Solid Backfilling Efficiency Optimization in Coal Mining: Spatiotemporal Linkage Analysis and Case Study

Abstract

:1. Introduction

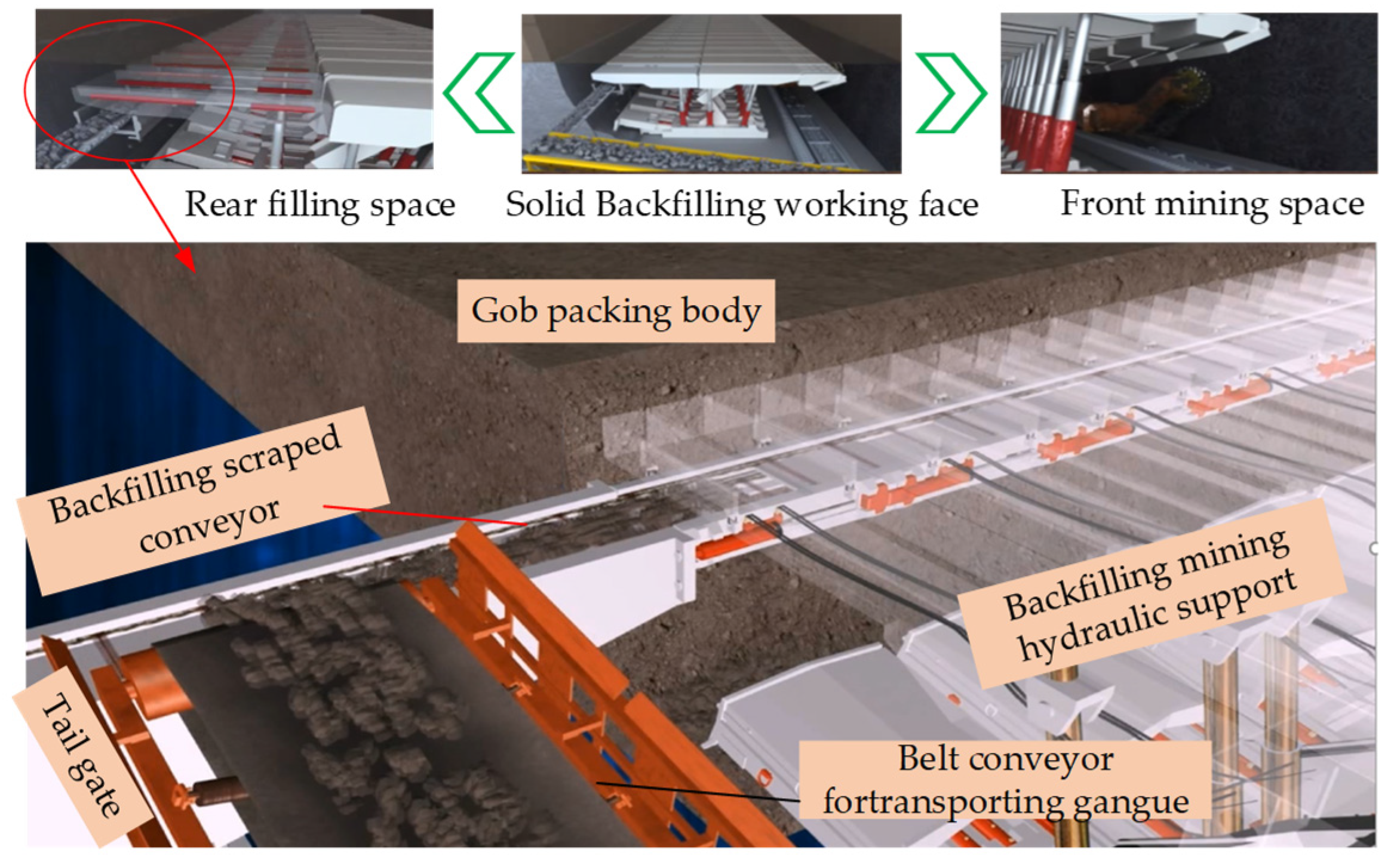

2. Evolution of Intelligent Mining and Backfilling Operations in Fully Mechanized Mining and the Connotation of the Mechanism of SPL

