Design Procedures for Sustainable Structural Concretes Using Wastes and Industrial By-Products

Abstract

1. Introduction

2. Experimental Program

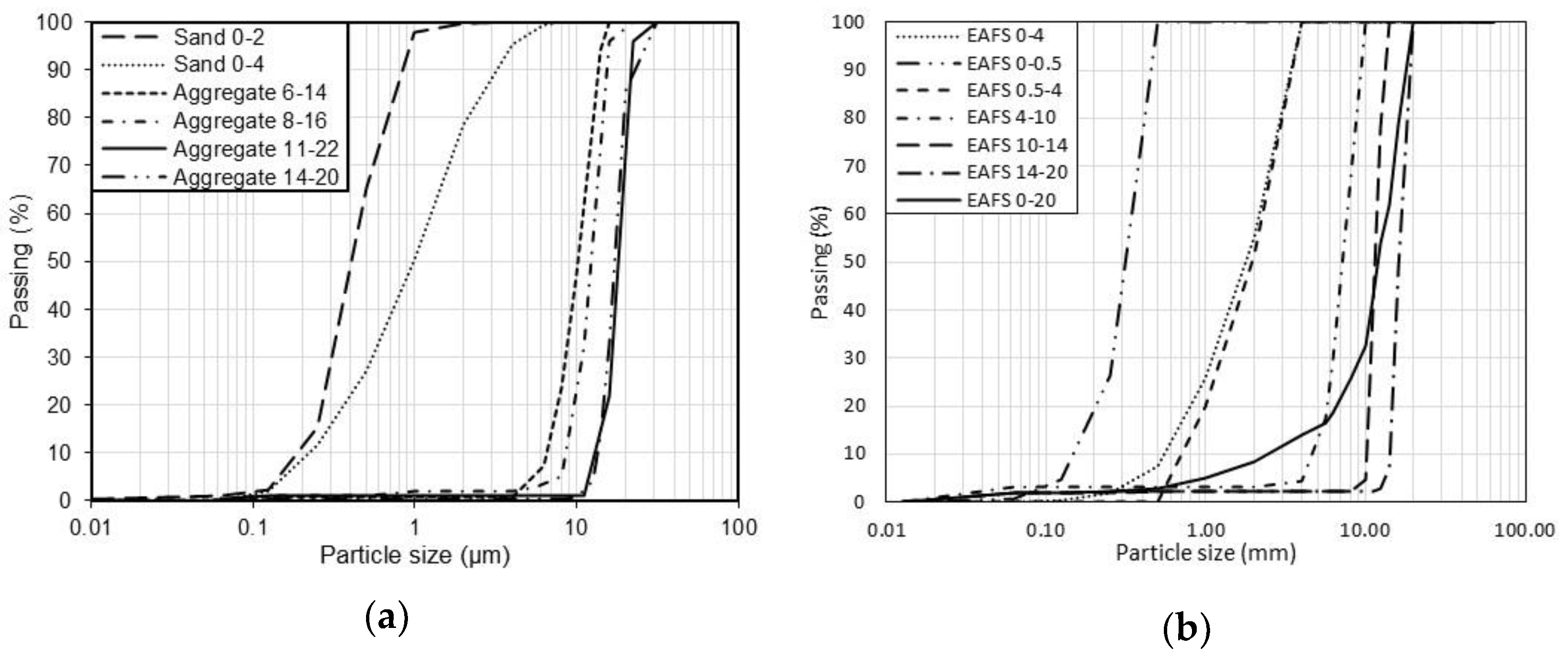

2.1. Materials

Mix Design of EAFS Structural Concrete

2.2. Mixing Procedure

2.3. Specimen Preparation

2.4. Testing Procedures

2.4.1. Fresh Properties

2.4.2. Mechanical Properties

2.4.3. Physical Properties

3. Results

3.1. Fresh Properties

3.2. Mechanical Properties

Compressive Strength

| q | Mixtures | fcm (MPa) | fck (MPa) | Strength Class | Ecm (GPa) | ||||

|---|---|---|---|---|---|---|---|---|---|

| 7 Days | 28 Days | 90 Days | 7 Days | 28 Days | 90 Days | ||||

| REF1 | 22.70 | 30.68 | 30.40 | 26.68 | C25/30 | 24.63 | 27.44 | 30.80 | |

| 0.35 | EAFS6 | 12.86 | 17.54 | 18.09 | 13.54 | C12/15 | 24.79 | 24.58 | 26.49 |

| EAFS2 | 12.38 | 19.43 | 23.35 | 15.43 | C12/15 | 26.22 | 30.47 | 31.31 | |

| EAFS3A | 10.29 | ― | ― | ― | ― | 18.76 | ― | ― | |

| EAFS4 | 10.61 | 9.43 | 13.17 | 6.59 | ― | 25.44 | 22.11 | 31.15 | |

| 0.25 | EAFS8B | 25.20 | 36.17 | ― | 33.01 | C30/37 | 34.02 | 37.97 | ― |

| EAFS3B | 18.60 | 26.29 | ― | 22.29 | C20/25 | 30.62 | 35.01 | ― | |

| 0.20 | EAFS8C | 20.88 | 35.14 | ― | 31.14 | C30/37 | 32.43 | 35.79 | ― |

| EAFS5C | 22.02 | 34.91 | ― | 30.91 | C30/37 | 31.78 | 35.25 | ― | |

| 0.15 | EAFS8D | 22.66 | 35.66 | ― | 31.66 | C30/37 | 34.90 | 35.37 | ― |

| REF2 | 18.40 | 27.37 | 35.85 | 24.10 | C20/25 | 24.58 | 27.01 | 30.14 | |

| 0.20 | EAFS8C1 | 17.87 | 31.14 | 39.93 | 27.14 | C25/30 | 32.76 | 37.95 | 39.91 |

| 0.15 | EAFS8D1 | 15.40 | 29.22 | 36.82 | 25.22 | C25/30 | 29.70 | 36.04 | 36.82 |

| FRC_EAFS | 13.60 | 25.09 | 31.64 | 21.09 | C20/25 | 30.07 | 37.37 | 36.74 | |

3.3. Physical Properties

3.3.1. Water Absorption by Immersion

3.3.2. Water Absorption by Capillarity

