Abstract

Soft actuators have been developed for a variety of applications, including soft grippers, artificial muscles, wearables, tactile devices, and medical devices. In this review, we will discuss a group of chemical materials and their robotic applications in soft actuators controlled with electrical stimuli. Soft actuators provide a deformable body and allow interaction with the environment to achieve the desired actuation pattern. We will also discuss the principles of operation and functionality and focus on important real-life applications of three groups of soft actuators: ionic polymer–metal composites (IPMCs), dielectric electroactive polymers (DEAPs), and magnetorheological elastomers (MREs). This review article aims to provide researchers interested in the field of soft robotics with a guide to various state-of-the-art chemistry methods used in electrically activated soft actuators, as well as the application areas for such devices.

1. Introduction

Along with other dynamic technological developments, new electrochemical materials are being developed, which have many properties desired in advanced automation and robotics systems [1,2,3,4]. One of the very interesting groups of such materials is electroactive polymers, which show a change in selected properties when stimulated with an electric field. We can distinguish three types of this kind of electrically stimulated material, like dielectric electroactive polymers (DEAP), ionic polymer–metal composites (IMPCs), and magnetorheological elastomers (MRE). Due to their properties, these materials are classified in the literature as “smart materials”, the definition of which determines the ability to control changes of properties in response to environmental stimuli [2,5]. The possibility of strong deformation simultaneously with low weight, high resistance to cracking, and quiet operation constitute a huge potential for possible applications of electroactive polymers. The potential application of soft actuators covers such areas as soft robotics, artificial muscles, wearable sensors, and biomimetics. The main advantage of soft actuators, compared to conventional mechanical actuators, is their much greater flexibility, ability to withstand higher loads, and lightness [1,2,3,4]. The application of soft actuators in soft robotics allows the obtaining of delicate tools. In addition to the mentioned advantages of soft actuators, there are several drawbacks that require further research and development. For instance, DEAPs require high voltage, in the range of kV, for their activation. Nowadays, it has been shown that it is possible to reduce the operating voltage to several hundred volts and even below 100 V by reducing the thickness of DEAPs and using stacked DEAPs [6]. However, reducing the thickness of the actuator to a few micrometers requires the development of a procedure for the DEAPs’ precise manufacture. In the case of IMPCs, a change in the gap size between electrodes (electrode separation) is applied to optimize the torsion performance. The IPMCs with patterned electrodes fabricated using a masking technique are designed to accomplish a twisting motion [7]. The new trend in MRE preparation is an approach for improving magnetic particle dispersion during the fabrication of MRE to provide better magnetorheological properties [8].

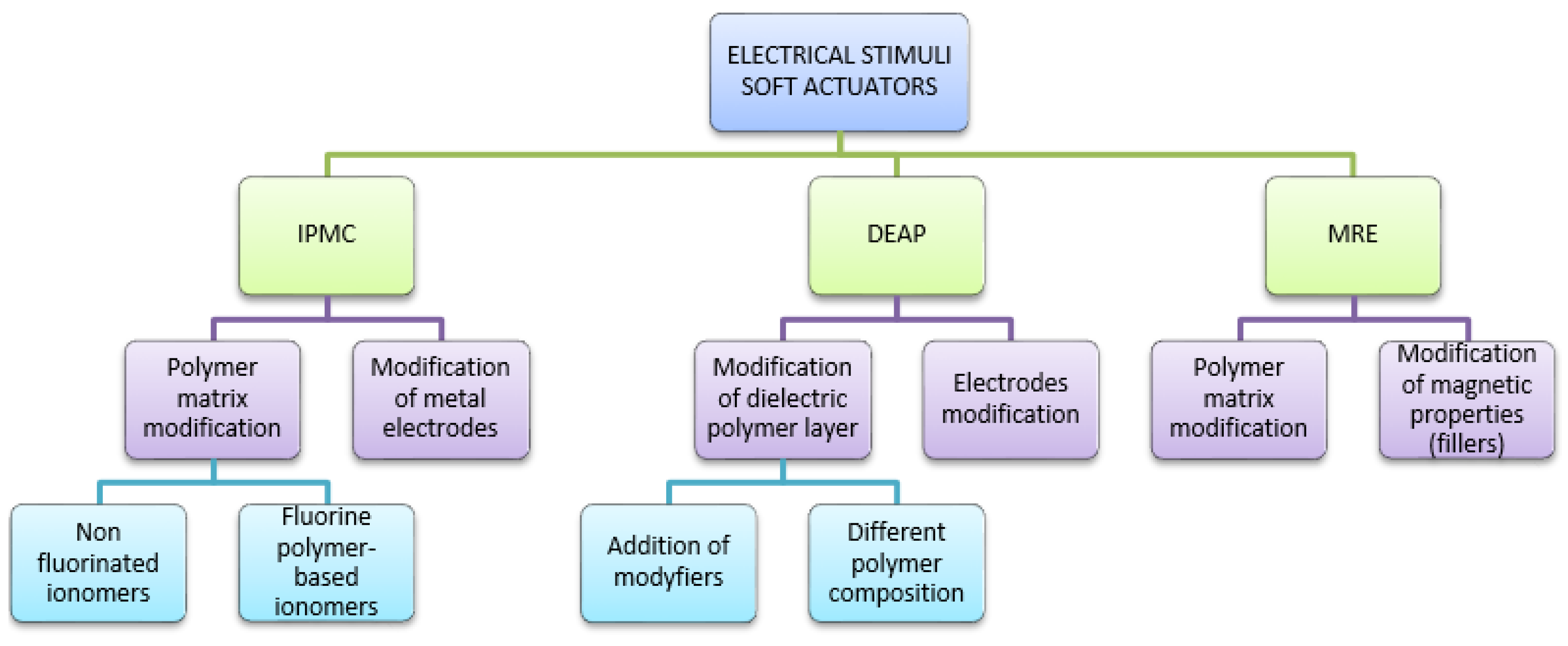

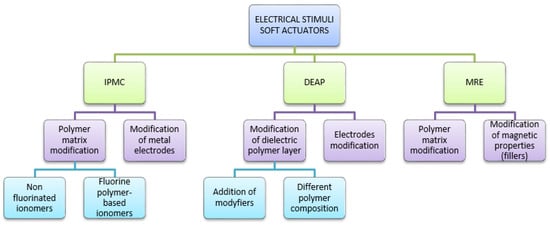

In this paper, we are focused on the recent progress in the preparation, modification, and application of electric-stimulated soft actuators, such as IPMCs, DEAPs, and MREs, especially in the last few years. Moreover, for a better presentation of the latest trends in the modification of soft actuators, we have prepared a diagram, shown in Figure 1.

Figure 1.

Recent trends in modification of electrical stimuli soft actuators.

2. Recent Progress in Development and Applications of Soft Actuators

2.1. Ionic Polymer Metal Composite (IPMC)

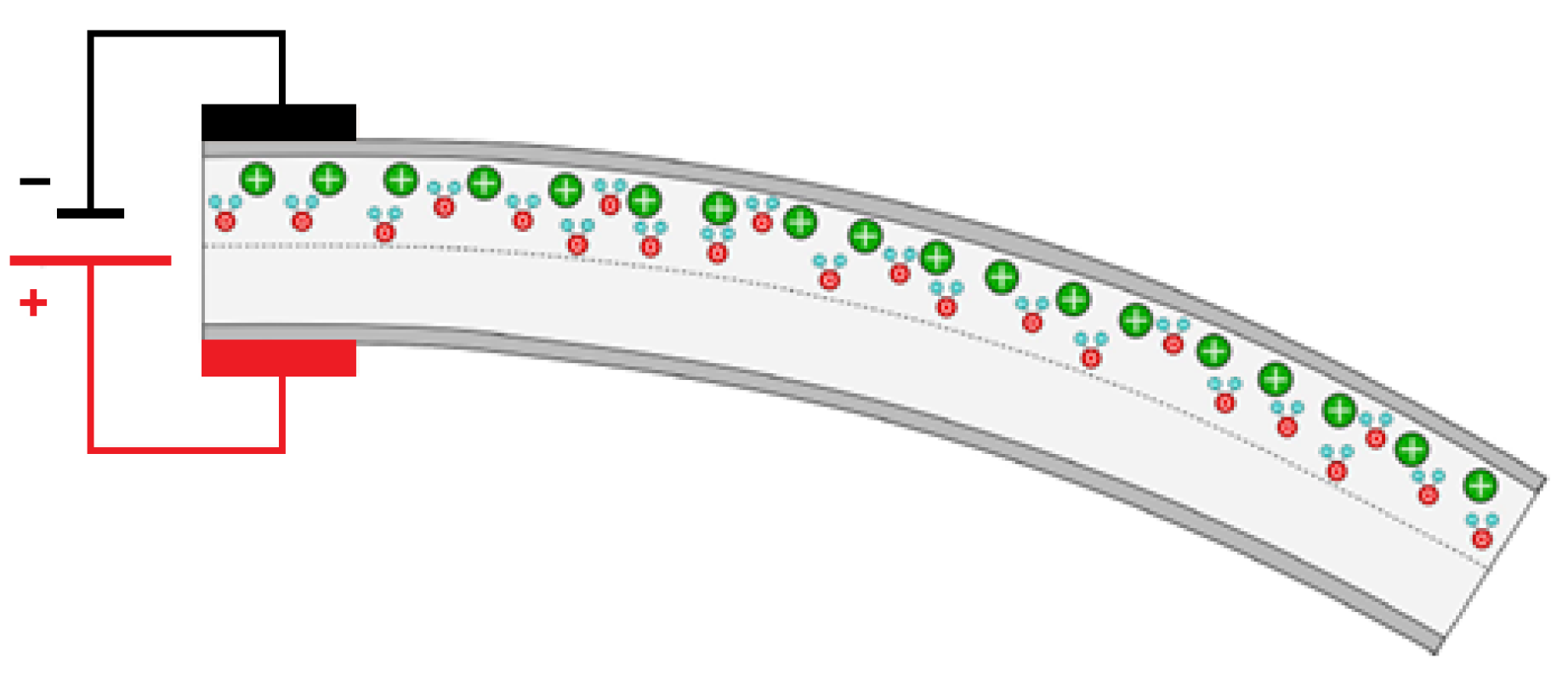

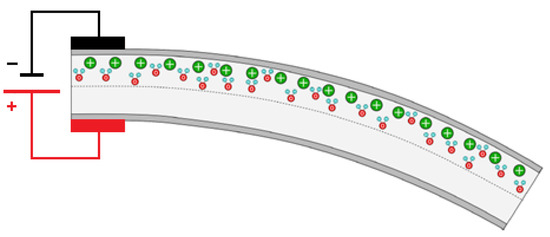

Ionic polymer–metal composite is composed of an ion-exchange (mostly cation-exchange) polymer membrane (ionomer) and metallic electrodes deposited on both surfaces of the membrane. The ionomer provides channels for selective ion migration and is mostly responsible for the mechanical properties of the IPMC. The metallic electrodes provide the applied voltage to the membrane surface and work as capacitor electrodes that can accumulate a certain amount of charge. The accumulated charge forces the ion migration in the membrane, which causes the bending of the IPMC actuators. Electroactive ionic polymers usually work in a humid environment and are driven by low voltages of 1–5 V. Inside the polymer structure, anions are clustered together to provide channels for the flow of the cations. When the material is hydrated, the hydrated cations diffuse under the influence of an electric field toward an electrode applied to the outer surface of a membrane. The accumulation of hydrated cations on the negative electrode side causes mechanical and electrostatic stress, which ultimately translates into the deformation of the IPMC actuator, as shown in Figure 2. The parameters of ion-exchange membranes, such as Young modulus, size of the ion-conducting channels, size of the counter ion (together with a solvation sphere), and the amount of absorbed solvent, as well as the insertion of different modifiers into the structure of the membrane, play a significant role on the final properties of IMPC. On the other hand, the conductivity of the electrode layer, their crack resistance during bending, and adhesion to the membrane surface are also crucial. Because the ion-exchange membrane and electrode properties mostly influence the IPMC parameters, two main routes of the IPMC modification can be distinguished. The first path focuses on the modification of the ionomer, and the second path focuses on the modification of electrodes.

Figure 2.

Reaction of IPMC Polymer to an applied potential.

2.1.1. Recent Trends in the Modification of IPMC

The ion-exchange membrane is an important part of the IMPC that influences the final properties of the actuator. Apart from the appropriate mechanical properties (Young modulus, elasticity, and strength) and a good ability for ion transport, the ionomer should be resistant to chemical corrosion and high temperature, which is related to “hard” conditions of electroless plating methods. Therefore, the most common ionomers used are prepared from perfluorinated membranes, mainly Nafion. Thanks to fluoric atoms introduced to polymer structure, these membranes provide great chemical and thermal stability, and resistance to chemical and electrochemical oxidation, which allows for avoiding degradation during the electroless metal plating and IPMC working. However, fluorinated polymers present very pure adhesive properties that cause a lot of trouble with the adhesion of metal electrodes to their surface.

Therefore, the IPMC manufacturing process requires additional membrane surface preparation prior to electroless metal plating. The surface of the membrane is sanded with sandpaper (improvement of mechanical adhesion) and the membrane is boiled in a hydrochloric acid solution. In the case of non-fluorinated membranes, there is no need to prepare the surface for the application of the metallic layer. This simplifies the preparation of the IPMC.

Another problem is related to the condition of the IPMC operation. In most cases, ionomers are swelled by the water, which provides conditions for ion diffusion in the membrane. The ion’s mobility in the water environment is high thus, the response to an electric signal is fast, but during the IPMC working, water can easily evaporate, causing high limitation in ion diffusion and dynamic response to the electric signal decrease. Another problem is the electrochemical stability window of water, which is equal ca 1.23 V (in a neutral environment). Above this value, water decomposes, which causes a progressive decrease in IPMC properties. Therefore, researchers are focusing on various paths of modification and improvement of the IMPCs to solve the described problems. Several important routes can be distinguished: (i) introduction of various modifiers to the Nafion suspension and subsequent preparation of the membrane, (ii) use of non-fluorinated ionomers (self-synthesized or commercially available), (iii) modification of the composition and properties of the metallic electrode.

