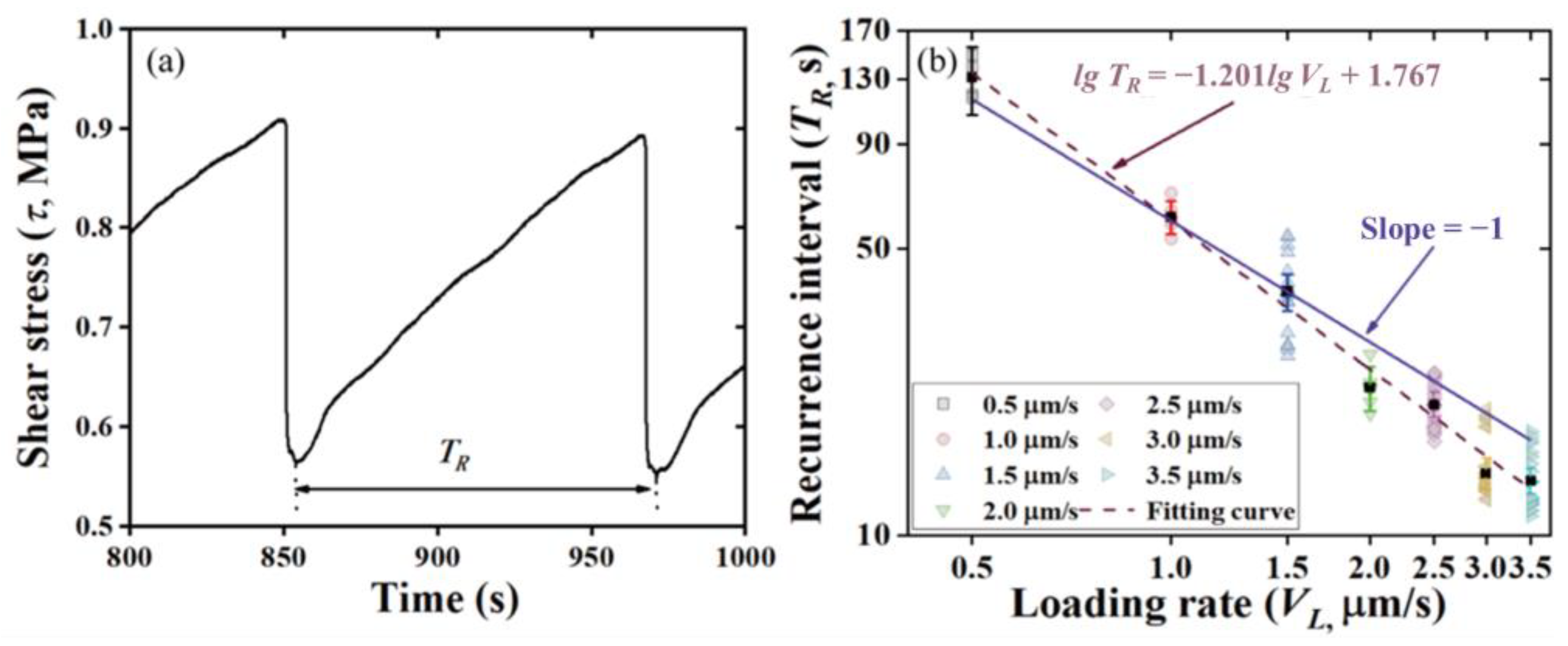

3.1. Stick–Slip Events

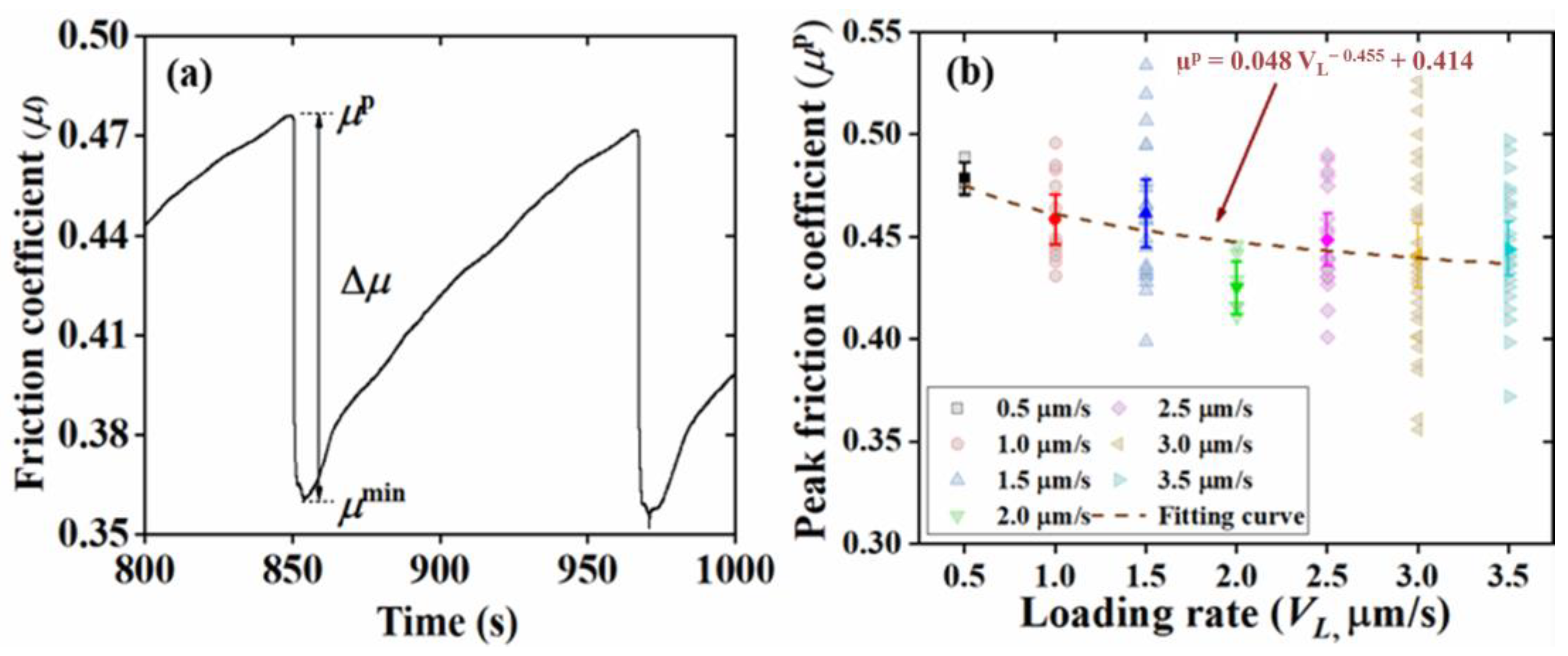

3.2. Effect of Loading Rate on the Features of Stick–Slip Events

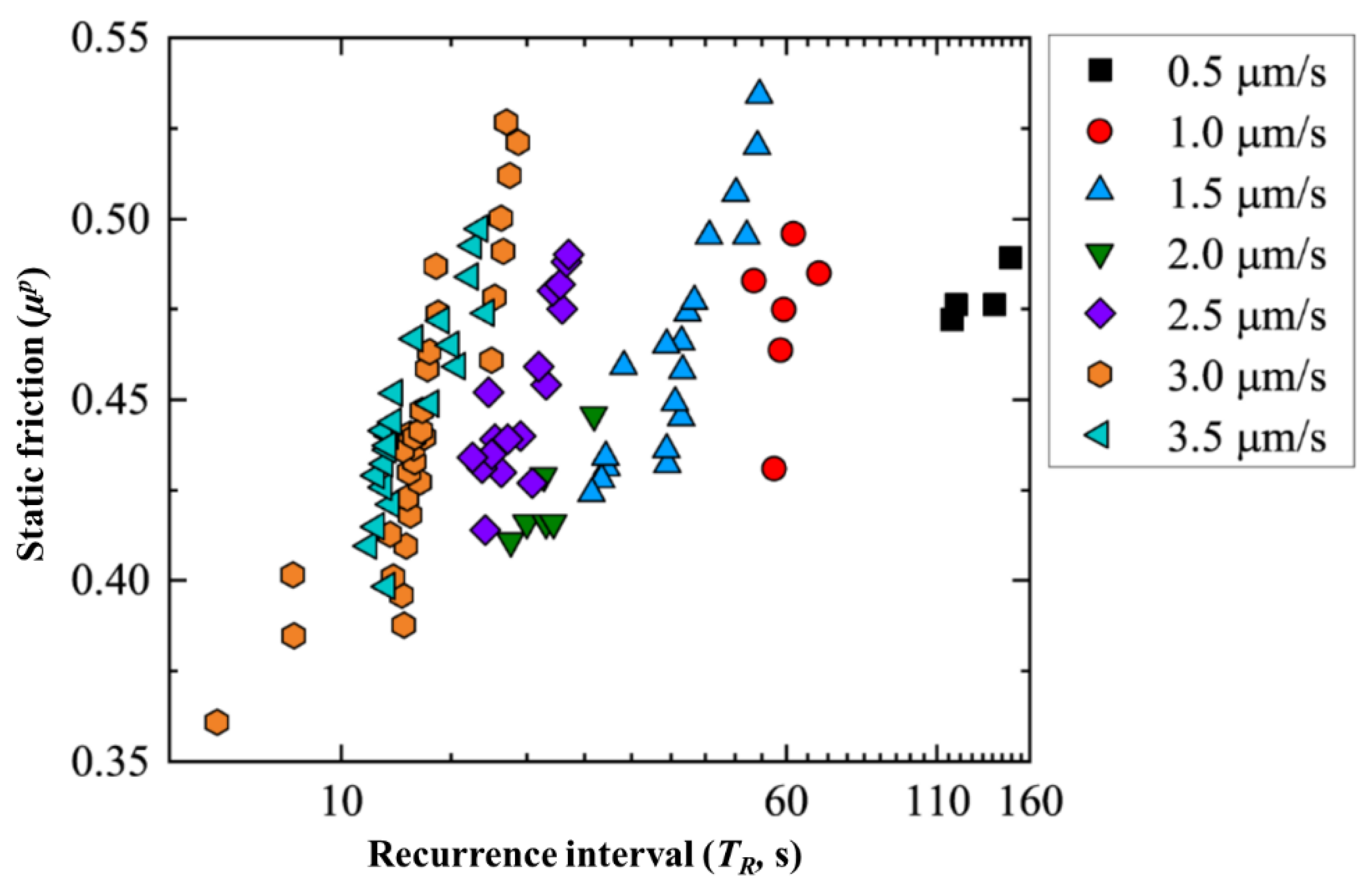

3.2.1. Shortening in Recurrence Interval

3.2.2. Static Friction

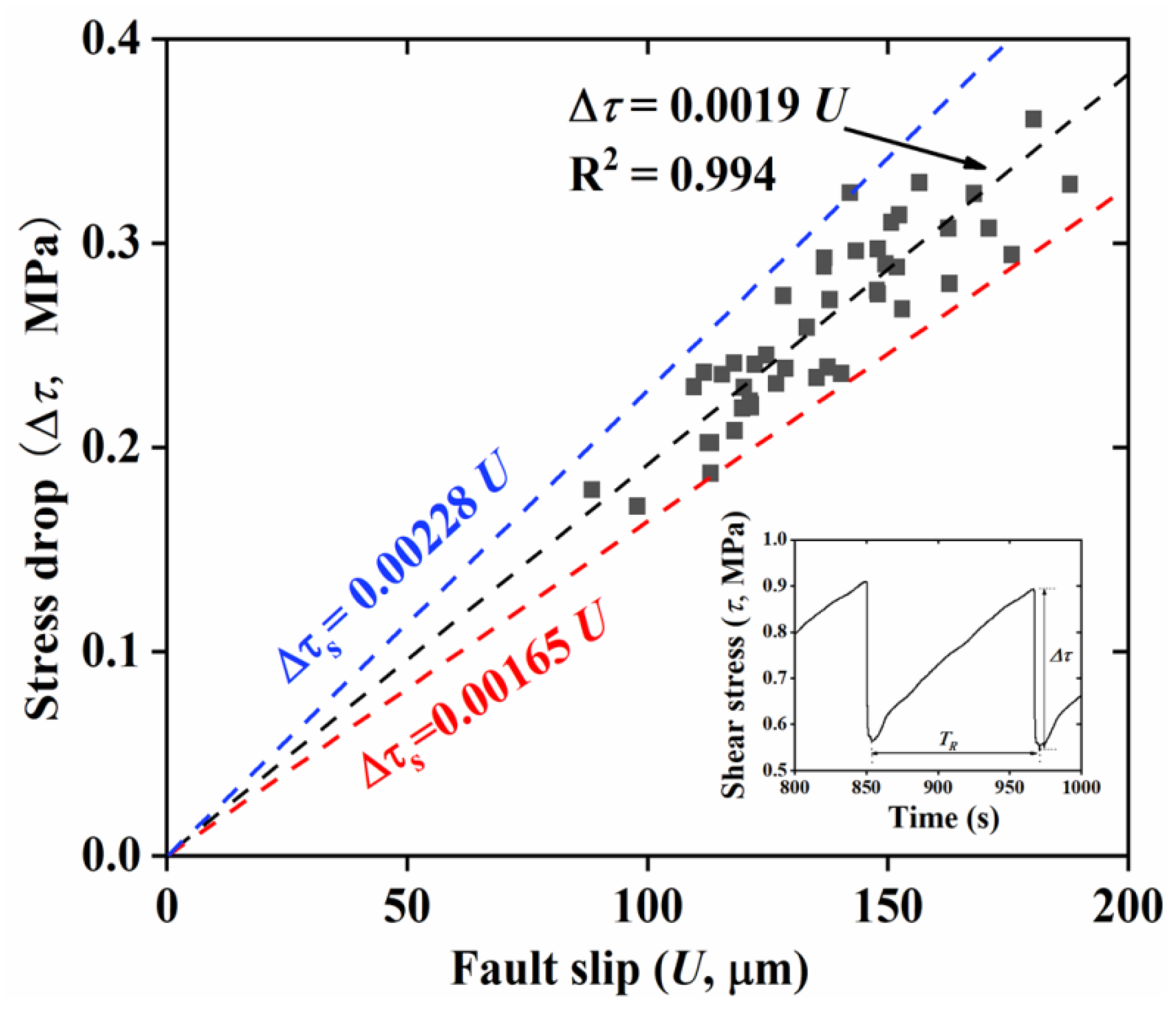

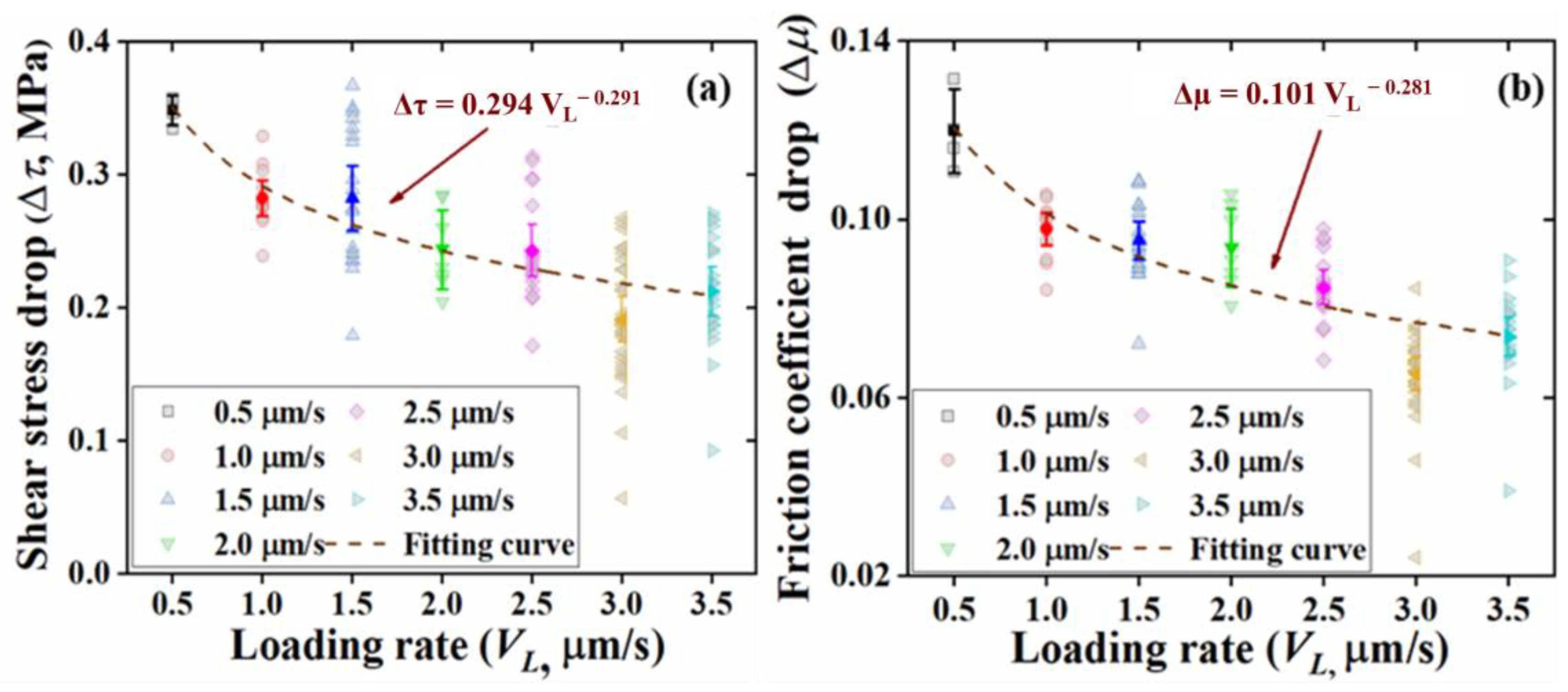

3.2.3. Stress Drop

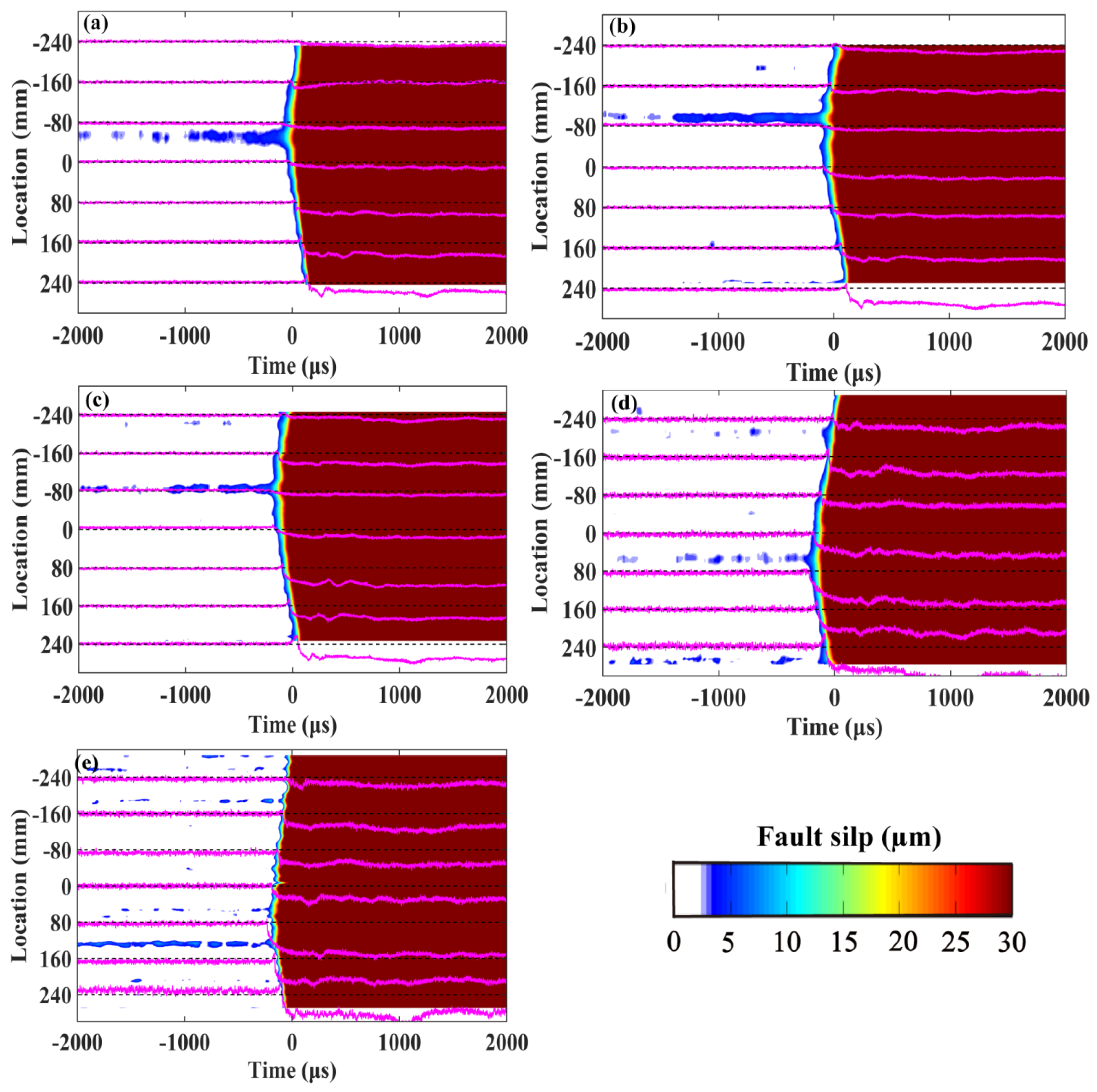

3.3. Effect of Loading Rate on Earthquake Nucleation Process

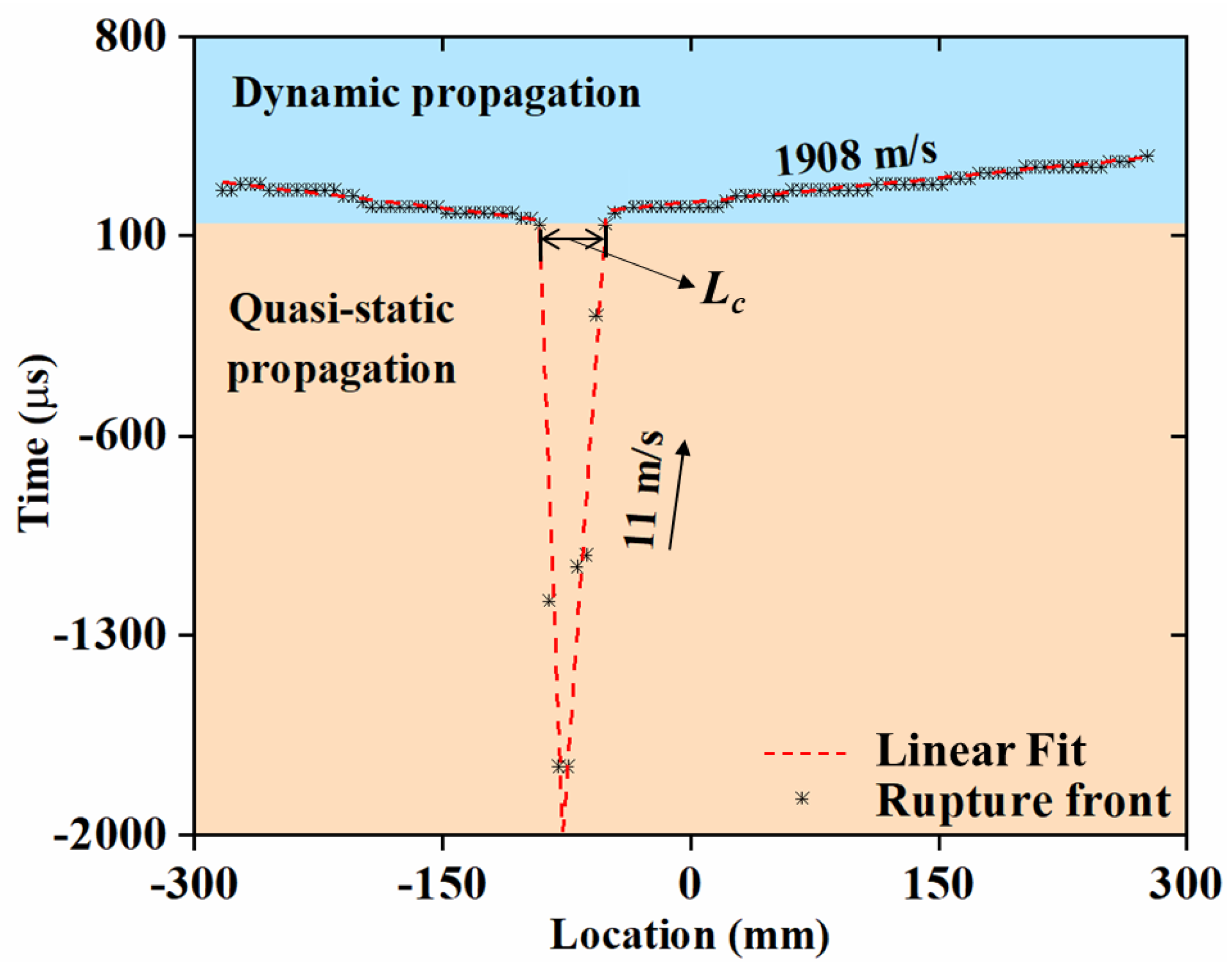

3.3.1. Basic Characteristics of Earthquake Nucleation

