Microstructure Evolution and Constitutive Modelling of Deformation Behavior for Al-Mg-Si-Cu-Sc-Zr Alloy Processed with Isothermal Multidirectional Forging

Abstract

:1. Introduction

2. Materials and Methods

3. Results

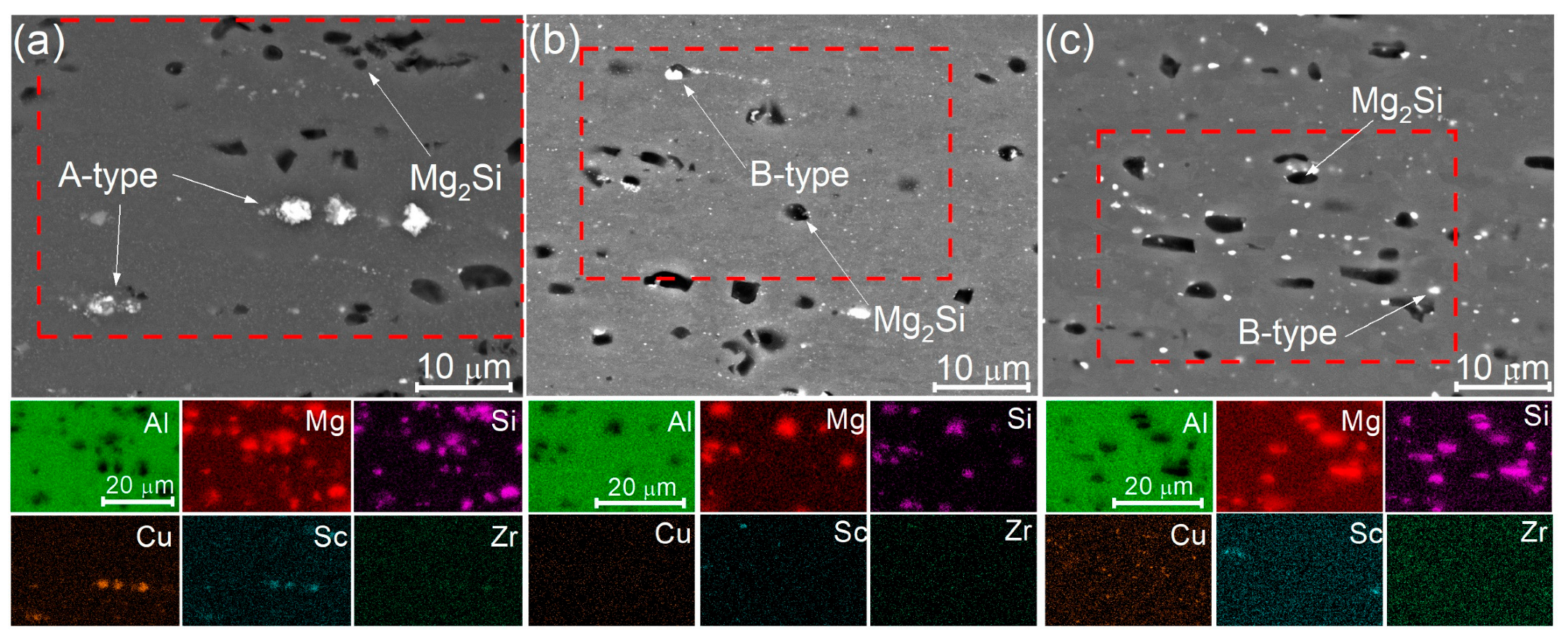

3.1. Microstructure in As-Cast and Homogenized States

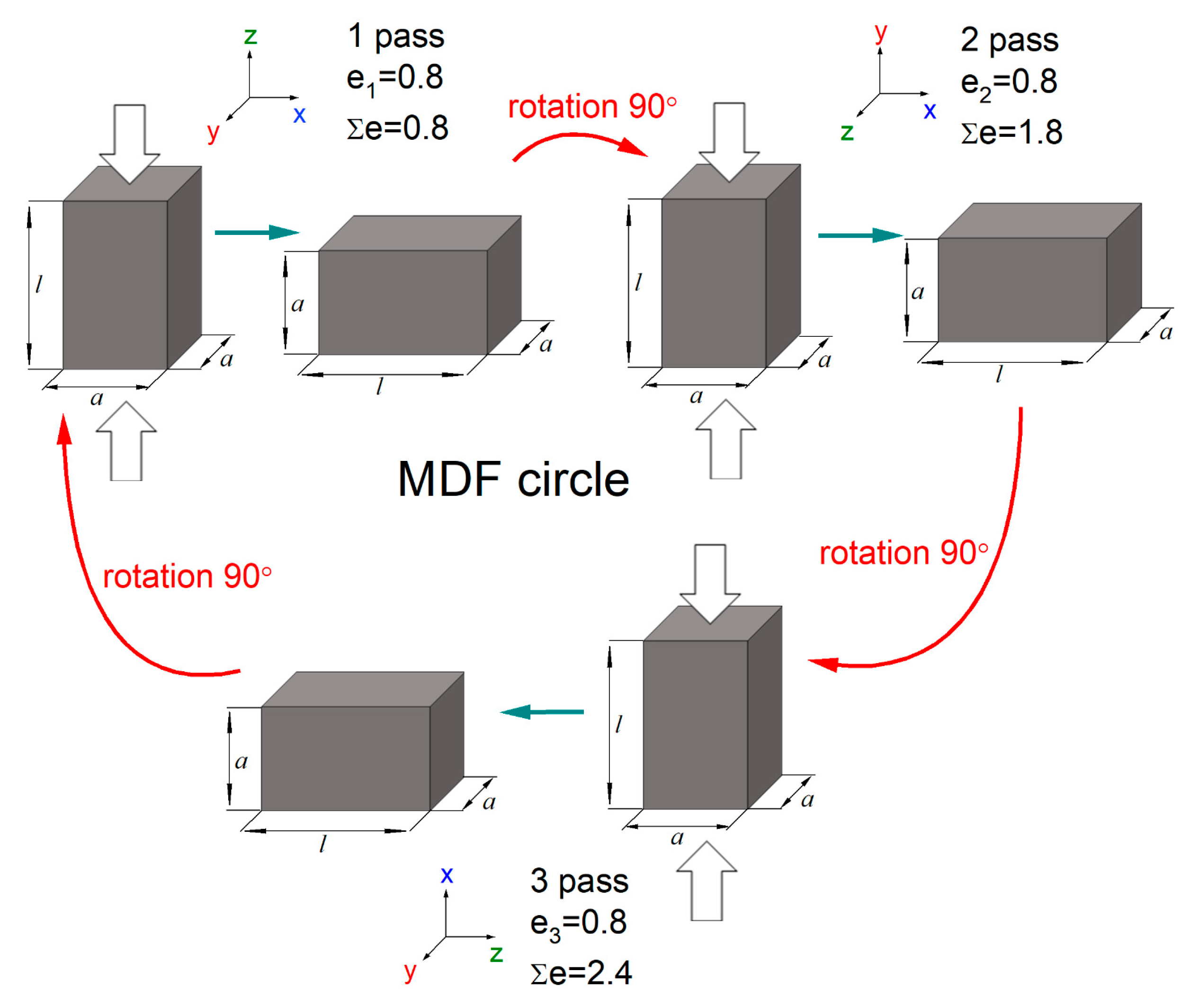

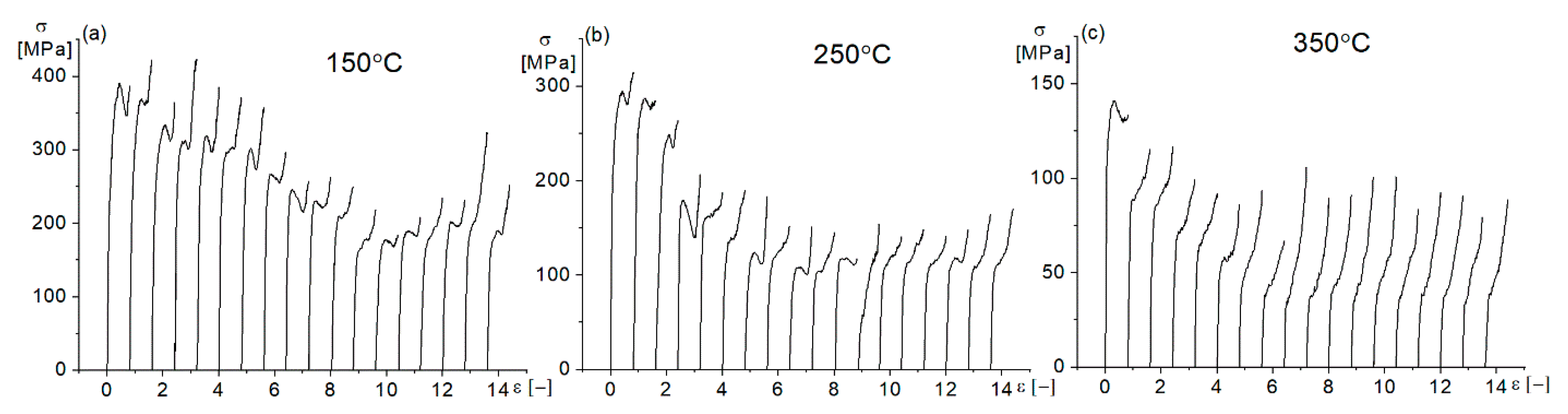

3.2. Deformation Behavior during MDF

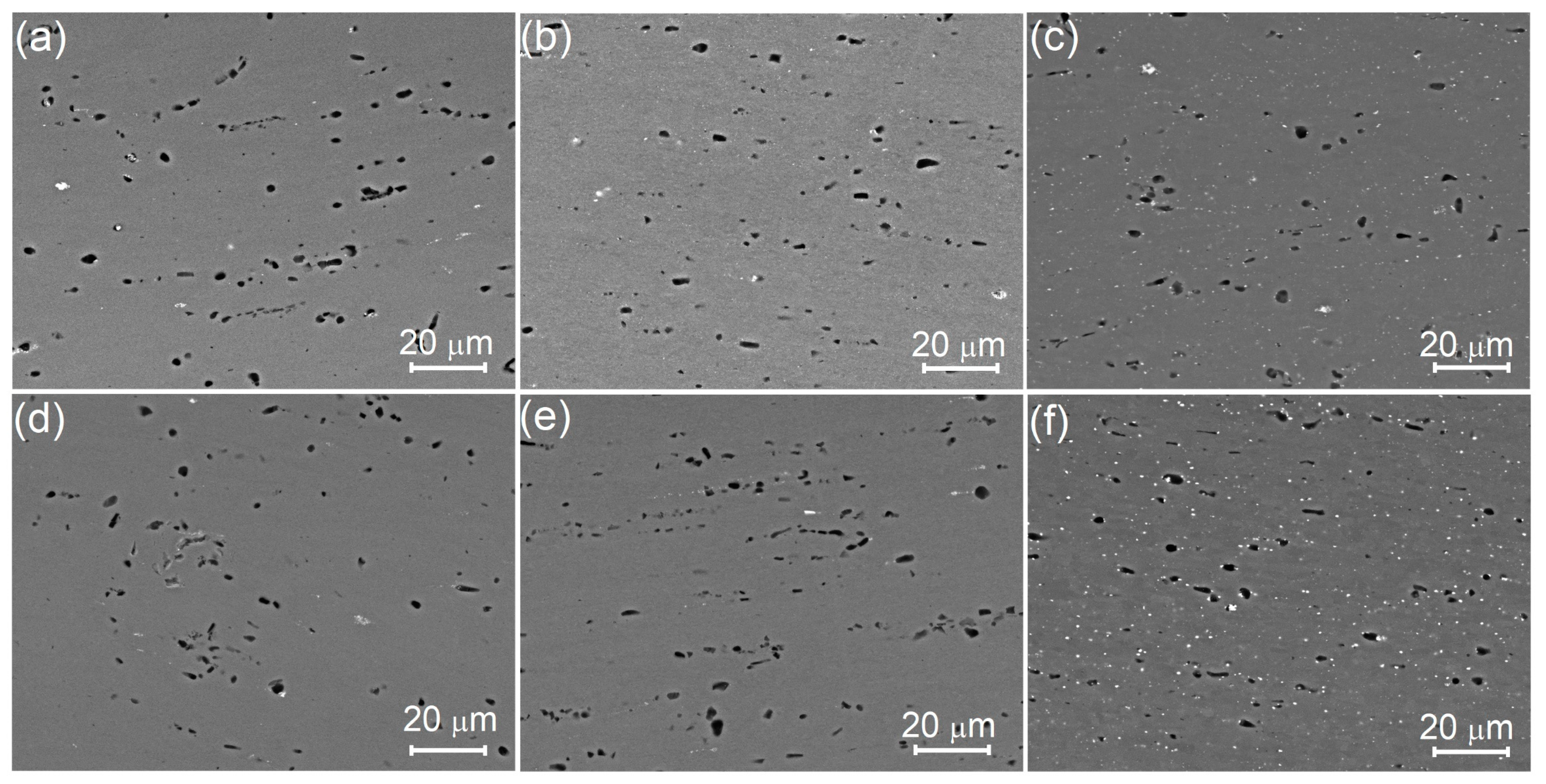

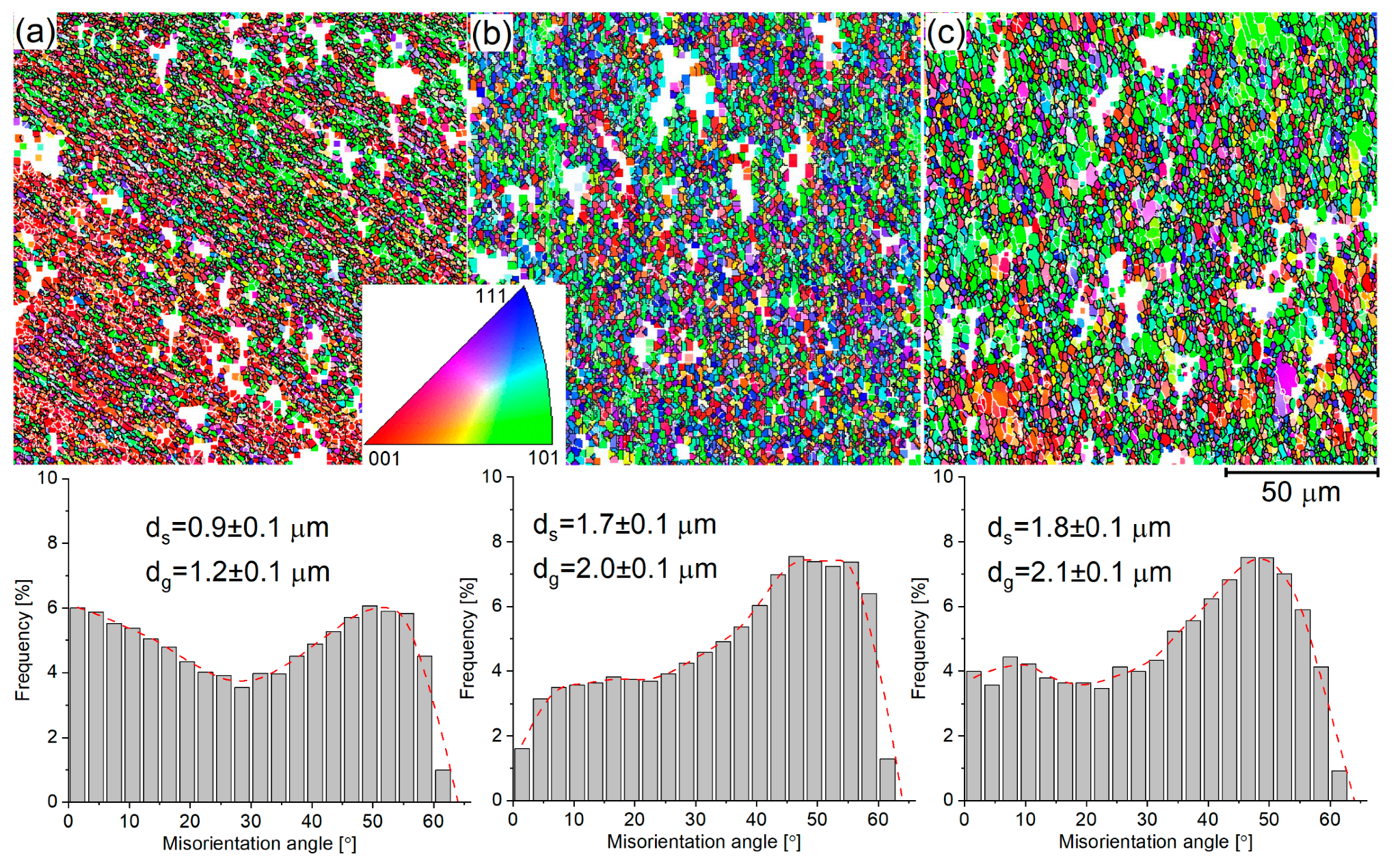

3.3. The Microstructure of Alloy after MDF

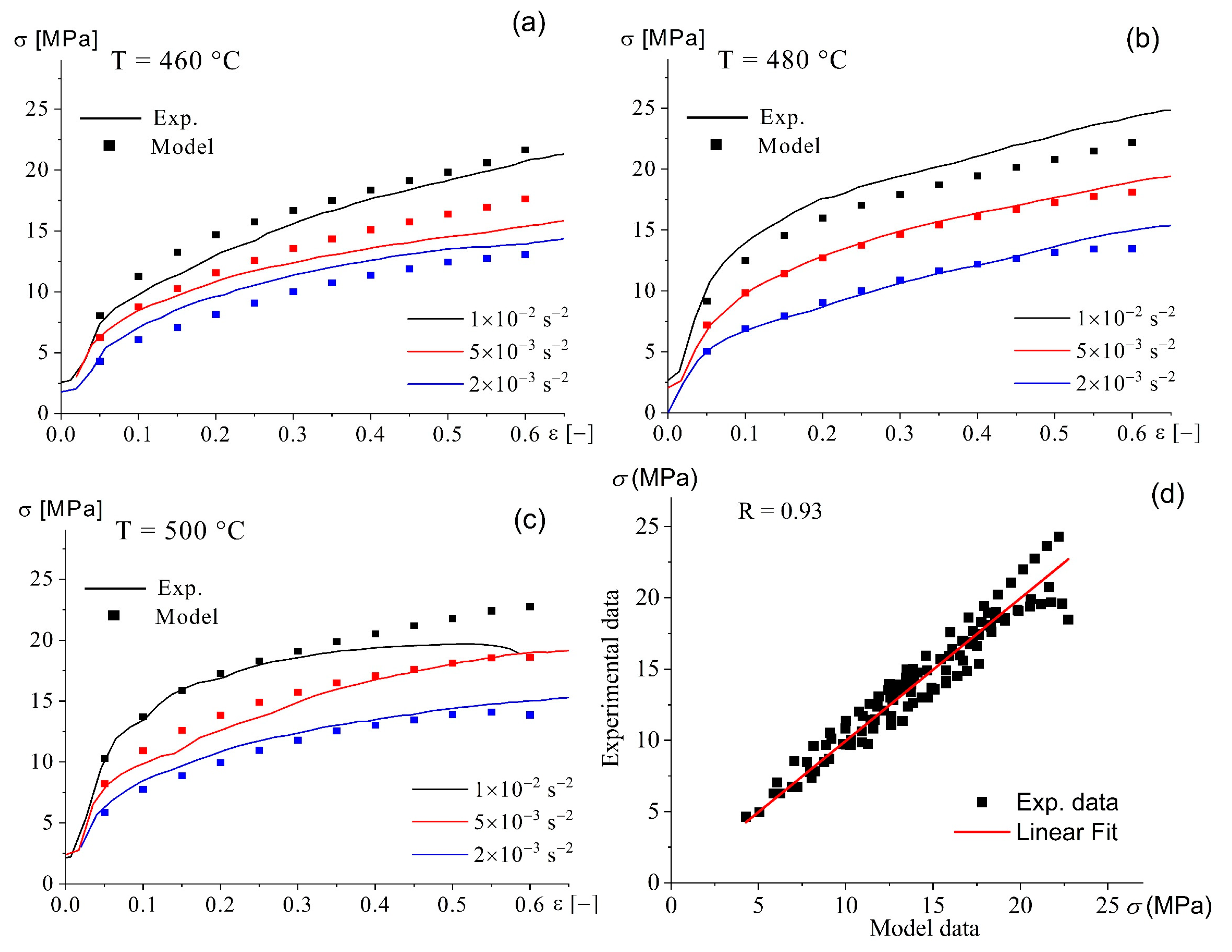

3.4. The Hot Deformation Behavior of Alloy after MDF

3.5. Room Temperature Mechanical Properties

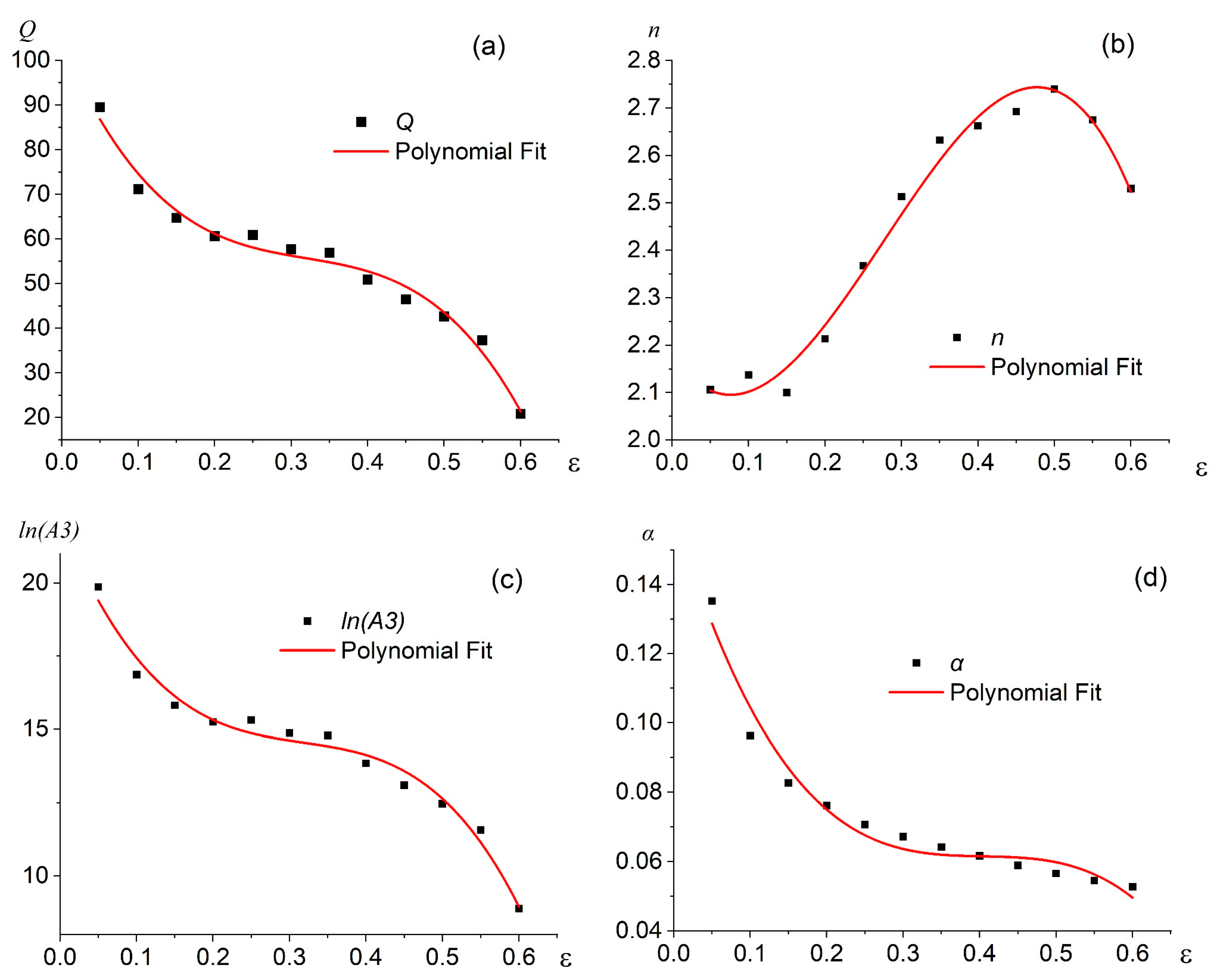

3.6. Arrhenius Constitutive Model

3.6.1. Calculation of the Arrhenius Constitutive Model Constants

3.6.2. Compensation of Strain Effect

4. Discussion

5. Conclusions

