Structural Multi-Tooth Modification of Hybrid-Excited Doubly Salient Dual-PM Machine for Torque Production Improvement

Abstract

1. Introduction

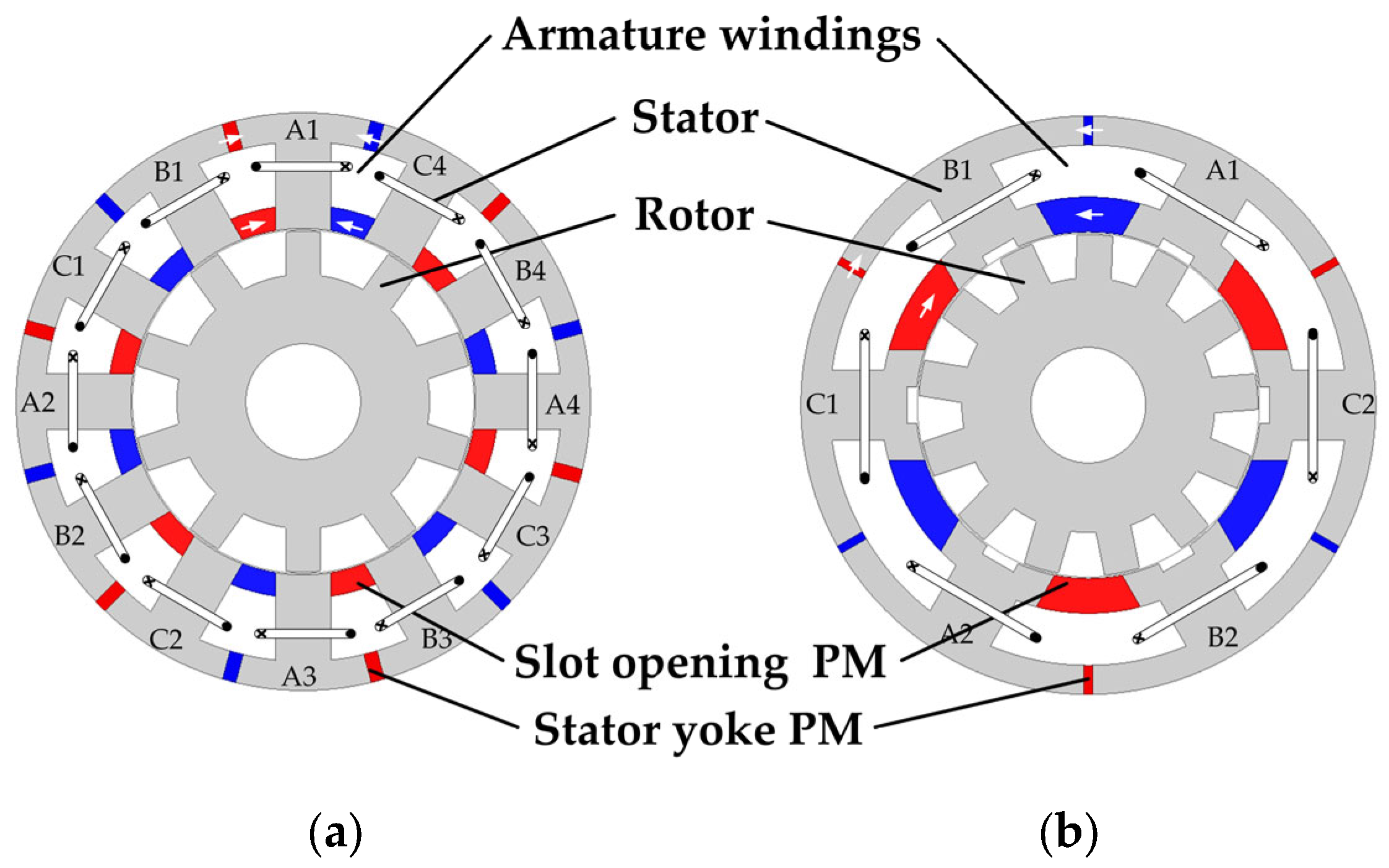

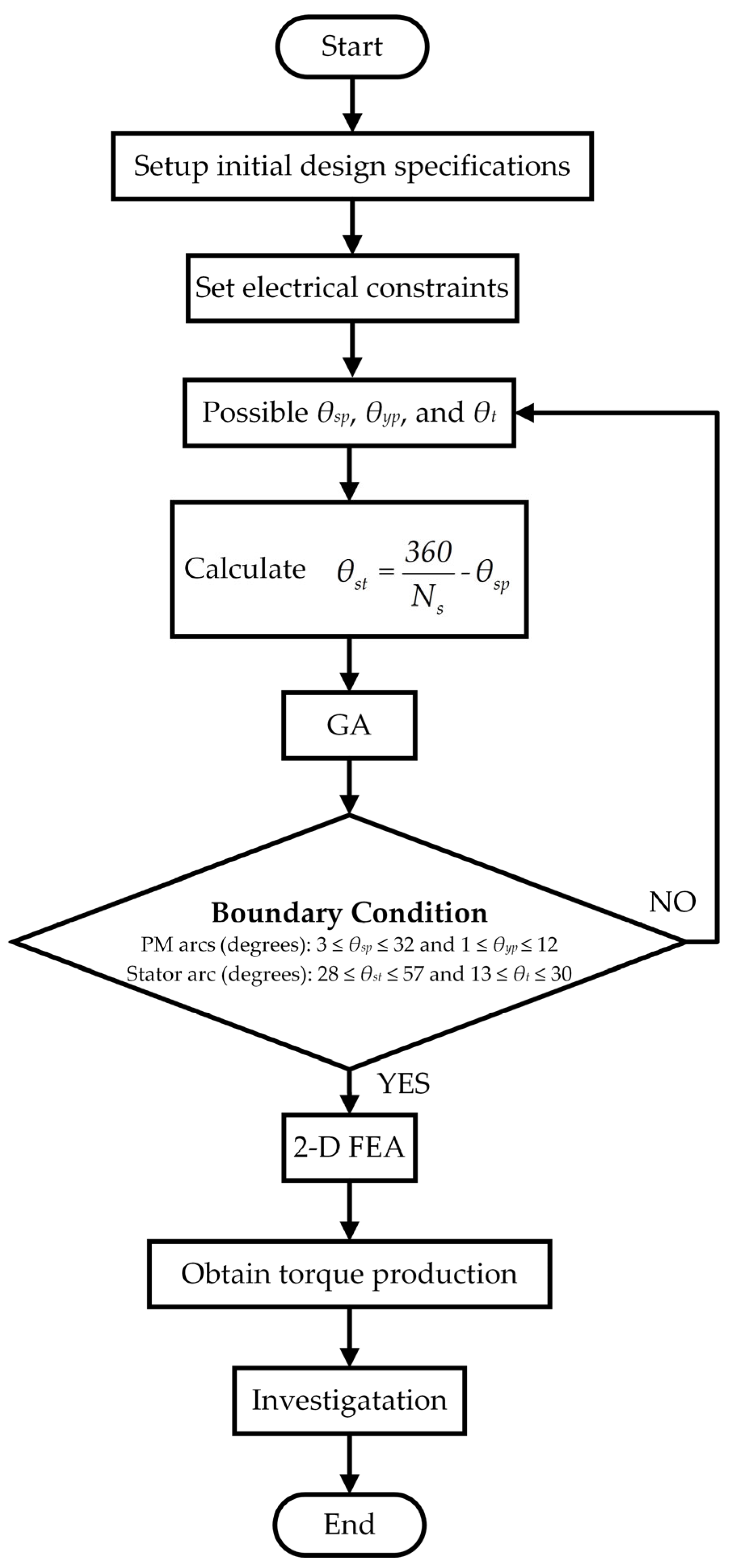

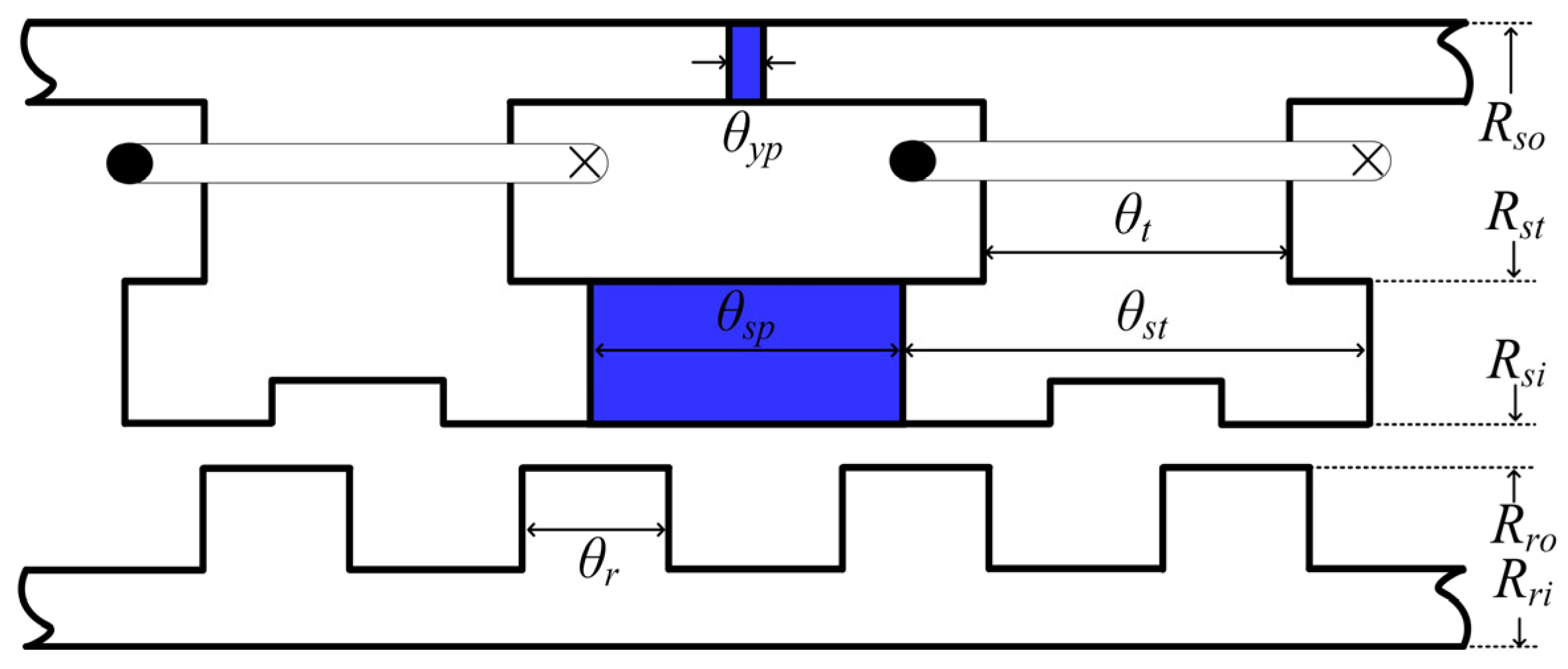

2. Structural Multi-Tooth Modification of HE-DSDPM