3.3.3. Permeability to Air and Water

3.3.4. Resistance to Carbonation

4. Discussion

4.1. Fresh Behavior

4.2. Mechanical Properties

4.2.1. Compressive Behavior of EAFS Mixtures

4.2.2. Optimal Parameters for Designing EAFS Concrete Based on the Andreasen and Andersen Particle Packing Model

4.3. Physical Properties

4.3.1. Porosity

4.3.2. Sorptivity

4.3.3. Permeability to Air and Water

4.3.4. Resistance to Carbonation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eštoková, A.; Fabiánová, M.W.; Ondová, M. Concrete Structures and Their Impacts on Climate Change and Water and Raw Material Resource Depletion. Int. J. Civ. Eng. 2022, 20, 735–747. [Google Scholar] [CrossRef]

- Dimoudi, A.; Tompa, C. Energy and environmental indicators related to construction of office buildings. Resour. Conserv. Recycl. 2008, 53, 86–95. [Google Scholar] [CrossRef]

- European Commission. Leading the Way to a Global Circular Economy: State of Play and Outlook Environment; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar] [CrossRef]

- Vu, H.M.; Forth, J.P.; Toropov, V. The Use of Glycerol and Cooking Oil in Masonry Unit Production; ICE (Institution of Civil Engineers) Publishing: London, UK, 2015; p. 14. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an eco-friendly Ultra-High Performance Concrete ( UHPC ) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Rodrigues, I.P. Ligantes de Baixo Impacto Ambiental e Baixo Custo, Baseados na Ativação Química de Escórias de Aciaria. Master’s Thesis, Escola de Engenharia da Universidade do Minho, Guimarães, Portugal, 2015. [Google Scholar]

- Ramos, T.; Juvandes, L.; Moreira, A. Utilização de ASIC em betão. In Proceedings of the Encontro Nacional Betão Estrutural-BE2012, Porto, Portugal, 24–26 October 2012; pp. 24–26. [Google Scholar]

