Numerical Simulation of Seepage Surface and Analysis of Phreatic Line Control from a Fine-Grained Tailings High Stacked Dam under Complicated Geography Conditions

Abstract

:1. Introduction

2. Materials and Methods

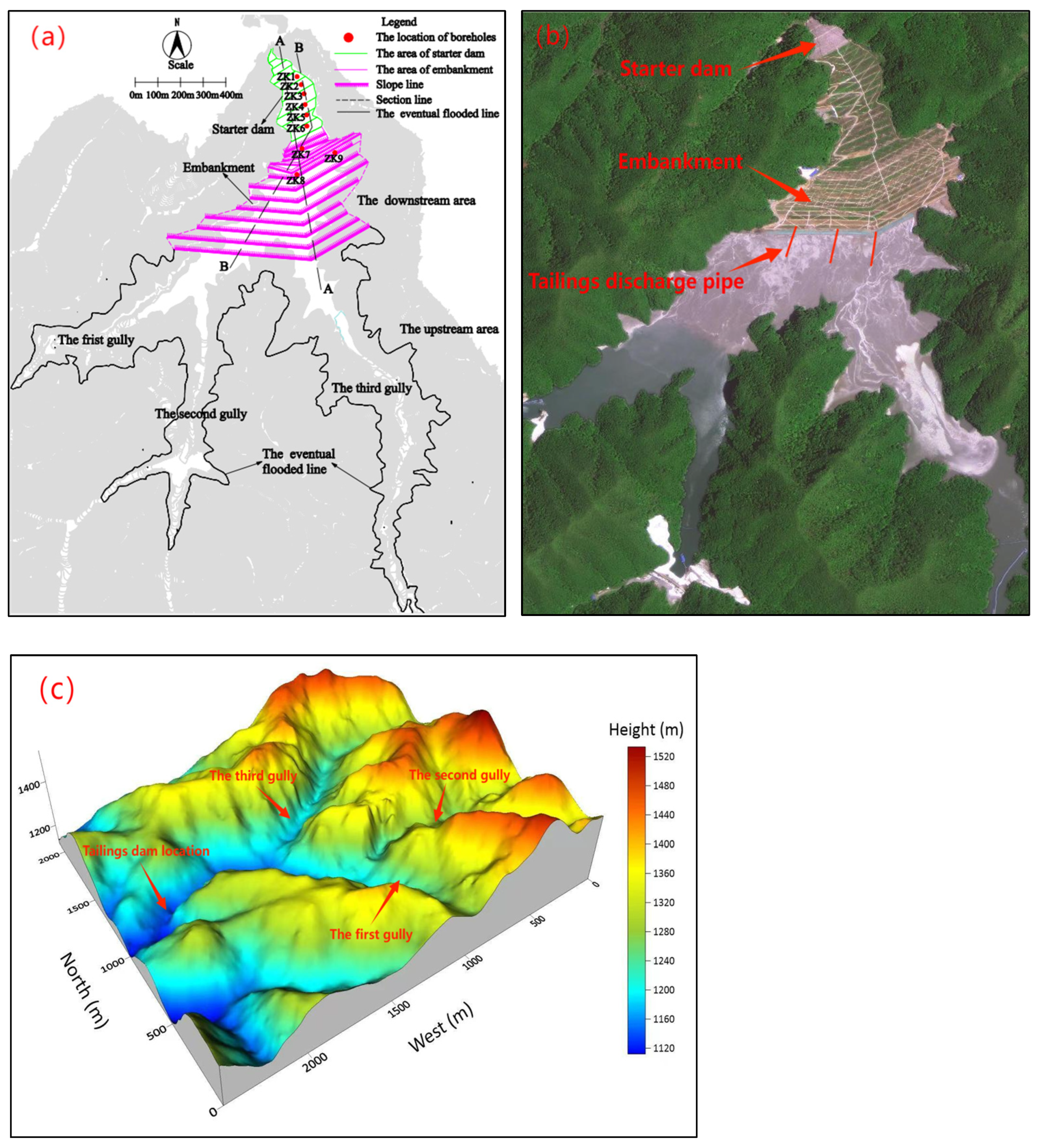

2.1. Basic Information about Tailings Dam

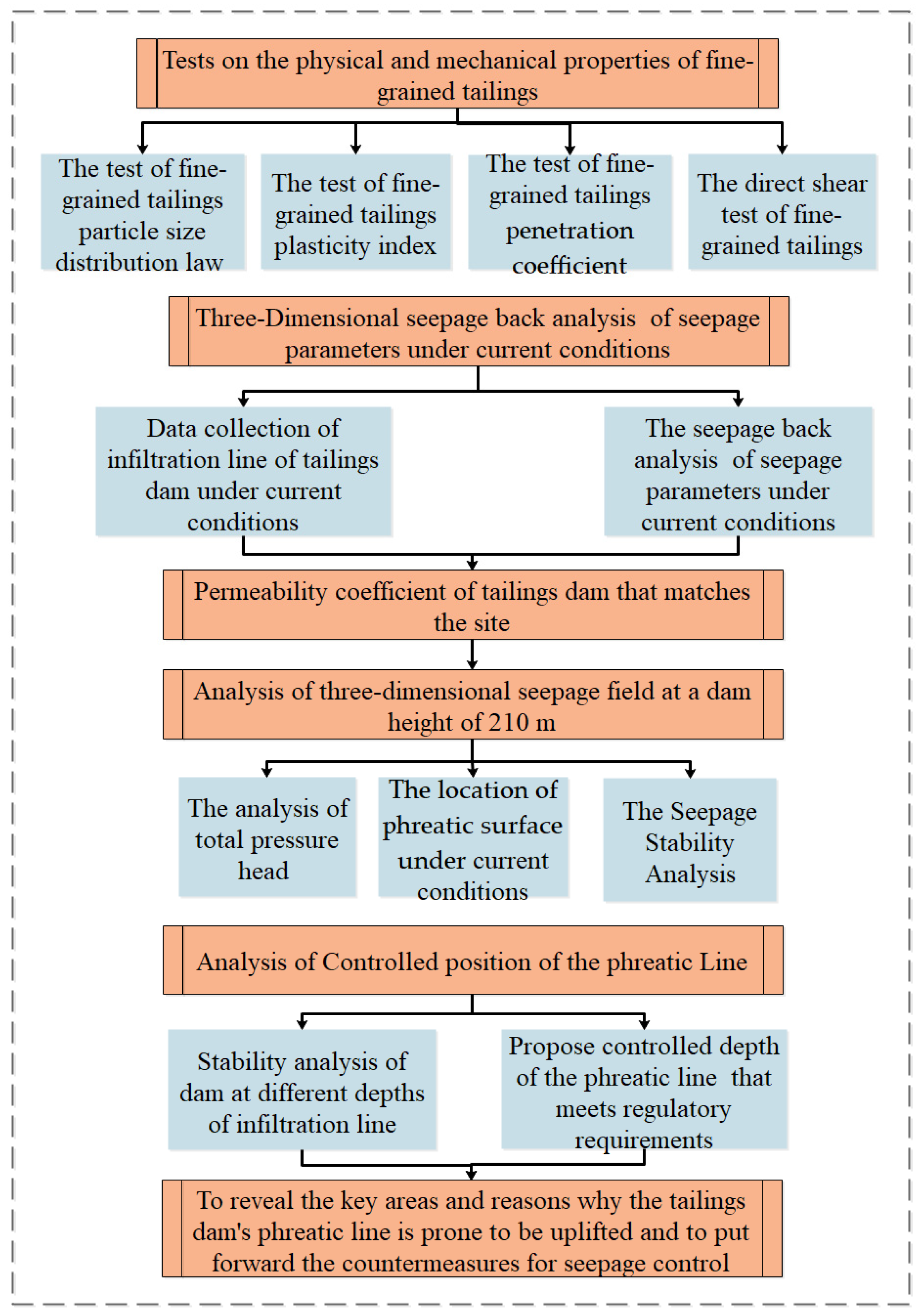

2.2. Research Processes

2.3. Physical Properties of Tailings Material

| Tailings Particle Size Range/mm | Mass Content/% |

|---|---|

| ≥0.074 | 29.4 |

| ≥0.037~<0.074 | 27.2 |

| ≥0.019~<0.037 | 5.4 |

| ≥0.005~<0.019 | 22.5 |

| <0.005 | 15.5 |

| Materials | Fine Sand Tailings | Silty Sand Tailings | Silt Tailings | Silty Clay Tailings |

