Alternative Fuels for the Marine Sector and Their Applicability for Purse Seiners in a Life-Cycle Framework

Abstract

:1. Introduction

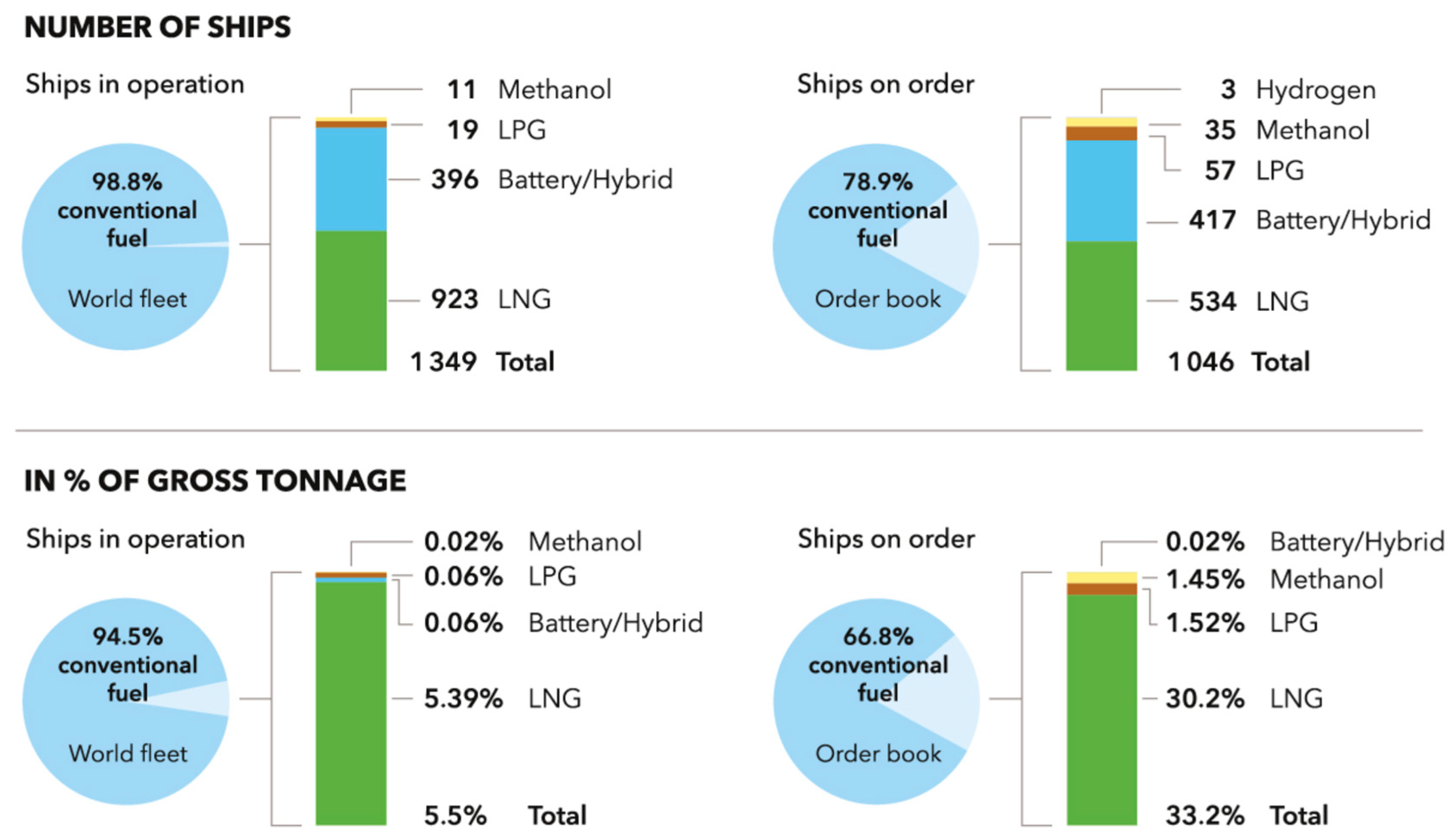

1.1. Research Background

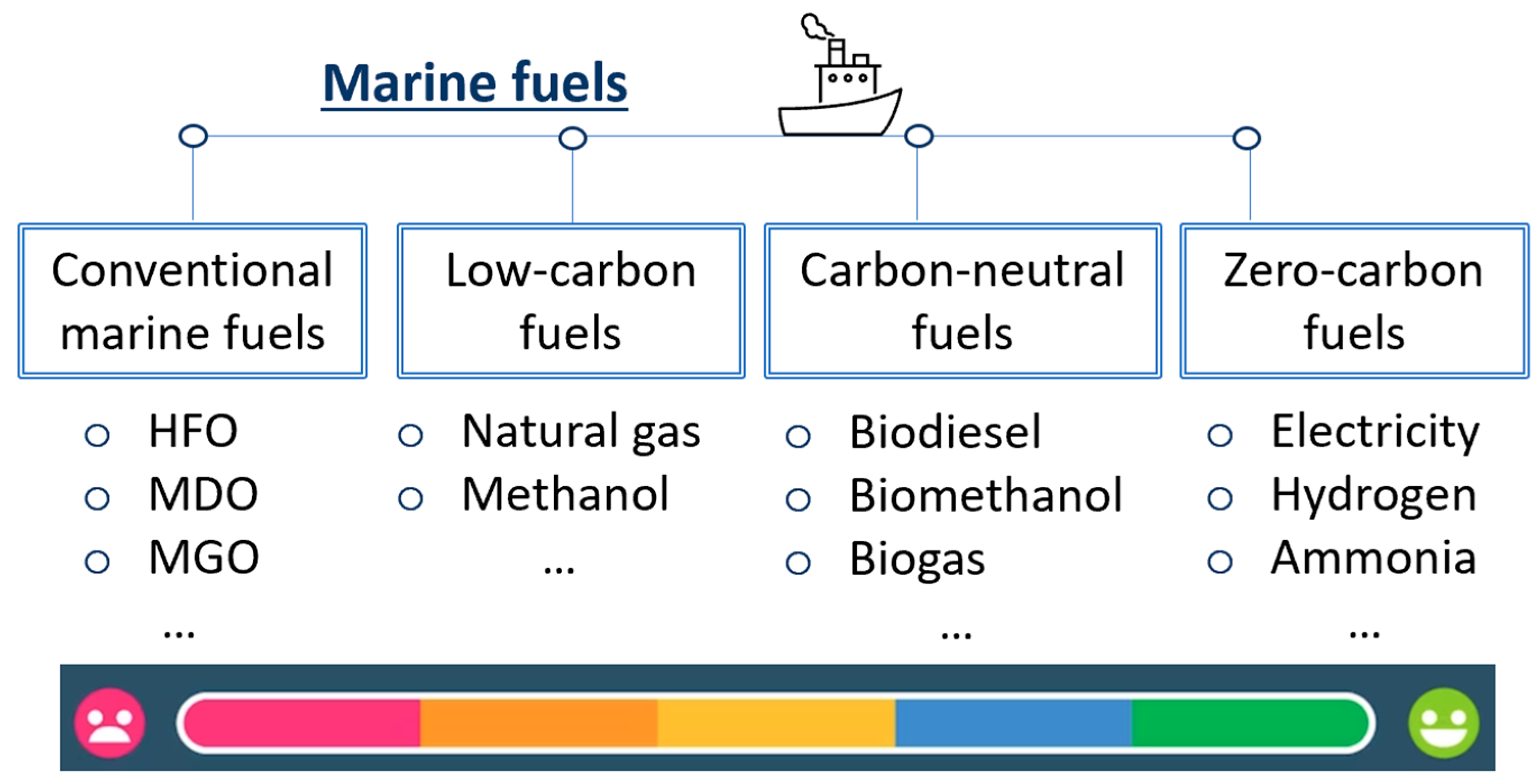

1.2. Review of Alternative Fuels for the Marine Sector

1.2.1. Low-Carbon Fuels

1.2.2. Carbon-Neutral Fuels

1.2.3. Zero-Carbon Fuels

1.2.4. Electro-Fuels

1.2.5. Comparison of Fuels

1.3. Emissions from the Fishing Sector

1.4. The Aim of This Paper

2. Methodology

2.1. Life-Cycle Assessment

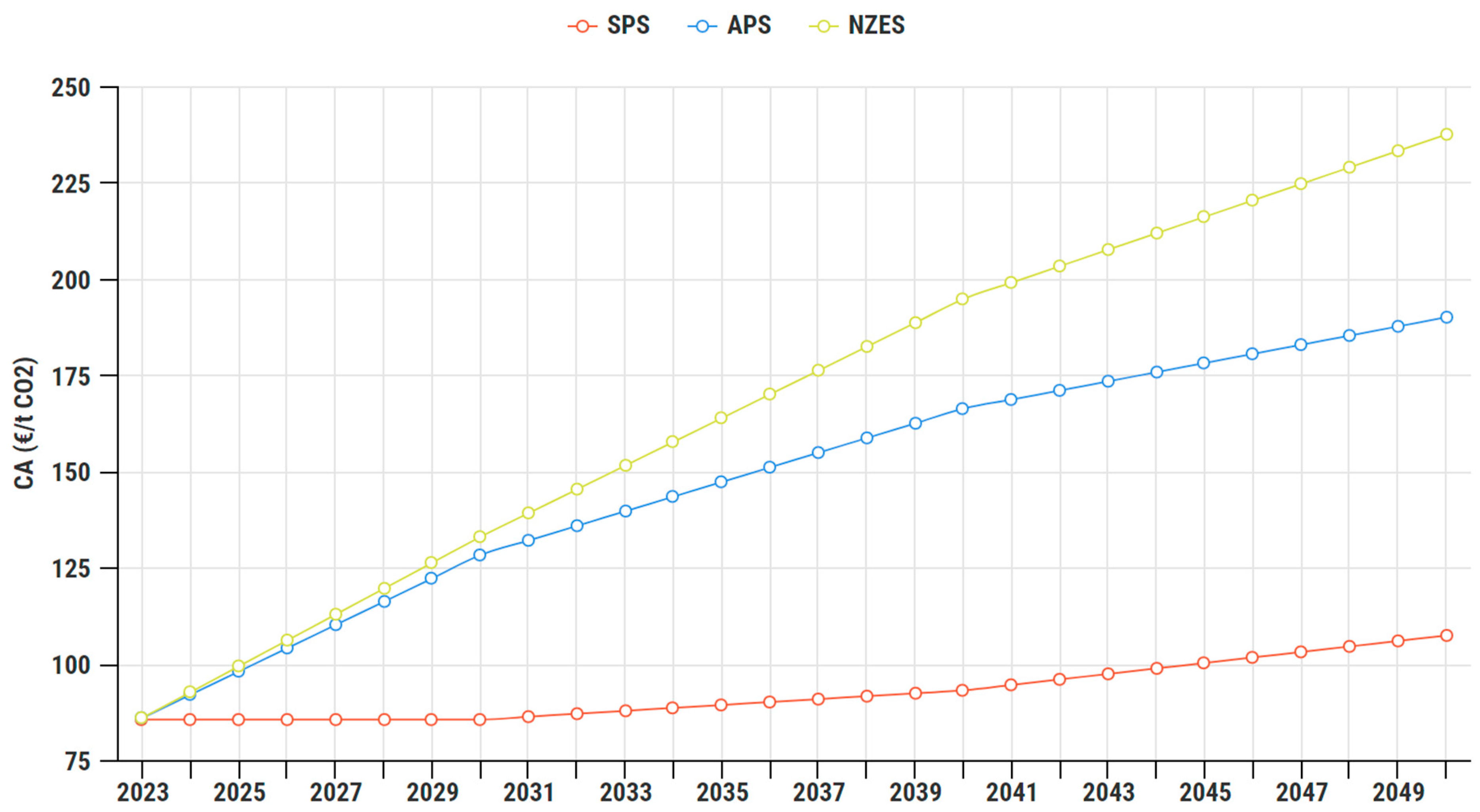

2.2. Life-Cycle Cost Assessment

- SPS: current policies and today’s policy intentions and targets for the EU;

