Application of Fatty Acids Distillation Products as a Substitute for Heavy Fuel Oil in Stationary Combustion Chambers

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

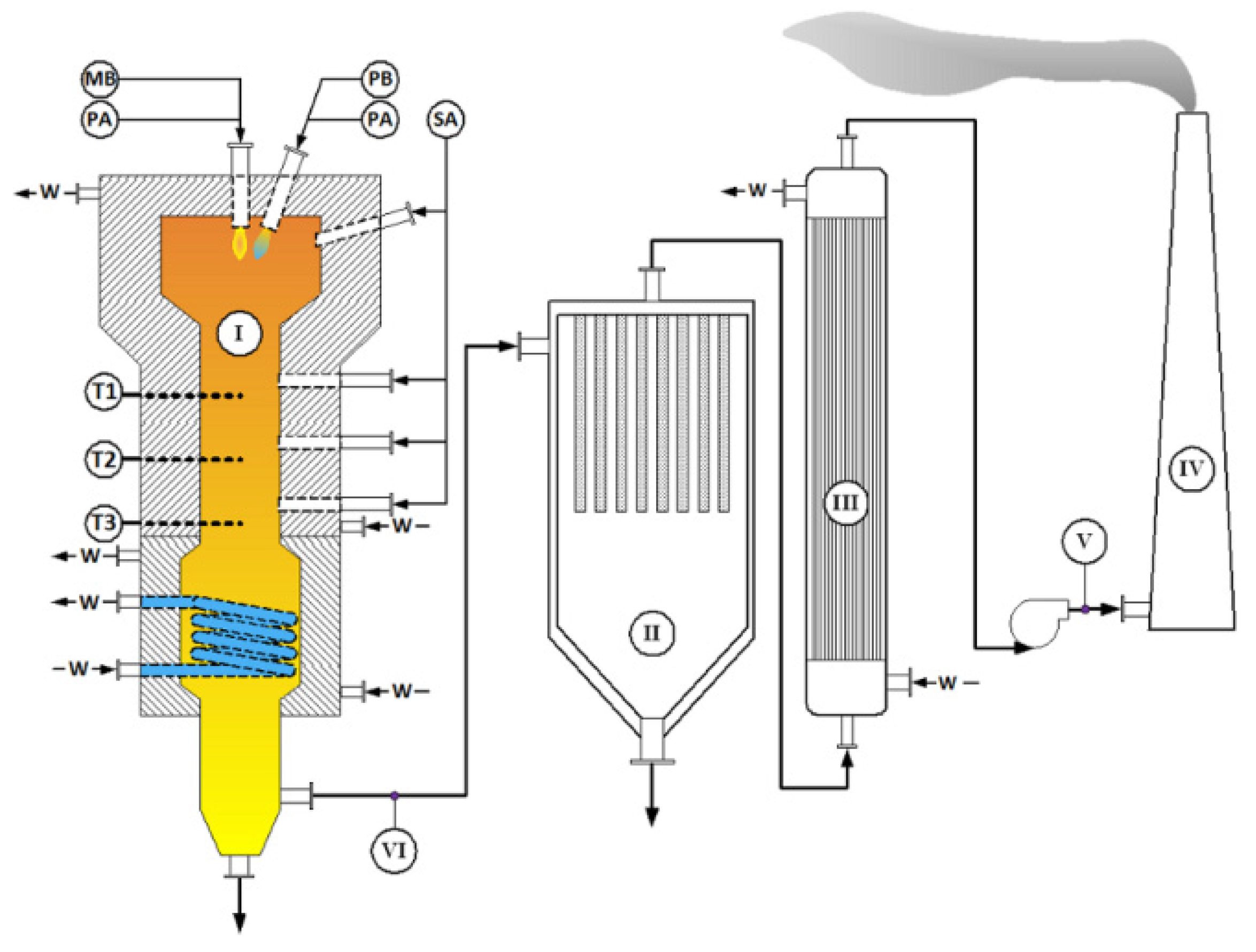

2.2. Combustion Test

2.3. Uncertainty Analyses

- energy density:

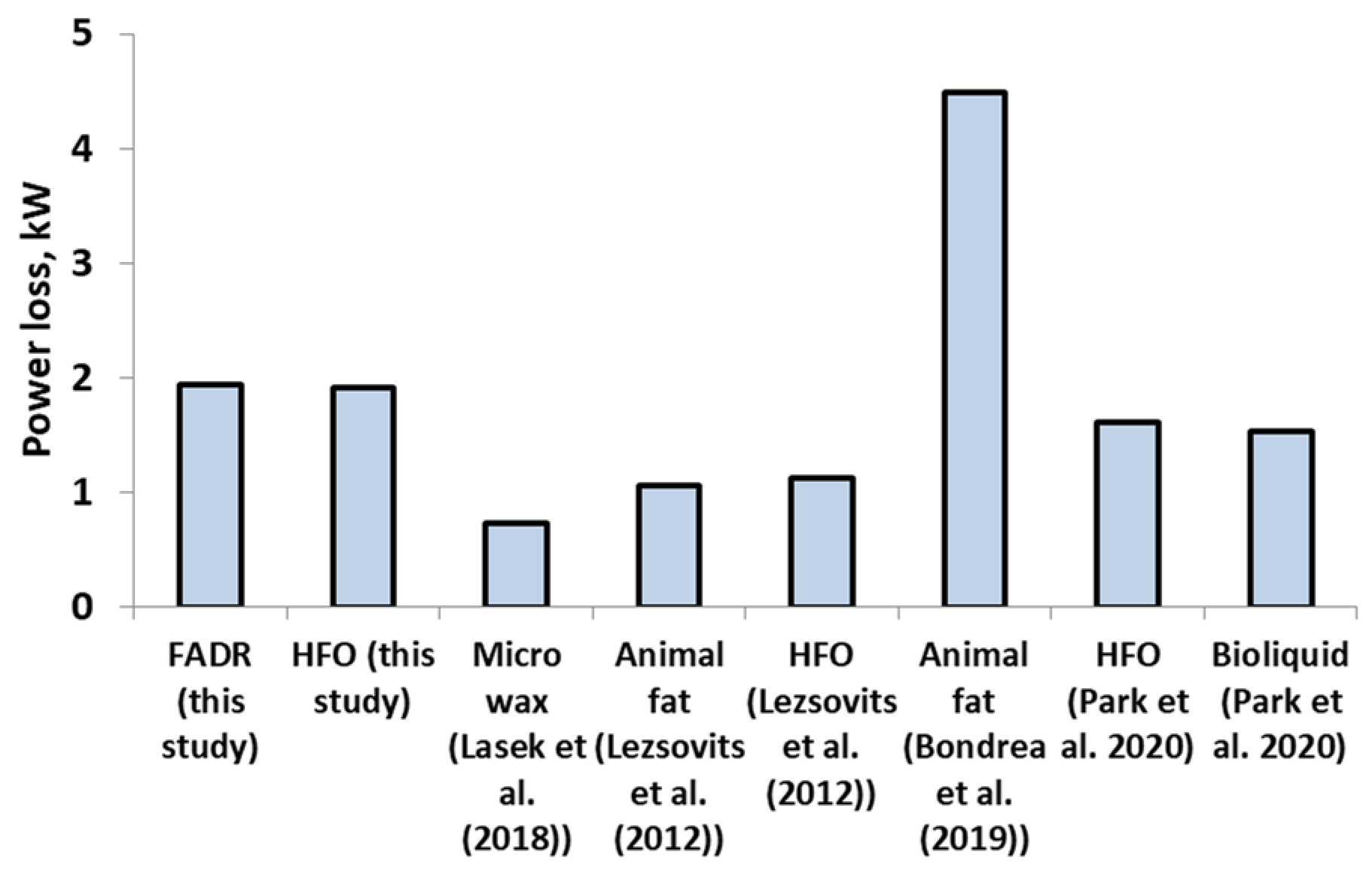

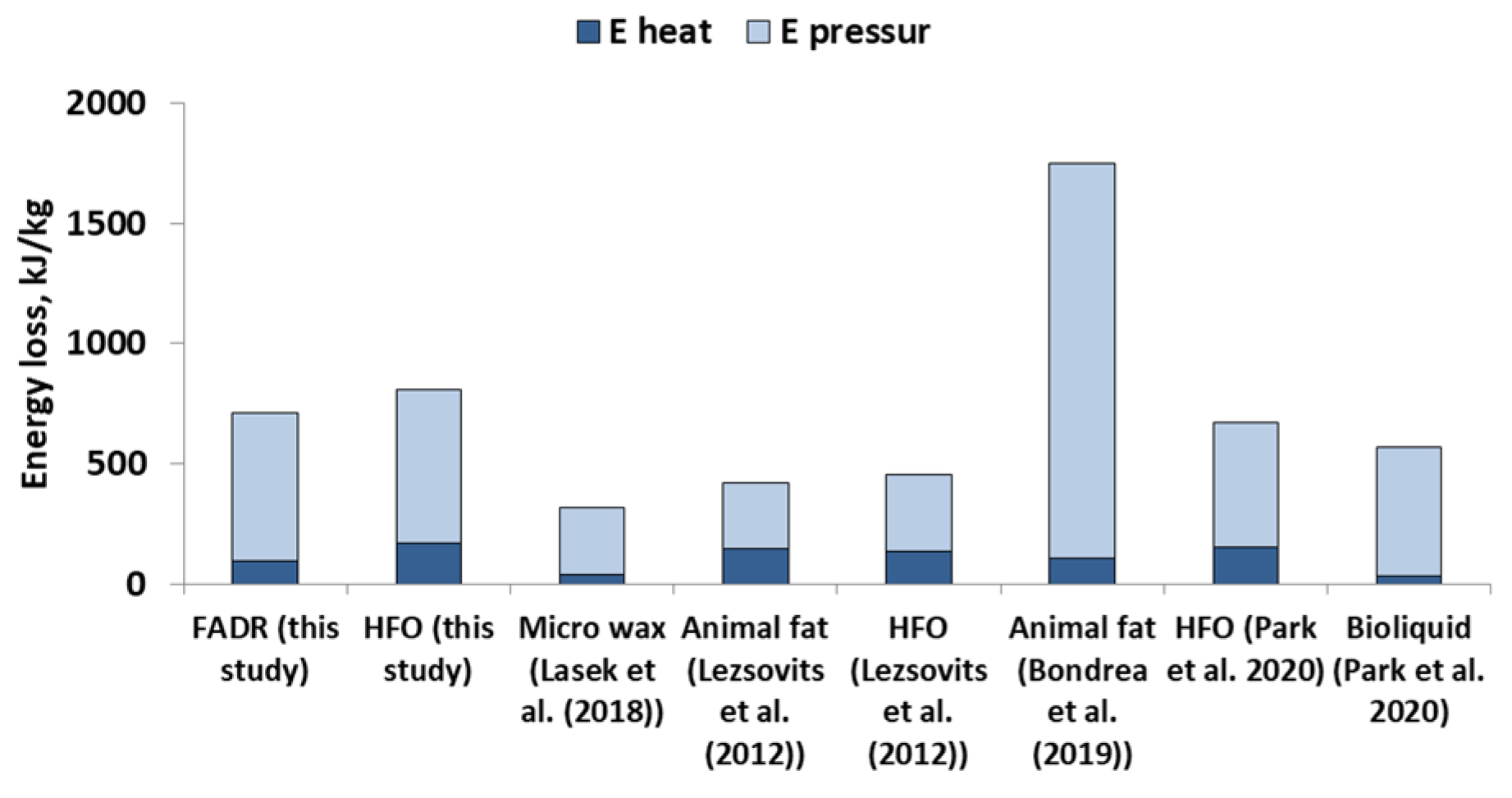

- the energy for fuel heating and fuel pressurization:

- nominal fuel feed:

- power loss:

3. Results and Discussion

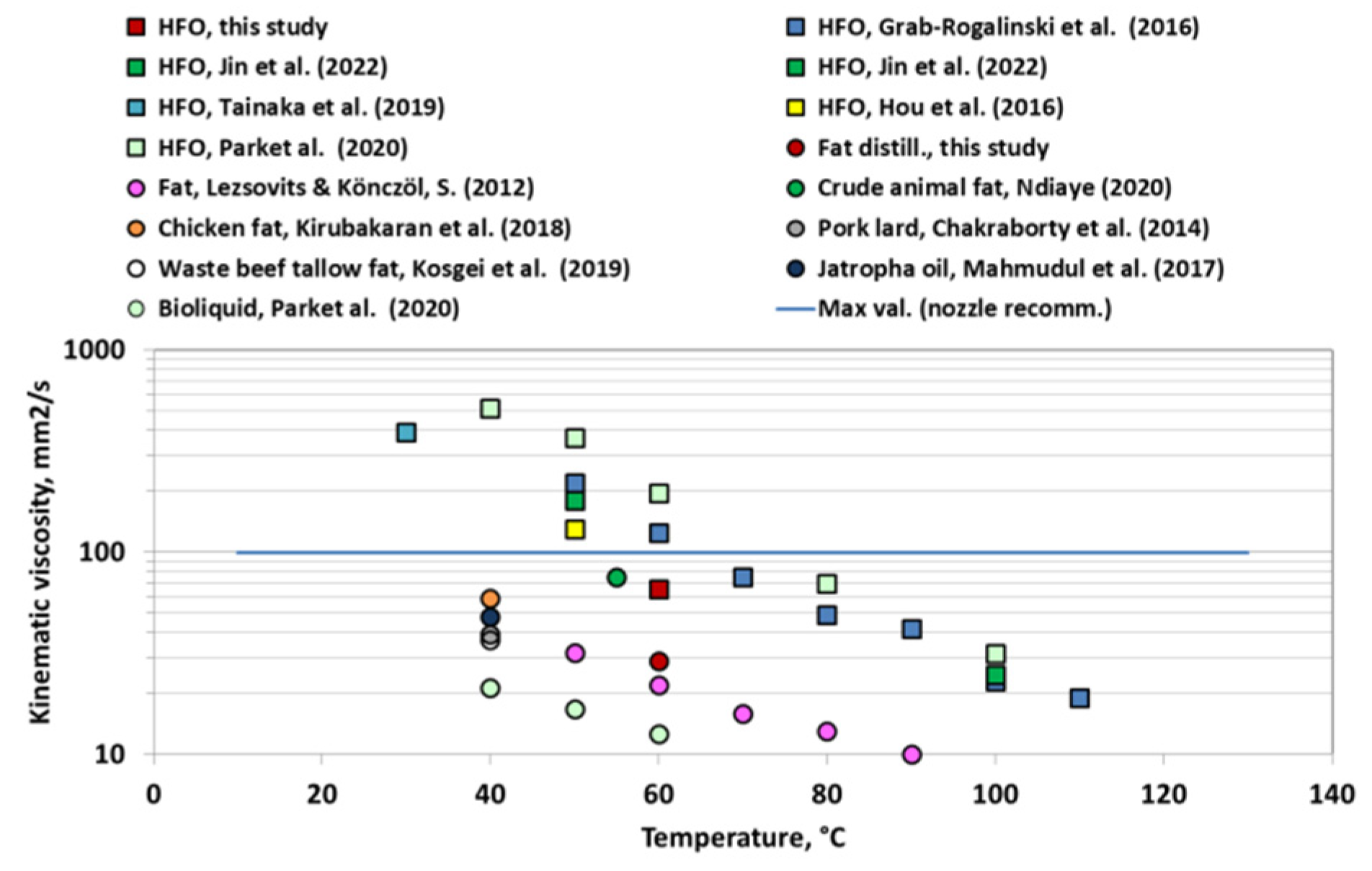

3.1. Fuel Properties

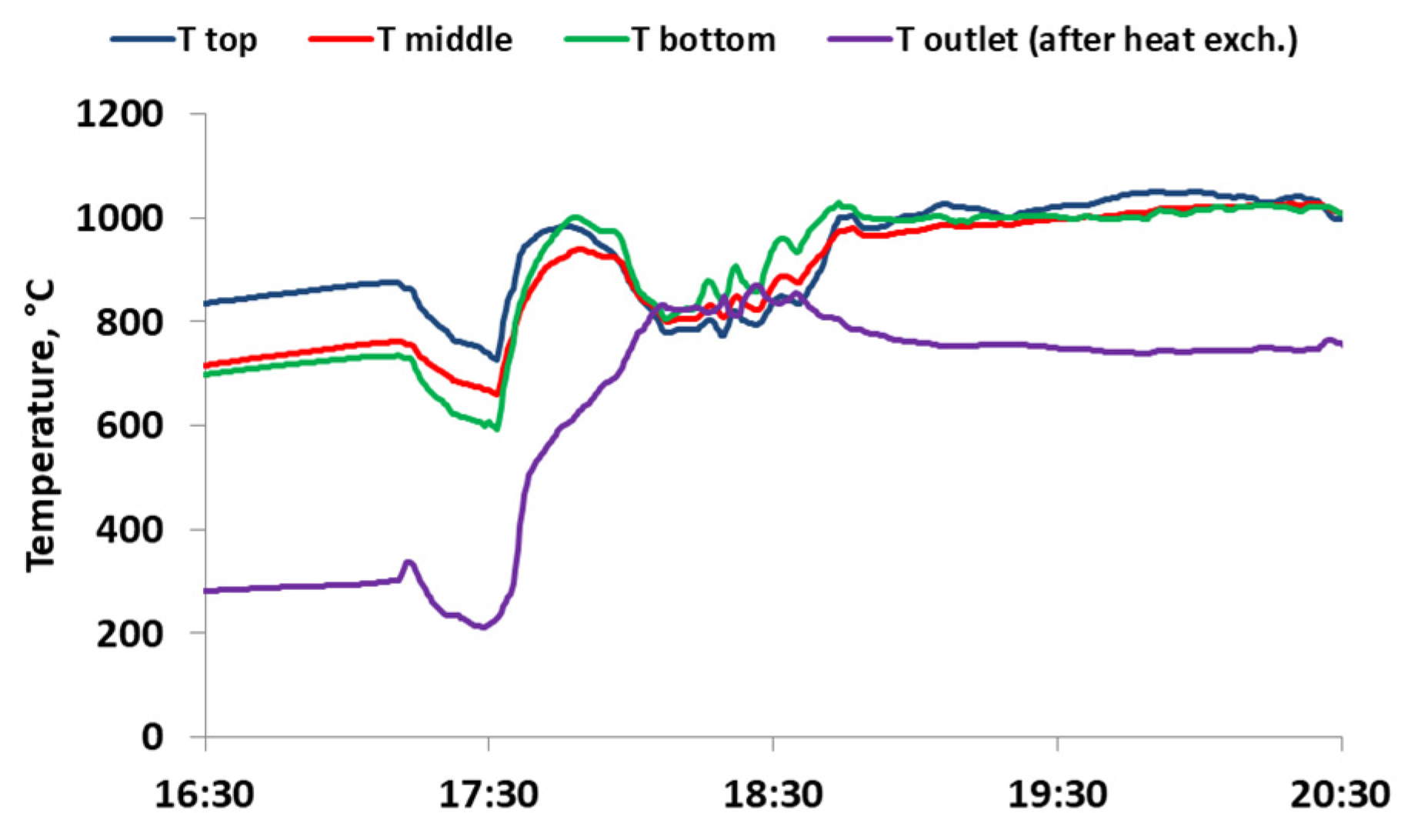

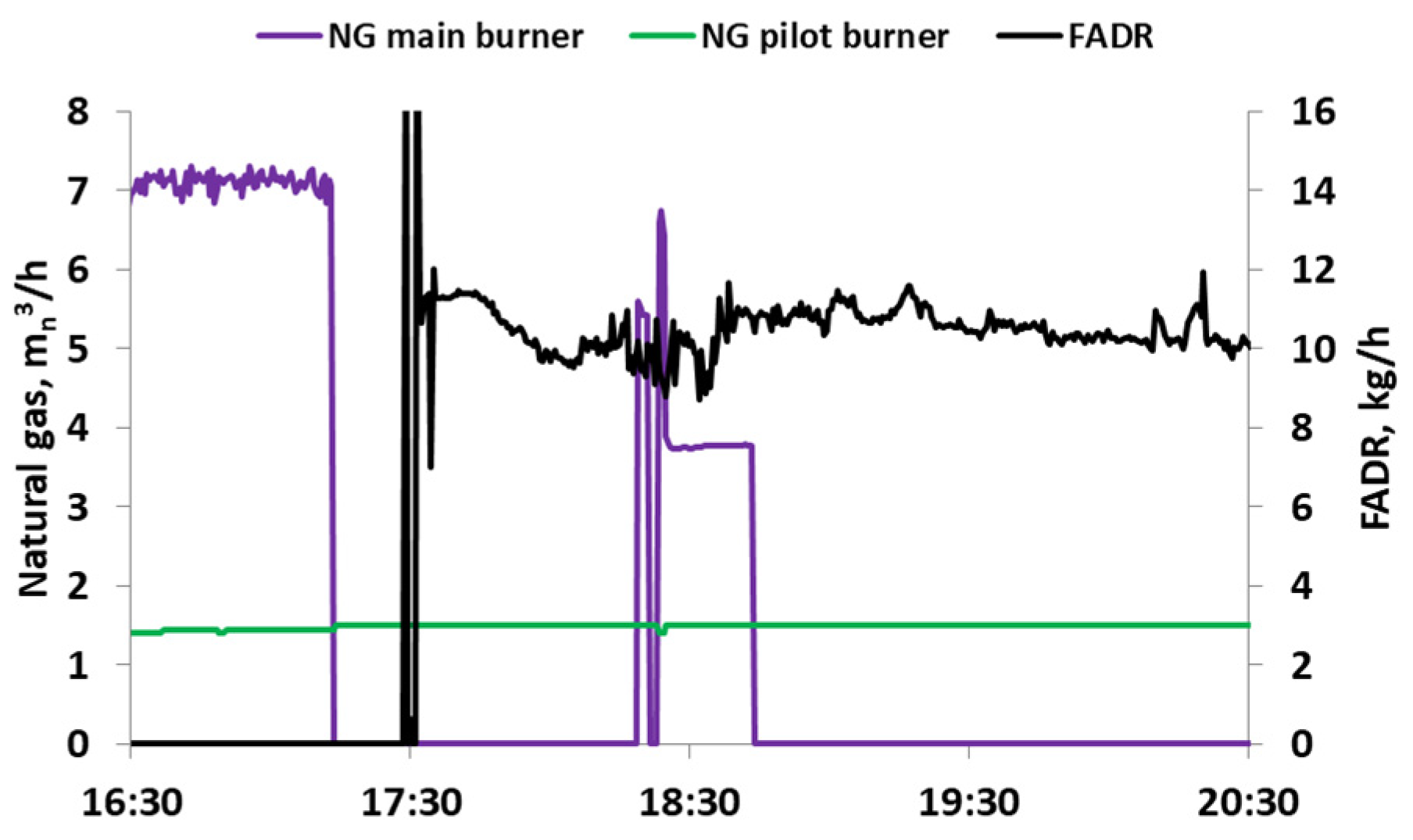

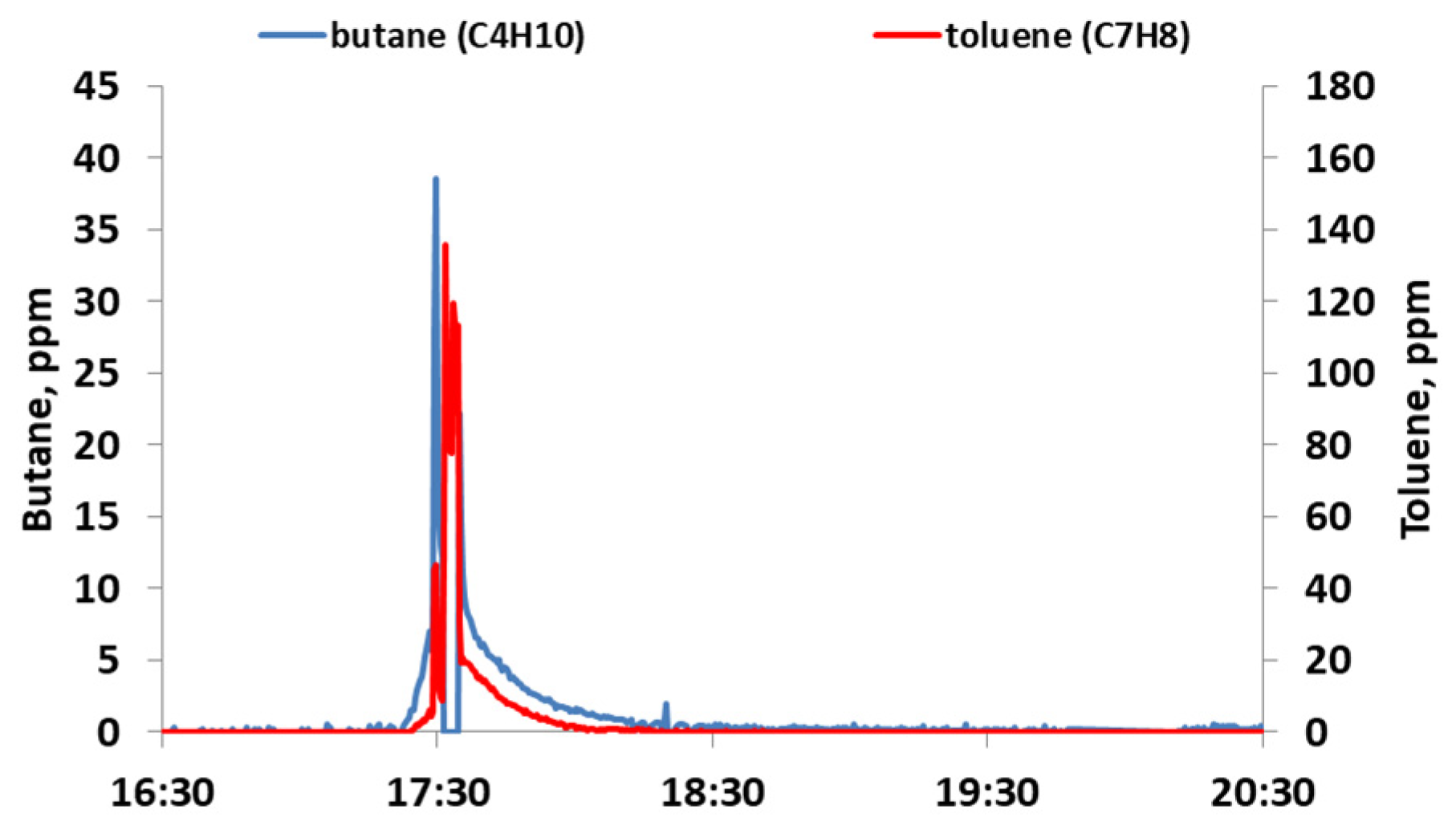

3.2. Combustion Test

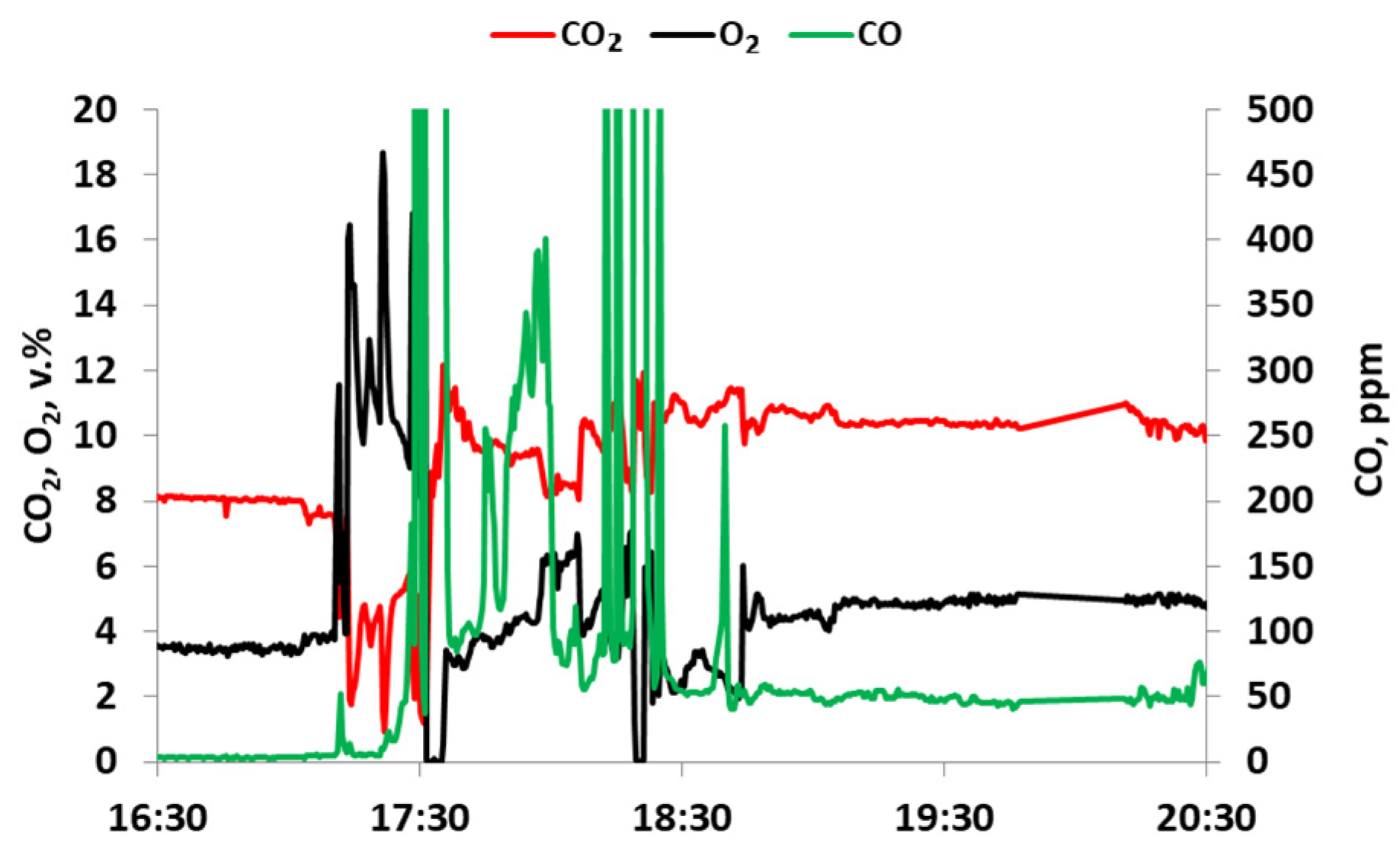

3.3. Emission

| Fuel | Type and Scale of the Facility | Emissions | O2 in Gases, % | Emissions (Calculated on 3% O2) | Ref. |

|---|---|---|---|---|---|

| FADR | 150 kW tech-scale combustion chamber | CO 55 ppm; NO 98 ppm; SO2 < 1 ppm | 5 | CO 64 ppm; NO 114 ppm; SO2 < 1 ppm | This study |

| HFO | 150 kW tech-scale combustion chamber | CO 26 ppm; NO 68 ppm; SO2 133 ppm | 7.9 | CO 35 ppm; NO 90 ppm; SO2 176 ppm | This study |

| Blend of diesel (60 w.%) and FF (40 w.%) | 26.7 kW boiler | CO 198 ppm; NO 27 ppm | 5.4 | CO 228 ppm; NO 31 ppm | [9] |

| Blend of diesel (60 w.%) and NF1 (40 w.%) | 26.7 kW boiler | CO 634 ppm; NO 98 ppm | 5.1 | CO 718 ppm; NO 111 ppm | [9] |

