Innovative Design of a Conductive Center Pole for an Active Thermal Insulation and Coring System in Deep Rock

Abstract

:1. Introduction

2. Related Works

3. Overdesign

3.1. The Position and Workflow of the Center Pole

3.2. Center Pole Size and Assembly Requirements

4. Detailed Design of the Conductive Center Pole Based on the Innovative Design Method

4.1. Innovative Design Strategy and Process of the Conductive Center Pole

4.2. Analysis of the Functional Requirements of the Conductive Center Pole

- The conductive module can realize the alignment of the positive and negative electrodes after the center pole is rotated and docked.

- The conductive module can realize the contact between the positive and negative electrodes after the center pole is rotated and connected.

- Avoid entanglement of the wire during the screwing process of the center pole.

- The whole operation process meets the requirements of insulation and 150 °C temperature resistance.

4.3. Establishing the Design Parameter Vector and Design Matrix of the Conductive Center Pole

4.4. Design Matrix Decoupling Based on TRIZ

4.5. Optimized Design of the Conductive Center Pole

4.6. Design Comprehensive Evaluation and Analysis

5. Strength Check of the Conductive Center Pole

6. Experiments and Results

6.1. Continuity Performance Test

6.2. Heating Performance Test of the Conductive Center Pole at Room Temperature

6.3. Heating Performance Test of the Conductive Center Pole at High Temperatures

6.4. Long-Term Effectiveness and Stability Test of the Energy Supply Transmission and Signal Transmission of the Conductive Central Rod

7. Conclusions

- According to the requirements for the in situ insulation and coring of deep rocks and referring to the design of smart drill pipes in logging, the overall design of the conductive center pole is proposed.

- The innovative design process of the conductive center pole is proposed, the functional requirements of the conductive center pole were analyzed, and the design matrix A was established and solved.

- The TRIZ solving tool was used to obtain a preliminary design scheme, and to further optimize the scheme to obtain a scheme with a higher comprehensive evaluation.

- The strength of the conductive center pole of the new structure was verified, and a physical prototype was made to conduct comparative experiments in a realistic environment to verify the feasibility of its function and structure.

- In addition, the feasibility of its application in the field of energy supply and signal transmission was verified through long-term heating experiments and sensor data acquisition tests.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, W.; Wu, J. Discussion on the roadmap of China’s energy transition framework under the goal of carbon neutrality. Price Theory Pract. 2021, 6, 9–12. [Google Scholar] [CrossRef]

- Xie, H.; Ren, S.; Xie, Y.; Jiao, X.M. Development opportunities of the coal industry towards the goal of carbon neutrality. J. China Coal Soc. 2021, 46, 2197–2211. [Google Scholar] [CrossRef]

- bp.com. Statistical Review of World Energy; Whitehouse Associates: London, UK, 2021; Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html (accessed on 21 June 2022).

- Xie, H.; Gao, F.; Ju, Y. Research and development of rock mechanics in deep ground engineering. Chin. J. Rock Mech. Eng. 2015, 34, 2161–2178. [Google Scholar] [CrossRef]

- Xie, H.; Gao, M.; Zhang, R.; Chen, L.; Liu, T.; Li, C.; Li, C.; He, Z. Study on concept and progress of in situ fidelity coring of deep rocks. Chin. J. Rock Mech. Eng. 2020, 39, 865–876. [Google Scholar] [CrossRef]

- Xue, Q.; Zhang, J. Advances in intelligent automatic drilling technologies and equipment. Explor. Eng. (Rock Soil Drill. Tunn.) 2020, 47, 9–14. [Google Scholar] [CrossRef]

- Xie, H.; Gao, F.; Ju, Y.; Gao, M.Z.; Zhang, R.; Gao, Y.N.; Liu, J.F.; Xie, L.Z. Quantitative definition and investigation of deep mining. J. China Coal Soc. 2015, 40, 1–10. [Google Scholar] [CrossRef]