- APS: advanced economies with net zero emissions pledges (including all OECD countries except Mexico);

- NZES: advanced economies with net zero emissions pledges (including all regions).

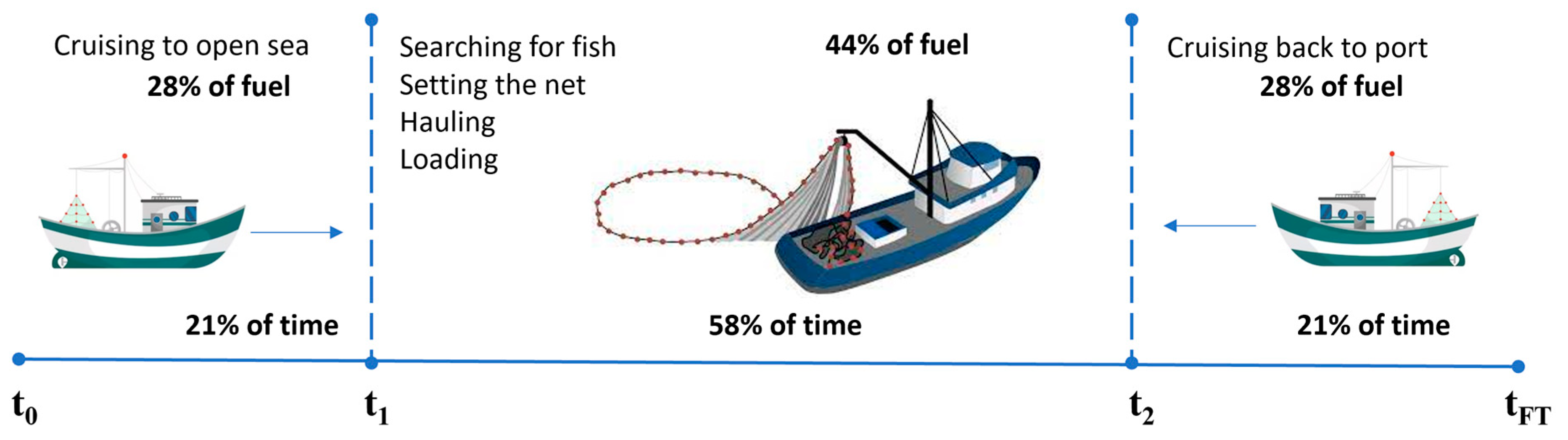

3. Case Study: Purse Seiner in the Adriatic Sea

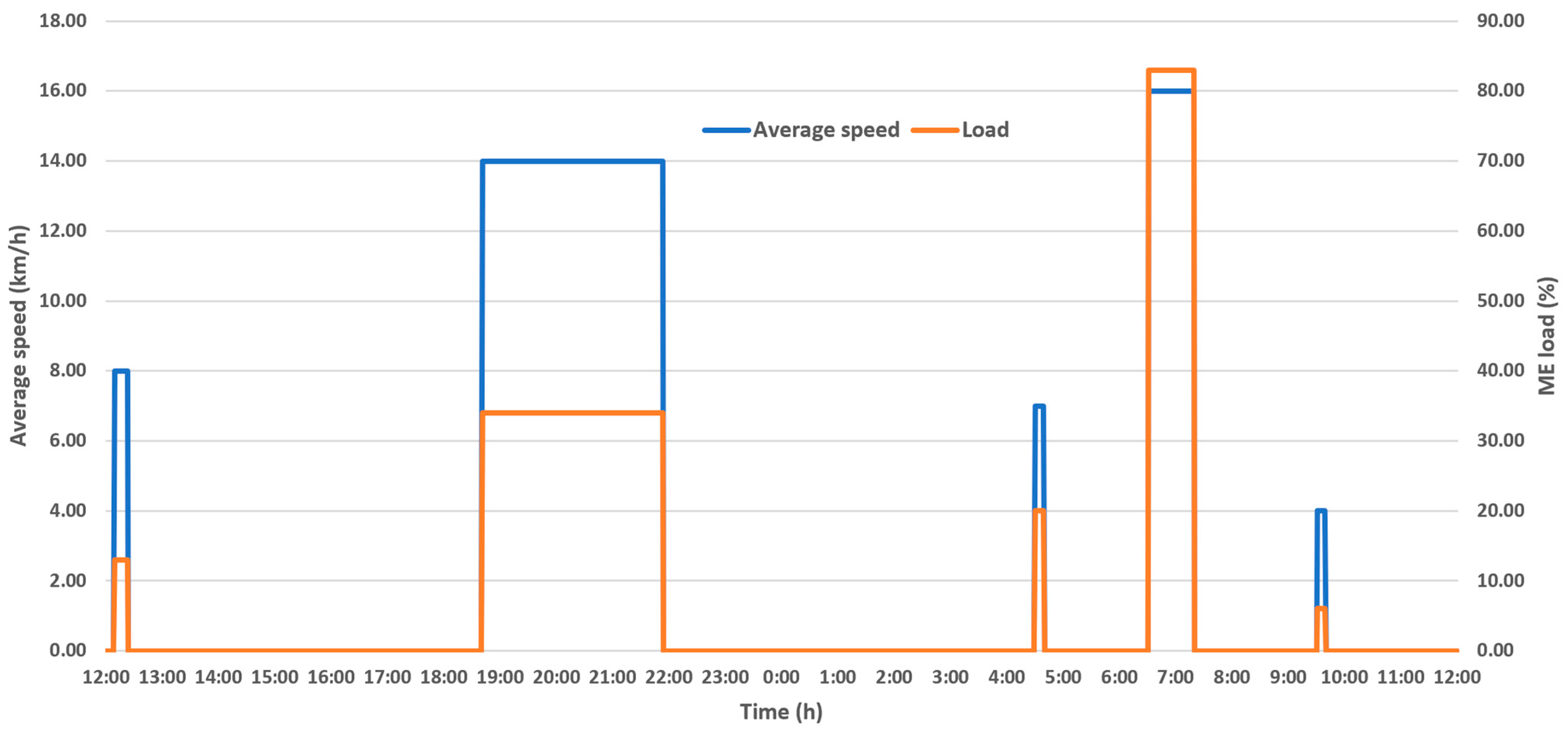

3.1. Ship Particulars and Operative Profile

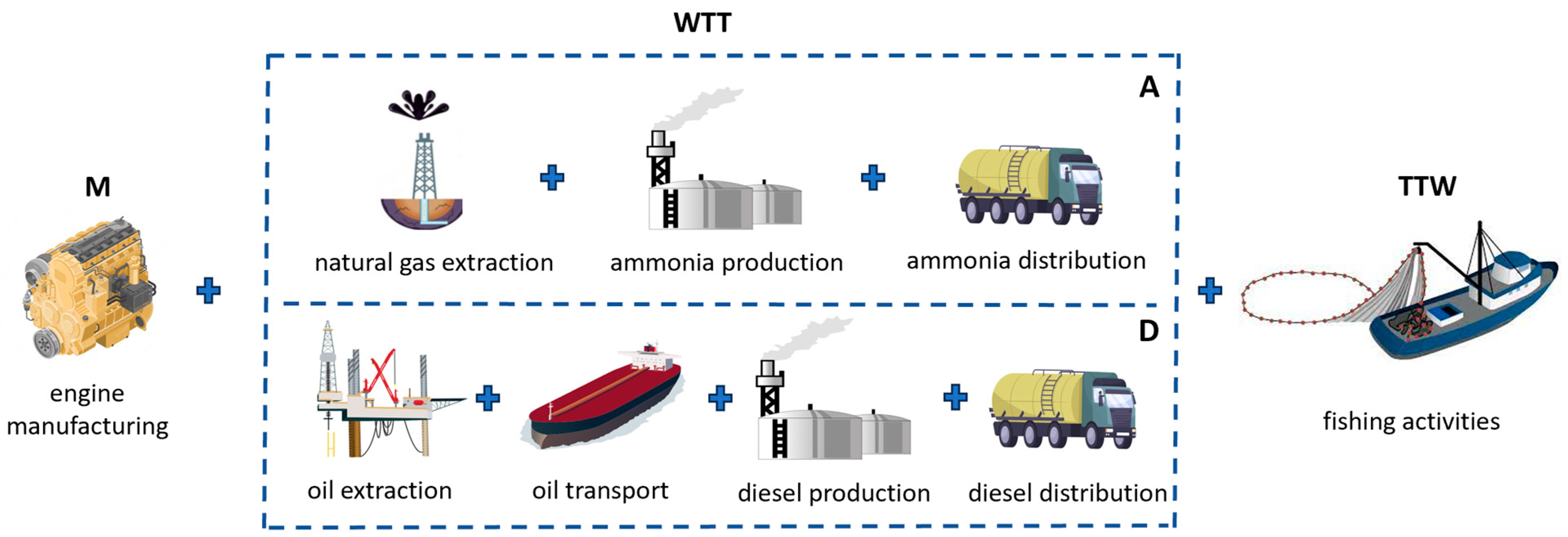

3.2. LCA Models for Different Power Systems

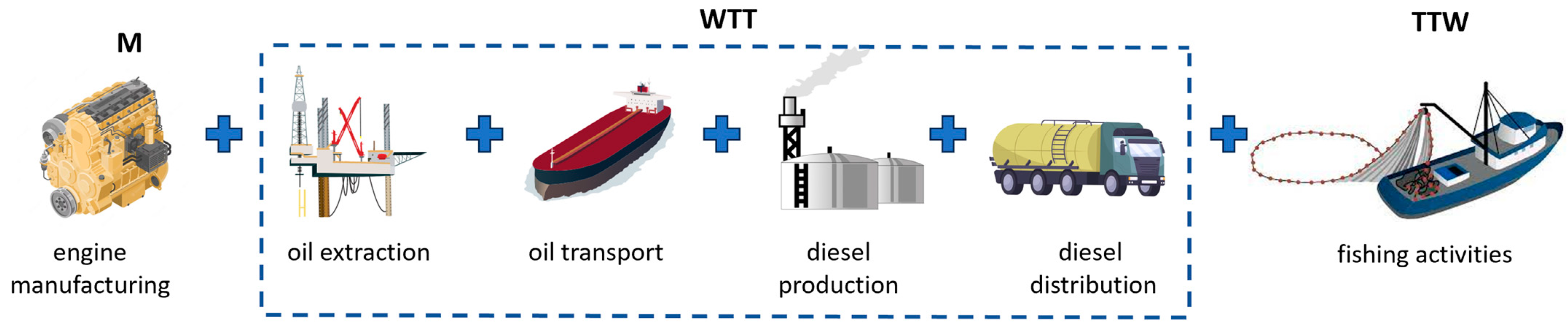

3.2.1. The LCA of a Diesel-Powered Ship

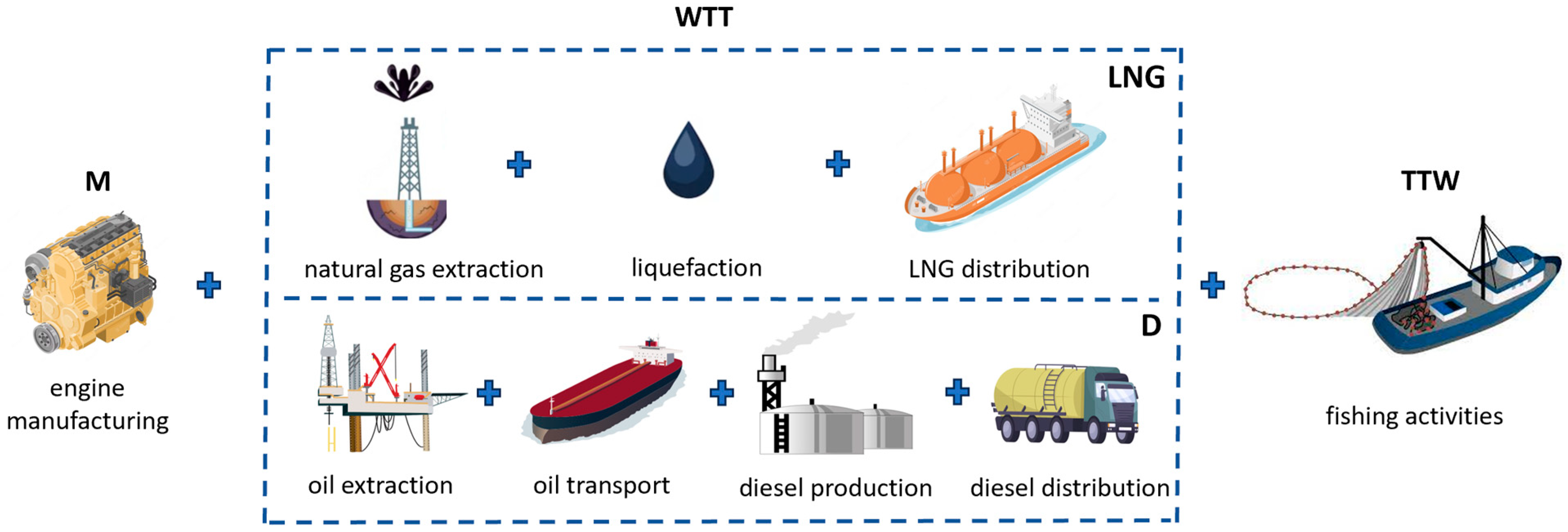

3.2.2. The LCA of an LNG-Powered Ship

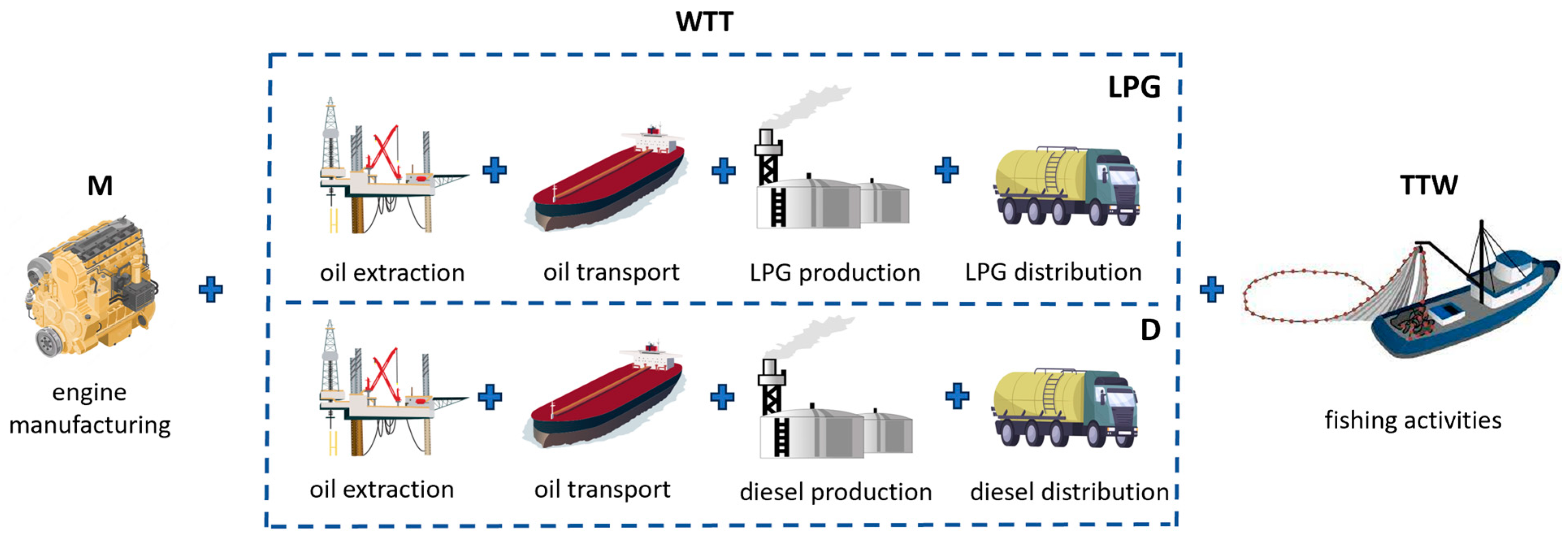

3.2.3. The LCA of an LPG-Powered Ship

3.2.4. The LCA of a Methanol-Powered Ship

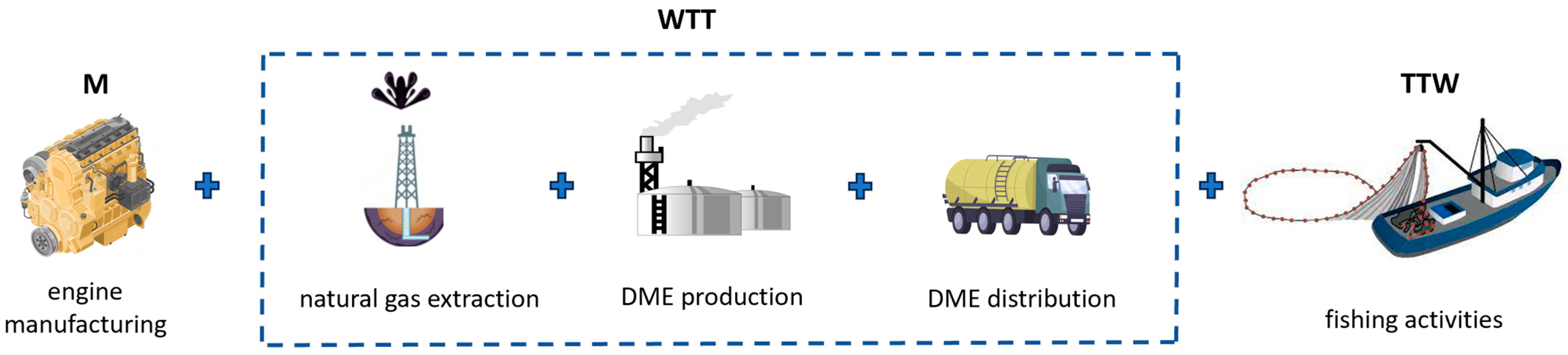

3.2.5. The LCA of a DME-Powered Ship

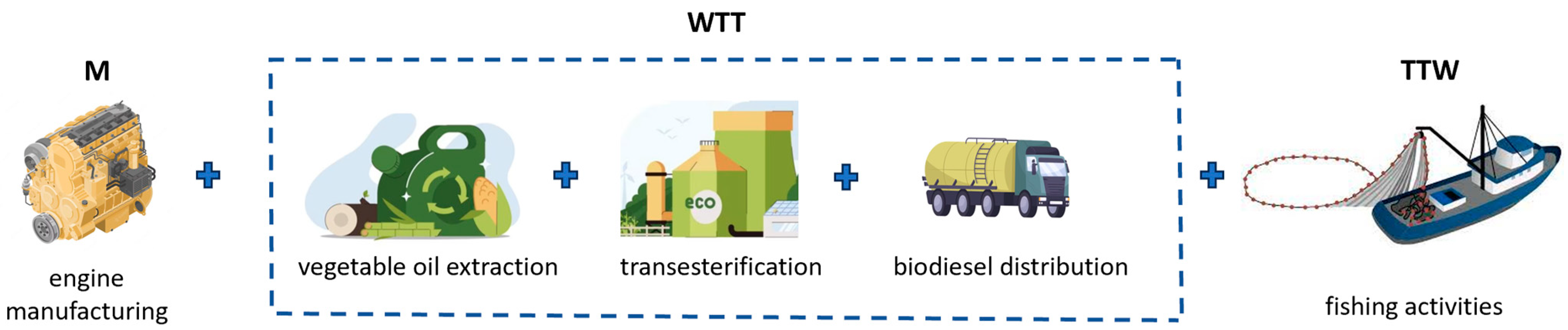

3.2.6. The LCA of a Biodiesel-Powered Ship

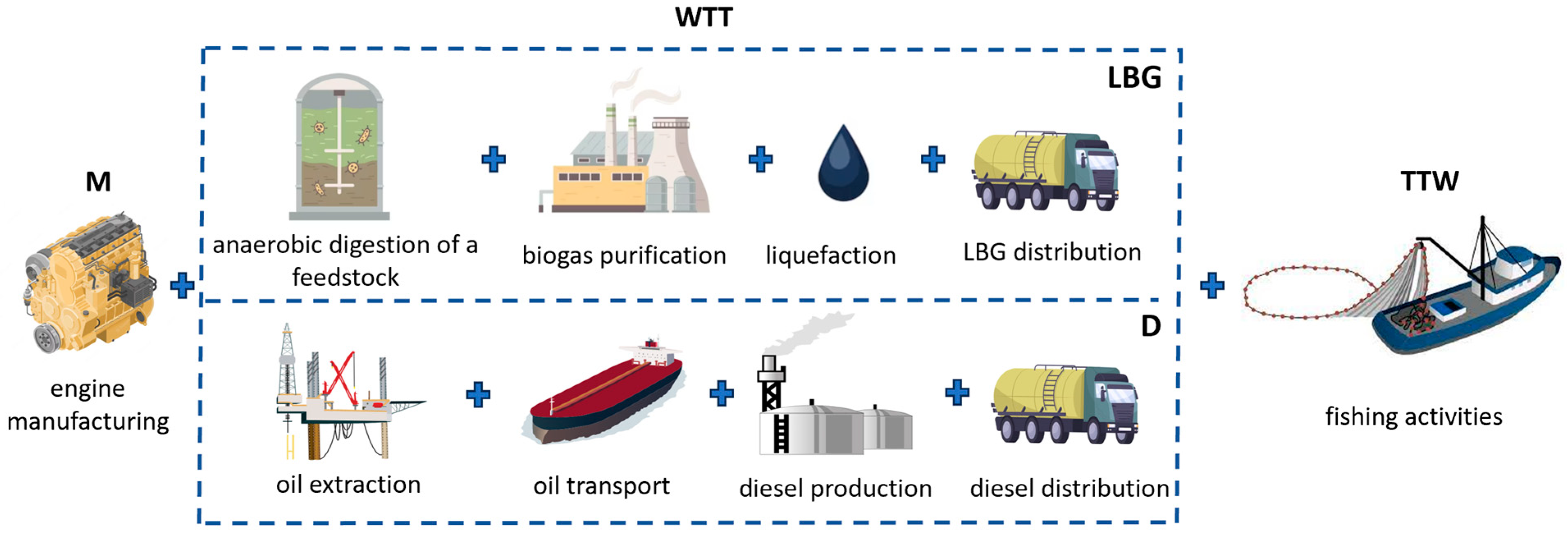

3.2.7. The LCA of an LBG-Powered Ship

3.2.8. The LCA of a Hydrogen-Powered Ship

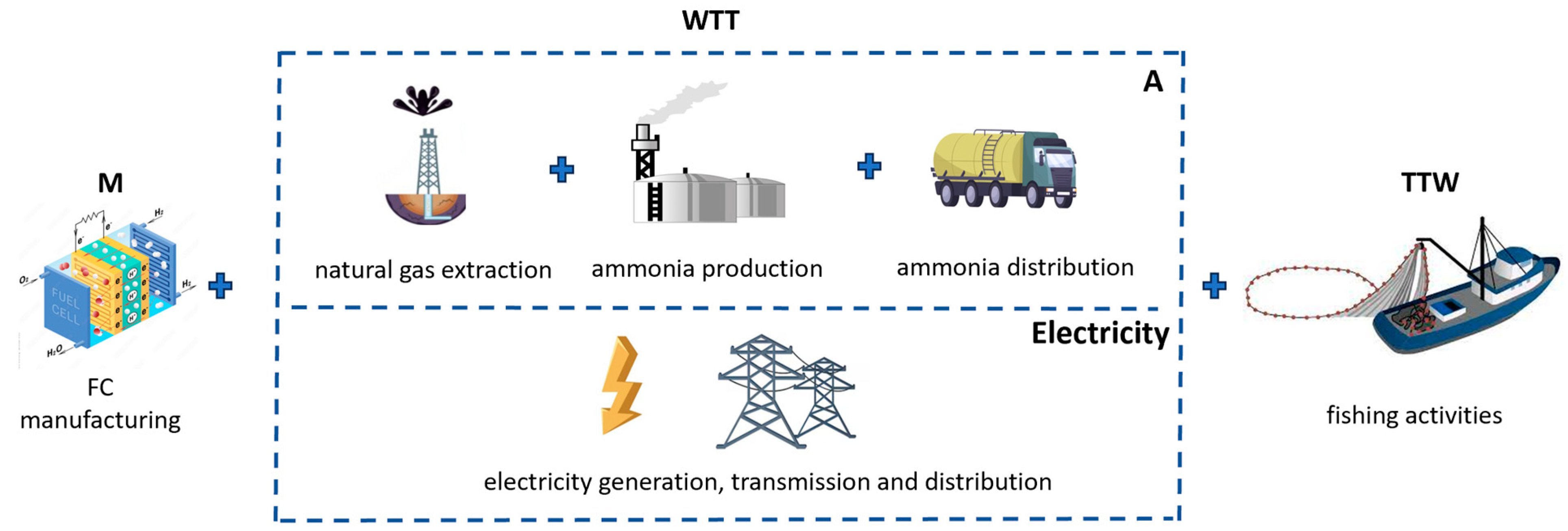

3.2.9. The LCA of an Ammonia-Powered Ship

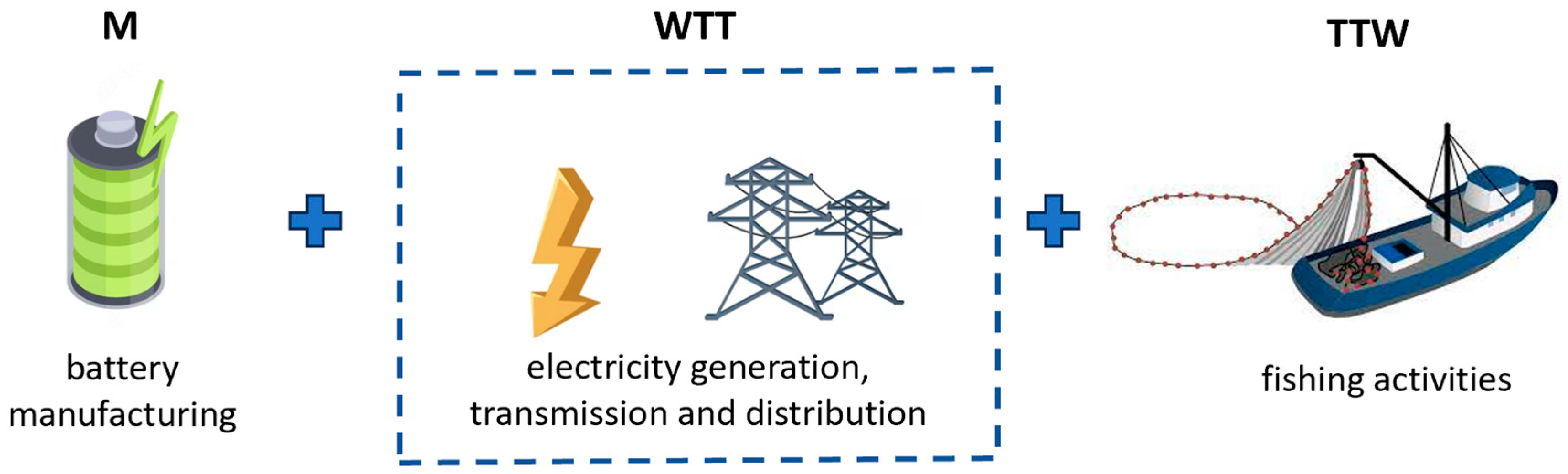

3.2.10. The LCA of an All-Electric Ship

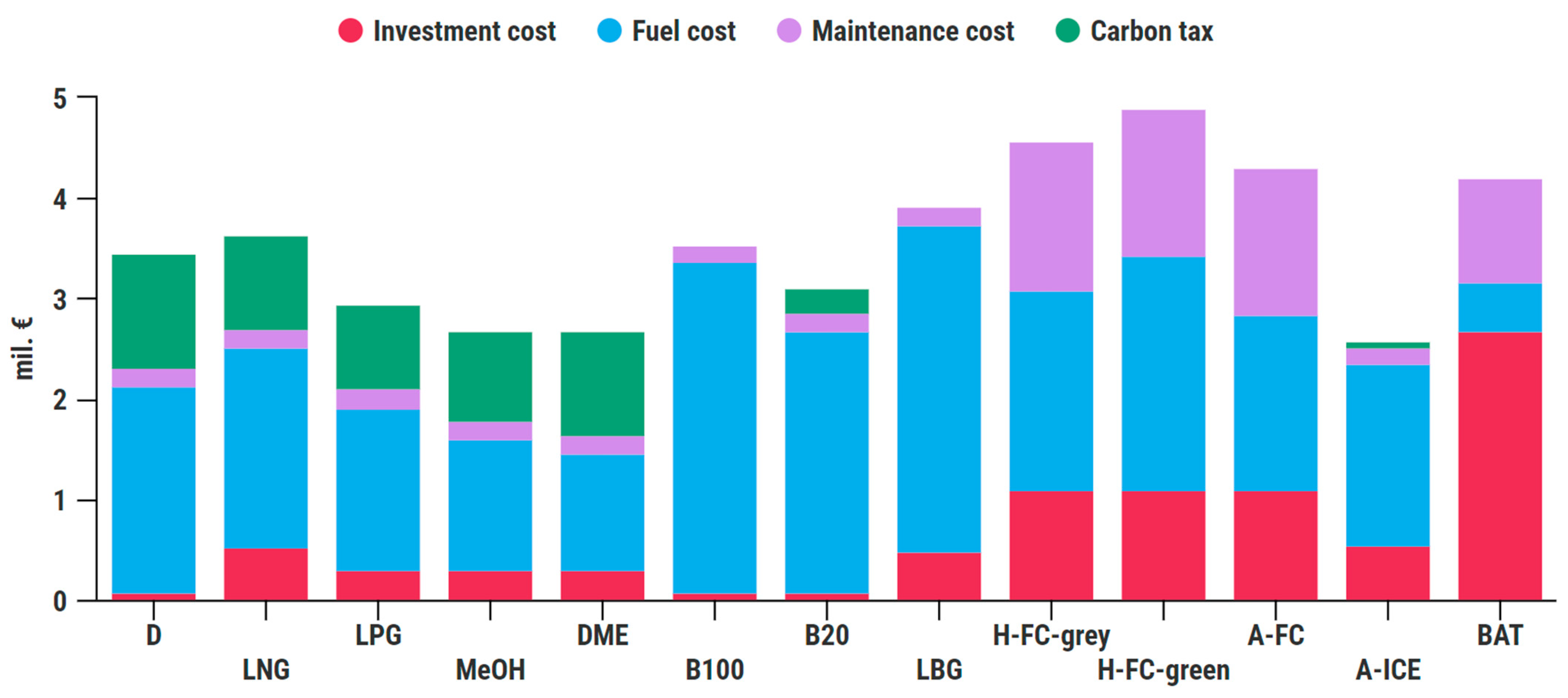

3.3. LCCA Models for Different Power Systems

3.3.1. The LCCA of a Diesel-Powered Ship

3.3.2. The LCCA of an LNG-Powered Ship

3.3.3. The LCCA of an LPG-Powered Ship

3.3.4. The LCCA of a Methanol-Powered Ship

3.3.5. The LCCA of a DME-Powered Ship

3.3.6. The LCCA of a Biodiesel-Powered Ship

3.3.7. The LCCA of an LBG-Powered Ship

3.3.8. The LCCA of a Hydrogen-Powered Ship

3.3.9. The LCCA of an Ammonia-Powered Ship

3.3.10. The LCCA of an All-Electric Ship

3.4. Limitations and Assumptions

- The system boundary of the assessments is placed on the ship, where only the power system is investigated. The other units of a ship (e.g., hull, additional equipment, crew, port operations, etc.) are not considered. However, this approach sufficiently identifies alternative power systems to reduce emissions at a reasonable cost, compared to the configuration of a conventional diesel power system.

- Since the considered purse seiner does not operate on a fixed route and its operative profile varies, an average load of 56% is taken for the calculation of energy needs.

- One of the assumptions in this paper is the simplification of fuel transportation processes. However, stationary processes are a major contributor to emissions from the WTT phase, so this assumption does not have a major impact on total emissions from the WTT phase.

