Effect of the Umbrella Arch Technique Modelled as a Homogenized Area above a Cross Passage

Abstract

:1. Introduction

2. Project Description and Geological Conditions

3. Modelling Approach

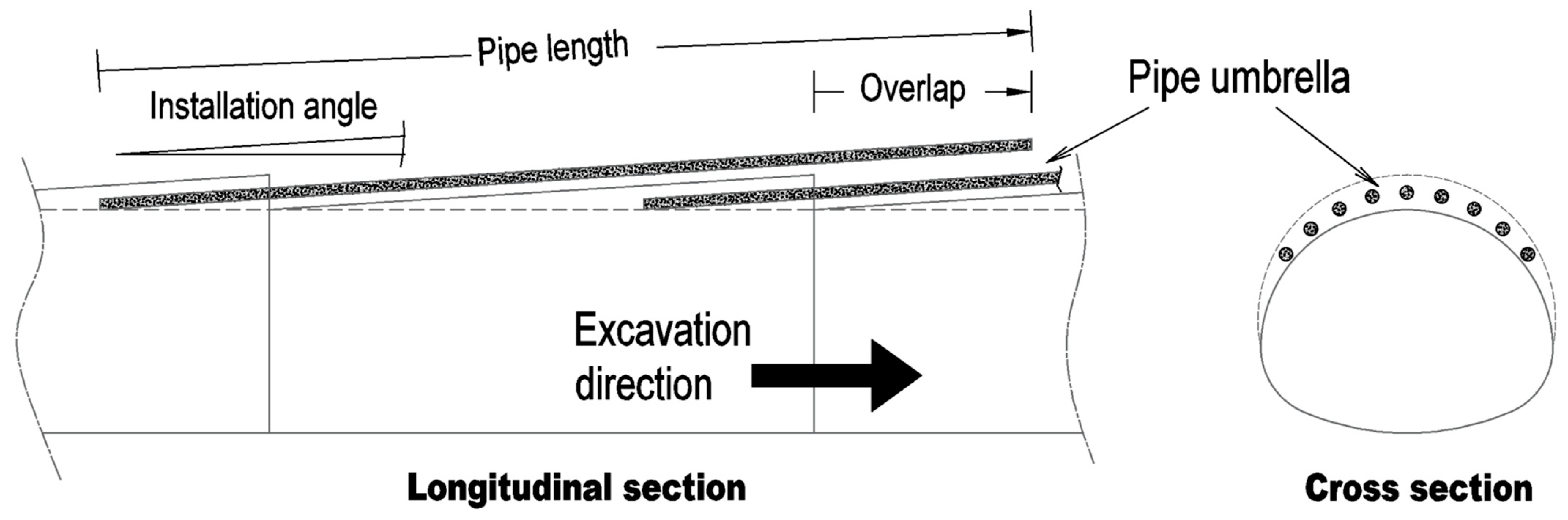

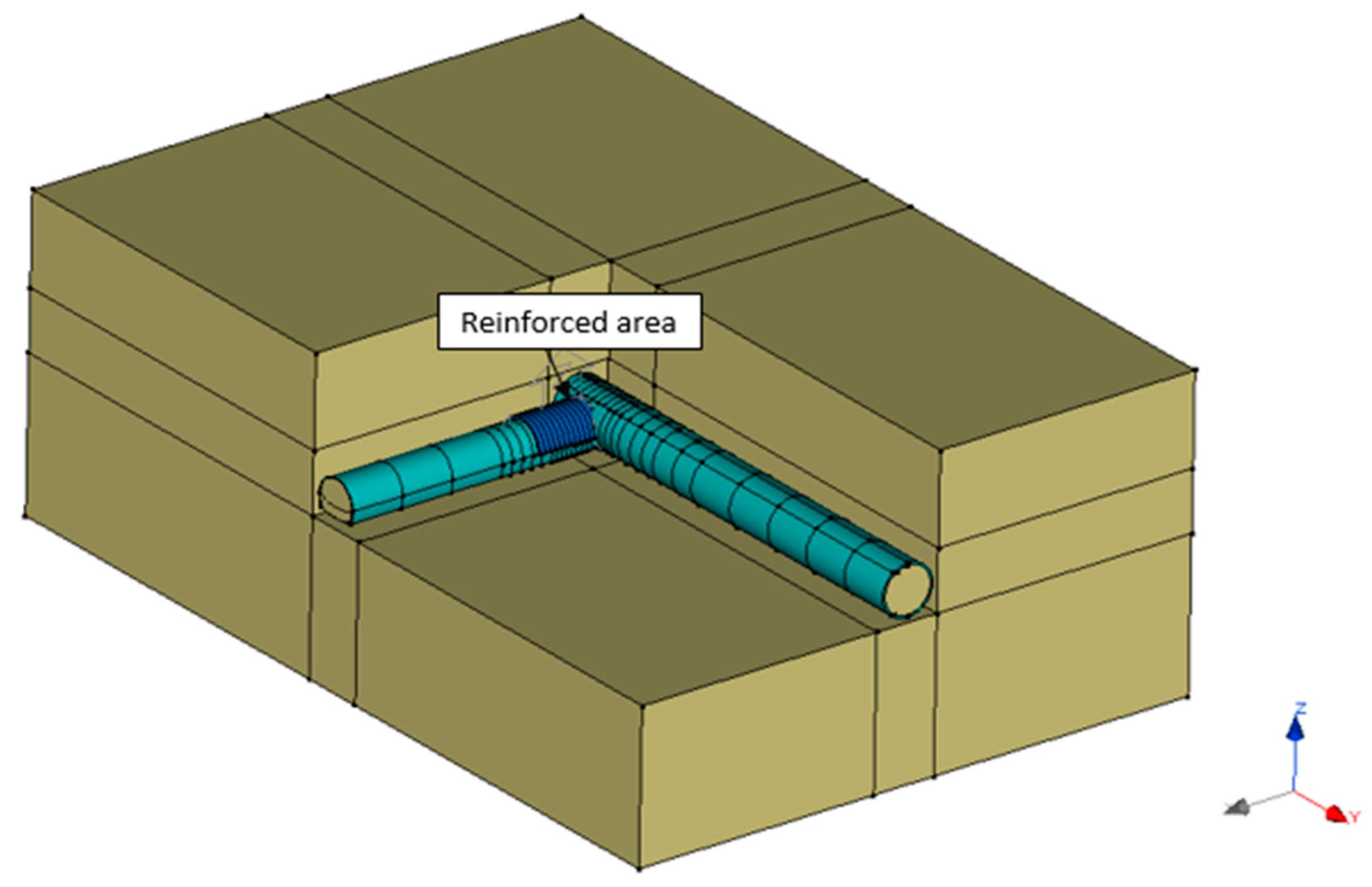

3.1. Geometric Description and Constitutive Model

3.2. Boundary Conditions

3.3. Modelling the Staged Construction

4. Results and Discussions

4.1. Transverse Settlement Trough

4.2. Extrusion at the Front Face along the Vertical Axis of the Cross Passage

4.3. Plastic Zones

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Volkmann, G.; Schubert, W. Geotechnical model for pipe roof supports in tunneling. In Proceedings of the 33rd ITA-AITES World Tunneling Congress—Underground Space—The 4th Dimension of Metropolises, Prague, Czech Republic, 5–10 May 2007. [Google Scholar] [CrossRef]

- Peila, D.; Pelizza, S. Ground Reinforcing for Tunneling the Example of Steel Pipe Umbrella. ITA-AITES Train. Course Istanb. 2005. [Google Scholar]

- Volkmann, G.; Schubert, W. A Contribution to the Effect and Behavior of Pipe Roof Supports. In Proceedings of the 53rd Geomechanics Colloquy and EUROCK, Salzburg, Austria, 7–9 October 2004; pp. 161–166. [Google Scholar]

- Oke, J.; Vlachopoulos, N.; Diederichs, M.S. Numerical analyses in the design of umbrella arch systems. J. Rock Mech. Geotech. Eng. 2004, 6, 546–564. [Google Scholar] [CrossRef] [Green Version]

