Innovative Acoustic-Hydraulic Method for High-Performance Fine Liquid Atomization

Abstract

:Featured Application

Abstract

1. Introduction

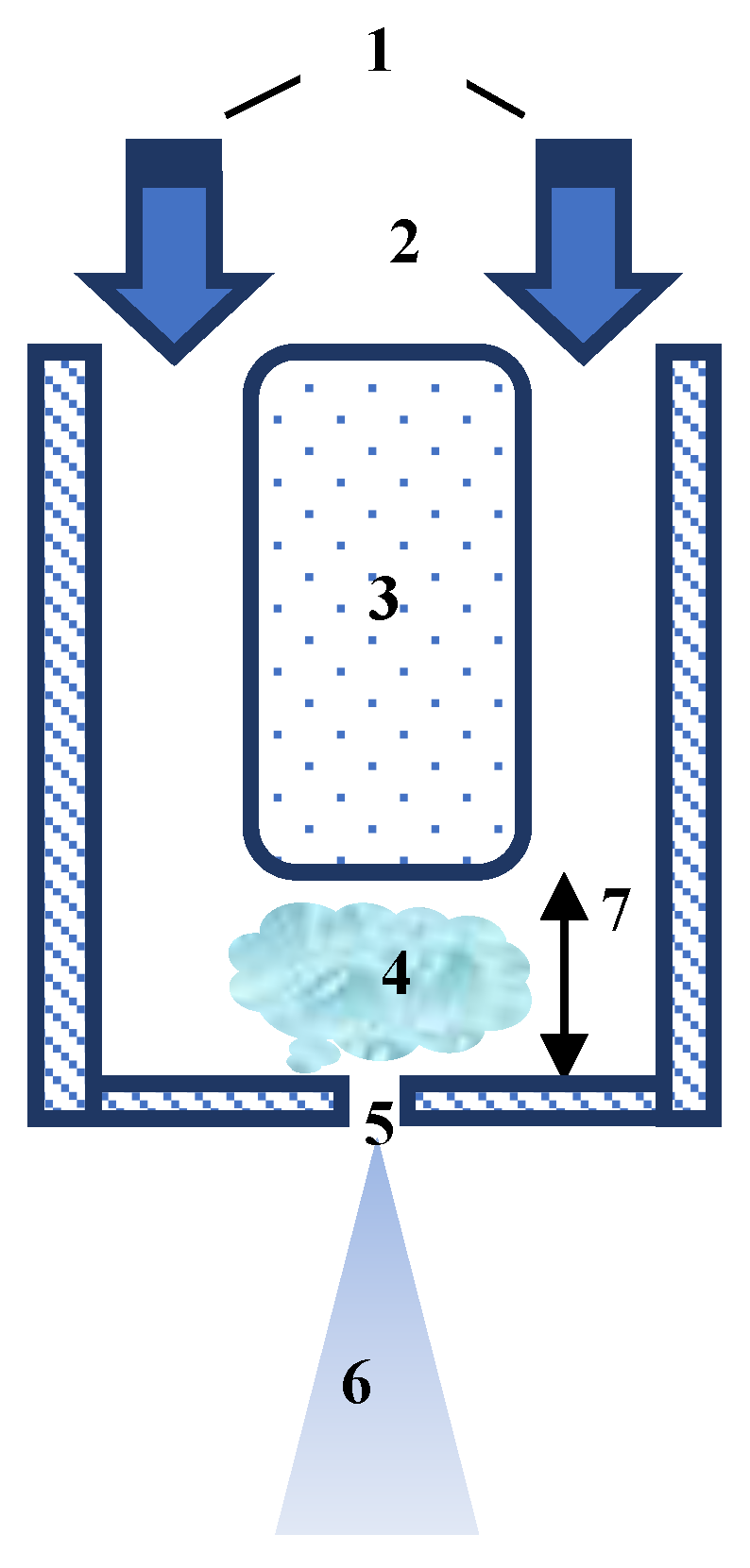

2. Materials and Methods

- The area of the end part of the ultrasonic emitter 3—S1;

- The area of the outlet 5—S2;

- The cross-sectional area of the tube 2—S3;

- The height of the cavitation zone (distance from the surface of emitter to the outlet) 7—L.

