1. Introduction

In recent years, with the rapid development of information technology, digital factories with few people or none at all are gradually replacing traditional factories. In the flexible workshop of digital factories, each equipment communicates with the information control system, and the flexible manufacturing system (FMS) and flexible transportation system (FTS) tend to be automated in a gradual fashion. AGVs play a crucial role in the workshop logistics system and have become an indispensable part of the transportation system [

1,

2,

3]. The logistics system is characterized by poor stability but strong dynamics. In factories, a single AGV is far from able to meet the transportation demand, but the path planning of multiple AGVs is more complex than that of a single AGV, which is prone to causing congestion and conflicts [

4]. Therefore, the AGVs dynamic scheduling strategy in the flexible job shop scheduling problem (FJSSP) is an NP (Non-deterministic Polynomial)-hard problem and is difficult to optimize. At the same time, dynamic interference in the workshop logistics system can lead to deviation between the actual production and plan. Dynamic scheduling is not only a real-time response to real data, but also a way to reschedule and adjust after uncontrollable emergencies [

5]. Besides the transportation tasks, task attributes, AGV number, AGV speeds under different working conditions, and the AGV battery power condition are also key points for the logistics system in terms of improving efficiency.

Currently, the market has put forward more stringent requirements for manufacturing enterprises’ production efficiency, response speed, personalized response degree and energy consumption reduction, which has presented new challenges for enterprises to participate in market competition. The traditional informatization has improved the production efficiency of enterprises, but it lacks the deep embedding of the production system, and the traditional informatization idea in particular has not realized the intelligent transformation of the logistics system. Therefore, enterprises respond to market changes quickly and effectively through intelligent manufacturing, the timely adjustment of production capacity, and transportation mode. The objective is to satisfy customers’ expectations and needs through lower manufacturing costs. Few researchers consider multi-AGVS and multi-objective scheduling rules, task allocation and reasonable allocation of AGVs resources at the same time. Dynamic scheduling mainly focuses on shop scheduling through real-time or offline production data, which means dynamic scheduling based on the connection between the digital world and the physical world. The complex environment and dynamic tasks in the discrete logistics system make it difficult to exchange data quickly. As a result, the digital space cannot obtain the data from the physical space in real time, and the adjusted scheduling plan cannot be carried out as expected. Therefore, data exchange between the digital space and physical space is the key to realizing AGVs multi-objective dynamic scheduling. In recent years, digital twin technology has become the research focus for institutions, scholars and enterprises. As one of the most authoritative research and consulting companies, Gartner has listed the digital twin as one of the top ten strategic technology development trends [

6]. Digital twin provides an idea and framework to solve the aforementioned problems.

1.1. Contribution

An AGVs multi-objective dynamic scheduling method (AMODS) for a factory logistics system is presented based on the digital twin in this paper. A virtual digital twin with high fidelity is constructed to provide a visual simulation platform for the verification of mechanical action, control logic, operation scheme of the production unit and the dynamic scheduling scheme in the physical world. A framework is set up to analyze the dynamic data and control mechanism of two-way interactions. A real-time updated dynamic task list is constructed to realize the dynamic scheduling of multi-objective routes for AGVs. The optimal number of AGVs and the speed optimization of AGVS under different working conditions are analyzed. In this study, a real logistics production line is chosen to verify the proposed methods.

1.2. Paper Organization

The remainder of this paper is organized as follows. The

Section 2 describes the related work. The

Section 3 discusses the logistics job-shop scheduling framework based on the digital twin. The

Section 4 presents the virtual digital twin of high fidelity. The

Section 5 formulates the problem of AGV scheduling. The

Section 6 introduces the AMODS method for complex discrete logistics systems.

Section 7 analyzes a practical case.

Section 8 provides some conclusions.

