Preparation of Cementitious Material with Wet Fly Ash by Hydrothermal Reaction and Calcination

Abstract

:1. Introduction

2. Experimental Section

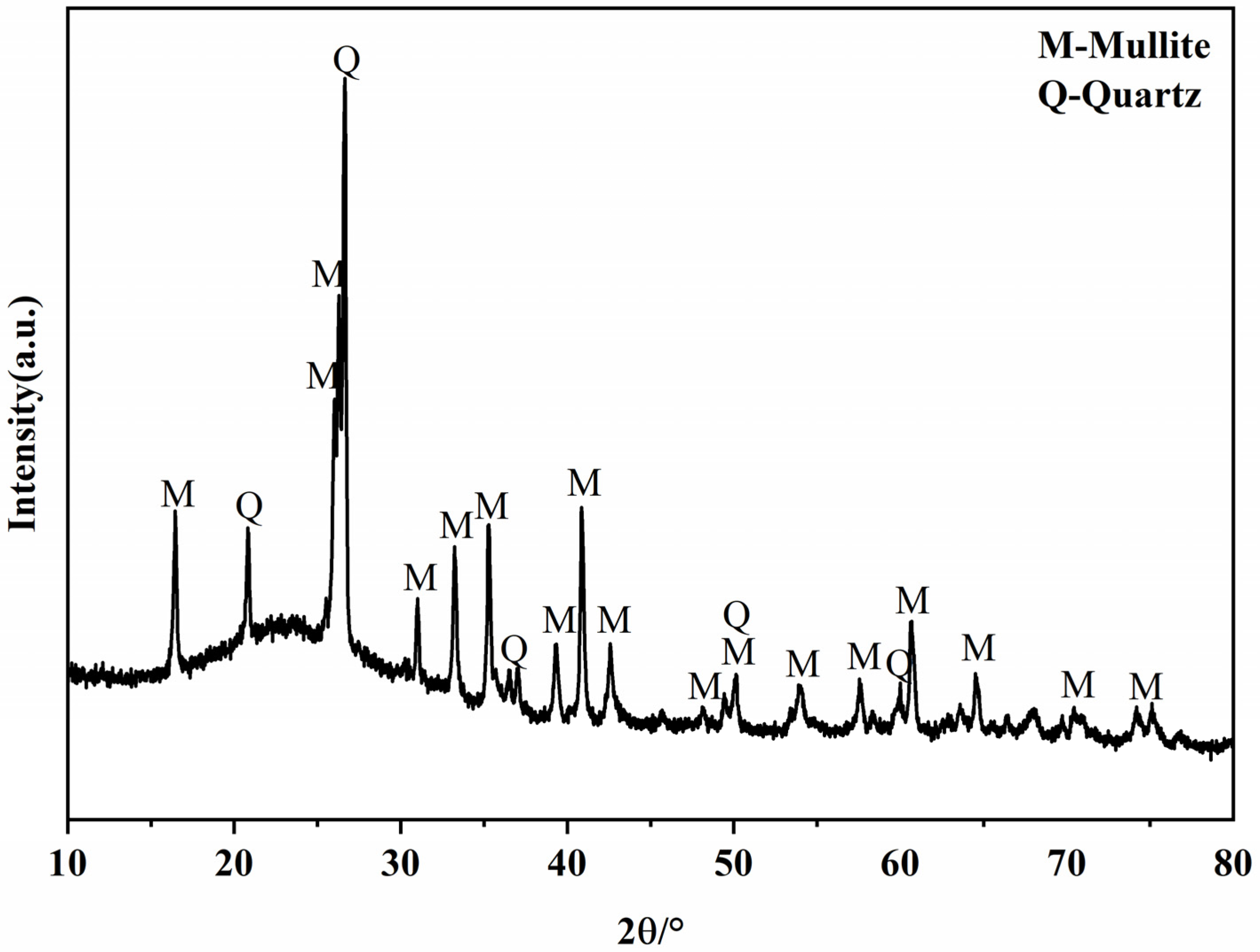

2.1. Raw Materials

2.2. Hydrothermal Synthesis Process

2.3. Calcination System

2.4. Test Methods

2.4.1. Fly Ash Reaction Degree Test

2.4.2. f-CaO Testing

3. Results and Discussion

3.1. Hydrothermal Synthesis System Analysis

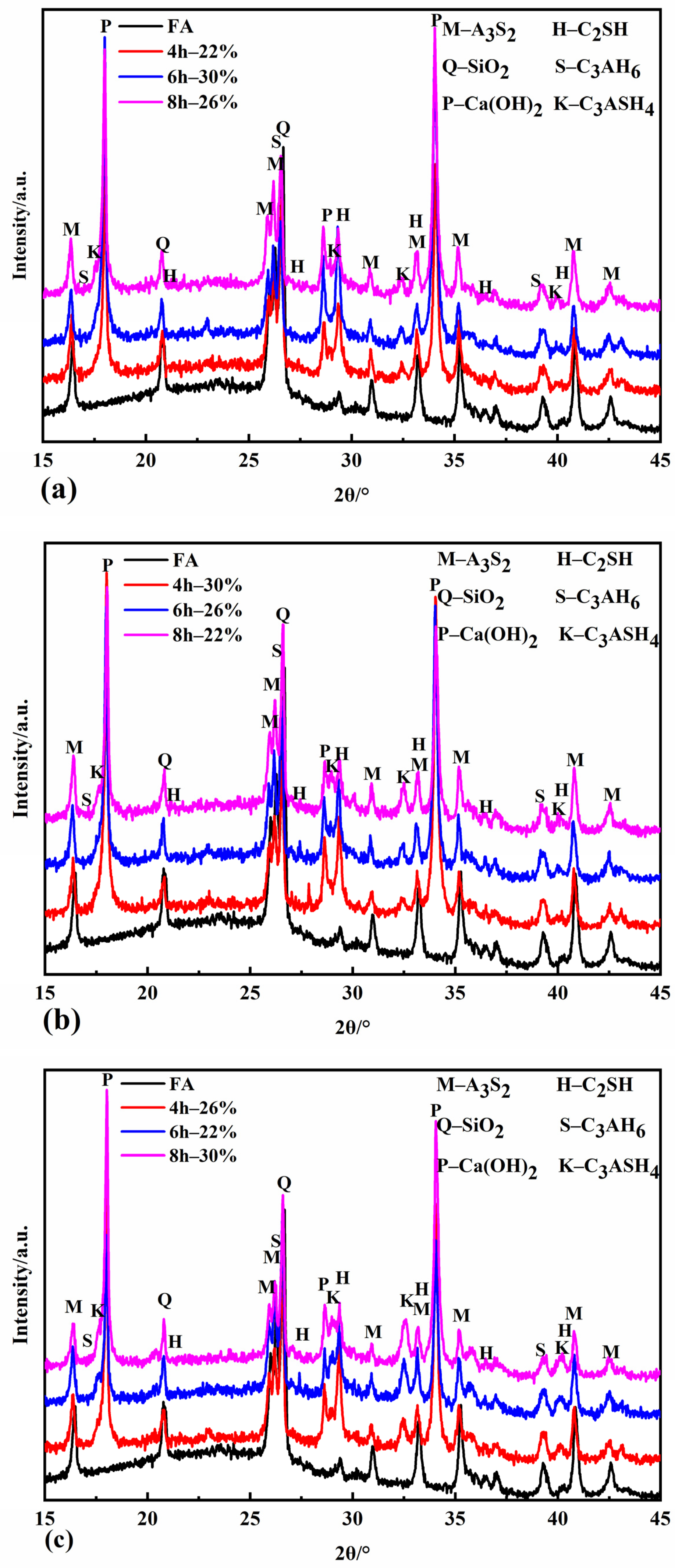

3.1.1. Reaction Products Analysis

3.1.2. CaO Reaction Degree Analysis

3.1.3. Fly Ash Reaction Degree Content

3.1.4. Quantitative Analysis of Reaction Products

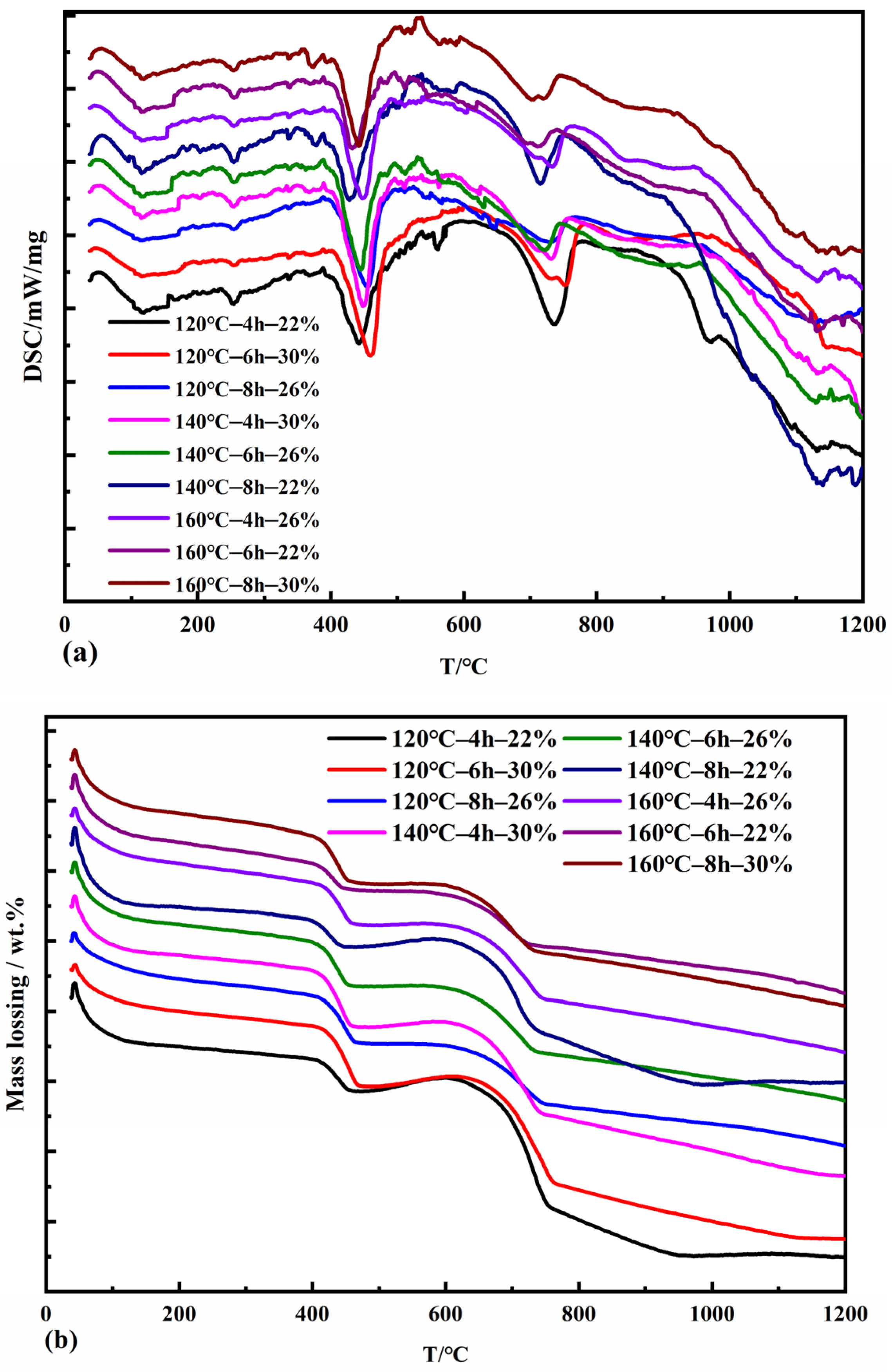