- Two Sc-bearing phases were formed in the studied alloy during solidification: the Cu-rich W(AlCuSc)-phase with dissolved Si atoms and the Cu-free V(AlSc2Si2) phase were suggested. A minor amount of particles of these phases with a size in a range of 0.2–2 µm were also observed after homogenization annealing and MDF. The dispersoids of the L12-Al3(Sc,Zr) phase with a mean size of 10 ± 1 nm were precipitated during homogenization annealing.

- Due to the Zener pinning effect of nanoscale L12 phase dispersoids and a large cumulative strain of 14.4, the fine-grained structure with a mean grain size of 1.2–2.1 µm was formed after MDF.

- Fine-grained as-forged at 350 °C alloy exhibited the maximum elongation to failure of ~300% at 460 °C in a strain-rate range of 2 × 10−3–1 × 10−2 s−1; at room temperature, the alloy exhibited yield strength of 326 ± 5 MPa, ultimate tensile strength of 366 ± 5 MPa, and elongation at fracture of 10 ± 3%.

- The hot deformation behavior was described using the Arrhenius type constitutive model. The developed model demonstrated a high predictability accuracy with a maximum average absolute relative error of 6.6%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guan, R.-G.; Tie, D. A Review on Grain Refinement of Aluminum Alloys: Progresses, Challenges and Prospects. Acta Metall. Sin. Engl. Lett. 2017, 30, 409–432. [Google Scholar] [CrossRef]

- Huang, Y.; Langdon, T.G. Advances in Ultrafine-Grained Materials. Mater. Today 2013, 16, 85–93. [Google Scholar] [CrossRef]

- Miller, W.; Zhuang, L.; Bottema, J.; Wittebrood, A.; De Smet, P.; Haszler, A.; Vieregge, A. Recent Development in Aluminium Alloys for the Automotive Industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Heinz, A.; Haszler, A.; Keidel, C.; Moldenhauer, S.; Benedictus, R.; Miller, W. Recent Development in Aluminium Alloys for Aerospace Applications. Mater. Sci. Eng. A 2000, 280, 102–107. [Google Scholar] [CrossRef]

- Hirsch, J. Recent Development in Aluminium for Automotive Applications. Trans. Nonferrous Met. Soc. China 2014, 24, 1995–2002. [Google Scholar] [CrossRef]

- Sotoudeh, K.; Bate, P.S. Diffusion Creep and Superplasticity in Aluminium Alloys. Acta Mater. 2010, 58, 1909–1920. [Google Scholar] [CrossRef]

- Troeger, L.P.; Starke, E.A. Particle-Stimulated Nucleation of Recrystallization for Grain-Size Control and Superplasticity in an Al–Mg–Si–Cu Alloy. Mater. Sci. Eng. A 2000, 293, 19–29. [Google Scholar] [CrossRef]

- Troeger, L.P.; Starke, E.A. Microstructural and Mechanical Characterization of a Superplastic 6xxx Aluminum Alloy. Mater. Sci. Eng. A 2000, 277, 102–113. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Nemoto, M.; Langdon, T.G. The Use of Severe Plastic Deformation for Microstructural Control. Mater. Sci. Eng. A 2002, 324, 82–89. [Google Scholar] [CrossRef]