2. Related Works

In a logistics system, the path planning and scheduling strategy of AGV is the core of the whole system, and the quality of the scheduling algorithm can directly affect the balance and stability of the system. Multi-AGV path planning has always been a hot research topic, and many researchers have improved the scheduling strategy of AGVs. Hu et al. [

7] considered the constraints of transportation time and transportation resources in the flexible job shop and proposed an improved local search algorithm combining greedy heuristic rules. Sahu et al. [

8] proposed a hybrid algorithm of democratic robotics PSO and improved Q-learning, and found that it is fast and available for a real-time environment. Saeed et al. [

9] studied the multi-objective path planning problem and found the shortest collision-free path connecting a set of given target points in the robot’s working environment. Zhang et al. [

10] proposed a dynamic scheduling method for self-organizing AGVs in a logistics system. Dynamic scheduling rules are learned by using improved gene expression programming and cooperate with other AGVs for transportation. Zhong et al. [

11] realized integrated scheduling and conflict-free path planning for multiple AGVs. By establishing a mixed integer programming model and using hybrid genetic algorithm-particle swarm optimization (HGA-PSO), AGV path conflict or deadlock is avoided. Hu et al. [

12] proposed a new variable neighborhood search algorithm for the conflict-free scheduling of large-scale multi-load AGVs. The retention time table is used to prevent collisions and deadlocks between multiple AGVs, which can achieve the scheduling of multiple AGVs in a large and dense network. Wang et al. [

13] proposed a new multi-state scheduling algorithm (MSSA) to make use of idle AGVs. Xu et al. [

14] took minimizing the completion time as the goal, analyzed the load time and no-load time of each station, and proposed an improved gray wolf algorithm to optimize the scheduling of AGVs in a flexible job-shop.

In addition to the design of AGVs scheduling strategy, most flexible job-shop logistics systems are based on the premise of multi-target objects. In view of the attributes of AGVs itself, Chen et al. [

15] proposed a multi-AGVs efficient routing combining centralized control and decentralized control. Centralized control optimized the AGV path nodes, while decentralized control adjusted the AGV speed. Gao et al. [

16] proposed a throughput evaluation methodology based on AGV route decomposition that is proposed for AGV transportation systems. AGV speed change and collision avoidance are considered, as well as the promotion of the productivity of AGV transportation system. Zou et al. [

17] proposed an efficient Multi-Objective Greed Algorithm (MOGA). The algorithm has effective strategies such as new population initialization, greedy operation, and an adaptive multi-domain local search, and optimizes the energy consumption of AGVs and the number of AGVs.

For the adaptability of the scheduling system to the real environment, the application of dynamic scheduling in the actual discrete shop floor has always been a difficult problem. Liu et al. [

18] constructed the mathematical model of flexible multi-objective dynamic scheduling of the shop floor and proposed a multi-objective flexible dynamic scheduling algorithm based on an adaptive genetic algorithm. Zhang et al. [

19] combined a dynamic interaction layer and particle swarm genetic hybrid algorithm to realize the dynamic scheduling of urgent tasks in view of the dynamic disturbance in flexible job shop scheduling. For the urgent orders for small batch production tasks, Liu et al. [

20] proposed a double-loop deep Q network based on a perception-cognition dual system to minimize the average load of equipment and to minimize the total completion time.

In reality, the power of AGVs is limited, and working for a period of time will consume the battery power. Many researchers have studied the problem of pre-sensing energy consumption data acquisition in the case of limited battery capacity. Gul et al. [

21] discussed the importance of energy sensing data collection for robots and wireless sensor networks, and researched the collection of energy sensing data in the robot network cluster, including the remaining battery capacity of UAV (Unmanned Aerial Vehicle). Gul et al. [

22] studied the problem of energy saving data collection and considered the data collection of limited capacity battery UAV to carry out path planning and the minimization of the total energy consumption of UAV and record the data of the lowest cost. Han et al. [

23] proposed an AGV dynamic scheduling method based on digital twins. The problem of AGV charging in an AGV scheduling system is solved by using the characteristics of virtual reality interactive data and fusion in digital twinning technology, and the operation efficiency of the workshop is effectively improved.