3. Influence of PM and Stator Arcs on Torque Production

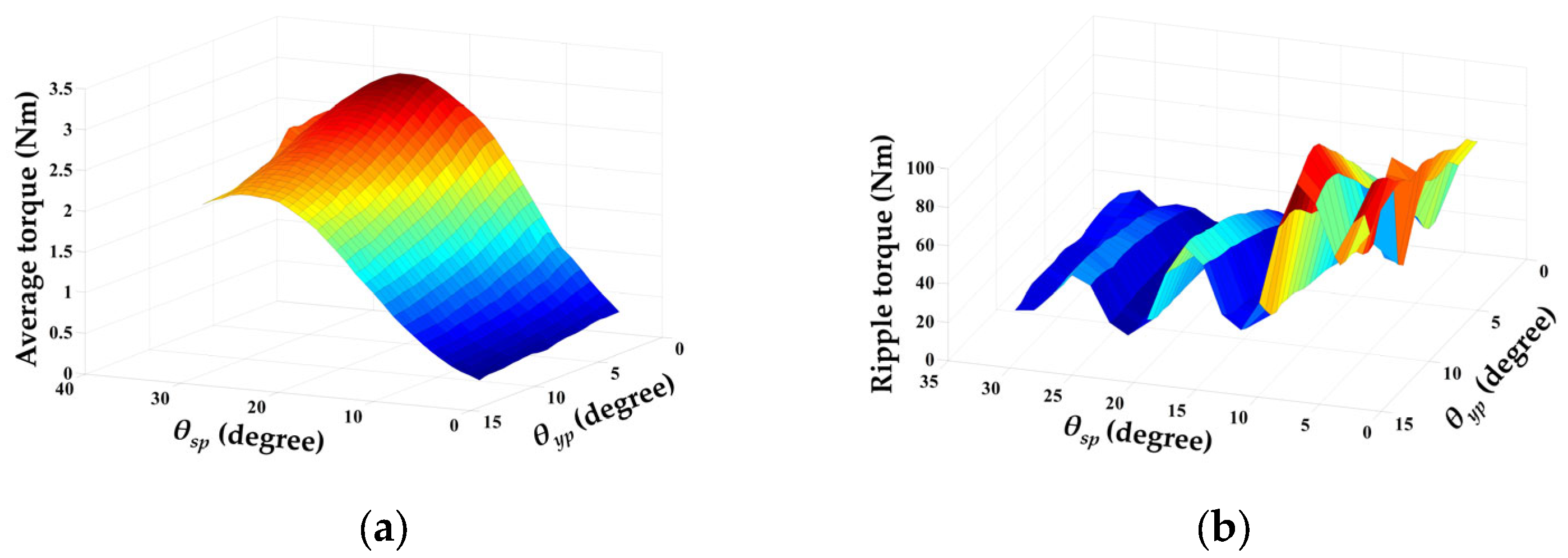

3.1. PM Arcs

3.2. Stator Arcs

4. Electromagnetic Performance Analysis

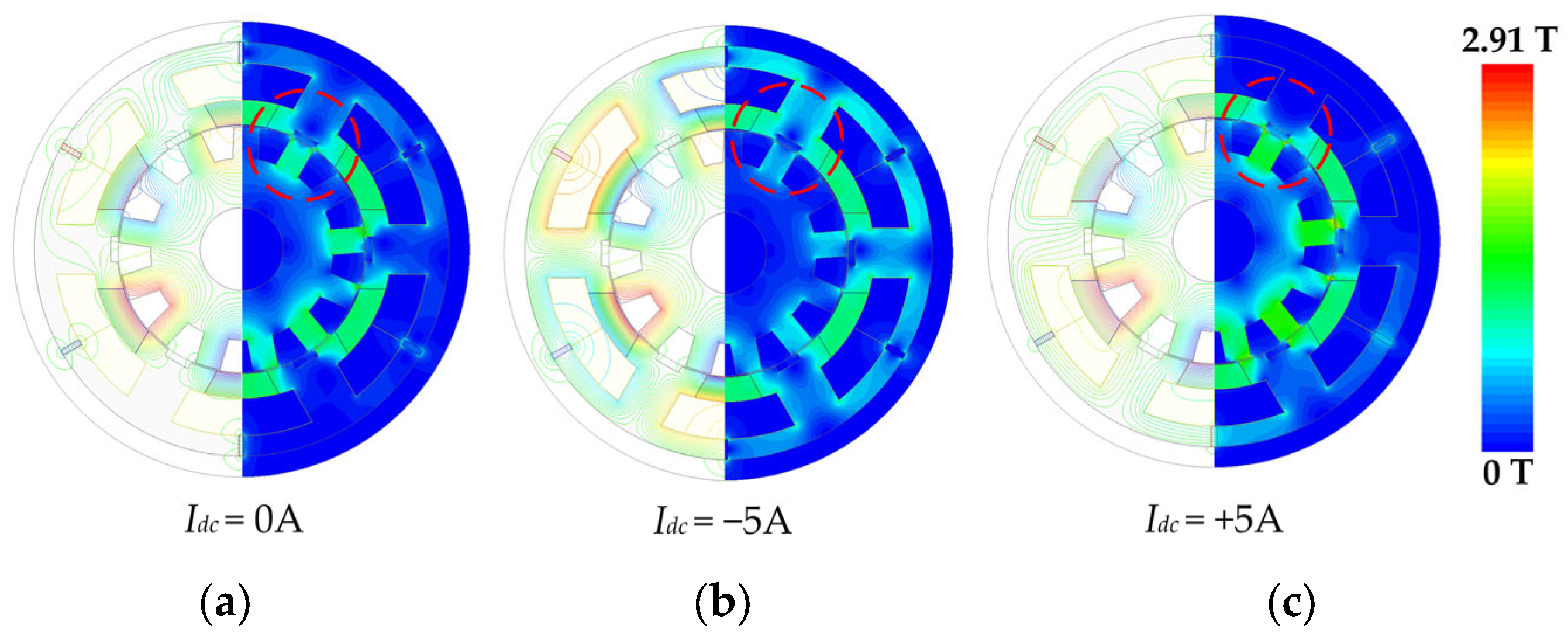

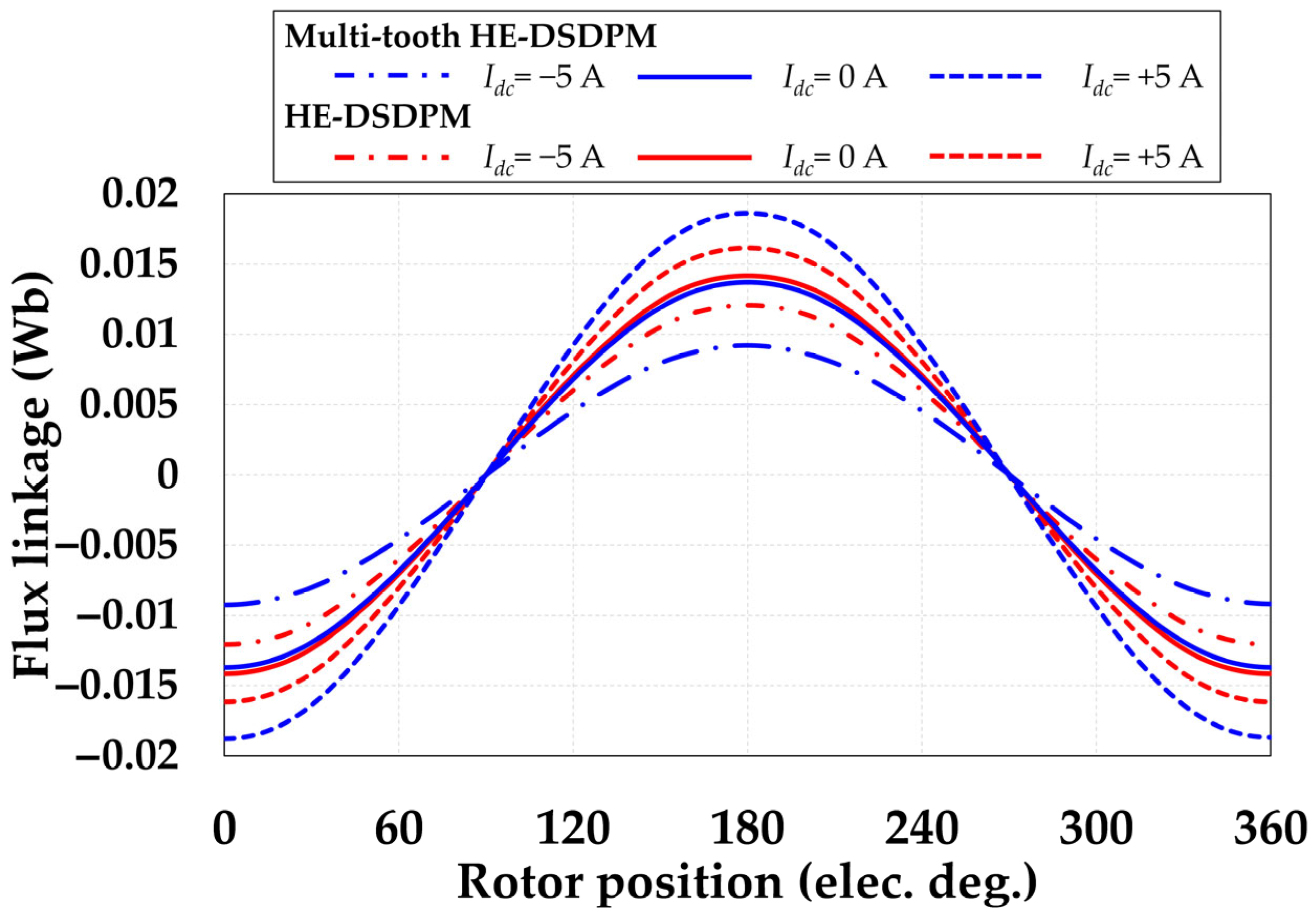

4.1. Magnetic Flux Distribution and Flux Linkage Analysis

4.2. Back-EMF Analysis

4.3. Torque Production Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chau, K.T.; Chan, C.C.; Liu, C. Overview of permanent-magnet brushless drives for electric and hybrid electric vehicles. IEEE Trans. Ind. Electron. 2008, 55, 2246–2257. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Howe, D. Electrical machines and drives for electric, hybrid, and fuel cell vehicles. IEEE Proc. 2007, 95, 746–765. [Google Scholar] [CrossRef]

- Vanchinathan, K.; Valluvan, K.R.; Gnanavel, C.; Gokul, C. Design methodology and experimental verification of intelligent speed controllers for sensorless permanent magnet brushless DC motor: Intelligent speed controllers for electric motor. Int. Trans. Electr. Energy Syst. 2021, 31, 12991. [Google Scholar] [CrossRef]

- Anuja, T.A.; Doss, M. Asymmetrical Magnets in Rotor Structure of a Permanent Magnet Brushless DC Motor for Cogging Torque Minimization. J. Electr. Eng. Technol. 2022, 17, 1271–1279. [Google Scholar] [CrossRef]