- Werenskiold, J.C.; Roven, H.J. Microstructure and Texture Evolution during ECAP of an AlMgSi Alloy: Observations, Mechanisms and Modeling. Mater. Sci. Eng. A 2005, 410–411, 174–177. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Álvarez-Leal, M.; Hidalgo-Manrique, P.; Cepeda-Jiménez, C.M.; Ruano, O.A.; Carreño, F. Grain Size versus Microstructural Stability in the High Strain Rate Superplastic Response of a Severely Friction Stir Processed Al-Zn-Mg-Cu Alloy. Mater. Sci. Eng. A 2017, 680, 329–337. [Google Scholar] [CrossRef]

- Han, J.-K.; Jang, J.; Langdon, T.G.; Kawasaki, M. Bulk-State Reactions and Improving the Mechanical Properties of Metals through High-Pressure Torsion. Mater. Trans. 2019, 60, 1131–1138. [Google Scholar] [CrossRef]

- Mulyukov, R.R.; Imayev, R.M.; Nazarov, A.A. Production, Properties and Application Prospects of Bulk Nanostructured Materials. J. Mater. Sci. 2008, 43, 7257–7263. [Google Scholar] [CrossRef]

- Alemdağ, Y.; Karabiyik, S.; Pürçek, G. Microstructure and Mechanical Properties of Severely Deformed Eutectic Al–Si–Cu–Mn Alloy. Met. Mater. Int. 2023, 29, 1181–1194. [Google Scholar] [CrossRef]

- Sitdikov, O.S.; Avtokratova, E.V.; Atanov, B.I.; Markushev, M.V. Effect of Multidirectional Isothermal Forging on the Formation of Ultrafine-Grained Structure in Alloy 1570 C. Inorg. Mater. 2022, 58, 544–554. [Google Scholar] [CrossRef]

- Kumara, B.; Preetham Kumar, G.V. Influence of Multi-Directional Room-Temperature Forging Process on Microstructure and Mechanical Behaviour of Eutectic Al-12Si Alloy. Metallogr. Microstruct. Anal. 2022, 11, 175–182. [Google Scholar] [CrossRef]

- He, H.; Chen, K.; Yi, Y.; You, W.; Guo, Y.; Wang, B.; Tang, J.; Guo, W.; Huang, S. Influence of Forging Temperature on the Microstructures and Mechanical Properties of a Multi-Directionally Forged Al–Cu–Li Alloy. Met. Mater. Int. 2022, 28, 433–447. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, L.; Ban, C.; Zhao, Z.; Zuo, Y.; Cui, J. Structure Uniformity and Limits of Grain Refinement of High Purity Aluminum during Multi-Directional Forging Process at Room Temperature. Trans. Nonferrous Met. Soc. China 2014, 24, 1301–1306. [Google Scholar] [CrossRef]

- Armstrong, P.E.; Hockett, J.E.; Sherby, O.D. Large Strain Multidirectional Deformation of 1100 Aluminum at 300 K. J. Mech. Phys. Solids 1982, 30, 37–58. [Google Scholar] [CrossRef]

- Sitdikov, O.; Garipova, R.; Avtokratova, E.; Mukhametdinova, O.; Markushev, M. Effect of Temperature of Isothermal Multidirectional Forging on Microstructure Development in the Al-Mg Alloy with Nano-Size Aluminides of Sc and Zr. J. Alloys Compd. 2018, 746, 520–531. [Google Scholar] [CrossRef]

- Sitdikov, O.S.; Avtokratova, E.V.; Murzinova, M.A.; Markushev, M.V. Effect of Multidirectional Forging with Decreasing Temperature on the Microstructure and Microhardness of the Aluminum-Magnesium-Scandium-Zirconium Alloy. Mater. Perform. Charact. 2020, 9, 20190006. [Google Scholar] [CrossRef]

- Rao, P.N.; Singh, D.; Jayaganthan, R. Mechanical Properties and Microstructural Evolution of Al 6061 Alloy Processed by Multidirectional Forging at Liquid Nitrogen Temperature. Mater. Des. 2014, 56, 97–104. [Google Scholar] [CrossRef]

- Hussain, M.; Rao, P.N.; Singh, D.; Jayaganthan, R.; Singh, S. Comparative Study of Microstructure and Mechanical Properties of Al 6063 Alloy Processed by Multi Axial Forging at 77K and Cryorolling. Procedia Eng. 2014, 75, 129–133. [Google Scholar] [CrossRef]

- Amer, S.M.; Barkov, R.Y.; Prosviryakov, A.S.; Pozdniakov, A.V. Pozdniakov. Structure and Properties of New Heat-Resistant Cast Alloys Based on the Al–Cu–Y and Al–Cu–Er Systems. Phys. Met. Metallogr. 2021, 122, 908–914. [Google Scholar] [CrossRef]

- Liu, F.; Zhu, X.; Qin, J.; Zhou, W.; Ling, J.; Dong, Q.; Yu, J.; Nagaumi, H.; Zhang, B. Effect of Mn/Cr Ratio on Precipitation Behaviors of α-Al(FeMnCr)Si Dispersoids and Mechanical Properties of Al–Mg–Si–Cu Alloys. Mater. Sci. Eng. A 2022, 860, 144269. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, C.-C.; Zhang, X.-Y.; Huang, Y.-C. Understanding Grain Refinement of Sc Addition in a Zr Containing Al-Zn-Mg-Cu Aluminum Alloy from Experiments and First-Principles. Intermetallics 2020, 123, 106823. [Google Scholar] [CrossRef]

- Jiang, H.; Xing, H.; Xu, Z.; Yang, B.; Liang, E.; Zhang, J.; Sun, B. Effect of Zn Content and Sc,Zr Addition on Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloys. J. Alloys Compd. 2023, 947, 169246. [Google Scholar] [CrossRef]

- Dorin, T.; Jiang, L.; Langan, T. Formation of Al3Sc Dispersoids and Associated Strengthening. In TMS Annual Meeting & Exhibition; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 1207–1212. [Google Scholar]

- Croteau, J.R.; Jung, J.-G.; Whalen, S.A.; Darsell, J.; Mello, A.; Holstine, D.; Lay, K.; Hansen, M.; Dunand, D.C.; Vo, N.Q. Ultrafine-Grained Al-Mg-Zr Alloy Processed by Shear-Assisted Extrusion with High Thermal Stability. Scr. Mater. 2020, 186, 326–330. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Mochugovskiy, A.G.; Levchenko, V.S.; Tabachkova, N.Y.; Mufalo, W.; Portnoy, V.K. Precipitation Behavior of L12 Al3Zr Phase in Al-Mg-Zr Alloy. Mater. Charact. 2018, 139, 30–37. [Google Scholar] [CrossRef]

- Monastyrska, T.O.; Berezina, A.L.; Molebny, O.A.; Kotko, A.V. Effect of Alloying with Transition Metals on the Aging of Anomalously Supersaturated Solid Solution of Al–Mg Alloys. Appl. Nanosci. 2022, 12, 513–521. [Google Scholar] [CrossRef]