- Ranjbarnia, M.; Rahimpour, N.; Oreste, P. A simple analytical approach to simulate the arch umbrella supporting system in deep tunnels based on convergence confinement method. Tunn. Undergr. Space Technol. 2018, 82, 39–49. [Google Scholar] [CrossRef]

- Hisatake, M.; Ohno, S. Effects of pipe roof supports and the excavation method on the displacements above a tunnel face. Tunn. Undergr. Space Technol. 2008, 23, 120–127. [Google Scholar] [CrossRef]

- Juneja, A.; Hegde, A.; Lee, F.H.; Yeo, C.H. Centrifuge modelling of tunnel face reinforcement using forepoling. Tunn. Undergr. Space Technol. 2010, 25, 377–381. [Google Scholar] [CrossRef]

- Hasanpour, R.; Chakeri, H.; Ozcelik, Y.; Denek, H. Evaluation of surface settlements in the Istanbul metro in terms of analytical, numerical and direct measurements. Bull. Eng. Geol. Environ. 2012, 71, 499–510. [Google Scholar] [CrossRef]

- Yasitli, N.E. Numerical modeling of surface settlements at the transition zone excavated by New Austrian Tunneling Method and Umbrella Arch Method in weak rock. Arab. J. Geosci. 2013, 6, 2699–2708. [Google Scholar] [CrossRef]

- Peila, D. A theoretical study of reinforcement influence on the stability of a tunnel face. Geotech. Geol. Eng. 1994, 12, 145–168. [Google Scholar] [CrossRef]

- Date, K.; Mair, R.J.; Soga, K. Reinforcing effects of forepoling and facebolts in tunnelling. In Geotechnical Aspects of Underground Construction in Soft Ground; CRC Press: Boca Raton, FL, USA, 2009; pp. 651–658. [Google Scholar]

- Aksoy, C.O.; Onargan, T. The role of umbrella arch and face bolt as deformation preventing support system in preventing building damages. Tunn. Undergr. Space Technol. 2010, 25, 553–559. [Google Scholar] [CrossRef]

- Janin, J.P. Tunnels en Milieu Urbain: Prévisions des Tassements Avec Prise en Compte des Effets des Présoutènements (Renforcement du Front de Taille et Voûte-Parapluie). Ph.D. Thesis, INSA de Lyon, Villeurbanne, France, 2012. [Google Scholar]

- Zarei, H.; Moarefvand, P.; Salmi, F. Numerical modeling of umbrella arch technique to reduce tunneling induced ground movements. Environ. Earth Sci. 2019, 78, 291. [Google Scholar] [CrossRef]

- Maghous, S.; Bernaud, D.; Couto, E. Three-dimensional numerical simulation of rock deformation in bolt-supported tunnels: A homogenization approach. Tunn. Undergr. Space Technol. 2012, 31, 68–79. [Google Scholar] [CrossRef]

- Bernaud, D.; De Buhan, P.; Maghous, S. Numerical simulation of the convergence of a bolt-supported tunnel through a homogenization method. Int. J. Numer. Anal. Methods Geomech. 1995, 19, 267–288. [Google Scholar] [CrossRef]

- Dias, D.; Kastner, R.; Jassionnesse, C. Sols renforcés par Boulonnage—Etude numérique et application au front de taille d’un tunnel profond. Géotechnique 2002, 52, 15–27. [Google Scholar] [CrossRef]

- Schumacher, F.P.; Kim, E. Modeling the pipe umbrella roof support system in a Western US underground coal mine. Int. J. Rock Mech. Min. Sci. 2013, 60, 114–124. [Google Scholar] [CrossRef]

- Song, K.I.; Cho, G.C.; Chang, S.B.; Lee, I.M. Beam–spring structural analysis for the design of a tunnel pre-reinforcement support system. Int. J. Rock Mech. Min. Sci. 2013, 59, 139–150. [Google Scholar] [CrossRef]

- Hounyevou Klotoé, C.; Bourgeois, E. Three dimensional finite element analysis of the influence of the umbrella arch on the settlements induced by shallow tunneling. Comput. Geotech. 2019, 110, 114–121. [Google Scholar] [CrossRef]

