Abstract

Earthwork scheduling (during the planning phase of road construction) is an important task that directly affects the cost and time of a project. However, the current scheduling methods are not performed at a detailed level and carry forward gaps from the actual schedule in the construction stage, causing problems, including time delays and additional costs, during the construction stage and thereby leading to the modification and supplementation of existing plans. Many studies related to scheduling have focused on process optimization or automation; therefore, the gaps between the planning and construction stages have not been studied well. These gaps must be determined in advance to solve the fundamental problem of earthwork scheduling in road construction. Therefore, this study proposes a detailed activity-based scheduling model for earthwork at the planning stage to minimize the gap between the planned schedule and the actual process at the construction stage. The proposed model comprises a detailed activity-based database of earthwork in road construction (DADER), which enables the subdivision of the existing earthwork schedule plan, and a dynamic programming (DP) procedure, which enables the combination of activities. The earthwork schedule at the case site, planned for only three activities, is subdivided using DADER into 36 activities. Additionally, the DP procedure is used to derive a combination of activity alternatives that minimizes the cost among the conditions that satisfied the input target duration. The model is verified through an expert survey using a 7-point Likert scale. Results show that the model has cost efficiency (4.19), onsite applicability (4.70), and task efficiency (4.48). The findings indicate that performing scheduling during the planning stage of earthwork projects can help reduce additional work caused by the gap between the site and the plan. This study will help improve the productivity of road construction projects by providing correct process optimization and automation research data.

1. Introduction

Scheduling is a vital aspect of linear projects, as exemplified by numerous road construction projects [1]. Moreover, the critical role of earthworks, constituting approximately 19.58% of the overall road construction expenditure, further underscores their pivotal nature in this domain [2].

In the construction industry, project scheduling is an indispensable factor that empowers project managers and teams to oversee time, expenses, resources, and fundamental facets of project management effectively [3,4]. Insufficient project planning and scheduling can induce setbacks in project completion timelines and financial overruns [5,6]. Moreover, precise determination of the appropriate level of detail for scheduling during the construction project planning stage is a major challenge. Finding complex conditions in detailed scheduling in construction projects is a very challenging task [7]. Scholarly exploration of the granularity of details in construction project scheduling remains noticeably underdeveloped [8].

While comprehensive scheduling is intrinsic to project planning [9], most of the scheduling during the construction planning phase is often subjected to recalibration by managers at successive sites. A substantial proportion of time-related delays stemming from these practices is attributed to limited exhaustive construction plans and timelines [10]. Consequently, one of the salient challenges pertains to the lack of meticulous detail as the construction periods, workforce inputs, and costs (outlined at the project’s outset) may diverge from the actual values as the construction progresses.

However, despite the importance of considering detailed activities in the construction scheduling process, in actual projects, it is common to perform scheduling without giving sufficient consideration to this aspect during the planning stage. A preliminary survey conducted for this study also confirmed that (on average) road construction projects were scheduled for fewer than five activities during the planning stage for earthworks. There is a considerable gap between the construction site and the plan, thus resulting in additional work, costs, time, and increased time consumption.

Hence, this study proposed a detailed activity-based scheduling model to mitigate the issues stemming from low-level earthwork scheduling during the road construction planning stage to solve the problems caused by the inadequate consideration of detailed activities. The research on this model was conducted in several steps. Firstly, the detailed database of earthwork in road construction [referred to as detailed activity-based database of earthwork in road construction (DADER)] was developed based on earthwork data. Secondly, the dynamic programming (DP) algorithm was applied using the standardized DADER as a foundation to perform scheduling by considering various combinations of activities. Thirdly, the proposed model was applied to a case study to derive scheduling results, which were then analyzed. Lastly, the model was validated through in-depth discussions with experts to assess its excellence from various aspects. The proposed model was designed to yield detailed scheduling results for earthwork activities directly usable at the construction site by inputting the planned workloads per activity. Furthermore, the proposed model can minimize the additional work, extra labor input, rework, plan changes, and associated increases in costs and time owing to the gap between the site and the plan by providing appropriate scheduling at the planning stage.

2. Earthwork Scheduling in Road Construction

To identify issues with the current scheduling methods used in the construction industry, problems arising during the planning phase of construction projects, particularly those related to earthwork in road construction, were identified following consultations with experts from the Korean construction industry. Based on discussions with 11 experts in the field of road construction project planning, the identified issues related to scheduling highlighted the prevalence of low-level details in establishing construction project schedules during the planning stage. Currently, scheduling during the planning stage of most construction projects is conducted at a basic level, primarily for project evaluation and reporting purposes. Subsequently, additional work is undertaken to add detail gradually using an incremental approach. The issue of insufficient scheduling results in significant challenges from a construction project perspective, thus leading to problems such as construction schedule delays and additional costs owing to the repetitive generation and modification of schedules. Consequently, insights were gathered from experts who manage and oversee projects on construction sites, thus indicating that the scheduling produced during the planning stage is underutilized and requires additional modifications in subsequent phases.

To conduct this study, scheduling data prepared during the planning stage were extensively reviewed. This review revealed that data application on actual construction sites was almost infeasible owing to issues associated with scheduling granularity. For instance, in the case of earthwork during road construction, the scheduling generated during the planning stage typically includes only 3–5 activity schedules (such as excavation, material transport, and earth placement); however, earthwork sites involve a minimum of 20 or more detailed activities. Consequently, current scheduling practices in construction projects often fail to satisfy the specific levels required in the field, thus resulting in substantial time and cost losses. Therefore, a detailed process scheduling that aligns with onsite feasibility is imperative for the successful completion of construction projects. To identify the problems in earthwork scheduling during the project planning stage, discussions were conducted with experts in the construction field. The results revealed that low-level scheduling was inefficient in terms of cost and time and led to additional tasks, ultimately impacting productivity negatively.