- Xue, C.; Wang, S.; Zhang, Y.; Tian, G.; Yang, X.; Chang, X.; Ke, Y.; Xie, Z.; Wang, J. Uncovering the Kinetics of Li-Rich Clusters and Monodisperse Core–Shell Al3(Zr, Sc) Structures in Al–Li–Cu Alloys. Mater. Sci. Eng. A 2023, 881, 145393. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.; Wu, R.; Turakhodjaev, N.; Hou, L.; Zhang, J.; Betsofen, S. Coarsening Kinetics and Strengthening Mechanisms of Core-Shell Nanoscale Precipitates in Al-Li-Yb-Er-Sc-Zr Alloy. J. Mater. Sci. Technol. 2021, 61, 197–203. [Google Scholar] [CrossRef]

- Manohar, P.A.; Ferry, M.; Chandra, T. Five Decades of the Zener Equation. ISIJ Int. 1998, 38, 913–924. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Avtokratova, E.; Apollonov, A.; Davies, R. High Strain Rate Superplasticity in an Al–Mg–Sc–Zr Alloy Subjected to Simple Thermomechanical Processing. Scr. Mater. 2006, 54, 2119–2124. [Google Scholar] [CrossRef]

- Sitdikov, O.; Avtokratova, E.; Markushev, M. Influence of Strain Rate on Grain Refinement in the Al-Mg-Sc-Zr Alloy during High-Temperature Multidirectional Isothermal Forging. Mater. Charact. 2019, 157, 109885. [Google Scholar] [CrossRef]

- Higashi, K.; Nagai, S.; Maeda, M.; Ohnishi, T. The Superplastic Behavior and Structural Changes during Hot Deformation of Al-Cu-Zr Alloys. J. Jpn. Inst. Light Met. 1986, 36, 361–371. [Google Scholar] [CrossRef]

- Avtokratova, E.; Sitdikov, O.; Markushev, M.; Mulyukov, R. Extraordinary High-Strain Rate Superplasticity of Severely Deformed Al–Mg–Sc–Zr Alloy. Mater. Sci. Eng. A 2012, 538, 386–390. [Google Scholar] [CrossRef]

- Smolej, A.; Klobčar, D.; Skaza, B.; Nagode, A.; Slaček, E.; Dragojević, V.; Smolej, S. Superplasticity of the Rolled and Friction Stir Processed Al–4.5 Mg–0.35Sc–0.15Zr Alloy. Mater. Sci. Eng. A 2014, 590, 239–245. [Google Scholar] [CrossRef]

- Duan, Y.L.; Tang, L.; Deng, Y.; Cao, X.W.; Xu, G.F.; Yin, Z.M. Superplastic Behavior and Microstructure Evolution of a New Al-Mg-Sc-Zr Alloy Subjected to a Simple Thermomechanical Processing. Mater. Sci. Eng. A 2016, 669, 205–217. [Google Scholar] [CrossRef]

- Cao, X.; Xu, G.; Duan, Y.; Yin, Z.; Lu, L.; Wang, Y. Achieving High Superplasticity of a New Al–Mg–Sc–Zr Alloy Sheet Prepared by a Simple Thermal–Mechanical Process. Mater. Sci. Eng. A 2015, 647, 333–343. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Mosleh, A.O.; Kotov, A.D.; Khokhlov, A.V.; Kaplanskaya, L.Y.; Mikhaylovskaya, A.V. Microstructure Evolution, Constitutive Modelling, and Superplastic Forming of Experimental 6XXX-Type Alloys Processed with Different Thermomechanical Treatments. Materials 2023, 16, 445. [Google Scholar] [CrossRef]

- Esmaeili Ghayoumabadi, M.; Mochugovskiy, A.G.; Tabachkova, N.Y.; Mikhaylovskaya, A.V. The Influence of Minor Additions of Y, Sc, and Zr on the Microstructural Evolution, Superplastic Behavior, and Mechanical Properties of AA6013 Alloy. J. Alloys Compd. 2022, 900, 163477. [Google Scholar] [CrossRef]

- Fridlyander, I.N.; Senatorova, O.G.; Ryazanova, N.A.; Nikiforov, A.O. Grain Structure and Superplasticity of High Strength AL-ZN-MG-CU Alloys with Different Minor Additions. Mater. Sci. Forum 1994, 170–172, 345–350. [Google Scholar] [CrossRef]

- Kumar, A.; Mukhopadhyay, A.K.; Prasad, K.S. Superplastic Behaviour of Al–Zn–Mg–Cu–Zr Alloy AA7010 Containing Sc. Mater. Sci. Eng. A 2010, 527, 854–857. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Pergamon Press: Oxford, UK, 1995. [Google Scholar]

- Belov, N.A.; Alabin, A.N.; Eskin, D.G.; Istomin-Kastrovskii, V.V. Optimization of Hardening of Al–Zr–Sc Cast Alloys. J. Mater. Sci. 2006, 41, 5890–5899. [Google Scholar] [CrossRef]

- Mousavi Anijdan, S.H.; Kang, D.; Singh, N.; Gallerneault, M. Precipitation Behavior of Strip Cast Al–Mg–0.4Sc–0.15Zr Alloy under Single and Multiple-Stage Aging Processes. Mater. Sci. Eng. A 2015, 640, 275–279. [Google Scholar] [CrossRef]

- Guo, Z.; Zhao, G.; Chen, X.-G. Effects of Two-Step Homogenization on Precipitation Behavior of Al3Zr Dispersoids and Recrystallization Resistance in 7150 Aluminum Alloy. Mater. Charact. 2015, 102, 122–130. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kotov, A.D.; Kishchik, M.S.; Prosviryakov, A.S.; Portnoy, V.K. The Effect of Isothermal Multi-Directional Forging on the Grain Structure, Superplasticity, and Mechanical Properties of the Conventional Al–Mg-Based Alloy. Metals 2019, 9, 33. [Google Scholar] [CrossRef]

- Kishchik, M.S.; Mochugovskiy, A.G.; Cuda, M.; Kishchik, A.A.; Mikhaylovskaya, A.V. Particle Stimulated Nucleation Effect for Al-Mg-Zr-Sc Alloys with Ni Addition during Multidirectional Forging. Metals 2023, 13, 1499. [Google Scholar] [CrossRef]

- Kai, X.; Zhao, Y.; Wang, A.; Wang, C.; Mao, Z. Hot Deformation Behavior of in Situ Nano ZrB2 Reinforced 2024Al Matrix Composite. Compos. Sci. Technol. 2015, 116, 1–8. [Google Scholar] [CrossRef]

- Kai, X.; Chen, C.; Sun, X.; Wang, C.; Zhao, Y. Hot Deformation Behavior and Optimization of Processing Parameters of a Typical High-Strength Al–Mg–Si Alloy. Mater. Des. 2016, 90, 1151–1158. [Google Scholar] [CrossRef]

- Amer, S.M.; Yu. Barkov, R.; Yakovtseva, O.A.; Loginova, I.S.; Pozdniakov, A.V. Effect of Zr on Microstructure and Mechanical Properties of the Al–Cu–Er Alloy. Mater. Sci. Technol. 2020, 36, 453–459. [Google Scholar] [CrossRef]