2.1. Evolution of Intelligent Mining and Backfilling Operations in Fully Mechanized Mining

2.2. Connotation of the SPL of Sequential Processes of Intelligent Mining and Backfilling Operations

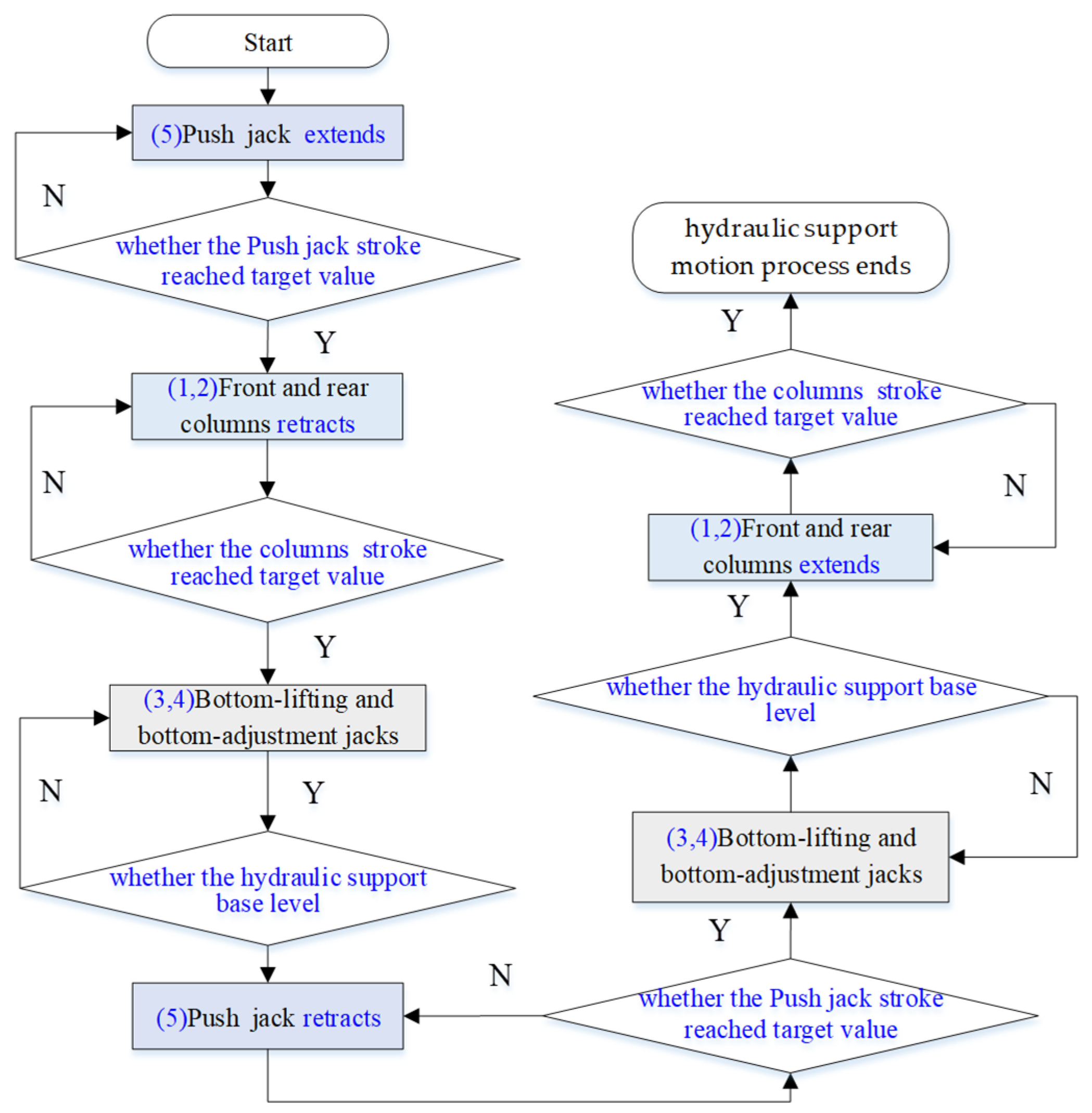

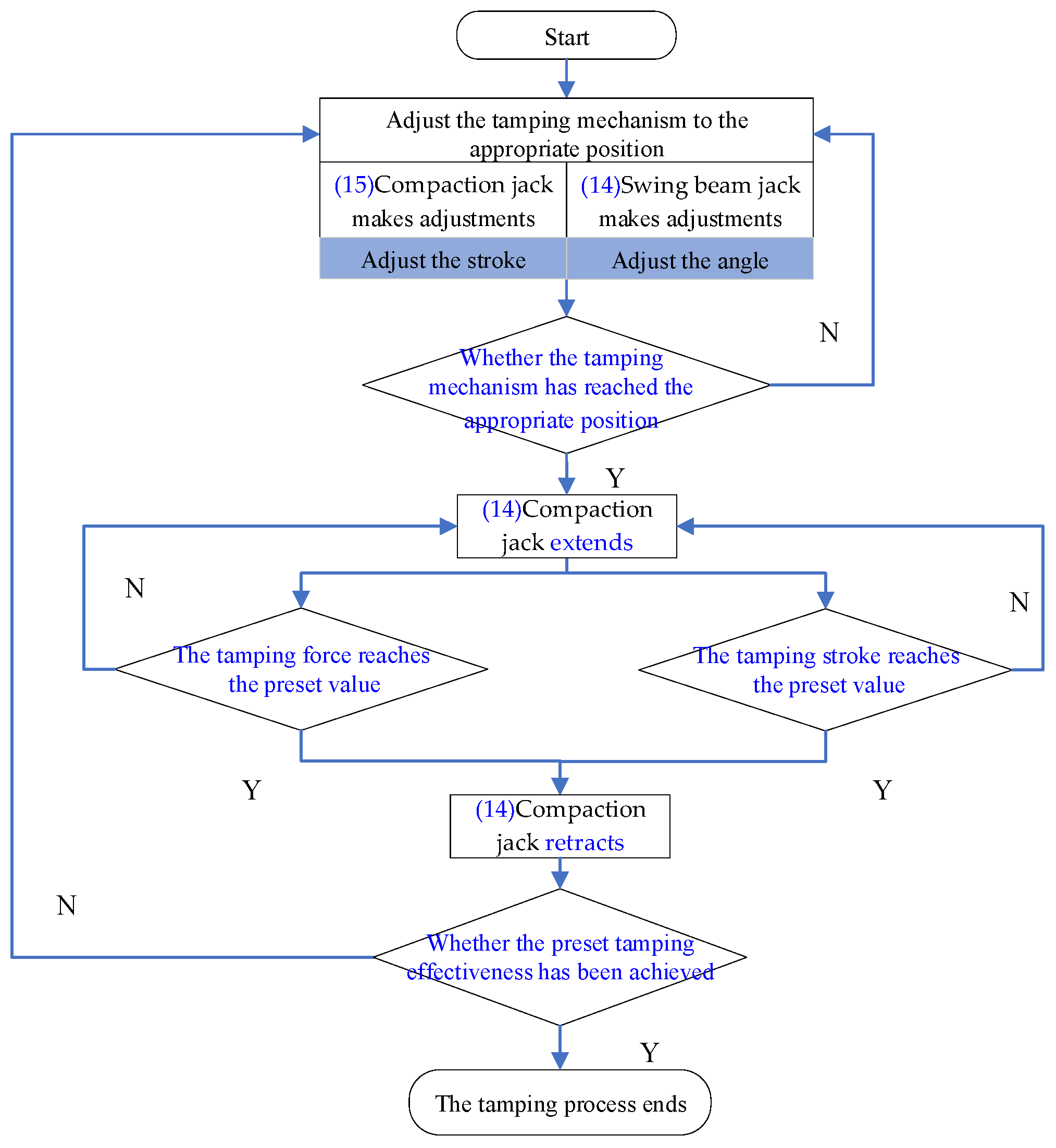

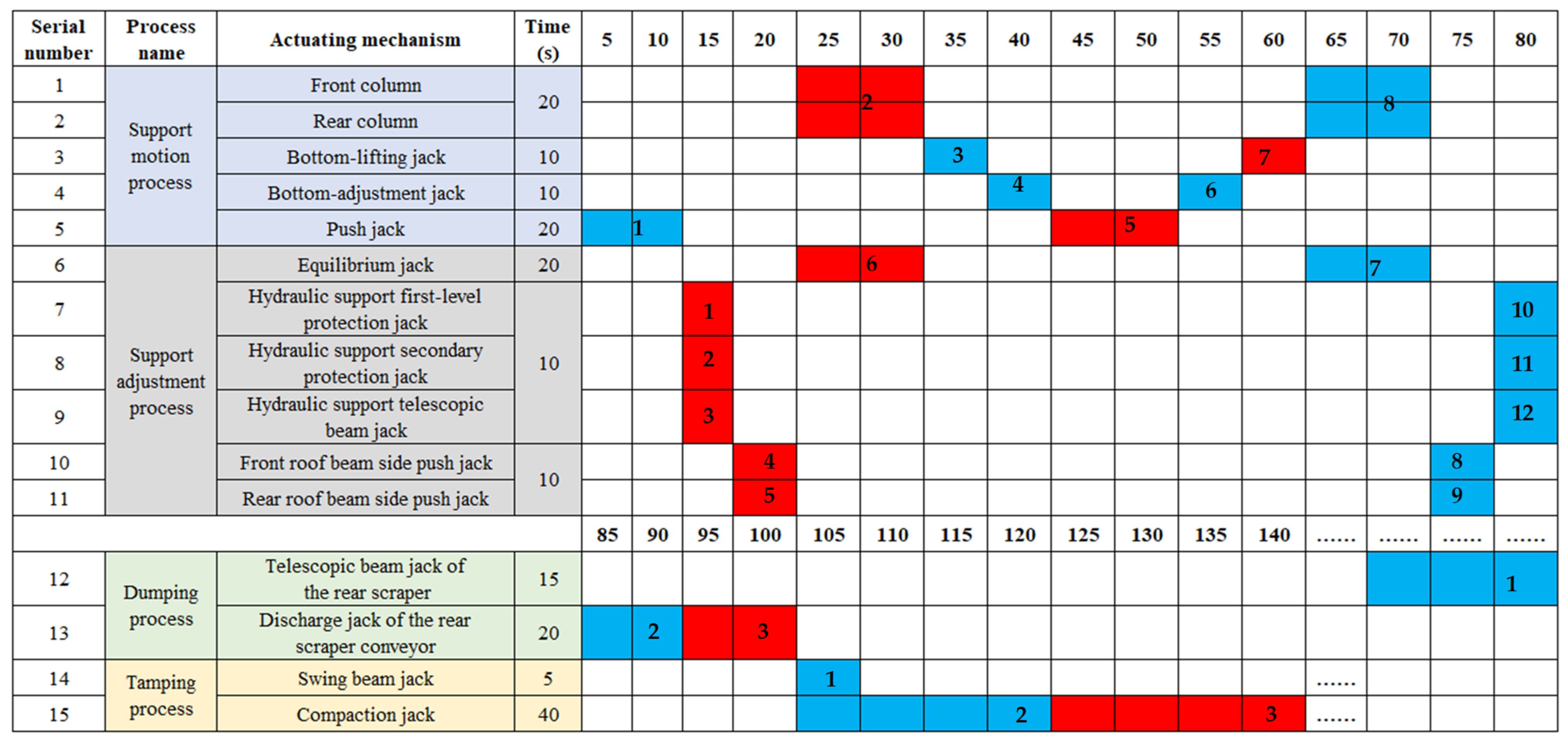