|---|---|---|---|---|

| Density (KN/m3) | 17.9 | 19.4 | 20.1 | 19.9 |

| Particles with particle size larger than 0.074 mm (%) | 88.2 | 60.4 | 40.3 | 28.4 |

| Mean particle size/dp (mm) | 0.26 | 0.10 | 0.06 | 0.04 |

| Plasticity index | / | / | 8.1 | 14.7 |

| Penetration coefficient (cm/sec) | 3.25 × 10−4 | 1.93 × 10−4 | 1.02 × 10−4 | 0.16 × 10−4 |

| Internal friction angle/φ (°) | 33.8 | 31.0 | 26.2 | 16.7 |

| Cohesion values/c (kPa) | 8.3 | 9.3 | 10.1 | 4.9 |

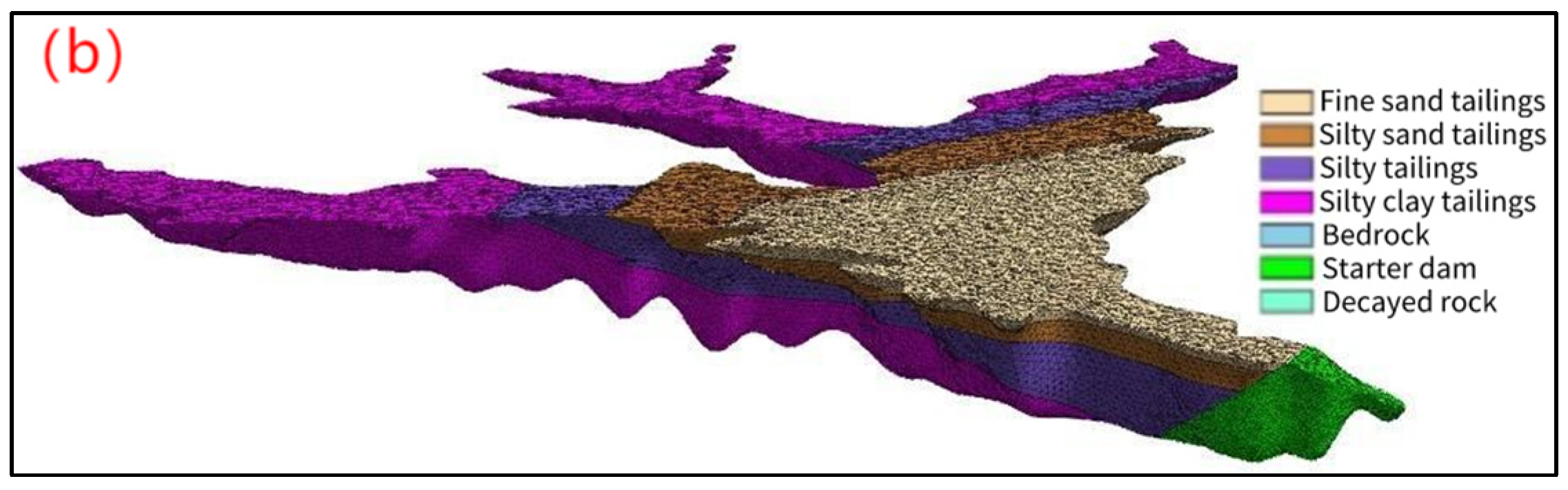

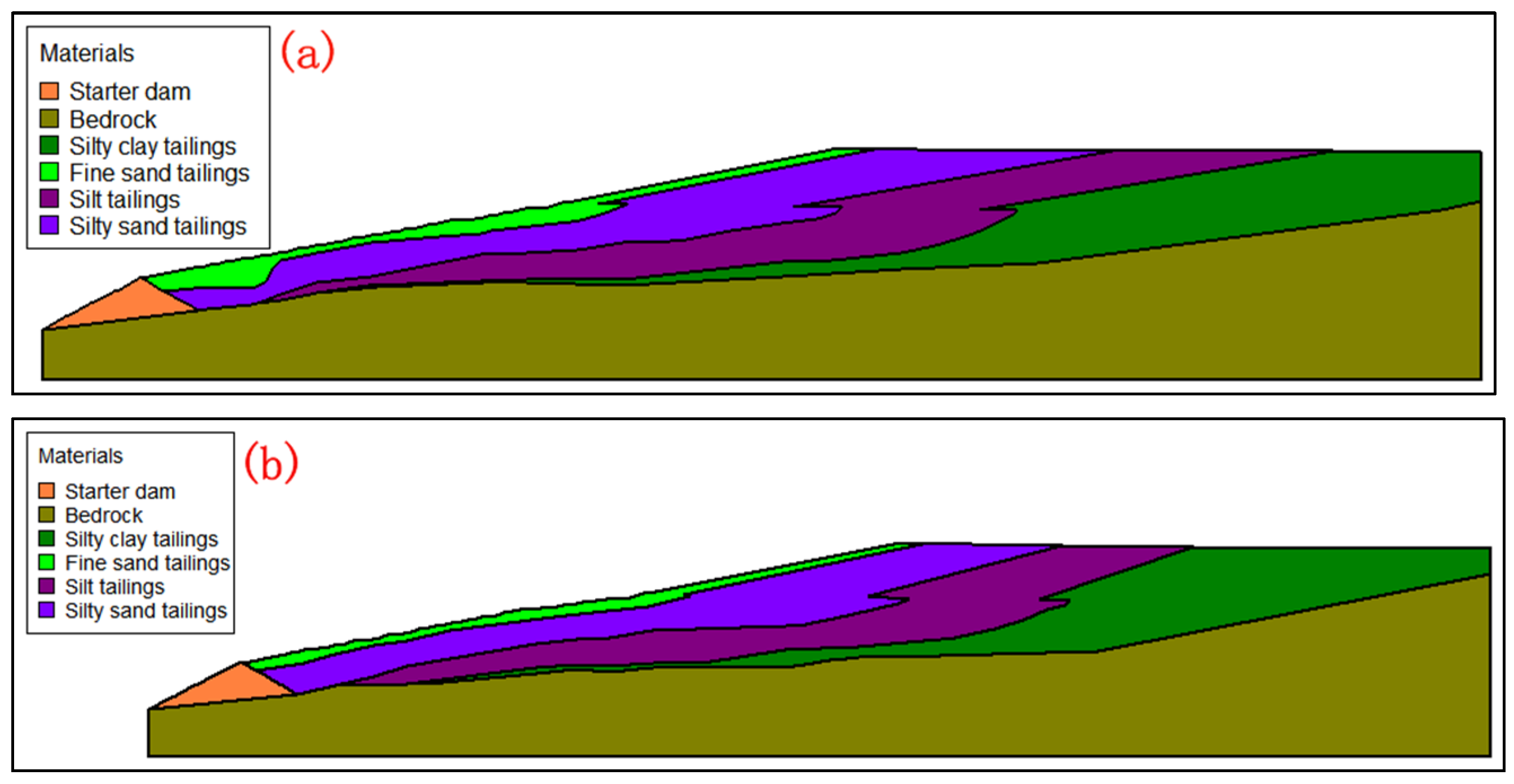

2.4. Tailings Dam Model