3. Mathematical Model of the Acoustic-Hydraulic Nozzle

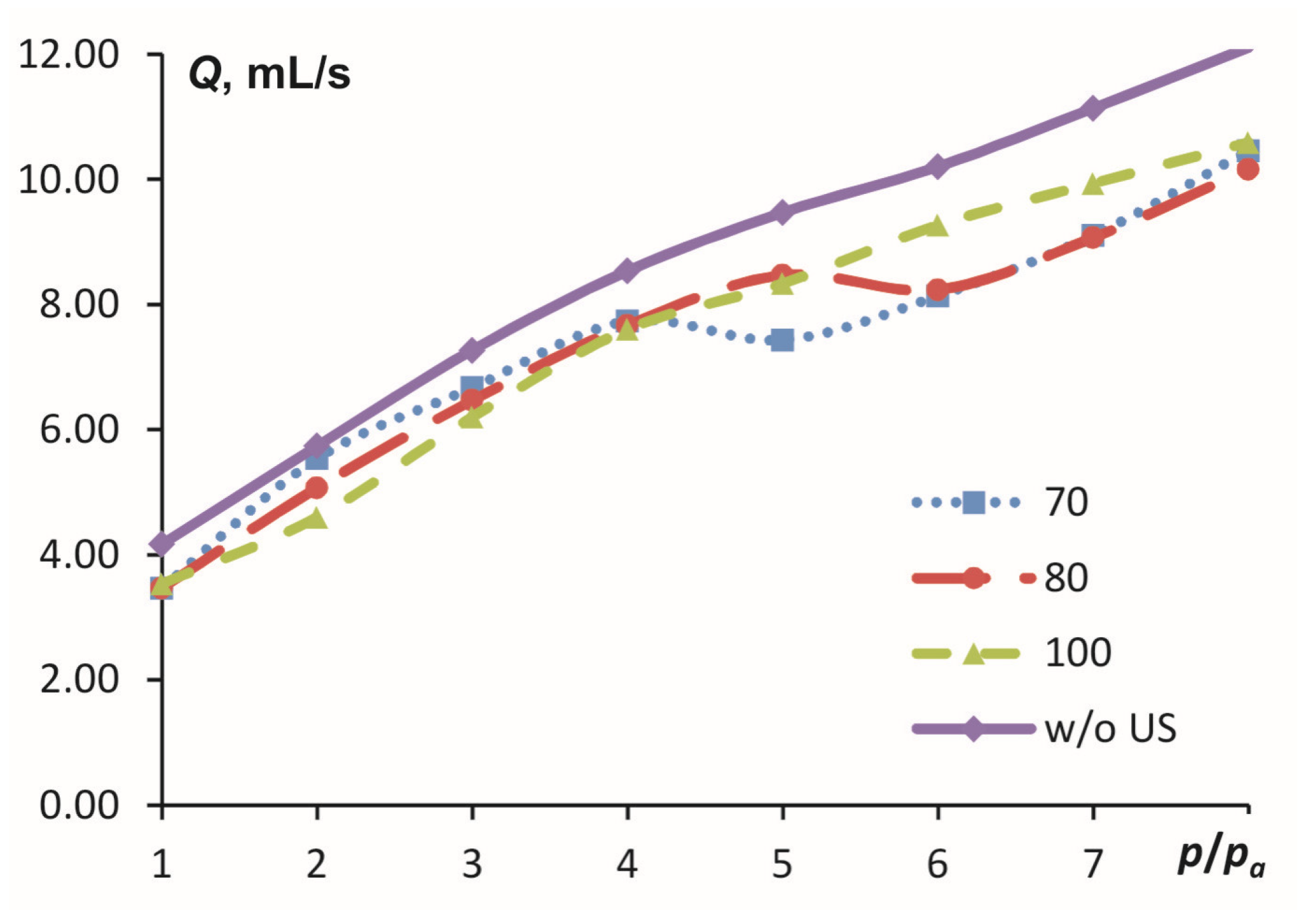

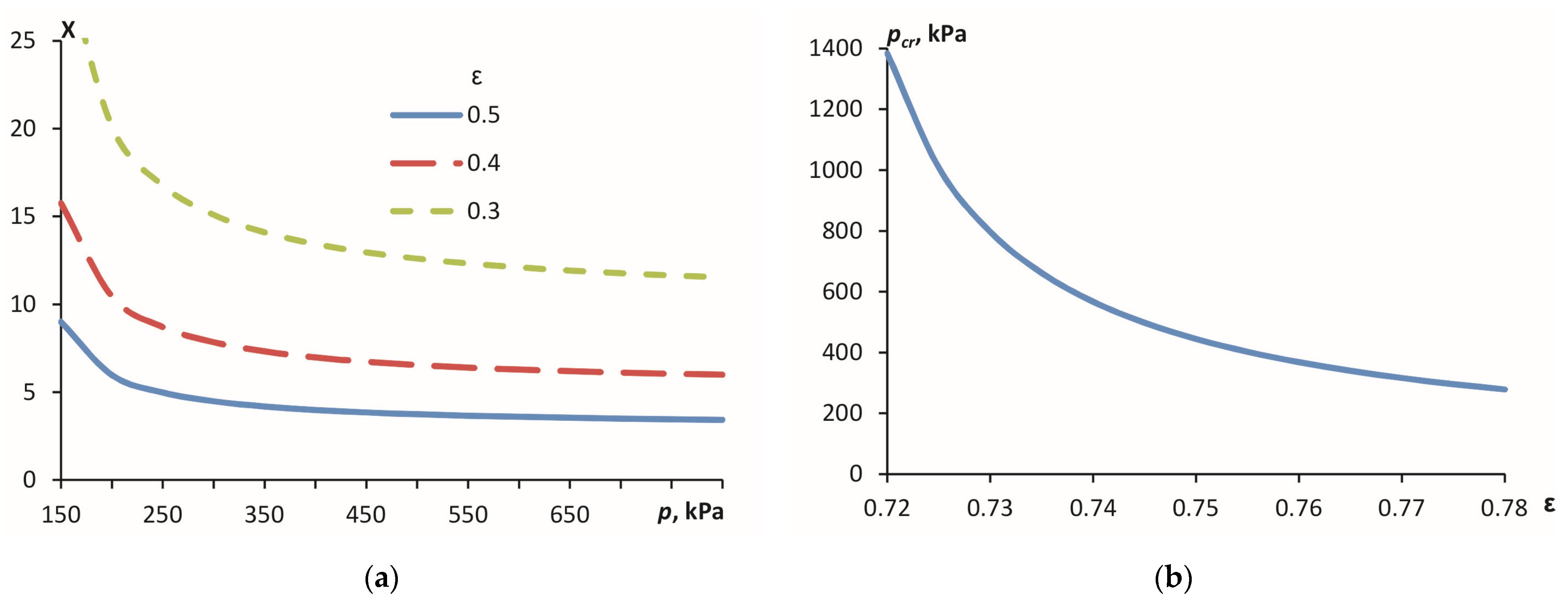

3.1. Hydrodynamic Processes:Hydrodynamic Cavitation Threshold

3.2. Ultrasonic Exposure: Acoustic Cavitation Threshold

3.3. Droplet Size upon Expiration of Cavitated Liquid