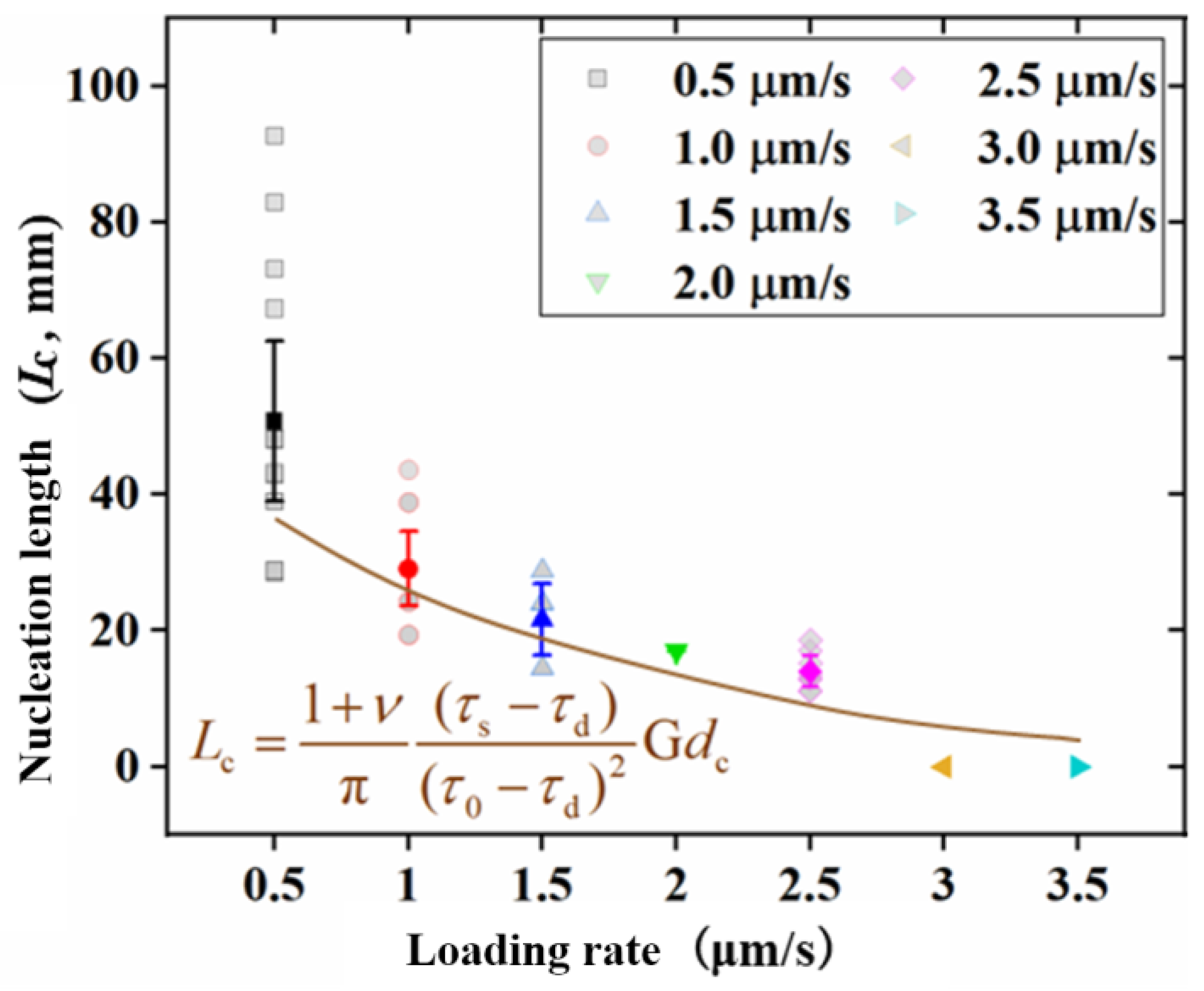

3.3.2. Critical Nucleation Length

= (1 + ν) · (aln(bVL) − µd) · G · dc/π · (0.048 VL−0.455 + 0.414 − µd)2

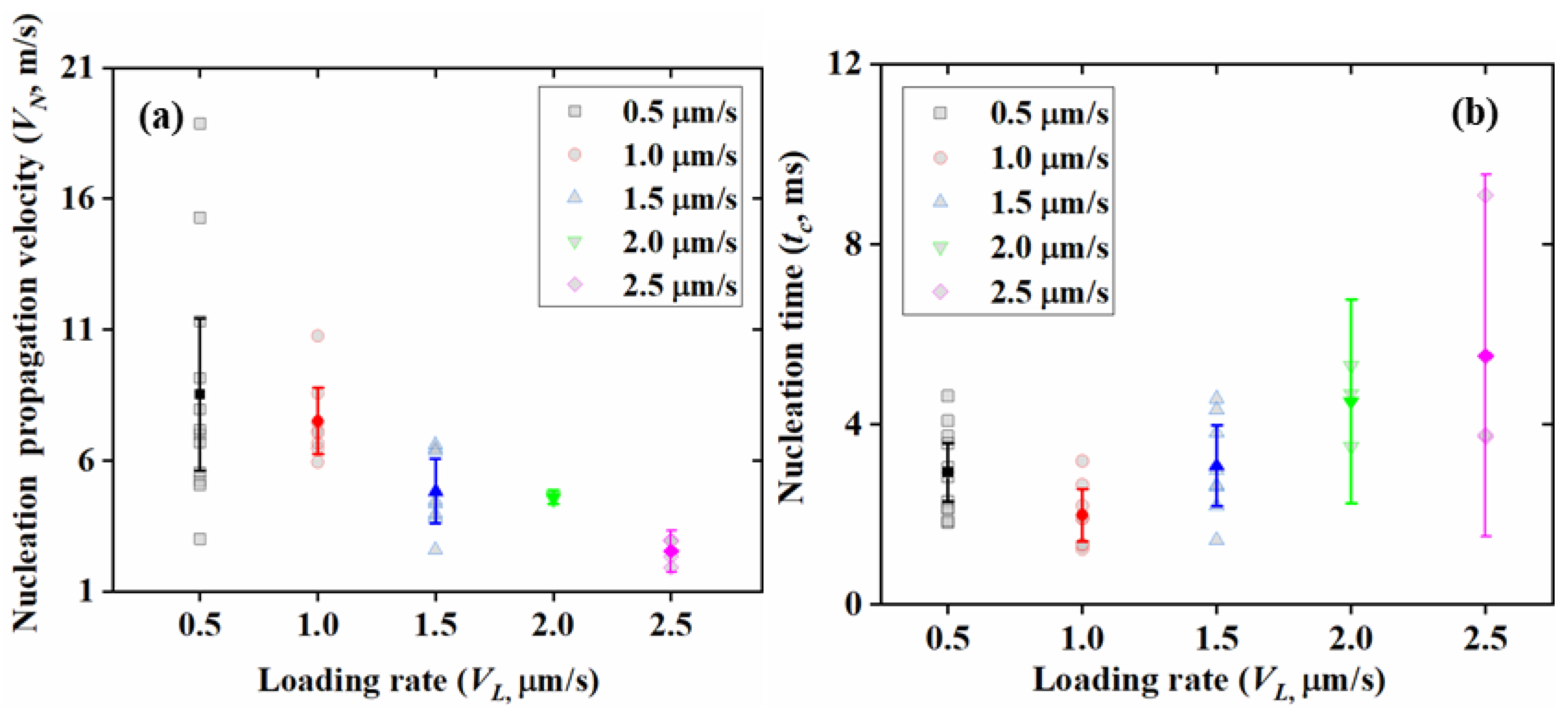

3.3.3. Nucleation Velocity and Duration of Nucleation Phase

3.4. Effect of Loading Rate on Rupture Velocity

4. Conclusions

- Recurrence intervals: As the loading rate increases, the recurrence intervals decrease. This suggests that at higher loading rates, faults require less time to accumulate the stress necessary for an earthquake, resulting in more frequent seismic events.

