An Improved Data-Driven Integral Sliding-Mode Control and Its Automation Application

Abstract

:1. Introduction

- (1)

- A new ISMC algorithm is proposed, which alleviates the chattering phenomenon of the system compared to the methods in [26,27]. The algorithm utilizes the improved sliding-mode surface and the convergence law to achieve more-efficient nonlinear control. At the same time, the algorithm also solves the problems of randomly selecting initial weights and excessive control parameters in traditional neural networks.

- (2)

- The FFDL data model used in this paper has the following advantages: High flexibility—the FFDL data model has high flexibility and can adapt to different types and structures of controlled systems. It can handle any amount and type of data sets, and the linearization length can be easily added, deleted or modified. Strong adaptability—The FFDL data model is very suitable for use in scenarios with frequent demand changes or unstable data structures. And, this data model does not require precise parameter information of the system and can handle systems with fast, unknown or unmeasurable parameter changes. It can also automatically learn and adjust control strategies to adapt to new changes.

- (3)

- Compared with most of the existing CFB control algorithms, the control scheme in this paper does not rely on the process model of the boiler water-level system and is a data-driven control scheme. The scheme can provide more accurate results, and by analyzing a large amount of real-time data, more accurate and reliable results and predictions can be obtained.

2. Traditional Model-Free Adaptive Controller

2.1. Dynamic Linearization

2.2. Traditional MFAC Design

3. Improved Model-Free Adaptive Sliding-Mode Controller

3.1. Integral Sliding-Mode Controller

3.2. Stability Analysis

- (1)

- is bounded;

- (2)

- Under any initial conditions, the system can reach the quasisliding-mode state;

- (3)

- converges to the region , where

4. Simulation and Experiment

4.1. Experiment 1: Numerical Simulation

- (1)

- MAE

- (2)