4. Results and Discussion

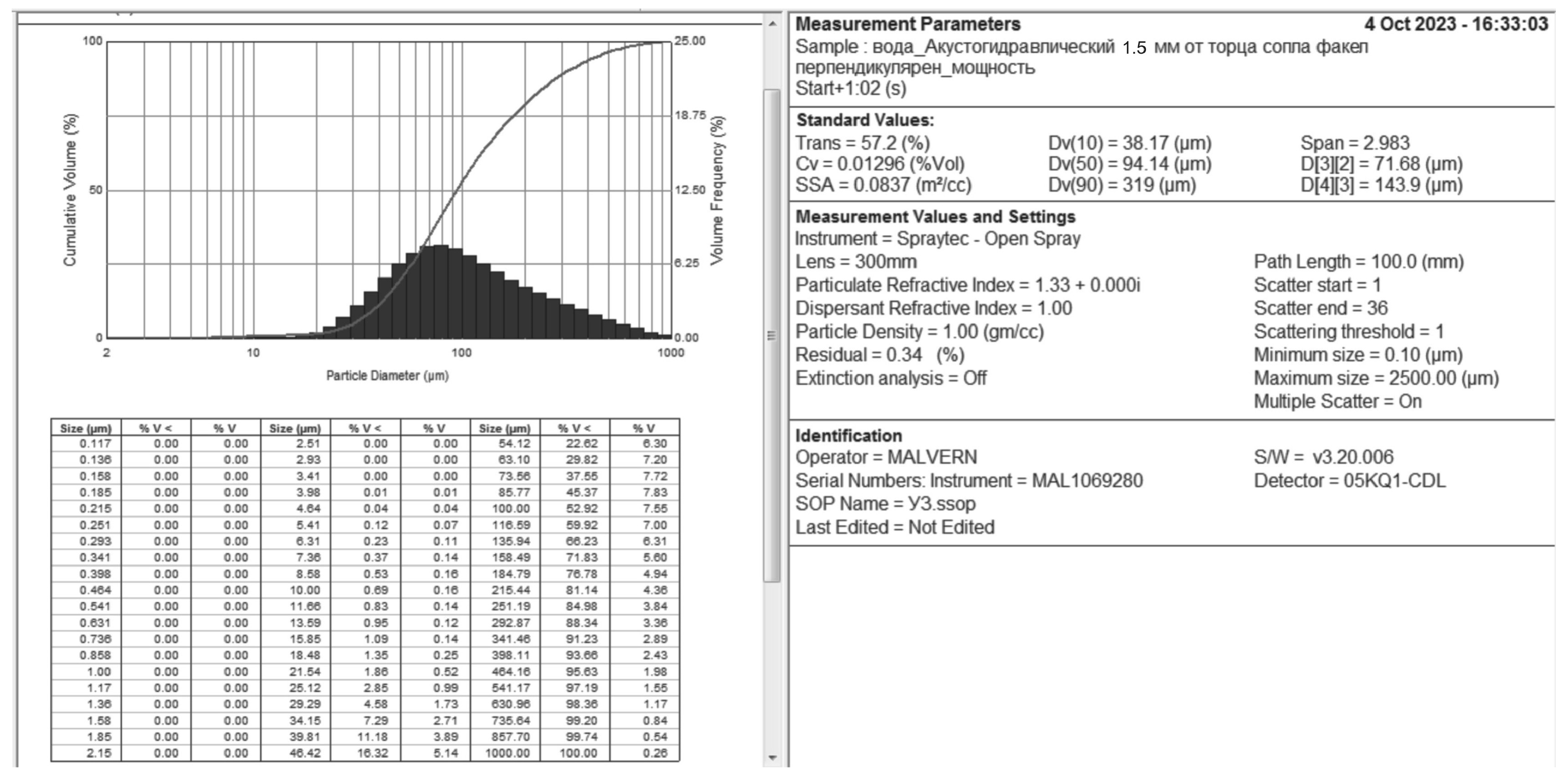

4.1. Experimental Results: Droplet Sizes, Critical Spraying Mode

- Outlet area S1 = 0.38 mm2;

- Area of the cavitation zone S2 = 50 mm2;

- Cross-sectional area of the tube S3 = 78.5 mm2;

- Height of the cavitation zone L = 1.5 cm.