- Storage tank dimensions for a particular fuel (LNG, LBG, hydrogen, etc.) are not considered, which is a limitation for their use onboard small fishing vessels. Such fuel tanks occupy additional space on ships that can be used for different purposes (e.g., for similar energy content, an LNG tank occupies 3–4 times greater a space than an MGO tank) [110]. Nevertheless, environmental and economic analyses performed within the study successfully identified the most appropriate power system configuration that satisfies both criteria.

- Biofuels are assumed to be climate-neutral, and their combustion does not result in CO2 emissions.

- The environmental impact of dual-fuel engines is assumed to be the same as for diesel engines. Since manufacturing emissions from engine manufacturing are rather small compared to batteries and fuel cells and their share in overall life-cycle emissions is small, this approach does not result in a great change in the final results.

- When the ship is powered by a dual-fuel engine, it is assumed that it is always operating in dual-fuel mode, and the pilot fuel share is 5% for each power system configuration that includes a dual-fuel engine.

- Despite recent fuel price fluctuations, fuel costs within the LCCA are calculated with average fuel prices obtained from the literature. Sensitivity analysis regarding an increase in fuel price is not considered.

- Another limitation regarding the LCCA is that the costs are investigated without analysing the net present value. However, the LCCA still identifies the most cost-efficient option.

- The use of ammonia in ICEs is still in the development phase, and commercial engines should be available in 2024. It can be assumed that the implementation phase of such a power system would yield different emissions and overall costs than what is obtained in this study. The LCA and LCCA of this power system configuration should be repeated when their technology readiness is higher.

4. Results and Discussion

5. Conclusions

- The LCA indicated that the most environmentally friendly option is green hydrogen used in a fuel cell, while the second alternative with the lowest emissions compared to the diesel-powered ship is B100. On the other hand, the power systems with the highest released GHGs are LNG in a dual-fuel engine (due to methane slip), ammonia (in fuel cells and ICE), and the use of grey hydrogen in a fuel cell system.

- The LCAs that investigated the impact of alternative fuels on acidification and human toxicity indicated that the most environmentally friendly options are LPG and a fully electrified ship, while the greatest contributor is diesel, due to its high sulphur content.

- Although the LCA indicated that the use of green hydrogen results in the lowest emissions, the LCCA showed that its use in a fuel cell has the highest costs. The power system configurations that are cost-effective are ammonia in ICE, methanol, and DME.