3. Literature Review

3.1. Earthwork Scheduling

Various studies have been conducted to achieve more efficient and accurate execution in fields related to the scheduling of earthworks in road construction. Shah developed an arithmetic algorithm-based model to address the uncertainties associated with earthwork scheduling, efficient resource planning, construction site safety, and earthwork monitoring; the study supported resource planning using various options [1]. This study automated key functions related to planning based on a road project case study. However, owing to the provision of weekly plans limited to excavation schedules, it is challenging to address the overall planning of the construction site. Askew et al. automated the earthwork-planning process for road construction projects to resolve complexities and efficiently support project planners by developing a model capable of time-efficient scheduling [11]. This study developed and tested a model to improve excavation planning assumptions. However, the scope of the research was limited to excavation operations. Rather than proposing scheduling results directly, it provided excavation operation data to aid scheduling. Li and Lu developed an automated prototype for earthwork planning in civil engineering projects by following the principles and framework of classical planning models [12]. The prototype enables automated planning and optimization for high-level analysis, but it is limited in encompassing overall scheduling owing to the restriction of activities to excavation operations for robotic excavation. Hare et al. expanded the classical linear program model for earthwork scheduling to a mixed integer linear program model for optimal planning in road construction projects [13]. This study, like the aforementioned publications, also focused on the optimization of excavation operations and thus researched a limited range of activities. Liu et al. proposed a simulation approach that considered temporary road networks for efficient earthmoving operations that led to cost reduction and time savings [14]. However, in this study, the algorithm was applied to seven activities that corresponded to excavation and transportation operations, suggesting that the level of detail may be somewhat insufficient for practical applications in the field. Marzouk and Moselhi proposed a discrete-event simulation and object-oriented simulation engine for modeling earthmoving operations and provided tools for estimating time and cost [15]. Given that this study was limited to equipment combinations in excavation operations, it only considered a small number of activities for scheduling throughout the entire earthwork project, thus highlighting its limitation in focusing on a few specific pieces of equipment.

Previous studies related to earthwork scheduling were mostly limited to excavation tasks, which constitutes a major limitation. While research focusing on excavation tasks within earthwork is reasonable given its crucial importance, the lack of studies addressing earthwork scheduling is evident. Considering that most studies have been conducted based on a few activities, the scarcity of research on earthwork scheduling at a comprehensive level introduces a major research gap. Studies considering activities at a detailed level are essential for the overall successful execution of construction projects.

3.2. Scheduling Method

Many studies have been conducted to derive more advanced types of scheduling using various technologies and algorithms to achieve optimized scheduling in the construction industry. Several studies have been conducted on construction scheduling techniques using mathematical algorithms. For example, Kallantzis and Lambropoulos proposed a method to introduce a scheduling approach for linear projects involving maximum time and distance constraints in addition to the minimum constraints [16]. This method classified activities based on their importance and influence on duration and demonstrated their effectiveness by applying them to low-pressure pipeline construction projects. This study investigated the key seven activities encompassed within the entire earthwork project, thus allowing the consideration of the overall earthwork scheduling. However, the application of the seven activity levels may pose challenges in practical implementations at construction sites. Ipsilandis proposed a multipurpose, linear programming model for scheduling linear iterative projects by considering cost factors associated with project duration, resource idle time, and project-by-project delivery time [17]. The proposed model allowed project managers to create alternative schedules based on a variety of cost factors and proposed a holistic approach to schedule decisions beyond the simple minimization of timeframe or the maximization of task continuity. This study also proposed a model by setting the number of activities to seven, primarily conducting time-based research without considering other conditions, such as the equipment involved in the activities.

Most recent studies on the optimization of construction scheduling employed metaheuristic algorithms as research methods, such as ACO, PSO, and genetic algorithm (GA), which have high versatility in solving optimization problems. Mollajafari and Shahhoseini used the ACO-based algorithm to solve the scheduling problem, and it was confirmed that the algorithm performed better than other algorithms in terms of result quality, execution time, and scalability [18]. Cheng et al. proposed a new approach based on PSO methods to solve the problem of task movement in construction projects, thus demonstrating its effectiveness in real-world project scenarios [19]. Toklu used a GA to optimize the scheduling process by integrating mathematical and genetic operators to solve the problem of scheduling with limited resources based on a simplified bridge construction case as an example [20]. These studies commonly employed state-of-the-art algorithms to propose efficient and accurate scheduling methods under the given conditions of predefined information, such as activities, duration, and costs.

Previous studies primarily aimed to optimize scheduling methods or automate the scheduling process using various state-of-the-art algorithms to improve existing practices. Such research is undoubtedly essential for efficient construction scheduling. However, these studies have limitations in addressing the fundamental issues of basic earthwork scheduling. While most of the research related to optimization of construction scheduling was actively conducted about a decade ago, optimization and automation in construction scheduling are still not adequately realized. Optimizing scheduling is a good approach when the right conditions are provided, but this approach has limitations. One limitation is that the optimization algorithms rely on the data provided, and if the detailed level of activities is not considered a priori, the results (irrespective of their accuracy) will not be in a form usable at construction sites. To address these fundamental issues, it is crucial to focus on the detailed level of activities that act as a type of bridge for proper scheduling. This should be a top priority for optimizing construction projects. Thus, considering the detailed level of activities is a critical factor for appropriate scheduling. However, research related to this aspect is lacking compared with its importance.

Therefore, this study proposed a scheduling model that considered detailed activities for earthwork scheduling in the planning stages of road construction projects. The proposed model can be effectively utilized in the establishment of schedules to eliminate the gap between planning and onsite construction. This model can be beneficial for creating schedules that are usable effectively onsite.

4. Model Development

This study developed a model to generate detailed levels of earthwork scheduling at the planning stage of road construction using DADER and DP in MATLAB (version 2023b, MathWorks, Natick, MA, USA).