- MSE

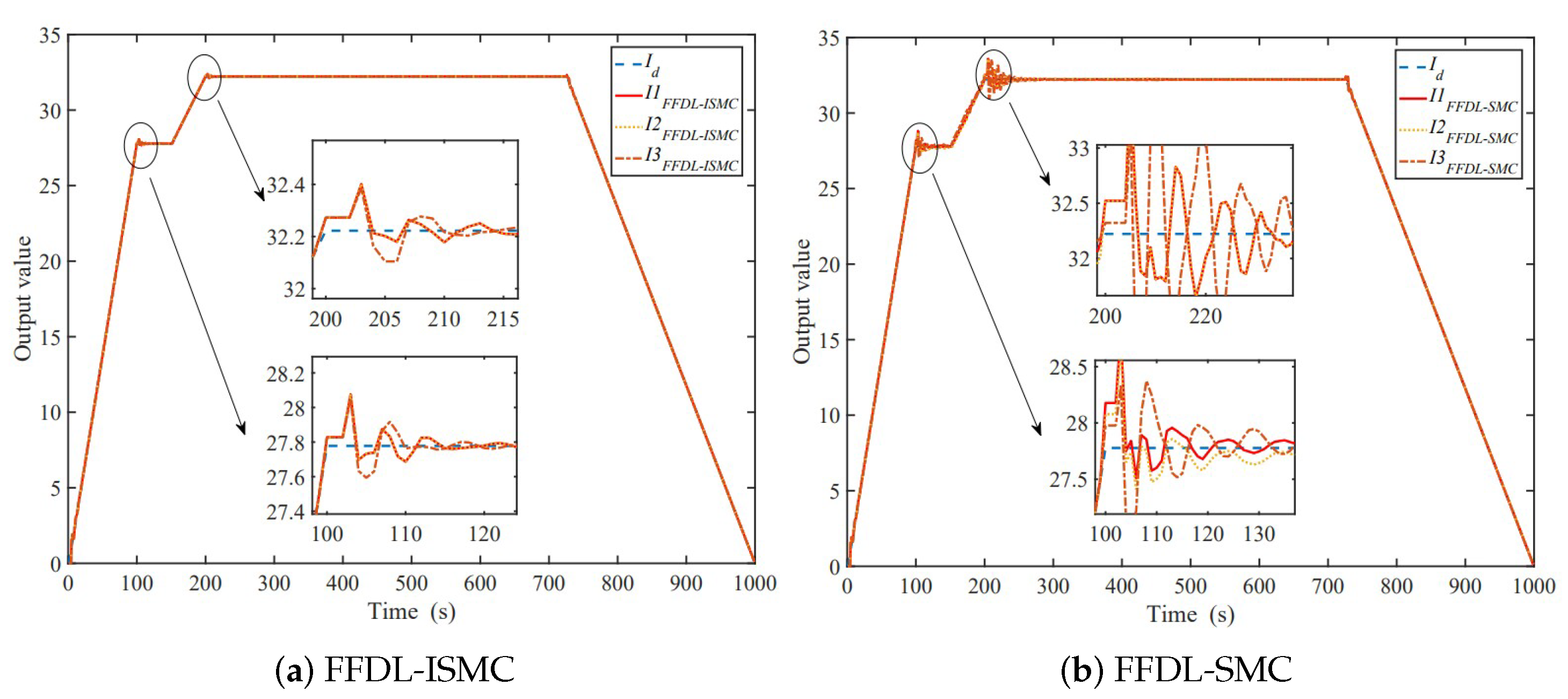

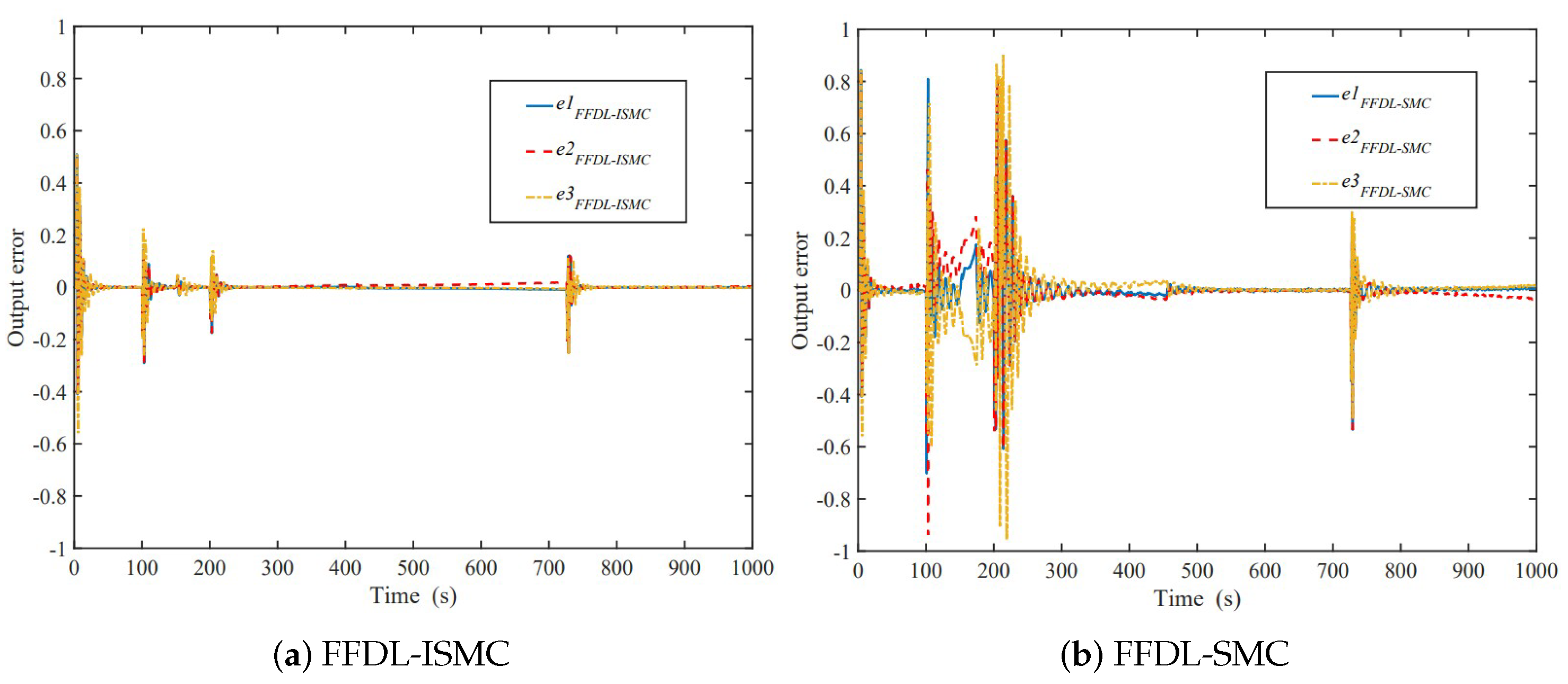

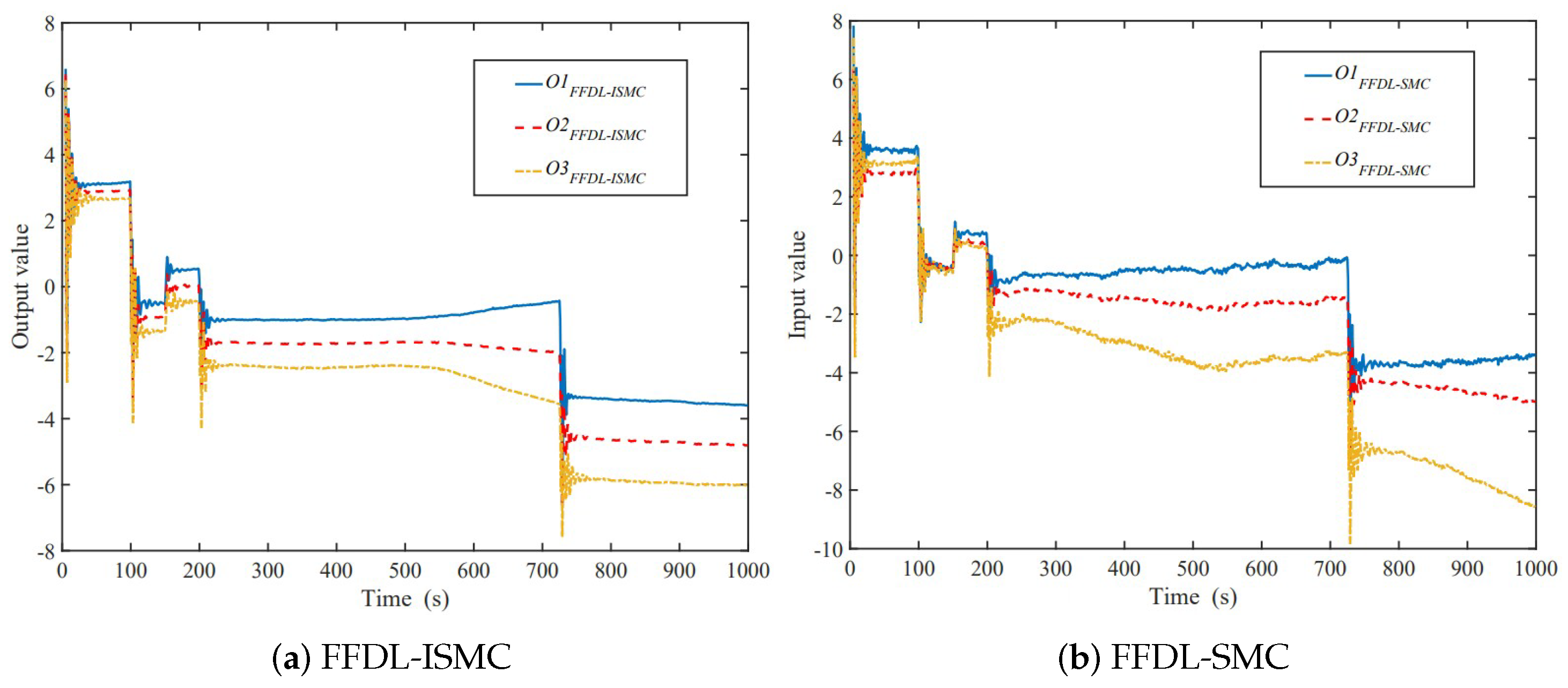

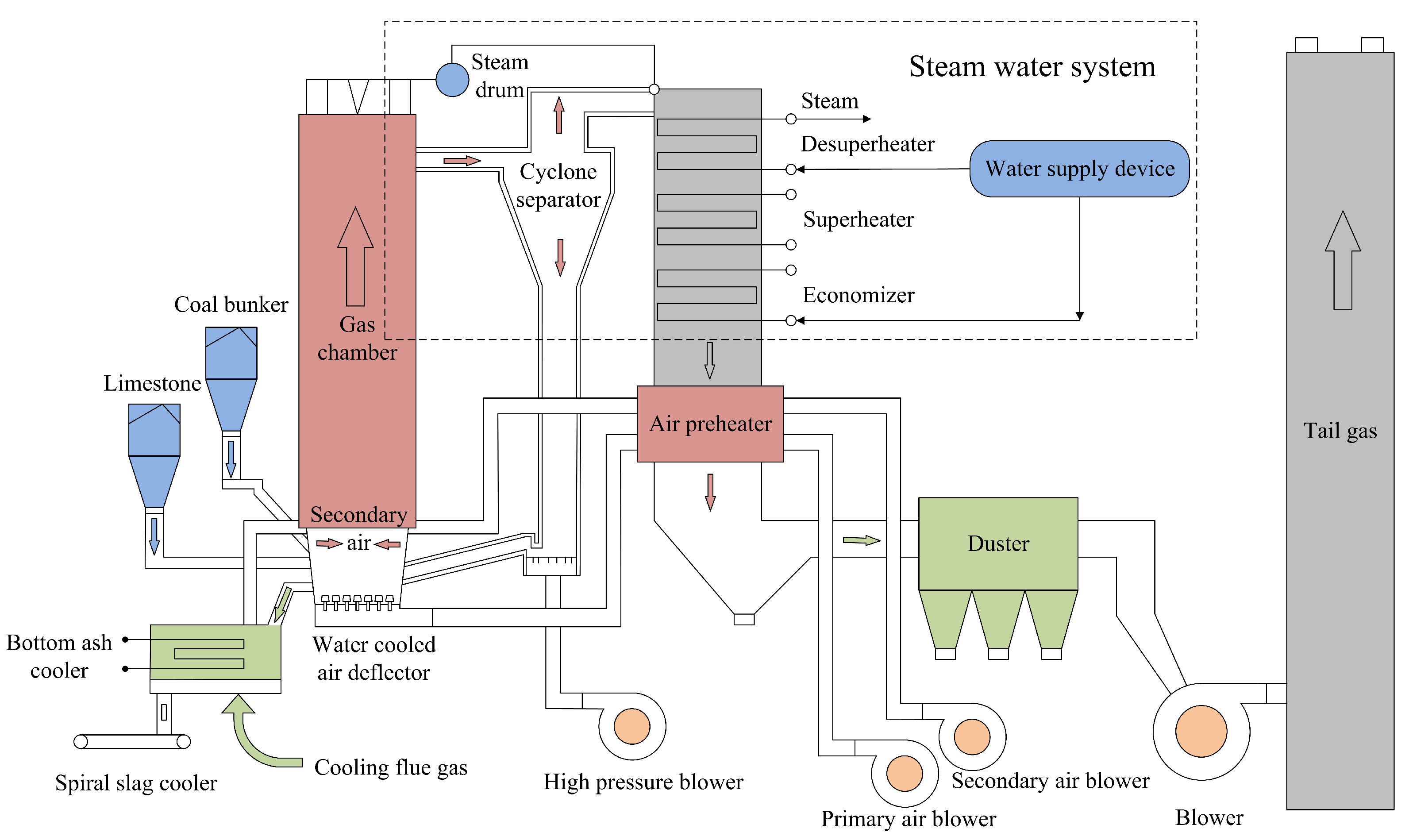

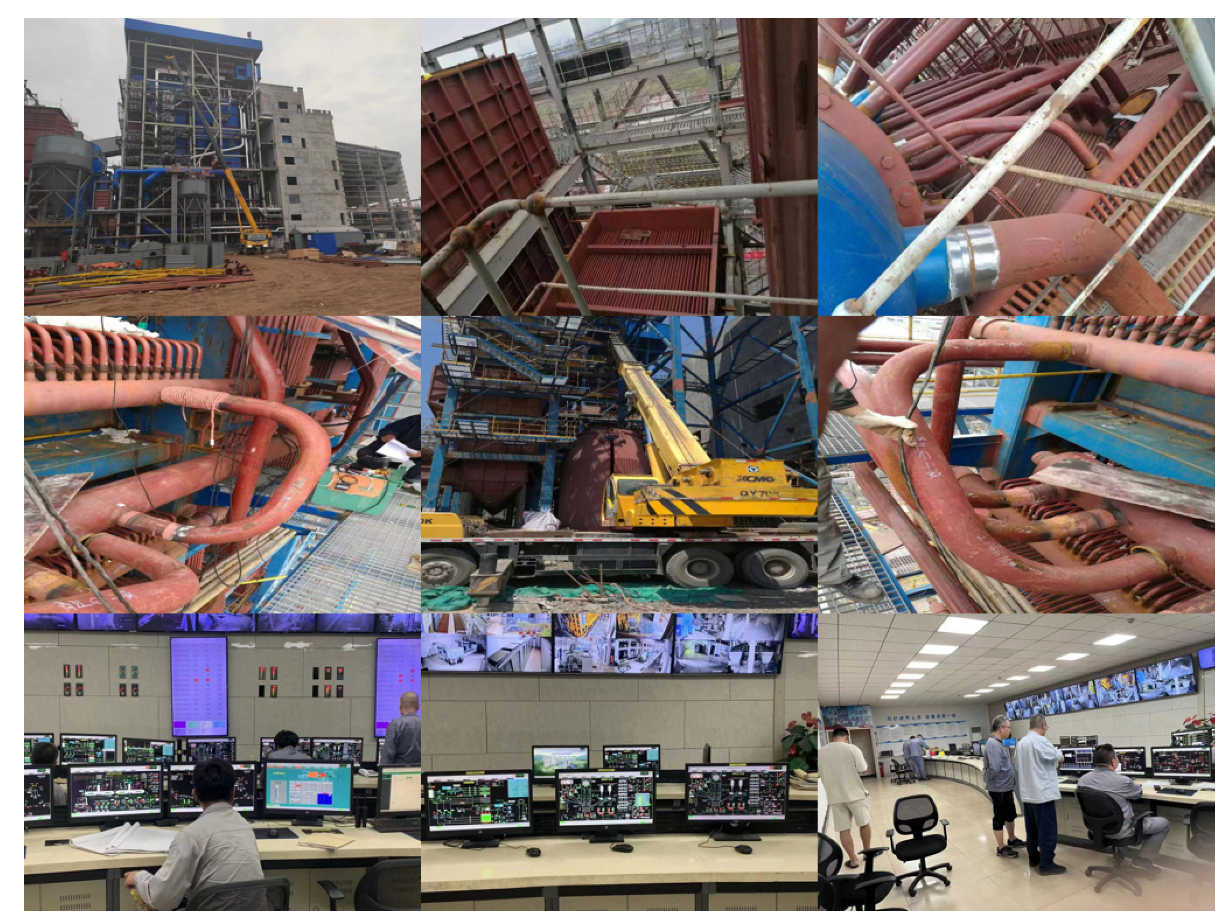

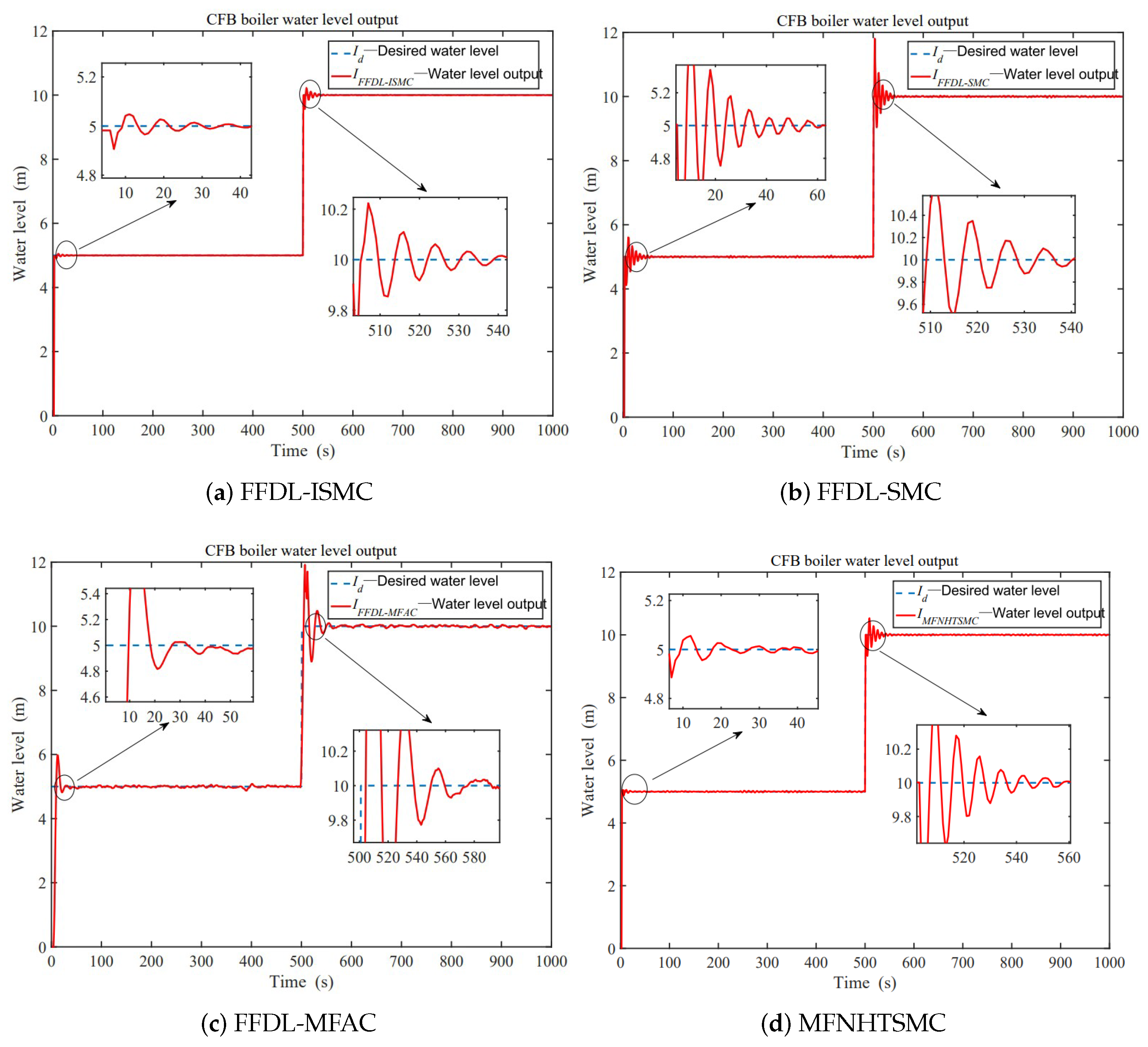

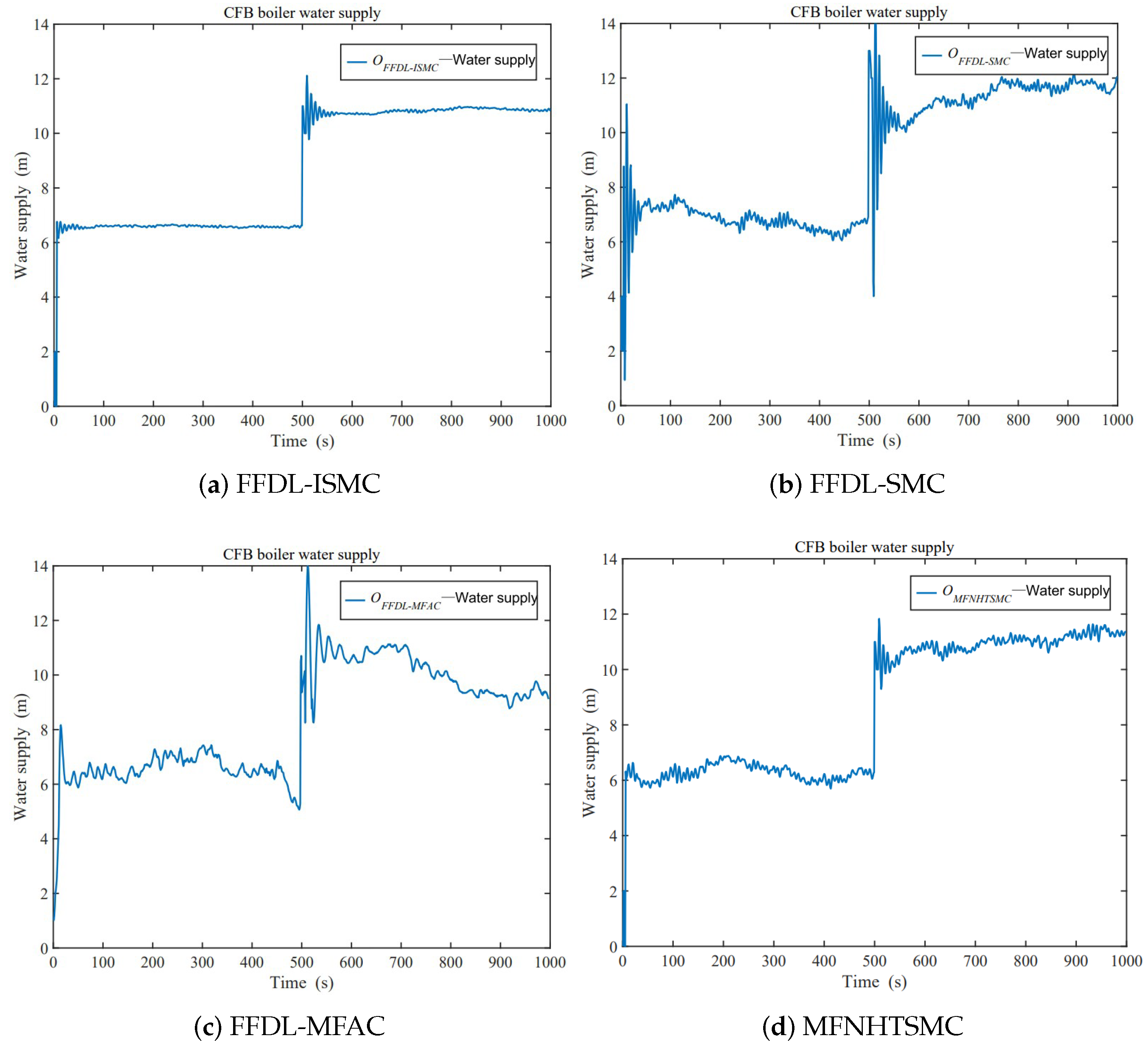

4.2. Experiment 2: Water-Level Control of CFB

- (1)

- Water-level measurement sensor: used to detect changes in the water level inside the CFB boiler and convert the signal into an electrical signal sent to the control system, usually using pressure or a capacitance-type water-level sensor.

- (2)

- Control system: receive the water-level signal sent by the sensor, and according to the difference between the set value and the actual value, automatically adjust the amount of supply water or discharge steam in order to maintain the water level in the safe range.

- (3)

- Water-supply system: according to the signal of the control system, adjust the working status and water inflow of the water-supply pump to maintain the level inside the CFB boiler.

- (4)

- Exhaust system: the exhaust valve is adjusted to control the discharge or recovery of steam in order to maintain the airtightness and stable working conditions of the CFB.

5. Conclusions

- (1)

- The FFDL-ISMC method improves the tracking speed and the fast-response characteristics of the MFAC strategy.

- (2)

- Compared with the FFDL-MFAC and FFDL-SMC methods, the FFDL-ISMC method provides higher accuracy and better stability. The FFDL-ISMC method is still able to respond faster to the feedback under variable operating conditions, thus better tracking the given boiler bubble level.