- Methanol and LPG used in a dual-fuel engine were highlighted as the most appropriate fuels that satisfy environmental and economic criteria, i.e., their implementation achieves a reduction in emissions and cost compared to diesel-powered ships. A methanol power system results in a reduction in GHG and costs of 23.3% and 22.4%. Although LPG showed a higher reduction in GHG emissions (15.0%) at a reduced cost (24.4%), methanol is a more appropriate fuel for purse seiners. It has been thoroughly investigated as a marine fuel, and it is used in many types of ships.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Variables | |

| AFP | aerosol formation potential (t PM 2.5 -eq) |

| AP | acidification potential (t SO2-eq) |

| BC | battery capacity (kWh) |

| CA | carbon allowance (EUR/t CO2) |

| E | emission (t) |

| EC | energy consumption (kWh) |

| EF | emission factor (g emission/kg) |

| EH | energy for heating of fuel cell system (kWh) |

| FC | fuel consumption (kg) |

| GWP | global warming potential (t CO2-eq) |

| LHV | lower heating value (MJ/kg) |

| m | weight of an engine/t) |

| P | power (kW) |

| SFC | specific fuel consumption (kg/kWh) |

| t | time (h) |

| x | share (%) |

| Subscripts | |

| A | annual |

| AE | auxiliary engine |

| ave | average |

| f | fuel |

| ME | main engine |

| p-f | pilot fuel |

| Greek letters | |

| η | efficiency (-) |

| Abbreviations | |

| AES | All-Electric Ship |

| A-FC | Ammonia in a Fuel Cell |

| A-ICE | Ammonia in an Internal Combustion Engine |

| APS | Announced Pledges Scenario |

| CII | Carbon Intensity Indicator |

| CNG | Compressed Natural Gas |

| D | Diesel |

| DME | Dimethyl-ether |

| ECA | Emission Control Area |

| EEDI | Energy Efficiency Design Index |

| EEXI | Energy Efficiency Existing Ship Index |

| ETS | Emission Trading System |

| FAO | Food and Agriculture Organisation |

| FU | Functional Unit |

| GHG | Greenhouse Gas |

| GT | Gross tonnage |

| H-FC | Hydrogen in fuel cell |

| HFO | Heavy Fuel Oil |

| ICE | Internal Combustion Engine |

| IES | Isolated Energy System |

| IMO | International Maritime Organisation |

| LBG | Liquefied Biogas |

| LCA | Life-Cycle Assessment |

| LCCA | Life-Cycle Cost Assessment |

| LNG | Liquefied Natural Gas |

| LPG | Liquefied Petroleum Gas |

| LSFO | Low-Sulphur Fuel Oil |

| M | Manufacturing |

| MDO | Marine Diesel Oil |

| MeOH | Methanol |

| NZES | Net Zero Emissions Scenario |

| PEMFC | Proton Exchange Membrane Fuel Cell |

| PM | Particulate Matter |

| RES | Renewable Energy Source |

| SEEMP | Ship Energy Efficiency Management Plan |

| SOFC | Solid Oxide Fuel Cell |

| SPS | Stated Policies Scenario |

| TTW | Tank-to-Wake |

| WTT | Well-to-Tank |

References

- United Nations Framework Convention Climate Change (UNFCCC). Climate Change Information Kit. Available online: https://unfccc.int/resource/iuckit/cckit2001en.pdf (accessed on 14 January 2021).