| Blend of diesel (60 w.%) and NF2 (40 w.%) | 26.7 kW boiler | CO 62 ppm; NO 28 ppm | 4.9 | CO 69 ppm; NO 31 ppm | [9] |

| AF | rotary cup type burner in 4 MWth boilers. | CO 1 ppm; NO 124 ppm | 7.4 | CO 1 ppm; NO 164 ppm | [16] |

| BL | 400-MWe power boiler | NO 126 ppm, SO2 40 ppm | 1 | NO 113 ppm, SO2 36 ppm | [43] |

| ABNIHC category 1 | technical-scale combustion chamber | CO 50 ppm; NO 56 ppm | 9.8 | CO 80 ppm; NO 90 ppm | [12] |

| ABNIHC category 2 | technical-scale combustion chamber | CO 32 ppm; NO 22 ppm | 11 | CO 58 ppm; NO 40 ppm | [12] |

| FADR | 4.5 MWth nominal capacity boiler | CO 4 ppm; NO 118 ppm; SO2 16 ppm | 5 | CO 5 ppm; NO 139 ppm; SO2 18 ppm | [18] |

| HFO | 4.5 MWth nominal capacity boiler | CO 6 ppm; NO 148 ppm; SO2 288 ppm | 5 | CO 7 ppm; NO 173 ppm; SO2 337 ppm | [18] |