- Cheng, M.; Hua, W.; Zhang, J.; Zhao, W. Overview of stator-permanent magnet brushless machines. IEEE Trans. Ind. Electron. 2011, 58, 5087–5101. [Google Scholar] [CrossRef]

- Niu, S.; Wang, S.; Zhao, X. Overview of Stator Slot-opening Permanent Magnet Machines. IEEE Trans. Transp. Electrif. 2022; early access. [Google Scholar]

- Sriwannarat, W.; Seangwong, P.; Lounthavong, V.; Khunkitti, S.; Siritaratiwat, A.; Khunkitti, P. An improvement of output power in doubly salient permanent magnet generator using Pole configuration adjustment. Energies 2020, 13, 4588. [Google Scholar] [CrossRef]

- Nissayan, C.; Seangwong, P.; Chamchuen, S.; Fernando, N.; Siritaratiwat, A.; Khunkitti, P. Modeling Optimal Configuration Design of Flux-Barrier for Torque Improvement of Rotor Flux Switching Permanent Magnet Machine. Energies 2022, 15, 8429. [Google Scholar] [CrossRef]

- Zhao, W.; Cheng, M.; Ji, J.; Cao, R.; Du, Y.; Li, F. Design and analysis of a new fault-tolerant linear permanent-magnet motor for maglev transportation applications. IEEE Trans. Appl. Supercond. 2012, 22, 5200204. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, Z. Hybrid excitation topologies and control strategies of stator permanent magnet machines for DC power system. IEEE Trans. Ind. Electron. 2012, 59, 4601–4616. [Google Scholar] [CrossRef]

- Qu, H.; Zhu, Z.Q.; Li, H. Analysis of novel consequent pole flux reversal permanent magnet machines. IEEE Trans. Ind. Appl. 2020, 57, 382–396. [Google Scholar] [CrossRef]

- Meng, Y.; Fang, S.; Pan, Z.; Liu, W.; Qin, L. Design and analysis of a new partitioned stator hybrid-excited flux reversal machine with dual-pm. IEEE Trans. Magn. 2021, 58, 8100806. [Google Scholar] [CrossRef]

- Sun, X.; Zhu, Z.Q. Investigation of DC winding induced voltage in hybrid-excited switched-flux permanent magnet machine. IEEE Trans. Ind. Appl. 2020, 56, 3594–3603. [Google Scholar] [CrossRef]

- Awah, C.C. Effect of permanent magnet material on the electromagnetic performance of switched-flux permanent magnet machine. Electr. Eng. 2021, 103, 1647–1660. [Google Scholar] [CrossRef]

- Liao, Y.; Liang, F.; Lipo, T.A. A novel permanent magnet motor with doubly salient structure. IEEE Trans. Ind. Appl. 1995, 31, 1069–1078. [Google Scholar] [CrossRef]

- Cheng, M.; Chau, K.T.; Chan, C.C. Static characteristics of a new doubly salient permanent magnet motor. IEEE Trans. Energy Convers. 2001, 16, 20–25. [Google Scholar] [CrossRef]

- Cheng, M.; Chau, K.T.; Chan, C.C. Design and analysis of a new doubly salient permanent magnet motor. IEEE Trans. Magn. 2001, 37, 3012–3020. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, L.J.; Huang, X.; Fang, Y.; Lu, Q. A novel structure of doubly salient permanent magnet machine in square envelope. IEEE Trans. Magn. 2019, 55, 8103505. [Google Scholar] [CrossRef]

- Wu, L.; Ming, G.; Zhang, L.; Fang, Y. Improved stator/rotor-pole number combinations for torque ripple reduction in doubly salient PM machines. IEEE Trans. Ind. Electron. 2020, 68, 10601–10611. [Google Scholar] [CrossRef]

- Du, Y.; Zhao, J.; Xiao, F.; Zhu, X.; Quan, L.; Li, F. Partitioned stator hybrid excitation doubly salient machine with slot Halbach PM arrays. IEEE Trans. Veh. Technol. 2021, 70, 3187–3196. [Google Scholar] [CrossRef]

- Seangwong, P.; Siritaratiwat, A.; Sriwannarat, W.; Fernando, N.; Khunkitti, P. Design of Doubly Salient Permanent Magnet Generator for Output Power Enhancement using Structural Modification. J. Appl. Comput. Mech. 2021, 7, 2171–2178. [Google Scholar]