Modification of Ionomers Based on Fluorine Polymers

Nafion is the most popular ionomer used in IPMC formulations. It can be purchased as a flat membrane or as a polymer suspension in water. The use of Nafion suspension offers great opportunities for IPMC modification, as it allows the suspension to be mixed with various types of modifiers [9,10,11,12,13]. Therefore a lot of scientists focus on this topic. D. Zhao et al. [12] have shown that the introduction of poly(ethylene oxide) (PEO) in proper concentration into the Nafion structure increases the water uptake, which has a significant influence on the IPMC properties. Increasing the concentration of PEO in the membrane causes a decrease in membrane stiffens, an increase in displacement (for PEO concentration up to 20%), and a decrease in blocking force. Other used modifiers are carbon nanotubes (CNTs) [10,11,12]. In that case, CNTs are often applied as membrane and electrode modifiers. J. Zhao et al. [12] have applied CNTs for modification of the Nafion membrane and surface of electrodes (electroless plating of Pt on membrane surface followed by electrophoretic deposition of CNTs). A high increase in the electrical conductivity of electrodes and IPMC performance was observed. Similar work was presented by J. Ru et al. [10], who used CNTs mixed with Nafion, prior to electroless plating, as an additional layer on the membrane surface. L. Qin et al. [11] improve the IPMC properties by application of multi-walled carbon nanotubes (MWCNTs) and carboxylic multi-walled carbon nanotubes (CMWCNTs). It was shown that the addition of a small number of MWCNTs or CMWCNTs improved the mechanical properties, output force, deformation rate, and displacement of the IPMC.

Modification of non-Fluorinated Ionomers

Self-preparation of an ionomer using direct polymerization of different non-fluorinated monomers [14] or by improving the propertiesof existing non-fluorinated polymers (for example by crosslinking) [15,16,17,18] provides great potential for modification of ionomer membrane properties. A significant number of non-fluorinated monomers and polymers allows for obtaining ionomers with very different properties. This gives the possibility of much better and greater control of the final properties of the IPMC. The application of a non-fluorinated membrane allows for more “friendly” conditions during electroless metal plating, without problems with the adhesion of the metal layer to the membrane surface. Moreover, in the case of Nafion-based ionomers, we are significantly limited and, as mentioned above, we can only modify the composition of the polymer suspension by introducing various types of modifiers before obtaining IPMC. Compared to the use of ready-made membranes or suspensions of fluorinated polymers, non-fluorinated polymers give much greater possibilities for IPMC modification at the stage of polymer membrane synthesis (through the appropriate selection of the monomers composition), even without introducing other modifiers.

M. Luqman et al. present the application of various co-polymers such as commercial pentablock copolymer—Kraton (obtained from such monomers as tert-butylstyrene, ethylene, propylene, styrene and styrene sulfonate) [15], poly(vinyl chloride) crosslinked with 4-sulphophthalic acid (SPVC) and modified using phosphotungstic acid (PTA) [16], and sulfonated poly(ether ether ketone) (SPEEK) [18] on the properties of IPMC. In these works, it was shown that the actuators based on SPVC-PTA and Kraton are characterized by similar force and displacement values of 0.1 mN and 10 mm, respectively, while the IMPCs based on SPEEK had better properties, i.e., force 0.3 mN, displacement—20 mm.

K. Engel et al. synthesized the ionomer membrane from acrylate monomers using digital light processing (DLP) [14]. It was shown that by changing the polymerizable mixture’s composition it was possible to modify the final properties of the IPMC. In addition, the use of 3D printing allows for obtaining membranes of different shapes, sizes, and thicknesses, which gives more possibilities in designing their shape compared to commercial flat membranes. Additionally, Y. Wang et al. have shown the application of DLP for ionomer preparation [19]. Thanks to the use of 3D printing, it was possible to quickly and easily obtain a membrane of various compositions, which led to the production of ionomers with different mechanical properties and different bending abilities. Due to the fact that the production of ionomers using 3D printing is a fast, cheap, easy-to-use technique, and gives a lot of possibilities for changing the composition of the membrane, it can be expected that in the near future, 3D printing will be intensively developed in terms of its application to obtain ionomers for IPMC actuators.

Modification of Metal Electrodes

The main route of electroless plating of the metal electrode on the surface of the ionomer is the chemical reduction of metal cations, mostly Pt2+, Pd2+, or Ag+ to its metallic form on the surface of the membrane [12,18,20,21,22,23]. Reduction of Pt2+ and Pd2+ is very common because the obtained metallic layer is electrochemically stable, does not oxidize, and is easy to fabricate, but the price of the complex solution for plating is very high. Therefore these cations are often replaced by Ag+, which also gives good plating results and, at the same time, is much cheaper [24,25,26,27]. The quality of the electrodes on the IPMC surface has a great impact on the properties and operation of the prepared IPMC actuators. Therefore, one of the intensively developed research directions is the modification of the electrode’s composition in order to improve its properties. During the fabrication of the electrode, the plating is usually performed twice. The first time the metal is deposited by chemical reduction, while the second layer can be deposited identically or by electrochemical metal deposition. Therefore, one direction of the actually conducted research is the use of other metals like Cu [26,28,29] or Ga/In [30] to deposit the metallic layer during the second plating. Another direction of investigation presents the application of metallic electrodes modified by other, nonmetallic additives like graphene [12,27], carbon nanotubes [27], or conductive polymers [17,18]. Additionally, conductive polymers (e.g., PEDOT) or polymer composites with conductive nanoparticles (e.g., Nafion with carbon nanotube), with sufficient conductivity that can replace metallic electrodes on polymer membranes, were widely studied [31,32].

2.1.2. Actual Trends in the Application of IMPCs in Soft Robotics

An IPMC is an electrically driven material that undergoes bending deformations in the presence of relatively low external voltages, exhibiting great potential as an actuator for applications in soft robotics, bio-engineering, or micro-robotics. It is certainly clear that the extent of applications of IPMCs goes beyond the scope of this paper. However, it presents the spectrum of such applications of IMPCs as soft actuators. Most of the work reported in robotics uses the IPMC as a simple actuator while the robot body is made from other materials [33,34,35,36,37,38].

The most important advantage of such IPMC actuators over conventional actuators is the softness of the membrane material. IPMC actuators have the ability to bend to a very large range, which is over 360 degrees [3]. The features of IMPC actuators make them useful for receiving haptic feedback during actuation because they can actuate and then sense, while only requiring a small voltage (bio-friendly) while generating large output sensing signals [39]. The IPMC actuator application study for optical lenses describes an IPMC actuator integrated into an intraocular lens (IOL) system.

The underwater microrobot is also a novel potential application of the IPMC. There are several studies on underwater propulsion robots using IPMC actuators. For example, in [40], the authors developed a propulsion robot using an IPMC actuator as a fin to generate a forward impelling force. Another work presents a fish-like microrobot that uses two actuators for right and left turns [41].

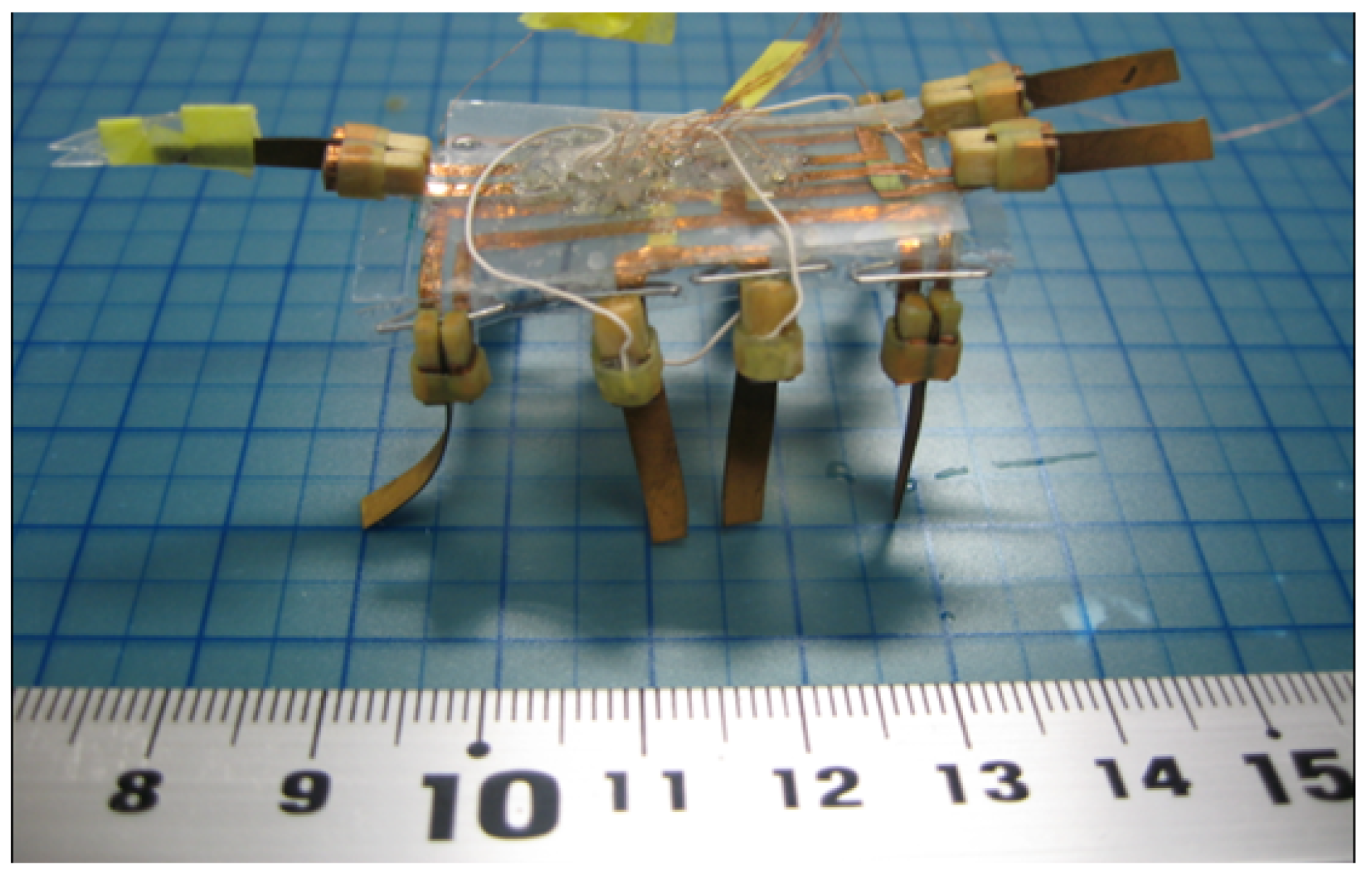

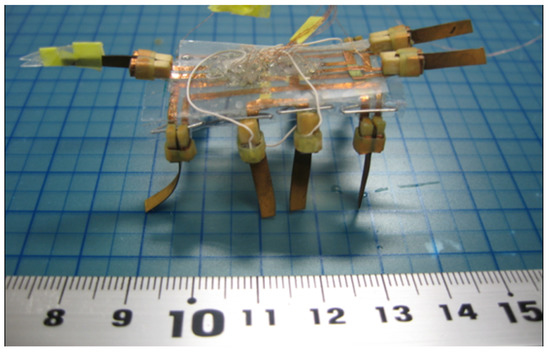

Figure 3 shows a prototype hybrid underwater soft biomimetic IPMC microrobot. The robot body was built with eleven IPMC actuators (two IPMC fingers, one tail, and eight IPMC legs) [42]. To date, multi-finger grippers that consist of two, four, and eight fingers have been produced. In [43] the authors proposed a three-fingered gripper in which each finger was an actuator, and each finger was actuated individually. As soft actuators, IPMCs can be applied in robotic optical systems, such as an auto-focus compact camera module and a tilting actuator for an endoscope [44,45]. Additionally, Tripathi et al. [46] developed an IPMC actuator that was used as a prototype for an active catheter-guidewire maneuvering application. The IPMC has some excellent characteristics for robotic applications compared with other soft polymer actuators as follows [47]:

Figure 3.

The prototype of IPMC microrobot (source: [42]).

- driven with low voltage (<3 V);

- low power consumption;

- fast response (>10 Hz in water);

- mechanically and chemically durable and stable;

- soft and compliant;

- works in wet conditions (or in water).

While significant progress has been made on new materials for IPMC soft actuators, it is also necessary to develop electrical control strategies at the same time. Based on various studies, the properties of the IPMC material were determined and various control algorithms were proposed. However, some studies showed that these classic strategies were not effective for such a material with highly nonlinear properties. Therefore, various adaptive control systems have recently been designed based on existing models to capture their dynamics and compensate for their changes [48,49,50].