4.1. Procedure of the Proposed Model

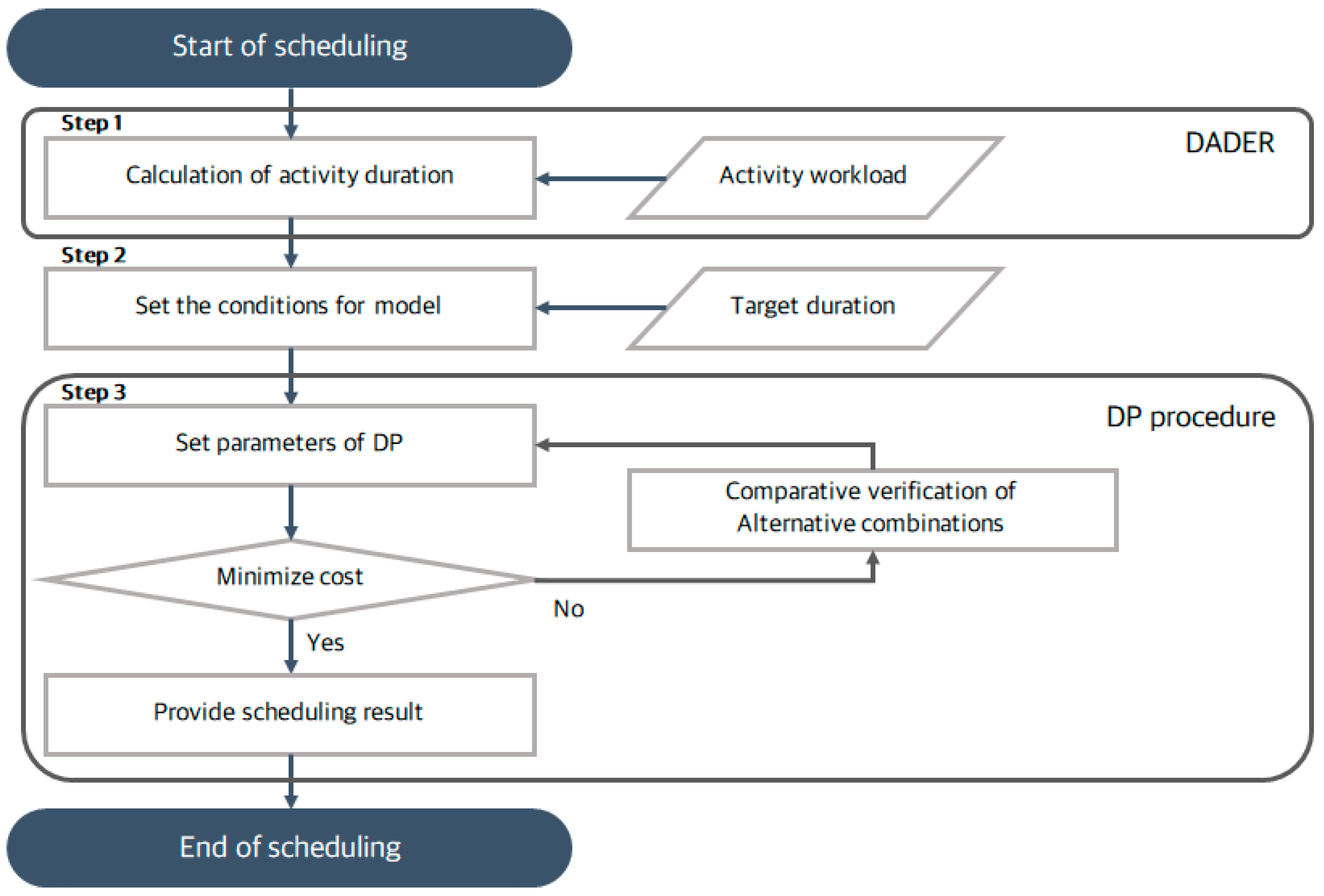

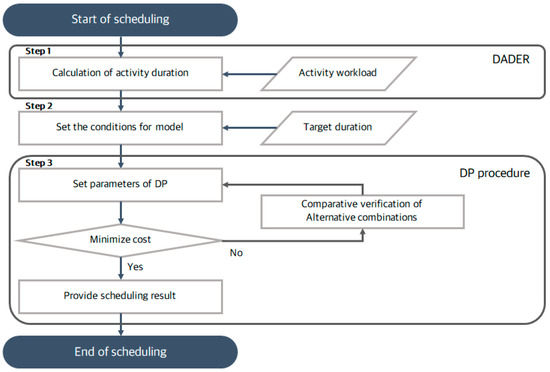

The process of the proposed model in this study is shown in Figure 1. In Step 1, activity durations, which refer to individual activities, were computed using the DADER. DADER incorporates all activity details pertinent to earthwork in road construction, along with daily workloads, costs, labor, and equipment information for each activity under standard conditions. The calculated duration data for each activity were obtained by inputting the activity workloads into DADER as input data.

Figure 1.

Summary of the procedure of the proposed model.

In Step 2, the model was provided with a target duration to generate pertinent scheduling outcomes. The term “target duration” refers to the total duration of the intended construction project and serves as a deadline parameter and as the input data to be scheduled by the user using the model of this study. As proposed in this study, the model formulated scheduling outcomes that incurred minimal costs while adhering to the stipulated target duration.

In Step 3, the scheduling results were derived using the DP algorithm, an optimization algorithm. Variables such as activity sequencing, cost, duration, and target duration were configured before applying the algorithm. By establishing appropriate combinations of alternative activities, efforts have been directed toward the minimization of costs. Iterative algorithmic processes yield scheduling combinations that fulfill the target duration and minimize costs. Consequently, the ultimate scheduling outcomes are presented.