- Pacheco, A. Estudo da Viabilidade da Utilização de Escórias de Aciaria (ASIC) em Betão Denso. Master’s Thesis, Faculdade de Engenharia da Universidade do Porto, Porto, Portugal, 2012. [Google Scholar]

- Torgal, F.P.; Jalali, S. Sustentabiliade-Tendências para a sustentabilidade dos materiais de construção. Eng. Vida 2008, 42, 2–5. [Google Scholar]

- Torgal, F.P.; Jalali, S. Eco-Eficiência dos Materiais de Construção. Rev. Assoc. Port. Empresas Betão Pronto 2010, 147, 48–55. [Google Scholar]

- Aiello, M.A.; Leuzzi, F. Waste tyre rubberized concrete: Properties at fresh and hardened state. Waste Manag. 2010, 30, 1696–1704. [Google Scholar] [CrossRef] [PubMed]

- Thomas, B.S.; Gupta, R.C. Long term behaviour of cement concrete containing discarded tire rubber. J. Clean Prod. 2015, 102, 78–87. [Google Scholar] [CrossRef]

- Su, H.; Yang, J.; Ling, T.; Ghataora, G.S.; Dirar, S. Properties of concrete prepared with waste tyre rubber particles of uniform and varying sizes. J. Clean Prod. 2015, 91, 288–296. [Google Scholar] [CrossRef]

- Li, G.; Garrick, G.; Eggers, J.; Abadie, C.; Stubblefield, M.A.; Pang, S. Waste tire fiber modified concrete. Compos. B Eng. 2004, 35, 305–312. [Google Scholar] [CrossRef]

- Azevedo, F.; Jesus, C.; de Aguiar, J.L.B.; Camões, A.F. Properties and durability of HPC with tyre rubber wastes. Constr. Build. Mater. 2012, 34, 186–191. [Google Scholar] [CrossRef]

- Bari, A.; Jel, M.; Pezer, M.; Nina, Š. Influence of recycled tire polymer fibers on concrete properties. Cem. Concr. Compos. 2018, 91, 29–41. [Google Scholar] [CrossRef]

- Sousa Coutinho, A. Fabrico e Propriedades do Betão; LNEC-Laboratorio Nacional de Engenharia Civil: Lisbon, Portugal, 1988; Volume 1. [Google Scholar]

- CPPE-Companhia Portuguesa de Produção de Electricidade SA (Grupo EDP). Cinzas Volantes-Aplicações em Cimentos e Betões. Boletim da Sociedade Portuguesa de Química, Correntes de Despolorizção Termostimuladas, March 1995. Available online: https://www.spq.pt/magazines/BSPQuimica/580/article/3000681/pdf (accessed on 1 November 2022).

- Torgal, F.P.; Jalali, S. Betão Eco-Eficiência: O Futuro da Indústria do Betão Pronto; Associação Portuguesa das Empresas de Betão Pronto: Amadora, Portugal, 2011; Volume 26, pp. 22–27. [Google Scholar]

- Andrade, R.M.A. Caracterização Laboratorial de Misturas Betuminosas com Incorporação de Agregado Siderúrgico Inerte para Construção (ASIC). Master’s Thesis, Instituto Superior de Engenharia de Lisboa, Lisbon, Portugal, 2015. [Google Scholar]

- Arribas, I.; Santamaría, A.; Ruiz, E.; Ortega-López, V.; Manso, J.M. Electric arc furnace slag and its use in hydraulic concrete. Constr. Build. Mater. 2015, 90, 68–79. [Google Scholar] [CrossRef]

- Santamaría, A.; Ortega-López, V.; Skaf, M.; Marcos, I.; San-José, J.T.; González, J.J. Performance of hydraulic mixes manufactured with electric arc furnace slag aggregates. In Proceedings of the 3rd Pan American Materials Congress, San Diego, CA, USA, 26 February–2 March 2017; No. 9783319521312. pp. 227–234. [Google Scholar] [CrossRef]

- San-José, J.T.; Vegas, I.; Arribas, I.; Marcos, I. The performance of steel-making slag concretes in the hardened state. Mater. Des. 2014, 60, 612–619. [Google Scholar] [CrossRef]

- Papayianni, I.; Anastasiou, E. Utilization of electric arc furnace steel slags in concrete products. In Proceedings of the 6th European Slag Conference, Madrid, Spain, 20–22 October 2010; pp. 319–334. Available online: https://www.researchgate.net/publication/255965247 (accessed on 4 January 2023).