3. Spatiotemporal Linkage between Different Steps of Intelligent Backfilling Operation Using Single Hydraulic Supports

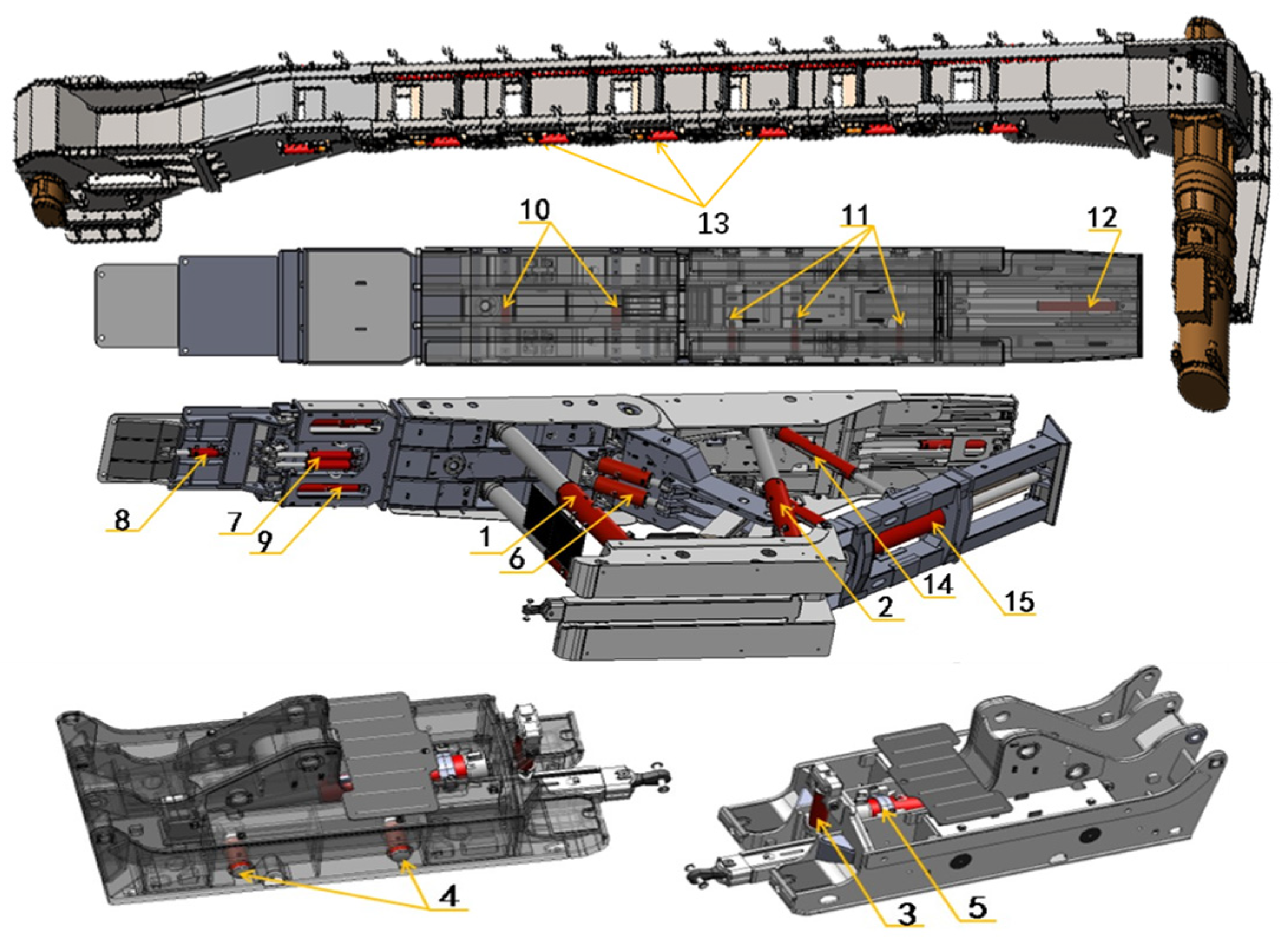

3.1. Division of Sequential Actions of Filling Using Single Hydraulic Supports

3.2. Theoretical Analysis of the Actuation Time of Sequential Actions of the Backfilling Operation Using Single Hydraulic Supports