- Nitschke, A.; Gall, V.; Ahuja, V. Modeling of pipe arch canopies in shallow soft ground tunnels constructed by sequential excavation methods. In Proceedings of the EURO: TUN 2009 2nd International Conference on Computational Methods in Tunnelling, Bochum, Germany, 9–11 September 2009. [Google Scholar]

- Wang, D.; Gao, Z.; Lee, J.L.; Gao, W. Assessment and Optimization of Soil Mixing and Umbrella Vault Applied to a Cross-Passage Excavation in Soft Soils. Int. J. Geomech. 2014, 14, 0000374. [Google Scholar] [CrossRef]

- Joneidi, M.; Golshani, A.; Naeimifar, I. Progressive deformation and mechanical behavior of intersecting tunnels in soft ground. Proc. Inst. Civ. Eng. Ground Improv. 2019, 172, 285–296. [Google Scholar] [CrossRef]

- Do, N.A.; Dias, D.; Oreste, P.; Djeran-Maigre, I. Three-dimensional numerical simulation for mechanized tunneling in soft ground: The influence of the joint pattern. Acta Geotech. 2014, 9, 673–694. [Google Scholar] [CrossRef]

- Mollon, G. Etude Déterministe et Probabiliste du Comportement des Tunnels. Ph.D Thesis, INSA de Lyon, Villeurbanne, France, 2012. [Google Scholar]

- Ocak, I. Control of surface settlements with umbrella arch method in second stage excavations of Istanbul Metro. Tunn. Undergr. Space Technol. 2008, 23, 674–681. [Google Scholar] [CrossRef]

- Le, B.T.; Taylor, R.N. A study on the reinforcing capabilities of Forepoling Umbrella System in urban tunneling. In Proceedings of the 3rd European Conference on Physical Modelling in Geotechnics, Nantes, France, 1–3 June 2016. [Google Scholar]

- Morovatdar, A.; Palassi, M.; Ashtiani, R.S. Effect of pipe characteristics in umbrella arch method on controlling tunneling-induced settlements in soft grounds. J. Rock Mech. Geotech. Eng. 2020, 12, 984–1000. [Google Scholar] [CrossRef]

- Kavvadas, M.; Georgiou, D.; Kalos, A. Numerical Investigation of Tunnel Face Stability Using Forepoling or Fiberglass Nails|SpringerLink. 2022. Available online: https://link.springer.com/article/10.1007/s10706-021-01930-9 (accessed on 14 July 2022).

- Elyasi, A.; Javadi, M.; Moradi, T.; Moharrami, J.; Parnian, S.; Amrac, M. Numerical modeling of an umbrella arch as a pre-support system in difficult geological conditions: A case study. Bull. Eng. Geol. Environ. 2016, 75, 211–221. [Google Scholar] [CrossRef]

| Parameter | Elasticity Modulus (MPa) | Thickness (m) | Poisson’s Ratio |

|---|---|---|---|

| Value | 9981 | 0.5 | 0.3 |

| Parameter | Marl | Support of the Main Tunnel | Support of the Cross Passage |

|---|---|---|---|

| Density | 21 | / | / |

| Elasticity modulus (MPa) | 111 | 35,000 | 25,000 |

| Poisson’s ratio | 0.3 | 0.2 | 0.2 |

| Cohesion (KPa) | 56 | / | / |

| Friction angle (°) | 21 | / | / |

| Expansion angle (°) | 10 | / | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siad, I.; Akchiche, M.; Spyridis, P. Effect of the Umbrella Arch Technique Modelled as a Homogenized Area above a Cross Passage. Appl. Sci. 2023, 13, 1588. https://doi.org/10.3390/app13031588

Siad I, Akchiche M, Spyridis P. Effect of the Umbrella Arch Technique Modelled as a Homogenized Area above a Cross Passage. Applied Sciences. 2023; 13(3):1588. https://doi.org/10.3390/app13031588

Chicago/Turabian StyleSiad, Ibtissem, Mustapha Akchiche, and Panagiotis Spyridis. 2023. "Effect of the Umbrella Arch Technique Modelled as a Homogenized Area above a Cross Passage" Applied Sciences 13, no. 3: 1588. https://doi.org/10.3390/app13031588