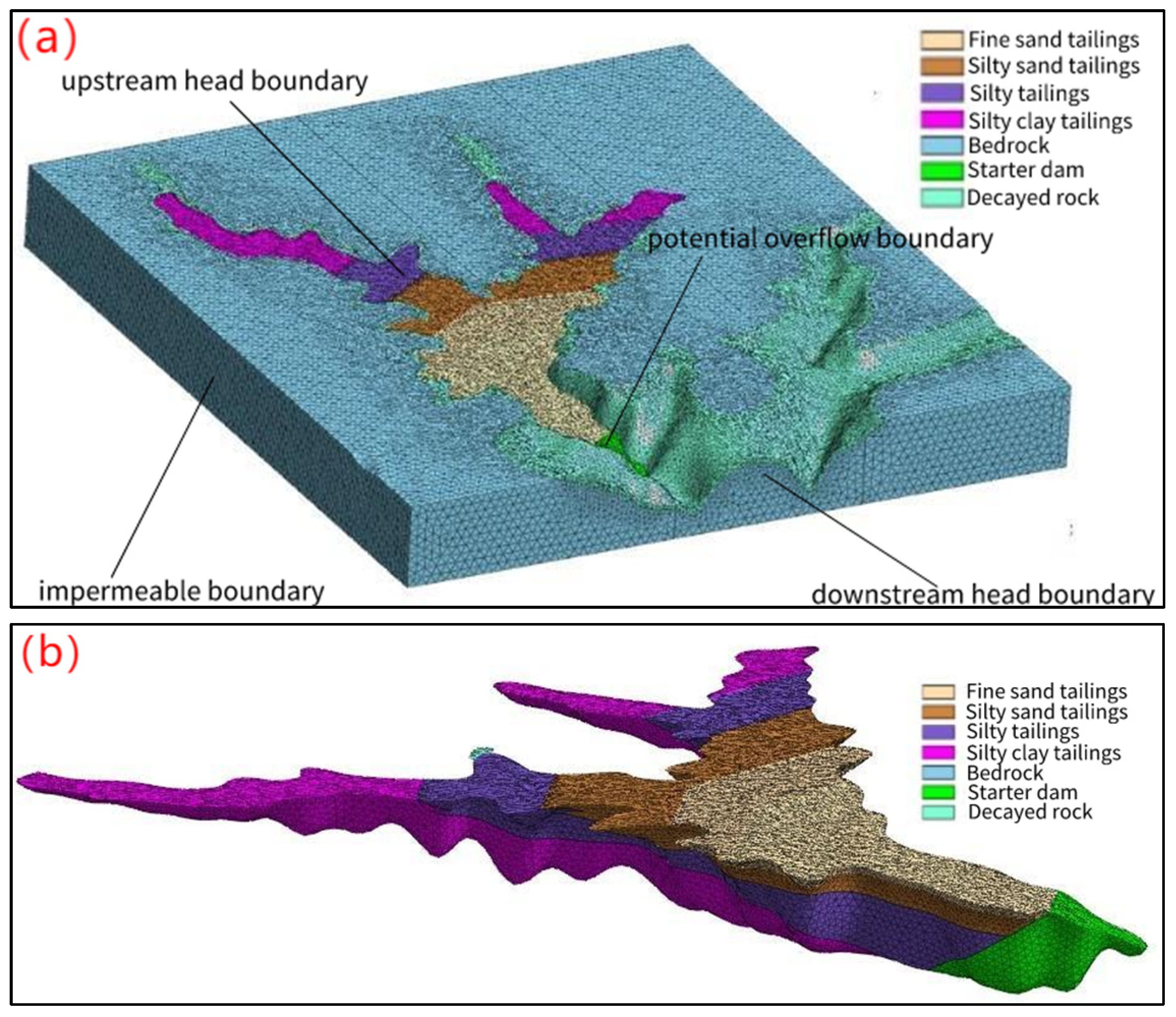

2.4.1. Three-Dimensional Seepage Back Analysis Model

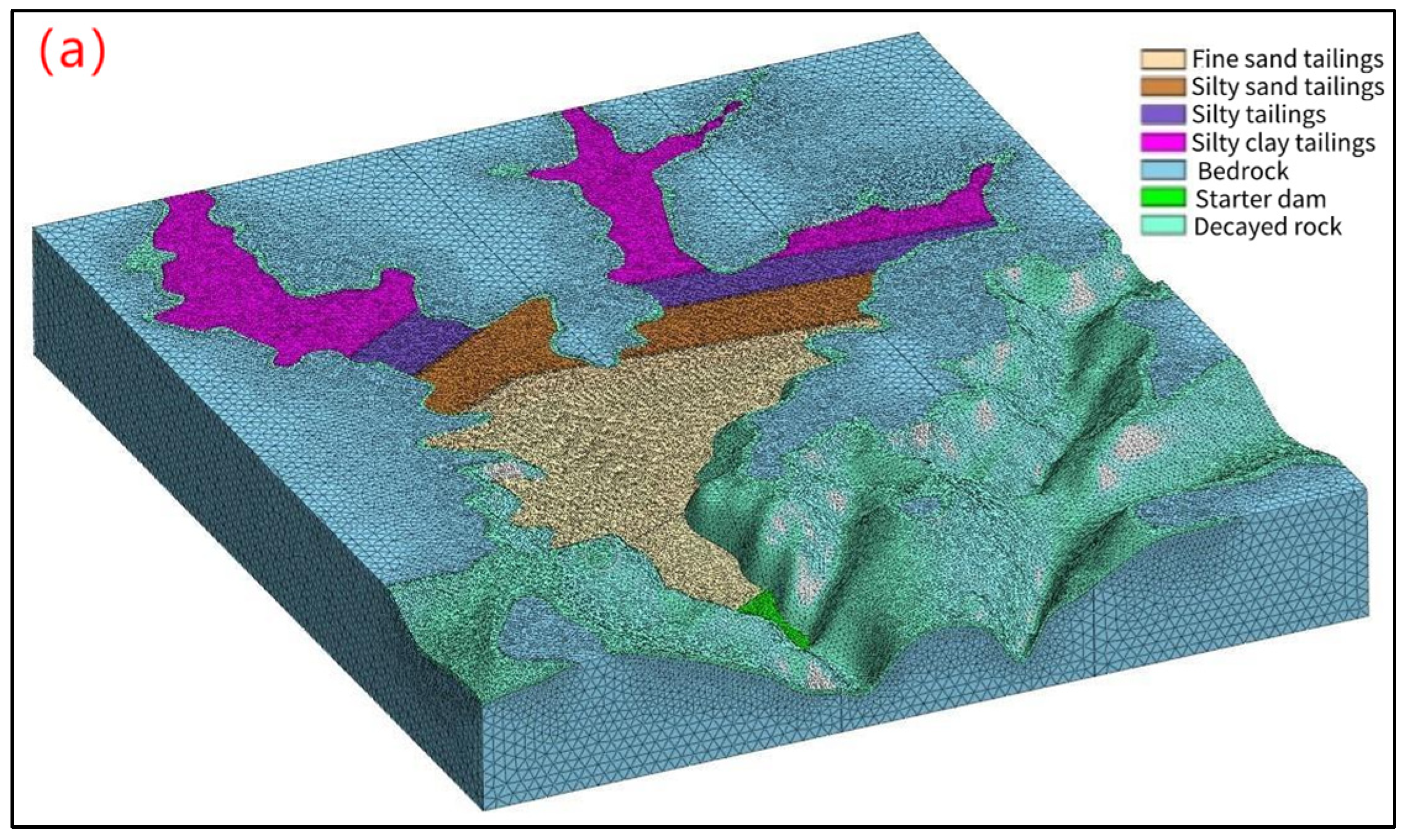

2.4.2. The Model of Three-Dimensional Seepage Simulation and Stability Analysis

3. Results

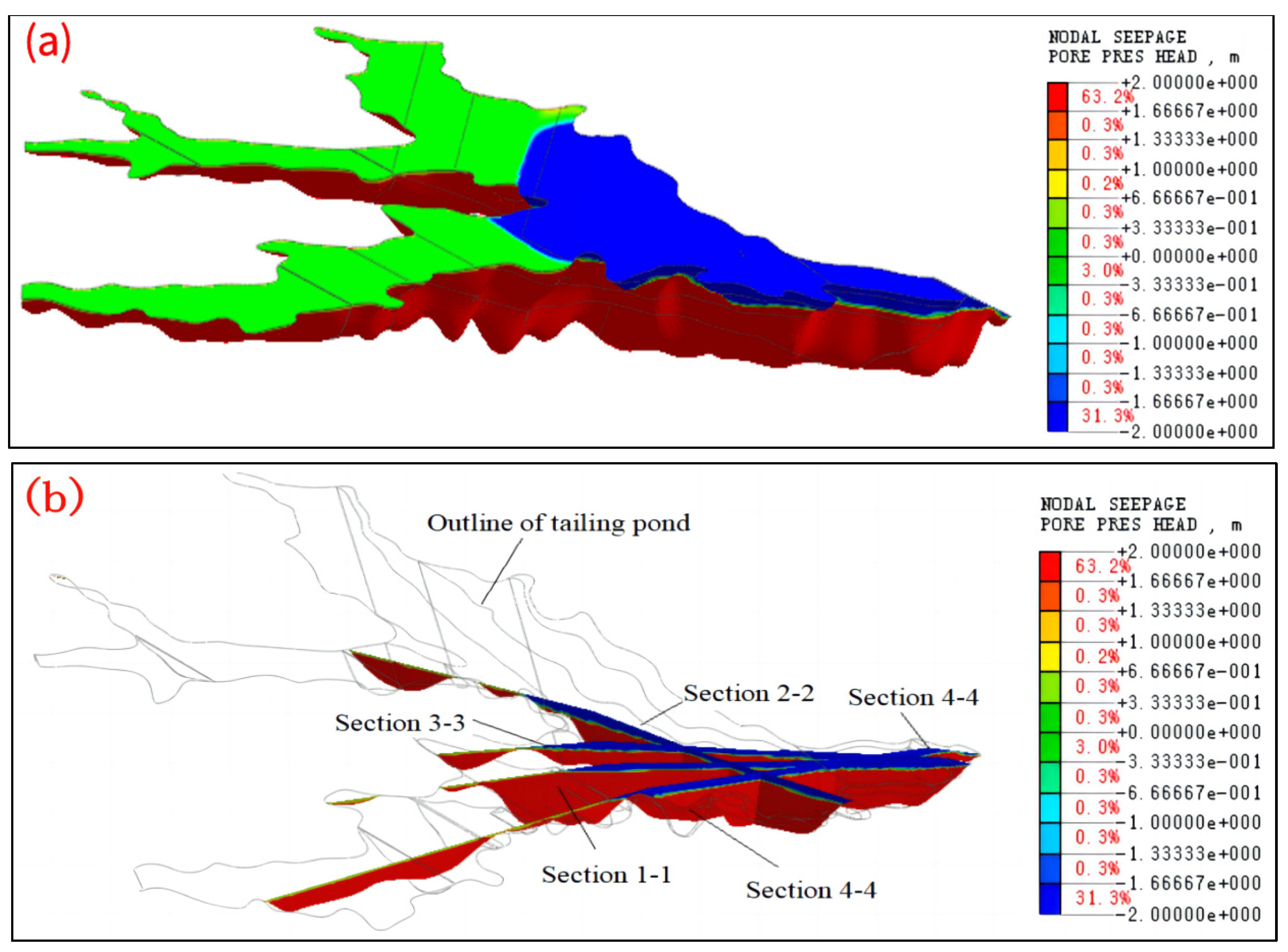

3.1. Three-Dimensional Seepage Back Analysis of the Penetration Coefficient

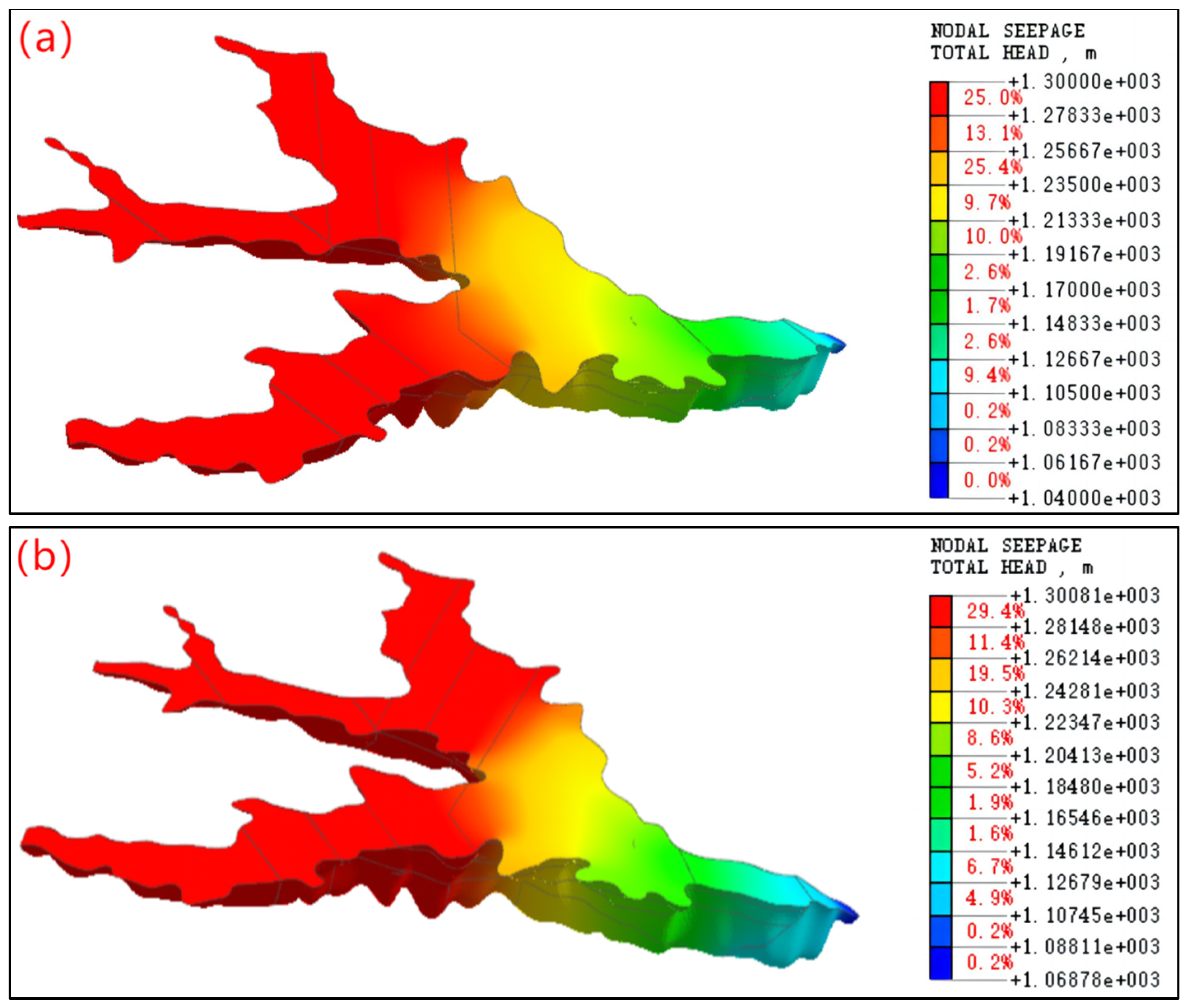

3.2. Analysis of Three-Dimensional Seepage Field at a Dam Height of 210 m

- (1)

- The total head value decreased gradually from upstream to downstream. Taking the flood condition as an example, the maximum value of the upstream head was 1300 m and the minimum value of the downstream head was 1060 m, which was in accordance with the engineering law. The distribution pattern of the total pressure head in the flood condition was basically consistent with that in the normal water-level condition, but the overall distribution increased slightly in the direction of the starter dam, mainly because the length of the beach width in the flood condition was smaller than the length of the dry beach in the normal water-level condition.

- (2)