- Sriwannarat, W.; Seangwong, P.; Siritaratiwat, A.; Fernando, N.; Dechgummarn, Y.; Khunkitti, P. Electromagnetic torque improvement of doubly salient permanent magnet machine using pole ratio adjustment technique. Front. Energy Res. 2021, 9, 726164–726174. [Google Scholar] [CrossRef]

- Tapia, J.A.; Leonardi, F.; Lipo, T.A. Consequent-pole permanent-magnet machine with extended field-weakening capability. IEEE Trans. Ind. Appl. 2003, 39, 1704–1709. [Google Scholar] [CrossRef]

- Owen, R.L.; Zhu, Z.Q.; Jewell, G.W. Hybrid-excited flux-switching permanent-magnet machines with iron flux bridges. IEEE Trans. Magn. 2010, 46, 1726–1729. [Google Scholar] [CrossRef]

- Afinowi, I.A.A.; Zhu, Z.Q.; Guan, Y.; Mipo, J.C.; Farah, P. Hybrid-excited doubly salient synchronous machine with permanent magnets between adjacent salient stator poles. IEEE Trans. Magn. 2015, 51, 8107909. [Google Scholar] [CrossRef]

- Cai, S.; Zhu, Z.Q.; Mipo, J.C.; Personnaz, S. Investigation of novel doubly salient hybrid excited machine with non-overlapped field winding. IEEE Trans. Energy Convers. 2020, 36, 2261–2275. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, S.; Fu, W. Design of a novel parallel-hybrid-excited dual-PM machine based on armature harmonics diversity for electric vehicle propulsion. IEEE Trans. Ind. Electron. 2018, 66, 4209–4219. [Google Scholar] [CrossRef]

- Zhang, Z.; Tao, Y.; Yan, Y. Investigation of a new topology of hybrid excitation doubly salient brushless DC generator. IEEE Trans. Ind. Electron. 2011, 59, 2550–2556. [Google Scholar] [CrossRef]

- Shen, Y.; Lu, Q. Design and analysis of linear hybrid-excited slot permanent magnet machines. IEEE Trans. Magn. 2018, 54, 8205506. [Google Scholar] [CrossRef]

- Mao, Y.; Niu, S. Topology Exploration and Analysis of a Novel Winding Factor Modulation-Based Hybrid-Excited Biased Flux Machine. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 10, 1788–1799. [Google Scholar] [CrossRef]

- Shen, Y.; Zeng, Z.; Lu, Q.; Li, Y. Investigation of a modular linear doubly salient machine with dual-PM in primary yoke and slot openings. IEEE Trans. Magn. 2019, 55, 8102606. [Google Scholar] [CrossRef]

- Wang, Q.; Niu, S.; Luo, X. A novel hybrid dual-PM machine excited by AC with DC bias for electric vehicle propulsion. IEEE Trans. Ind. Electron. 2017, 64, 6908–6919. [Google Scholar] [CrossRef]

- Meng, Y.; Fang, S.; Pan, Z.; Qin, L. A New Hybrid-Excited Doubly Salient Dual-PM Machine With DC-biased Sinusoidal Current. IEEE Trans. Appl. Supercond. 2021, 31, 5203205. [Google Scholar] [CrossRef]

- Chen, J.T.; Zhu, Z.Q.; Howe, D. Stator and rotor pole combinations for multi-tooth flux-switching permanent-magnet brushless AC machines. IEEE Trans. Magn. 2008, 44, 4659–4667. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Chen, J.T. Advanced flux-switching permanent magnet brushless machines. IEEE Trans. Magn. 2010, 46, 1447–1453. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Chen, J.T.; Pang, Y.; Howe, D.; Iwasaki, S.; Deodhar, R. Analysis of a novel multi-tooth flux-switching PM brushless AC machine for high torque direct-drive applications. IEEE Trans. Magn. 2008, 44, 4313–4316. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Al-Ani, M.; Lee, B.; Liu, X. Comparative study of the electromagnetic performance of switched flux permanent magnet machines. IET Electr. Power Appl. 2015, 9, 297–306. [Google Scholar] [CrossRef]

- Zhao, G.; Hua, W. Comparative study between a novel multi-tooth and a V-shaped flux-switching permanent magnet machines. IEEE Trans. Magn. 2019, 55, 8104908. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, J.; Liu, X. Hybrid-excited multi-tooth flux switching brushless machines for EV propulsion. In Proceedings of the 2019 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 19-21 June 2019; pp. 1–5. [Google Scholar]

- Farahani, E.F.; Kondelaji, M.A.J.; Mirsalim, M. An innovative hybrid-excited multi-tooth switched reluctance motor for torque enhancement. IEEE Trans. Ind. Electron. 2020, 68, 982–992. [Google Scholar] [CrossRef]