| HFO | 1.4 MWth experimental rig. The heavy-fuel-oil-fired regenerator-burner system with the 1200 °C highly preheated combustion air, furnace temp 1300 °C | NO 394 ppm | 6 | NO 473 ppm | [50] |

| HFO | 325 MW boiler | NO 398 ppm | 4.4 | NO 432 ppm | [47] |

| HFO | 400-MWe power boiler | NO 201 ppm, SO2 1180 ppm | 0.125 | NO 173 ppm, SO2 1017 ppm | [43] |

| HFO | rotary cup type burner in 4 MWth boilers. | CO 36 ppm; NO 279 ppm | 4 | CO 38 ppm; NO 295 ppm | [16] |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alrashidi, A.M.R.N.; Adam, N.M.; Bin Mohd Ariffin, M.K.A.; Fnyees, A.; Alajmi, A.; Naser, A.; Abdul Aziz, H. Impact of Plasma Combustion Technology on Micro Gas Turbines Using Biodiesel Fuels. Appl. Sci. 2022, 12, 4321. [Google Scholar] [CrossRef]

- Lee, C.Y.; Sun, W.C.; Li, Y.H. Biodiesel Economic Evaluation and Biomass Planting Allocation Optimization in Global Supply Chain. IEEE Trans. Eng. Manag. 2022, 69, 602–615. [Google Scholar] [CrossRef]