- (3)

- The FFDL-ISMC method maintains the feedwater level within a reasonable operating range with little variation. When the working conditions change, it can also respond quickly.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.H.; He, Z.; Zhang, X.G.; Jiang, X.; Jin, Z.H.; Li, J.P.; Ma, L.; Wang, H.L.; Chang, Y.L. In-situ gas flow separation between biochar and the heat carrier in a circulating fluidized bed reactor for biomass pyrolysis. Chem. Eng. J. 2023, 472, 145099. [Google Scholar] [CrossRef]

- Xu, J.L.; Xu, F.; Wang, Y.L.; Sui, Z. An Improved Model-Free Adaptive Nonlinear Control and Its Automatic Application. Appl. Sci. 2023, 13, 9145. [Google Scholar] [CrossRef]

- Zhou, L.; Li, Z.-Q.; Yang, H.; Fu, Y.-T. Data-driven integral sliding mode control based on disturbance decoupling technology for electric multiple unit. J. Frankl. Inst. 2023, 360, 9399–9426. [Google Scholar] [CrossRef]

- Li, H.T.; Zheng, S.Q.; Ren, H.L. Self-correction of commutation point for high-speed sensorless BLDC motor with low inductance and nonideal back EMF. IEEE Trans. Power Electron. 2016, 32, 642–651. [Google Scholar] [CrossRef]

- Song, L.L.; Sun, W.L.; Liu, H. Fuzzy Adaptive PID Control of Drum Water Level in Boiler. Ind. Control. Comput. 2021, 34, 74–76. [Google Scholar]

- Zhen, L.C.; Gao, X. Research of Incomplete Differential PID Control in Boiler Water System. Boil. Technol. 2007, 4, 11–14. [Google Scholar]

- Guo, K. Design and Simulation of Cascade Fuzzy Control System for Boilers. Sci. Discov. 2020, 7, 446–452. [Google Scholar]

- Grin, E.A.; Panfilov, D.N. Monitoring the Percentage of Service Life Usage for Unheated High-Temperature Elements of Boilers. Therm. Eng. 2023, 70, 630–638. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, S. Simulation and Research of CFB Boiler Level Control System Based on DMC-PID Algorithms. Mod. Ind. Econ. Informationization 2019, 9, 4–8. [Google Scholar]

- Zhou, L.; Li, Z.Q.; Yang, H.; Fu, Y.T.; Yan, Y. Data-Driven Model-Free Adaptive Sliding Mode Control Based on FFDL for Electric Multiple Units. Appl. Sci. 2022, 12, 10983. [Google Scholar] [CrossRef]

- Ma, Y.S.; Che, W.W.; Deng, C. Distributed model-free adaptive control for learning nonlinear MASs under DoS attacks. IEEE Trans. Neural Netw. Learn. Syst. 2021, 34, 1146–1155. [Google Scholar] [CrossRef] [PubMed]

- Hou, Z.S. Nonlinear System Parameter Identification, Adaptive Control and Model Free Adaptive Learning Control. Ph.D. Thesis, Northeastern University, Beijing, China, 1994. [Google Scholar]

- Jiang, Q.Q.; Liao, Y.L.; Cheng, C.S. Unmanned surface vessel heading control of model-free adaptive method with variable integral separated and proportion control. Int. J. Adv. Robot. Syst. 2019, 16, 141–149. [Google Scholar] [CrossRef]

- Wang, H.J.; Hou, Z.S. Model-free adaptive fault-tolerant control for subway trains with speed and traction/braking force constraints. IET Control. Theory Appl. 2020, 14, 1557–1566. [Google Scholar] [CrossRef]

- Moreno-Gonzalez, M.; Artuñedo, A.; Villagra, J.; Join, C.; Fliess, M. Speed-Adaptive Model-Free Path-Tracking Control for Autonomous Vehicles: Analysis and Design. Vehicles 2023, 5, 698–717. [Google Scholar] [CrossRef]

- Li, S.J.; Xu, C.Q.; Liu, J.L.; Xu, Z.Q.; Meng, F.B. Tracking control of ships based on ADRC-MFAC. Chin. J. Ship Res. 2023, 18, 1–10. [Google Scholar] [CrossRef]

- Pan, X.L.; Xian, B. Model-free adaptive robust control design for a small unmanned helicopter. Control. Theory Appl. 2017, 34, 1171–1178. [Google Scholar]

- Zhen, X.J.; Ding, M.; Wu, H.L.; Guo, M. Model-free adaptive control of cable-driven continuum manipulator. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2023, 51, 116–121. [Google Scholar]

- Wang, X.F.; Li, X.; Wang, J.H. Active Interaction Exercise Control of Exoskeleton Upper Limb Rehabilitation Robot Using Model-free Adaptive Methods. Acta Autom. Sin. 2016, 42, 1899–1914. [Google Scholar]

- Wei, H.; Jie, T. On Simulation for Coal Mine Belt Servo System Based on MFAC. Comput. Simul. 2014, 31, 373–376. [Google Scholar]