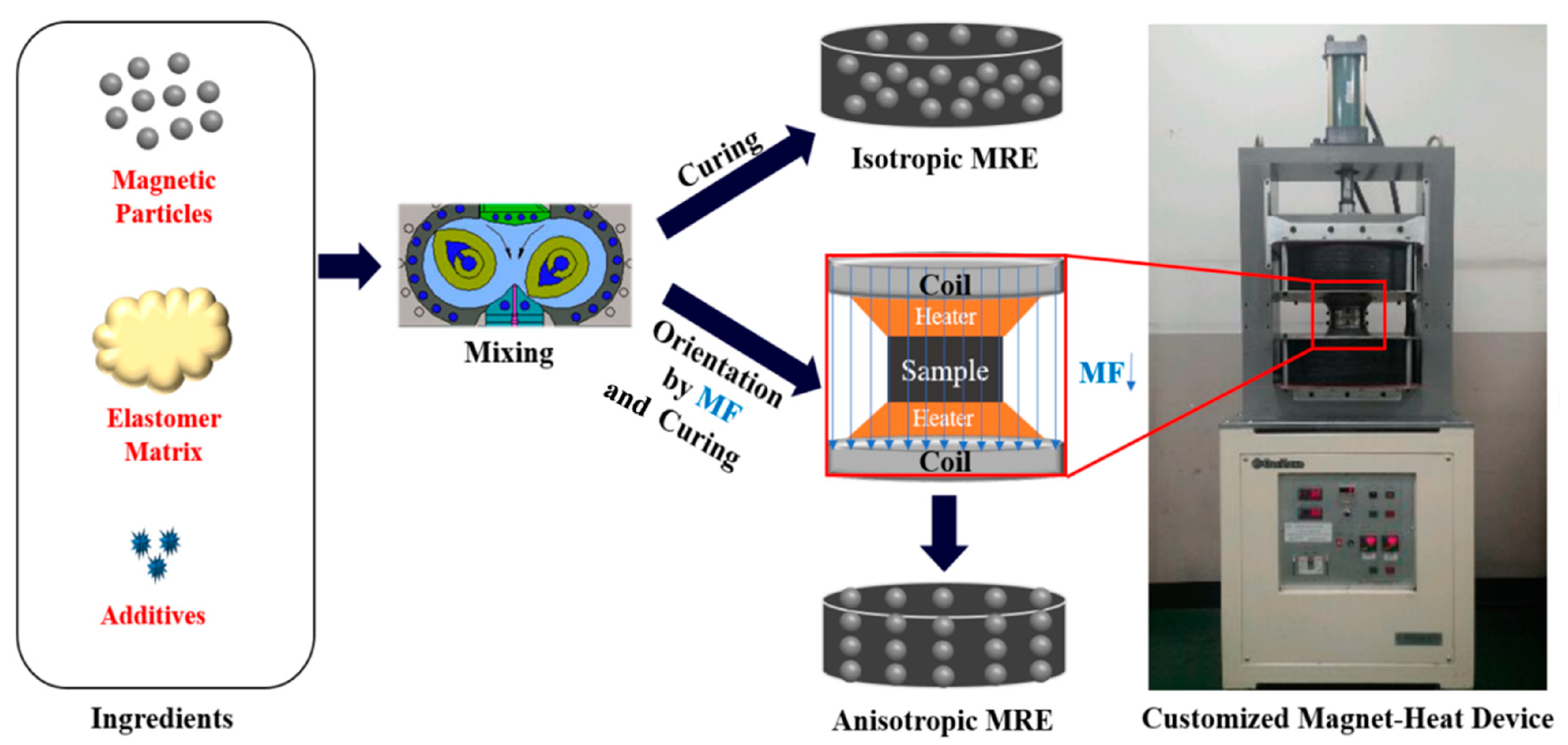

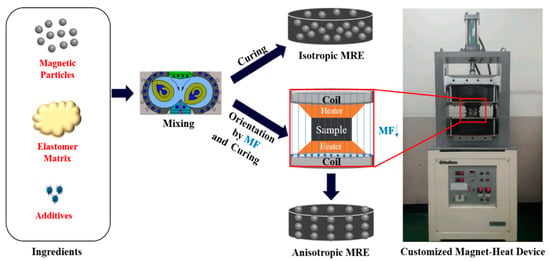

2.2. Dielectric Electroactive Polymers (DEAPs)

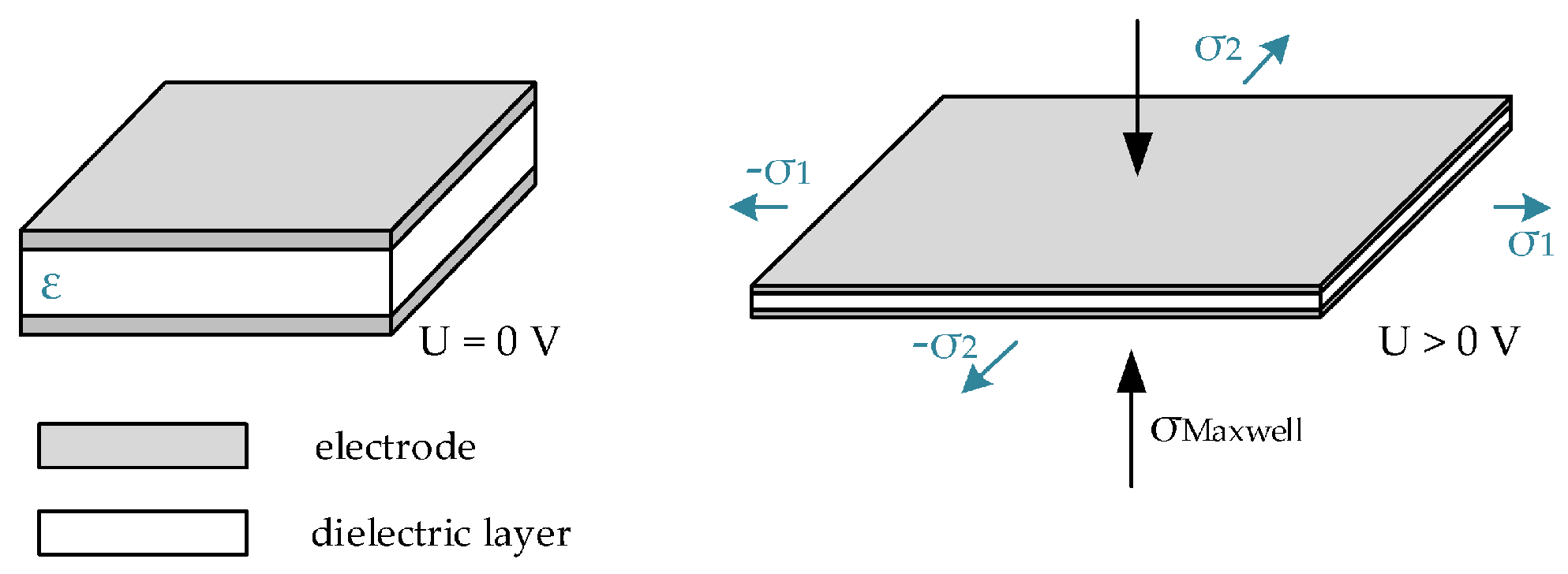

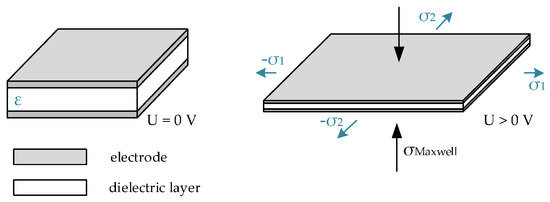

Dielectric electroactive polymer (DEAP) actuators are extensively studied because of their low cost, easy manufacturing, and fast response. The manufacturing costs of the DEAP actuator are low compared to the IPMC actuators discussed in the previous chapter. This applies to both VHB tape and the silicones most often used in the production of dielectric actuators (for example, Silicone Mold Start or Dragon Skin). The materials, as well as a thorough analysis of the methods used to produce dielectric electroactive performance membranes, are discussed in detail by the authors in [51] while for the production of IPMC, the expensive Nafion membrane is used [3]. DEAPs are composed of a soft, thin, dielectric elastomer membrane coated on both sides with conducting electrodes (Figure 4) [52]. This makes the DEAP actuators soft capacitors in terms of design features. When the electrodes are connected to the current, they accumulate the charge and cause the appearance of a Coulomb force between the electrodes. Because the dielectric membrane between electrodes is a highly soft and flexible elastomer, the appearance of the Coulomb force causes its deformation. After the voltage is released, the DEAP restores to the original size. The materials most commonly used as flexible membranes are silicone elastomers [19,53,54], and acrylate elastomers—mainly VHB tape produced by 3M [55,56,57]. Additionally, the literature reports on the use of other materials acting as elastomers in DEAPs could be found, but they are not very common [30,58]. Due to the construction and operation of DEAPs, different directions of their modification can be distinguished. The first concerns the modification of the properties of the dielectric membrane, while the second concerns the modification of the conductive electrodes. Another direction of development of DEAPs is the construction of actuators of various, new shapes and the modeling of their behavior.

Figure 4.

Principle of operation of the DEAP actuator (source: [52]).

2.2.1. Recent Trends in the Modification of DEAPs

VHB elastomer is commercial, widely available acrylic tape produced by 3M company. It is a ready-to-use product that only needs to be covered by electrodes to be used as a DEAP. The use of VHB tape makes it possible to obtain DEAP actuators very quickly (no elastomer synthesis is necessary) with reproducible properties of the dielectric layer (Young’s modulus, flexibility, thickness, dielectric permeability) and dependent only on the degree of pre-stretching of the tape. This gives the opportunity to study, among others, the effect of the composition of the electrodes on the properties of a DEAP [55,56,57]. However, the use of VHB tape has significant limitations. Due to the fact that it is a ready-to-use product, the modification of DEAPs with this elastomer is significantly limited to the modification of the electrode layer. Therefore silicons, next to VHB, are the most important group of elastomers used in the preparation of DEAP actuators. The use of silicone elastomer enables the selection of its composition in a wide range and the easy modification of parameters such as Young’s modulus, flexibility, or thickness of the dielectric layer [6,54]. It also allows the introduction of modifiers into the elastomer that change its mechanical or dielectric properties. This makes it possible to obtain DEAPs with very different properties. The synthesis and modification of DEAPs using silicone elastomers is currently the most popular research direction in the literature. In addition to VHB and silicone elastomers, the information on the use of other polymers for dielectric membranes to obtain DEAP, such as polyurethane elastomers [58] or elastomers based on poly(styrene-b-butyl acrylate-b-styrene) copolymer (SBAS) [30], can be found. However, the use of dielectric membranes other than VHB and silicones is currently very uncommon, which may result from a more complicated procedure for their preparation.

Another direction of research on DEAPs is related to the preparation and modification of electrodes. The simplest method of obtaining an electrode on the surface of an elastomer is the use of carbon grease [56,59]. However, this method does not allow for precise control of its properties, including thickness or mechanical properties. In addition, the use of carbon grease means that after the application of the electrode, it has the consistency of grease all the time (does not dry), which makes it difficult to manipulate the DEAP actuator. Therefore, other materials that can be used as electrodes are often applied, for example, carbon nanotubes [54,55], carbon powder [60], and others [6,57].

A significant disadvantage of DEAP actuators is the necessity of high driving voltage application, in the range of several kV, which limits their application in the devices. Therefore, much attention has been paid to reducing the driving voltage of DEAPs. This can be achieved by reducing the thickness of the actuator (both the dielectric layer and electrodes), increasing the dielectric permittivity, and reducing the modulus of the elasticity of the actuator [61,62]. Reducing the driving voltage below 100 V requires reducing the thickness of the DEAP to a few µm or even less than 1 µm, however, such a significant reduction in the DEAP thickness results in a reduction in power density [6]. The solution to this problem may be a construction of a stacked DEAP multi-layer actuator [54,63], but this requires precise and sophisticated methods of DEAP production.

Z. Ren et al. present the fabrication method and results of investigations of multi-layer DEAP actuators [54]. The authors show that proper fabrication of DEAPs allows obtaining actuators composed of 6 to 20 layers with the thickness of each silicone-based dielectric layer about 36 to 10 µm and the thickness of electrodes equal to 30 nm. Fabrication of such thin multi-layer DEAPs allows for a decrease in the operating voltage to about 500 V and exceeds the DEAP lifetime to 2 million actuation cycles. Another example of thin DEAP actuator fabrication is investigations presented by A. Wiranata et al. [6]. The authors present DEAPs with a 600 nm thick silicon membrane covered by 200 nm thick electrodes composed of poly(3,4-ethylenedioxythiophene):poly(4-styrenesulfonate) (PEDOT:PSS). The application of such a thin dielectric membrane allows DEAPs to operate at a voltage of about 70 V. That low voltage increases the safety and decreases the complexity of the electric circuit required to drive the DEAP. DEAP thickness reduction is an important direction of current research in this field.

Another direction of studies, which in the near future may become more and more important, is the use of dielectric membranes other than silicone or VHB tape. J. He et al. present the DEAP fiber actuator with a dielectric elastomer of poly(styrene-b-butyl acrylate-b-styrene) (SBAS) (elastomer thickness of about 24 µm) with isotropic and anisotropic structure. The DEAP fiber was obtained by rolling the rectangular DEAP with low thickness. Fabricated anisotropic SBAS film exhibits high linear actuation strain and works output energy density. J. Zhu et al. present the application of thermoplastic polyurethane–styrene ethylene butylene styrene (SEBS/TPU) blend as a dielectric membrane for DEAP preparation [30]. The obtained DEAP presents improved maximum actuation strain and electrical breakdown strength Z. Kang et al. [64] present the DEAP actuator with dielectric elastomer obtained with thiol–ene reaction of mercaptopropyl silicone with 1-vinylimidazole and later crosslinked with 1,12-dibromododecane. As a result, imidazole-grafted silicone has been developed and applied as a dielectric layer. Synthesized polymers have much higher relative permittivity in comparison with standard silicon membranes. The presented papers show that the application of new elastomers as a dielectric membrane in DEAPs can improve their properties, and this is a promising direction for future research.

2.2.2. Actual Trends in the Application of DEAP in Soft Robotics

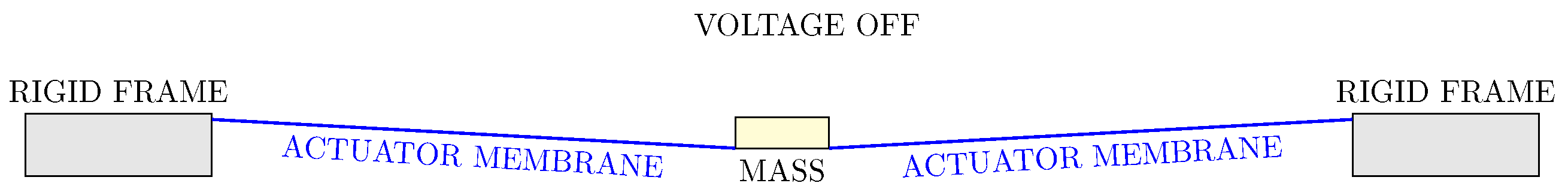

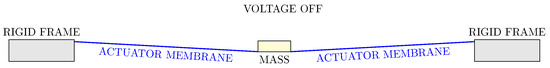

The principle of operation of the actuator is similar to the electromechanical transduction of a parallel two-plate capacitor. When an electric potential is applied across the polymer membrane coated with compliant electrodes on both sides, the material is compressed in thickness and expands in the lateral direction. This process is well explained in many publications [47,65,66,67]. Figure 5 and Figure 6 show graphically how the actuator membrane stretches under the influence of the applied voltage.

Figure 5.

Diagram of DEAP actuator with power off.

Figure 6.

Diagram of DEAP actuator with power on.

Due to this design, a mechanical actuating force is generated. The effective mechanical pressure, called Maxwell stress along the thickness direction, is given by the formula (1):

where E is applied electric fields, is electric permittivity of free space and is the relative permittivity.

In recent years, a lot of research has been carried out to improve the parameters of DEAP actuators by adding initial mechanical stress to the polymer membrane [68,69]. Through theoretical modeling and numerical analyses, it is revealed that pre-stretch helps to reduce the drive voltage required to induce a desired bending deformation. Pre-stretching the actuator membrane improves the response speed and removes the boundary constraint caused by the inactive actuation area of the actuator. He et al. investigated the effects of pre-stretch on the bending deformation of the DEA actuator [70]. In [71], cyclic tensile properties of VHB4905 and VHB4910 were investigated, and the actuation displacement and output force of the DEA are analyzed and discussed in detail with different pre-stretching indexes. It has been shown, that the stress–strain curves of VHB materials show hysteresis under cyclic loading. The thinner the thickness of the VHB, the larger the unit stress and the unit hysteresis loss rate. The hysteresis in DEA materials, resulting in nonlinearities of the system, limits their performance when operating in an open-loop configuration. So pre-strain plays an important role in generating large strain, however, there are several disadvantages due to the pre-strain, such as stress relaxation and hysteresis. Their ranges depend on the materials used and are still a key issue for the actuator.