Digital twin technology is designed to create a virtual model of a physical entity in a digital way, to simulate the behavior of a physical entity in the real environment with the help of data, and to expand new capabilities for the physical entity by interactions between digital space and physical space, data fusion, and decision iterative optimization. It is oriented to the whole product life cycle and plays the role of bridge and link between the physical world and the digital world, to achieve digitization, intelligence and the networking of the factories. Many scholars have researched the construction, data collection and monitoring of digital twins. Tao et al. [

24] proposed the concept of the digital twin workshop, described the system composition, principal mechanism, characteristics and key technologies of a digital twin workshop, and further discussed the theory and implementation methods of the interaction and integration between physical space and digital space based on workshop data. Dahman et al. [

25] proposed a simulation framework based on testable digital twins and virtual test platforms, combining the latest virtual reality and 3D simulation technology. Tao et al. [

26] proposed a dynamic scheduling method for the discrete assembly shop of complex products based on digital twin to realize data interactive dynamic scheduling between physical space and digital space. Mahesh et al. [

27] has developed a digital twin framework to improve productivity through bottleneck analysis, process mining and diagnostic analysis.

4. Construction of Digital Twin

There are usually two steps to construct the digital twin of a factory. The first step is to use a stereoscopic virtual action model to simulate the factories. The model is drawn at equal scale through three-dimensional software, or the virtual model is obtained with the help of a 3D (3 Dimensions) modeling scanner. The stereo models are light weighted, and then the motion joint is bonded with signals to achieve the interactions. The second step is to build a model for production simulation and analysis. The model reflects the logic of the production process, and carries out simulation analysis, calculation and verification on the scheduling strategy of the production process.

4.1. Construction of Virtual Action Model

Mechanical equipment in industrial workshops is usually very complex. In the process of 3D modeling, high precision models generally have multiple geometric faces. A large amount of computer memory is occupied. Therefore, it is necessary to light weight the models, simplifying the unnecessary structure. For example, the chamfers, fillets, redundant points, lines and surfaces are removed, and the non-moving parts should be combined into one component. Finally, the light weighted models are imported into the virtual engine platform for rendering, physical characteristics and behavioral logic are added, and relevant signals are configured.

In this section, only AGVs and single stations are taken as examples. As shown in

Figure 3, the light weighted AGV and workstations are imported into the virtual engine platform. The operation logic and collision sensing device of AGV and station are added, and the sensing signal and data interface are configured. Socket communication based on a TCP/UDP protocol is used in the platform, which transmits the collected data of the physical equipment to its digital twin through the network port and matches the relevant signals.

4.2. Model Establishment for Production Simulation Analysis

The production simulation analysis models are often used for discrete event simulation. Pre- production can be carried out on this model before the actual logistics system runs, and the scheduling strategy can be simulated and verified in advance. The production simulation and analysis models have no high requirements on the appearance and action effect restoration of the equipment model. Its core feature is to reflect the operation logic of the whole production line or the whole workshop. The data are processed and analyzed, and the algorithms are verified and optimized, in order to greatly reduce resource consumption and improve production efficiency.