- Li, C.; Xie, H.; Gao, M.; Chen, L.; Zhao, L.; Li, C.; Wu, N.; He, Z.; Li, J. Novel designs of pressure controllers to enhance the upper pressure limit for gas-hydrate-bearing sediment sampling. Energy 2021, 227, 120405. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, W.; Chen, L.; Gao, M.; He, Z.; Wan, H. Innovative design of active insulation system for in-situ fidelity coring in deep strata. Chin. J. Eng. Des. 2020, 27, 407–415. [Google Scholar] [CrossRef]

- Kashefi, K.; Lovley Derek, R. Extending the Upper Temperature Limit for Life. Science 2003, 301, 934. [Google Scholar] [CrossRef]

- Borgonie, G.; García-Moyano, A.; Litthauer, D.; Bert, W.; Bester, A.; van Heerden, E.; Möller, C.; Erasmus, M.; Onstott, T.C. Nematoda from the terrestrial deep subsurface of South Africa. Nature 2011, 474, 79–82. [Google Scholar] [CrossRef]

- Teske, A.P. The deep subsurface biosphere is alive and well. Trends Microbiol. 2005, 13, 402–404. [Google Scholar] [CrossRef]

- Lupton, N.; Connell, L.D.; Heryanto, D.; Sander, R.; Camilleri, M.; Down, D.I.; Pan, Z. Enhancing biogenic methane generation in coalbed methane reservoirs—Core flooding experiments on coals at in-situ conditions. Int. J. Coal Geol. 2020, 219, 103377. [Google Scholar] [CrossRef]

- Yan, T.; Xu, R.; Liu, W.; Sun, W.; Hou, Z.; Shao, Y. Research and development of intelligent drilling technology in China. J. Northeast. Pet. Univ. 2020, 44, 15–21+6. [Google Scholar] [CrossRef]

- Abid, K.; Spagnoli, G.; Teodoriu, C.; Falcone, G. Review of pressure coring systems for offshore gas hydrates research. Underw. Technol. 2015, 33, 19–30. [Google Scholar] [CrossRef]

- Abegg, F.; Hohnberg, H.-J.; Pape, T.; Bohrmann, G.; Freitag, J. Development and application of pressure-core-sampling systems for the investigation of gas- and gas-hydrate-bearing sediments. Deep Sea Res. Part I 2008, 55, 1590–1599. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Liu, Q.Y.; Wong, G.R.; Xiao, X.H.; Zhu, X.H.; Jiang, Z.L.; Zhang, D.Y. A Pressure and Temperature Preservation System for Gas-hydrate-bearing Sediments Sampler. Pet. Sci. Technol. 2013, 31, 652–662. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Sun, Y.; Jia, R.; Liu, H.N.; Xue, J. The Development of Wire-line Sampling Drilling Tool for Gas Hydrates by Hole Bottom Freezing with Development of Wire-line Sampling Drilling Tool for Gas Hydrates by Hole Bottom Freezing with Liquid Nitrogen as Ex-ternal Cold Source. Drill. Eng. 2013, 40, 1–3. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Y.; Liu, H.; Ruan, H.; Chem, Y.; Shen, L.; Wu, H.; Liang, Q. Comparative Study on Sampling Tools for Insulation and Pressure-holding of Marine Gas Hydrate. Equip. Geotech. Eng. 2018, 19, 11–15. [Google Scholar] [CrossRef]

- Li, S.; Cheng, Y.; Qin, H. Development of pressure piston corer for exploring natural gas hydrates. J. Zhejiang Univ. (Eng. Sci.) 2006, 40, 888–892. [Google Scholar] [CrossRef]

- Wan, B.; Huang, Y.; Qian, X. Deep-sea hard rock fidelity corer. CN Patent CN 200958379Y, 10 October 2007. [Google Scholar]

- Yang, L.; Sun, W.; Luo, J.; Wang, G.; Wang, J. Study and application of GWY194-70BB heat and pressure preservation coring tool. Oil Drill. Prod. Technol. 2014, 36, 58–61. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, D.; Yang, L.; Gao, W.; Sun, S.; Su, Y. Development and Field Application of a Coalbed Methane Coring Tool with Pressure Maintenance, Thermal Insulation, and Shape Preservation Capabilities. Pet. Drill. Tech. 2021, 49, 94–99. [Google Scholar] [CrossRef]