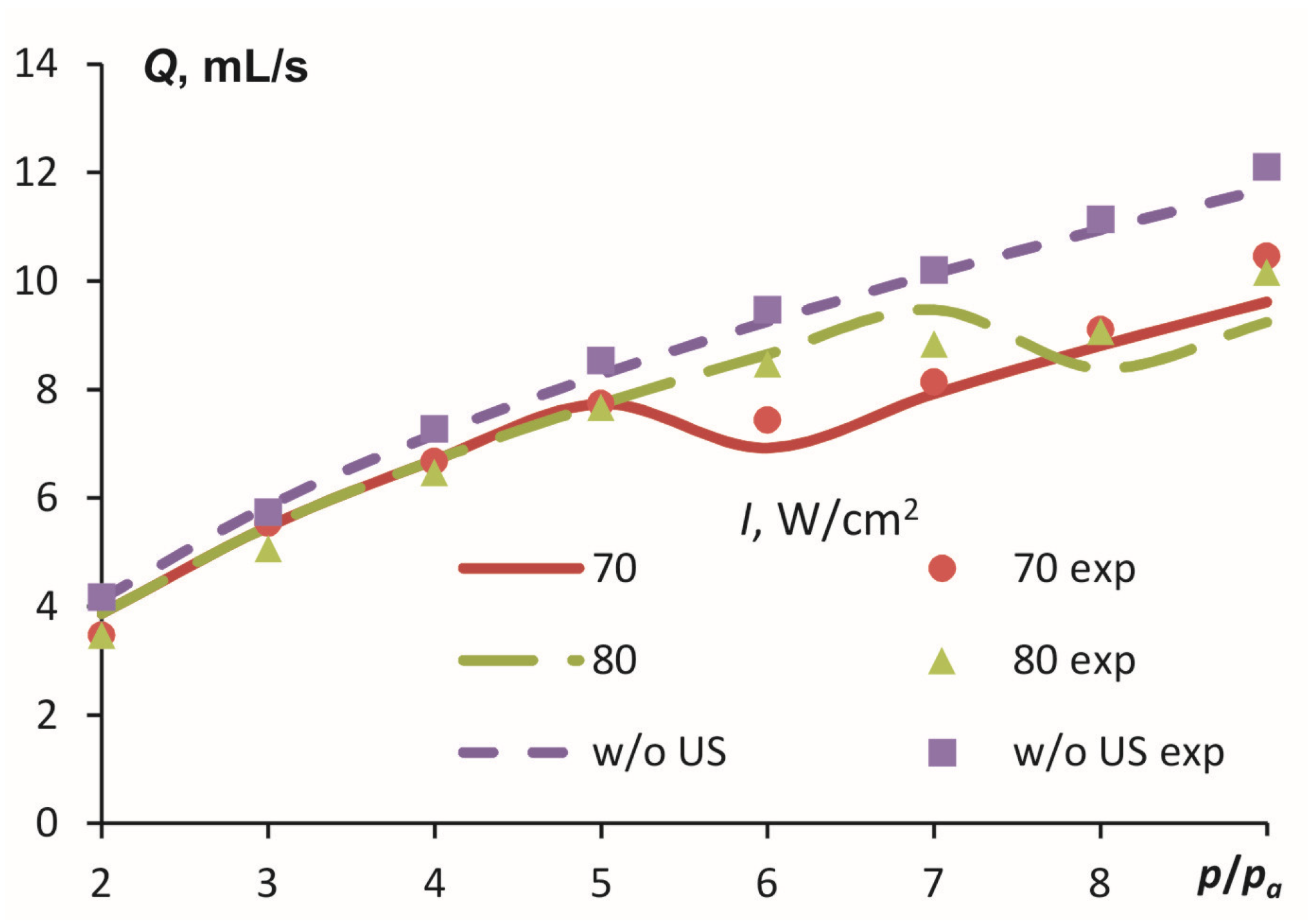

4.2. Calculation Results: Comparison of Theoretical and Experimental Results

4.2.1. Possibility of Hydrodynamic Cavitation

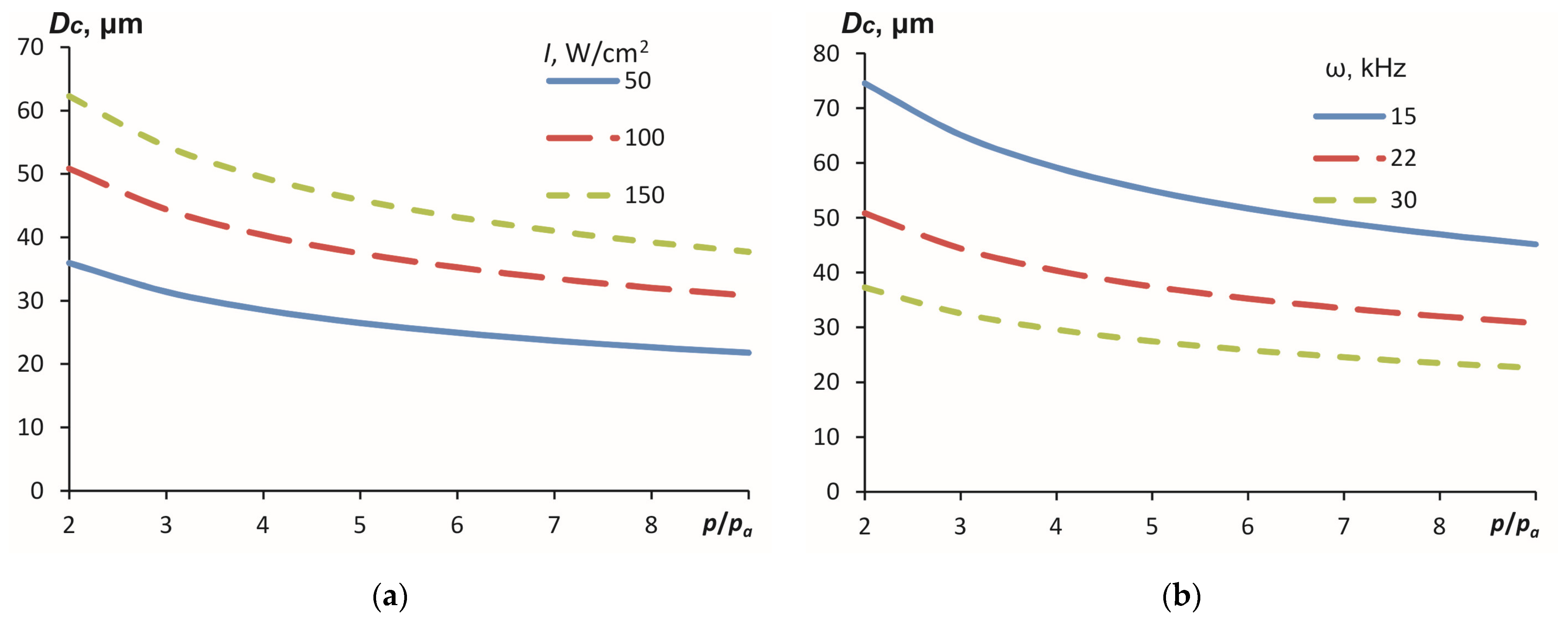

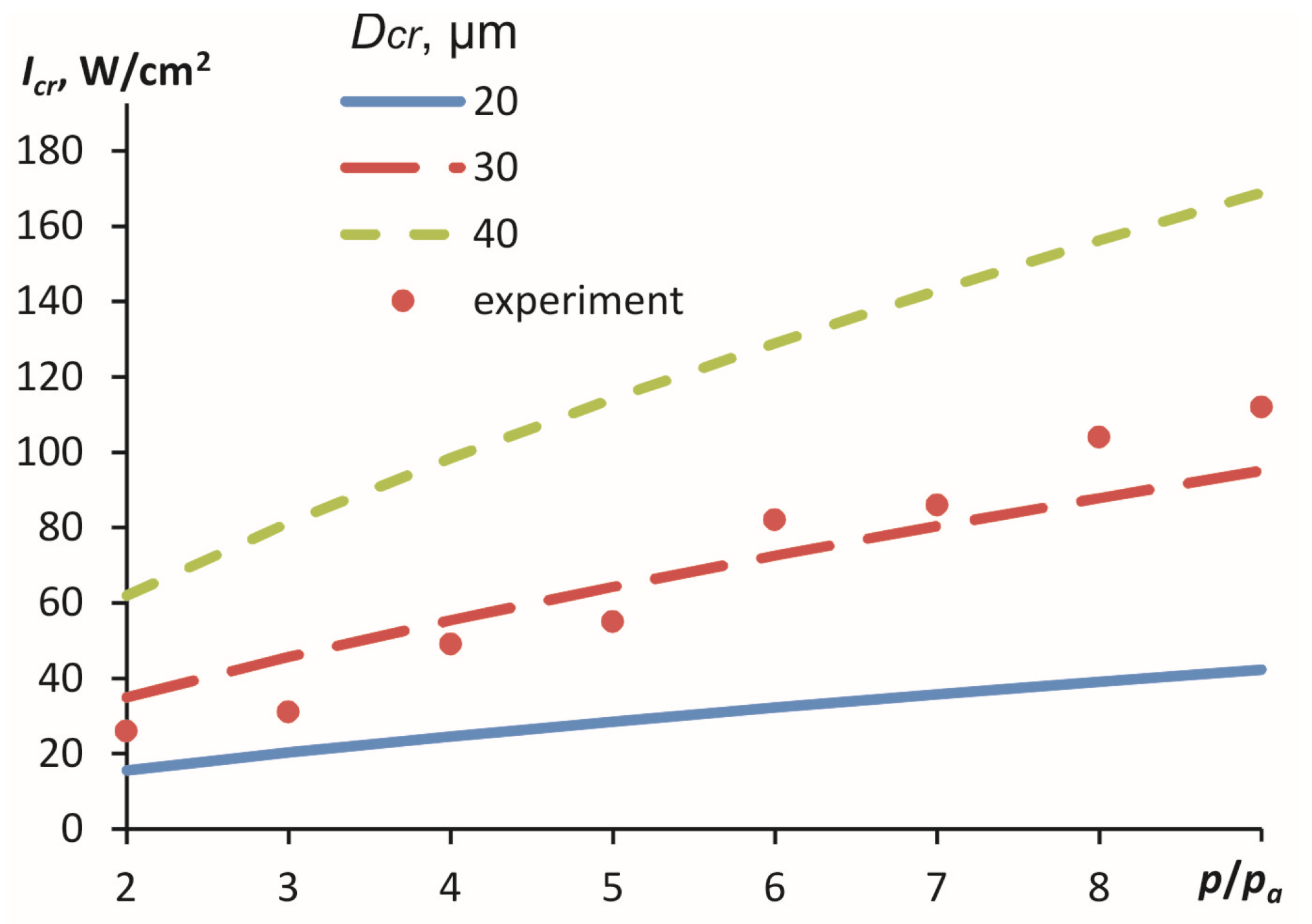

4.2.2. Ultrasonic Cavitation

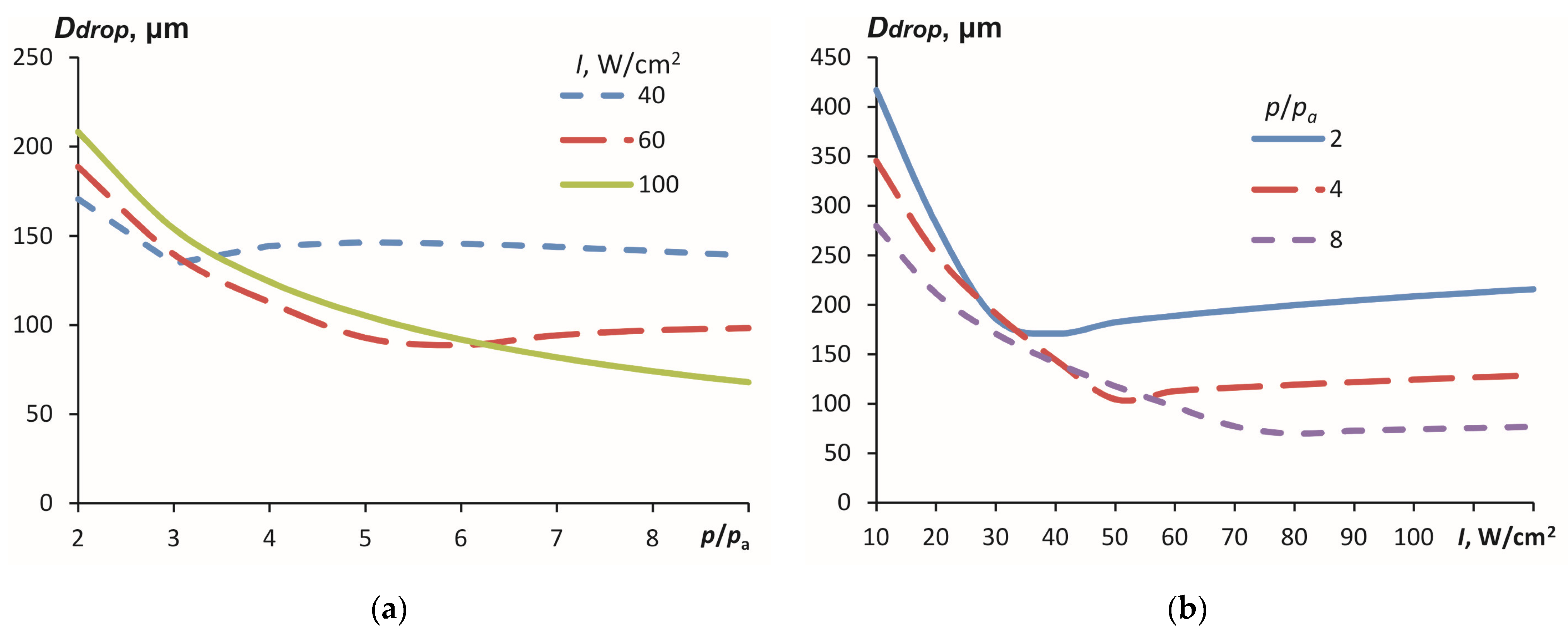

4.2.3. Droplet Size

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | vibration amplitude (m) |

| c | sound speed (m/s) |

| D0 | diameter of the cavitation element (m) |

| D32 | Sauter diameter of droplets (m) |

| Dc | diameter of the bubbles (m) |

| Dcr | critical diameter of cavitation bubbles (m) |

| Ddrop | minimum diameter of the droplet (m) |

| Dend | diameter of the cavitation element before destruction (m) |

| Dmax | maximum diameter of the bubble before destruction (m) |

| I | ultrasound intensity (W/m2) |