- Wei, F.; Zhu, Z.Q.; Yan, L.; Qi, J. Investigation of Stator/Rotor Pole Number Combinations and PM Numbers in Consequent-Pole Hybrid Excited Flux Reversal Machine. IEEE Trans. Energy Convers. 2022, 37, 2092–2106. [Google Scholar] [CrossRef]

| Initial Parameters | Units | Values |

|---|---|---|

| Outer stator radius, Rso | mm | 50 |

| Inner stator radius, Rsi | mm | 30 |

| Stator teeth radius, Rst | mm | 34 |

| Outer rotor radius, Rro | mm | 29.5 |

| Inner rotor radius, Rri | mm | 10 |

| Rotor pole arcs, θr | degrees | 12 |

| Stack length | mm | 50 |

| Steel type | - | Silicon steel 1010 |

| PM type | - | NdFeB—N35 |

| Magnetic flux remanent | T | 1.23 |

| Armature current, Iac | A | 8 |

| Current density | A/mm2 | 2 |

| Slot opening PM arc, θsp | degrees | 3–32 |

| Stator yoke PM arc, θyp | degrees | 1–12 |

| Stator tip arc, θst | degrees | 28–57 |

| Stator teeth arc, θt | degrees | 13–30 |

| Main Parameter | Unit | Conventional HE-DSDPM [29] | Optimal Multi-Tooth HE-DSDPM |

|---|---|---|---|

| Number of stator poles | pole | 12 | 6 |

| Number of stator tooth | teeth | - | 2 |

| Number of rotor poles | pole | 10 | 13 |

| Rate speed | rpm | 1000 | |

| Outer stator radius, Rso | mm | 50 | |

| Inner stator radius, Rsi | mm | 30 | |

| Stator teeth radius, Rst | mm | 34 | |

| Outer rotor radius, Rro | mm | 29.5 | |

| Inner rotor radius, Rri | mm | 10 | |

| Air gap length | mm | 0.5 | |

| Stack length | mm | 50 | |

| Stator yoke PM height | mm | 5 | |

| Slot opening PM height | mm | 4 | |

| Rotor pole arc, θr | degrees | 12 | |

| Slot opening PM arc, θsp | degrees | 11.5 | 23 |

| Stator yoke PM arc, θyp | degrees | 3 | 1.75 |

| Stator tip arc, θst | degrees | - | 36 |

| Stator teeth arc, θt | degrees | 18.5 | 23 |

| Number of turns/coil | degrees | 28 | 56 |

| Slot area/coil | mm2 | 121 | 264 |

| Steel type | - | Silicon steel 1010 | |

| PM type | - | NdFeB—N35 | |

| Magnetic flux remanent | T | 1.23 | |

| Armature current | A | 8 | |

| Current density | A/mm2 | 2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sriwannarat, W.; Phuangpornpitak, N.; Thasnas, N.; Butkaew, A.; Seangwong, P.; Khunkitti, P.; Siritaratiwat, A. Structural Multi-Tooth Modification of Hybrid-Excited Doubly Salient Dual-PM Machine for Torque Production Improvement. Appl. Sci. 2023, 13, 1414. https://doi.org/10.3390/app13031414

Sriwannarat W, Phuangpornpitak N, Thasnas N, Butkaew A, Seangwong P, Khunkitti P, Siritaratiwat A. Structural Multi-Tooth Modification of Hybrid-Excited Doubly Salient Dual-PM Machine for Torque Production Improvement. Applied Sciences. 2023; 13(3):1414. https://doi.org/10.3390/app13031414

Chicago/Turabian StyleSriwannarat, Warat, Napaporn Phuangpornpitak, Natakorn Thasnas, Authumporn Butkaew, Pattasad Seangwong, Pirat Khunkitti, and Apirat Siritaratiwat. 2023. "Structural Multi-Tooth Modification of Hybrid-Excited Doubly Salient Dual-PM Machine for Torque Production Improvement" Applied Sciences 13, no. 3: 1414. https://doi.org/10.3390/app13031414

APA StyleSriwannarat, W., Phuangpornpitak, N., Thasnas, N., Butkaew, A., Seangwong, P., Khunkitti, P., & Siritaratiwat, A. (2023). Structural Multi-Tooth Modification of Hybrid-Excited Doubly Salient Dual-PM Machine for Torque Production Improvement. Applied Sciences, 13(3), 1414. https://doi.org/10.3390/app13031414