- Katz, B.J. Hydrocarbon shows and source rocks in scientific ocean drilling. Int. J. Coal Geol. 2003, 54, 139–154. [Google Scholar] [CrossRef]

- Xing, D.; Qi, L.; Zhao, J.; Wang, Y. The design of computer controlled ground information transmission down platform in drilling. MATEC Web Conf. 2020, 309, 04017. [Google Scholar] [CrossRef] [Green Version]

- Lurie, P.; Head, P.; Smith, J. Smart Drilling with ELECTRIC DRILLSTRING. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 19–21 February 2003. [Google Scholar] [CrossRef]

- Hu, Y.; Li, X.; Huang, Y.; Liu, Y. Design of Downhole Automatic Power Supply Device based on TPS2121. Pet. Drill. Tech. 2020, 48, 76–81. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, G.; Zhang, H.; Li, X.; Tian, H.; Guo, X. Noteworthy advanced international petroleum engineering technology. Oil Forum 2012, 31, 36–44. [Google Scholar] [CrossRef]

- Jellison, M.; Hall, D.; Howard, D.; Hall, H.T.J.; Long, R.C.; Chandler, R.B.; Pixton, D.S. Telemetry Drill Pipe: Enabling Technology for the Downhole Internet. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 19–21 February 2003. [Google Scholar] [CrossRef]

- Jiang, J.; Li, Y.; Li, L.; Zhou, C.; Huo, Y.; Li, Q. An Innovation Design Approach for Product Service Systems Based on TRIZ and Function Incentive. Complexity 2021, 2021, 5592272. [Google Scholar] [CrossRef]

- Chou, J.-R. A TRIZ-based product-service design approach for developing innovative products. Comput. Ind. Eng. 2021, 161, 107608. [Google Scholar] [CrossRef]

- Li, M.; Ming, X.; He, L.; Zheng, M.; Xu, Z. A TRIZ-based Trimming method for Patent design around. Comput.-Aided Des. 2015, 62, 20–30. [Google Scholar] [CrossRef]

- Liu, A.; Lu, S. Functional design framework for innovative design thinking in product development. CIRP J. Manuf. Sci. Technol. 2020, 30, 105–117. [Google Scholar] [CrossRef]

- Jahanmir, S.; Saka, N.; Tucker, C., II; Kim, S.-G. Axiomatic Design. In Advances in Multidisciplinary Engineering; ASME Press: New York, NY, USA, 2016. [Google Scholar]

- Li, X.; Qiu, S.; Ming, H.X.G. An integrated module-based reasoning and axiomatic design approach for new product design under incomplete information environment. Comput. Ind. Eng. 2019, 127, 63–73. [Google Scholar] [CrossRef]

- Benavides, E.M. Axiomatic design. In Advanced Engineering Design; Woodhead Publishing: Sawston, UK, 2012. [Google Scholar]

- Kulak, O.; Kahraman, C.J.I.S. Fuzzy multi-attribute selection among transportation companies using axiomatic design and analytic hierarchy process. Inf. Sci. 2005, 170, 191–210. [Google Scholar] [CrossRef]

- Delgado-Maciel, J.; Cortés-Robles, G.; Sánchez-Ramírez, C.; García-Alcaraz, J.; Méndez-Contreras, J.M. The evaluation of conceptual design through dynamic simulation: A proposal based on TRIZ and system Dynamics. Comput. Ind. Eng. 2020, 149, 106785. [Google Scholar] [CrossRef]

- Liu, A.; Wang, Y.; Teo, I.; Lu, S. Constraint management for concept ideation in conceptual design. CIRP J. Manuf. Sci. Technol. 2019, 24, 35–48. [Google Scholar] [CrossRef]

- Li, Z.; Tate, D.; Lane, C.; Adams, C. A framework for automatic TRIZ level of invention estimation of patents using natural language processing, knowledge-transfer and patent citation metrics. Comput.-Aided Des. 2012, 44, 987–1010. [Google Scholar] [CrossRef]