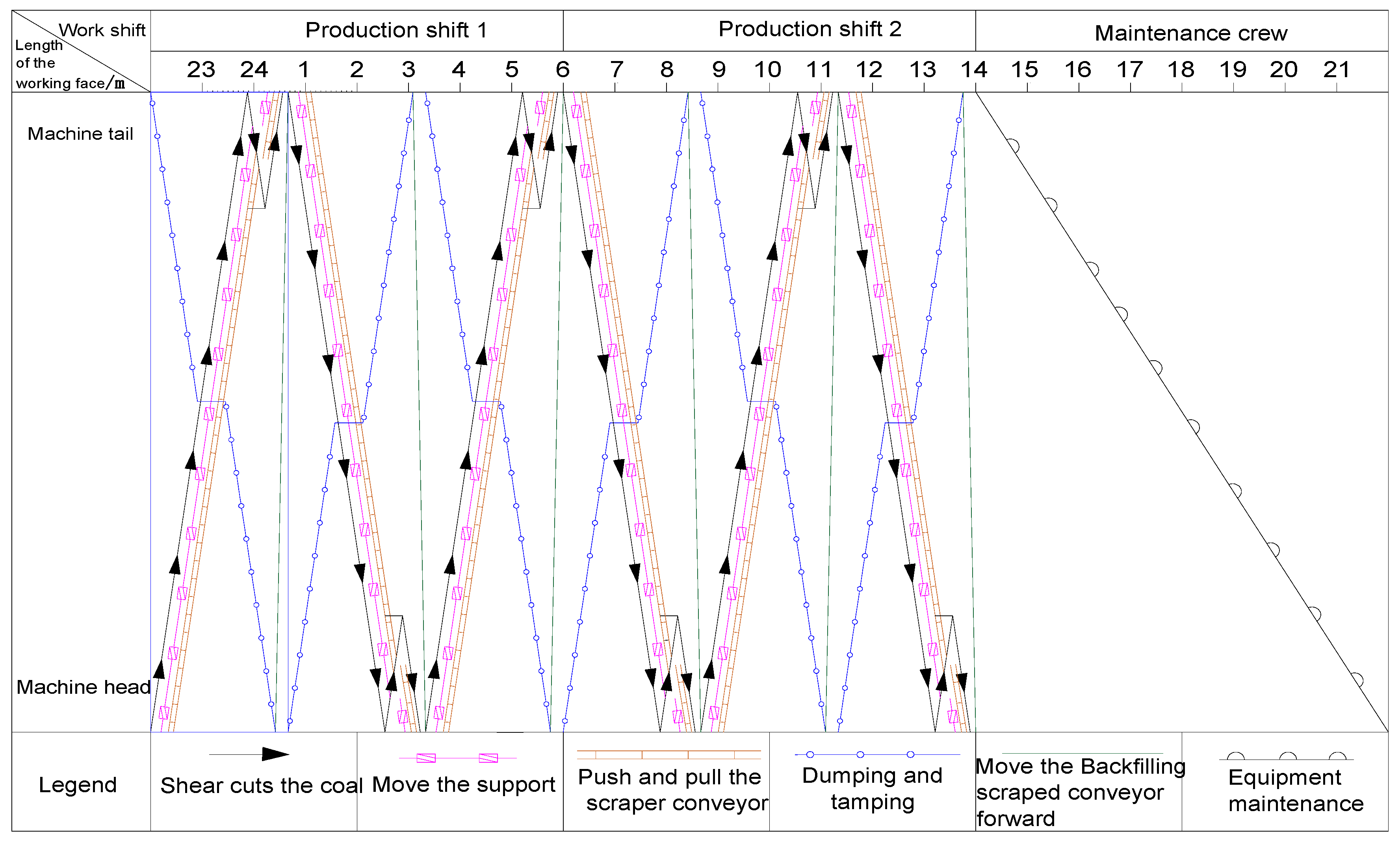

4. SPL between Different Steps of Intelligent Mining and Backfilling Operations for the Whole Face

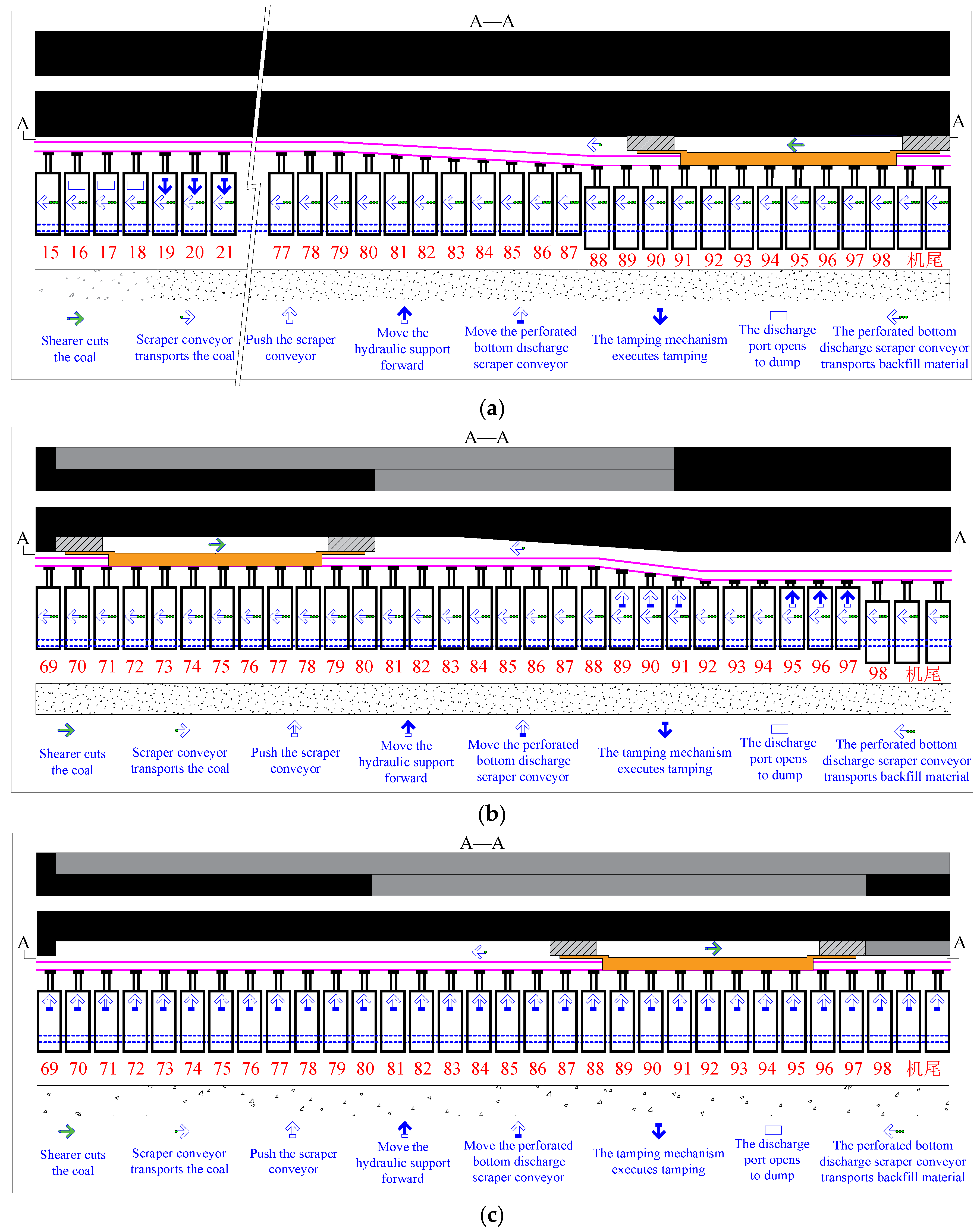

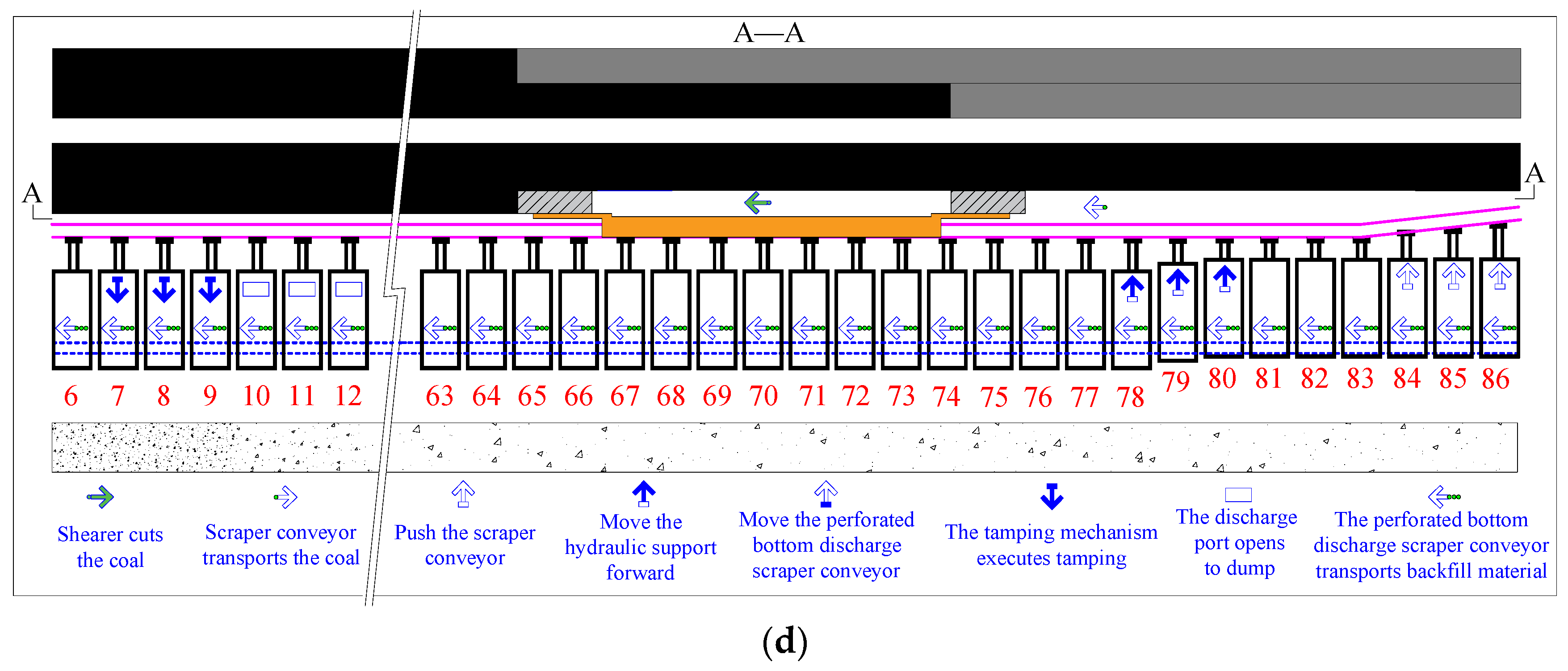

4.1. Division of Sequential Actions of the Intelligent Backfilling Operation for the Whole Face

- (1)

- End-oblique cutting knife stage: When the shearer moves to the end of the working face, the hydraulic support behind it follows the shearer and moves to the position of the rear drum. The scraper conveyor follows accordingly, and a curved segment for oblique knife-cutting is formed at the end. The shearer moves reversely, obliquely cutting the coal bodies ahead via the curved segment. As the end-oblique cutting knife stage is completed, the backfilling operation is orderly. The perforated bottom discharge scraper conveyor dumps the backfill material in groups, followed by tamping by the tamping mechanism.

- (2)

- Cutting triangular coal stage: Following the end-oblique cutting knife stage, the supports, located from the end of the working face to the position of oblique knife cutting, push the scraper conveyor forward to form a straight line. The shearer moves in the reverse direction, cutting the triangular coal left by oblique knife cutting. The backfilling operation is conducted in an orderly manner. The perforated bottom discharge scraper conveyor dumps the backfill material in groups, followed by tamping by the tamping mechanism.

- (3)

- End-brake bottom coal cleaning: After the shearer returns to cut triangular coals, the front drum drops down, cutting the triangular residual coal equal in length and height to the shearer’s body. The backfilling operation is conducted in an orderly manner. The perforated bottom discharge scraper conveyor dumps the backfill material in groups, followed by tamping by the tamping mechanism.

- (4)

- Central coal-cutting stage: The front drum of the shearer is lifted to cut the coal bodies in the reverse direction. The hydraulic supports behind the shearer follow, and the scraper conveyor is pushed accordingly. The backfilling operation is conducted in an orderly manner. The perforated bottom discharge scraper conveyor dumps the backfill material in groups, followed by tamping by the tamping mechanism.