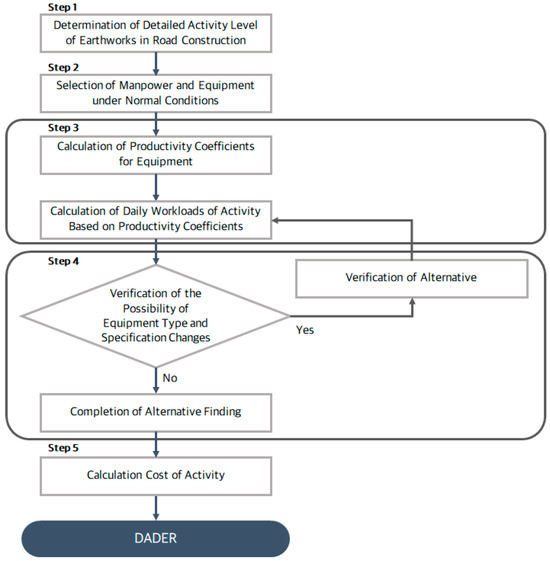

4.2. DADER

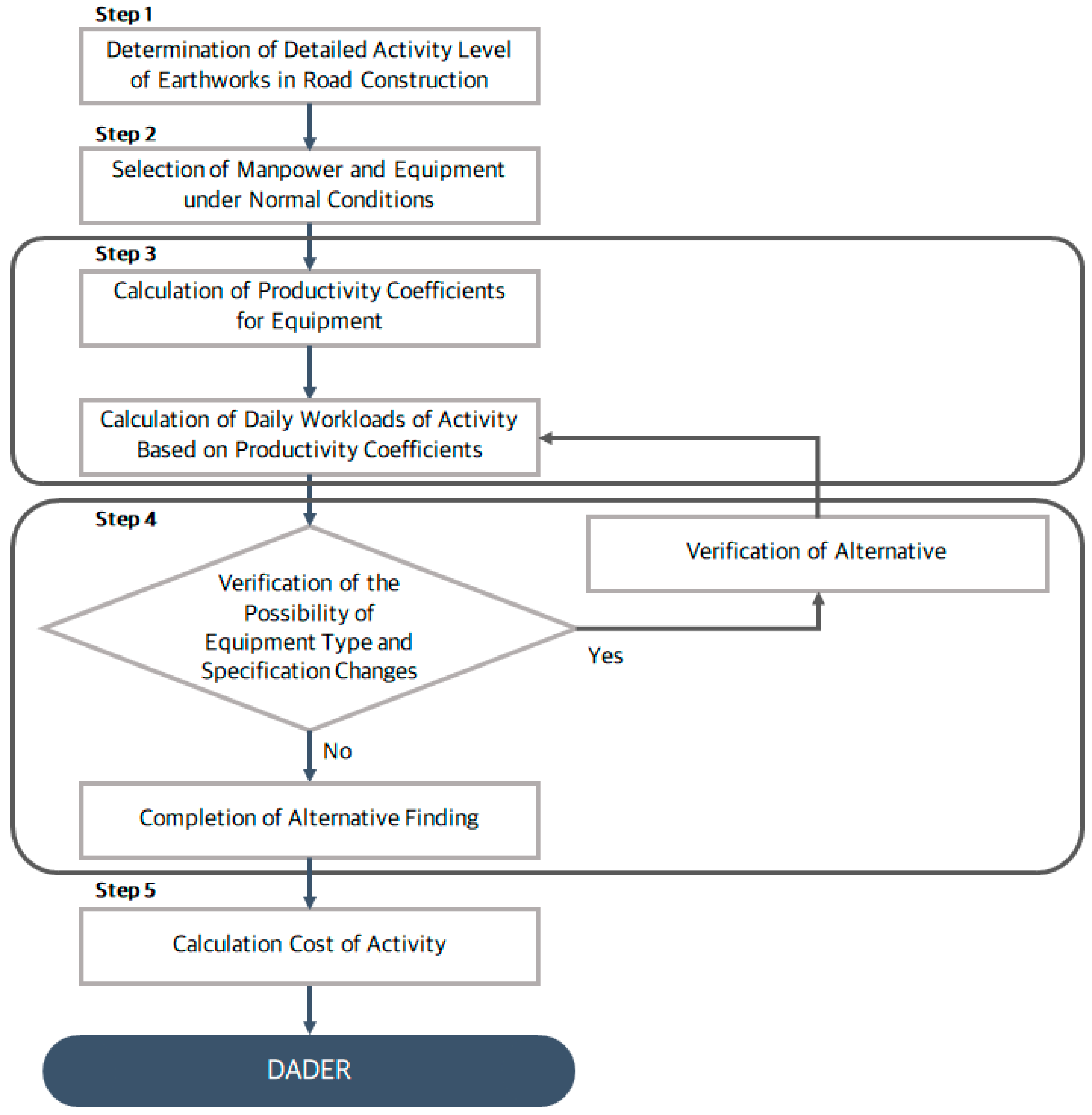

DADER is a comprehensive database that encompasses highly detailed information to facilitate scheduling based on intricate activities during the earthwork phase during the road construction planning stage and is supported by the construction cost estimation standard, which is a fundamental manual extensively utilized in project planning in the Korean construction industry. Furthermore, the Construction Cost Estimation Standard is particularly suitable for utilization in this study owing to its handling of data at a highly detailed level of activity, which distinguishes it from other sources. This system is annually updated by the Ministry of Land, Infrastructure, and Transport of South Korea. In this study, the 2023 edition (the most recent version) was used. The detailed process of creating DADER is shown in Figure 2.

Figure 2.

Procedure used to set DADER.

Before constructing a detailed database for earthworks in road construction, the level of detail to be studied was determined. In this study, the database was structured according to the Korean standard manual WBS 7-2 with the final level of detail confirmed via the incorporation of additional criteria from the construction cost estimation standard. The allocation of labor and equipment typically used at construction sites is defined under normal conditions. The term “normal conditions” refers to the average construction scale and environmental factors prevalent in typical road construction projects in Korea. This information is based on the criteria established by the Korean Institute of Civil Engineering and Building Technology and was refined based on a review of the existing literature and consultation with experts. The productivity coefficients of the equipment employed were calculated based on the construction cost estimation standard. These coefficients were used to compute the daily workloads of the activities. The productivity coefficients of the equipment were determined using various variables.

In this study, the coefficients were calculated using the most common conditions. Based on these productivity coefficients, the daily workloads for all earthwork activities were calculated as shown in Table 1. In addition, the possibility of deploying equipment in addition to the commonly used equipment for activities was considered. While we initially performed calculations based on the most representative equipment for each activity to establish a baseline, it was acknowledged that not all construction sites employed identical equipment. An alternative concept was introduced to address this issue. When equipment substitution was not feasible owing to the nature of the activity, a single alternative was assigned. In situations wherein the equipment type or specification changes were viable, up to three alternatives were considered. Consequently, DADER considered various equipment combinations, thus facilitating the selection of the most appropriate values during the subsequent scheduling process using the algorithm. The costs of all the alternative earthwork activities within DADER were computed using data from a prominent South Korean construction company. These data encompassed the daily costs incurred, including labor and equipment expenses. The cost data calculated in this phase were subsequently utilized to implement the model algorithm and determine the total project cost.

Table 1.

Equipment productivity coefficient (19ton Bulldozer).

DADER was developed through the five steps, with certain aspects of DADER contents presented in Table 2.

Table 2.

Detailed activity-based database of earthwork in road construction (DADER) (site preparation/breaking existing structures).

4.3. DP Procedure

The multifaceted nature of construction management is manifested in an array of interdependent tasks, strict resource allocations, and bounded deadlines set against overarching budget constraints. It is not merely a logistical venture but a computational conundrum where numerous variables, such as material procurement, manpower deployment, machinery scheduling, and potential environmental variables, intertwine. To address these issues, an algorithm having an appropriate form for the problem structure is needed.

DP is an algorithmic technique used to solve complex problems by breaking them down into smaller subproblems. A particular problem is divided into smaller subproblems, with their solution values stored to avoid redundant calculations, ultimately facilitating the derivation of a final solution.

In the context of this research, the desired model development required an algorithm that could produce solutions decisively, ensuring rapid and accurate results rather than relying on highly complex optimization algorithms. Therefore, a scheduling model for detailed earthwork in road construction at the planning stage was developed using the DP method.

The DP algorithm starts by considering various processes, each comprising different tasks. Every task within a process has an assigned cost and duration. Some of these processes can operate simultaneously, and there is a specified deadline. To facilitate the algorithm, a DP table is constructed, determined by the deadline and the number of processes. This DP table’s main purpose is to identify the smallest possible cost to meet the deadline for every process.

During the implementation phase, the algorithm examines each time unit for every process, from the onset to the given deadline. For processes that operate independently, the algorithm evaluates their tasks. It then updates the table by adding the cost of the task to the time previously used and subtracts the duration of the task. Conversely, for processes that can run concurrently with others, the algorithm assesses tasks from all simultaneous processes. The table is then adjusted by considering the total task costs and subtracting the duration of the task that takes the longest.

This methodology is particularly relevant in the context of construction projects. Large construction projects often involve multiple phases, each with its unique challenges and variables. DP provides a systematic mechanism for identifying each phase, thus examining it individually and determining a cost-effective strategy tailored to it. The process then builds on the solutions derived from the initial subproblems to address subsequent phases, thus ensuring that the cumulative strategy is not only effective but also efficient.