- Arribas, I.; Vegas, I.; San-José, J.T.; Manso, J.M. Durability studies on steelmaking slag concretes. Mater. Des. 2014, 63, 168–176. [Google Scholar] [CrossRef]

- Manso, J.M.; Gonzalez, J.J.; Polanco, J.A. Electric Arc Furnace Slag in Concrete. J. Mater. Civ. Eng. 2004, 16, 639–645. [Google Scholar] [CrossRef]

- García-Cortés, V.; Estévez, D.G.; San-José, J.T. Assessment of particle packing models for aggregate dosage design in limestone and EAFS aggregate-based concretes. Constr. Build. Mater. 2022, 328, 126977. [Google Scholar] [CrossRef]

- Chatzopoulos, A.; Sideris, K.K.; Tassos, C. Production of concretes using slag aggregates: Contribution of increasing the durability and sustainability of constructions. Case Stud. Constr. Mater. 2021, 15, e00711. [Google Scholar] [CrossRef]

- González-Ortega, M.A.; Cavalaro, S.H.P.; de Sensale, G.R.; Aguado, A. Durability of concrete with electric arc furnace slag aggregate. Constr. Build. Mater. 2019, 217, 543–556. [Google Scholar] [CrossRef]

- Correia, A.G.; Roque, A.J.; Ferreira, S.F.; Castro, F.; Fortunato, E.; de Santayana, F.P.; Trigo, L. A Valorização de Agregados Siderúrgicos Inertes Reciclados em Obras Geotécnicas-Um Projeto Nacional. Valorização Resíduos, Guimarães, Portugal, pp. 19–25, November 2007. Available online: http://repositorio.lnec.pt:8080/jspui/handle/123456789/1004012 (accessed on 4 January 2023).

- Fazli, A.; Rodrigue, D. Recycling waste tires into Ground Tire Rubber (GTR)/rubber compounds: A review. J. Compos. Sci. 2020, 4, 103. [Google Scholar] [CrossRef]

- Andreasen, A.H.M.; Andersen, J. Über die Beziehung zwischen Kornabstufung und Zwischenraum in Produkten aus losen Körnern (mit einigen Experimenten). Kolloid-Zeitschrift 1930, 50, 217–228. [Google Scholar] [CrossRef]

- Funk, J.E.; Dinger, D. Predictive Process Control of Crowded Particulate Suspensions: Applied to Ceramic Manufacturing; Springer: New York, NY, USA, 1994. [Google Scholar] [CrossRef]

- Husken, G. A Multifunctional Design Approach for Sustainable Concrete-with Application to Concrete Mass Products. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2010. [Google Scholar]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Yu, R.; Tang, P.; Spiesz, P.; Brouwers, H.J.H. A study of multiple effects of nano-silica and hybrid fibres on the properties of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC) incorporating waste bottom ash (WBA). Constr. Build. Mater. 2014, 60, 98–110. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC): Towards an efficient utilization of binders and fibres. Constr. Build. Mater. 2015, 79, 273–282. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Effect of nano-silica on the hydration and microstructure development of Ultra-High Performance Concrete (UHPC) with a low binder amount. Constr. Build. Mater. 2014, 65, 140–150. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Static properties and impact resistance of a green Ultra-High Performance Hybrid Fibre Reinforced Concrete (UHPHFRC): Experiments and modeling. Constr. Build. Mater. 2014, 68, 158–171. [Google Scholar] [CrossRef]

- Yu, Q.L.; Spiesz, P.; Brouwers, H.J.H. Cement & Concrete Composites Ultra-lightweight concrete: Conceptual design and performance evaluation. Cem. Concr. Compos. 2015, 61, 18–28. [Google Scholar] [CrossRef]

- Yu, R.; Van Onna, D.V.; Spiesz, P.; Yu, Q.L.; Brouwers, H.J.H. Development of Ultra-Lightweight Fibre Reinforced Concrete applying expanded waste glass. J. Clean Prod. 2016, 112, 690–701. [Google Scholar] [CrossRef]

- ASTM C 566-97; Standard Test Method for Total Evaporable Moisture Content of Aggregate by Drying. ASTM International Standarts: West Conshohocken, PA, USA, 2004; p. 3.