4.2. Theoretical Analysis of the Time of Cyclic Backfilling Operation for the Whole Face

5. Analysis of Key Factors Influencing the Cyclic Operation Time

5.1. Time Gaps in Cylinder Actions

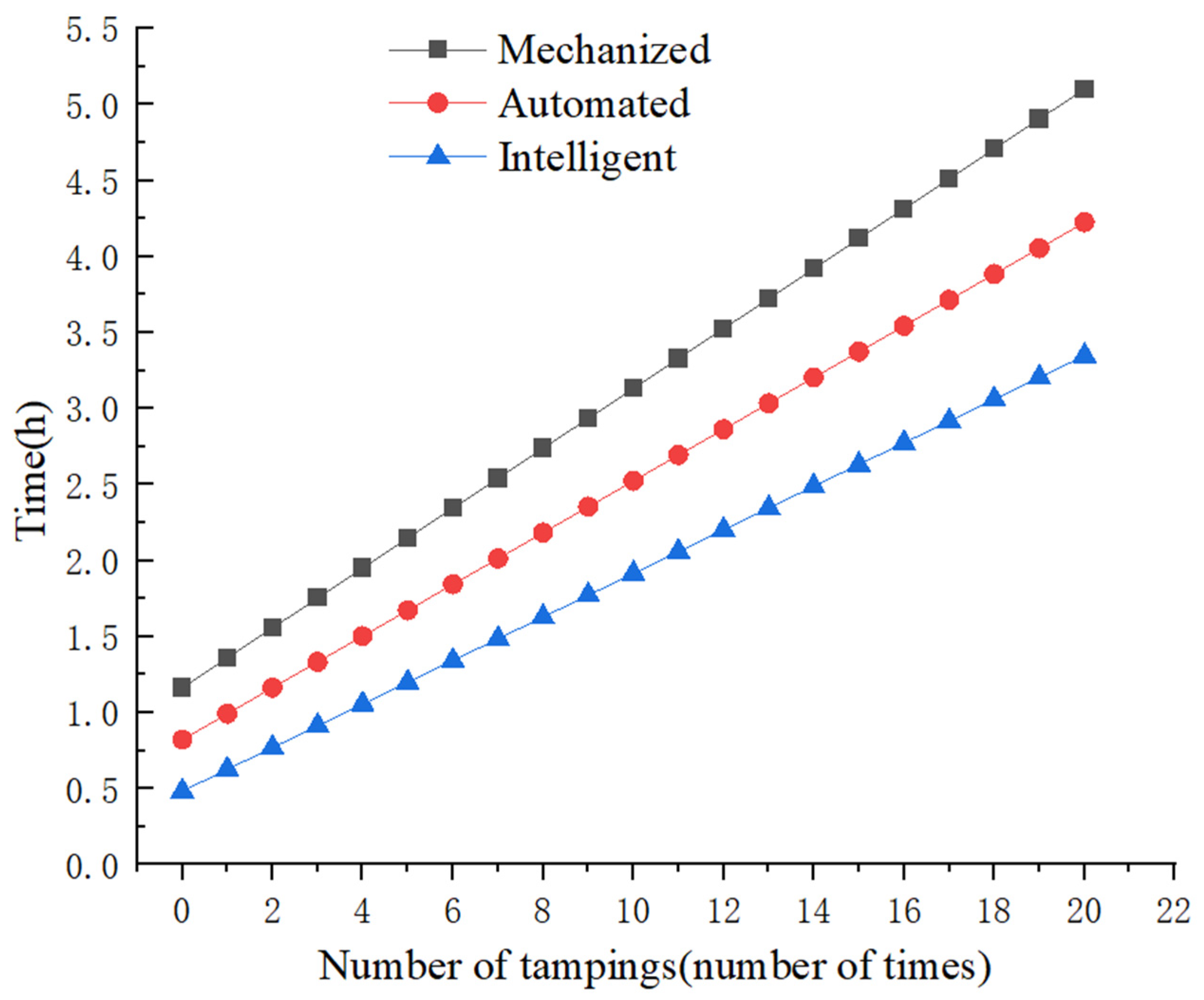

5.2. Number of Tampings

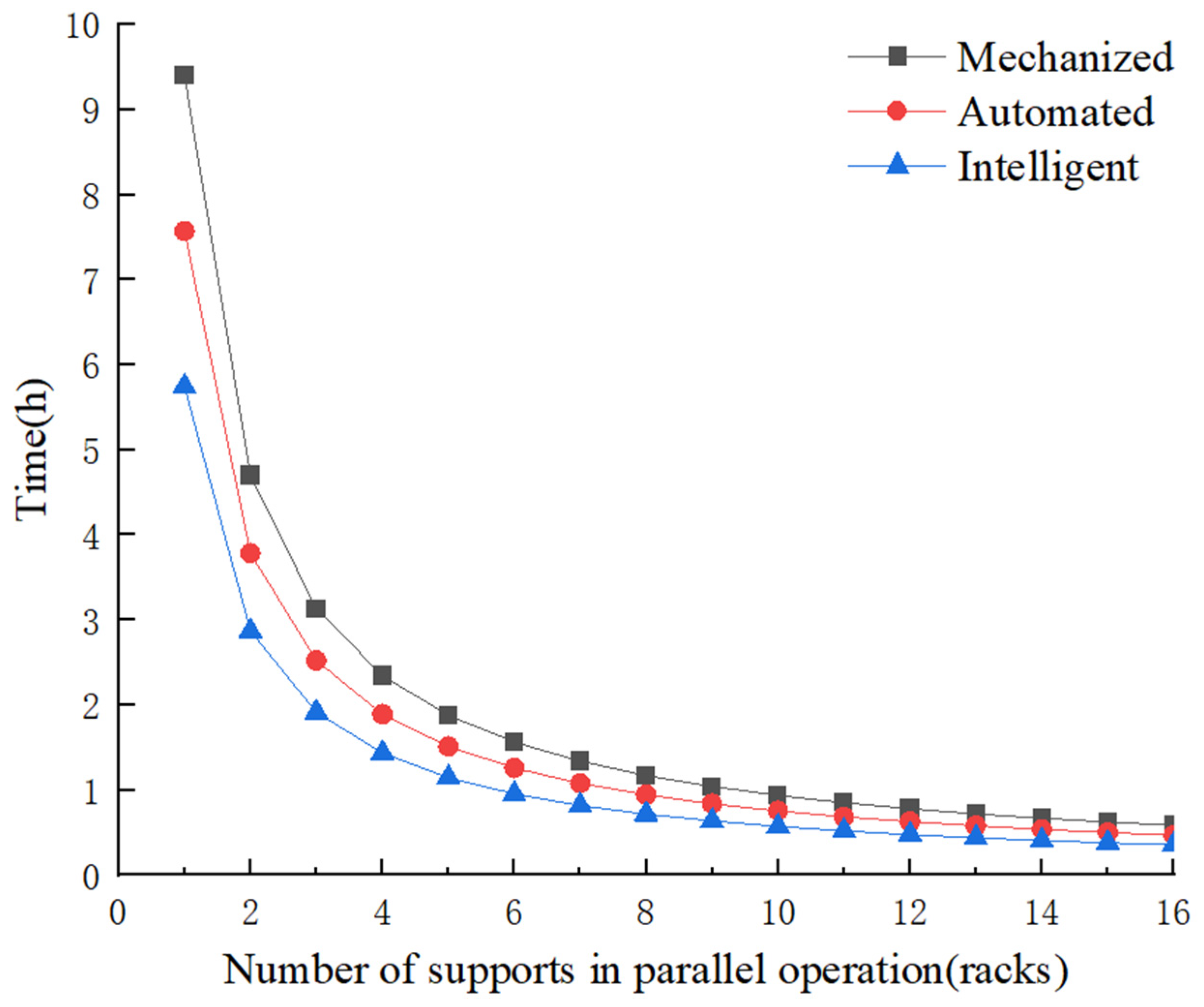

5.3. Number of Supports in Parallel Operation

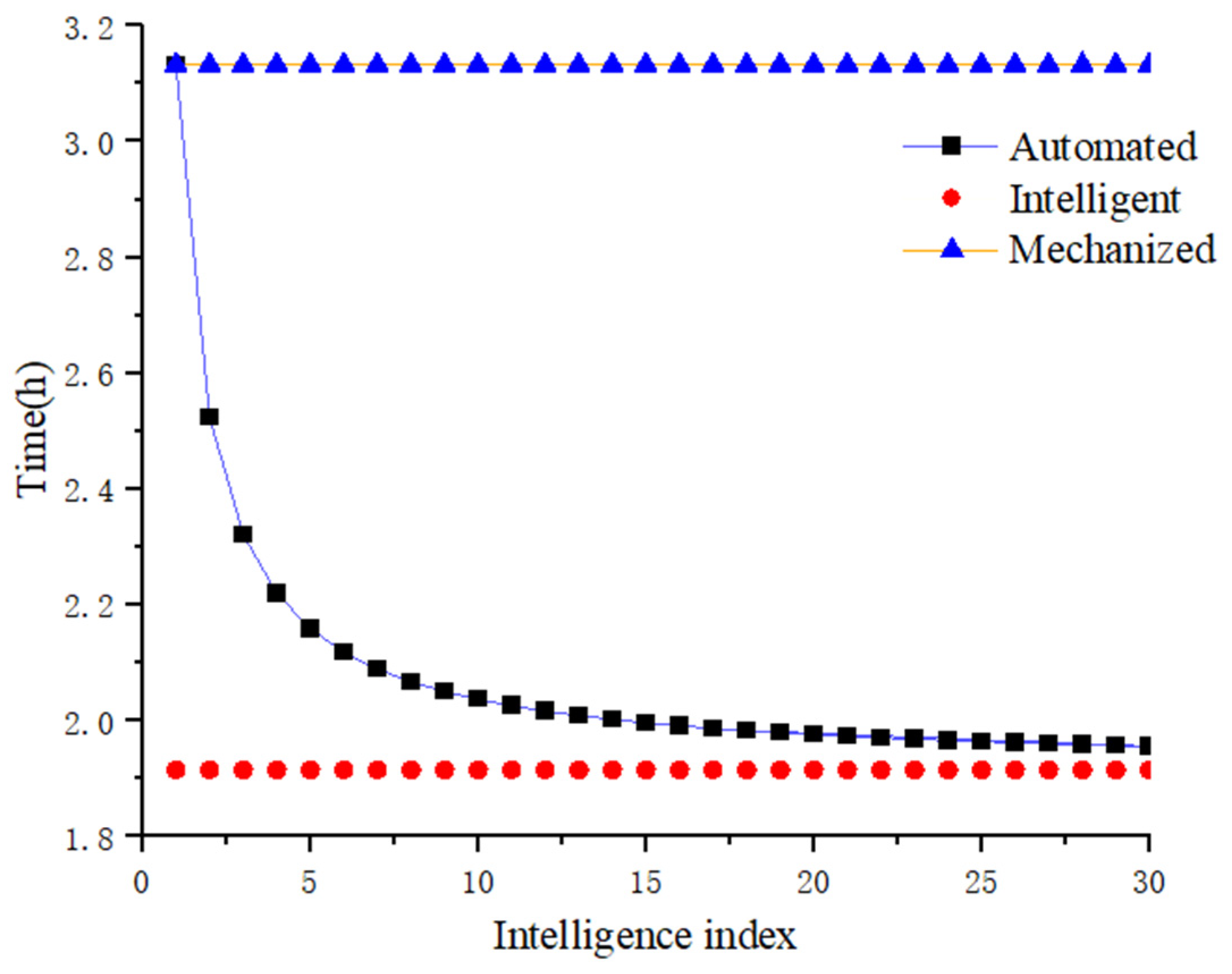

5.4. Degree of Intelligence

6. Efficiency Analysis of Intelligent Solid Backfilling Mining

6.1. An Overview of the Case Study’s Filling Working Face

6.2. Backfilling Efficiency Analysis and Optimization Plan

6.2.1. Efficiency Analysis

6.2.2. Recommended Actions for Optimizing the Backfilling Efficiency

7. Conclusions

- (1)

- Based on the spatiotemporal linkage (SPL) of the mining and backfilling operations for single supports, the operations were divided into four processes involving cylinder actions for single support: support motion, support adjusting, dumping, and tamping. Theoretical formulas for calculating the actuation time of single support in the three solid backfilling technologies were derived and further validated via a case study.

- (2)

- The SPL of different mining and backfilling processes in the whole face for intelligent parallel operations was studied. The intelligent solid backfilling operation for the whole face was subdivided into four distinct stages. We further presented the theoretical formula for estimating the time of cyclic operation for the whole face in the three mining technologies.

- (3)

- The influence of key factors on the time of cyclic operation of three backfilling techniques was analyzed. It is concluded that the time of cyclic operation is positively correlated with the time gap between hydraulic cylinder actions and the number of tampings; it is hyperbolically correlated with the number of supports in parallel operation and the intelligence index. Moreover, reducing the number of tampings, increasing the number of supports in parallel operation, and the intelligence index can significantly improve the backfilling efficiency.

- (4)

- A case study was performed for the #11233 filling working face of Xingdong Mine, China, operated by Jizhong Energy Resources Co., Ltd. Keeping other parameters unchanged, by adopting the optimized method of grain diameter grading of backfilling materials to reduce the number of tampings to 3 times and increasing the number of parallel supports to 4, with the intelligence index being 1, the backfilling efficiency can be increased by 39%. The improvement of backfilling efficiency is the most significant. It has great significance for improving production capacity, reducing staff, and improving efficiency and safety of the backfilling working face.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Skrzypkowski, K. Comparative Analysis of the Mining Cribs Models Filled with Gangue. Energies 2020, 13, 5290. [Google Scholar] [CrossRef]