- UNFCCC. The Glasgow Climate Pact. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-glasgow-climate-pact-key-outcomes-from-cop26 (accessed on 5 April 2022).

- UNFCCC. The Paris Agreement. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement (accessed on 3 November 2021).

- International Maritime Organization. Fourth IMO GHG Study 2020; International Maritime Organization: London, UK, 2020. [Google Scholar]

- IMO. Initial IMO GHG Study. Available online: https://www.imo.org/en/MediaCentre/HotTopics/pages/reducing-greenhouse-gas-emissions-from-ships.aspx (accessed on 21 July 2023).

- DNV. Achieving the IMO Decarbonization Goals. Available online: https://www.dnv.com/expert-story/maritime-impact/How-newbuilds-can-comply-with-IMOs-2030-CO2-reduction-targets.html (accessed on 24 June 2021).

- Czermański, E.; Oniszczuk-Jastrząbek, A.; Spangenberg, E.F.; Kozłowski, Ł.; Adamowicz, M.; Jankiewicz, J.; Cirella, G.T. Implementation of the Energy Efficiency Existing Ship Index: An Important but Costly Step towards Ocean Protection. Mar. Policy 2022, 145, 105259. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A.; Jovanović, I. Holistic Energy Efficiency and Environmental Friendliness Model for Short-Sea Vessels with Alternative Power Systems Considering Realistic Fuel Pathways and Workloads. J. Mar. Sci. Eng. 2022, 10, 613. [Google Scholar] [CrossRef]

- DNV. EU ETS: Preliminary Agreement to Include Shipping in the EU’s Emission Trading System from 2024; DNV: Oslo, Norway, 2024. [Google Scholar]

- DNV. Alternative Fuel Uptake in the World Fleet in 2022. Available online: https://www.dnv.com/expert-story/maritime-impact/Collaboration-is-key-to-scale-up-fuel-availability-in-time.html (accessed on 26 July 2023).

- Solakivi, T.; Paimander, A.; Ojala, L. Cost Competitiveness of Alternative Maritime Fuels in the New Regulatory Framework. Transp. Res. Part D Transp. Environ. 2022, 113, 103500. [Google Scholar] [CrossRef]

- Wan, C.; Yan, X.; Zhang, D.; Yang, Z. A Novel Policy Making Aid Model for the Development of LNG Fuelled Ships. Transp. Res. Part A Policy Pract. 2019, 119, 29–44. [Google Scholar] [CrossRef]

- Lee, H.-J.; Yoo, S.-H.; Huh, S.-Y. Economic Benefits of Introducing LNG-Fuelled Ships for Imported Flour in South Korea. Transp. Res. Part D Transp. Environ. 2020, 78, 102220. [Google Scholar] [CrossRef]

- Kumar, S.; Kwon, H.T.; Choi, K.H.; Lim, W.; Cho, J.H.; Tak, K.; Moon, I. LNG: An Eco-Friendly Cryogenic Fuel for Sustainable Development. Appl. Energy 2011, 88, 4264–4273. [Google Scholar] [CrossRef]

- Ekanem Attah, E.; Bucknall, R. An Analysis of the Energy Efficiency of LNG Ships Powering Options Using the EEDI. Ocean Eng. 2015, 110, 62–74. [Google Scholar] [CrossRef]

- Wärtsilä Dual-Fuel Engines. Available online: https://www.wartsila.com/encyclopedia/term/dual--fuel-engines-from-w%C3%A4rtsil%C3%A4 (accessed on 8 February 2021).