- EN 12390-1; Testing Hardened Concrete-Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds. European Standard: Brussels, Belgium, 2012; pp. 1–14.

- EN 12390-2; Testing Hardened Concrete-Part 2: Making and Curing Specimens for Strength Tests. European Standard: Brussels, Belgium, 2009; p. 8.

- EN 12350-2; Testing Fresh Concrete-Part 2: Slump-Test. European Standard: Brussels, Belgium, 2009; p. 8.

- EN 12390-13; Testing Hardened Concrete-Part 13: Determination of Secant Modulus of Elasticity in Compression. European Standard: Brussels, Belgium, 2013; p. 14. [CrossRef]

- EN 12390-3; Testing Hardened Concrete-Part 3: Compressive Strength of Test Specimens. European Standard: Brussels, Belgium, 2009; p. 21.

- LNEC E 394; Determination of the Absorption of Water by Immersion. Laboratório Nacional de Engenharia Civil: Lisbon, Portugal, 1993.

- LNEC E 395; Determination of the Absorption of Water by Immersion under Vacuum. Laboratório Nacional de Engenharia Civil: Lisbon, Portugal, 1993.

- LNEC E 393; Determination of the Absorption of Water through Capillarity. Laboratório Nacional de Engenharia Civil: Lisbon, Portugal, 1993.

- Rilem, T.C. CPC 11.1 Absorption of water by immersion. In RILEM Recommendations for the Testing and Use of Constructions Materials; Rilem, E., Sponed, F.N., Eds.; Springer: Berlin, Germany, 1994; p. 33. [Google Scholar] [CrossRef]

- Rilem, T.C. CPC 11.2 Absorption of water by capilarity. In RILEM Recommendations for the Testing and Use of Constructions Materials; Rilem, E., Sponed, F.N., Eds.; Springer: Berlin, Germany, 1994; pp. 34–35. [Google Scholar] [CrossRef]

- Rilem, T.C. CPC 11.3 Absorption of water by concrete by immersion under vacuum. In RILEM Recommendations for the Testing and Use of Constructions Materials; Rilem, E., Sponed, F.N., Eds.; Springer: Berlin, Germany, 1994; Volume 17, pp. 36–37. [Google Scholar] [CrossRef]

- Cabrera, J.G. Design an Productionb of High Performance Durable Concrete. In Proceedings of the International Conference: Infrastructure Regeneration and Rehabilitation Inproving the Quality of Life through Better Cronstruction-A Vision for the Next Millennium, Sheffield, UK, 28 June–2 July 1999; Sheffield Academic Press: Sheffield, UK, 1999; pp. 1–14. [Google Scholar]

- BS 1881-210; Testing Hardened Concrete-Part 210: Determination of the Potential Carbonation Resistance of Concrete-ACCELERATED Carbonation Method. European Standard: London, UK, 2013; p. 14.

- NP EN 206-1; Concrete-Part 1: Specification, Performance, Production and Conformity. European Standard: Brussels, Belgium, 2000; p. 84.

- LNEC E 465; Betões. Metodologia para Estimar as Propriedades de Desempenho do Betão que Permitem Satisfazer a Vida útil de Projecto de Estruturas de Betão Armado ou Pré-Esforçado Sob as Exposições Ambientais XC e XS. Laboratório Nacional de Engenharia Civil: Lisbon, Portugal, 2007; pp. 1–24.

- EN 1992-1-1; Design of Concrete Structures-Part 1-1: General Rules and Rules for Buildings. European Standard: Brussels, Belgium, 2004; p. 230.