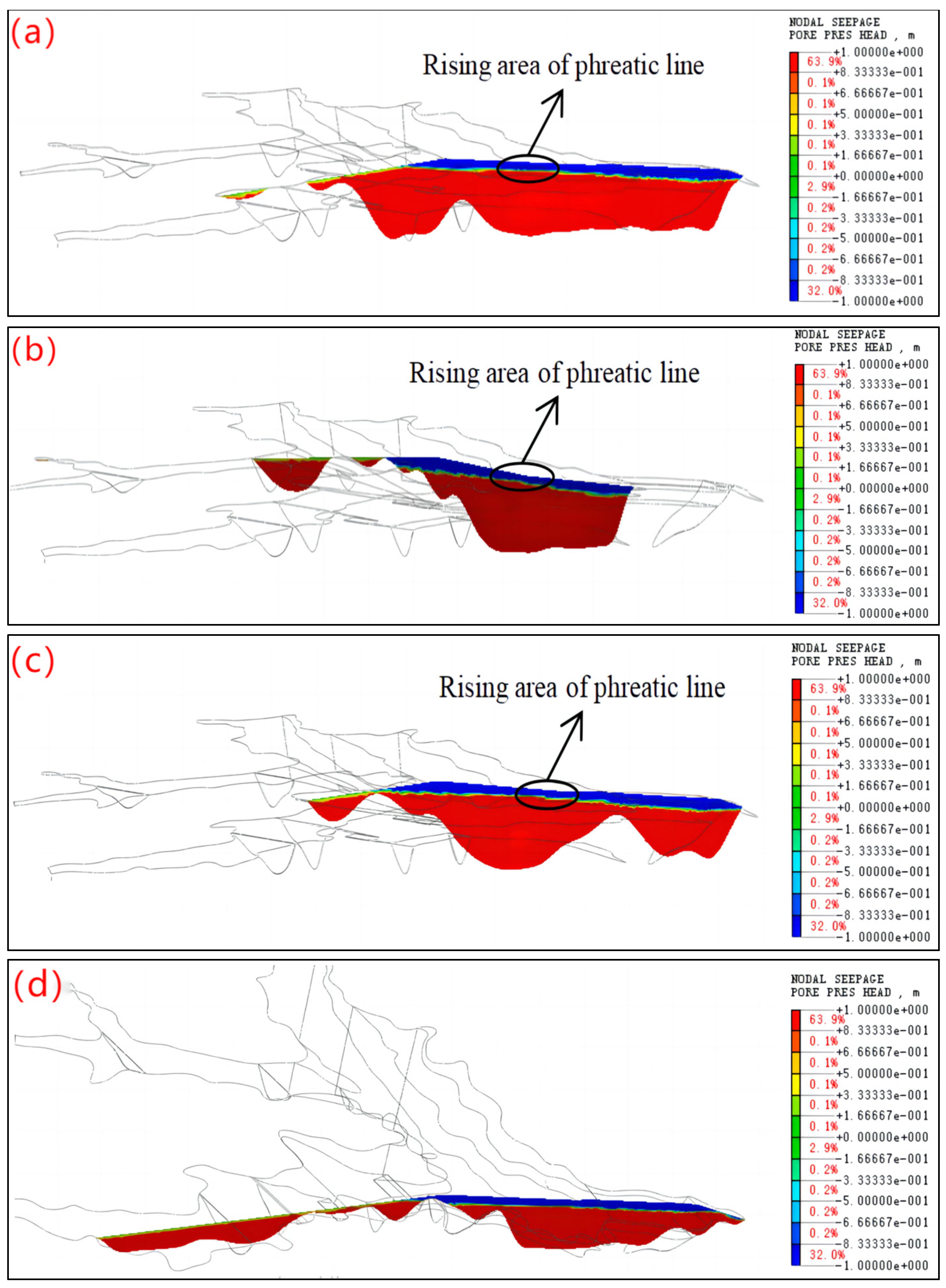

- Under normal water-level conditions, the phreatic surface was uniformly distributed, presenting shallow upper and deeper lower parts, rapidly decreasing after infiltration from the beach surface, and then infiltrating downward along the tailing chalk layer to reach the overflow near the initial dam. The location of the phreatic line of most of the areas of the embankment was approximately 25 m~28 m. Under the flood-level condition, the distribution pattern of the phreatic line was similar to that of the normal water-level condition. However, due to the relatively high water level, the location of the phreatic surface of the dam was elevated compared to that of the normal water-level condition, and the depth of the phreatic line of the embankment was approximately 23~25 m in most areas.

- (3)

- The distribution patterns of the phreatic lines in the four profiles were basically the same; neither no seepage overflow from the stacked dam slopes nor the starter dam slopes occurred, and all of them showed a relative elevation of the measured phreatic lines at the turn of the gully.