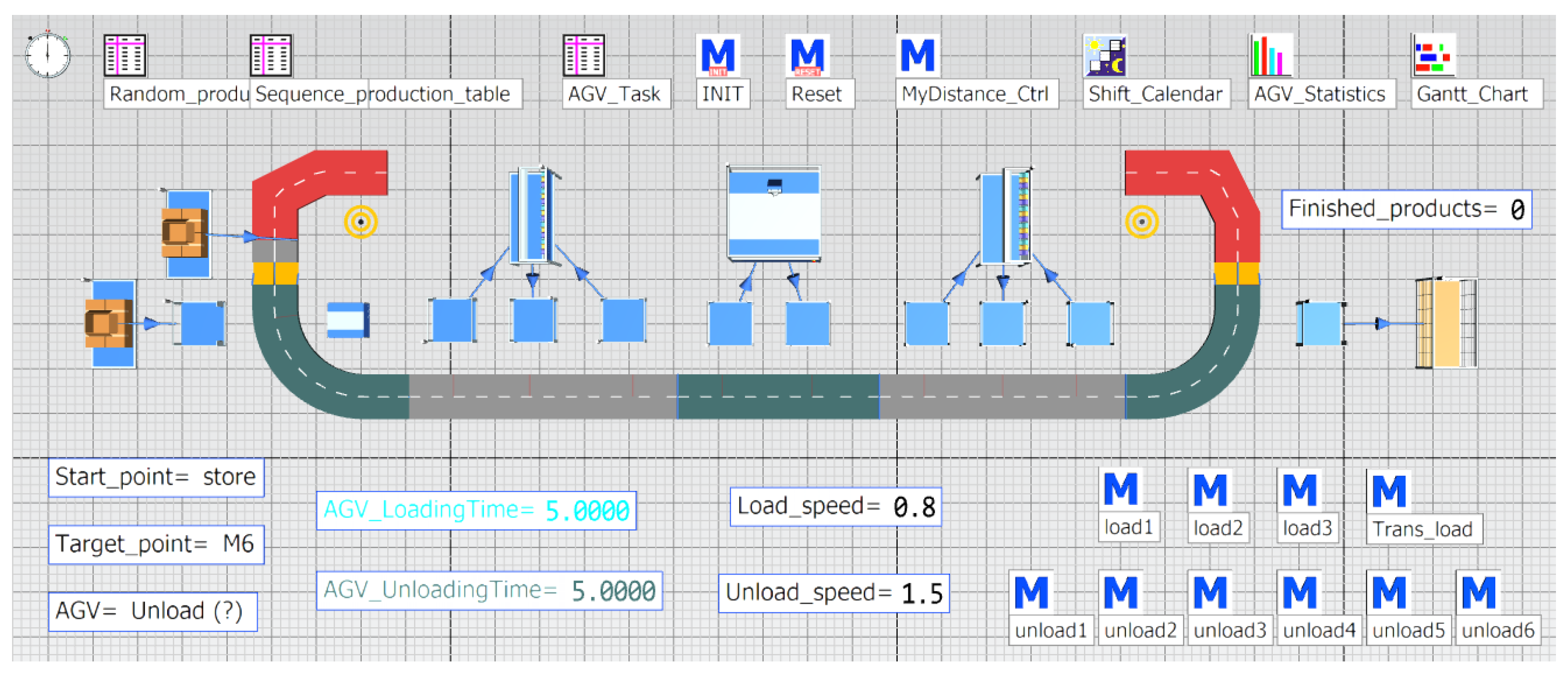

In this section, only AGVs and single stations are taken as an example. The software used to build the simulation analysis model is Plant Simulation. As shown in

Figure 4, the model can be divided into four modules: a simulation module, control module, analysis module and communication module. The simulation module simulates the production process of the actual workshop production line. The control module is responsible for the optimal control of the scheduling algorithm, production scheduling, and path planning during transportation. The analysis module generates the corresponding analysis report chart during the simulation to prove the applicability of the transportation plans and scheduling algorithms. The data is stored in MySQL (My Structured Query Language) database for reference of the service management system. The communication module provides many interfaces for dynamic interaction between simulation models and physical plants, such as OPC UA, PLCSIM, ODBC (Open Database Connectivity), SQL and Socket. At the same time, the production simulation analysis models are integrated with MES, WMS and Excel to obtain real-time logistics data, form dynamic reports, and feedback the status of the production line in a timely and visual manner.

4.3. Interaction between the Digital Twin and Physical Equipment

In the digital twin system, both data and model are indispensable. The virtual action model provides a high-fidelity animation model, which can restore the entire logistics system. However, the virtual action model needs to be matched with the physical device and complete the virtual action through an external data drive. The implementation of the data drive can generally be divided into two types. The first one is the data driving of the actual workshop communication interface, and the other one is the data from the external simulation analysis software. The simulation analysis model plays an important role in the production process simulation, algorithm verification and data analysis capabilities. At the same time, it is combined with the service management system to obtain real-time logistics data, generate dynamic reports, and verify and predict future trends of the logistics system in advance.

A high fidelity digital twin receives data from a physical device and evolves in real time, so it keeps consistent contact with physical device objects throughout their life cycle. To ensure real-time data exchange in a digital twin system, the interaction between a virtual action model, simulation analysis model and a physical device should be established as shown in

Figure 5. The virtual action model and the simulation analysis model communicates via the TCP protocol. The IOT (Internet of Things) equipment in the physical workshop acquires PLC/sensor data and uploads it in JSON (JavaScript Object Notation) format in real time. The digital twin then acquires the data from the server in real time through socket communication. Physical devices communicate with the digital twin in real time as well. At present, the common PLC/sensor supported communication protocols in intelligent factories include OPC UA and Modbus. At the same time, a communication converter is required between different communication protocols. In the data exchange among the virtual action model, simulation analysis model and physical equipment, data input and output logic can be divided into the physical workshop server driver and the simulation analysis model server driver. The physical workshop server driver drives the virtual action model and the simulation analysis model with the data collected from the real physical workshop. The simulation analysis model server driver is used to optimize the simulation based on the received service management system data or the corresponding transportation route, and drive the virtual action model and physical equipment. The simulation analysis model server driver focuses on pre-validation, algorithm analysis and demand forecasting.