- Freitas, N.E.D. Sustentabilidade de Estruturas de Betão em Ambiente Marítimo com Recurso a FRP; Escola de Engenharia da Universidade do Minho: Guimarães, Portugal, 2016. [Google Scholar]

- Pereira, J. Dissertação de Mestrado em Engenharia Civil-Estruturas de Betão Reforçadas com Materiais Compósitos em Ambiente Marítimo e Concebidas com Água do Mar; Escola de Engenharia da Universidade do Minho: Guimarães, Portugal, 2016. [Google Scholar]

- Ferreira, R.M. Avaliação de Ensaios de Durabilidade do Betão. Master’s Thesis, Universidade do Minho, Guimarães, Portugal, 2000. [Google Scholar]

- Camões, A. Betões de Elevado Desempenho com Incorporação de Cinzas Volantes. Ph.D. Thesis, University of Minho, Guimarães (Portugal), Guimarães, Portugal, 2002. [Google Scholar]

- Evangelista, L.; de Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Camões, A. Betões de Elevado Desempenho com Elevado Volume de Cinzas Volantes; Universidade do Minho: Guimarães, Portugal, 2005. [Google Scholar]

- Martins, I.M.; Gonçalves, A.; Marques, J. Durability and Strength Properties of Concrete Containing Coal Bottom Ash. In Proceedings of the pro077: International RILEM Conference on Material Science, Aachen, Germany, 6–10 September 2010; pp. 275–283. Available online: http://eprints.whiterose.ac.uk/76421/ (accessed on 10 February 2021).

- Gaibor, N.; Leitão, D.; Miranda, T.; Cristelo, N.; Pereira, E.N.B.; Cunha, V.M.C.F. Effect of polyacrylonitrile fiber on the properties of alkali-activated ceramic/slag-based mortar. J. Build. Eng. 2021, 44, 103367. [Google Scholar] [CrossRef]

- Coutinho, J.D.S. Melhoria da Durabilidade dos Betões Por Tratamento da Cofragem. Ph.D. Thesis, Universidade do Porto, Porto, Portugal, 1998. [Google Scholar]

- Hassan, K.E.; Cabrera, J.G. Control of concrete performance by limiting oxygen permeability and oxygen diffusion. In Proceedings of the International Conference: Infrastructure Regeneration and Rehabilitation Inproving the Quality of Life through Better Cronstruction—A Vision for the Next Millennium, Sheffield, UK, 28 June–2 July 1999; Sheffield Academic Press: Sheffield, UK, 1999; pp. 1085–1095. [Google Scholar]

- Ferreira, R.M.; Jalali, S. Avaliação dos Ensaios Correntes para a Medição da Durabilidade do Betão; Universidade do Minho: Guimarães, Portugal, 2001. [Google Scholar]

- De Ceukelaire, L.; van Nieuwenburg, D. Accelerated Carbonation of a Blast-furnace Cement Concrete. Cem. Concr. Res. 1993, 23, 442–452. [Google Scholar] [CrossRef]

- Dias, W.P.S. Reduction of concrete sorptivity with age through carbonation. Cem. Concr. Res. 2000, 30, 1255–1261. [Google Scholar] [CrossRef]

- Gonen, T.; Yazicioglu, S. The influence of compaction pores on sorptivity and carbonation of concrete. Constr. Build. Mater. 2007, 21, 1040–1045. [Google Scholar] [CrossRef]

- Kassim, D.; Lamaa, G.; Silva, R.V.; de Brito, J. Performance Enhancement of Alkali-Activated Electric Arc Furnace Slag Mortars through an Accelerated CO2 Curing Process. Appl. Sci. 2022, 12, 1662. [Google Scholar] [CrossRef]

| Component | Apparent Particle Density, ρa (Mg/m3) | Particle Density on an Oven-Dried Basis, ρrd (Mg/m3) | Particle Density on a Saturated-Dried Basis, ρssd (Mg/m3) | Water Absorption, WA24 (%) |