- Rongmin, C.; Hongwei, L. Model-free adaptive control on linear motor servo system. J. Beijing Inf. Sci. Technol. Univ. 2012, 27, 39–44. [Google Scholar]

- Hu, Y.M.; Li, G.Q.; Zhang, J.L. Revamping of parameter input of MFAC and utilization in gas fractionation unit. CIESC J. 2015, 66, 4076–4084. [Google Scholar]

- Dong, N.; Lv, W.; Zhu, S.; Li, D. Anti-noise model-free adaptive control and its application in the circulating fluidized bed boiler. Proc. Inst. Mech. Eng. Part-J. Syst. Control. Eng. 2021, 235, 1472–1481. [Google Scholar] [CrossRef]

- Zhu, M.S.; Liu, J.M.; Hu, X.H.; Yu, S.; Xu, S.C.; Ye, Z.H. Research on Model Free Adaptive Control of Boiler Water Circulation System. J. Chongqing Univ. Technol. (Natural Sci.) 2019, 33, 214–220. [Google Scholar]

- Dong, N.; Lv, W.; Zhu, S.; Gao, Z.; Grebogi, C. Model-free adaptive nonlinear control of the absorption refrigeration system. Nonlinear Dyn. 2022, 107, 1623–1635. [Google Scholar] [CrossRef]

- Wang, Y.S.; Hou, M.D. Model-free adaptive integral terminal sliding mode predictive control for a class of discrete-time nonlinear systems. ISA Trans. 2019, 93, 209–217. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.T.; Wu, A.G. Integral sliding mode predictive control with disturbance attenuation for discrete-time systems. IET Control. Theory Appl. 2022, 16, 1751–1766. [Google Scholar] [CrossRef]

- Ma, Y.S.; Che, W.W.; Deng, C. Dynamic event-triggered model-free adaptive control for nonlinear CPSs under aperiodic DoS attacks. Inf. Sci. 2022, 589, 790–801. [Google Scholar] [CrossRef]

- Xiong, S.S.; Hou, Z.S. Model-free adaptive control for unknown MIMO nonaffine nonlinear discrete-time systems with experimental validation. IEEE Trans. Neural Netw. Learn. Syst. 2022, 33, 1727–1739. [Google Scholar] [CrossRef]

- Dong, N.; Zhu, S. Model-free Adaptive De-noising Control and Its Application. J. Hunan Univ. (Nat. Sci.) 2020, 47, 74–81. [Google Scholar]

- Nie, X.; Xie, H.Y.; Yang, D.; Liu, H.; Zhou, K.; Zhou, Z.P.; Li, Y.H.; Liu, Z.G. Safety analysis for boiler thermal-hydraulic circulation with severe peak load regulation of a CFB unit. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 2766–2776. [Google Scholar]

- Ma, Y.F.; Niu, F.F.; Lv, J.F.; Jin, X.; Ma, H. Study of controlling thermal deviation in platen superheaters of a CFB boiler by utilizing header effect. J. Cent. South Univ. (Sci. Technol.) 2021, 52, 4454–4463. [Google Scholar]

- Huang, S.Z.; Li, X.S. Research and application on bed material preparation system of CFB boiler. Int. J. Energy Power Eng. 2020, 9, 108–114. [Google Scholar]

- Zhu, S. Research on Improve Model-Free Adaptive Control and its Application. Master’s Thesis, Tianjin University, Tianjin, China, 2019. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, W.; Liu, Z.; Jia, L.; Huang, G. Model-Free High Sliding Mode Control for Permanent Magnet Synchronous Motor. Trans. China Electrotech. Soc. 2023, 38, 1472–1485. [Google Scholar] [CrossRef]

| Methods | FFDL-SMC | FFDL-ISMC |

|---|---|---|

| Rise time (s) | 6 | 3 |

| Adjust time (s) | 32 | 10 |

| MAE | ||

| MSE |

| Methods | FFDL-MFAC | FFDL-SMC | FFDL-ISMC | MFNHTSMC |

|---|---|---|---|---|

| Rise time (s) | 9 | 15 | 4 | 4 |

| Adjust time (s) | 75 | 58 | 35 | 35 |

| MAE | ||||

| MSE |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Sui, Z.; Wang, Y.; Xu, J. An Improved Data-Driven Integral Sliding-Mode Control and Its Automation Application. Appl. Sci. 2023, 13, 13094. https://doi.org/10.3390/app132413094

Xu F, Sui Z, Wang Y, Xu J. An Improved Data-Driven Integral Sliding-Mode Control and Its Automation Application. Applied Sciences. 2023; 13(24):13094. https://doi.org/10.3390/app132413094

Chicago/Turabian StyleXu, Feng, Zhen Sui, Yulong Wang, and Jianliang Xu. 2023. "An Improved Data-Driven Integral Sliding-Mode Control and Its Automation Application" Applied Sciences 13, no. 24: 13094. https://doi.org/10.3390/app132413094