3.2. Calcination System Analysis

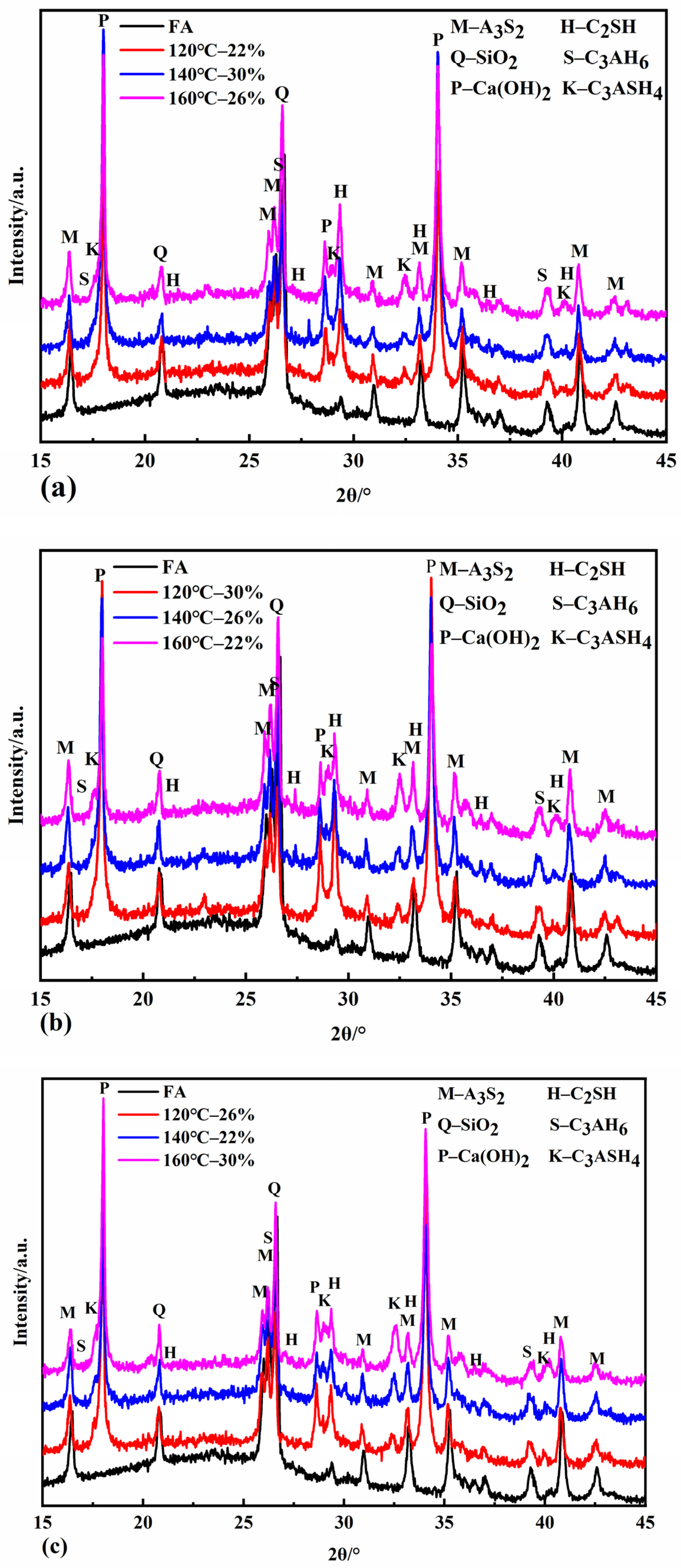

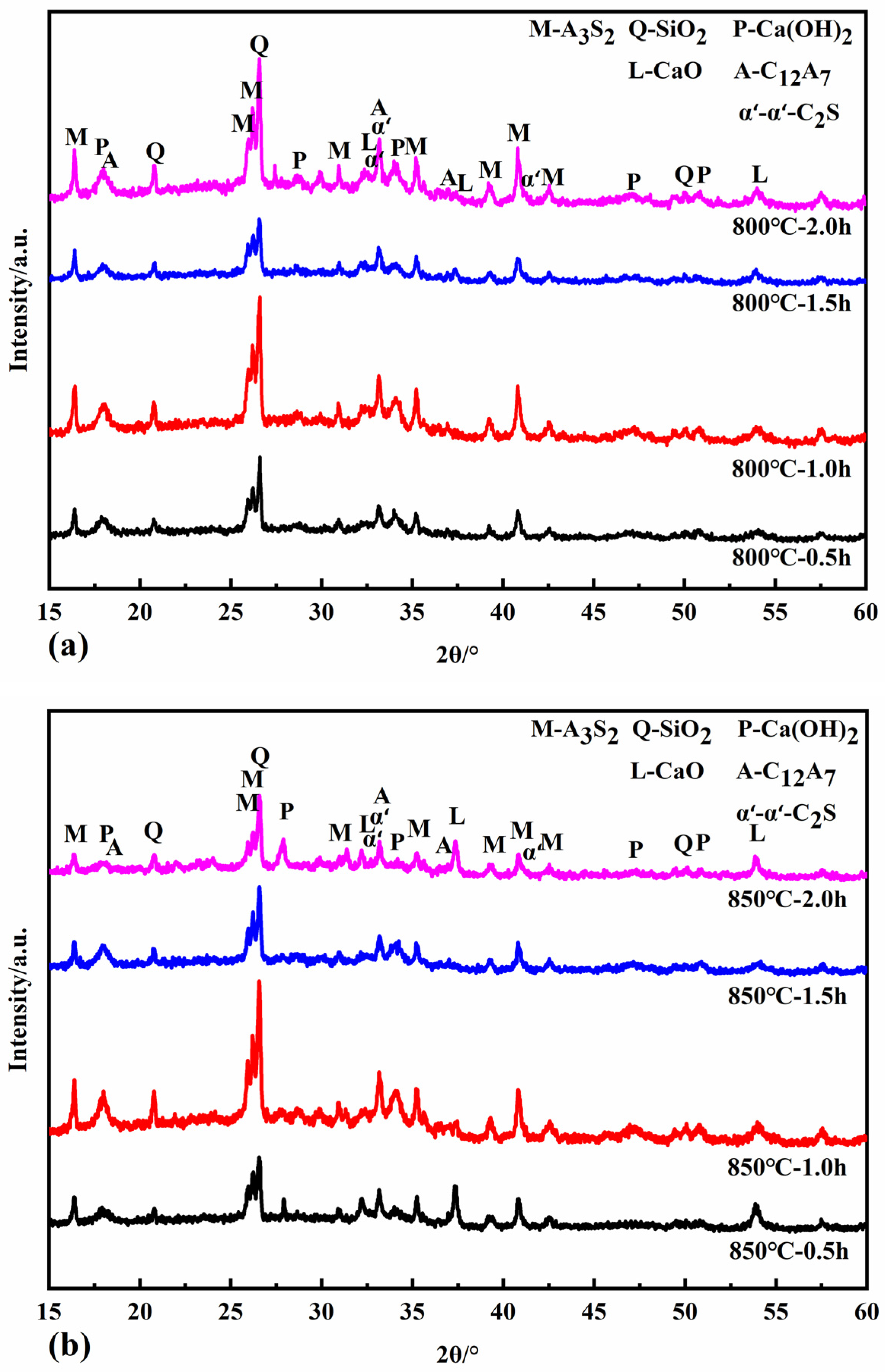

3.2.1. The Effect of Calcination Temperature on the Formation of Calcined Minerals

3.2.2. The effect of Calcination Time on the Formation of Calcined Minerals

3.3. Properties of Wet Fly Ash Cementitious Material

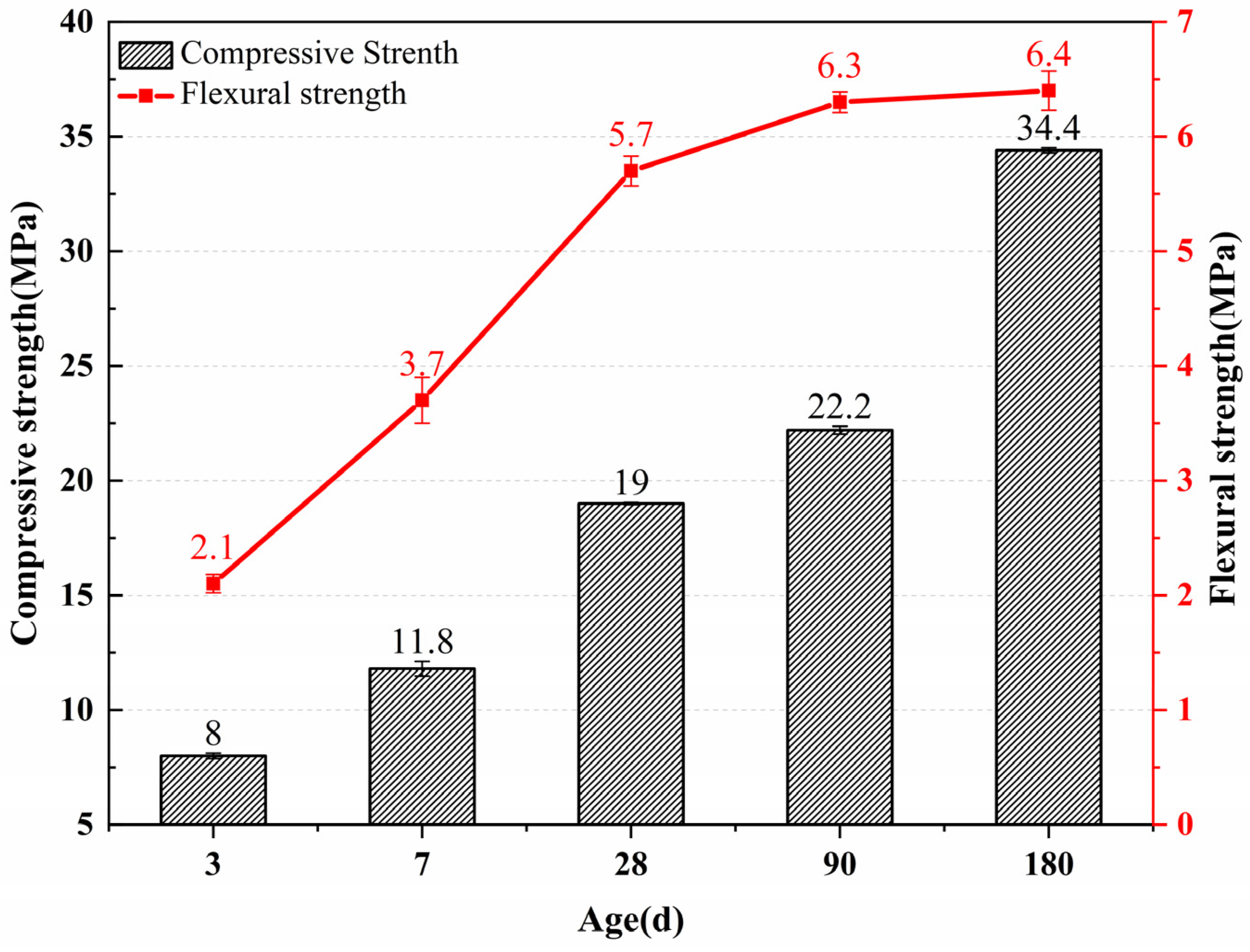

3.3.1. Compressive and Flexural Strength

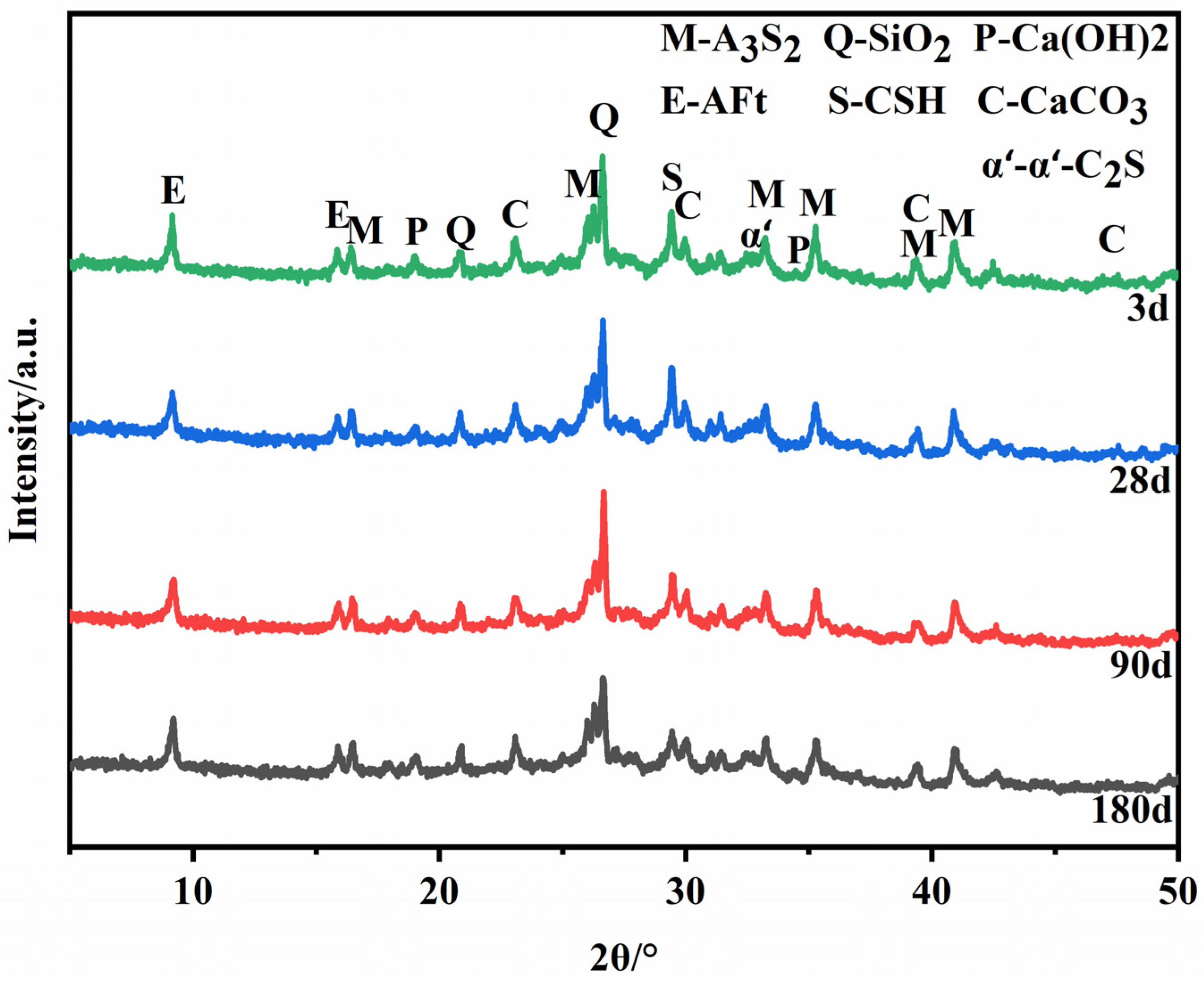

3.3.2. Hydration Products

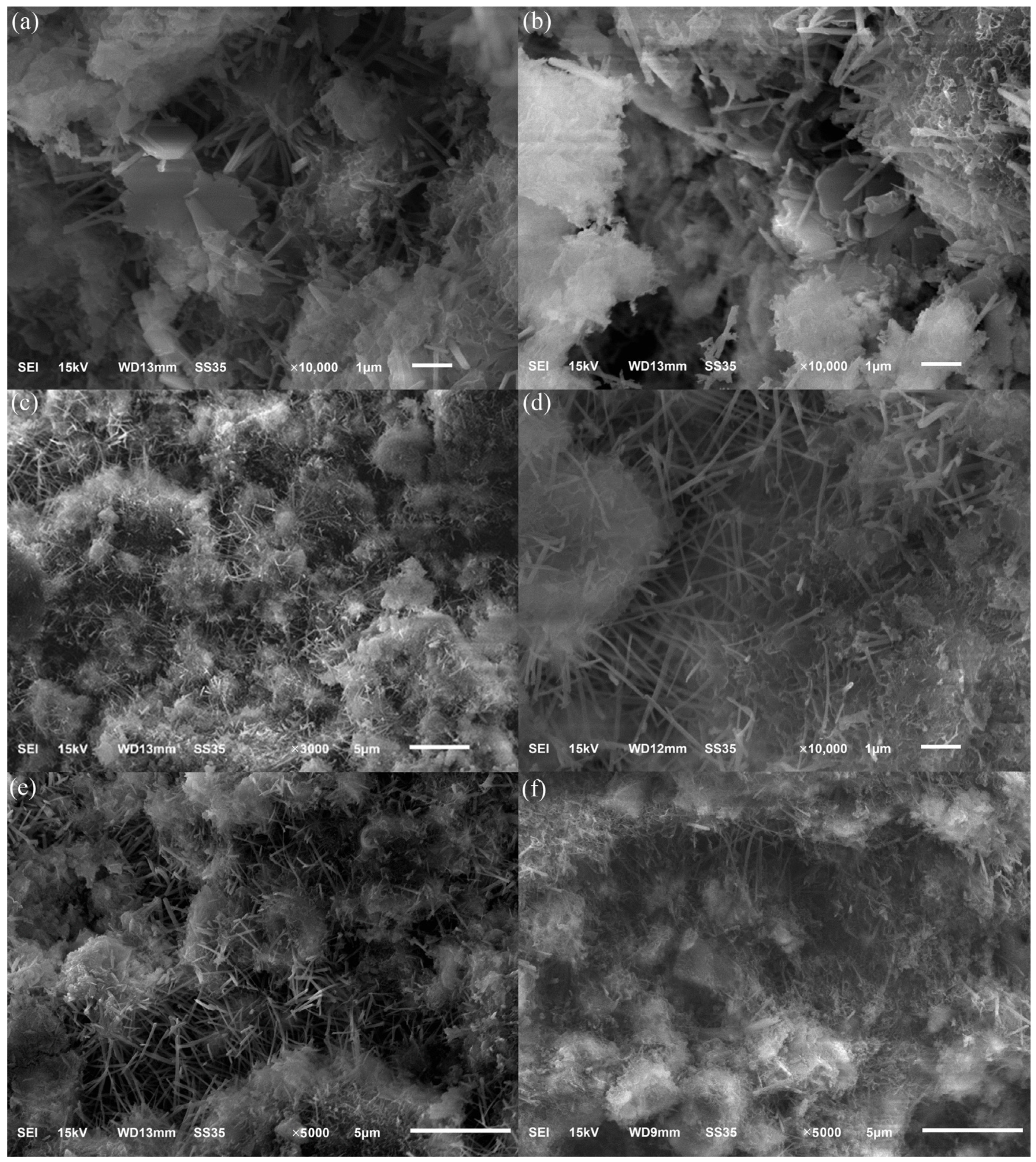

3.3.3. Surface Morphology Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shen, L.; Gao, T.; Zhao, J.; Wang, L.; Wang, L.; Liu, L.; Chen, F.; Xue, J. Factory-level measurements