- Schinas, O.; Butler, M. Feasibility and Commercial Considerations of LNG-Fueled Ships. Ocean Eng. 2016, 122, 84–96. [Google Scholar] [CrossRef]

- Taghavifar, H.; Perera, L.P. Life Cycle Emission and Cost Assessment for LNG-Retrofitted Vessels: The Risk and Sensitivity Analyses under Fuel Property and Load Variations. Ocean Eng. 2023, 282, 114940. [Google Scholar] [CrossRef]

- Butarbutar, R.; Gurning, R.O.S. Semin Prospect of LNG as Marine Fuel in Indonesia: An Economic Review for a Case Study of 600 TEU Container Vessel. Appl. Sci. 2023, 13, 2760. [Google Scholar] [CrossRef]

- Kim, J.K.; Jeong, B.; Choi, J.-H.; Lee, W.-J. Life Cycle Assessment of LPG Engines for Small Fishing Vessels and the Applications of Bio LPG Fuel in Korea. J. Mar. Sci. Eng. 2023, 11, 1488. [Google Scholar] [CrossRef]

- Yeo, S.-J.; Kim, J.; Lee, W.-J. Potential Economic and Environmental Advantages of Liquid Petroleum Gas as a Marine Fuel through Analysis of Registered Ships in South Korea. J. Clean. Prod. 2022, 330, 129955. [Google Scholar] [CrossRef]

- Ha, S.; Jeong, B.; Jang, H.; Park, C.; Ku, B. A Framework for Determining the Life Cycle GHG Emissions of Fossil Marine Fuels in Countries Reliant on Imported Energy through Maritime Transportation: A Case Study of South Korea. Sci. Total Environ. 2023, 897, 165366. [Google Scholar] [CrossRef]

- Ammar, N.R. An Environmental and Economic Analysis of Methanol Fuel for a Cellular Container Ship. Transp. Res. Part D Transp. Environ. 2019, 69, 66–76. [Google Scholar] [CrossRef]

- Dierickx, J.; Verbiest, J.; Janvier, T.; Peeters, J.; Sileghem, L.; Verhelst, S. Retrofitting a High-Speed Marine Engine to Dual-Fuel Methanol-Diesel Operation: A Comparison of Multiple and Single Point Methanol Port Injection. Fuel Commun. 2021, 7, 100010. [Google Scholar] [CrossRef]

- International Maritime Organization (IMO). Methanol as Marine Fuel: Environmental Benefits, Technology Readiness, and Economic Feasibility; International Maritime Organization: London, UK, 2016. [Google Scholar]

- Strazza, C.; Del Borghi, A.; Costamagna, P.; Traverso, A.; Santin, M. Comparative LCA of Methanol-Fuelled SOFCs as Auxiliary Power Systems on-Board Ships. Appl. Energy 2010, 87, 1670–1678. [Google Scholar] [CrossRef]

- Svanberg, M.; Ellis, J.; Lundgren, J.; Landälv, I. Renewable Methanol as a Fuel for the Shipping Industry. Renew. Sustain. Energy Rev. 2018, 94, 1217–1228. [Google Scholar] [CrossRef]

- Bayraktar, M.; Yuksel, O.; Pamik, M. An Evaluation of Methanol Engine Utilization Regarding Economic and Upcoming Regulatory Requirements for a Container Ship. Sustain. Prod. Consum. 2023, 39, 345–356. [Google Scholar] [CrossRef]

- Oloruntobi, O.; Chuah, L.F.; Mokhtar, K.; Gohari, A.; Onigbara, V.; Chung, J.X.; Mubashir, M.; Asif, S.; Show, P.L.; Han, N. Assessing Methanol Potential as a Cleaner Marine Fuel: An Analysis of Its Implications on Emissions and Regulation Compliance. Clean. Eng. Technol. 2023, 14, 100639. [Google Scholar] [CrossRef]

- Moirangthem, K.; Baxter, D. Alternative Fuels for Marine and Inland Waterways 2016; EU Publications: Luxembourg, 2016. [Google Scholar]

- Pham, V.C.; Rho, B.-S.; Kim, J.-S.; Lee, W.-J.; Choi, J.-H. Effects of Various Fuels on Combustion and Emission Characteristics of a Four-Stroke Dual-Fuel Marine Engine. J. Mar. Sci. Eng. 2021, 9, 1072. [Google Scholar] [CrossRef]

- Bilgili, L. Comparative Assessment of Alternative Marine Fuels in Life Cycle Perspective. Renew. Sustain. Energy Rev. 2021, 144, 110985. [Google Scholar] [CrossRef]

- Hammond, G.P.; Seth, S.M. Carbon and Environmental Footprinting of Global Biofuel Production. Appl. Energy 2013, 112, 547–559. [Google Scholar] [CrossRef]

- Mahapatra, S.; Kumar, D.; Singh, B.; Sachan, P.K. Biofuels and Their Sources of Production: A Review on Cleaner Sustainable Alternative against Conventional Fuel, in the Framework of the Food and Energy Nexus. Energy Nexus 2021, 4, 100036. [Google Scholar] [CrossRef]

- Gilbert, P.; Walsh, C.; Traut, M.; Kesieme, U.; Pazouki, K.; Murphy, A. Assessment of Full Life-Cycle Air Emissions of Alternative Shipping Fuels. J. Clean. Prod. 2018, 172, 855–866. [Google Scholar] [CrossRef]

- Korberg, A.D.; Brynolf, S.; Grahn, M.; Skov, I.R. Techno-Economic Assessment of Advanced Fuels and Propulsion Systems in Future Fossil-Free Ships. Renew. Sustain. Energy Rev. 2021, 142, 110861. [Google Scholar] [CrossRef]

- Gabrielii, C.H.; Jafarzadeh, S. Alternative Fuels and Propulsion Systems for Fishing Vessels; SINTEF Energi AS: Trondheim, Norway, 2020. [Google Scholar]

- Wu, G.; Li, J.; Guo, H.; Wang, X.; Jiang, G. Numerical Method for Predicting Emissions from Biodiesel Blend Fuels in Diesel Engines of Inland Waterway Vessels. J. Mar. Sci. Eng. 2023, 11, 86. [Google Scholar] [CrossRef]

- Wang, Z.; Paulauskiene, T.; Uebe, J.; Bucas, M. Characterization of Biomethanol–Biodiesel–Diesel Blends as Alternative Fuel for Marine Applications. J. Mar. Sci. Eng. 2020, 8, 730. [Google Scholar] [CrossRef]

- Hazrat, M.A.; Rasul, M.G.; Mofijur, M.; Khan, M.M.K.; Djavanroodi, F.; Azad, A.K.; Bhuiya, M.M.K.; Silitonga, A.S. A Mini Review on the Cold Flow Properties of Biodiesel and Its Blends. Front. Energy Res. 2020, 8, 598651. [Google Scholar] [CrossRef]

- Christensen, E.; McCormick, R.L. Long-Term Storage Stability of Biodiesel and Biodiesel Blends. Fuel Process. Technol. 2014, 128, 339–348. [Google Scholar] [CrossRef]

- Lindstad, E.; Lagemann, B.; Rialland, A.; Gamlem, G.M.; Valland, A. Reduction of Maritime GHG Emissions and the Potential Role of E-Fuels. Transp. Res. Part D Transp. Environ. 2021, 101, 103075. [Google Scholar] [CrossRef]

- Sterling PlanB Energy Solutions (SPBES). Electrification of Ships. Available online: https://spbes.com/ (accessed on 13 January 2021).

- Gagatsi, E.; Estrup, T.; Halatsis, A. Exploring the Potentials of Electrical Waterborne Transport in Europe: The E-Ferry Concept. In Transportation Research Procedia; Elsevier B.V.: Amsterdam, The Netherlands, 2016; Volume 14, pp. 1571–1580. [Google Scholar]

- Nuchturee, C.; Li, T.; Xia, H. Energy Efficiency of Integrated Electric Propulsion for Ships—A Review. Renew. Sustain. Energy Rev. 2020, 134, 110145. [Google Scholar] [CrossRef]

- Lindstad, H.E.; Eskeland, G.S.; Rialland, A. Batteries in Offshore Support Vessels—Pollution, Climate Impact and Economics. Transp. Res. Part D Transp. Environ. 2017, 50, 409–417. [Google Scholar] [CrossRef]

- Perčić, M.; Frković, L.; Pukšec, T.; Ćosić, B.; Li, O.L.; Vladimir, N. Life-Cycle Assessment and Life-Cycle Cost Assessment of Power Batteries for All-Electric Vessels for Short-Sea Navigation. Energy 2022, 251, 123895. [Google Scholar] [CrossRef]

- Wang, L.; Hu, J.; Yu, Y.; Huang, K.; Hu, Y. Lithium-Air, Lithium-Sulfur, and Sodium-Ion, Which Secondary Battery Category Is More Environmentally Friendly and Promising Based on Footprint Family Indicators? J. Clean. Prod. 2020, 276, 124244. [Google Scholar] [CrossRef]

- Arcos, J.M.M.; Santos, D.M.F. The Hydrogen Color Spectrum: Techno-Economic Analysis of the Available Technologies for Hydrogen Production. Gases 2023, 3, 25–46. [Google Scholar] [CrossRef]

- Morales-Ospino, R.; Celzard, A.; Fierro, V. Strategies to Recover and Minimize Boil-off Losses during Liquid Hydrogen Storage. Renew. Sustain. Energy Rev. 2023, 182, 113360. [Google Scholar] [CrossRef]

- De-Troya, J.J.; Álvarez, C.; Fernández-Garrido, C.; Carral, L. Analysing the Possibilities of Using Fuel Cells in Ships. Int. J. Hydrogen Energy 2016, 41, 2853–2866. [Google Scholar] [CrossRef]

- Sapra, H.; Stam, J.; Reurings, J.; van Biert, L.; van Sluijs, W.; de Vos, P.; Visser, K.; Vellayani, A.P.; Hopman, H. Integration of Solid Oxide Fuel Cell and Internal Combustion Engine for Maritime Applications. Appl. Energy 2021, 281, 115854. [Google Scholar] [CrossRef]

- Ahn, J.; Park, S.H.; Noh, Y.; Choi, B.I.; Ryu, J.; Chang, D.; Brendstrup, K.L.M. Performance and Availability of a Marine Generator-Solid Oxide Fuel Cell-Gas Turbine Hybrid System in a Very Large Ethane Carrier. J. Power Sources 2018, 399, 199–206. [Google Scholar] [CrossRef]

- Offshore Energy MF Hydra Starts World’s First Voyage on Emission-Free Liquid Hydrogen. Available online: https://www.offshore-energy.biz/watch-mf-hydra-starts-worlds-first-voyage-on-emission-free-liquid-hydrogen/#:~:text=MF%20Hydra%2C%20the%20world’s%20first,from%20the%20Norwegian%20Maritime%20Authority (accessed on 21 September 2023).