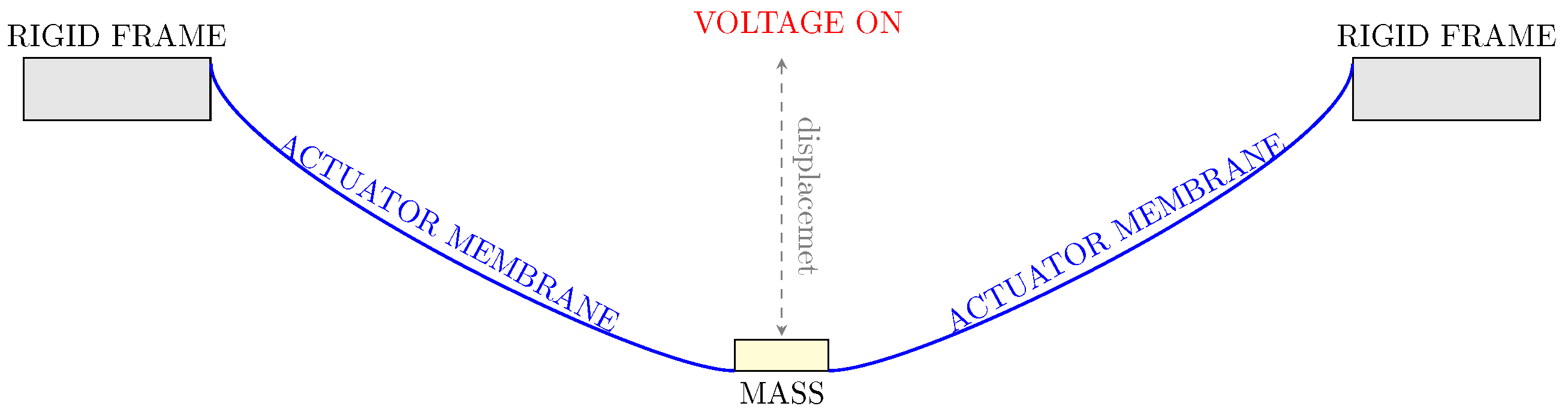

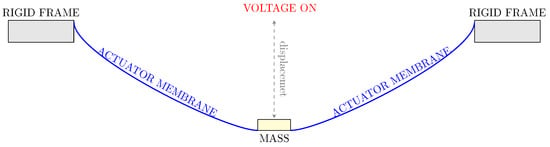

DEAP actuators can provide quiet operation, low weight, high power density, and fast response. These features have enabled these actuators to be used in robotics and haptic applications. In work [72], the authors demonstrate a rolled dielectric elastomer actuator being used as a telepresence device in a heartbeat measurement application. While at work [73] it is proposed a thin, highly flexible, and lightweight vibrotactile dielectric elastomer actuator, which is experimentally optimized to provide a variety of haptic sensations in real time (see Figure 7).

Figure 7.

Proposed flexible vibrotactile actuator based on dielectric elastomer: overall structure of the proposed actuator and assembled vibrotactile actuator (a); the bottom surface of the upper layer (b); proposed actuator attached to a foldable smartphone (c) (source: [73]).

Pei et al. [74] developed two kinds of six-legged robots based on the spring roll actuator. In the field of soft robots, grasping objects of different shapes and types is one of the most challenging problems. Araromi et al. [75] presented a new design of DEA with multisegments. The repetitive segments enable the gripper to grab objects of different sizes and shapes.

The crucial aspect of DEAP actuators is the type of bias. Based on the early works on DEAP actuators, it is known that properly applied bias can extend its working range. In the literature, the following types of bias are known: mass, linear spring, negative non-linear spring with positive linear spring, permanent magnet, and pneumatic [76,77,78,79,80]. Currently, the best result in terms of the working range is obtained by combining a negative non-linear spring with a positive linear spring [81]. The nonlinear bias can be applied to obtain a fast movement like in work [82], where the inspiration is taken from biological systems. The interesting result is also magnetic, where two magnets attract to each other, causing the movement of the DEAP membrane [67,80,83]. In comparison to the mechanical spring, the connection by two magnets is done by a magnetic field. Lately, the cone actuator is analyzed in various configurations. The most popular combination is the single membrane and a bias. However, in recent times the advantage of the double cone has shown higher power efficiency [84,85].

The typical application of a DEAP is an intelligent actuator with a single input as voltage and single output as displacement or force. As described above, most DEAP actuators work with applied bias. This kind of structure can be applied to various devices like actuators, pumps, or loudspeakers [80,86,87]. As an example, we can see the pump designed for soft robotics application, which is studied in [80]. Another example is shown in [88], where the actuator applied in the rehabilitation system is presented. It is also possible to create a linear DEAP actuator as presented in [89].

2.3. Magnetorheological Elastomers (MRE)

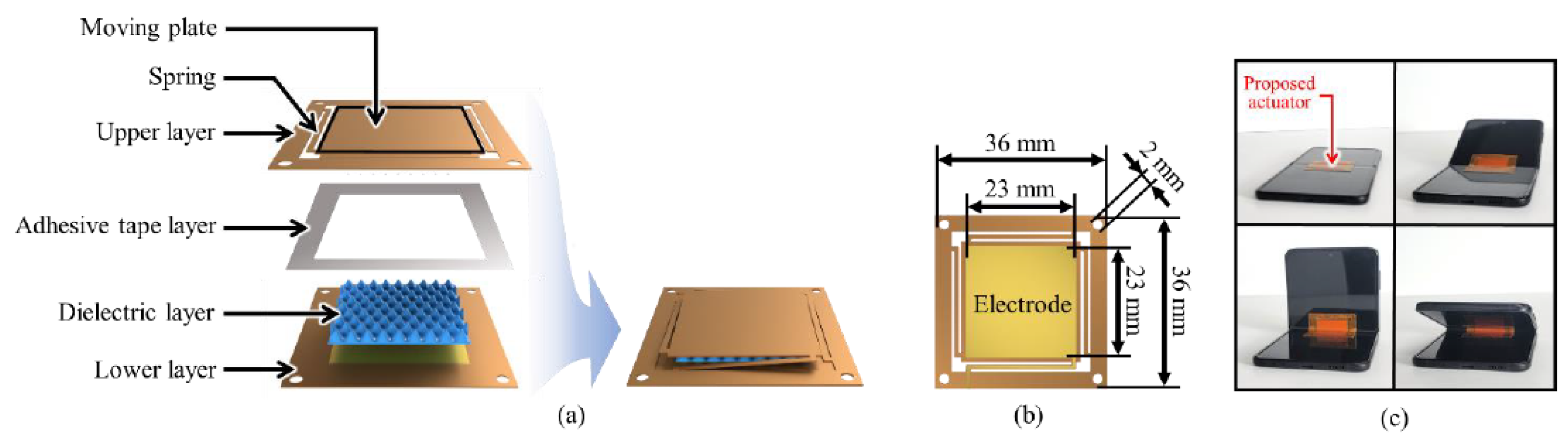

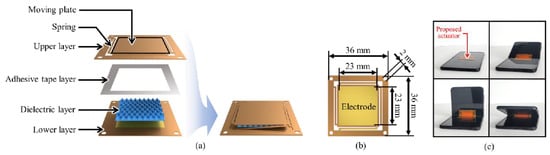

Magnetorheological elastomers (MREs) are composed of non-magnetic elastomeric polymer matrix filled with magnetizable particles and other additives (not always present in MREs). The elastomer selection plays a very important role as it greatly affects the mechanical properties of the MRE, such as Young modulus, elasticity, hardness, etc. Therefore, polymeric elastomers such as silicons [90,91,92,93,94], polyurethanes [95,96], natural rubber [97,98,99] and other rubbers [100,101] are used. However, silicons, thanks to the possibility of selecting their mechanical properties in a wide range, ease of handling and processing, wide range of operating temperature, non-toxicity, and aging resistance, are the most commonly used polymer matrices for MRE fabrication. The second key component of MREs is magnetic particles. They are responsible for the interaction of the MRE with the magnetic field. Nowadays, carbonyl–iron powder (CIP), due to its high saturation magnetization and a wide range of particle size availability, is the most commonly used magnetic filler in MRE preparation. Apart from CIP, other magnetic fillers are used, such as cobalt, cobalt ferrites, nickel, magnetite (Fe3O4), and others [90,94,98,101,102,103]. Various non-magnetic modifiers can be added to improve the mechanical properties of MREs, including reinforcements, plasticizers, cross-linking agents, and more. The fabrication of MREs is similar to the fabrication of conventional elastomers containing fillers. The MRE manufacturing process involves mixing magnetic particles with an elastomeric resin and then curing it to produce an isotropic MRE. However, due to the interaction of the magnetic particles in the magnetic field, it is possible to apply an external magnetic field to force the magnetic particles to orient in space and then cure the resin. In this case, the resulting MRE will be anisotropic (Figure 8) [104].

Figure 8.

Diagram showing the production process of isotropic and anisotropic MREs (source: [104]).

2.3.1. Actual Trends in the Modification of MREs

Due to the composition of MREs, we can distinguish two basic directions of their development in order to improve the response performance to the magnetic field. The first direction is the selection and modification of the polymer matrix, while the second is the selection and modification of the magnetic particles. The selection of the appropriate polymer matrix is an extremely important stage of MRE preparation. The choice of the polymer matrix is primarily related to its mechanical properties, and, thus, to the dynamic properties of MREs. Generally, a softer polymer matrix leads to higher magnetorheological effects. Other aspects of the polymer matrix or resin before their curing are also important. The viscosity of the resin before curing significantly affects the MRE fabrication, for example, lower viscosity facilitates the orientation of magnetic particles in the magnetic field during the preparation of anisotropic MREs or improves the miscibility of the magnetic particles with the resin. Other factors are also important, such as aging resistance, the ability to stably disperse magnetic particles, as well as price and availability. The listed properties of polymer matrices and resins for their preparation can be additionally modified by various types of additives, such as plasticizers [8,105], carbon additives (carbon nanotubes, carbon black, graphite, graphene) [106,107], and others. Each additive enhances the magnetorheological effect in a different way

M. H. A. Khairi et al. [8] have investigated the influence of silicon oil plasticizers on MRE properties. It has been shown that the increasing content of silicon oil causes a decrease in the zero-field storage modulus and an increasing relative magnetorheological effect for both isotropic and anisotropic MREs.

Magnetic properties, on the other hand, can be adjusted by introducing compounds with different magnetic properties as well as introducing modified magnetic compounds. One of the directions of investigation presented in the literature is the application of different magnetic fillers themselves, or as modifiers for an MRE containing CIP. G. W. Kim et al. [108] and V. Kumar et al. [103] present the application of Fe2O3 while D. Balogh et al. [102] and C. Shen et al. [101] present the application of Fe3O4 nanoplates as magnetic filler. S. Tahir et al. [94] present the influence of Ni and Co powder additive on the properties of MREs. However, keep in mind, that the additives of magnetic fillers have an influence on the magnetic as well as mechanical properties of MRE, which allows for modification of the properties of the MREs depending on their application.

A good example of the investigation presenting both the influence of plasticizer–silicon oil and magnetic modifier–CoFe2O4 additives in the MRE (silicone-based + CIP) properties was presented by M. H. A. Khairi et al. [105]. It was shown that the introduction of CoFe2O4 increases the magnetic properties, but also the hardness and elasticity modulus, while the introduction of plasticizer gives the opposite effect. An MRE with the best properties was obtained after the introduction of both modifiers—plasticizer and CoFe2O4.

An interesting course of research that may gain popularity may also be the use of 3D printing [109,110,111,112]. 3D printing allows fabrication of the MRE with sophisticated shapes. It is a very interesting method of MRE fabrication that may gain popularity in this field of research in the near future and it could be expected that the number of papers describing the application of 3D printing will increase.

2.3.2. Actual Trends in the Application of MRE in Soft Robotics

The magnetorheological elastomers respond to the external magnetic field with the change of material properties and deformation, which has contributed over the last 20 years to the construction of devices that are widely used in industry and research [2,4,113]. Firstly, we consider the different response types of the MRE material under a magnetic field. The most popular property used for MRE applications is to change its mechanical stiffness by turning on/off the magnetic field. This phenomenon is used in the construction of passive and active vibration control systems [113]. However, various MRE responses to the magnetic field have recently become increasingly popular. The magnetic field can ensure that the MRE deforms linearly or radially. It is applicable in building valves, pumps, and robotics systems [2,4]. In the following sections, we will discuss the novel applications of MREs in these fields.