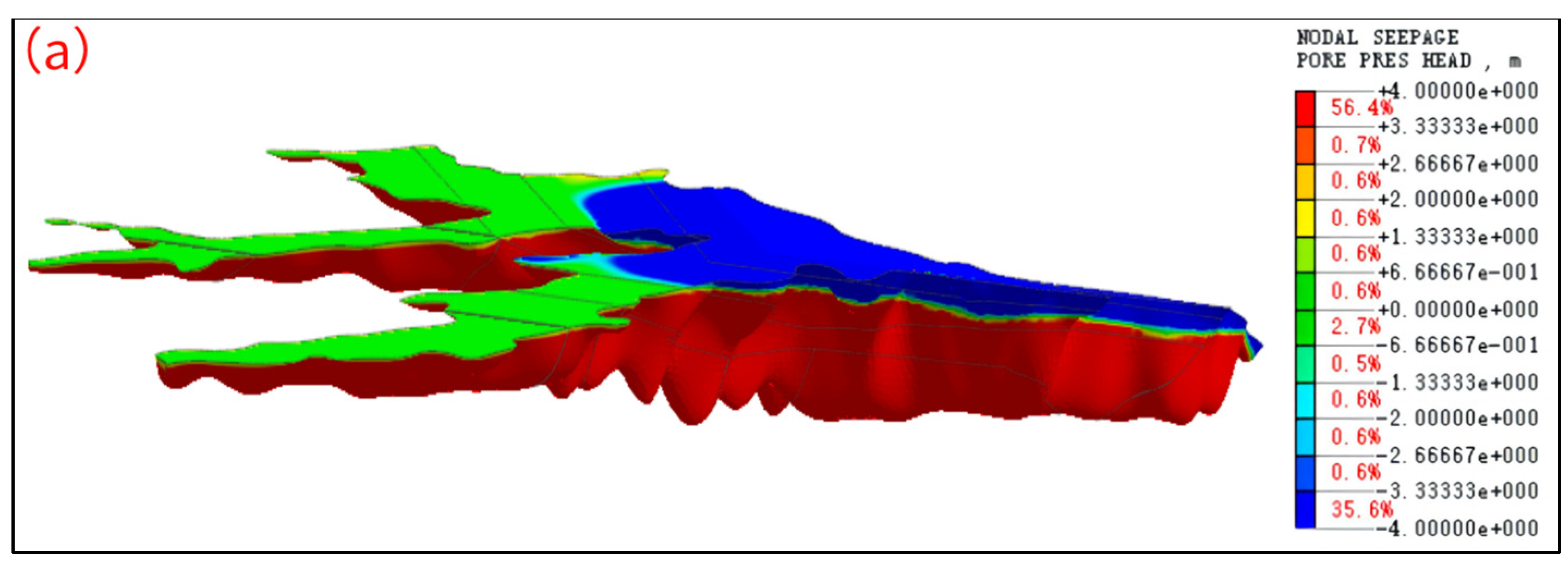

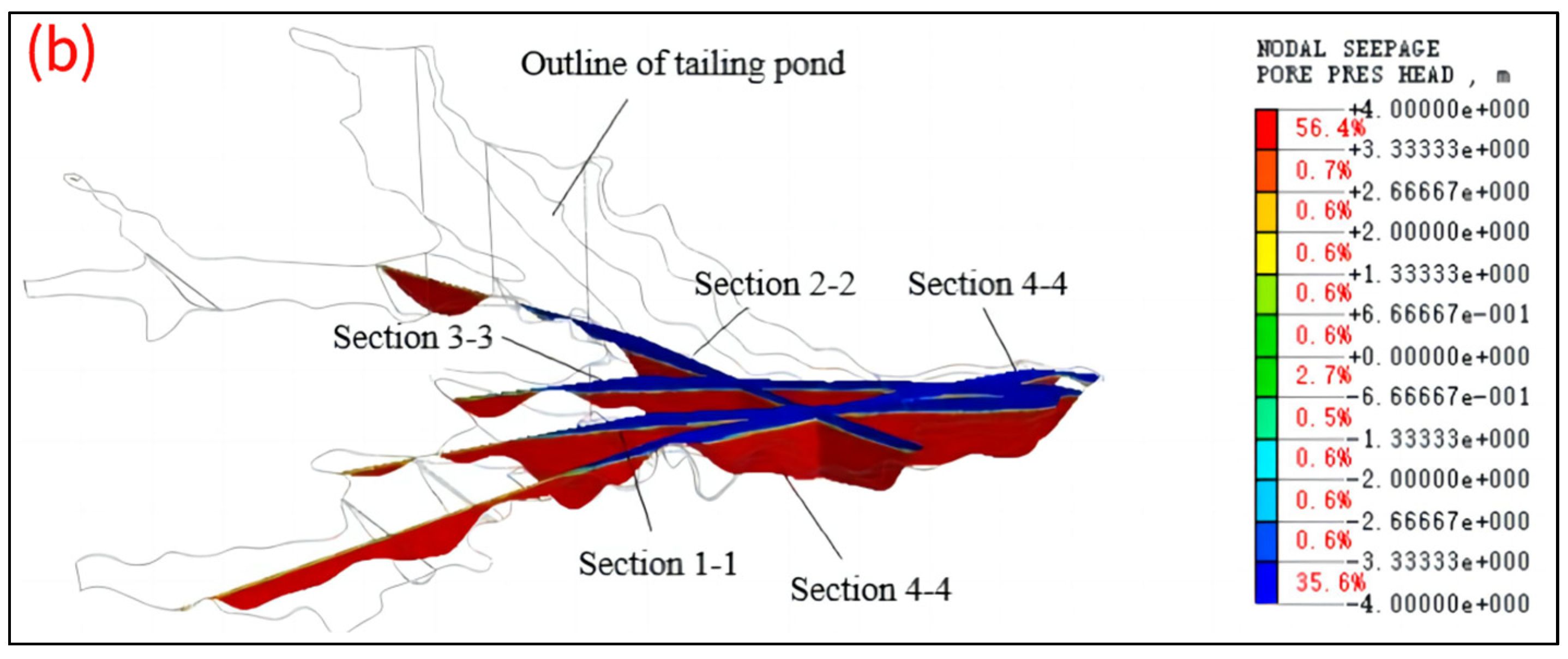

3.3. Regional Analysis of the Minimum Phreatic Line of Dams

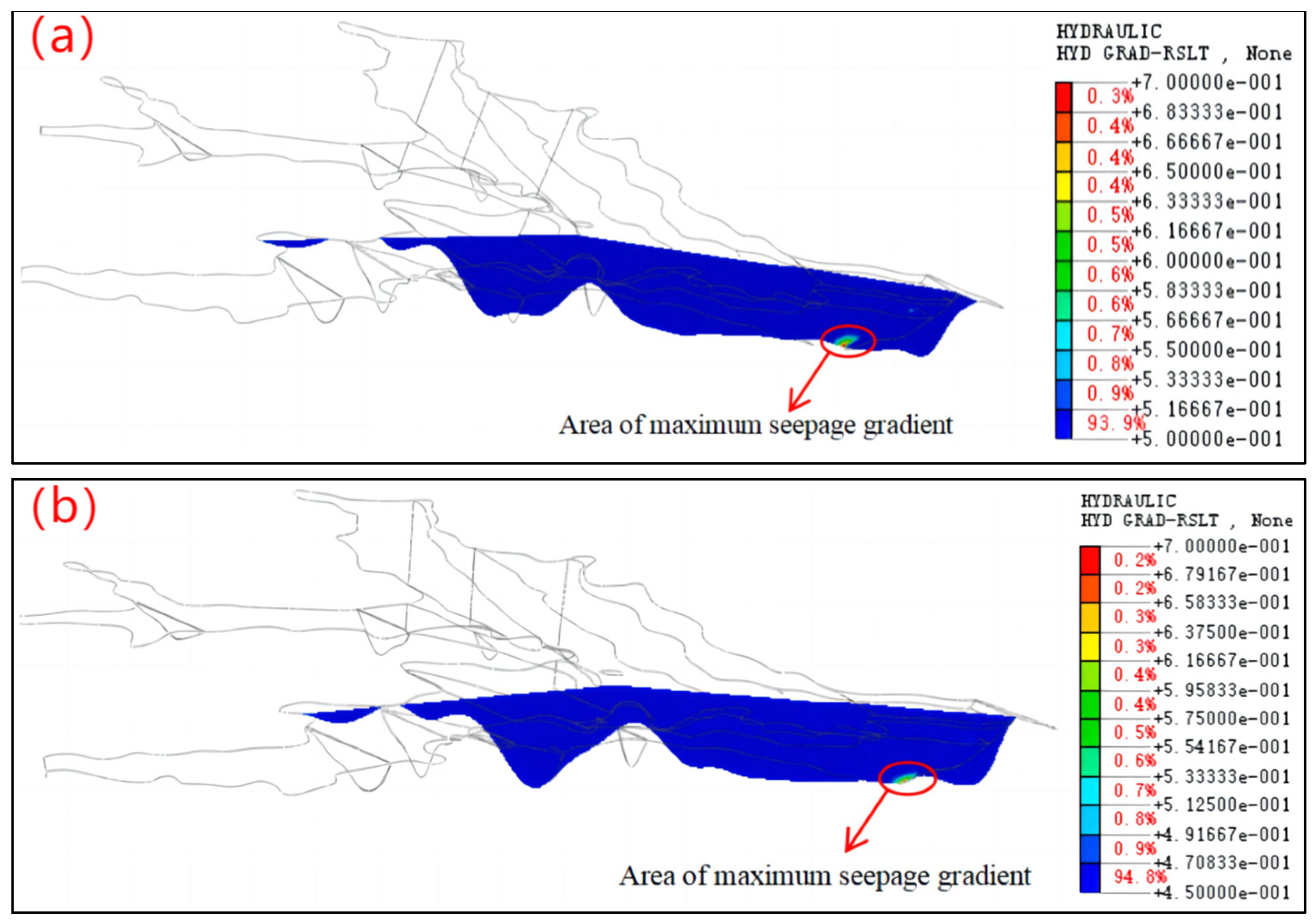

3.4. Seepage Stability Analysis

- (1)

- The seepage gradient of the dam body slightly increased under flood-level conditions compared to normal water-level conditions, which was due to the shortening of the seepage diameter under flood-level conditions.

- (2)

- Whether under flood-level conditions or normal water-level conditions, the seepage gradient of tailings near the starter dam slope was less than the critical seepage gradient of 1.02, indicating that there would be no seepage deformation or seepage damage, and the stability of seepage of the tailings dam body was safe.

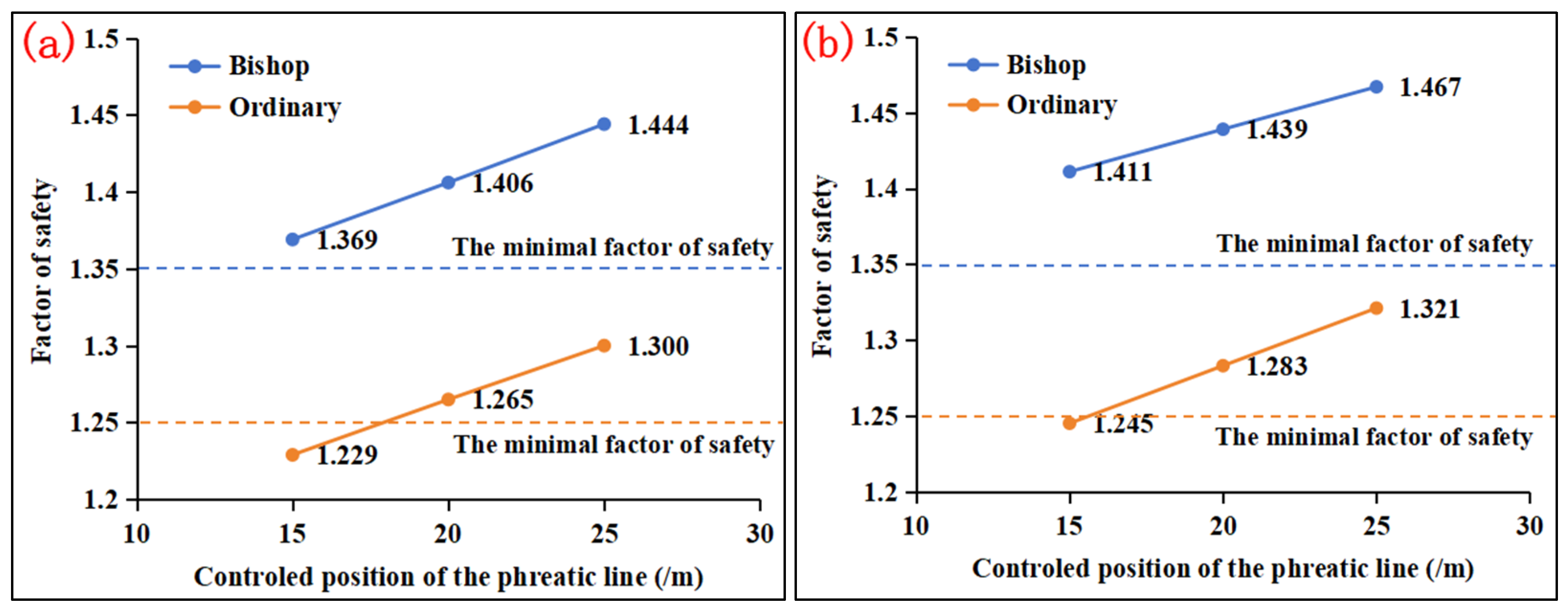

3.5. Analysis of Controlled Position of the Phreatic Line

- (1)

- For section A-A, when the controlled position of the phreatic line was at a buried depth of 20 m, the ordinary method calculation result under normal operation was 1.265 and was greater than the minimum safety factor specified of 1.250, while the simplified Bishop method calculation result was 1.406 and greater than the minimum safety factor specified of 1.350. When the controlled position of the phreatic line was at a buried depth of 15 m, the calculation result of the ordinary method under normal operation was 1.229, which was less than the minimum safety factor specified of 1.250. After the interpolation calculation, when the controlled position of the phreatic line was 19 m, the calculation result of the ordinary method was greater than 1.250, which meets the requirements of the specification. According to the “Safety Regulations for Tailings Ponds” (GB39496-2020), the buried depth of the controlled position of the phreatic line of the embankment should not be less than 1.2 times that obtained by calculation. Therefore, the controlled position of the phreatic line of section A-A was controlled at a buried depth of 23 m.