- Mamzurina, O.I.; Amer, S.M.; Glavatskikh, M.V.; Barkov, R.Y.; Loginova, I.S.; Pozdniakov, A.V. Microstructure and Mechanical Properties of Novel Heat Resistant Cast Al-Cu-Yb(Gd)-Mg-Mn-Zr Alloys. Metals 2022, 12, 2079. [Google Scholar] [CrossRef]

- Huang, H.; Jiang, M.; Wei, L.; Liu, C.; Liu, S. Microstructural and Mechanical Behavior of Al-Mg-Mn-Sc-Zr Alloy Subjected to Multi-Axial Forging at Room Temperature. Mater. Charact. 2021, 171, 110734. [Google Scholar] [CrossRef]

- Sitdikov, O.; Avtokratova, E.; Markushev, M. Development of Ultrafine Grain Structure in an Al–Mg–Mn–Sc–Zr Alloy During High-Temperature Multidirectional Isothermal Forging. Met. Mater. Int. 2021, 27, 2743–2755. [Google Scholar] [CrossRef]

- Ringeval, S.; Piot, D.; Desrayaud, C.; Driver, J.H. Texture and Microtexture Development in an Al–3Mg–Sc(Zr) Alloy Deformed by Triaxial Forging. Acta Mater. 2006, 54, 3095–3105. [Google Scholar] [CrossRef]

- Sitdikov, O.S.; Avtokratova, E.V.; Krymskyi, S.V.; Ilyasov, R.R.; Markushev, M.V. Effect of Severe Forging and Rolling on the Microstructure and Mechanical Properties of Al–Mg–Sc–Zr Alloy. Inorg. Mater. 2021, 57, 101–111. [Google Scholar] [CrossRef]

- Dumbre, J.; Kairy, S.K.; Anber, E.; Langan, T.; Taheri, M.L.; Dorin, T.; Birbilis, N. Understanding the Formation of (Al,Si)3Sc and V-Phase (AlSc2Si2) in Al-Si-Sc Alloys via Ex Situ Heat Treatments and in Situ Transmission Electron Microscopy Studies. J. Alloys Compd. 2021, 861, 158511. [Google Scholar] [CrossRef]

- Vo, N.Q.; Dunand, D.C.; Seidman, D.N. Improving Aging and Creep Resistance in a Dilute Al–Sc Alloy by Microalloying with Si, Zr and Er. Acta Mater. 2014, 63, 73–85. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Prosviryakov, A.S.; Tabachkova, N.Y.; Mikhaylovskaya, A.V. The Effect of Ce on the Microstructure, Superplasticity, and Mechanical Properties of Al-Mg-Si-Cu Alloy. Metals 2022, 12, 512. [Google Scholar] [CrossRef]

- Humphreys, F.J. The Nucleation of Recrystallization at Second Phase Particles in Deformed Aluminium. Acta Metall. 1977, 25, 1323–1344. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Ryazantseva, M.A.; Portnoy, V.K. Effect of Eutectic Particles on the Grain Size Control and the Superplasticity of Aluminium Alloys. Mater. Sci. Eng. A 2011, 528, 7306–7309. [Google Scholar] [CrossRef]

- Loginova, I.S.; Sazerat, M.V.; Loginov, P.A.; Pozdniakov, A.V.; Popov, N.A.; Solonin, A.N. Evaluation of Microstructure and Hardness of Novel Al-Fe-Ni Alloys with High Thermal Stability for Laser Additive Manufacturing. JOM 2020, 72, 3744–3752. [Google Scholar] [CrossRef]

- Gazizov, M.; Teleshov, V.; Zakharov, V.; Kaibyshev, R. Solidification Behaviour and the Effects of Homogenisation on the Structure of an Al–Cu–Mg–Ag–Sc Alloy. J. Alloys Compd. 2011, 509, 9497–9507. [Google Scholar] [CrossRef]

- Kharakterova, M.L.; Eskin, D.G.; Toropova, L.S. Precipitation Hardening in Ternary Alloys of the Al-Sc-Cu and Al-Sc-Si Systems. Acta Metall. Mater. 1994, 42, 2285–2290. [Google Scholar] [CrossRef]

- Chakrabarti, D.J.; Peng, Y.; Laughlin, D.E. Precipitation in Al-Mg-Si Alloys with Cu Additions and the Role of the Q’ and Related Phases. Mater. Sci. Forum 2002, 396–402, 857–862. [Google Scholar] [CrossRef]

- Staab, T.E.M.; Krause-Rehberg, R.; Hornauer, U.; Zschech, E. Study of Artificial Aging in AlMgSi (6061) and AlMgSiCu (6013) Alloys by Positron Annihilation. J. Mater. Sci. 2006, 41, 1059–1066. [Google Scholar] [CrossRef]

- Kishchik, A.A.; Kishchik, M.S.; Kotov, A.D.; Mikhaylovskaya, A.V. Effect of Multidirectional Forging on the Microstructure and Mechanical Properties of the Al–Mg–Mn–Cr Alloy. Phys. Met. Metallogr. 2020, 121, 489–494. [Google Scholar] [CrossRef]

- Kishchik, M.S.; Mikhaylovskaya, A.V.; Kotov, A.D.; Mosleh, A.O.; AbuShanab, W.S.; Portnoy, V.K. Effect of Multidirectional Forging on the Grain Structure and Mechanical Properties of the Al-Mg-Mn Alloy. Materials 2018, 11, 2166. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and Post-Dynamic Recrystallization under Hot, Cold and Severe Plastic Deformation Conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Sakai, T.; Jonas, J.J. Plastic Deformation: Role of Recovery and Recrystallization. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 7079–7084. [Google Scholar]

- Humphreys, F.J. A Unified Theory of Recovery, Recrystallization and Grain Growth, Based on the Stability and Growth of Cellular Microstructures—II. The Effect of Second-Phase Particles. Acta Mater. 1997, 45, 5031–5039. [Google Scholar] [CrossRef]

- Humphreys, F.J. A Unified Theory of Recovery, Recrystallization and Grain Growth, Based on the Stability and Growth of Cellular Microstructures—I. The Basic Model. Acta Mater. 1997, 45, 4231–4240. [Google Scholar] [CrossRef]

- Xia, Y.; Shu, X.; Zhang, Q.; Pater, Z.; Li, Z.; Xu, H.; Ma, Z.; Xu, C. Modified Arrhenius Constitutive Model and Simulation Verification of 2A12-T4 Aluminum Alloy during Hot Compression. J. Mater. Res. Technol. 2023, 26, 1325–1340. [Google Scholar] [CrossRef]

- Li, J.; Yang, X.; Zhu, Y.; Zhang, Y.; Qiu, Y.; Sanders, R.E. Study of Thermal Compression Constitutive Relation for 5182-Sc-Zr Alloy Based on Arrhenius-Type and ANN Model. Crystals 2022, 12, 611. [Google Scholar] [CrossRef]