- Chen, G.-B.; Li, Y.-H.; Lan, C.-H.; Lin, H.-T.; Chao, Y.-C. Micro-explosion and burning characteristics of a single droplet of pyrolytic oil from castor seeds. Appl. Therm. Eng. 2017, 114, 1053–1063. [Google Scholar] [CrossRef]

- Kupczyk, A.; Mączyńska, J.; Redlarski, G.; Tucki, K.; Bączyk, A.; Rutkowski, D. Selected Aspects of Biofuels Market and the Electromobility Development in Poland: Current Trends and Forecasting Changes. Appl. Sci. 2019, 9, 254. [Google Scholar] [CrossRef]

- Ndiaye, M.; Arhaliass, A.; Legrand, J.; Roelens, G.; Kerihuel, A. Reuse of waste animal fat in biodiesel: Biorefining heavily-degraded contaminant-rich waste animal fat and formulation as diesel fuel additive. Renew. Energy 2020, 145, 1073–1079. [Google Scholar] [CrossRef]

- Rosson, E.; Sgarbossa, P.; Pedrielli, F.; Mozzon, M.; Bertani, R. Bioliquids from raw waste animal fats: An alternative renewable energy source. Biomass Convers. Biorefin. 2021, 11, 1475–1490. [Google Scholar] [CrossRef]

- Toldrá-Reig, F.; Mora, L.; Toldrá, F. Trends in Biodiesel Production from Animal Fat Waste. Appl. Sci. 2020, 10, 3644. [Google Scholar] [CrossRef]

- Borychowska, H.; Dziejowska, I.; Orżanowska, A.; Rafa, W.; Wróblewska, A. Statistical Yearbook of Agriculture; Statistics: Warsaw, Poland, 2022. [Google Scholar]

- Alonso, J.F.S.J.; Arribas, I.G.; Miñambre, S.A. Study of combustion in residential oil burning equipment of animal by-products and derived products not intended for human consumption. Int. J. Energy Environ. Eng. 2013, 4, 31. [Google Scholar] [CrossRef]

- Brahma, S.; Nath, B.; Basumatary, B.; Das, B.; Saikia, P.; Patir, K.; Basumatary, S. Biodiesel production from mixed oils: A sustainable approach towards industrial biofuel production. Chem. Eng. J. Adv. 2022, 10, 100284. [Google Scholar] [CrossRef]

- Xiu, S.; Shahbazi, A. Bio-oil production and upgrading research: A review. Renew. Sustain. Energy Rev. 2012, 16, 4406–4414. [Google Scholar] [CrossRef]

- Alonso, J.S.J.; Romero-Ávila, C.; Hernández, L.S.J.; Awf, A.-K. Characterising biofuels and selecting the most appropriate burner for their combustion. Fuel Process. Technol. 2012, 103, 39–44. [Google Scholar] [CrossRef]

- Tsui, T.-H.; Wong, J.W. A critical review: Emerging bioeconomy and waste-to-energy technologies for sustainable municipal solid waste management. Waste Dispos. Sustain. Energy 2019, 1, 151–167. [Google Scholar] [CrossRef]

- Fakudze, S.; Wei, Y.; Shang, Q.; Ma, R.; Li, Y.H.; Chen, J.; Zhou, P.; Han, J.; Liu, C. Single-pot upgrading of run-of-mine coal and rice straw via Taguchi-optimized hydrothermal treatment: Fuel properties and synergistic effects. Energy 2021, 236, 121482. [Google Scholar] [CrossRef]

- Li, Y.H.; Kuo, W.C. The study of optimal parameters of oxygen-enriched combustion in fluidized bed with optimal torrefied woody waste. Int. J. Energy Res. 2020, 44, 7416–7434. [Google Scholar] [CrossRef]

- Lezsovits, F.; Könczöl, S. Animal-fat investigation and combustion test. J. Therm. Anal. Calorim. 2012, 107, 271–278. [Google Scholar] [CrossRef]

- Bondrea, D.A.; Mihaescu, L.; Lazaroiu, G.; Pisa, I.; Negreanu, G. Researches on the mixture limits of animal fats with liquid hydrocarbons for combustion at industrial level. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; p. 02001. [Google Scholar]

- Wasielewski, R.; Głód, K. Emission results of combustion process of fatty acids distillation residue in an oil boiler–comparison to heavy fuel oil. Sci. Rev. Eng. Environ. Sci. 2020, 2020, 62–71. [Google Scholar] [CrossRef]

- Lazaroiu, G.; Mihaescu, L.; Negreanu, G.; Pana, C.; Pisa, I.; Cernat, A.; Ciupageanu, D.-A. Experimental investigations of innovative biomass energy harnessing solutions. Energies 2018, 11, 3469. [Google Scholar] [CrossRef]

- Lasek, J.A.; Matuszek, K.; Hrycko, P.; Piechaczek, M. Adaptation of hard coal with high sinterability for solid fuel boilers in residential heating systems. Fuel 2018, 215, 239–248. [Google Scholar] [CrossRef]

- Biernat, K. Criteria for the Quality Assessment of Engine Fuels in Storage and Operating Conditions. In Storage Stability of Fuels; IntechOpen: London, UK, 2015. [Google Scholar]

- Lasek, J.; Hrycko, P.; Wasielewski, R.; Kopczyński, M.; Bodora, K.; Kaczmarzyk, G.; Adamczyk, M. Combustion of micro wax from polyethylene pyrolysis. Combust. Sci. Technol. 2018, 190, 1246–1258. [Google Scholar] [CrossRef]

- Lasek, J.; Matuszek, K.; Stelmach, S.; Sobolewski, A.; Hrycko, P. Smokeless Fuel for Residential Heating as a Remedy for Air Pollution: Laboratory and Pilot-Scale Operational Investigations. Energy Fuels 2019, 33, 11757–11767. [Google Scholar] [CrossRef]

- Lasek, J.A.; Kopczyński, M.; Janusz, M.; Iluk, A.; Zuwała, J. Combustion properties of torrefied biomass obtained from flue gas-enhanced reactor. Energy 2017, 119, 362–368. [Google Scholar] [CrossRef]

- Eryilmaz, T.; Yesilyurt, M.K. Influence of blending ratio on the physicochemical properties of safflower oil methyl ester-safflower oil, safflower oil methyl ester-diesel and safflower oil-diesel. Renew. Energy 2016, 95, 233–247. [Google Scholar] [CrossRef]

- Jiang, G.; Zhang, Y.; Wen, H.; Xiao, G. Study of the generated density of cavitation inside diesel nozzle using different fuels and nozzles. Energy Convers. Manag. 2015, 103, 208–217. [Google Scholar] [CrossRef]

- Chen, D.; Zhou, J.; Zhang, Q.; Zhu, X. Evaluation methods and research progresses in bio-oil storage stability. Renew. Sustain. Energy Rev. 2014, 40, 69–79. [Google Scholar] [CrossRef]

- Grab-Rogalinski, K.; Szwaja, S. The combustion properties analysis of various liquid fuels based on crude oil and renewables. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; p. 012066. [Google Scholar]