on CO2 emission factors of cement production in China. Renew. Sustain. Energy Rev. 2014, 34, 337–349. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Andrew, R.M.; Global, C.O. Emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Khan, K.; Salami, B.A.; Iqbal, M.; Amin, M.N.; Ahmed, F.; Jalal, F.E. Compressive Strength Estimation of Fly Ash/Slag Based Green Concrete by Deploying Artificial Intelligence Models. Materials 2022, 15, 3722. [Google Scholar] [CrossRef]

- Izquierdo, M.; Querol, X. Leaching behaviour of elements from coal combustion fly ash: An overview. Int. J. Coal Geol. 2012, 94, 54–66. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, A.; Amin, M.N.; Ahmad, W.; Nazar, S.; Arab, A.M.A. Comparative Study of Experimental and Modeling of Fly Ash-Based Concrete. Materials 2022, 15, 3762. [Google Scholar] [CrossRef]

- He, Y.; Luo, Q.; Hu, H. Situation Analysis and Countermeasures of China’s Fly Ash Pollution Prevention and Control. Procedia Environ. Sci. 2012, 16, 690–696. [Google Scholar] [CrossRef]

- Tiwari, M.K.; Bajpai, S.; Dewangan, U.K.; Tamrakar, R.K. Suitability of leaching test methods for fly ash and slag: A review. J. Radiat. Res. Appl. Sci. 2015, 8, 523–537. [Google Scholar] [CrossRef]

- Amin, M.N.; Hissan, S.; Shahzada, K.; Khan, K.; Bibi, T. Pozzolanic Reactivity and the Influence of Rice Husk Ash on Early-Age Autogenous Shrinkage of Concrete. Front. Mater. 2019, 6, 150. [Google Scholar] [CrossRef]