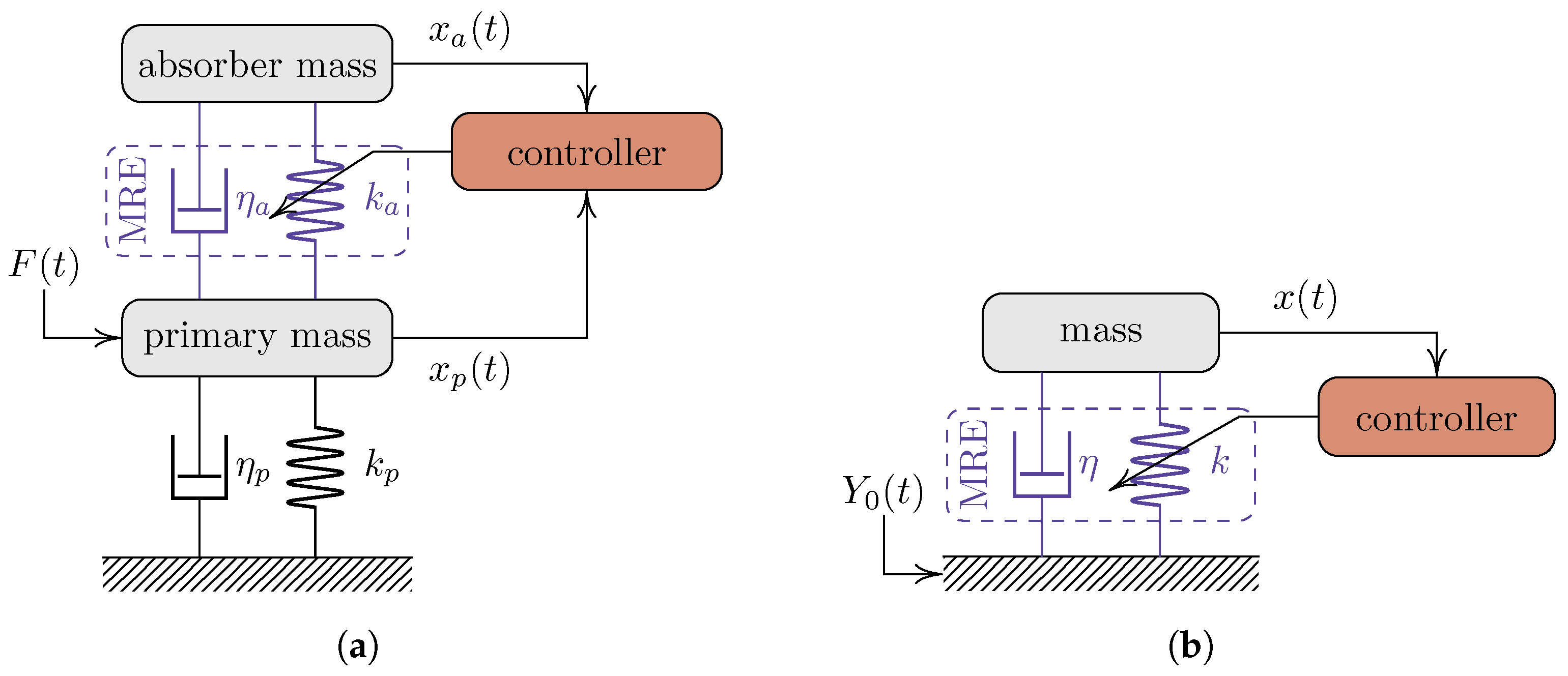

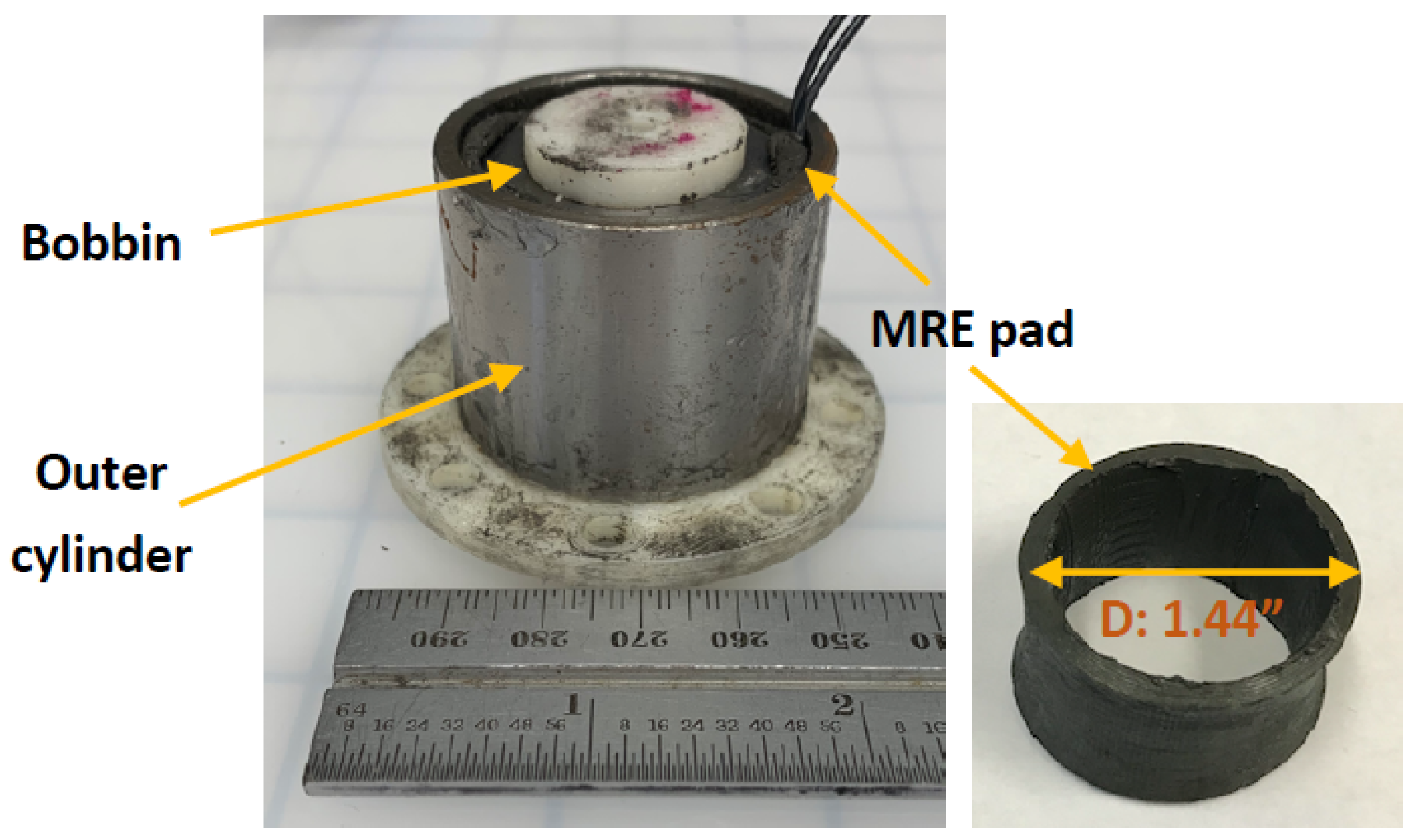

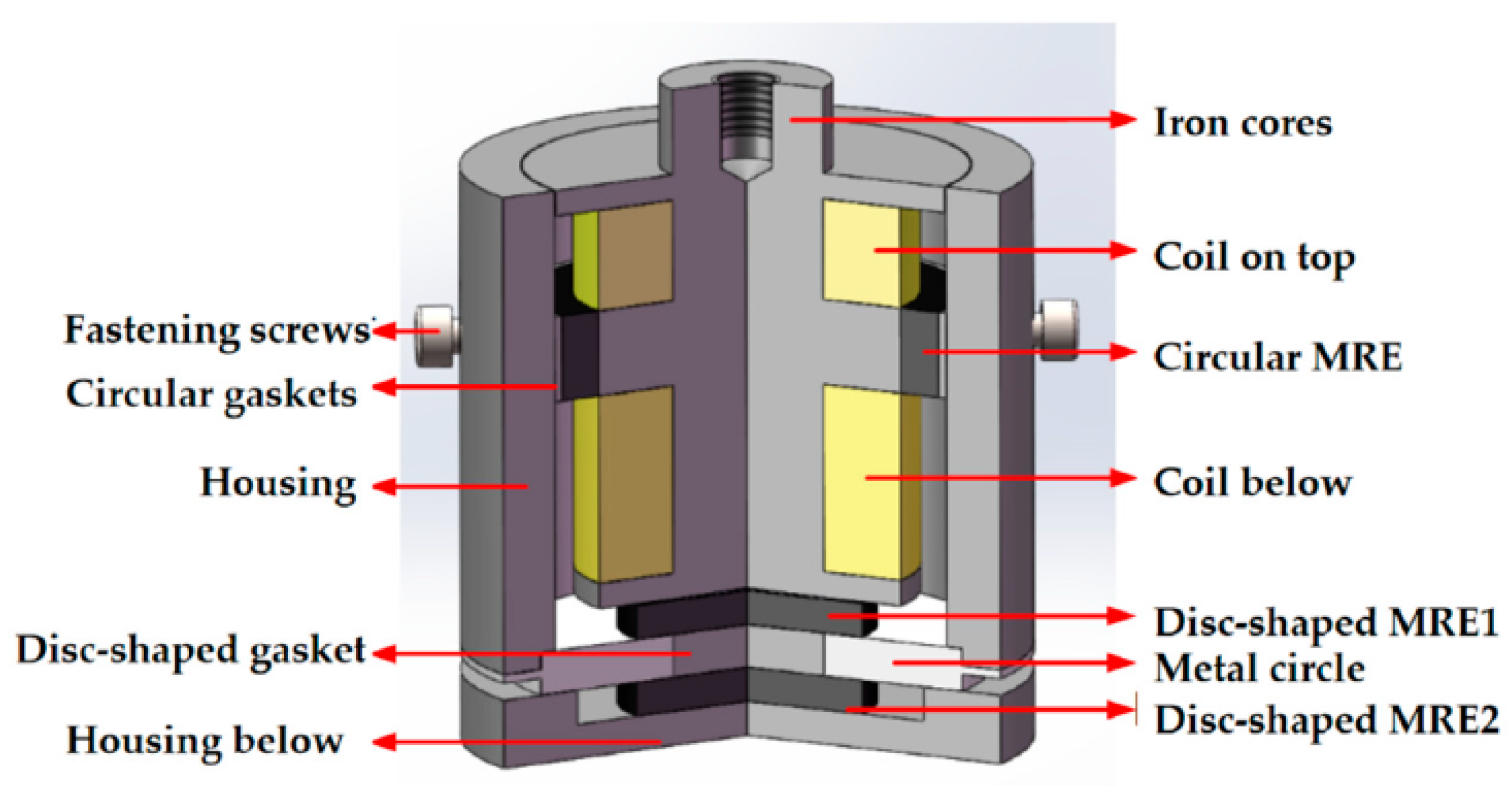

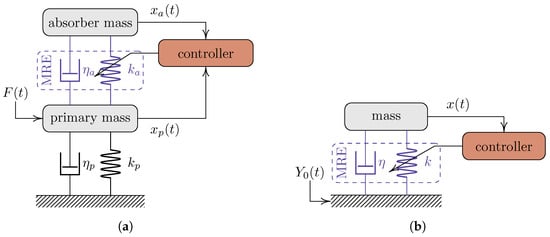

One of the most important applications of MREs is the vibration systems [113]. The property of variable stiffness under a magnetic field allows the construction of active vibration absorbers or insulators. The principle of the operation of absorber and insulator is presented in Figure 9. The construction of both device types has similar elements, however, their definitions are different. The main goal of these devices is to attenuate the vibrations. Firstly, the passive solutions were applied, which have constant frequency characteristics. This means that the operation can be desired for a specific frequency. The application of varying stiffness allowed extending the working range. This type of MRE application has been widely known for the last 20 years. In recent times, the new applications of absorbers are found in works [114,115,116]. The main feature of these applications is working in a high-frequency zone [114], extending with control systems based on the Hilbert–Huang transformation [115], designing torsional absorber for power train system [116], tuning to variable-frequency excitation [117,118]. The example of a vibration absorber is presented in Figure 10, which was presented in work [114]. Furthermore, the applications of insulators are also still developing as in [119]. In these devices, the new direction of research is designing advanced controllers like fuzzy PID [119], integrating the MRE insulator in new extended mechanical structures [120]. The example of an insulator is presented in Figure 11. Additionally, the MRE’s universality allows the building of custom MREs devices as in works [121,122,123,124], where the unique features of MREs allow to solve advanced problems from vibration control. From the authors’ point of view, the vibration control systems are well-analyzed with multiple applications.

Figure 9.

The schema of typical vibration control systems. The vibration absorber (a). The vibration isolator (b).

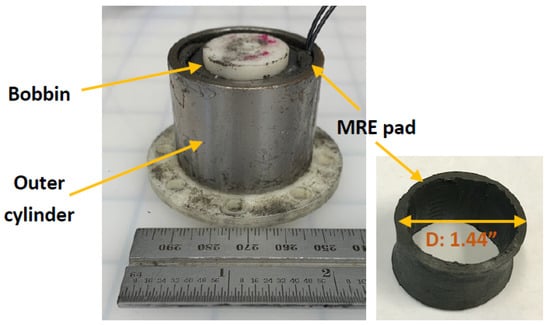

Figure 10.

The example of a vibration absorber designed for working in the high-frequency range (source: [114]).

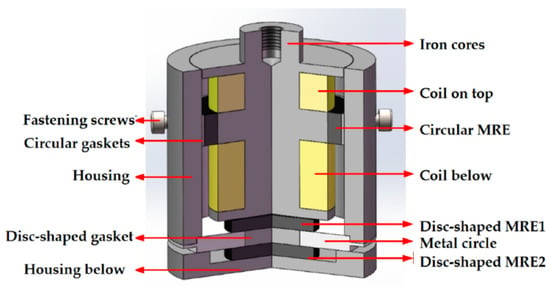

Figure 11.

The example of vibration insulator (source: [119]).