|---|---|---|---|---|

| SP | ― | 1.18 | ― | ― |

| PL | ― | 1.18 | ― | ― |

| CEM | ― | 3.11 | ― | ― |

| Filler | ― | 2.70 | ― | ― |

| FA_1 | ― | 2.42 | ― | ― |

| FA_2 | ― | 2.35 | ― | ― |

| Sand 0–2 | 2.64 | 2.62 | 2.63 | 0.2 |

| Sand 0–4 | 2.65 | 2.61 | 2.63 | 0.6 |

| Aggregate 6–20 | 2.70 | 2.64 | 2.66 | 0.8 |

| EAFS 0–4 | 3.58 | 3.49 | 3.51 | 0.7 |

| EAFS 4–10 | 3.47 | 3.25 | 3.31 | 2.0 |

| EAFS 10–14 | 3.40 | 3.22 | 3.27 | 1.6 |

| EAFS 14–20 | 3.34 | 3.18 | 3.22 | 1.6 |

| EAFS 0–20 | 3.42 | 3.25 | 3.29 | 1.6 |

| REF1 | REF2 | |

|---|---|---|

| CEM II/A-L 42.5 R | 280 | 205 |

| FA_2 | 115 | |

| Sand 0–2 | 415 | 350 |

| Sand 0–4 | 495 | 530 |

| Aggregate 6–14 | 552 | 388 |

| Aggregate 14–20 | 430 | 580 |

| SP | 1.6 | 1.6 |

| PL | 1.4 | 1.6 |

| Water | 165 | 154.1 |

| w/p | 0.54 | 0.35 |

| w/c | 0.59 | 0.75 |

| % Aggregates | 87.11 | 81.48 |

| % FA | ― | 9.48 |

| EAFS | FA | |||

|---|---|---|---|---|

| XRF | XRF | EDS | XRD | |

| Al2O3 | 8.91 | 27.30 | 28.59 | 22.1 vitreous * |

| BaO | 0.15 | |||

| C | 3.65 | |||

| CaO | 26.73 | 2.36 | 1.80 | |

| Cl | 0.02 | |||

| Cr2O3 | 1.70 | |||

| CuO | 0.03 | |||

| Fe2O3 | 32.33 | 8.19 | 6.86 | 4.8 vitreous * |

| K2O | 0.23 | 3.34 | 1.97 | |

| MgO | 4.27 | 1.42 | ||

| MnO | 3.25 | |||

| Na2O | 0.30 | 0.99 | 1.78 | |

| Nb2O5 | 0.02 | |||

| P2O5 | 0.51 | |||

| SiO2 | 20.29 | 49.12 | 56.83 | 28.7 vitreous * |

| SO3 | 0.29 | 1.30 | ||

| SrO | 0.04 | |||

| TiO2 | 0.67 | 2.32 | ||

| V2O5 | 0.14 | |||

| WO3 | 0.01 | |||

| ZnO | 0.02 | |||

| Other | 15.4 vitreous * | |||

| Quartz | 18.41 | |||

| Mullite | 7.18 | |||

| Hematite | 3.41 | |||

| Total crystalline phase * | 29.00 | |||

| Total glassy phase | 71.00 | |||

| Diameter (mm) | Length (mm) | Developed Length (mm) | Slenderness | Curvature Index | |

|---|---|---|---|---|---|

| Minimum | 0.1 | 5.0 | 19.0 | 45.5 | 0.1 |

| Maximum | 1.2 | 92.0 | 129.0 | 651.2 | 0.9 |

| Mode | 0.3 | 33.0 | 34.0 | 225.0 | 0.3 |

| Average | 0.3 | 33.2 | 53.3 | 199.0 | 0.4 |

| CoV | 0.448 | 0.411 | 0.358 | 0.392 | 0.529 |

| q = 0.35 | q = 0.25 | q = 0.20 | q = 0.15 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| EAFS Mixtures | 2 | 3A | 4 | 6 | 3B | 8B | 5C | 8C | 8D |

