Study on Improvement Characteristics of a Novel Geotextile with Stitched Transverse Ribs

Abstract

:1. Introduction

2. Direct Shear Tests

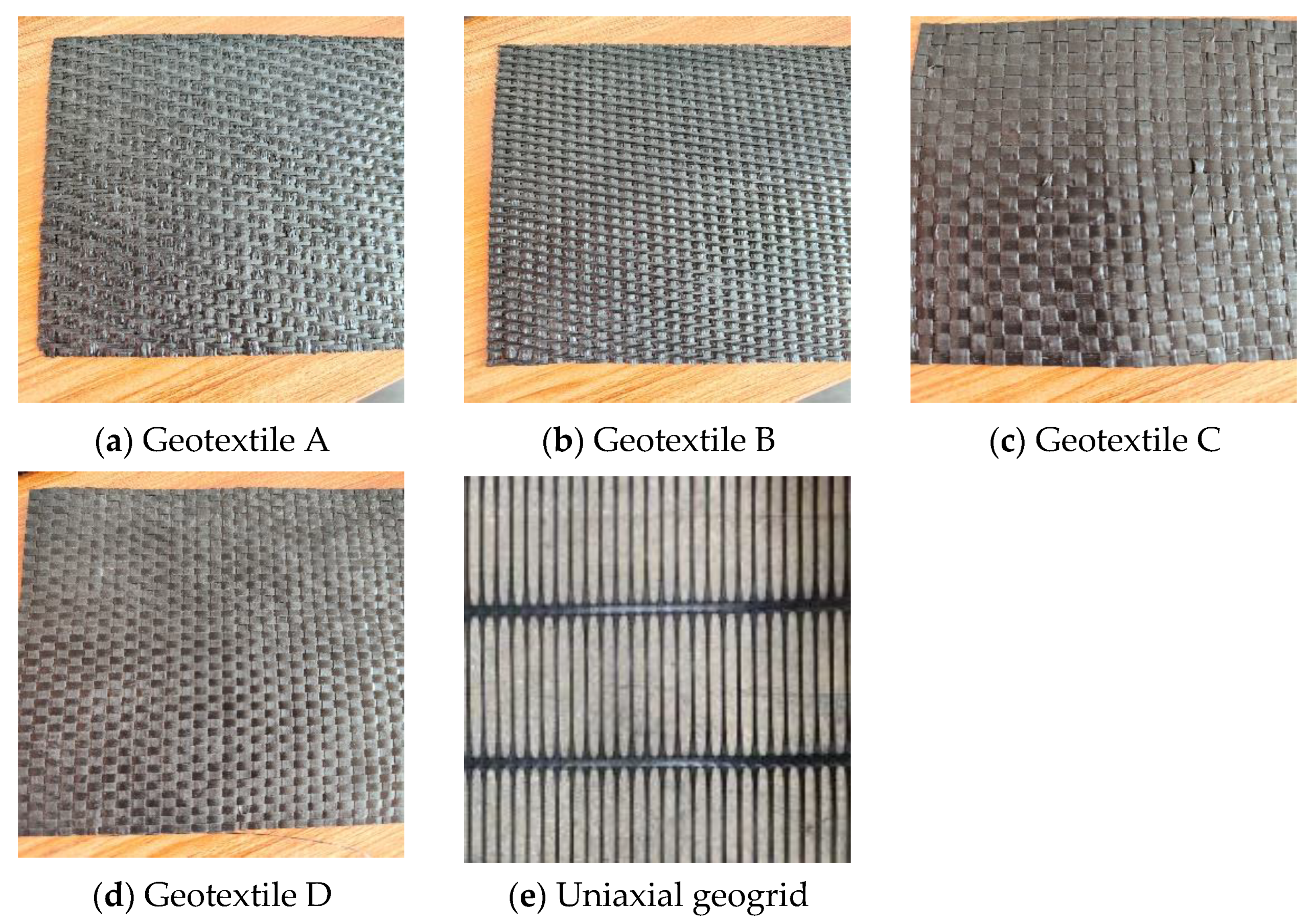

2.1. Test Materials

2.2. Test Equipment

2.3. Test Method

3. Experimental Results

3.1. Comparison of Reinforcement Effect of Different Reinforcement Materials

3.2. Comparison of Shear Strength of Stitched Rib Geotextile Reinforcement

3.3. Reinforcement Mechanism of the Novel Geotextile with Stitched Transverse Ribs

4. Conclusions

- (1)

- Geotextile B exhibits the best reinforcement effect among the four conventional geotextiles, and the shear strength of geotextile B is 20% higher than that of pure sandy soil. Moreover, the surface of geotextile B is rough enough to provide larger friction and form a certain embedded locking effect with sandy soil when geotextile B is compared with geotextiles C and D. Geotextile B has a greater thickness, higher strength and better reinforcement effect compared with the woven geotextile A. However, geogrid shows a better reinforcement effect than the four conventional geotextiles.