- Jin, C.; Sun, T.; Ampah, J.D.; Liu, X.; Geng, Z.; Afrane, S.; Yusuf, A.A.; Liu, H. Comparative study on synthetic and biological surfactants’ role in phase behavior and fuel properties of marine heavy fuel oil-low carbon alcohol blends under different temperatures. Renew. Energy 2022, 195, 841–852. [Google Scholar] [CrossRef]

- Tainaka, K.; Fan, Y.; Hashimoto, N.; Nishida, H. Effects of blending crude Jatropha oil and heavy fuel oil on the soot behavior of a steam atomizing burner. Renew. Energy 2019, 136, 358–364. [Google Scholar] [CrossRef]

- Hou, S.-S.; Huang, W.-C.; Rizal, F.M.; Lin, T.-H. Co-firing of fast pyrolysis bio-oil and heavy fuel oil in a 300-kWth furnace. Appl. Sci. 2016, 6, 326. [Google Scholar] [CrossRef]

- Kirubakaran, M.; Selvan, V.A.M. A comprehensive review of low cost biodiesel production from waste chicken fat. Renew. Sustain. Energy Rev. 2018, 82, 390–401. [Google Scholar] [CrossRef]

- Kosgei, C.; Inambao, F.L. A Comprehensive Review of Low-Cost Biodiesel Production from Waste Beef Tallow. Int. J. Mech. Eng. Technol. 2019, 10, 285–305. [Google Scholar]

- Chakraborty, R.; Gupta, A.K.; Chowdhury, R. Conversion of slaughterhouse and poultry farm animal fats and wastes to biodiesel: Parametric sensitivity and fuel quality assessment. Renew. Sustain. Energy Rev. 2014, 29, 120–134. [Google Scholar] [CrossRef]

- Mahmudul, H.; Hagos, F.; Mamat, R.; Adam, A.A.; Ishak, W.; Alenezi, R. Production, characterization and performance of biodiesel as an alternative fuel in diesel engines—A review. Renew. Sustain. Energy Rev. 2017, 72, 497–509. [Google Scholar] [CrossRef]

- Park, H.Y.; Han, K.; Kim, H.H.; Park, S.; Jang, J.; Yu, G.S.; Ko, J.H. Comparisons of combustion characteristics between bioliquid and heavy fuel oil combustion in a 0.7 MWth pilot furnace and a 75 MWe utility boiler. Energy 2020, 192, 116557. [Google Scholar] [CrossRef]

- Geller, D.P.; Adams, T.T.; Goodrum, J.W.; Pendergrass, J. Storage stability of poultry fat and diesel fuel mixtures: Specific gravity and viscosity. Fuel 2008, 87, 92–102. [Google Scholar] [CrossRef]

- Dzida, M.; Prusakiewicz, P. The effect of temperature and pressure on the physicochemical properties of petroleum diesel oil and biodiesel fuel. Fuel 2008, 87, 1941–1948. [Google Scholar] [CrossRef]

- Safarov, J.; Ashurova, U.; Ahmadov, B.; Abdullayev, E.; Shahverdiyev, A.; Hassel, E. Thermophysical properties of Diesel fuel over a wide range of temperatures and pressures. Fuel 2018, 216, 870–889. [Google Scholar] [CrossRef]

- Ismail, I.; Mulyanto, A.T.; Rahman, R.A. Development of free water knock-out tank by using internal heat exchanger for heavy crude oil. EUREKA Phys. Eng. 2022, 4, 77–85. [Google Scholar] [CrossRef]

- Cao, J.; Liu, L.; Liu, C.; He, C. Phase transition mechanisms of paraffin in waxy crude oil in the absence and presence of pour point depressant. J. Mol. Liq. 2022, 345, 116989. [Google Scholar] [CrossRef]

- Ukrainczyk, N.; Kurajica, S.; Šipušić, J. Thermophysical comparison of five commercial paraffin waxes as latent heat storage materials. Chem. Biochem. Eng. Q. 2010, 24, 129–137. [Google Scholar]

- Park, J.K.; Park, S.; Ryu, C.; Baek, S.H.; Kim, Y.J.; Park, H.Y. CFD analysis on bioliquid co-firing with heavy fuel oil in a 400MWe power plant with a wall-firing boiler. Appl. Therm. Eng. 2017, 124, 1247–1256. [Google Scholar] [CrossRef]

- Park, J.-K.; Park, S.; Kim, M.; Ryu, C.; Baek, S.H.; Kim, Y.J.; Kim, H.H.; Park, H.Y. CFD analysis of combustion characteristics for fuel switching to bioliquid in oil-fired power plant. Fuel 2015, 159, 324–333. [Google Scholar] [CrossRef]

- Li, Y.-H.; Pangestu, S.; Purwanto, A.; Chen, C.-T. Synergetic combustion behavior of aluminum and coal addition in hybrid iron-methane-air premixed flames. Combust. Flame 2021, 228, 364–374. [Google Scholar] [CrossRef]

- Lehto, J.; Oasmaa, A.; Solantausta, Y.; Kytö, M.; Chiaramonti, D. Review of fuel oil quality and combustion of fast pyrolysis bio-oils from lignocellulosic biomass. Appl. Energy 2014, 116, 178–190. [Google Scholar] [CrossRef]

- Darbandi, M.; Fatin, A.; Bordbar, H. Numerical study on NOx reduction in a large-scale heavy fuel oil-fired boiler using suitable burner adjustments. Energy 2020, 199, 117371. [Google Scholar] [CrossRef]

- Rebola, A.; Costa, M. Simultaneous reduction of NOx and particulate emissionsfrom heavy fuel oil-fired furnaces. Proc. Combust. Inst. 2002, 29, 2243–2250. [Google Scholar] [CrossRef]

- Bazooyar, B.; Hashemabadi, S.H.; Shariati, A. NOX formation of biodiesel in utility power plant boilers; Part B. Comparison of NO between biodiesel and petrodiesel. Fuel 2016, 182, 323–332. [Google Scholar] [CrossRef]

- Wu, S.-R.; Chang, W.-C.; Chiao, J. Low NOx heavy fuel oil combustion with high temperature air. Fuel 2007, 86, 820–828. [Google Scholar] [CrossRef]