- Ávalos-Rendón, T.L.; Chelala, E.A.P.; Escobedo, C.J.M.; Figueroa, I.A.; Lara, V.H.; Palacios-Romero, L.M. Synthesis of belite cements at low temperature from silica fume and natural commercial zeolite. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2018, 22, 979–985. [Google Scholar] [CrossRef]

- Rungchet, A.; Poon, C.S.; Chindaprasirt, P.; Pimraksa, K. Synthesis of low-temperature calcium sulfoaluminate-belite cements from industrial wastes and their hydration: Comparative studies between lignite fly ash and bottom ash. Cem. Concr. Compos. 2017, 83, 10–19. [Google Scholar] [CrossRef]

- Han, Y.; Lin, R.; Wang, X.Y. Performance and sustainability of quaternary composite paste comprising limestone, calcined Hwangtoh clay, and granulated blast furnace slag. J. Build. Eng. 2021, 43, 102655. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- Singh, N.B. Hydrothermal synthesis of β-dicalcium silicate (β-Ca2SiO4). Prog. Cryst. Growth Charact. Mater. 2006, 52, 77–83. [Google Scholar] [CrossRef]

- Amin, M.N.; Khan, K.; Javed, M.F.; Aslam, F.; Qadir, M.G.; Faraz, M.I. Prediction of Mechanical Properties of Fly-Ash/Slag-Based Geopolymer Concrete Using Ensemble and Non-Ensemble Machine-Learning Techniques. Materials 2022, 15, 3478. [Google Scholar] [CrossRef]