| Icr | critical intensity (W/m2) |

| k | increasing coefficient for droplet diameter |

| L | height of the cavitation zone (m) |

| N | number of cavitation bubbles |

| p | hydrostatic pressure (Pa) |

| pa | atmospheric pressure (Pa) |

| pcr | cavitation pressure threshold (Pa) |

| pmin | minimum pressure in the bubble (Pa) |

| ps | vapor pressure of the liquid (Pa) |

| Q | volumetric flow rate of the liquid (m3/s) |

| S1 | area of the end part of the ultrasonic emitter (m2) |

| S2 | area of the outlet (m2) |

| S3 | cross-sectional area of the tube (m2) |

| Sc | area of the surface of cavitation bubble (m2) |

| V1 | flow velocity in the cavitation zone (m/s) |

| Vx | flow velocity after the outflow (m/s) |

| Wc | volume of cavitation bubble (m3) |

| Wg | volume of gas (m3) |

| Wl | wave resistance (kg/(m2·s)) =ρ·c |

| Ww | volume of liquid (m3) |

| Greek letters | |

| γ | adiabatic index of liquid vapor |

| ε | S2/S1 |

| ρ | liquid density (kg/m3) |

| σ | liquid surface tension (N/m) |

| ω | ultrasound frequency (Hz) |

| Dimensionless numbers | |

| K | cavitation coefficient |

| X | hydrodynamic cavitation threshold |

References

- Vasilyev, Y.A.; Domrina, E.S.; Kaufman, S.V.; Maiorova, A.I. Classification of atomization devices. J. Phys. Conf. Ser. 2019, s1359, 012131. [Google Scholar] [CrossRef]

- Gong, J.; Fan, W.; Peng, J. Application analysis of hydraulic nozzle and rotary atomization sprayer on plant protection UAV. Int. J. Precis. Agric. Aviat. 2019, 2, 25–29. [Google Scholar] [CrossRef]

- Inoue, C.; Watanabe, T.; Himeno, T. Liquid sheet dynamics and primary breakup characteristics at impingement type injector. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Denver, CO, USA, 2–5 August 2009; p. 5041. [Google Scholar] [CrossRef]

- Moiz, A.A.; Naber, J.; Lee, S.Y.; Barros, S.; Atkinson, W. High-Speed Spray-to-Spray Collision Study on Two-Hole Impinging Jet Nozzles; SAE Technical Paper 2015-01-0948; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Wang, P.; Yang, W. Pneumatic rotary nozzle structure optimization design and airflow characteristics analysis. Adv. Mech. Eng. 2023, 15, 16878132231195016. [Google Scholar] [CrossRef]

- Lefebvre, A.H.; McDonell, V.G. Atomization and Sprays; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Nandiyanto, A.B.D.; Okuyama, K. Progress in developing spray-drying methods for the production of controlled morphology particles: From the nanometer to submicrometer size ranges. Adv. Powder Technol. 2011, 22, 1–19. [Google Scholar] [CrossRef]