- Sadeghi, L.; Dantan, J.-Y.; Mathieu, L.; Siadat, A.; Aghelinejad, M.M. A design approach for safety based on Product-Service Systems and Function–Behavior–Structure. CIRP J. Manuf. Sci. Technol. 2017, 19, 44–56. [Google Scholar] [CrossRef] [Green Version]

- Saaty, T. That is not the analytic hierarchy process: What the AHP is and what it is not. J. Multi-Criteria Decis. Anal. 1997, 6, 324–335. [Google Scholar] [CrossRef]

- Chen, C.; Tao, Y.; Li, Y.; Liu, Q.; Li, S.; Tang, Z. A structure-function knowledge extraction method for bio-inspired design. Comput. Ind. 2021, 127, 103402. [Google Scholar] [CrossRef]

- Gong, H.; Liu, J.; Feng, H. Review on anti-loosening methods for threaded fasteners. Chin. J. Aeronaut. 2021, 35, 47–61. [Google Scholar] [CrossRef]

| Name of Core Sampler | R&D Country or Institution | Insulation Method |

|---|---|---|

| PTCS | Japan | Active insulation |

| MAC | Germany/R.V.SONNE cruises | External cooling device |

| DAPC | Germany/R.V.SONNE cruises | External cooling device |

| PTPS | First Ocean Institute | Passive insulation |

| FCS | Jilin University | Dry ice, low-temperature alcohol |

| TKP-1 | Beijing Institute of Prospecting Engineering | Passive insulation |

| Gravity piston fidelity sampler | Zhejiang University | Passive insulation |

| Deep-sea hard rock fidelity core sampler | Changsha Mine Research Institute | Passive insulation |

| GW194-70BB type heat preservation pressure core tool | PetroChina Great Wall Drilling Engineering Technology Research Institute | Passive insulation |

| Coal-bed methane thermal insulation, pressure-maintaining and shape-preserving coring tool | PetroChina Great Wall Drilling Engineering Technology Research Institute | Passive insulation |