For the study in question, the implementation strategy adopted to structure the problem was based on a comprehensive exploration of the DP landscape. Specifically, all possible transitions in each state of the problem were examined. This exhaustive approach ensured that all possible combinations of tasks and activities that could be performed within the given time frame were explored. The aim was to identify the particular sequence or combination that produced the most cost-effective outcome. This rigorous approach to DP ensures that the final strategy is both cost-optimal and feasible given the constraints. For readers seeking a detailed breakdown of the algorithm used, Table 3 explains each step in detail.

Table 3.

Dynamic programming (DP) implementation approach.

The pseudocode of the algorithm used in the proposed model in this study is listed in Algorithm 1.

| Algorithm 1 Dynamic Programming for Task Optimization with Parallel and Sing Tasks | |

| 1: | Initialization: |

| 2: | dp[][] = ∞: Min cost DP table |

| 3: | for = 1 to : |

| 4: | for = 1 to : |

| 5: | if is not parallel |

| 6: | dp[[] = min(dp[][1] l ); |

| 7: | else |

| 8: | For each combination of tasks , from parallel processes |

| 9: | dp[[] = min(dp[ l ][1] l ); |

| 10: | end |

| 11: | end |

| 12: | = min( l dp[][] ∞, ) |

| 13: | = dp[][] |

| 14: | end |

| 15: | Backtrack from dp[][] to get |

5. Case Study

Workload data acquired from an actual road construction project were used to validate the proposed model. The workload included data created from the planning stage of the construction project derived from the onsite measurement performed in advance. The road construction data utilized in this study were obtained from the planning stage of a highway project conducted by the construction company D. The details of the case study are listed in Table 4.

Table 4.

Case study information.

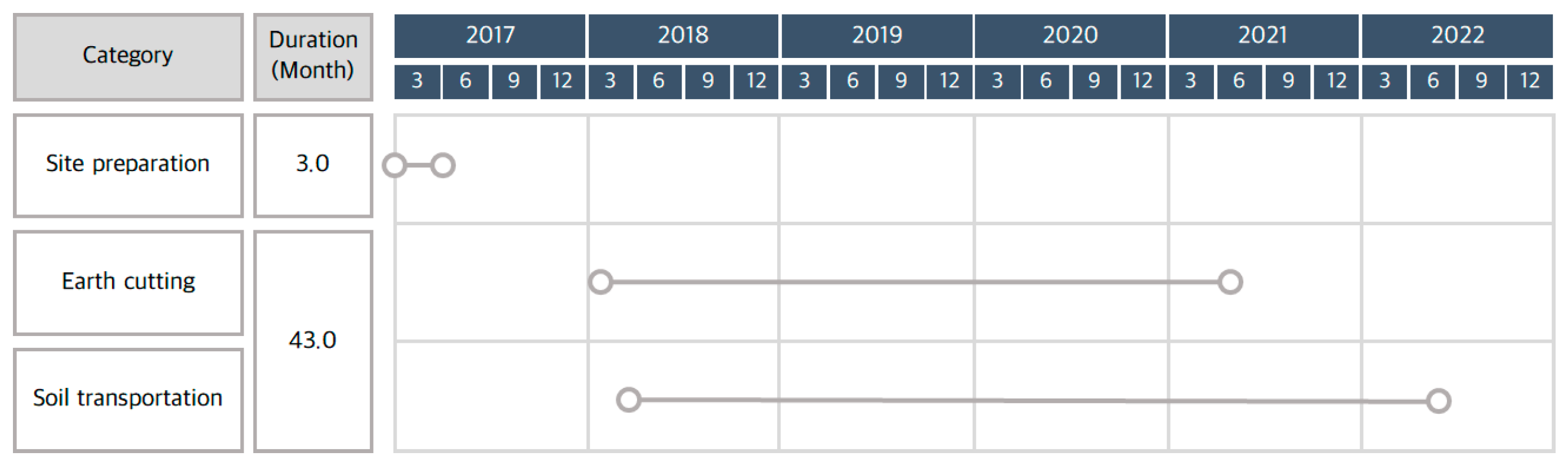

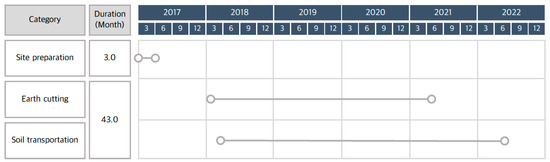

The scheduling result for this project’s planning stage is shown in Figure 3; as previously mentioned, the level of detail of this result was considerably low for direct utilization at the construction site.

Figure 3.

Case study scheduling result (conventional method).

As is evident from the actual construction project scheduling of this study, the scheduling of earthworks at the planning stage was at a low level of detail (in the case of this study, there were only three activities: site preparation, earth cutting, and soil transportation), thus making construction activities at construction sites (based on these results) challenging. Owing to the previously conducted, low-detail scheduling of the case study project, subsequent scheduling rework or repetitive modifications occurred at the construction site. This resulted in additional costs and time consumption that had a negative impact on the project’s productivity. To complete a case study on the proposed model, this study utilized data related to the highway construction plan of Construction Company D, as mentioned earlier. The workload data for each highway construction project activity used in the model case study are presented in Table 5.

Table 5.

Case study data.

6. Results and Discussion

6.1. Case Study Results

In this study, a target duration of 2500 d was set to apply casestudy data to the proposed scheduling model. To examine the difference between the two sets of outcomes (applying and not applying DP), different conditions were applied to derive two sets of results.