- Khan, K.; Ashfaq, M.; Iqbal, M.; Khan, M.A.; Amin, M.N.; Shalabi, F.I.; Faraz, M.I.; Jalal, F.E. Multi Expression Programming Model for Strength Prediction of Fly-Ash-Treated Alkali-Contaminated Soils. Materials 2022, 15, 4025. [Google Scholar] [CrossRef]

- Guerrero, A.; Goñi, S.; Macías, A.; Luxán, M.P. Effect of the starting fly ash on the microstructure and mechanical properties of fly ash-belite cement mortars. Cem. Concr. Res. 2000, 30, 553–559. [Google Scholar] [CrossRef]

- Guerrero, A.; Goñi, S.; Macías, A.; Luxán, M.P. Hydraulic activity and microstructural characterization of new fly ash-belite cements synthesized at different temperatures. J. Mater. Res. 1999, 14, 2680–2687. [Google Scholar] [CrossRef]

- Guerrero, A.; Goñi, S.; Campillo, I.; Moragues, A. Belite cement clinker from coal fly ash of high Ca content. Optimization of synthesis parameters. Environ. Sci. Technol. 2004, 38, 3209–3213. [Google Scholar]

- Goñi, S.; Guerrero, A.; De Luxan, M.P.; Macıas, A. Dehydration of pozzolanic products hydrothermally synthesized from flyash: Microstructure evolution. Mater. Res. Bull. 2000, 35, 1333–1344. [Google Scholar] [CrossRef]

- Singh, N.B.; Sarita, R.; Neelam, S. Highly reactive—Dicalcium silicate. J. Am. Ceram. Soc. 2002, 85, 2171–2176. [Google Scholar] [CrossRef]

- Mazouzi, W.; Kacimi, L.; Cyr, M.; Clastres, P. Properties of low temperature belite cements made from aluminosilicate wastes by hydrothermal method. Cem. Concr. Compos. 2014, 53, 170–177. [Google Scholar] [CrossRef]

- Georgescu, M.; Tipan, J.; Badanoiu, A.; Crisan, D.; Dragan, I. Highly reactive dicalcium silicate synthesised by hydrothermal processing. Cem. Concr. Compos. 2000, 22, 315–319. [Google Scholar] [CrossRef]

- Nanru, Y. Research progress in hydrothermal synthesis of β-C2S. J. Build. Mater. 2011, 14, 145–154. [Google Scholar]

- Yonghao, F.; Liqing, C.; Yongfan, G.; Wenjuan, Y. Research Status and Prospect of Fly Ash Belite Cement. J. Silic. 2015, 43, 165–173. [Google Scholar]

- Guerrero, A.; Goni, S.; Allegro, V.R. Durability of class c fly ash belite cement in simulated sodium chloride radioactive liquid waste: Influence of temperature. J. Hazard. Mater. 2008, 162, 1099–1102. [Google Scholar] [CrossRef]

- Guerrero, A.; Goñi, S.; Macıas, A.; Luxán, M.P. Mechanical properties, pore size distribution, and pore solution of fly ash-belite cement mortars. Cem. Concr. Res. 1999, 29, 1753–1758. [Google Scholar] [CrossRef]

- Guerrero, A.; Goñi, S.; Moragues, A.; Dolado, J.S. Microstructure and Mechanical Performance of Belite Cements from High Calcium Coal Fly Ash. J. Am. Ceram. Soc. 2005, 88, 1845–1853. [Google Scholar] [CrossRef]

- GB/T 1596-2017; Fly Ash for Use in Cement and Concrete. National Standard of the People’s Republic of China: Beijing, China, 2017.

- Gong, Y.; Fang, Y. Preparation of belite cement from stockpiled high-carbon fly ash using granule-hydrothermal synthesis method. Constr. Build. Mater. 2016, 111, 175–181. [Google Scholar] [CrossRef]

- Pimraksa, K.; Hanjitsuwan, S.; Chindaprasirt, P. Synthesis of belite cement from lignite fly ash. Ceram. Int. 2009, 35, 2415–2425. [Google Scholar] [CrossRef]

- GB/T 12960-2019; Quantitative Determination of Cement Components. National Standard of the People’s Republic of China: Beijing, China, 2019.

- Peirong, Z.; Shuqing, Z.; Xueli, W.; Shiyuan, H. Effect advantages of grade I fly ash used in the three gorges project and its contribution to the strength of cement mortar. Compr. Util. Fly Ash 2001, 03, 5–9. [Google Scholar]

- Shiyuan, H.; Zhi, L.; Cheng, H.; Ping, J. Reaction kinetics in fly ash-Ca(OH)2•2H2O system. J. Silic. 1986, 02, 191–197. [Google Scholar]

- GB/T 176-2017; Method for the Chemical Analysis of Cement. National Standard of the People’s Republic of China: Beijing, China, 2017.

- Changjun, K.; Jun, W. Structure of Common Hydrated Products in Autoclaved Silicate Products. Build. Mater. Technol. Appl. 2007, 1, 17–20. [Google Scholar]

- Xiaoqin, P.; Xiaohan, Y.; Lijuan, H. Study on Preparation of Ultrafine Powder Materials from Fly Ash by Hydrothermal Synthesis. J. Shenyang Jianzhu Univ. Nat. Sci. Ed. 2005, 21, 333–337. [Google Scholar]

- Guokuang, S.; Yuping, Z. Study on Hydrated Products Related to Autoclaved Products in System CaO-SiO2-Al2O3•H2O. J. Silic. 1983, 02, 149–158. [Google Scholar]

- Nanru, Y. Preliminary Study on Low Carbon Cement with C2S as the Main Mineral Composition. Cem. Technol. 2010, 4, 20–25. [Google Scholar]