5. Problem Formulation

In the workshop logistics systems, the customers place an order in the remote service management system. The order is scheduled and distributed to the production line. The AGVs in the empty state receive the new task in real time, go to the task point to load the cargo, transport the cargo to the designated destination, unload them, and then continue to receive new tasks. The initial position of AGVs is the default starting point, and the initial state of AGV is a no-load state. If no new task information is received after the current task is completed, the AGV completing the task will stay at the current point. When the AGV power is lower than 25%, it goes to the nearby charging area for charging. By combining the characteristics of the digital twin system, the real-time dynamic data exchange between the real production line and the virtual digital twin is established, and the dynamic scheduling strategy and AGV attribute configuration are verified and predicted. Finally, the method is implemented on the real production line. In this study, there are several important assumptions and constraints:

- 1.

The distribution capacity and scope of each AGV are the same, and all AGVs are the same;

- 2.

An AGV can only load and distribute one cargo each time;

- 3.

The task allocation rule is on a first come, first serve basis [

28] (FCFS);

- 4.

AGVs adopt the shortest path;

- 5.

The failure of AGVs should be considered; the availability of the AGVs is 95%, and the mean time to repair (MTTR) is 5;

- 6.

The transportation track can only allow one AGV to pass without overtaking, and there should be a safe distance between any two AGVs;

- 7.

AGVs have different speeds under load and no load, which lies in ranges;

- 8.

The loading and unloading time of AGVs should be considered;

- 9.

An AGV cannot go to the charging area during transportation.

8. Conclusions

In this paper, an AGVs multi-objective dynamic scheduling method (AMODS) based on digital twins in a factory logistics system is proposed. The proposed AMODS method is applied to the AGV dynamic scheduling problem of a digital twin system, and an application example is given. The main conclusions are as follows:

In the traditional factory logistics system, the data of information space and physical space lack integration and interaction, and the whole process elements in the transportation process have low predictability, linkage and global optimization level. The scheduling framework based on digital twins is built, and the virtual digital twin is constructed to map the physical logistics system with data and model. Through the combination of data and model, the interaction of a virtual action model, simulation analysis model and physical equipment is achieved.

The real-time updated dynamic task list is introduced to generate a scheduling plan according to the actual production line demand. An AGVs multi-objective dynamic scheduling (AMODS) method based on digital twins was designed. The test results indicate that the time cost of the traditional scheduling is about 12 min, while the time cost of the real-time dynamic task list scheduling is about 10 min, which is 16.7% shorter than the traditional scheduling. The advantages of this method are verified and the transportation efficiency is improved.

The AGVs attributes are optimized with multi-level experiments. Through the case study, it proves the feasibility and good scheduling performance of the production line with the help of the AGVs multi-objective dynamic scheduling method (AMODS) based on the digital twin. The experimental results show that the optimal number of AGVs is three, the optimal no-load speed of AGVs is 1.5 m/s, and the optimal load speed of AGVs is 0.8 m/s.

This provides a new solution for AGVs scheduling in a workshop logistics system. Based on the dynamic data exchange and fusion of the digital twin system, it can realize the synchronization of the digital and physical workshop and the demand prediction and optimal utilization of resources. However, the dynamic intelligent algorithm and predictive demand analysis studied in this paper are not comprehensive. Furthermore, it only considers the simulation development of the production line by understanding the working characteristics. At the same time, the production line layout and AGV routes of this study case are relatively simple, while the actual shop floor layouts are more complex. In the future, the scheduling and optimization based on artificial intelligent algorithms, AGV fault prediction and AGV power consumption prediction still need to studied further. They also need to act on a real workshop scene with a complex layout.