- Skrzypkowski, K. Decreasing Mining Losses for the Room and Pillar Method by Replacing the Inter-Room Pillars by the Construction of Wooden Cribs Filled with Waste Rocks. Energies 2020, 13, 3564. [Google Scholar] [CrossRef]

- Bo, L.; Yang, S.; Liu, Y.; Zhang, Z.; Wang, Y.; Wang, Y. Coal Mine Solid Waste Backfill Process in China: Current Status and Challenges. Sustainability 2023, 15, 13489. [Google Scholar] [CrossRef]

- Hu, B.; Liu, P.; Cui, F.; Wang, H. Review and development status of backfill coal mining technology in China. Coal Sci. Technol. 2020, 48, 39–47. [Google Scholar] [CrossRef]

- Chang, Q.; Chen, J.; Zhou, H.; Bai, J. Implementation of Paste Backfill Mining Technology in Chinese Coal Mines. Sci. World J. 2014, 8, 2014. [Google Scholar] [CrossRef]

- Qing, D.; Wang, X. Study on rapid filling material and key technology of paste in coal mine. Coal Chem. Ind. 2015, 38, 6–8. [Google Scholar] [CrossRef]

- Dong, P.; Kou, X.; Li, X.; Zhang, Y. Modification of Filling Automation System Based on PLC Control. Min. Technol. 2021, 21, 187–190. [Google Scholar] [CrossRef]

- Shi, Y. Design of a Filling Automation System Based on DCS Control Technology. Min. Technol. 2021, 21, 150–154. [Google Scholar] [CrossRef]

- Zhang, J.; Tu, S.; Cao, Y. Theory and technique of greening mining integrating mining, separating and backfilling in deep coal resources. J. China Coal Soc. 2018, 43, 377–389. [Google Scholar] [CrossRef]

- Tu, S.; Hao, D.; Miao, K.; Liu, X.; Li, W. Research of synergetic mining for mining, dressing and backfilling integrated deep mines with complicated systems. J. China Univ. Min. Technol. 2021, 50, 431–441. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; An, T.; Huang, Y. Deformation characteristic of key stratum overburden by raw waste backfilling with fully-mechanized coal mining technology. J. China Coal Soc. 2010, 35, 357–360. [Google Scholar] [CrossRef]

- Yao, B. Application of gangue filling process and the study of surface rock shift deformation. Coal Chem. Ind. 2021, 44, 31–33. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, M. Research on following automation technology of hydraulic support on fully-mechanized coal mining face. J. Mine Autom. 2018, 44, 14–17. [Google Scholar] [CrossRef]

- Liu, Q.; Han, X.; Xu, L.; Qing, W. Cooperative control technology of shear and hydraulic support on fully-mechanized coal mining face. J. Mine Autom. 2020, 46, 43–48. [Google Scholar] [CrossRef]

- Shi, Y.; Jiang, L.; Cui, Z.; Yan, X. Mathematical model of automatic following control in the middle of fully-mechanized mining face. J. Mine Autom. 2016, 42, 14–19. [Google Scholar] [CrossRef]

- Liu, F.; Cao, W.; Zhang, J.M. Progress of scientific and technological innovation in my country’s coal industry and the development direction of the “14th Five-Year Plan”. Coal J. 2021, 46, 1–15. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, L.; Bi, J.; Xie, G. Research and application on automatic control of comprehensive mechanized solid backfill coal mining. Coal Sci. Technol. 2016, 44, 149–156. [Google Scholar] [CrossRef]