- Shahpouri, S.; Gordon, D.; Hayduk, C.; Rezaei, R.; Koch, C.R.; Shahbakhti, M. Hybrid Emission and Combustion Modeling of Hydrogen Fueled Engines. Int. J. Hydrogen Energy 2023, 48, 24037–24053. [Google Scholar] [CrossRef]

- Mallouppas, G.; Yfantis, E.A. Decarbonization in Shipping Industry: A Review of Research, Technology Development, and Innovation Proposals. J. Mar. Sci. Eng. 2021, 9, 415. [Google Scholar] [CrossRef]

- International Transport Forum. The Potential of E-Fuels to Decarbonise Ships and Aircraft. In International Transport Forum Policy Papers; OECD Publishing: Paris, France, 2023. [Google Scholar]

- Methanol Institute. Methanol as a Marine Fuel Report; Methanol Institute: Alexandria, VA, USA, 2015. [Google Scholar]

- Deniz, C.; Zincir, B. Environmental and Economical Assessment of Alternative Marine Fuels. J. Clean. Prod. 2016, 113, 438–449. [Google Scholar] [CrossRef]

- Park, J.; Choi, I.; Oh, J.; Lee, C. Preliminary Numerical Study on Exhaust Emission Characteristics of Particulate Matters and Nitrogen Oxide in a Marine Engine for Marine Diesel Oil and Dimethyl Ether Fuel. J. Mar. Sci. Eng. 2020, 8, 316. [Google Scholar] [CrossRef]

- Machaj, K.; Kupecki, J.; Malecha, Z.; Morawski, A.W.; Skrzypkiewicz, M.; Stanclik, M.; Chorowski, M. Ammonia as a Potential Marine Fuel: A Review. Energy Strategy Rev. 2022, 44, 100926. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A. Life-Cycle Cost Assessment of Alternative Marine Fuels to Reduce the Carbon Footprint in Short-Sea Shipping: A Case Study of Croatia. Appl. Energy 2020, 279, 115848. [Google Scholar] [CrossRef]

- Spoof-Tuomi, K.; Niemi, S. Environmental and Economic Evaluation of Fuel Choices for Short Sea Shipping. Clean. Technol. 2020, 2, 34–52. [Google Scholar] [CrossRef]

- Jeong, H.; Yun, H. A Stochastic Approach for Economic Valuation of Alternative Fuels: The Case of Container Ship Investments. J. Clean. Prod. 2023, 418, 138182. [Google Scholar] [CrossRef]

- Chen, Z.S.; Lam, J.S.L. Life Cycle Assessment of Diesel and Hydrogen Power Systems in Tugboats. Transp. Res. Part D Transp. Environ. 2022, 103, 103192. [Google Scholar] [CrossRef]

- Huang, J.; Fan, H.; Xu, X.; Liu, Z. Life Cycle Greenhouse Gas Emission Assessment for Using Alternative Marine Fuels: A Very Large Crude Carrier (VLCC) Case Study. J. Mar. Sci. Eng. 2022, 10, 1969. [Google Scholar] [CrossRef]

- Lee, G.N.; Kim, J.M.; Jung, K.H.; Park, H.; Jang, H.S.; Lee, C.S.; Lee, J.W. Environmental Life-Cycle Assessment of Eco-Friendly Alternative Ship Fuels (MGO, LNG, and Hydrogen) for 170 GT Nearshore Ferry. J. Mar. Sci. Eng. 2022, 10, 755. [Google Scholar] [CrossRef]

- Koričan, M.; Perčić, M.; Vladimir, N.; Alujević, N.; Fan, A. Alternative Power Options for Improvement of the Environmental Friendliness of Fishing Trawlers. J. Mar. Sci. Eng. 2022, 10, 1882. [Google Scholar] [CrossRef]

- Fan, A.; Wang, J.; He, Y.; Perčić, M.; Vladimir, N.; Yang, L. Decarbonising Inland Ship Power System: Alternative Solution and Assessment Method. Energy 2021, 226, 120266. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A. Techno-Economic Assessment of Alternative Marine Fuels for Inland Shipping in Croatia. Renew. Sustain. Energy Rev. 2021, 148, 111363. [Google Scholar] [CrossRef]

- Hwang, S.S.; Gil, S.J.; Lee, G.N.; Lee, J.W.; Park, H.; Jung, K.H.; Suh, S.B. Life Cycle Assessment of Alternative Ship Fuels for Coastal Ferry Operating in Republic of Korea. J. Mar. Sci. Eng. 2020, 8, 660. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Fisheries and Aquaculture. Available online: https://www.fao.org/fishery/en (accessed on 17 August 2023).

- Food and Agriculture Organization of the United Nations. Review of the Techno-Economic Performance of the Main Global Fishing Fleets; Food and Agriculture Organization of the United Nations: Rome, Italy, 2021. [Google Scholar]

- Gilman, E.; Humberstone, J.; Wilson, J.R.; Chassot, E.; Jackson, A.; Suuronen, P. Matching Fishery-Specific Drivers of Abandoned, Lost and Discarded Fishing Gear to Relevant Interventions. Mar. Policy 2022, 141, 105097. [Google Scholar] [CrossRef]

- Yalcin, E.; Suner, M. The Changing Role of Diesel Oil-Gasoil-LPG and Hydrogen Based Fuels in Human Health Risk: A Numerical Investigation in Ferry Ship Operations. Int. J. Hydrogen Energy 2020, 45, 3660–3669. [Google Scholar] [CrossRef]

- Avadí, A.; Fréon, P. Life Cycle Assessment of Fisheries: A Review for Fisheries Scientists and Managers. Fish. Res. 2013, 143, 21–38. [Google Scholar] [CrossRef]

- Monteiro, A.; Russo, M.; Gama, C.; Borrego, C. How Important Are Maritime Emissions for the Air Quality: At European and National Scale. Environ. Pollut. 2018, 242, 565–575. [Google Scholar] [CrossRef]

- Basurko, O.C.; Gabiña, G.; Quincoces, I. Fuel Consumption Monitoring in Fishing Vessels and Its Potential for Different Stakeholders. Available online: https://conferences.ncl.ac.uk/media/sites/conferencewebsites/scc2016/1.1.2.pdf (accessed on 26 August 2023).

- Koričan, M.; Frković, L.; Vladimir, N. Electrification of Fishing Vessels and Their Integration into Isolated Energy Systems with a High Share of Renewables. J. Clean. Prod. 2023, 425, 138997. [Google Scholar] [CrossRef]

- European Commission European Platform on LCA. Available online: https://eplca.jrc.ec.europa.eu/lifecycleassessment.html (accessed on 27 September 2023).

- ISO 14040; International Organization for Standardization (ISO). Available online: https://www.iso.org/standard/37456.html (accessed on 12 December 2020).

- GREET 2022 LCA Software. Available online: https://greet.es.anl.gov/index.php (accessed on 27 September 2023).

- Jovanović, I.; Vladimir, N.; Perčić, M.; Koričan, M. The Feasibility of Autonomous Low-Emission Ro-Ro Passenger Shipping in the Adriatic Sea. Ocean Eng. 2022, 247, 110712. [Google Scholar] [CrossRef]

- Karvounis, P.; Dantas, J.L.D.; Tsoumpris, C.; Theotokatos, G. Ship Power Plant Decarbonisation Using Hybrid Systems and Ammonia Fuel—A Techno-Economic–Environmental Analysis. J. Mar. Sci. Eng. 2022, 10, 1675. [Google Scholar] [CrossRef]

- Zero Carbon Shipping Managing Emissions from Ammonia-Fueled Vessels. Available online: https://cms.zerocarbonshipping.com/media/uploads/documents/Ammonia-emissions-reduction-position-paper_v4.pdf (accessed on 24 November 2023).

- Perčić, M.; Vladimir, N.; Jovanović, I.; Koričan, M. Application of Fuel Cells with Zero-Carbon Fuels in Short-Sea Shipping. Appl. Energy 2022, 309, 118463. [Google Scholar] [CrossRef]

- International Energy Agency. Global Energy and Climate Model—Macro Drivers. Available online: https://www.iea.org/reports/global-energy-and-climate-model/macro-drivers (accessed on 10 October 2023).

- International Energy Agency. World Energy Outlook 2022. Available online: https://iea.blob.core.windows.net/assets/830fe099-5530-48f2-a7c1-11f35d510983/WorldEnergyOutlook2022.pdf (accessed on 27 September 2023).

- Ministry of Agriculture of Republic of Croatia, 2023. Directory of Fisheries Fishing Vessel Particulars. Available online: https://ribarstvo.mps.hr/default.aspx?id=13 (accessed on 29 August 2023).

- General Fisheries Commission for the Mediterranean Authorized Vessel List. Available online: https://www.fao.org/gfcm/data/fleet/avl/en/ (accessed on 29 August 2023).

- Kurniawati, V.R. Sustainable Development of Fishing Operations: A Case Study Focusing on Small Vessels in Palabuhanratu, Indonesia. Ph.D. Thesis, Newcastle University, Tyne, UK, 2019. [Google Scholar]

- MAPON Fleet Management & Asset Tracking Platform. Available online: https://www.mapon.com/en (accessed on 14 September 2023).

- Koričan, M.; Vladimir, N.; Fan, A. Investigation of the Energy Efficiency of Fishing Vessels: Case Study of the Fishing Fleet in the Adriatic Sea. Ocean Eng. 2023, 286, 115734. [Google Scholar] [CrossRef]

- International Maritime Organization (IMO). Fourth IMO GHG Study-Final Report. Available online: https://safety4sea.com/wp-content/uploads/2020/08/MEPC-75-7-15-Fourth-IMO-GHG-Study-2020-Final-report-Secretariat.pdf (accessed on 14 January 2021).