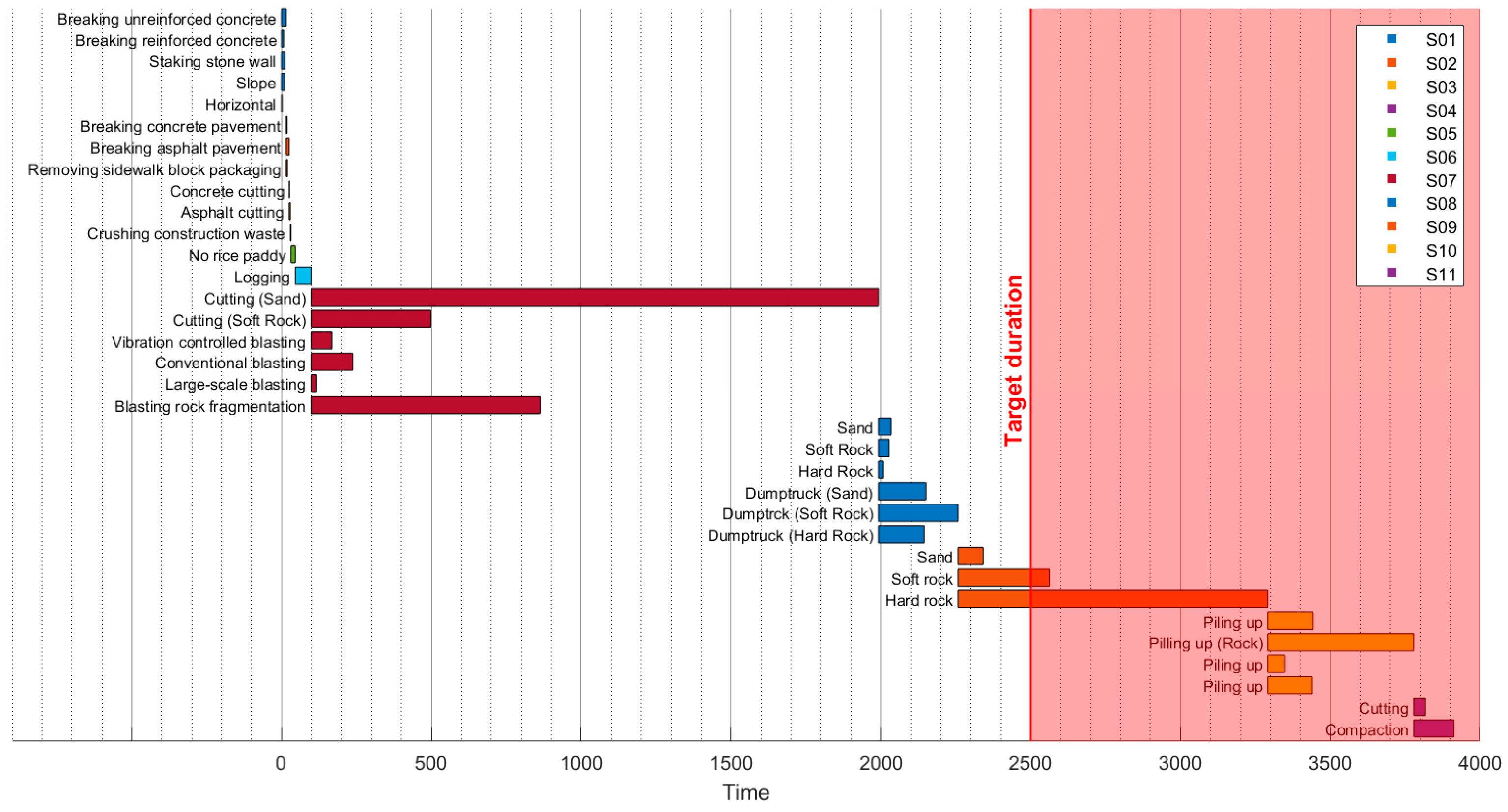

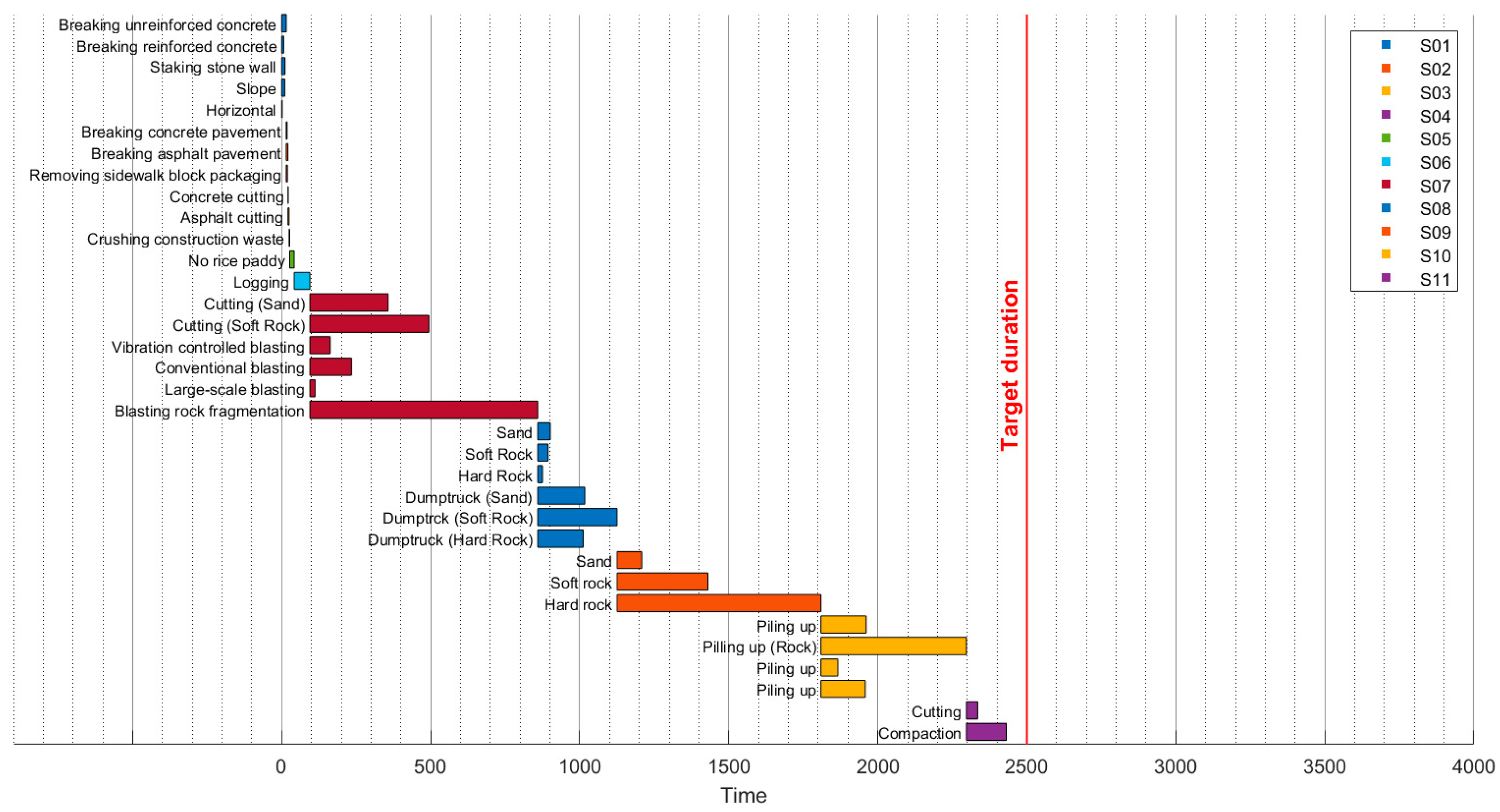

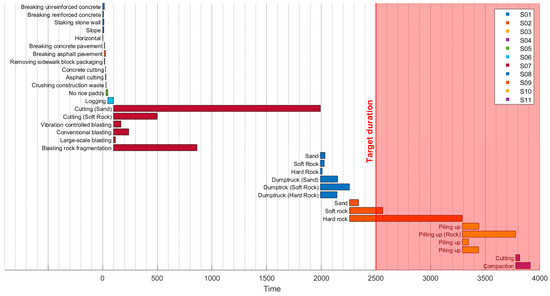

First, the algorithm was implemented to schedule all activities by selecting only the alternatives with the minimum cost (without applying DP) during the scheduling process. The results are shown in Figure 4.