- Xie, Q.; Wu, Y.; Peng, S.; Yuan, Z. Prediction Flow Behaviour of a Magnesium Alloy in Hot Deformation and a Comparative Study by Using Hyperbolic Sine Model and ANN Model. Phys. Met. Metallogr. 2022, 123, 1471–1478. [Google Scholar] [CrossRef]

- Kalish, D.; LeFevre, B.G. Subgrain Strengthening of Aluminum Conductor Wires. Metall. Trans. A 1975, 6, 1319–1324. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Mikhaylovskaya, A.V.; Zadorognyy, M.Y.; Golovin, I.S. Effect of Heat Treatment on the Grain Size Control, Superplasticity, Internal Friction, and Mechanical Properties of Zirconium-Bearing Aluminum-Based Alloy. J. Alloys Compd. 2021, 856, 157455. [Google Scholar] [CrossRef]

- Knipling, K.E.; Karnesky, R.A.; Lee, C.P.; Dunand, D.C.; Seidman, D.N. Precipitation Evolution in Al–0.1Sc, Al–0.1Zr and Al–0.1Sc–0.1Zr (at.%) Alloys during Isochronal Aging. Acta Mater. 2010, 58, 5184–5195. [Google Scholar] [CrossRef]

- Mahmudi, R.; Rezaee-Bazzaz, A.; Banaie-Fard, H.R. Investigation of Stress Exponent in the Room-Temperature Creep of Sn–40Pb–2.5Sb Solder Alloy. J. Alloys Compd. 2007, 429, 192–197. [Google Scholar] [CrossRef]

- Langdon, T.G. Identifiying Creep Mechanisms at Low Stresses. Mater. Sci. Eng. A 2000, 283, 266–273. [Google Scholar] [CrossRef]

- Yang, X.; Guo, H.; Liang, H.; Yao, Z.; Yuan, S. Flow Behavior and Constitutive Equation of Ti-6.5Al-2Sn-4Zr-4Mo-1W-0.2Si Titanium Alloy. J. Mater. Eng. Perform. 2016, 25, 1347–1359. [Google Scholar] [CrossRef]

- Mandal, S.; Rakesh, V.; Sivaprasad, P.V.; Venugopal, S.; Kasiviswanathan, K.V. Constitutive Equations to Predict High Temperature Flow Stress in a Ti-Modified Austenitic Stainless Steel. Mater. Sci. Eng. A 2009, 500, 114–121. [Google Scholar] [CrossRef]

- Pu, Z.J.; Wu, K.H.; Shi, J.; Zou, D. Development of Constitutive Relationships for the Hot Deformation of Boron Microalloying Ti-Al-Cr-V Alloys. Mater. Sci. Eng. A 1995, 192–193, 780–787. [Google Scholar] [CrossRef]

- Rao, K.P.; Hawbolt, E.B. Development of Constitutive Relationships Using Compression Testing of a Medium Carbon Steel. J. Eng. Mater. Technol. 1992, 114, 116–123. [Google Scholar] [CrossRef]

| Particle Parameter | Number of Circles | Temperature of MDF | ||

|---|---|---|---|---|

| 150 °C | 250 °C | 350 °C | ||

| Mean particle size, µm | 3 | 1.3 ± 0.1 | 1.3 ± 0.2 | 1.5 ± 0.2 |

| 6 | 1.3 ± 0.1 | 1.4 ± 0.1 | 1.5 ± 0.2 | |

| Aspect ratio | 3 | 0.62 ± 0.04 | 0.68 ± 0.03 | 0.65 ± 0.04 |

| 6 | 0.63 ± 0.03 | 0.67 ± 0.03 | 0.66 ± 0.03 | |

| Mean interparticle distance, µm | 3 | 53 ± 11 | 47 ± 10 | 53 ± 8 |

| 6 | 49 ± 12 | 44 ± 8 | 43 ± 8 | |

| Standard deviation of interparticle distance | 3 | 42.9 | 36.8 | 34.9 |

| 6 | 49.2 | 35.1 | 36.7 | |

| Strain Rate (s−1) | Temperature | ||

|---|---|---|---|

| 460 °C | 480 °C | 500 °C | |

| 1 × 10−2 | 310 ± 20 | 130 ± 10 | 110 ± 20 |

| 5 × 10−3 | 290 ± 10 | 210 ± 10 | 120 ± 20 |

| 2 × 10−3 | 310 ± 10 | 240 ± 20 | 200 ± 20 |

| ln(A1) | n1 | Q1 [KJ/mol] | ln(A2) | β [MPa−1] | Q2 [KJ/mol] | α | ln(A3) | n2 | Q3 [KJ/mol] |

|---|---|---|---|---|---|---|---|---|---|

| 23 | 3.5 | 51 ± 5 | 17 | 0.22 | 50 ± 5 | 0.062 | 14 | 2.67 | 51 ± 6 |

| Parameter | Y0 | B1 | B2 | B3 | Adj. R-Square (Third Order) | Adj. R-Square (Fifth Order) |

|---|---|---|---|---|---|---|

| 0.161 | −0.729 | 1.792 | −1.478 | 0.96 | 0.99 | |

| 2.176 | −2.210 | 16.755 | −20.177 | 0.98 | 0.98 | |

| 22.178 | −64.456 | 190.923 | −200.369 | 0.97 | 0.99 | |

| 103.819 | −394.307 | 1143.484 | −1192.050 | 0.98 | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mochugovskiy, A.G.; Kaplanskaya, L.Y.; Mosleh, A.O.; Palacheva, V.V.; Mikhaylovskaya, A.V. Microstructure Evolution and Constitutive Modelling of Deformation Behavior for Al-Mg-Si-Cu-Sc-Zr Alloy Processed with Isothermal Multidirectional Forging. Appl. Sci. 2023, 13, 13054. https://doi.org/10.3390/app132413054

Mochugovskiy AG, Kaplanskaya LY, Mosleh AO, Palacheva VV, Mikhaylovskaya AV. Microstructure Evolution and Constitutive Modelling of Deformation Behavior for Al-Mg-Si-Cu-Sc-Zr Alloy Processed with Isothermal Multidirectional Forging. Applied Sciences. 2023; 13(24):13054. https://doi.org/10.3390/app132413054

Chicago/Turabian StyleMochugovskiy, Andrey G., Ludmila Yu. Kaplanskaya, Ahmed O. Mosleh, Valeria V. Palacheva, and Anastasia V. Mikhaylovskaya. 2023. "Microstructure Evolution and Constitutive Modelling of Deformation Behavior for Al-Mg-Si-Cu-Sc-Zr Alloy Processed with Isothermal Multidirectional Forging" Applied Sciences 13, no. 24: 13054. https://doi.org/10.3390/app132413054

APA StyleMochugovskiy, A. G., Kaplanskaya, L. Y., Mosleh, A. O., Palacheva, V. V., & Mikhaylovskaya, A. V. (2023). Microstructure Evolution and Constitutive Modelling of Deformation Behavior for Al-Mg-Si-Cu-Sc-Zr Alloy Processed with Isothermal Multidirectional Forging. Applied Sciences, 13(24), 13054. https://doi.org/10.3390/app132413054