| Separation Principles | Invention Principles |

|---|---|

| Space separation | 1,2,3,4,7,13,17,24,26,30 |

| Time separation | 9,10,11,15,16,18,19,20,21,29,34,37 |

| Separation of the whole and its parts | 12,28,31,32,35,36,38,39,40 |

| Condition separation | 1,5,6,7,8,13,14,22,23,25,27,33,35 |

| Optimized Parameters | Deteriorating Parameters | Invention Principles |

|---|---|---|

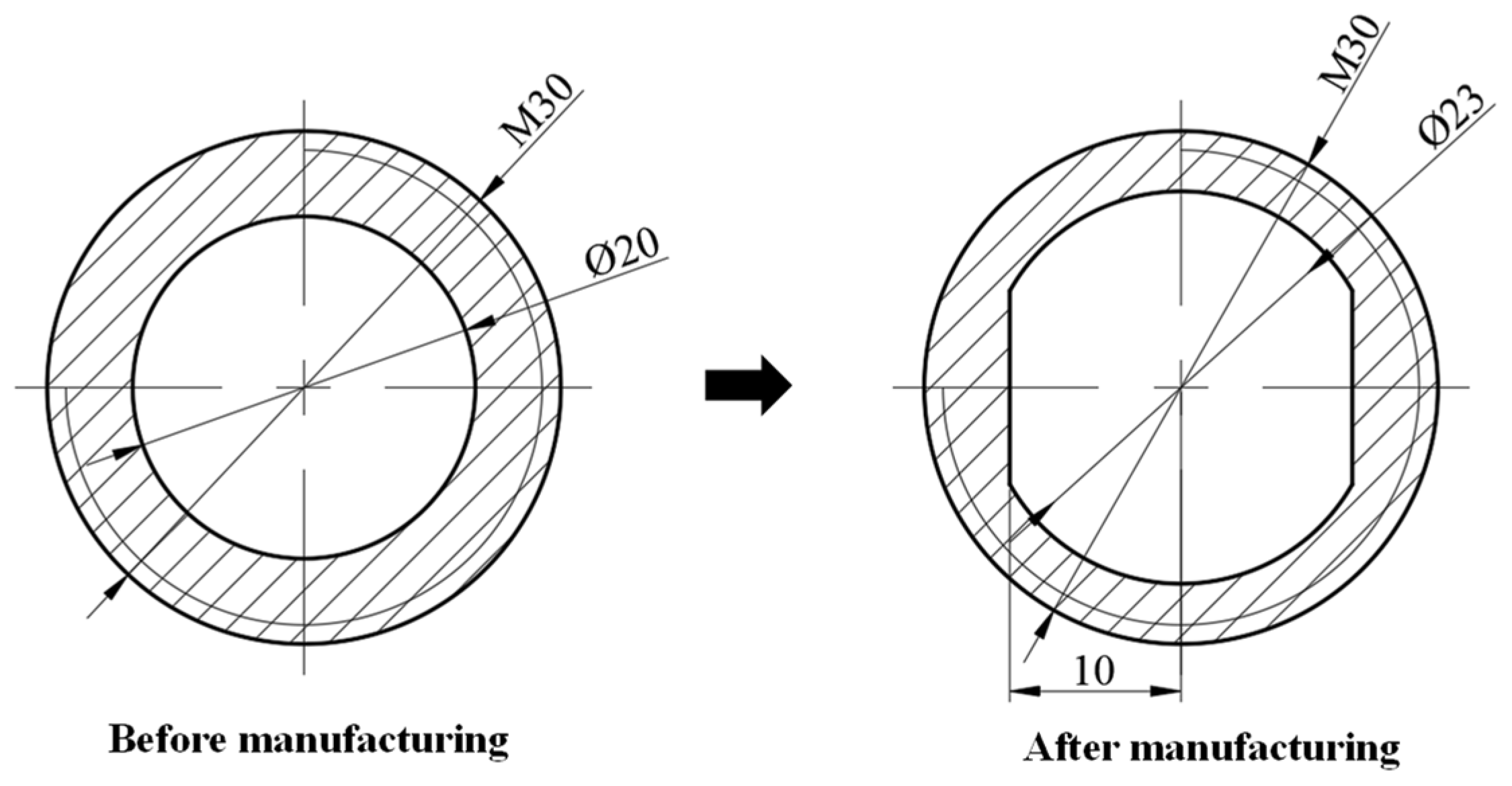

| Shape (9) | Manufacturability (32) | 01,32,17,28 |

| System complexity (36) | 16,29,01,28 |

| Scoring Item and Weight | Design Scheme | Schematic Diagram | ||

|---|---|---|---|---|

| Scheme A | Scheme B | Scheme C | ||

| Structural design (0.1309) | 0.4931 | 0.3342 | 0.1727 |  |

| Installation and assembly (0.2032) | 0.2413 | 0.1235 | 0.6352 | |

| Material properties (0.0343) | 0.3333 | 0.3333 | 0.3333 | |

| Independence (0.2051) | 0.1572 | 0.3193 | 0.5235 | |

| Functionality (0.3231) | 0.1616 | 0.3025 | 0.5359 | |

| Manufacturability (0.1034) | 0.4025 | 0.3291 | 0.2684 | |

| Comprehensive score | 0.2511 | 0.2776 | 0.4712 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, B.; He, Z.; Yang, J.; Wei, Z.; Li, C.; Xie, H. Innovative Design of a Conductive Center Pole for an Active Thermal Insulation and Coring System in Deep Rock. Appl. Sci. 2023, 13, 1242. https://doi.org/10.3390/app13031242

Yu B, He Z, Yang J, Wei Z, Li C, Xie H. Innovative Design of a Conductive Center Pole for an Active Thermal Insulation and Coring System in Deep Rock. Applied Sciences. 2023; 13(3):1242. https://doi.org/10.3390/app13031242

Chicago/Turabian StyleYu, Bo, Zhiqiang He, Jianping Yang, Zijie Wei, Cong Li, and Heping Xie. 2023. "Innovative Design of a Conductive Center Pole for an Active Thermal Insulation and Coring System in Deep Rock" Applied Sciences 13, no. 3: 1242. https://doi.org/10.3390/app13031242