- Frictional dynamics: The peak friction coefficient, the change in the friction coefficient, and the change rate of the friction coefficient decrease with the increasing loading rate. This could imply limited interactions between the fault surfaces at higher rates, potentially undermining the fault’s locking mechanisms.

- Shear stress and energy release: The shear stress drop (or the relative shear stress drop) decreases with the loading rate, which indicates that seismic events at slower loading rates release a more significant portion of accumulated energy. A lower loading rate means a larger recurrence interval and thus longer holding time of the two contact surfaces. This may favor the strengthening of the fault.

- Critical nucleation length: The critical nucleation length decreases with the loading rate. In simpler terms, higher tectonic activities can trigger earthquakes even in shorter fault segments. We propose a theoretical model to explain the loading rate dependence on the critical nucleation length.

- Aseismic slip: Our findings revealed that during the initial stages of the nucleation phase, aseismic or stable slip is the only activity. As the process evolves, this slip shifts towards a cascading process. This observation aligns with the results from other studies [16]. However, a long-lasting question is whether the primary seismic event, or the mainshock, is genuinely initiated by this cascade-like sequence. Essentially, it is debated whether the mainshock is merely an amplified foreshock resulting from the rupture of a sufficiently large or weak segment which then propagates across the entire fault plane. Recent seismic data point to a similarity between small and large earthquakes [45], suggesting that this might indeed be the scenario.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brace, W.F.; Byerlee, J.D. Stick-slip as a mechanism for earthquakes. Science 1966, 153, 990–992. [Google Scholar] [CrossRef] [PubMed]

- Passelègue, F.X.; Schubnel, A.; Nielsen, S.; Bhat, H.S.; Deldicque, D.; Madariaga, R. Dynamic rupture processes inferred from laboratory microearthquakes. J. Geophys. Res. Solid. Earth 2016, 121, 4343–4365. [Google Scholar] [CrossRef]

- McLaskey, G.C.; Yamashita, F. Slow and fast ruptures on a laboratory fault controlled by loading characteristics. J. Geophys. Res. Solid. Earth 2017, 122, 3719–3738. [Google Scholar] [CrossRef]