- (2)

- For Section B-B, when the controlled position of the phreatic line was at a buried depth of 20 m, the ordinary method calculation result under normal operation was 1.283 and was greater than the minimum safety factor specified of 1.250, while the simplified Bishop method calculation result was 1.439 and greater than the minimum safety factor specified of 1.350. When the controlled position of the phreatic line was at a buried depth of 15 m, the calculation result of the ordinary method under normal operation was 1.245, which was less than the minimum safety factor specified of 1.250. After the interpolation calculation, when the controlled position of the phreatic line was 16 m, the calculation result of the ordinary method was greater than 1.250, which meets the requirements of the specification. According to the “Safety Regulations for Tailings Ponds” (GB39496-2020), the buried depth of the controlled position of the phreatic line of the embankment should be more than 1.2 times that obtained by calculation. Therefore, the controlled position of the phreatic line of section B-B was controlled at a buried depth of 19.2 m.

- (3)

- According to the stability test results of different controlled positions of the phreatic lines for Sections A-A and B-B, it can be concluded that the stability requirements and minimum controlled position of the phreatic line requirements could be met when the controlled position of the phreatic line was 23 m.

4. Analysis and Discussion

- (1)

- The seepage from three valleys was superimposed in the common area of the three valleys in the tailings dam; therefore, the seepage amount in this area was larger than that in other areas.

- (2)

- The confluence area was affected by the conditions of valley and reservoir types, and the length of the dam axis was significantly narrowed, forming a bottleneck effect.

- (3)

- The second gully in this area turned and the dam body deflected. In addition, due to the blocking effect of the left bank mountain, the left phreatic line in this area was slightly higher than the right phreatic line.

5. Conclusions

- (1)

- This study used seepage back analysis to obtain the permeability coefficients of tailings in different layers and conducted an analysis of the mutual influence law of seepage field by the coefficients, revealing the key areas and reasons, and proposed countermeasures for seepage control. These findings will provide reference and guidance for the construction and daily safety management of high pile tailings dams with fine-grained tailings under similar complex terrain conditions. The next study will investigate the impact of different drainage measures on the control of seepage in sensitive areas and conduct on-site practice.

- (2)

- Back analysis using drilling data to establish a finite element model was a very practical and effective method in practical engineering, which could accurately reflect the actual permeability coefficient of each partition of tailings dams and lay the foundation for the later seepage calculation of the tailings dam.

- (3)

- Due to the comprehensive influence of complicated geography conditions such as multiple areas of seepage accumulation, large valley corners, and narrowing of the dam axis, there was a significant difference in the spatial seepage characteristics of a high fine-grained tailings dam. In the region of 1220 m to 1250 m a.s.l. on the left shoulder of the tailing dam, the phreatic line was elevated by 2 m~3 m compared to the surrounding area and was the most critical region of the tailings dam seepage control.

- (4)

- The seepage gradient of the starter dam at the inner slope foot was the largest, which was smaller than the critical seepage gradient, and seepage failure could not occur. When the tailings dam was 210 m high, the depth of the phreatic line was controlled to be 23 m, which could be easily controlled by setting corresponding drainage facilities.

- (5)

- In addition to strengthening the daily monitoring of the key areas of the tailings dam, it was critical to control the local phreatic line and ensure the safe of the tailings dam by adopting local horizontal seepage drainage measures or radiation wells. It is recommended to carry out determination tests of the permeability coefficient and particle size at regular intervals, and ensure that the permeability coefficient of the tailing sand does not change accordingly, and strengthen the monitoring of the exfiltration facilities. The research results can possibly be applied to a tailing dam with similar geological conditions, particle size distribution, sedimentation pattern, and permeability coefficient as this tailing dam.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, E.; Zhang, X.; Li, Z. The internet of things (IOT) and cloud computing (CC) based tailings dam monitoring and pre-alarm system in mines. Safety Sci. 2012, 50, 811–815. [Google Scholar] [CrossRef]

- Mura, J.; Gama, F.; Paradella, W.; Negrão, P.; Carneiro, S.; de Oliveira, C.; Brandão, W. Monitoring the Vulnerability of the Dam and Dikes in Germano Iron Mining Area after the Collapse of the Tailings Dam of Fundão (Mariana-MG, Brazil) Using DInSAR Techniques with TerraSAR-X Data. Remote Sens. 2018, 10, 1507. [Google Scholar] [CrossRef]

- Yin, G.; Li, G.; Wei, Z.; Wan, L.; Shui, G.; Jing, X. Stability analysis of a copper tailings dam via laboratory model tests: A Chinese case study. Miner. Eng. 2011, 24, 122–130. [Google Scholar] [CrossRef]

- Zou, W.; Zhang, Q.; Shi, L.; Miao, Y. Release Rules and Groundwater Contamination Risk of Heavy Metals from Dump and Tailings Pond of a Copper Mine in Jiangxi. Nonferrous Met. Eng. 2016, 6, 90–94. [Google Scholar]

- Wang, G.; Hu, B.; Tian, S.; Ai, M.; Liu, W.; Kong, X. Seepage field characteristic and stability analysis of tailings dam under action of chemical solution. Sci. Rep. 2021, 11, 4073. [Google Scholar] [CrossRef]

- Santamarina, J.C.; Torres-Cruz, L.A.; Bachus, R.C. Why coal ash and tailings dam disasters occur. Science 2019, 364, 526–528. [Google Scholar] [CrossRef]

- Liang, Y. Tailings Dam Collapse in Nandan on 18 October. Coast. Environ. 2000, 12, 7. [Google Scholar]

- Palmer, J. Anatomy of a Tailings Dam Failure and a Caution for the Future. Engineering 2019, 5, 605–606. [Google Scholar] [CrossRef]

- Van Niekerk, H.J.; Viljoen, M.J. Causes and consequences of the Merriespruit and other tailings-dam failures. Land. Degrad. Dev. 2005, 16, 201–212. [Google Scholar] [CrossRef]

- Liu, H. Enlightenment of the Brumadinho Tailings Pond Collapse in Brazil to the Upstream Embankment. Nonferrous Met. Eng. Res. 2020, 41, 49–51. [Google Scholar]

- Chronology of Major Tailings Dam Failures, World Information Service on Energy. Available online: https://www.wise-uranium.org/mdaf.html (accessed on 21 December 2021).

- Azam, S.; Li, Q. Tailings dam failures: A review of the last one hundred years. Geotech. News 2010, 28, 50–54. [Google Scholar]

- Yong, W.; Li, X.K.; Xin, Z. Discussion on the causes for tailings dam accidents at home and abroad. Met. Mine 2009, 7, 139–142. [Google Scholar]

- Gan, H.; Bi, Q.; Cui, X. Three-dimensional seepage field analysis of high-stack tailings dam by upstream method under complex reservoir type condition. Nonferr. Metal. 2018, 70, 26–30. [Google Scholar]

- Shahriari, M.; Aydin, M.E. Lessons Learned from Analysis of Los Frailes Tailing Dam Failure. In International Conference on Applied Human. Factors and Ergonomics; Springer: Cham, Switzerland, 2017; pp. 309–317. [Google Scholar]

- Gui, R.; He, G. The Effects of Internal Erosion on the Physical and Mechanical Properties of Tailings under Heavy Rainfall Infiltration. Appl. Sci. 2021, 11, 9496. [Google Scholar] [CrossRef]

- Kang, F.; Wang, G.; Li, Y.; Cai, B.; Li, S.; Zhao, L.; Li, X. Analysis of the Dynamic Stability of Tailing Dams: An Experimental Study on the Dynamic Characteristics of Tailing Silt. Appl. Sci. 2023, 13, 5250. [Google Scholar] [CrossRef]

- Chai, X.; Sheng, Y.; Liu, J.; Xu, Y.; Liu, H. Experimental Study on the Mechanical Properties of Saturated Tailing Sand with Different Particle Sizes. Appl. Sci. 2022, 12, 12231. [Google Scholar] [CrossRef]

- Zhang, C. Dynamic Properties of Tailings and the Stability Analysis of Tailings Dam; Institute of Rock & Soil Mechanics, The Chinese Academy of Sciences: Wuhan, China, 2005. [Google Scholar]

- Zhang, C.; Yang, C. Effect of fines content on liquefaction properties of tailings material. Rock Soil. Mech. 2006, 27, 1133–1137. [Google Scholar]

- Zhang, C.; Man, C.; Yang, C.; Chen, Q.; Pan, Z. Effects of particle diameter on shear strength of tailings and stability of tailings dams. Chin. J. Geotech. Eng. 2019, 41, 145–148. [Google Scholar]