Figure 4.

Scheduling results (without the use of DP).

In this case, the target duration was set sufficiently long and resulted in scheduling outcomes in which only alternatives with lower costs for each activity were selected. Therefore, activities exceeding the target duration occurred, thus indicating that the scheduling method employed in this approach was incorrect.

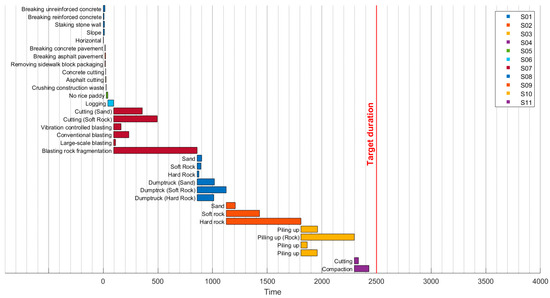

Subsequently, to confirm that the algorithm performs appropriately under the constraints of a limited target duration, scheduling was performed by applying DP. The results are shown in Figure 5.

Figure 5.

Scheduling results (with the use of DP).

The form of scheduling performed using DP is similar to Figure 4, but the scheduling was performed by selecting alternatives that satisfy the target duration while minimizing costs during the selection of activity alternatives. Furthermore, the result of applying the case study to the model provides scheduling results at a detailed level of activity, which differ from the scheduling results using conventional methods, such as those shown in Figure 4, based on the DADER developed in this study. These results play a role in reducing the gap between the planning stage and the construction phase onsite, thereby minimizing unnecessary tasks such as additional work or rescheduling.

The results of cost and duration comparison analysis performed using two methods are shown in Table 6. When the DP algorithm was applied to the model, the total cost was calculated to be 62,991,065 ₩, and the total duration was 2431 d. Without applying the DP algorithm, the total cost was 62,631,441 ₩ and the total duration was 3913 d. In the case where the DP algorithm was not applied to the model, the selection of activity alternatives would be directed toward the minimization of costs, regardless of the input target duration, thus resulting in a low cost but a significantly higher total duration. In contrast, when the DP algorithm was applied to the model, it derived the combination of activity alternatives that minimized the cost among the conditions that satisfied the input target duration. Therefore, when the DP algorithm was applied, the model obtained the values that minimized the total cost among the combinations that satisfied the initially input target duration of 2500 d. Thus, when the user sets the target duration of the construction period as input data during the earthwork planning stage, the model proposed in this study can obtain scheduling results that minimize construction costs among various conditions.

Table 6.

Comparison results.

6.2. Model Validation

The suitability of the model developed in this study for real construction sites was validated based on a survey that engaged 28 experts currently employed in the construction industry. The information gathered from the surveyed experts is presented in Table 7.

Table 7.

Expert information.

A survey was conducted with experts using a 7-point Likert scale to assess the effects of the model developed in this study compared with the existing scheduling methods in terms of cost, onsite applicability, and task efficiency. In addition, the opinions of experts on the reasons for scoring the items were gathered based on supplementary survey questions. To ensure the validity of the expert survey results, a reliability analysis was conducted using the software IPM SPSS Statistics (version 29.0.1.0). A reliability analysis was performed on the Likert scale-based survey items, which yielded a Cronbach’s alpha coefficient of 0.875, thus confirming the high reliability of the survey. The survey results are summarized below.

6.2.1. Cost

The item that experts considered would make this study’s model superior in terms of cost compared with current scheduling methods, received a score of 4.19. Experts indicated that using the developed model could reduce the additional costs incurred owing to plan changes. However, certain experts indicated that they were uncertain whether the model would directly contribute toward the reduction of construction project costs.

6.2.2. Onsite Applicability

The item that experts considered would make the study’s model superior in terms of the onsite applicability compared with the current scheduling methods received a score of 4.70. Many experts indicated that scheduling methods at the planning stage often do not align well with the construction phase. Consequently, using the proposed model could bridge this gap. They believed that this would facilitate scheduling tailored to actual onsite conditions.

6.2.3. Task Efficiency

The item that experts considered would make the study’s model superior in terms of task efficiency compared with the current scheduling methods received a score of 4.48. Experts stated that using the developed model could reduce the time spent on document preparation for scheduling. They also believed that generating detailed initial schedules at the planning stage using the developed model could minimize onsite scheduling modifications and consequently reduce workload.

The results of the expert survey confirmed that the model developed in this study can effectively address the issues present in the planning stage process charts currently utilized in the construction industry. Notably, according to the expert survey results, the primary advantage of the developed model was its ability to enhance task efficiency, which is particularly important for construction site operations where a thorough understanding of the detailed processes is essential. Therefore, it can be inferred that the characteristics of the model in this study contributed to its effectiveness in devising detailed process plans from the planning stage onward for successful construction site operations.

6.3. Discussion

In this study, a model based on DADER was developed to perform scheduling at the planning stage of construction projects. The model was applied to a case study to derive results. Despite the current efforts in the construction industry to enhance scheduling efficiency using building information modeling (BIM), digital twins, and artificial intelligence (AI), the persistent challenge of addressing the level of detail led to the development of DADER. This model aims to effectively address the issue of level of detail in construction scheduling and make it applicable to real construction sites.

The application of the model in a case study revealed that utilizing our developed model enables the generation of schedules at a detailed activity level, minimizing costs within the target duration. Additionally, validation through expert surveys confirmed the model’s efficiency in terms of cost, onsite applicability, and task efficiency. Thus, our developed model is identified as a solution to bridge the gap between planning and onsite execution in construction scheduling.

However, it is essential to acknowledge the limitations of this study. The model falls short of achieving a scheduling implementation level suitable for real construction sites. The actual construction environment introduces numerous variables such as weather conditions, material transportation delays, and site-specific factors like noise. Given that our model was developed under the most ideal conditions, future research aims to refine the model to a level applicable in real construction settings. This refinement would address various disputes and policy challenges arising from scheduling issues in the construction industry.