- McLaskey, G.C.; Kilgore, B.D. Foreshocks during the nucleation of stick-slip instability. J. Geophys. Res. Solid. Earth 2013, 118, 2982–2997. [Google Scholar] [CrossRef]

- Ohnaka, M.; Kuwahara, Y. Characteristic features of local breakdown near a crack-tip in the transition zone from nucleation to unstable rupture during stick-slip shear failure. Tectonophysics 1990, 175, 197–220. [Google Scholar] [CrossRef]

- Kato, N.; Yamamoto, K.; Yamamoto, H.; Hirasawa, T. Strain-rate effect on frictional strength and the slip nucleation process. Tectonophysics 1992, 211, 269–282. [Google Scholar] [CrossRef]

- Ohnaka, M. Earthquake source nucleation: A physical model for short-term precursors. Tectonophysics 1992, 211, 149–178. [Google Scholar] [CrossRef]

- Ellsworth, W.L.; Beroza, G.C. Seismic evidence for an earthquake nucleation phase. Science 1995, 268, 851–855. [Google Scholar] [CrossRef]

- Kato, A.; Obara, K.; Igarashi, T.; Tsuruoka, H.; Nakatani, M.; Hirata, N. Propagation of slow slip leading up to the 2011Mw 9.0 Tohoku-Oki earthquake. Science 2012, 335, 705–708. [Google Scholar] [CrossRef]

- Bouchon, M.; Karabulut, H.; Aktar, M.; Ozalaybey, S.; Schmittbuhl, J.; Bouin, M.P. Extended nucleation of the 1999 Mw 7.6 Izmit earthquake. Science 2011, 331, 877–880. [Google Scholar] [CrossRef]

- Ruiz, S.; Metois, M.; Fuenzalida, A.; Ruiz, J.; Campos, J. Intense foreshocks and a slow slip event preceded the 2014 Iquique Mw 8.1 earthquake. Science 2014, 345, 1165–1169. [Google Scholar] [CrossRef] [PubMed]

- Ruiz, S.; Aden-Antoniow, F.; Baez, J.C.; Otarola, C.; Potin, B. Nucleation phase and dynamic inversion of the Mw 6.9 valparaíso 2017 earthquake in central chile. Geophys. Res. Lett. 2017, 44, 10.290–10.297. [Google Scholar] [CrossRef]

- Dong, P.; Xu, R.; Yang, H.; Guo, Z.; Xia, K. Fault slip behaviors modulated by locally increased fluid pressure: Earthquake nucleation and slow slip events. J. Geophys. Res. Solid. Earth 2022, 127, e2022JB024612. [Google Scholar] [CrossRef]

- Latour, S.; Schubnel, A.; Nielsen, S.; Madariaga, R.; Vinciguerra, S. Characterization of nucleation during laboratory earthquakes. Geophys. Res. Lett. 2013, 40, 5064–5069. [Google Scholar] [CrossRef]

- McLaskey, G.C. Earthquake Initiation from Laboratory Observations and Implications for Foreshocks. J. Geophys. Res. Solid. Earth 2019, 124, 12882–12904. [Google Scholar] [CrossRef]

- Marty, S.; Schubnel, A.; Bhat, H.S.; Aubry, J.; Fukuyama, E.; Latour, S.; Nielsen, S.; Madariaga, R. Nucleation of Laboratory Earthquakes: Quantitative Analysis and Scalings. J. Geophys. Res. Solid. Earth 2023, 128, e2022JB026294. [Google Scholar] [CrossRef]

- Dong, P.; Xia, K. Laboratory investigations probing earthquake source process. Chin. Sci. Bull. 2022, 67, 1378–1389. [Google Scholar] [CrossRef]

- Kaneko, Y.; Nielsen, S.B.; Carpenter, B.M. The onset of laboratory earthquakes explained by nucleating rupture on a rate-and-state fault. J. Geophys. Res. Solid. Earth 2016, 121, 6071–6091. [Google Scholar] [CrossRef]

- Andrews, D.J. Rupture velocity of plane strain shear cracks. J. Geophys. Res. 1976, 81, 5679–5687. [Google Scholar] [CrossRef]

- Teng-Fong, W.; Zhao, Y. Effects of load point velocity on frictional instability behavior. Tectonophysics 1990, 175, 177–195. [Google Scholar] [CrossRef]

- Bouissou, S.; Petit, J.P.; Barquins, M. Normal load, slip rate and roughness influence on the polymethylmethacrylate dynamics of sliding 1. Stable sliding to stick-slip transition. Wear 1998, 214, 156–164. [Google Scholar] [CrossRef]

- Karner, S.L.; Marone, C. Effects of loading rate and normal stress on stress drop and stick-slip recurrence interval. In Geocomplexity and the Physics of Earthquake; Geophysical Monograph Series; American Geophysical Union: Washington, DC, USA, 2000; pp. 187–198. [Google Scholar]

- Zhou, X.; He, Y.; Shou, Y. Experimental investigation of the effects of loading rate, contact roughness, and normal stress on the stick-slip behavior of faults. Tectonophysics 2021, 816, 229027. [Google Scholar] [CrossRef]

- Dong, P.; Xia, K.; Xu, Y.; Elsworth, D.; Ampuero, J.P. Laboratory earthquakes decipher control and stability of rupture speeds. Nat. Commun. 2023, 14, 2427. [Google Scholar] [CrossRef]

- Klein, E.; Bock, Y.; Xu, X.; Sandwell, D.T.; Golriz, D.; Fang, P.; Su, L. Transient deformation in california from two decades of GPS displacements: Implications for a three-dimensional kinematic reference frame. J. Geophys. Res. Solid. Earth 2019, 124, 12189–12223. [Google Scholar] [CrossRef]

- Bacques, G.; de Michele, M.; Raucoules, D.; Aochi, H.; Rolandone, F. Shallow deformation of the San Andreas fault 5 years following the 2004 Parkfield earthquake (Mw6) combining ERS2 and Envisat InSAR. Sci. Rep. 2018, 8, 6032. [Google Scholar] [CrossRef] [PubMed]