- Li, Q.; Wu, B.; Li, X.; Jia, S.; Zhen, F.; Gao, S. The Relatively Stable Seepage Field: A New Concept to Determine Seepage Field in the Design of a Dry-Stack Tailings Pond. Appl. Sci. 2022, 12, 12123. [Google Scholar] [CrossRef]

- Qi, Q.; Zhang, L.; Li, G. Numerical simulation of 3-D seepage field in the tailings of complex terrain. J. Hydro. Eng. 2012, 31, 157–161. [Google Scholar]

- Liu, H.; Li, N.; Liao, X.; Gong, J.; Fang, F. Unsteady seepage analysis of tailing dams considering coupling of stress and seepage fields. Chin. J. Geotech. Eng. 2004, 23, 2870–2875. [Google Scholar]

- Zhang, C.; Chai, J.; Cao, J.; Xu, Z.; Qin, Y.; Lv, Z. Numerical Simulation of Seepage and Stability of Tailings Dams: A Case Study in Lixi, China. Water 2020, 12, 742. [Google Scholar] [CrossRef]

- Rico, M.; Benito, G.; Diez-Herrero, A. Floods from tailings dam failures. J. Hazard. Mater. 2008, 154, 79–87. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.; Liang, L.; Chen, T.; Xu, H.; Dong, T. The Seepage Calculation and the Drainage Design of Tailings Dam. Met. Mine. 2013, 6, 155–157. [Google Scholar]

- Bascetin, A.; Tuylu, S.; Adiguzel, D.; Eker, H.; Odabas, E. Numerical Modelling of Pb-Zn Mine Tailing Dam Based on Soil Stability. In Proceedings of the 18th Symposium on Environmental Issues and Waste Management in Energy and Mineral Production 2019, SWEMP 2018, Santiago, Chile, 19–23 November 2018; pp. 181–187. [Google Scholar]

- Bascetin, A.; Adiguzel, D.; Eker, H.; Tuylu, S. The investigation of geochemical and geomechanical properties in surface paste disposal by pilot-scale tests. Int. J. Min. Reclam. Env. 2022, 36, 537–551. [Google Scholar] [CrossRef]

- Yin, G.; Wei, Z.; Wang, L. Numerical simulation analysis about seepage field of Longdu tail bay. Rock Soil. Mech. 2003, 24, 25–28. [Google Scholar]

- Yin, G.; Jing, X.; Wei, Z.; Li, X. Study of model test of seepage character eristic and field measurement of course and fine tailings dam. Chin. J. Rock Mech. Eng. 2010, 29, 3710–3718. [Google Scholar]

- Deng, H.; Li, S.; Deng, J. 3D-numerical simulation on the stability of tailings dam under the coupled stress and seepage fields. J. Saf. Environ. 2016, 16, 133–138. [Google Scholar]

- Wang, W.; Yin, G.; Wei, Z.; Jing, X.; Yang, Y.; Chen, Y. Analysis of the dynamic response and stability of fine-grained tailings dam by upstream embankment method in the area of high intensity earthquake. Chin. J. Rock Mech. Eng. 2017, 36, 1201–1214. [Google Scholar]

- Yang, J.; Hu, J.; Wu, Y.; Zhang, B. Numerical Simulation of Seepage and Stability of Tailing Dams: A Case Study in Ledong, China. Sustainability 2022, 14, 12393. [Google Scholar] [CrossRef]

- Xu, Z.; Yang, X.; Chai, J.; Qin, Y.; Li, Y. Permeability Characteristics of Tailings considering Chemical and Physical Clogging in Lixi Tailings Dam, China. J. Chem. 2016, 2016, 8147845. [Google Scholar] [CrossRef]

- Yang, Y.; Wei, Z.; Cao, G.; Yang, Y.; Wang, H.; Zhuang, S.; Lu, T. A case study on utilizing geotextile tubes for tailings dams construction in China. Geotext. Geomembr. 2019, 47, 187–192. [Google Scholar] [CrossRef]

- Liu, C.; Shen, Z.; Gan, L.; Xu, L.; Zhang, K.; Jin, T. The Seepage and Stability Performance Assessment of a New Drainage System to Increase the Height of a Tailings Dam. Appl. Sci. 2018, 8, 1840. [Google Scholar] [CrossRef]

- Peng, K.; Zhou, J.; Zou, Q.; Zhang, J.; Wu, F. Effects of stress lower limit during cyclic loading and unloading on deformation characteristics of sandstones. Constr. Build. Mater. 2019, 217, 202–215. [Google Scholar] [CrossRef]

- Wu, T.; Qin, J. Experimental Study of a Tailings Impoundment Dam Failure Due to Overtopping. Mine Water Environ. 2018, 37, 272–280. [Google Scholar] [CrossRef]

- Jing, X.; Chen, Y.; Xie, D.; Williams, D.J.; Wu, S.; Wang, W.; Yin, T. The Effect of Grain Size on the Hydrodynamics of Mudflow Surge from a Tailings Dam-Break. Appl. Sci. 2019, 9, 2474. [Google Scholar] [CrossRef]

- Li, K.; Deng, X.; He, M.; Chai, J.; Li, S. Finite element modeling of back analysis of permeability coefficient of tailing dam based on boring data. Chin. J. Rock Mech. Eng. 2004, 23, 4329–4332. [Google Scholar]

- Xu, W.; Chai, J.; Chen, X.; Liu, Z.; Du, C. Inversion analysis of seepage parameters for Donggou tailing filling dam. Geotech. Investig. Surv. 2009, 37, 66–69. [Google Scholar]

| Borehole Number | ZK1 | ZK2 | ZK3 | ZK4 | ZK5 | ZK6 | ZK7 | ZK8 | ZK9 |

|---|---|---|---|---|---|---|---|---|---|

| Measured depth of phreatic line/m | 25.9 | 35.5 | 35.8 | 33.2 | 32.8 | 33.3 | 33.9 | 32.1 | 32.8 |

| Materials | Density (KN/m3) | Penetration Coefficient (cm/s) |

|---|---|---|

| Starter dam | 21.0 | 1.50 × 10−1 |

| Fine sand tailings | 17.9 | 7.24 × 10−4 |

| Silty sand tailings | 19.4 | 5.27 × 10−4 |

| Silt tailings | 20.1 | 2.51 × 10−4 |

| Silty clay tailings | 19.9 | 0.62 × 10−4 |

| Decayed rock | 22.0 | 2.02 × 10−6 |

| Bedrock | 27.0 | 3.10 × 10−6 |

| Operating Mode | Position | Critical Seepage Gradient | Calculated Seepage Gradient | Analysis Results |

|---|---|---|---|---|

| Normal water-level conditions | At the foot of the starter dam slope | 1.02 | 0.679 | Steady |

| Flood-level conditions | At the foot of the starter dam slope | 1.02 | 0.690 | Steady |

| Calculation Method | Operating Condition | Grade of Dam | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4, 5 | ||

| Simplified Bishop method | Normal operation | 1.50 | 1.35 | 1.30 | 1.25 |

| Ordinary method | Normal operation | 1.30 | 1.25 | 1.20 | 1.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Wang, G.; Zhang, X.; Zhao, B. Numerical Simulation of Seepage Surface and Analysis of Phreatic Line Control from a Fine-Grained Tailings High Stacked Dam under Complicated Geography Conditions. Appl. Sci. 2023, 13, 12859. https://doi.org/10.3390/app132312859

Han Y, Wang G, Zhang X, Zhao B. Numerical Simulation of Seepage Surface and Analysis of Phreatic Line Control from a Fine-Grained Tailings High Stacked Dam under Complicated Geography Conditions. Applied Sciences. 2023; 13(23):12859. https://doi.org/10.3390/app132312859

Chicago/Turabian StyleHan, Yabing, Guangjin Wang, Xudong Zhang, and Bing Zhao. 2023. "Numerical Simulation of Seepage Surface and Analysis of Phreatic Line Control from a Fine-Grained Tailings High Stacked Dam under Complicated Geography Conditions" Applied Sciences 13, no. 23: 12859. https://doi.org/10.3390/app132312859

APA StyleHan, Y., Wang, G., Zhang, X., & Zhao, B. (2023). Numerical Simulation of Seepage Surface and Analysis of Phreatic Line Control from a Fine-Grained Tailings High Stacked Dam under Complicated Geography Conditions. Applied Sciences, 13(23), 12859. https://doi.org/10.3390/app132312859