7. Conclusions

In this research, an activity-based scheduling model designed for detailed earthwork scheduling during the road construction planning stage was proposed. The model proposed comprises DADER, incorporating intricate earthwork activities, and employs a DP algorithm for scheduling. DADER is equipped with comprehensive daily data on workload, labor, equipment, and costs for detailed-level activities. The DP algorithm in our model assesses various combinations within detailed-level activities to identify optimal scheduling solutions. Applying the proposed model to a case study demonstrated the establishment of a rational earthwork schedule, contrasting favorably with initial schedules generated through conventional methods. This underscores the applicability and advantages of our proposed model. The case study involved a comparative analysis between scheduling outcomes derived from the existing method and those from our research model. Additionally, it illustrated how the improved scheduling results prove effective in practical construction settings. The suggested model aids planning personnel in formulating specific and pragmatic earthwork plans during the planning stage. By addressing detailed-level scheduling, it minimizes the need for additional plan changes and reduces extra work on the construction site, ultimately leading to time and cost savings. Mitigating time and cost losses in a project significantly contributes to the successful completion of construction projects.

However, it is crucial to note that the proposed model was developed under standard conditions. To enhance scheduling accuracy, it is imperative to conduct scheduling under diverse environmental conditions and account for factors like equipment and workforce allocation for earthwork. In future research, the model developed under standard conditions will serve as the basis for constructing a practical scheduling model for the planning stage, immediately applicable in real construction sites while accommodating various variables.

Author Contributions

Conceptualization, C.L. and M.C.; methodology, C.L.; software, C.L.; validation, C.L., H.K. and H.C.; formal analysis, C.L.; investigation, H.K.; resources, H.C.; data curation, M.C.; writing—original draft preparation, C.L.; writing—review and editing, M.C.; visualization, H.K.; supervision, M.C.; project administration, M.C.; funding acquisition, H.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was conducted with the support of the “National R&D Project for Smart Construction Technology (No. 23SMIP-A158708-04)” funded by the Korea Agency for Infrastructure Technology Advancement under the Ministry of Land, Infrastructure and Transport, and managed by the Korea Expressway Corporation.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors. The data are not publicly available due to privacy.

Acknowledgments

We thank Chiwoo Lee who works at the Korea Institute of Science and Technology (KIST) for their support.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Shah, R.K. A new approach for automation of location-based earthwork scheduling in road construction projects. Autom. Constr. 2014, 43, 156–169. [Google Scholar] [CrossRef]

- Castro, S. Integrated Simulation Models Applied to Road Construction Management. Ph.D. Thesis, Teesside University, Middlesbrough, UK, 2005. [Google Scholar]

- Hendrickson, C.; Zozaya-Gorostiza, C.; Rehak, D.; Baracco-Miller, E.; Lim, P. Expert system for construction planning. J. Comput. Civ. Eng. 1987, 1, 253–269. [Google Scholar] [CrossRef]

- Faghihi, V.; Nejat, A.; Reinschmidt, K.F.; Kang, J.H. Automation in construction scheduling: A review of the literature. Int. J. Adv. Manuf. Technol. 2015, 81, 1845–1856. [Google Scholar] [CrossRef]

- Jung, Y.; Fouad, A.; Golparvar-Fard, M. A systematic Review on the Requirements on BIM Maturity and Formal Representation of Sequencing Knowledge for Automated Construction Scheduling. In Proceedings of the 38th International Conference of CIB, Luxembourg, 11–15 October 2021; pp. 11–15. [Google Scholar]

- Pallesteros-Peres, P.; Sanz-Ablanedo, E.; Soetanto, R.; Gonzalez-Cruz, M.C.; Larsen, G.D.; Cerezo-Narvaez, A. Duration and cost variability of construction activities: An empirical study. J. Constr. Eng. Manag. 2019, 146, 04019093. [Google Scholar] [CrossRef]

- Lukas, J.A. Is Your Schedule Correct? Common Scheduling Mistakes and How to Avoid Them; Paper presented at PMI® Global Congress 2007–North America; Project Management Institute: Atlanta, GA, USA; Newtown Square, PA, USA.

- Kolarić, S.; Vukomanović, M.; Ramljak, A. Analyzing the level of detail of construction schedule for enabling site logistics planning (SLP) in the building information modeling (BIM) environment. Sustainability 2022, 14, 6701. [Google Scholar] [CrossRef]

- Farzad Moosavi, S.; Moselhi, O. Review of detailed schedules in building construction. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2014, 6, 05014001. [Google Scholar] [CrossRef]

- Shah, R.K.; Dawood, N. An Innovative Approach for Improvement of Communications Through Visual Schedule Model in Road Construction. In Proceedings of the 7th International Conference on Construction Application of Virtual Reality, State College, PA, USA, 22–23 October 2007; pp. 216–223. [Google Scholar]

- Askew, W.H.; Al-Jibouri, S.H.; Mawdesley, M.J.; Patterson, D.E. Planning linear construction projects: Automated method for the generation of earthwork activities. Autom. Constr. 2002, 11, 643–653. [Google Scholar] [CrossRef]

- Li, D.; Lu, M. Classical planning model-based approach to automating construction planning on earthwork projects. Comp. Aid. Eng. 2019, 34, 299–315. [Google Scholar] [CrossRef]

- Hare, W.L.; Koch, V.R.; Lucet, Y. Models and algorithms to improve earthwork operations in road design using mixed integer linear programming. Eur. J. Oper. Res. 2011, 215, 470–480. [Google Scholar] [CrossRef]

- Liu, C.; Lu, M.; Johnson, S. Simulation and Optimization of Temporary Road Network in Mass Earthmoving Projects. In Proceedings of the Winter Simulations Conference (WSC), Washington, DC, USA, 8–11 December 2013; Volume 2013, pp. 3181–3190. [Google Scholar] [CrossRef]

- Marzouk, M.; Moselhi, O. Object-oriented simulation model for earthmoving operations. J. Constr. Eng. Manag. 2003, 129, 173–181. [Google Scholar] [CrossRef]

- Kallantzis, A.; Lambropoulos, S. Critical path determination by incorporating minimum and maximum time and distance constraints into linear scheduling. Eng. Constr. Archit. Manag. 2004, 11, 211–222. [Google Scholar] [CrossRef]

- Ipsilandis, P.G. Multiobjective linear programming model for scheduling linear repetitive projects. J. Constr. Eng. Manag. 2007, 133, 417–424. [Google Scholar] [CrossRef]

- Mollajafari, M.; Shahhoseini, H.S. An efficient ACO-based algorithm for scheduling tasks onto dynamically reconfigurable hardware using TSP-likened construction graph. Appl. Intell. 2016, 45, 695–712. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Huang, K.Y.; Hutomo, M. Multiobjective dynamic-guiding PSO for optimizing work shift schedules. J. Constr. Eng. Manag. 2018, 144, 04018089. [Google Scholar] [CrossRef]

- Toklu, Y.C. Application of genetic algorithms to construction scheduling with or without resource constraints. Can. J. Civ. Eng. 2002, 29, 421–429. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).