- Hanft, D.; Exner, J.; Schubert, M.; Stöcker, T.; Fuierer, P.; Moos, R. An overview of the aerosol deposition method: Process fundamentals and new trends in materials applications. J. Ceram. Sci. Technol. 2015, 6, 147–182. [Google Scholar] [CrossRef]

- Schubert, M.; Hanft, D.; Nazarenus, T.; Exner, J.; Schubert, M.; Nieke, P.; Moos, R. Powder aerosol deposition method—Novel applications in the field of sensing and energy technology. Funct. Mater. Lett. 2019, 12, 1930005. [Google Scholar] [CrossRef]

- Dolovich, M.B.; Dhand, R. Aerosol drug delivery: Developments in device design and clinical use. Lancet 2011, 377, 1032–1045. [Google Scholar] [CrossRef] [PubMed]

- Gallego-Juárez, J.A.; Graff, K.F.; Lucas, M. (Eds.) Power Ultrasonics: Applications of High-Intensity Ultrasound; Woodhead Publishing: London, UK, 2023. [Google Scholar]

- Kustron, P.; Korzeniowski, M.; Sajbura, A.; Piwowarczyk, T.; Kaczynski, P.; Sokolowski, P. Development of High-Power Ultrasonic System Dedicated to Metal Powder Atomization. Appl. Sci. 2023, 13, 8984. [Google Scholar] [CrossRef]

- Guerra-Bravo, E.; Lee, H.-J.; Baltazar, A.; Loh, K.J. Vibration Analysis of a Piezoelectric Ultrasonic Atomizer to Control Atomization Rate. Appl. Sci. 2021, 11, 8350. [Google Scholar] [CrossRef]

- Ramisetty, K.A.; Pandit, A.B.; Gogate, P.R. Investigations into Ultrasound Induced Atomization. Ultrason. Sonochem. 2013, 20, 254–264. [Google Scholar] [CrossRef] [PubMed]

- Khmelev, V.N.; Shalunov, A.V.; Khmelev, S.S.; Tsyganok, S.N. Ultrasound. Devices and Technologies: Monograph; AltSTU Publishing House: Biysk, Russia, 2015. (In Russian) [Google Scholar]

- Brennen, C.E. Cavitation and Bubble Dynamics; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Rosenberg, L.D. Physical Foundations of Ultrasonic Technology; Nauka: Moscow, Russia, 1970. (In Russian) [Google Scholar]

- Kedrinsky, V.K. Hydrodynamics of explosion. Appl. Mech. Tech. Phys. 1987, 28, 491–515. [Google Scholar] [CrossRef]

- Kudryashova, O.B.; Muravlev, E.V.; Vorozhtsov, B.I. Generation of a Fine Aerosol in a Cavitation Regime. J. Eng. Phys. Thermophys. 2020, 93, 1138–1146. [Google Scholar] [CrossRef]

- Wang, Z.H.; Liu, X.Y.; Zhang, H.Q.; Wang, Y.; Xu, Y.F.; Peng, B.L.; Liu, Y. Modeling of kinetic characteristics of alkaline-surfactant-polymer-strengthened foams decay under ultrasonic standing wave. Petrol. Sci. 2020, 19, 1825–1839. [Google Scholar] [CrossRef]

- Lang, R.J. Ultrasonic atomization of liquids. J. Acoustic. Soc. Am. 1962, 34, 6–8. [Google Scholar] [CrossRef]

- Pages, D.G.; Galustov, V.S. Fundamentals of Liquid Spraying Technique; Chemistry: Moscow, Russia, 1984. (In Russian) [Google Scholar]

| p/pa | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

|---|---|---|---|---|---|---|---|---|---|

| Icr, W/cm2 | 70 | 190 | 146 | 126 | 111 | 71 | 44 | 39 | 42 |

| 80 | 217 | 139 | 122 | 98 | 73 | 77 | 35 | 28 |

| p/pa | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|

| Icr, W/cm2 | 26 | 31 | 49 | 55 | 82 | 86 | 104 | 112 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kudryashova, O.; Shalunov, A.; Genne, D.; Dorovskikh, R.; Titov, S. Innovative Acoustic-Hydraulic Method for High-Performance Fine Liquid Atomization. Appl. Sci. 2023, 13, 12330. https://doi.org/10.3390/app132212330

Kudryashova O, Shalunov A, Genne D, Dorovskikh R, Titov S. Innovative Acoustic-Hydraulic Method for High-Performance Fine Liquid Atomization. Applied Sciences. 2023; 13(22):12330. https://doi.org/10.3390/app132212330

Chicago/Turabian StyleKudryashova, Olga, Andrey Shalunov, Dmitry Genne, Roman Dorovskikh, and Sergey Titov. 2023. "Innovative Acoustic-Hydraulic Method for High-Performance Fine Liquid Atomization" Applied Sciences 13, no. 22: 12330. https://doi.org/10.3390/app132212330