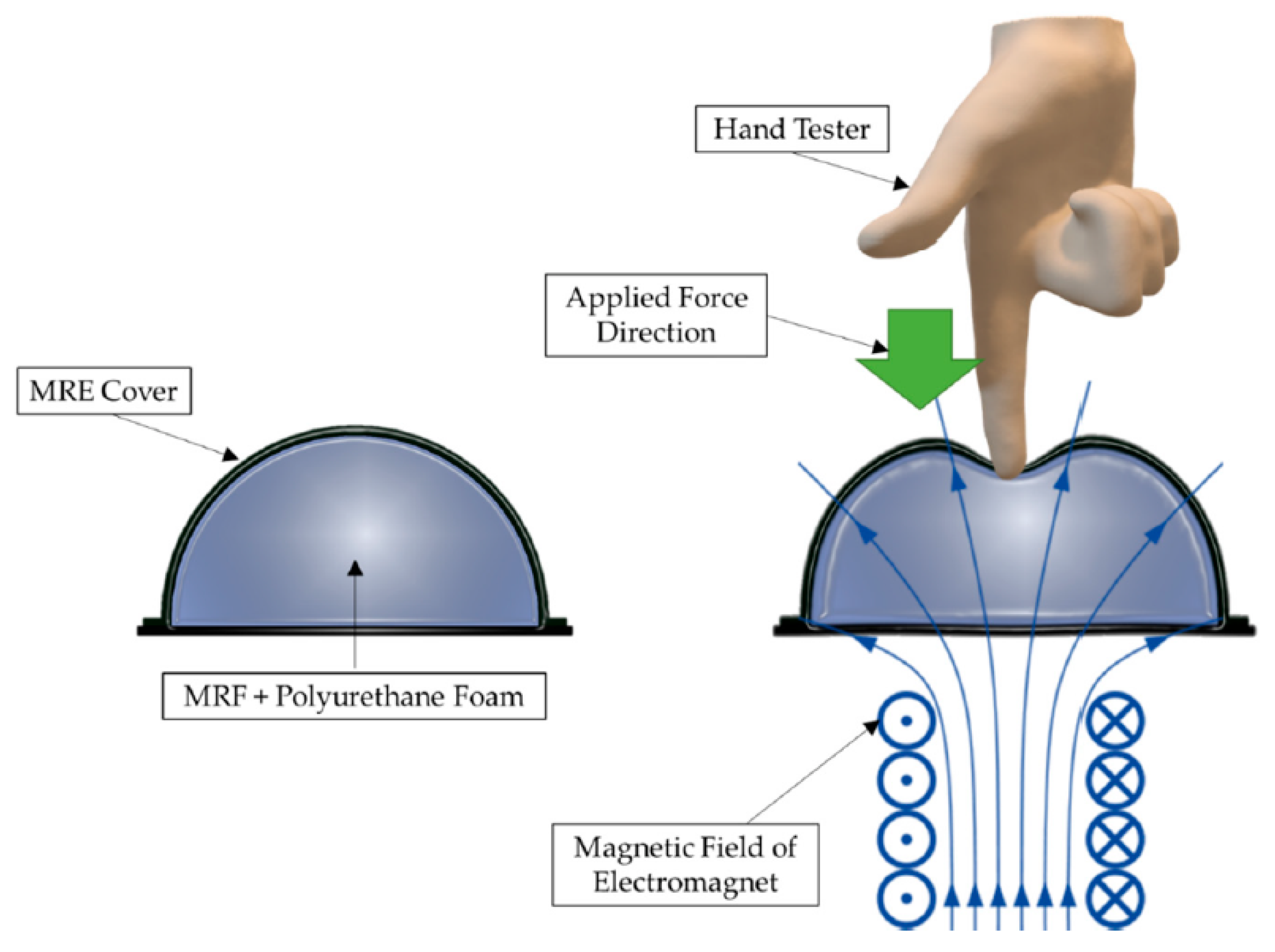

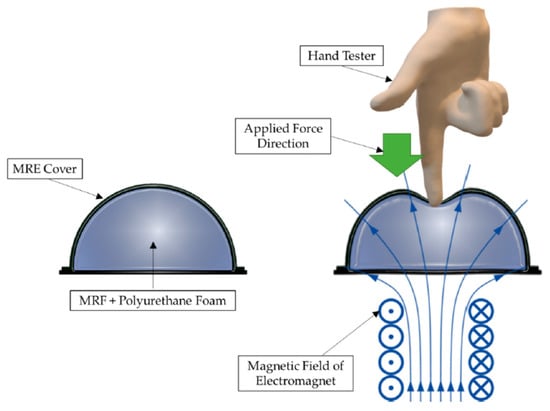

Alternatives to the vibration control systems presented in the previous paragraph are the MRE devices actuated to produce radial stretch, linear movement, or custom shape bending. In the group of devices using the radial stretch is the proportional valve presented in [2]. The linear movement can be applied in haptic devices to create varying stiffness buttons [2]. In this area, the recent developments are the application of MREs in robotics. The interesting applications are especially for grippers [125,126,127,128,129]. In the study [128], MRE and magnetorheological fluid (MRF) materials are used to prepare a universal gripper that enables catching various objects. In [130], the grippers with soft skin are prepared to allow for fitting the gripper finger to hold an object. In [126], the preliminary concept of the soft gripper is examined with fully soft fingers. In [127], the new MRE material prepared using direct ink writing 3D printing technology is applied to build the soft grippers activated with a magnetic field. An interesting application of MREs in robotics is proposed in the work [129], where the suction cup is created to build the climbing robot. Another application of MREs in robotics is haptic devices. The haptic devices are made in robotics systems to allow remote surgery [131,132,133], an example is presented in Figure 12. In our opinion, the use of MREs in robotics is currently being widely developed, and new types of applications are being sought.

Figure 12.

The example of haptic device (source: [131]).

3. Conclusions

This work has reviewed recent studies on the preparation and application of soft actuators controlled by electrical stimuli, i.e., ionic polymer metal composites, dielectric electroactive polymers, and magnetorheological elastomers. Stimulating these materials with electricity is a very convenient way to get them to work because this power source is the most readily available of all others. In addition, softness, flexibility, and small thickness, thanks to which they are light, and the ease of changing the properties by appropriate selection of polymer (using compounds with different structures and with different amounts) or filler, make soft actuators promising materials for applications in advanced automation and robotic systems. The brief summary of the advantages and disadvantages of all described materials is given in Table 1. The types of elastomer (flexible, soft polymer), as well as types of filler used for obtaining these kinds of materials and their improvements, are presented. Additionally, improvement by modification of other parts of soft actuators as electrodes is shown.

Table 1.

Advantages and disadvantages of IPMCs, DEAPs, and MREs.

In the latter, the modification of Nafion with carbon nanotubes or the use of conductive polymers (e.g., PEDOT) can replace metal electrodes for polymer membranes in IPMC actuators. The other way is electroless plating of the metal electrode on the surface of the ionomer using the chemical reduction of metal cations such as Ag+ (much cheaper than platinum or palladium) or lately other metals such as Cu or Ga/In. The future aspect of an IPMC is to increase the force versus volume ratio.

In DEAP materials, multilayer systems decrease operating voltage and extend the lifetime of the prepared actuator. The improvement of the membrane properties can be realized by the addition of various types of fillers, reinforcements, or plasticizers that can modify mechanical and electrical properties, output force, deformation rate, or displacement of known polymers. Another way to modify these materials is the synthesis of new types of elastomers with polymerization or copolymerization. This is an easy way to prepare membranes with designed properties using e.g., an appropriate selection of monomers and their concentration for synthesis. The future aspect of DEAPs is to decrease the operating voltage and increase the permittivity without losing the stretch ratio. Furthermore, the possibility of developing new actuators with custom shapes seems to be insufficiently used.

The most important challenge in MREs is to improve their permeability (so as to improve its possibility for energy storage) without losing flexibility. In this area, the anisotropic character of magnetic material is exploited. Furthermore, in a robotics system like a gripper, it is important to overcome the low response of MREs if the source of the magnetic field is far away.

Currently, the most promising method of preparing soft actuators seems to be 3D printing. It offers great possibilities for the design of actuators of various shapes, sizes, and thicknesses. Preparing soft actuators using 3D printing takes less time than the conventional method and is less expensive, as well as easy to use. It is therefore expected that this method will be extensively developed in the near future.

Author Contributions

J.B., P.G., J.K., and A.M. contributed equally to this work. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Ministry of Science and Higher Education.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict to interest.

References

- Bar-Cohen, Y. Electroactive Polymer (EAP) Actuators as Artificial Muscles: Reality, Potential, and Challenges; SPIE Press: Bellingham, UK, 2001. [Google Scholar]

- Böse, H.; Gerlach, T.; Ehrlich, J. Magnetorheological elastomers—An underestimated class of soft actuator materials. J. Intell. Mater. Syst. Struct. 2021, 32, 1550–1564. [Google Scholar] [CrossRef]

- Park, S.W.; Kim, S.J.; Park, S.H.; Lee, J.; Kim, H.; Kim, M.K. Recent Progress in Development and Applications of Ionic Polymer–Metal Composite. Micromachines 2022, 13, 1290. [Google Scholar] [CrossRef] [PubMed]

- Bira, N.; Dhagat, P.; Davidson, J.R. A Review of Magnetic Elastomers and Their Role in Soft Robotics. Front. Robot. AI 2020, 7. [Google Scholar] [CrossRef] [PubMed]

- Rosset, S.; Araromi, O.A.; Schlatter, S.; Shea, H.R. Fabrication Process of Silicone-based Dielectric Elastomer Actuators. JoVE 2016, 108, e53423. [Google Scholar] [CrossRef]

- Wiranata, A.; Kanno, M.; Chiya, N.; Okabe, H.; Horii, T.; Fujie, T.; Hosoya, N.; Maeda, S. High-Frequency, low-voltage oscillations of dielectric elastomer actuators. Appl. Phys. Express 2022, 15, 011002. [Google Scholar] [CrossRef]

- Xu, B.; Wang, S.; Zhang, Z.; Ling, J.; Wu, X. Improving the torsion performance of IPMC by changing the electrode separation. Sci. Rep. 2021, 11, 7639. [Google Scholar] [CrossRef]

- Khairi, M.H.A.; Fatah, A.Y.A.; Mazlan, S.A.; Ubaidillah, U.; Nordin, N.A.; Ismail, N.I.N.; Bok-Choi, S.; Aziz, S.A.A. Enhancement of Particle Alignment Using Silicone Oil Plasticizer and Its Effects on the Field-Dependent Properties of Magnetorheological Elastomers. Int. J. Mol. Sci. 2019, 20, 4085. [Google Scholar] [CrossRef]

- Yin, G.X.; He, Q.S.; Yu, M.; Wu, Y.W.; Xu, X.R. Ionic polymer metal composites actuators with enhanced driving performance by incorporating graphene quantum dots. J. Cent. South Univ. 2022, 29, 1412–1422. [Google Scholar] [CrossRef]

- Ru, J.; Zhao, D.; Zhu, Z.; Wang, Y. Fabrication and Characterization of a Novel Smart-Polymer Actuator with Nanodispersed CNT/Pd Composite Interfacial Electrodes. Polymers 2022, 14, 3494. [Google Scholar] [CrossRef]

- Qin, L.; Gong, C.; Hafezi, M.; Mawignon, F.J.; Huang, X.; Zeng, Q.; Zhang, Y.; Dong, G. Carboxylic Multi–Walled Carbon Nanotubes as Reinforcing Fillers in Ionic Polymer–Metal Composite Actuators with Enhanced Driving Performance. Adv. Eng. Mater. 2022, 24, 2200008. [Google Scholar] [CrossRef]

- Zhao, D.; Ru, J.; Wang, T.; Wang, Y.; Chang, L. Performance Enhancement of Ionic polymer–metal Composite Actuators with Polyethylene Oxide. Polymers 2021, 14, 80. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Shao, J.; Zhang, Z.; Liang, B.; Liu, X. Preparation and characterization analysis of carbon nanotubes and graphene electrode modified carbon nanotubes reinforced IPMC. Adv. Mech. Eng. 2021, 13, 168781402110407. [Google Scholar] [CrossRef]

- Engel, K.; Kilmartin, P.A.; Diegel, O. Additive manufacture of ionic polymer–metal composite actuators using digital light processing techniques. Rapid Prototyp. J. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Luqman, M.; Anis, A.; Shaikh, H.M.; Al-Zahrani, S.M.; Alam, M.A. Synthesis, Characterization and Fabrication of Copper Nanoparticles Embedded Non-Perfluorintaed Kraton Based Ionic Polymer Metal Composite (IPMC) Actuator. Actuators 2022, 11, 183. [Google Scholar] [CrossRef]

- Luqman, M.; Anis, A.; Shaikh, H.M.; Al-Zahrani, S.M.; Alam, M.A. Development of a Soft Robotic Bending Actuator Based on a Novel Sulfonated Polyvinyl Chloride-Phosphotungstic Acid Ionic polymer–metal Composite (IPMC) Membrane. Membranes 2022, 12, 651. [Google Scholar] [CrossRef]

- Luqman, M.; Shaikh, H.; Anis, A.; Al-Zahrani, S.M.; Hamidi, A.; Inamuddin. Platinum-coated silicotungstic acid-sulfonated polyvinyl alcohol-polyaniline based hybrid ionic polymer metal composite membrane for bending actuation applications. Sci. Rep. 2022, 12, 4467. [Google Scholar] [CrossRef]

- Luqman, M.; Shaikh, H.M.; Anis, A.; Al-Zahrani, S.M.; Alam, M.A. A Convenient and Simple Ionic polymer–metal Composite (IPMC) Actuator Based on a Platinum-Coated Sulfonated Poly(ether ether ketone)-Polyaniline Composite Membrane. Polymers 2022, 14, 668. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, Y.; Bansode, A.; Lou, X.; Zhang, X.; Beckingham, B.S.; Auad, M.L. 3D–Printed Poly(acrylic acid–vinylimidazole) Ionic Polymer Metal Composite Actuators. Macromol. Mater. Eng. 2022, 2200440. [Google Scholar] [CrossRef]

- Burawudi, K.K.; D’Anniballe, R.; Langius, R.G.; Carloni, R. A Comparative Study of Predictive Models for Nafion-117 IPMC Soft Actuators. In Proceedings of the 2021 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Delft, The Netherlands, 12–16 July 2021; pp. 1124–1129. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, H.; Lin, Z.; Ma, S.; Ren, L.; Ren, L. High Specific Surface Area Pd/Pt Electrode-Based Ionic Polymer–Metal Composite for High-Performance Biomimetic Actuation. ACS Sustain. Chem. Eng. 2022, 10, 2645–2652. [Google Scholar] [CrossRef]

- Omiya, M.; Kurokawa, M. Deformation mechanism of hydrogen-assisted ionic polymer metal composite actuator. Mech. Adv. Mater. Struct. 2021, 1–11. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, Y.; Liang, Y.; Wang, M.; Ma, S.; Ren, L. Electromechanical performances of IPMC actuator enhanced by high-quality Pd/Pt electrodes. In Proceedings of the 2021 27th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Shanghai, China, 26–28 November 2021; pp. 647–650. [Google Scholar] [CrossRef]

- Xu, Y.; Jia, W.; Zhang, Y.; Wang, F.; Zhao, G.; Zang, D. Mechanical properties analysis and surface composition research of Ag-IPMC. Sens. Actuators Phys. 2021, 319, 112565. [Google Scholar] [CrossRef]

- Biswal, D.K.; Moharana, B.R.; Mohapatra, T.P. Bending response optimization of an ionic polymer–metal composite actuator using orthogonal array method. Mater. Today: Proc. 2022, 49, 1550–1555. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, D.; Zhang, X.; Tian, A. Electroless copper deposition and interface characteristics of ionic electroactive polymer. J. Mater. Res. Technol. 2021, 11, 849–856. [Google Scholar] [CrossRef]

- Yesaswi, C.S.; Sreekanth, P.S.R. Characterisation of Silver-coated Teflon fabric-reinforced Nafion ionic polymer metal composite with carbon nanotubes and graphene nanoparticles. Iran. Polym. J. 2022, 31, 485–502. [Google Scholar] [CrossRef]

- Li, J.; Tian, A.; Wang, X.; Zhai, Z.; Zhang, X.; Feng, B.; Yao, S.; Du, H. Dendrite Growth and Performance of Self-Healing Composite Electrode IPMC Driven by Cu2. ACS Omega 2022, 7, 17575–17582. [Google Scholar] [CrossRef] [PubMed]