- Peng, Z.; Caizhen, Y. Reaction Mechanism of Extracting Alumina from Fly Ash by Autoclave Reaction and Low Temperature Calcination. Coal Eng. 2009, 05, 82–84. [Google Scholar]

- Kuijie, Z. Study on Reaction Kinetics of Fly Ash-Ca(OH)2 System under Steam Curing Condition. J. Harbin Jianzhu Univ. 2001, 2, 90–93. [Google Scholar]

| SiO2 | Al2O3 | Fe2O3 | CaO | K2O | TiO2 | MgO | Na2O | P2O5 | SO3 | MnO | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 49.31 | 28.46 | 4.87 | 2.18 | 1.22 | 1.05 | 0.66 | 0.35 | 0.22 | 0.10 | 0.03 | 11.52 |

| Factors | Lime Dosing /wt% | Press Steam Time /h | Press Steam Temperature /°C | |

|---|---|---|---|---|

| Sample No. | ||||

| 1 | 22 | 4 | 120 | |

| 2 | 30 | 6 | 120 | |

| 3 | 26 | 8 | 120 | |

| 4 | 30 | 4 | 140 | |

| 5 | 26 | 6 | 140 | |

| 6 | 22 | 8 | 140 | |

| 7 | 26 | 4 | 160 | |

| 8 | 22 | 6 | 160 | |

| 9 | 30 | 8 | 160 | |

| Sample No. | Experimental Parameters | Ca(OH)2 Weight Loss /wt% | CaO Reaction Rate /% |

|---|---|---|---|

| 1 | 120 °C–4 h—22% | 2.17 | 71.71 |

| 2 | 120 °C–8 h—26% | 3.30 | 63.85 |

| 3 | 120 °C–6 h—30% | 3.90 | 62.83 |

| 4 | 140 °C–8 h—22% | 1.66 | 78.63 |

| 5 | 140 °C–6 h—26% | 3.02 | 68.69 |

| 6 | 140 °C–4 h—30% | 3.99 | 62.00 |

| 7 | 160 °C–6 h—22% | 1.76 | 77.36 |

| 8 | 160 °C–4 h—26% | 3.10 | 66.06 |

| 9 | 160 °C–8 h—30% | 3.16 | 69.87 |

| Sample No. | Experimental Parameters | Reaction Rate of Fly Ash/% |

|---|---|---|

| 1 | 120 °C–4 h—22% | 10.26 |

| 2 | 140 °C–8 h—22% | 15.39 |

| 3 | 160 °C–6 h—22% | 15.39 |

| 4 | 160 °C–4 h—26% | 13.52 |

| 5 | 140 °C–6 h—26% | 16.22 |

| 6 | 120 °C–8 h—26% | 16.32 |

| 7 | 140 °C–4 h—30% | 15.71 |

| 8 | 120 °C–6 h—30% | 17.14 |

| 9 | 160 °C–8 h—30% | 20.00 |

| Sample No. | Experimental Parameters | C2SH /wt% | C3AH6 /wt% | C3ASH4 /wt% |

|---|---|---|---|---|

| 1 | 120 °C–4 h—22% | 6.94~17.69 | 0~17.14 | 2.91~5.99 |

| 2 | 160 °C–6 h—22% | 13.87~17.46 | 0~5.74 | 15.03~16.08 |

| 3 | 140 °C–8 h—22% | 14.33~18.53 | 0~6.70 | 14.06~15.26 |

| 4 | 160 °C–4 h—26% | 14.90~25.98 | 0~17.64 | 1.34~4.46 |

| 5 | 140 °C–6 h—26% | 16.05~20.67 | 0~7.35 | 12.26~13.59 |

| 6 | 120 °C–8 h—26% | 13.91~15.53 | 0~2.59 | 17.35~17.81 |

| 7 | 140 °C–4 h—30% | 16.82~24.64 | 0~12.46 | 5.77~7.98 |

| 8 | 120 °C–6 h—30% | 18.51~24.45 | 0~9.44 | 8.95~10.61 |

| 9 | 160 °C–8 h—30% | 22.08~24.59 | 0~4.02 | 14.75~15.48 |

| Calcination Conditions | f-CaO /wt% | Calcination Conditions | f-CaO /wt% | Calcination Conditions | f-CaO /wt% |

|---|---|---|---|---|---|

| 800 °C–0.5 h | 7.02 | 850 °C–0.5 h | 5.82 | 900 °C–0.5 h | 4.35 |

| 800 °C–1.0 h | 7.32 | 850 °C–1.0 h | 6.60 | 900 °C–1.0 h | 4.08 |

| 800 °C–1.5 h | 7.55 | 850 °C–1.5 h | 5.76 | 900 °C–1.5 h | 5.27 |

| 800 °C–2.0 h | 6.65 | 850 °C–2.0 h | 6.07 | 900 °C–2.0 h | 5.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, P.; Huang, B. Preparation of Cementitious Material with Wet Fly Ash by Hydrothermal Reaction and Calcination. Appl. Sci. 2023, 13, 1768. https://doi.org/10.3390/app13031768

Shi P, Huang B. Preparation of Cementitious Material with Wet Fly Ash by Hydrothermal Reaction and Calcination. Applied Sciences. 2023; 13(3):1768. https://doi.org/10.3390/app13031768

Chicago/Turabian StyleShi, Peiyu, and Bei Huang. 2023. "Preparation of Cementitious Material with Wet Fly Ash by Hydrothermal Reaction and Calcination" Applied Sciences 13, no. 3: 1768. https://doi.org/10.3390/app13031768

APA StyleShi, P., & Huang, B. (2023). Preparation of Cementitious Material with Wet Fly Ash by Hydrothermal Reaction and Calcination. Applied Sciences, 13(3), 1768. https://doi.org/10.3390/app13031768