- Chaussard, E.; Bürgmann, R.; Fattahi, H.; Johnson, C.W.; Nadeau, R.; Taira, T.; Johanson, I. Interseismic coupling and refined earthquake potential on the Hayward-Calaveras fault zone. J. Geophys. Res. Solid. Earth 2015, 120, 8570–8590. [Google Scholar] [CrossRef]

- De Michele, M.; Raucoules, D.; Rolandone, F.; Briole, P.; Salichon, J.; Lemoine, A.; Aochi, H. Spatiotemporal evolution of surface creep in the Parkfield region of the San Andreas Fault (1993–2004) from synthetic aperture radar. Earth Planet. Sci. Lett. 2011, 308, 141–150. [Google Scholar] [CrossRef]

- Ohnaka, M. Experimental studies of stick-slip and their application to the earthquake source mechanism. J. Phys. Earth 1973, 21, 285–303. [Google Scholar] [CrossRef]

- Logan, J.M.; Teufel, L.W. The effect of normal stress on the real area of contact during frictional sliding in rocks. Pure Appl. Geophys. 1986, 124, 471–485. [Google Scholar] [CrossRef]

- Baumberger, T.; Heslot, F.; Perrin, B. Crossover from creep to inertial motion in friction dynamics. Nature 1994, 367, 544–546. [Google Scholar] [CrossRef]

- Togo, T.; Shimamoto, T.; Yamashita, F.; Fukuyama, E.; Mizoguchi, K.; Urata, Y. Stick–slip behavior of Indian gabbro as studied using a NIED large-scale biaxial friction apparatus. Earthq. Sci. 2015, 28, 97–118. [Google Scholar] [CrossRef]

- Xu, S.; Fukuyama, E.; Yamashita, F.; Mizoguchi, K.; Takizawa, S.; Kawakata, H. Strain rate effect on fault slip and rupture evolution: Insight from meter-scale rock friction experiments. Tectonophysics 2018, 733, 209–231. [Google Scholar] [CrossRef]

- Gounon, A.; Latour, S.; Letort, J.; El Arem, S. Rupture nucleation on a periodically heterogeneous interface. Geophys. Res. Lett. 2022, 49, e2021GL096816. [Google Scholar] [CrossRef]

- Guérin-Marthe, S.; Nielsen, S.; Bird, R.; Giani, S.; Di Toro, G. Earthquake nucleation size: Evidence of loading rate dependence in laboratory faults. J. Geophys. Res. Solid. Earth 2019, 124, 689–708. [Google Scholar] [CrossRef] [PubMed]

- Ben-David, O.; Cohen, G.; Fineberg, J. The dynamics of the onset of frictional slip. Science 2010, 330, 211–214. [Google Scholar] [CrossRef]

- Dong, P.; Chen, R.; Xia, K.; Yao, W.; Peng, Z.; Elsworth, D. Earthquake Delay and Rupture Velocity in Near-Field Dynamic Triggering Dictated by Stress-Controlled Nucleation. Seism. Res. Lett. 2022, 94, 913–924. [Google Scholar] [CrossRef]

- Leeman, J.R.; Saffer, D.M.; Scuderi, M.M.; Marone, C. Laboratory observations of slow earthquakes and the spectrum of tectonic fault slip modes. Nat. Commun. 2016, 7, 11104. [Google Scholar] [CrossRef]

- Rice, J.R.; Ruina, A.L. Stability of steady frictional slipping. J. Appl. Mech. 1983, 50, 343–349. [Google Scholar] [CrossRef]

- Beeler, N.M.; Hickman, S.H.; Wong, T.F. Earthquake stress drop and laboratory-inferred interseismic strength recovery. J. Geophys. Res. Solid. Earth 2001, 106, 30701–30713. [Google Scholar] [CrossRef]

- Marone, C. Laboratory-derived friction laws and their application to seismic faulting. Annu. Rev. Earth Planet. Sci. 1998, 26, 643–696. [Google Scholar] [CrossRef]

- Dieterich, J.H. Time-dependent friction in rocks. J. Geophys. Res. 1972, 77, 3690–3697. [Google Scholar] [CrossRef]

- Dieterich, J.H.; Kilgore, B. Direct observation of frictional contacts: New insights for state-dependent properties. Pure Appl. Geophys. 1994, 143, 283–302. [Google Scholar] [CrossRef]

- Palmer, A.C.; Rice, J.R. Growth of Slip Surfaces in Progressive Failure of over- Consolidated Clay. Proc. R. Soc. London Ser. A Math. Phys. Eng. Sci. 1973, 332, 527–548. [Google Scholar]

- Ide, S. Frequent observations of identical onsets of large and small earthquakes. Nature 2019, 573, 112–116. [Google Scholar] [CrossRef]

| Properties | Parameters |

|---|---|

| Fault size | 700 × 20 mm |

| Young’s modulus | 6.24 GPa |

| Shear modulus | 2.4 GPa |

| Fault surface roughness | <1 µm |

| P-wave velocity | 2.60 km/s |

| S-wave velocity | 1.43 km/s |

| Poisson’s ratio | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, G.; Zhang, K.; Wang, C.; Li, X. Nucleation Mechanism and Rupture Dynamics of Laboratory Earthquakes at Different Loading Rates. Appl. Sci. 2023, 13, 12243. https://doi.org/10.3390/app132212243

Wu G, Zhang K, Wang C, Li X. Nucleation Mechanism and Rupture Dynamics of Laboratory Earthquakes at Different Loading Rates. Applied Sciences. 2023; 13(22):12243. https://doi.org/10.3390/app132212243

Chicago/Turabian StyleWu, Gongcheng, Kanghua Zhang, Chonglang Wang, and Xing Li. 2023. "Nucleation Mechanism and Rupture Dynamics of Laboratory Earthquakes at Different Loading Rates" Applied Sciences 13, no. 22: 12243. https://doi.org/10.3390/app132212243

APA StyleWu, G., Zhang, K., Wang, C., & Li, X. (2023). Nucleation Mechanism and Rupture Dynamics of Laboratory Earthquakes at Different Loading Rates. Applied Sciences, 13(22), 12243. https://doi.org/10.3390/app132212243