- (2)

- The shear strength of the novel geotextile with stitched transverse ribs is significantly increased. When the number of ribs increases, the magnitude of stress and the friction angle increase, but the cohesion does not significantly change. When the shear displacement is small, the shear strength of the novel geotextile with three ribs is higher than that of the geogrid. However, when the shear displacement becomes larger, the shear strength of the novel geotextile is higher than that of the geogrid, indicating that the novel geotextile exhibits a very good reinforcement effect.

- (3)

- The frictional resistance from the underlying fabric, the locking effect, the transverse restraint effect, and the frictional effect of ribs contribute to the novel geotextile’s shear strength. When normal stress is low, the transverse rib is the key stress part of the geotextile, and the overall reinforcement effect is mainly from the transverse rib while the friction force of the underlying fabric requires a large normal force.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, J.F.; Li, H.L. Research status and prospect of interface properties of geosynthetics reinforced soil. J. Undergr. Space Eng. 2009, 5, 1049–1054. [Google Scholar]

- Markiewicz, A.; Koda, E.; Kawalec, J. Geosynthetics for Filtration and Stabilisation: A Review. Polymers 2022, 14, 5492. [Google Scholar] [CrossRef] [PubMed]

- El-kady Mahmoud, S.; Azam, A.; Yosri Ahmed, M.; Nabil. Modelling of railway embankment stabilized with geotextile, geo-foam, and waste aggregates. Case Stud. Constr. Mater. 2023, 18, e01800. [Google Scholar] [CrossRef]

- Dabir, V.; Khare, K.; Munireddy, M.G. A Composite Permeable Sloping Seawall for Effective Energy Dissipation: A Quasi-Soft Alternative Solution for Shore Protection. J. Mar. Sci. Eng. 2022, 10, 1423. [Google Scholar] [CrossRef]

- Sinha, P.K.; Raj, A.; Kumar, S.; Singh, D. Mechanical Behavior of Geotextile and Geogrids on Soil Stabilization: A Review. Recent Adv. Mech. Eng. 2023, 299–308. [Google Scholar] [CrossRef]

- Wysokowski, A. Influence of single-layer geotextile reinforcement on load capacity of buried steel box structure based on laboratory full-scale tests. Thin-Walled Struct. 2020, 159, 107312. [Google Scholar] [CrossRef]

- Mosallanezhad, M.; Alfaro, M.C.; Hataf, N.; Sadat Taghavi, S.H. Performance of the new reinforcement system in the increase of shear strength of typical geogrid interface with soil. Geotext. Geomembr. 2016, 44, 457–462. [Google Scholar] [CrossRef]

- Mehmet, S.; Selçuk, A. Experimental investigation of influence of clay in soil on interface friction between geotextile and clayey soil. Arab. J. Geosci. 2020, 13, 342. [Google Scholar]

- Fattah Mohammed, Y.; Salim Nahla, M.; Ismaiel Mohammad, S. Influence of Geogrid Reinforcement of Sand in Transfer of Dynamic Loading to Underground Structure. IOP Conf. Ser. Earth Environ. Sci. 2021, 856, 1–10. [Google Scholar]

- Nunes, G.B.; Portelinha, F.H.M.; Futai, M.M.; Yoo, C. Numerical study of the impact of climate conditions on stability of geocomposite and geogrid reinforced soil walls. Geotext. Geomembr. 2022, 50, 807–824. [Google Scholar] [CrossRef]

- Lin, H.; Tang, S.; Xia, Y.; Zhou, Q. Shear behavior of geotextile tailings interface under fold condition. J. Nat. Disasters 2021, 30, 147–154. [Google Scholar]

- Chen, R.; Li, B.; Hao, D.X.; Gao, Y.C. Simulation method of geogrid reinforcement soil interface based on cohesion model. Chin. J. Geotech. Eng. 2020, 42, 934–940. [Google Scholar]

- Chen, J.F.; Li, H.L.; Liu, J.X.; Zhou, J. Study on meso-interface properties of geogrids and sand. Rock Soil Mech. 2011, 32 (Suppl. S1), 66–71. [Google Scholar]

- Bao, C.G. Research and experimental verification of interface properties of geosynthetics. Chin. J. Rock Mech. Eng. 2006, 25, 1735–1744. [Google Scholar]

- Eyyüb, K. Factors Effecting the Shear Strength of Geotextile Reinforced Compacted Clays. Dokuz Eylül Üniversitesi Mühendislik Fakültesi Fen Ve Mühendislik Derg. 2018, 20, 725–742. [Google Scholar]

- Aliyeh, A.N.; Ali, L.; Piltan, T.S. Influence of particle shape on the shear strength and dilation of sand-woven geotextile interfaces. Geotext. Geomembr. 2017, 45, 54–66. [Google Scholar]