- Wu, G.; Ge, J.C.; Choi, N.J. A Comprehensive Review of the Application Characteristics of Biodiesel Blends in Diesel Engines. Appl. Sci. 2020, 10, 8015. [Google Scholar] [CrossRef]

| Parameter | FADR | HFO | ||

|---|---|---|---|---|

| Absolute Uncertainty | Relative Uncertainty | Absolute Uncertainty | Relative Uncertainty | |

| Density, kg/m3 | 1 | 0.11 | 1 | 0.1 |

| HHV, kJ/kg | 87 | 0.22 | 87 | 0.2 |

| LHV, kJ/kg | 120 | 0.33 | 120 | 0.3 |

| C, w.% | 1 | 1.31 | 1 | 1.16 |

| H, w.% | 0.50 | 4 | 0.54 | 4 |

| N, w.% | 0.05 | 6 | 0.03 | 6 |

| S, w.% | 0.05 | 31 | 0.05 | 8 |

| Ash content, w.% | 0.04 | 14 | 0.04 | 6 |

| Ignition temperature, °C | 1 | 0.4 | 1 | 0.4 |

| E density (LHV), GJ/m3 | 0.142 | 0.4 | 0.146 | 0.4 |

| E density (HHV), GJ/m3 | 0.155 | 0.4 | 0.156 | 0.4 |

| Eheat, kJ/kg | 2.85 | 3 | 5.13 | 3 |

| Epressur, kJ/kg | 10.8 | 1.8 | 6.4 | 1.0 |

| Etotal, kJ/kg | 13.7 | 1.9 | 11.5 | 1.4 |

| Ploss, kW | 0.044 | 2.3 | 0.033 | 1.7 |

| Parameter | FADR | HFO |

|---|---|---|

| Density (60 °C), kg/m3 | 882 | 864 |

| Ignition temperature (open vessel), °C | 227 | 250 |

| LHV, kJ/kg | 36,619 | 42,251 |

| HHV, kJ/kg | 39,914 | 45,222 |

| Energy density, Ed, LHV, GJ/m3 (from LHV) | 32.298 | 36.505 |

| Energy density, Ed, HHV GJ/m3 (from HHV) | 35.20 | 39.07 |

| Ash content, w.% | 0.28 | 0.36 |

| C, w.% | 76.6 | 86.1 |

| H, w.% | 12.45 | 13.61 |

| N, w.% | 0.85 | 0.56 |

| S, w.% | 0.16 | 0.62 |

| Cl, w.% | <0.005% | <0.005% |

| Distillation beginning, °C | 98 | 168 |

| to 235 °C | 1.9 | 2 |

| 235–270 °C | 1 | 1.8 |

| 270–300 °C | 3 | 2.4 |

| 300–330 °C | 52.5 | 5.5 |

| 330–360 °C | 35.9 | |

| Distillation residue, % | 31.9 | 47.5 |

| Distillation loses, % | 9.7 | 4.9 |

| Viscosity, Pa∙s, at temperature | ||

| 30 °C | 0.1954 | |

| 40 °C | 0.0541 | |

| 50 °C | 0.136 | |

| 60 °C | 0.0255 | 0.057 |

| 70 °C | 0.034 | |

| 80 °C | 0.0142 | 0.0244 |

| 90 °C | 0.0189 | |

| 100 °C | 0.0152 |

| Pressure | Flow Rate | Expected Input Power, kW | Visual Evaluation of Atomization |

|---|---|---|---|

| kPa | kg//h | kW | |

| Nozzle 1 mm | |||

| 56 | 1.1 | 11 | Droplets |

| 67 | 1.3 | 13 | Compact flow |

| 82 | 4.9 | 50 | Compact flow |

| 112 | 11 | 112 | Compact flow |

| 150 | 17 | 173 | Compact flow |

| 165 | 19.5 | 198 | Compact flow |

| 168 | 20 | 203 | Compact flow |

| 195 | off the scale | Compact flow | |

| Nozzle 0.5 mm | |||

| 385 | 7.4 | 75 | Compact flow |

| 429 | 8.2 | 83 | Compact flow |

| 470 | 9.3 | 95 | Compact flow |

| 502 | 9.9 | 101 | Compact flow with spontaneous droplets |

| 512 | 10.2 | 104 | Fine droplets |

| 528 | 10.3 | 105 | Ultra-fine droplets and fog-like flow |

| FADR | HFO | ||||

|---|---|---|---|---|---|

| Parameter | Unit | Aver. | ± | ||

| The temperature in the chamber, top zone | °C | 1028 | 15 | 1070 | 9 |

| The temperature in the chamber, middle zone | °C | 1006 | 15 | 985 | 2 |

| The temperature in the chamber, bottom zone | °C | 1007 | 9 | 890 | 2 |

| The temperature in the chamber outlet (after heat exch.) | °C | 748 | 6 | 550 | 3 |

| Temperature of liquid fuel at burner inlet | °C | 70 | <1 | 110 | <1 |

| Primary air flow rate | Nm3/h | 105 | 1 | 70 | 1 |

| Secondary air flow rate | Nm3/h | 30 | <1 | 18 | <1 |

| Liquid fuel flow rate | kg/h | 10.6 | 0.4 | 5.27 | 0.21 |

| Liquid fuel overpressure behind the pump | kPa | 542 | 8 | 549 | 4 |

| Compound | Emission | ||

|---|---|---|---|

| HFO | FADR | Micro Wax Data from [22] | |

| naphthalene | 8.5 | 10.9 | 2.1 |

| acenaphthylene | 10.2 | 57.4 | 2.0 |

| acenaphthene | 12.6 | 49.8 | 1.0 |

| fluorene | 14 | 48.2 | 5.0 |

| phenanthrene | 72.2 | 53.5 | 12.2 |

| anthracene | 34.2 | 50.6 | 1.7 |

| fluoranthene | 75.4 | 29.2 | 9.7 |

| pyrene | 81.4 | 26.2 | 4.8 |

| benzo(a)anthracene | 15.1 | 3.5 | 1.0 |

| chrysene | 9.5 | 1.4 | 13.3 |

| benzo (b + k) fluoranthene | 30.5 | 20.7 | 110.6 |

| benzo(e)pyrene | 290.3 | 0.55 | 1.0 |

| benzo(a)pyrene | 30.6 | 0.73 | 22.7 |

| perylene | 11.5 | 2.8 | 8.2 |

| bibenzo(a, h) anthracene + indeno (1,2,3) pyrene | 98.4 | 0.02 | 1.8 |

| benzo(g, h, i)perylene | 16 | 0.04 | 1.4 |

| Total PAHs | 810.4 | 355.5 | 198.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lasek, J.; Głód, K.; Czardybon, A.; Li, Y.-H.; Huang, C.-W. Application of Fatty Acids Distillation Products as a Substitute for Heavy Fuel Oil in Stationary Combustion Chambers. Appl. Sci. 2023, 13, 13233. https://doi.org/10.3390/app132413233

Lasek J, Głód K, Czardybon A, Li Y-H, Huang C-W. Application of Fatty Acids Distillation Products as a Substitute for Heavy Fuel Oil in Stationary Combustion Chambers. Applied Sciences. 2023; 13(24):13233. https://doi.org/10.3390/app132413233

Chicago/Turabian StyleLasek, Janusz, Krzysztof Głód, Agata Czardybon, Yueh-Heng Li, and Chao-Wei Huang. 2023. "Application of Fatty Acids Distillation Products as a Substitute for Heavy Fuel Oil in Stationary Combustion Chambers" Applied Sciences 13, no. 24: 13233. https://doi.org/10.3390/app132413233

APA StyleLasek, J., Głód, K., Czardybon, A., Li, Y.-H., & Huang, C.-W. (2023). Application of Fatty Acids Distillation Products as a Substitute for Heavy Fuel Oil in Stationary Combustion Chambers. Applied Sciences, 13(24), 13233. https://doi.org/10.3390/app132413233