- Tian, A.; Li, J.; Wang, X.; Sun, Y.; Zhang, X.; Yao, S.; Du, H. Formation and characterization of Pt-Cu-IPMC with high specific surface area and dendritic electrode. Compos. Interfaces 2022, 29, 1203–1215. [Google Scholar] [CrossRef]

- He, Z.; Jiao, S.; Wang, Z.; Wang, Y.; Yang, M.; Zhang, Y.; Liu, Y.; Wu, Y.; Shang, J.; Chen, Q.; et al. An Antifatigue Liquid Metal Composite Electrode Ionic polymer–metal Composite Artificial Muscle with Excellent Electromechanical Properties. ACS Appl. Mater. Interfaces 2022, 14, 14630–14639. [Google Scholar] [CrossRef]

- Guo, D.; Wang, L.; Wang, X.; Xiao, Y.; Wang, C.; Chen, L.; Ding, Y. PEDOT coating enhanced electromechanical performances and prolonged stable working time of IPMC actuator. Sens. Actuators Chem. 2020, 305, 127488. [Google Scholar] [CrossRef]

- Neuhaus, R.; Zahiri, N.; Petrs, J.; Tahouni, Y.; Siegert, J.; Kolaric, I.; Dahy, H.; Bauernhansl, T. Integrating Ionic Electroactive Polymer Actuators and Sensors Into Adaptive Building Skins–Potentials and Limitations. Front. Built Environ. 2020, 6, 95. [Google Scholar] [CrossRef]

- Shahinpoor, M.; Kim, K. Ionic polymer–metal composites: IV. Industrial and medical applications. Smart Mater. Struct. 2005, 14, 197–214. [Google Scholar] [CrossRef]

- Shen, Q.; Wang, T.; Wen, L.; Liang, J. Modelling and Fuzzy Control of an Efficient Swimming Ionic polymer–metal Composite Actuated Robot. Int. J. Adv. Robot. Syst. 2013, 10, 350. [Google Scholar] [CrossRef]

- Hubbard, J.J.; Fleming, M.; Palmre, V.; Pugal, D.; Kim, K.J.; Leang, K.K. Monolithic IPMC Fins for Propulsion and Maneuvering in Bioinspired Underwater Robotics. IEEE J. Ocean. Eng. 2014, 39, 540–551. [Google Scholar] [CrossRef]

- Du, R.; Li, Z.; Youcef-Toumi, K.; Alvarado, P. Robot Fish: Bio-Inspired Fishlike Underwater Robots; Springer Tracts in Mechanical Engineering, Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Chen, Z. A review on robotic fish enabled by ionic polymer–metal composite artificial muscles. Robot. Biomimetics 2017, 4, 24. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Hou, P.; Ye, Z. Robotic Fish Propelled by a Servo Motor and Ionic polymer–metal Composite Hybrid Tail. J. Dyn. Syst. Meas. Control 2019, 141, 071001. [Google Scholar] [CrossRef]

- Nakano, M.; Mazzone, A.; Piffaretti, F.; Gassert, R.; Nakao, M.; Bleuler, H. IPMC actuator array as a 3D haptic display. In Proceedings of the Smart Structures and Materials 2005: Electroactive Polymer Actuators and Devices (EAPAD); Bar-Cohen, Y., Ed.; International Society for Optics and Photonics, SPIE: Bellingham, DC, USA, 2005; Volume 5759, pp. 331–339. [Google Scholar] [CrossRef]

- Mojarrad, M.; Shahinpoor, M. Biomimetic robotic propulsion using polymeric artificial muscles. In Proceedings of the International Conference on Robotics and Automation, Albuquerque, NM, USA, 20–25 April 1997; Volume 3, pp. 2152–2157. [Google Scholar] [CrossRef]

- Guo, S.; Fukuda, T.; Asaka, K. A new type of fish-like underwater microrobot. IEEE/ASME Trans. Mechatron. 2003, 8, 136–141. [Google Scholar] [CrossRef]

- Shi, L.; Guo, S.; Li, M.; Mao, S.; Xiao, N.; Gao, B.; Song, Z.; Asaka, K. A Novel Soft Biomimetic Microrobot with Two Motion Attitudes. Sensors 2012, 12, 16732–16758. [Google Scholar] [CrossRef] [PubMed]

- Yun, K.; Kim, W.J. System identification and microposition control of ionic polymer metal composite for three-finger gripper manipulation. Proc. Inst. Mech. Eng. Part J. Syst. Control. Eng. 2006, 220, 539–551. [Google Scholar] [CrossRef]

- Kim, C.; Kim, S.; Yang, H.; Park, N.; Park, Y. An auto-focus lens actuator using ionic polymer metal composites: Design, fabrication and control. Int. J. Prec. Eng. Manuf. 2012, 13, 1883–1887. [Google Scholar] [CrossRef]

- Tsai, S.A.; Wei, H.C.; Su, G.D.J. Polydimethylsiloxane coating on an ionic polymer metallic composite for a tunable focusing mirror. Appl. Opt. 2012, 51, 8315–8323. [Google Scholar] [CrossRef]

- Tripathi, A.; Chattopadhyay, B.; Das, S. Cost-effective fabrication of ionic polymer based artificial muscles for catheter-guidewire maneuvering application. Microsyst. Technol. 2019, 25, 1129–1136. [Google Scholar] [CrossRef]

- Kim, K.J.; Tadokoro, S. Electroactive Polymers for Robotic Applications Artificial Muscles and Sensors, 1st ed.; Springer: London, UK, 2007. [Google Scholar]

- Hao, L.; Li, Z. Modeling and adaptive inverse control of hysteresis and creep in ionic polymer–metal composite actuators. Smart Mater. Struct. 2010, 19, 025014. [Google Scholar] [CrossRef]

- Sun, Z.; Hao, L.; Chen, W.; Li, Z.; Liu, L. A novel discrete adaptive sliding-mode-like control method for ionic polymer–metal composite manipulators. Smart Mater. Struct. 2013, 22, 095027. [Google Scholar] [CrossRef]

- Chen, X.; Su, C.Y. Adaptive Control for Ionic polymer–metal Composite Actuators. IEEE Trans. Syst. Man, Cybern. Syst. 2016, 46, 1468–1477. [Google Scholar] [CrossRef]

- Bernat, J.; Gajewski, P.; Kołota, J.; Marcinkowska, A. Silicone-Based Membranes as Potential Materials for Dielectric Electroactive Polymer Actuators. Energies 2022, 15, 6324. [Google Scholar] [CrossRef]

- Katzer, K.; Kanan, A.; Pfeil, S.; Grellmann, H.; Gerlach, G.; Kaliske, M.; Cherif, C.; Zimmermann, M. Thermo-Electro-Mechanical Characterization of PDMS-Based Dielectric Elastomer Actuators. Materials 2021, 15, 221. [Google Scholar] [CrossRef] [PubMed]

- Jang, Y.; Nabae, H.; Endo, G.; Suzumori, K. Analysis of the multi-balloon dielectric elastomer actuator for traveling wave motion. Sens. Actuators Phys. 2022, 333, 113243. [Google Scholar] [CrossRef]

- Ren, Z.; Kim, S.; Ji, X.; Zhu, W.; Niroui, F.; Kong, J.; Chen, Y. A High-Lift Micro-Aerial-Robot Powered by Low-Voltage and Long-Endurance Dielectric Elastomer Actuators. Adv. Mater. 2022, 34, e2106757. [Google Scholar] [CrossRef]

- Li, A.L.; Lee, S.; Shahsa, H.; Duduta, M. Real time high voltage capacitance for rapid evaluation of dielectric elastomer actuators. Soft Matter 2022, 18, 7123–7130. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Nguyen, T.; Sun, L.; Tran, D. The dissipative dynamic performances of dielectric elastomer actuator with viscoelastic effects. Mater. Res. Express 2022, 9, 075701. [Google Scholar] [CrossRef]

- Reis Carneiro, M.; Majidi, C.; Tavakoli, M. Dielectric Elastomer Actuators with Biphasic Ag–EGaIn Electrodes. Adv. Eng. Mater. 2022, 24, 2100953. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, L.; Zhao, Y.; Yin, L.J.; Zha, J.W.; Dang, Z.M. Advanced dielectric elastomer based on optimized thermoplastic polyurethane–styrene ethylene butylene styrene blend: Experiment and simulation. J. Appl. Polym. Sci. 2022, 139, 51595. [Google Scholar] [CrossRef]

- Wu, C.; Yan, H.; Cai, A.; Cao, C. A Dielectric Elastomer Actuator-Driven Vibro-Impact Crawling Robot. Micromachines 2022, 13, 1660. [Google Scholar] [CrossRef] [PubMed]

- Ogawa, K.; Nishimura, T.; Ming, A. Development of Bendable Elliptical Cone Dielectric Elastomer Actuator. In Proceedings of the 2022 IEEE International Conference on Mechatronics and Automation (ICMA), Guilin, China, 7–9 August 2022; pp. 1233–1238. [Google Scholar] [CrossRef]

- Poulin, A.; Rosset, S.; Shea, H.R. Printing low-voltage dielectric elastomer actuators. Appl. Phys. Lett. 2015, 107, 244104. [Google Scholar] [CrossRef]

- Borayek, R.; Zhang, P.; Willy, H.J.; Zedan, M.; Zhu, J.; Ding, J. Programmable, UV-Printable Dielectric Elastomers Actuate at Low Voltage without Prestretch and Supporting Frames. ACS Appl. Electron. Mater. 2020, 2, 4042–4053. [Google Scholar] [CrossRef]

- Maas, J.; Tepel, D.; Hoffstadt, T. Actuator design and automated manufacturing process for DEAP-based multilayer stack-actuators. Meccanica 2015, 50, 2839–2854. [Google Scholar] [CrossRef]

- Kang, Z.; Yu, L.; Nie, Y.; Skov, A.L. Crosslinking Methodology for Imidazole-Grafted Silicone Elastomers Allowing for Dielectric Elastomers Operated at Low Electrical Fields with High Strains. ACS Appl. Mater. Interfaces 2022, 14, 51384–51393. [Google Scholar] [CrossRef] [PubMed]

- Bernat, J.; Kolota, J.; Rosset, S. Identification of a Nonlinear Dielectric Elastomer Actuator Based on the Harmonic Balance Method. IEEE/ASME Trans. Mechatron. 2021, 26, 2664–2675. [Google Scholar] [CrossRef]

- Bernat, J.; Kołota, J. Modeling of Dielectric Electroactive Polymer Actuators with Elliptical Shapes. Energies 2021, 14, 5633. [Google Scholar] [CrossRef]

- Kolota, J. The FEM model of the pump made of dielectric electroactive polymer membrane. Appl. Sci. 2020, 10, 2283. [Google Scholar] [CrossRef]

- Newell, B.; Garcia, J.; Krutz, G. Dielectric Electroactive Polymers with Chemical Pre-Strain: An Experimentally Validated Model. Actuators 2018, 7, 50. [Google Scholar] [CrossRef]

- Choi, H.; Jung, K.; Nguyen, C.; Jung, M.; Koo, I.; Koo, I.; Lee, J.; Lee, J.; Nam, J.; Cho, M.; et al. Effects of prestrain on behavior of dielectric elastomer actuator. Proc. SPIE 2005, 5759. [Google Scholar] [CrossRef]

- He, L.; Lou, J.; Du, J.; Wang, J. Finite bending of a dielectric elastomer actuator and pre-stretch effects. Int. J. Mech. Sci. 2017, 122, 120–128. [Google Scholar] [CrossRef]

- Wang, H.; Yang, L.; Zhang, X.; Ang, M.H. Effect of different prestretching index and preloading on actuation behaviors of dielectric elastomer actuator. J. Mater. Res. Technol. 2021, 15, 4064–4073. [Google Scholar] [CrossRef]

- Ozsecen, Y.; Sivak, M.; Mavroidis, C. Haptic Interfaces Using Dielectric Electroactive Polymers. Proc. SPIE 2010, 7647, 847244. [Google Scholar] [CrossRef]

- Heo, Y.H.; Choi, D.S.; Kim, D.E.; Kim, S.Y. Flexible Vibrotactile Actuator Based on Dielectric Elastomer for Smart Handheld Devices. Appl. Sci. 2021, 11, 2020. [Google Scholar] [CrossRef]

- Pei, Q.; Pelrine, R.; Stanford, S.; Kornbluh, R.D.; Rosenthal, M.S.; Meijer, K.; Full, R.J. Multifunctional electroelastomer rolls and their application for biomimetic walking robots. In Proceedings of the Smart Structures and Materials 2002: Industrial and Commercial Applications of Smart Structures Technologies; McGowan, A.M.R., Ed.; International Society for Optics and Photonics, SPIE: Bellingham, DC, USA, 2002; Volume 4698, pp. 246–253. [Google Scholar] [CrossRef]

- Araromi, O.A.; Gavrilovich, I.; Shintake, J.; Rosset, S.; Richard, M.; Gass, V.; Shea, H.R. Rollable Multisegment Dielectric Elastomer Minimum Energy Structures for a Deployable Microsatellite Gripper. IEEE/ASME Trans. Mechatron. 2015, 20, 438–446. [Google Scholar] [CrossRef]

- Kaal, W.; Herold, S. Electroactive polymer actuators in dynamic applications. IEEE/ASME Trans. Mechatron. 2011, 16, 24–32. [Google Scholar] [CrossRef]

- Hodgins, M.; York, A.; Seelecke, S. Experimental comparison of bias elements for out-of-plane DEAP actuator system. Smart Mater. Struct. 2013, 22, 094016. [Google Scholar] [CrossRef]

- Rizzello, G.; Naso, D.; York, A.; Seelecke, S. Modeling, Identification, and Control of a Dielectric Electro-Active Polymer Positioning System. IEEE Trans. Control. Syst. Technol. 2015, 23, 632–643. [Google Scholar] [CrossRef]

- Hau, S.; Rizzello, G.; Seelecke, S. A novel dielectric elastomer membrane actuator concept for high-force applications. Extrem. Mech. Lett. 2018, 23, 24–28. [Google Scholar] [CrossRef]

- Cao, C.; Gao, X.; Conn, A. A Magnetically Coupled Dielectric Elastomer Pump for Soft Robotics. Adv. Mater. Technol. 2019, 4, 1900128. [Google Scholar] [CrossRef]