- Guo, W.; Chu, J.; Zhou, B. Method to increase seam efficiency for woven geotextile materials. Geosynth. Int. 2015, 22, 404–410. [Google Scholar] [CrossRef]

| Characteristic Particle Size | Uniformity Coefficient Cu | Curvature Coefficient Cc | ||

|---|---|---|---|---|

| d60/mm | d30/mm | d10/mm | ||

| 0.94 | 0.45 | 0.18 | 5.22 | 1.20 |

| Reinforcing Material | Mass per Unit Area/(g/m2) | Ultimate Tensile Strength/(kN/m) | Ultimate Elongation/% | ||

|---|---|---|---|---|---|

| Vertical | Horizontal | Vertical | Horizontal | ||

| Geotextile A | 460.0 | 90.20 | 58.45 | 15.37% | 14.21% |

| Geotextile B | 428.5 | 99.65 | 83.45 | 13.21% | 15.66% |

| Geotextile C | 290.0 | 58.75 | 46.30 | 19.14% | 14.37% |

| Geotextile D | 200.0 | 30.30 | 36.00 | 11.26% | 12.74% |

| Uniaxial geogrid | - | 97.30 | - | 11.60% | - |

| Groups | Reinforcing Material | Shear Rate (mm/min) | Reinforcement Method | Normal Stress (kPa) | |

|---|---|---|---|---|---|

| Without reinforcement | I | None | 1 | flattening | 25, 50, 100, 150 |

| Conventional geotextiles | II | Geotextiles A | 1 | flattening | 25, 50, 100, 150 |

| III | Geotextiles B | 1 | flattening | 25, 50, 100, 150 | |

| IV | Geotextiles C | 1 | flattening | 25, 50, 100, 150 | |

| V | Geotextiles D | 1 | flattening | 25, 50, 100, 150 | |

| Geogrid | VI | Uniaxial geogrid | 1 | flattening | 25, 50, 100, 150 |

| Novel geotextiles with stitched transverse ribs | VII | Geotextiles B | 1 | stitching 1 rib | 25, 50, 100, 150 |

| VIII | Geotextiles B | 1 | stitching 2 ribs | 25, 50, 100, 150 | |

| IX | Geotextiles B | 1 | stitching 3 ribs | 25, 50, 100, 150 | |

| Interface | Cohesion/kPa | Friction Angle/° |

|---|---|---|

| Steel plate–sand | 2.54 | 20.86 |

| Geotextile A–sand | 5.07 | 22.67 |

| Geotextile B–sand | 5.38 | 23.82 |

| Geotextile C–sand | 4.20 | 22.44 |

| Geotextile D–sand | 6.64 | 20.18 |

| Geogrid–sand | 13.86 | 25.85 |

| Reinforcement Method | Normal Stress (kPa) | The Proportion of Each Part (%) | |

|---|---|---|---|

| Friction Force of the Underlying Geotextile F1 | Stress Force Provided by Transverse Ribs F2 + F3 | ||

| Stitching 1 rib | 25 | 42.5 | 57.5 |

| 50 | 49.1 | 50.9 | |

| 100 | 62.7 | 37.3 | |

| 150 | 70.0 | 30.0 | |

| Stitching 2 ribs | 25 | 30.9 | 69.1 |

| 50 | 38.2 | 61.8 | |

| 100 | 52.2 | 47.8 | |

| 150 | 61.4 | 38.6 | |

| Stitching 3 ribs | 25 | 27.4 | 72.6 |

| 50 | 32.5 | 67.5 | |

| 100 | 44.8 | 55.2 | |

| 150 | 50.0 | 50.0 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Li, H.; Yang, Y.; Xu, P.; Dai, Z.; Yang, G.; Wang, H.; Wang, Z. Study on Improvement Characteristics of a Novel Geotextile with Stitched Transverse Ribs. Appl. Sci. 2023, 13, 1536. https://doi.org/10.3390/app13031536

Liu W, Li H, Yang Y, Xu P, Dai Z, Yang G, Wang H, Wang Z. Study on Improvement Characteristics of a Novel Geotextile with Stitched Transverse Ribs. Applied Sciences. 2023; 13(3):1536. https://doi.org/10.3390/app13031536

Chicago/Turabian StyleLiu, Weichao, He Li, Yan Yang, Peng Xu, Zhengjie Dai, Guangqing Yang, He Wang, and Zhijie Wang. 2023. "Study on Improvement Characteristics of a Novel Geotextile with Stitched Transverse Ribs" Applied Sciences 13, no. 3: 1536. https://doi.org/10.3390/app13031536

APA StyleLiu, W., Li, H., Yang, Y., Xu, P., Dai, Z., Yang, G., Wang, H., & Wang, Z. (2023). Study on Improvement Characteristics of a Novel Geotextile with Stitched Transverse Ribs. Applied Sciences, 13(3), 1536. https://doi.org/10.3390/app13031536