- Pavlenko, N.; Comer, B.; Zhou, Y.; Clark, N.; Rutherford, D. The Climate Implications of Using LNG as a Marine Fuel; Swedish Environmental Protection Agency: Stockholm, Sweden, 2020. [Google Scholar]

- MAN MAN B&W ME-LGIP Propulsion. Available online: https://www.maritimeinformed.com/datasheets/man-energy-solutions-man-b-w-me-lgip-prime-mover/co-1624023192-ga/man-b-w-me-lgip.pdf (accessed on 7 September 2023).

- MAN ME-LGIM Engine. Available online: https://man-es.com/applications/projectguides/2stroke/content/printed/G95ME-C10_5-LGIM.pdf (accessed on 21 November 2023).

- Mohammadzadeh, A.; Naghib Zadeh, S.K.; Saidi, M.H.; Sharifzadeh, M. Mechanical Engineering of Solid Oxide Fuel Cell Systems: Geometric Design, Mechanical Configuration, and Thermal Analysis. In Design and Operation of Solid Oxide Fuel Cells: The Systems Engineering Vision for Industrial Application; Elsevier: Amsterdam, The Netherlands, 2019; pp. 85–130. ISBN 9780128152539. [Google Scholar]

- Quach, T.-Q.; Giap, V.-T.; Keun Lee, D.; Pineda Israel, T.; Young Ahn, K. High-Efficiency Ammonia-Fed Solid Oxide Fuel Cell Systems for Distributed Power Generation. Appl. Energy 2022, 324, 119718. [Google Scholar] [CrossRef]

- DNV Ammonia-Fuelled Engines for Carbon Free Shipping. Available online: https://www.dnv.com/research/review-2021/featured-projects/ammonia-fuelled-engines.html (accessed on 23 September 2023).

- European Maritime Safety Agency (EMSA). Potential of Ammonia as Fuel in Shipping; European Maritime Safety Agency: Lisbon, Portugal, 2022. [Google Scholar]

- Gandoman, F.H.; Jaguemont, J.; Goutam, S.; Gopalakrishnan, R.; Firouz, Y.; Kalogiannis, T.; Omar, N.; Van Mierlo, J. Concept of Reliability and Safety Assessment of Lithium-Ion Batteries in Electric Vehicles: Basics, Progress, and Challenges. Appl. Energy 2019, 251, 113343. [Google Scholar] [CrossRef]

- International Energy Agency. Biodiesel and Diesel Prices, 2019 to April 2022. Available online: https://www.iea.org/data-and-statistics/charts/biodiesel-and-diesel-prices-2019-to-april-2022 (accessed on 28 September 2023).

- Global Petrol Prices LPG Prices. Available online: https://www.globalpetrolprices.com/lpg_prices/#:~:text=LPG%20prices%2C%2025%2DSep%2D,in%20these%20prices%20among%20countries (accessed on 29 September 2023).

- Trading Economics Methanol Price. Available online: https://tradingeconomics.com/commodity/methanol (accessed on 28 September 2023).

- Statista Projected Low and High Prices for Marine Fuels in 2050. Available online: https://www.statista.com/statistics/1367303/forecasted-low-and-high-prices-for-marine-fuels/ (accessed on 28 September 2023).

- Iannaccone, T.; Landucci, G.; Tugnoli, A.; Salzano, E.; Cozzani, V. Sustainability of Cruise Ship Fuel Systems: Comparison among LNG and Diesel Technologies. J. Clean. Prod. 2020, 260, 121069. [Google Scholar] [CrossRef]

- Lagemann, B.; Lindstad, E.; Fagerholt, K.; Rialland, A.; Ove Erikstad, S. Optimal Ship Lifetime Fuel and Power System Selection. Transp. Res. Part D Transp. Environ. 2022, 102, 103145. [Google Scholar] [CrossRef]

- Ellis, J.; Tanneberger, K. Study on the Use of Ethyl and Methyl Alcohol as Alternative Fuels in Shipping; European Maritime Safety Agency: Lisbon, Portugal, 2015. [Google Scholar]

- Jafarzadeh, S.; Paltrinieri, N.; Utne, I.B.; Ellingsen, H. LNG-Fuelled Fishing Vessels: A Systems Engineering Approach. Transp. Res. Part D Transp. Environ. 2017, 50, 202–222. [Google Scholar] [CrossRef]

| Diesel | LNG | LPG | Methanol | DME | Hydrogen | Ammonia | |

|---|---|---|---|---|---|---|---|

| LHV (MJ/kg) | 42.5 | 46–50.2 | 46.3 | 20 | 28.8 | 120 | 18.6 |

| Density (kg/m3) | 833–881 | 450 | 500.5 | 798 | 667 | 0.0838 | 682.3 |

| Carbon content (%) | >85 | 75 | 82.6 | 38 | 52 | 0 | 0 |

| Flashpoint (°C) | 52–96 | −136 | 470 | 11 | 235 | - | 132 |

| Boiling point (°C) | 163–399 | −160 | −42 | 64.5 | −25 | −253 | −33 |

| Cetane rating | >40 | 0 | - | <5 | <55 | - | - |

| Year | Studies | Coverage | Scope | |

|---|---|---|---|---|

| Fuels | Test Case | |||

| 2023 | Jeong and Yun [64] | LSFO; LNG; ammonia | container ship | Economic analysis |

| Kim et al. [20] | Diesel; gasoline; LPG; bio-LPG | small fishing vessel | LCA | |

| Ha et al. [22] | HFO; LNG; LPG; methanol | bulk carrier | LCA | |

| 2022 | Chen and Lam [65] | Diesel; hydrogen | tugboat | LCA |

| Huang et al. [66] | MGO; LNG; methanol; ammonia | very large crude carrier | LCA | |

| Lee et al. [67] | MGO; LNG; hydrogen | ferry | LCA | |

| Solakivi et al. [11] | MDO; LSMGO; LNG; methanol; biodiesel; e-fuels (hydrogen, ammonia) | ro-ro ship | Economic analysis | |

| Koričan et al. [68] | Diesel; electricity; methanol; LNG; ammonia; B20; hydrogen | fishing vessel (trawler) | LCA; LCCA | |

| 2021 | Fan et al. [69] | Diesel; LNG; electricity | container ship; bulk carrier | LCA; LCCA |

| Perčić et al. [70] | Diesel; electricity; methanol; LNG; hydrogen; ammonia; B20 | inland navigation ships (tanker; small passenger ship; dredger) | LCA; LCCA | |

| Korberg et al. [36] | Biofuels, bio-e-fuels, and e-fuels (methanol; DME; diesel; liquefied methane gas; LBG; ammonia); hydrotreated vegetable oil; MGO; hydrogen | ro-ro passenger ship; general cargo ship, bulk carrier; container ship | Economic analysis | |

| 2020 | Perčić et al. [62] | Diesel; electricity; methanol; DME; CNG; LNG; hydrogen; ammonia; B20 | ferry | LCA; LCCA |

| Spoof-Tuomi and Niemi [63] | MDO; LNG; LBG | ferry | LCA | |

| Hwang et al. [71] | MGO; LNG; hydrogen | ferry | LCA | |

| EF (g/kg) | ||||||||

|---|---|---|---|---|---|---|---|---|

| MDO | LNG | LPG | Methanol | DME | LBG | Biodiesel | Ammonia | |

| CO2 | 3206 | 2750 | 3015 | 1375 | 1927 | - | - | - |

| CH4 | 0.06 | 51.6 | 0.006 | - | - | 51.6 | 0.06 | - |

| N2O | 0.15 | 0.11 | 0.025 | - | - | 0.11 | 0.15 | 0.0003 |

| NOX | 61.21 | 7.83 | 3.1 | 8 | 8 | 7.83 | 61.21 | 0.003 |

| SOX | 2.64 | 0.02 | 0.03 | - | - | 0.02 | 2.64 | 0 |

| PM | 1.02 | 0.18 | 0.12 | - | - | 0.18 | 1.02 | 0 |

| Length overall, (m) | 32.28 |

| Breadth, m | 7.40 |

| Draught, m | 2.88 |

| GT | 182 |

| Main engine power, PME (kW) | 480 |

| Installed auxiliary power, PAE (kW) | 370 |

| Fuel Price (EUR/GJ) | |

|---|---|

| Diesel | 22.8 [103] |

| LNG | 17.5 [18,63] |

| LPG | 18.6 [42,104] |

| Methanol | 15.3 [105] |

| DME | 10.7 [105] |

| Biodiesel | 34.4 [103] |

| LBG | 25.9 [106] |

| Hydrogen (grey) | 25.8 [42,86] |

| Hydrogen (green) | 30.2 [42] |

| Ammonia | 20.8 [42,86] |

| Electricity | 10.3 [42] |

| GWP | AP | AFP | Costs | |

|---|---|---|---|---|

| H-FC-green | −88.4% | −84.5% | −90.5% | +29.7 |

| A-ICE | +27.1% | −79.5% | −80.1% | −25.2% |

| DME | −2.3% | −79.3% | −79.3% | −22.0% |

| AES | −33.1% | −87.2% | −92.0% | +18.2% |

| B100 | −87.1% | −0.3% | −0.6% | +2.8% |

| LPG | −24.4% | −90.7% | −90.7% | −15.0% |

| MeOH | −23.3% | −73.8% | −73.4% | −22.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perčić, M.; Vladimir, N.; Koričan, M.; Jovanović, I.; Haramina, T. Alternative Fuels for the Marine Sector and Their Applicability for Purse Seiners in a Life-Cycle Framework. Appl. Sci. 2023, 13, 13068. https://doi.org/10.3390/app132413068

Perčić M, Vladimir N, Koričan M, Jovanović I, Haramina T. Alternative Fuels for the Marine Sector and Their Applicability for Purse Seiners in a Life-Cycle Framework. Applied Sciences. 2023; 13(24):13068. https://doi.org/10.3390/app132413068

Chicago/Turabian StylePerčić, Maja, Nikola Vladimir, Marija Koričan, Ivana Jovanović, and Tatjana Haramina. 2023. "Alternative Fuels for the Marine Sector and Their Applicability for Purse Seiners in a Life-Cycle Framework" Applied Sciences 13, no. 24: 13068. https://doi.org/10.3390/app132413068

APA StylePerčić, M., Vladimir, N., Koričan, M., Jovanović, I., & Haramina, T. (2023). Alternative Fuels for the Marine Sector and Their Applicability for Purse Seiners in a Life-Cycle Framework. Applied Sciences, 13(24), 13068. https://doi.org/10.3390/app132413068