- Rizzello, G.; Naso, D.; Turchiano, B.; York, A.; Seelecke, S. LMI-based design of PI controllers for micropositioning dielectric electro-active polymer membranes. In Proceedings of the 2015 American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2015; pp. 5509–5514. [Google Scholar] [CrossRef]

- Baumgartner, R.; Kogler, A.; Stadlbauer, J.M.; Foo, C.C.; Kaltseis, R.; Baumgartner, M.; Mao, G.; Keplinger, C.; Koh, S.J.A.; Arnold, N.; et al. A Lesson from Plants: High-Speed Soft Robotic Actuators. Adv. Sci. 2020, 7, 1903391. [Google Scholar] [CrossRef] [PubMed]

- Loew, P.; Rizzello, G.; Seelecke, S. A novel biasing mechanism for circular out-of-plane dielectric actuators based on permanent magnets. Mechatronics 2018, 56, 48–57. [Google Scholar] [CrossRef]

- Cao, C.; Conn, A.T. Performance Optimization of a Conical Dielectric Elastomer Actuator. Actuators 2018, 7, 32. [Google Scholar] [CrossRef]

- Cao, C.; Gao, X.; Burgess, S.; Conn, A.T. Power optimization of a conical dielectric elastomer actuator for resonant robotic systems. Extrem. Mech. Lett. 2020, 35, 100619. [Google Scholar] [CrossRef]

- Sideris, E.; de Lange, H. Pumps operated by solid-state electromechanical smart material actuators—A review. Sens. Actuators Phys. 2020, 307, 111915. [Google Scholar] [CrossRef]

- Ye, Z.; Chen, Z. Modeling and Control of a 2-DOF Dielectric Elastomer Diaphragm Actuator. IEEE/ASME Trans. Mechatron. 2019, 24, 218–227. [Google Scholar] [CrossRef]

- Behboodi, A.; Lee, S. Benchmarking of a Commercially Available Stacked Dielectric Elastomer as an Alternative Actuator for Rehabilitation Robotic Exoskeletons. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; pp. 499–505. [Google Scholar] [CrossRef]

- Zhao, H.; Hussain, A.M.; Duduta, M.; Vogt, D.M.; Wood, R.J.; Clarke, D.R. Compact Dielectric Elastomer Linear Actuators. Adv. Funct. Mater. 2018, 28, 1804328. [Google Scholar] [CrossRef]

- Lucarini, S.; Moreno-Mateos, M.A.; Danas, K.; Garcia-Gonzalez, D. Insights into the viscohyperelastic response of soft magnetorheological elastomers: Competition of macrostructural versus microstructural players. Int. J. Solids Struct. 2022, 256, 111981. [Google Scholar] [CrossRef]

- Lin, D.; Yang, F.; Gong, D.; Li, R. A new vibration isolator integrating tunable stiffness-damping and active driving properties based on radial-chains magnetorheological elastomer. Mech. Syst. Signal Process. 2023, 183, 109633. [Google Scholar] [CrossRef]

- Wang, B.; Li, Y.; Gao, Y.; Zhang, J.; Xu, Z.; Li, J.; Li, J.; Kari, L.; Wang, Y.; Gong, X. The influence of particle chain-magnetic field spatial location, frequency, dynamic strain amplitude and the prestrain on the mechanical performance of anisotropic magneto-rheological elastomer. Polym. Test. 2021, 104, 107411. [Google Scholar] [CrossRef]

- Clark, A.T.; Marchfield, D.; Cao, Z.; Dang, T.; Tang, N.; Gilbert, D.; Corbin, E.A.; Buchanan, K.S.; Cheng, X.M. The effect of polymer stiffness on magnetization reversal of magnetorheological elastomers. APL Mater. 2022, 10, 041106. [Google Scholar] [CrossRef]

- Tahir, S.; Usman, M.; Umer, M.A. Effect of Volume Fraction on Shear Mode Properties of Fe-Co and Fe-Ni Filled Magneto-Rheological Elastomers. Polymers 2022, 14, 2968. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Zhang, S.; Wang, Q.; Wang, Y.; Xuan, S.; Gong, X.; Zhang, D. Self-healing and printable elastomer with excellent shear stiffening and magnetorheological properties. Compos. Sci. Technol. 2022, 223, 109430. [Google Scholar] [CrossRef]

- Kumar, B.S.; Raju, P.R.M.; Ratnam, C. Dynamic mechanical properties of magnetorheological polyurethane elastomers in comparison to existing antivibration rubbers. Adv. Mater. Process. Technol. 2022, 8, 2247–2261. [Google Scholar] [CrossRef]

- Yoon, J.H.; Lee, S.W.; Bae, S.H.; Kim, N.I.; Yun, J.H.; Jung, J.H.; Kim, Y.G. Effect of Cyclic Shear Fatigue under Magnetic Field on Natural Rubber Composite as Anisotropic Magnetorheological Elastomers. Polymers 2022, 14, 1927. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.; Li, Q.; Cao, Y.; Qie, J.; Zou, J.; You, J.; Lu, H.; Wang, W.; Wang, G. The effect of graphene-coating material (G-Fe) on the dynamic mechanical characteristics of magnetorheological elastomer (MRE). Appl. Phys. A 2022, 128, 657. [Google Scholar] [CrossRef]

- Mat Song, R.; Mazlan, S.A.; Johari, N.; Imaduddin, F.; Abdul Aziz, S.A.; Abd Fatah, A.Y.; Ubaidillah, U. Semi-Active Controllable Stiffness Engine Mount Utilizing Natural Rubber-Based Magnetorheological Elastomers. Front. Mater. 2022, 9, 875787. [Google Scholar] [CrossRef]

- Alam, M.N.; Kumar, V.; Jo, C.R.; Ryu, S.R.; Lee, D.J.; Park, S.S. Mechanical and magneto-mechanical properties of styrene-butadiene-rubber-based magnetorheological elastomers conferred by novel filler-polymer interactions. Compos. Sci. Technol. 2022, 229, 109669. [Google Scholar] [CrossRef]

- Shen, C.; Matsubara, M.; Masui, T.; Kishimoto, H.; Yamanaka, S.; Muramatsu, A.; Kanie, K. Magnetorheological Elastomer Films with Controlled Anisotropic Alignment of Polystyrene-Modified Fe 3 O 4 Nanoplates. ACS Appl. Polym. Mater. 2022, 4, 7240–7249. [Google Scholar] [CrossRef]

- Balogh, D.; Guba, S.; Horváth, B.; Szalai, I. Magnetic Field-Induced Deformation of Isotropic Magnetorheological Elastomers. Magnetochemistry 2022, 8, 146. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Park, S.S. Robust magneto-rheological elastomers performance for composites based on iron oxide and carbon black in silicone rubber. J. Polym. Res. 2022, 29. [Google Scholar] [CrossRef]

- Kwon, S.H.; Lee, J.H.; Choi, H.J. Magnetic Particle Filled Elastomeric Hybrid Composites and Their Magnetorheological Response. Materials 2018, 11, 1040. [Google Scholar] [CrossRef] [PubMed]

- Khairi, M.H.A.; Noor, E.E.M.; Ubaidillah, U.; Aziz, S.A.A.; Mazlan, S.A.; Tarmizi, S.M.A.; Nordin, N.A. Enhancement of Magneto-Induced Modulus by the Combination of Filler and Plasticizer Additives-Based Magnetorheological Elastomer. Materials 2022, 15, 6396. [Google Scholar] [CrossRef]

- Bica, I.; Bunoiu, O.M. Magnetorheological Hybrid Elastomers Based on Silicone Rubber and Magnetorheological Suspensions with Graphene Nanoparticles: Effects of the Magnetic Field on the Relative Dielectric Permittivity and Electric Conductivity. Int. J. Mol. Sci. 2019, 20, 4201. [Google Scholar] [CrossRef]

- Chen, L.; Gong, X.L.; Li, W.H. Effect of carbon black on the mechanical performances of magnetorheological elastomers. Polym. Test. 2008, 27, 340–345. [Google Scholar] [CrossRef]

- Kim, G.W.; Kim, S.; Choi, H.J. Enhanced performance of nano-sized maghemite added carbonyl iron-based magnetorheological soft elastomer. J. Magn. Magn. Mater. 2022, 560, 169659. [Google Scholar] [CrossRef]

- Fischer, N.A.; Robinson, A.L.; Lee, T.J.; Calascione, T.M.; Koerner, L.; Nelson-Cheeseman, B.B. Magnetic annealing of extruded thermoplastic magnetic elastomers for 3D-Printing via FDM. J. Magn. Magn. Mater. 2022, 553, 169266. [Google Scholar] [CrossRef]

- Bastola, A.K.; Paudel, M.; Li, L. Development of hybrid magnetorheological elastomers by 3D printing. Polymer 2018, 149, 213–228. [Google Scholar] [CrossRef]

- Bastola, A.K.; Paudel, M.; Li, L. Dot-patterned hybrid magnetorheological elastomer developed by 3D printing. J. Magn. Magn. Mater. 2020, 494, 165825. [Google Scholar] [CrossRef]

- Morgenstern, A.H.; Calascione, T.M.; Fischer, N.A.; Lee, T.J.; Wentz, J.E.; Nelson-Cheeseman, B.B. Thermoplastic magnetic elastomer for fused filament fabrication. AIMS Mater. Sci. 2019, 6, 363–376. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Li, W.; Du, H. A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 2014, 23, 123001. [Google Scholar] [CrossRef]

- Choi, Y.; Wereley, N.M. Vibration Isolation Performance of an Adaptive Magnetorheological Elastomer-Based Dynamic Vibration Absorber. Actuators 2022, 11, 157. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, Y.; Tu, J.; Li, Z.; Wang, Q. Development and Vibration Control of Frequency Adjustable Tuned Mass Damper Based on Magnetorheological Elastomer. Materials 2022, 15, 1829. [Google Scholar] [CrossRef]

- Gao, P.; Liu, H.; Xiang, C.; Yan, P.; Mahmoud, T. A new magnetorheological elastomer torsional vibration absorber: Structural design and performance test. Mech. Sci. 2021, 12, 321–332. [Google Scholar] [CrossRef]

- Jeong, U.C. Application of Adaptive Tuned Magneto-Rheological Elastomer for Vibration Reduction of a Plate by a Variable-Unbalance Excitation. Appl. Sci. 2020, 10, 3934. [Google Scholar] [CrossRef]

- Gao, P.; Xiang, C.; Liu, H.; Walker, P.; Zhang, N. Design of the frequency tuning scheme for a semi-active vibration absorber. Mech. Mach. Theory 2019, 140, 641–653. [Google Scholar] [CrossRef]

- Huang, X.; Zhai, Y.; He, G. Research on Vibration Control Technology of Robot Motion Based on Magnetorheological Elastomer. Materials 2022, 15, 6479. [Google Scholar] [CrossRef]

- Leng, D.; Feng, W.; Ning, D.; Liu, G. Analysis and design of a semi-active X-structured vibration isolator with magnetorheological elastomers. Mech. Syst. Signal Process. 2022, 181, 109492. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.; Sun, J.; Ha, S.K.; Guan, Z. Theoretical and experimental investigations on active vibration control of the MRE multifunctional grille composite sandwich plates. Compos. Struct. 2022, 295, 115783. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, Z.; Li, H.; Wong, P.K.; Xie, Z. Semi-active control for the nonlinear vibration suppression of square-celled sandwich plate with multi-zone MRE filler core. Mech. Syst. Signal Process. 2022, 172, 108953. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, J.; Chen, Z.; Gong, X.; Du, H.; Zhang, S.; Li, W.; Sun, S. Investigation of a novel MRE metamaterial sandwich beam with real-time tunable band gap characteristics. J. Sound Vib. 2022, 527, 116870. [Google Scholar] [CrossRef]

- Yao, J.; Gao, Y.; Fan, J.; Scarpa, F.; Li, Y. Design and verification of a magnetorheological elastomer-based actuator to reduce rotor vibration. Int. J. Mech. Mater. Des. 2022, 18, 701–718. [Google Scholar] [CrossRef]

- Kashima, S.; Miyasaka, F.; Hirata, K. Novel Soft Actuator Using Magnetorheological Elastomer. IEEE Trans. Magn. 2012, 48, 1649–1652. [Google Scholar] [CrossRef]

- Bernat, J.; Gajewski, P.; Kapela, R.; Marcinkowska, A.; Superczyńska, P. Design, Fabrication and Analysis of Magnetorheological Soft Gripper. Sensors 2022, 22, 2757. [Google Scholar] [CrossRef]

- Guan, R.; Zheng, H.; Liu, Q.; Ou, K.; sen Li, D.; Fan, J.; Fu, Q.; Sun, Y. DIW 3D printing of hybrid magnetorheological materials for application in soft robotic grippers. Compos. Sci. Technol. 2022, 223, 109409. [Google Scholar] [CrossRef]

- Choi, Y.T.; Hartzell, C.M.; Leps, T.; Wereley, N.M. Gripping characteristics of an electromagnetically activated magnetorheological fluid-based gripper. AIP Adv. 2018, 8, 056701. [Google Scholar] [CrossRef]

- Zhang, P.; Kamezaki, M.; Otsuki, K.; He, Z.; Sakamoto, H.; Sugano, S. Development of a Vacuum Suction Cup by Applying Magnetorheological Elastomers for Objects with Flat Surfaces. In Proceedings of the 2020 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Boston, MA, USA, 6–9 July 2020; pp. 777–782. [Google Scholar] [CrossRef]

- Choi, D.S.; Kim, T.H.; Lee, S.H.; Pang, C.; Bae, J.W.; Kim, S.Y. Beyond Human Hand: Shape-Adaptive and Reversible Magnetorheological Elastomer-Based Robot Gripper Skin. ACS Appl. Mater. Interfaces 2020, 12, 44147–44155. [Google Scholar] [CrossRef]

- Park, Y.J.; Choi, S.B. A New Tactile Transfer Cell Using Magnetorheological Materials for Robot-Assisted Minimally Invasive Surgery. Sensors 2021, 21, 3034. [Google Scholar] [CrossRef]

- Hooshiar, A.; Payami, A.; Dargahi, J.; Najarian, S. Magnetostriction-based force feedback for robot-assisted cardiovascular surgery using smart magnetorheological elastomers. Mech. Syst. Signal Process. 2021, 161, 107918. [Google Scholar] [CrossRef]

- Park, Y.J.; Lee, E.S.; Choi, S.B. A Cylindrical Grip Type of Tactile Device Using Magneto-Responsive Materials Integrated with Surgical Robot Console: Design and Analysis. Sensors 2022, 22, 1085. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).