- Wang, G.; Ren, H.; Peng, Y. Research and engineering progress of coal mine intelligent (primary stage) technology system. Coal Sci. Technol. 2020, 48, 1–27. [Google Scholar] [CrossRef]

- Wang, G.; Du, Y.; Ren, H. Research and practice of top-level design of intelligent coal mines. Chin. J. Coal 2020, 45, 1909–1924. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, F.; Zhang, S. Research on the architecture and key technologies of intelligent coal mining system. Chin. J. Coal 2020, 45, 1959–1972. [Google Scholar] [CrossRef]

- Present situation and prospect of coal gangue treatment technology. J. Min. Saf. Eng. 2020, 37, 136–146. [CrossRef]

- Wang, Y.; Shi, Y.; Wang, Y.Y.; Qi, M.; Wang, H. Full pose measurement and virtual simulation of solid filling hydraulic support. J. Mine Autom. 2022, 48, 81–89. [Google Scholar] [CrossRef]

- Zuo, X. Solid Intelligent Filling Method and Engineering Case Analysis in Coal Mine. Master’s Thesis, China University of Mining & Technology, Xuzhou, China, 2021. [Google Scholar] [CrossRef]

- Ren, H.; Li, S.; Zhao, G.; Zhang, K.; Du, M.; Zhou, J. Measurement method of support height and roof beam posture angles for working face hydraulic support based on depth vision. J. Min. Saf. Eng. 2022, 39, 72–81. [Google Scholar] [CrossRef]

- Zhang, H. Autonomous Identification of Working Conditions and Forms of Key Equipment for Solid Intelligent Filling and Control Methods. Master’s Thesis, China University of Mining & Technology, Xuzhou, China, 2022. [Google Scholar] [CrossRef]

- Ralston, J.C.; Hargrave, C.O.; Dunn, M.T. Longwall automation: Trends, challenges and opportunities. Int. J. Min. Sci. Technol. 2017, 27, 733–739. [Google Scholar] [CrossRef]

- Ralston, J.C.; Reid, D.C.; Dunn, M.T.; Hainsworth, D.W. Longwall automation: Delivering enabling technology to achieve safer and more productive underground mining. Int. J. Min. Sci. Technol. 2015, 25, 865–876. [Google Scholar] [CrossRef]

- Guo, G.; Feng, W.; Zha, J.; Liu, Y.X.; Wang, Q. Subsidence control and farmland conservation by solid backfilling mining technology. Trans. Nonferrous Met. Soc. China 2011, 21, 665–669. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.; Guo, S.; Gao, R.; Li, W. Design and application of solid, dense backfill advanced mining technology with two pre-driving entries. Int. J. Min. Sci. Technol. 2015, 1, 127–132. [Google Scholar] [CrossRef]

- Zong, T.; Zhang, Q.; Shi, P.; Wang, Y.; Li, F.; Chang, T. Critical characterization of solid-filled hydraulic support mechanism interference and autonomous demodulation method. Coal Sci. Technol. 2023, 2051, 260–270. [Google Scholar] [CrossRef]

| Serial No. | Process | Specification | Number | Functions |

|---|---|---|---|---|

| 1 | Hydraulic support motion process | Front column | 2 | Lift the support canopy |

| 2 | Rear column | 2 | Lift the support canopy | |

| 3 | Bottom-lifting jack | 1 | Lift the bottom up during support movement to facilitate the movement | |

| 4 | Bottom-adjustment jack | 2 | Maintain a proper distance between the supports, and adjust the bottom as appropriate during support movement | |

| 5 | Push jack | 1 | Pull the support | |

| 6 | Hydraulic support adjusting process | Equilibrium jack | 2 | Adjust the support pose so that the canopy is better connected to the roof |

| 7 | Hydraulic support first-level protection jack | 2 | Drive the first-level face guard to protect the coal walls and prevent rib spalling. Retrieve the jack before the shearer passes through and stretch out again to protect the coal walls after the shearer passes through | |

| 8 | Hydraulic support secondary protection jack | 1 | Drive the secondary face guard to protect the coal walls and prevent rib spalling. Retrieve the jack before the shearer passes through and stretch out again to protect the coal walls after the shearer passes through | |

| 9 | Hydraulic support telescopic beam jack | 2 | After the coal cutting and before support pulling, drive the telescopic beam to stretch out and temporarily support the roof; retrieve the telescopic beam during support pulling | |

| 10 | Front roof beam-side push jack | 2 | Front roof beam stretches out and retrieves the mobile side guard | |

| 11 | Rear roof beam-side push jack | 3 | Rear roof beam stretches out and retrieves the mobile side guard | |

| 12 | Dumping process | Expansion jack of Backfilling scraped conveyor | 1 | Pull the filling conveyor, fulfilling similar functions as the push jack |

| 13 | Expansion jack of Backfilling scraped conveyor | 1 | The backfilling scraped conveyor dumps the backfill material | |

| 14 | Tamping process | Swing beam jack | 2 | Adjust the angle of the tamping mechanism |

| 15 | Compaction jack | 1 | Make the backfill material compact |

| Technology | Mechanized | Automated | Intelligent | |

|---|---|---|---|---|

| Type | ||||

| Number of workers required for each shift (workers) | 20–30 | 15–20 | 7–10 | |

| Time of cyclic operation for a single support (min) | 20–35 | 10–20 | 5–10 | |

| Time of cyclic operation for the whole face (h) | 3.5–5.0 | 2.0–3.5 | 1.0–2.0 | |

| Backfilling efficiency | Moderate | Improve efficiency by 20% | Improve efficiency by 40–80% | |

| Interference and adjustment | Manual | Manual | Automated | |

| Electrohydraulic control system | No | Yes | Yes | |

| Intelligent system | No | No | Yes | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zong, T.; Zhu, G.; Zhang, Q.; Yang, K.; Wang, Y.; Han, Y.; Lv, H.; Cao, J. Solid Backfilling Efficiency Optimization in Coal Mining: Spatiotemporal Linkage Analysis and Case Study. Appl. Sci. 2023, 13, 12298. https://doi.org/10.3390/app132212298

Zong T, Zhu G, Zhang Q, Yang K, Wang Y, Han Y, Lv H, Cao J. Solid Backfilling Efficiency Optimization in Coal Mining: Spatiotemporal Linkage Analysis and Case Study. Applied Sciences. 2023; 13(22):12298. https://doi.org/10.3390/app132212298

Chicago/Turabian StyleZong, Tingcheng, Gaolei Zhu, Qiang Zhang, Kang Yang, Yunbo Wang, Yu Han, Haonan Lv, and Jinming Cao. 2023. "Solid Backfilling Efficiency Optimization in Coal Mining: Spatiotemporal Linkage Analysis and Case Study" Applied Sciences 13, no. 22: 12298. https://doi.org/10.3390/app132212298

APA StyleZong, T., Zhu, G., Zhang, Q., Yang, K., Wang, Y., Han, Y., Lv, H., & Cao, J. (2023). Solid Backfilling Efficiency Optimization in Coal Mining: Spatiotemporal Linkage Analysis and Case Study. Applied Sciences, 13(22), 12298. https://doi.org/10.3390/app132212298