| CEM | 234 | 233.7 | 233.8 | 233.7 | 241.5 | 252.2 | 254.4 | 257.4 | 257.4 |

| FA_1 | 3.6 | 123.7 | 135.5 | 169.3 | 210.4 | 286.5 | |||

| Filler | 22.4 | ||||||||

| Sand 0–2 | 528.3 | 176.8 | 66.9 | 234.7 | 194.5 | 225 | 247.3 | ||

| Sand 0–4 | 654.1 | ||||||||

| EAFS 0–0.5 | 316.7 | 498.2 | |||||||

| EAFS 0.5–4 | 810.6 | 879.8 | |||||||

| EAFS 0–4 | 848.2 | 792.1 | 1050.1 | 832.5 | 933 | ||||

| EAFS 4–10 | 734.4 | 414.4 | 394.4 | 363.1 | 452.5 | ||||

| EAFS 10–14 | 144.9 | ||||||||

| EAFS 14–20 | 257.4 | ||||||||

| EAFS 0–20 | 981.8 | 958 | 931 | 1448.5 | 721.1 | 978.5 | 828.4 | 705.9 | |

| * SP | 2.61 | 2.61 | 2.61 | 2.61 | 2.69 | 2.81 | 2.84 | 2.87 | 2.87 |

| * Water | 155.7 | 151 | 153.9 | 158.9 | 188.5 | 153.0 | 199.8 | 221.5 | 195.7 |

| w/p (b) | 0.55 | 0.55 | 0.55 | 0.55 | 0.48 | 0.37 | 0.43 | 0.45 | 0.35 |

| w/c | 0.67 | 0.65 | 0.66 | 0.68 | 0.78 | 0.61 | 0.79 | 0.86 | 0.76 |

| RSS | 0.07 | 0.02 | 0.02 | 0.10 | 0.02 | 0.03 | 0.02 | 0.03 | 0.03 |

| % EAFS (a) | 69.2 | 84.3 | 91.3 | 59.7 | 75.8 | 77.7 | 84.0 | 70.6 | 67.4 |

| % FA (a) | 0.1 | 5.0 | 5.2 | 6.4 | 8.9 | 11.8 | |||

| q = 0.20 | q = 0.15 | ||

|---|---|---|---|

| EAFS Mixtures | 8C1 | 8D1 | FRC_EAFS |

| CEM | 194 | 209.2 | 205.8 |

| FA_2 | 177.1 | 244 | 249.5 |

| Sand 0–2 | 235.9 | 279.5 | 288.5 |

| EAFS 0–4 | 1020.1 | 979.9 | 995.4 |

| EAFS 0–20 | 860.5 | 764.1 | 776.4 |

| * SP | 1.51 | 1.63 | 1.61 |

| * PL | 1.51 | 1.63 | 1.61 |

| * Water | 177.3 | 165.5 | 181.33 |

| RTSF | 39.3 | ||

| w/p (b) | 0.45 | 0.35 | 0.38 |

| w/c | 0.91 | 0.79 | 0.88 |

| RSS | 0.03 | 0.03 | |

| % EAFS (a) | 75.6 | 70.4 | 70.4 |

| % FA (a) | 7.1 | 9.9 | 9.9 |

| Mixtures | Description |

|---|---|

| REF1 | Reference mixture with a slump class of S3 and a strength class of C30/C37 |

| EAFS2 | Mixture based on REF1 with EAFS aggregate size fraction of 4–10 and 0–20 for q = 0.35 |

| EAFS3A | Mixture based on REF1 with EAFS aggregate size fraction of 0–4, 4–10 and 0–20 for q = 0.35 |

| EAFS3B | Mixture based on REF1 with EAFS aggregate size fraction of 0–4, 4–10 and 0–20 for q = 0.25 |

| EAFS4 | Mixture based on REF1 with EAFS aggregate size fraction of 0–0.5, 0.5–4, 4–10 and 0–20 for q = 0.35 |

| EAFS5C | Mixture based on REF1 with EAFS aggregate size fraction of 0–0.5, 0.5–4, 4–10, 10–14 and 14–20 for q = 0.25 |

| EAFS6 | Mixture based on REF1 with EAFS aggregate size fraction of 0–20 for q = 0.35 |

| EAFS8B | Mixture based on REF1 with EAFS aggregate size fraction of 0–4 and 0–20 for q = 0.25 |

| EAFS8C | Mixture based on REF1 with EAFS aggregate size fraction of 0–4 and 0–20 for q = 0.20 |

| EAFS8D | Mixture based on REF1 with EAFS aggregate size fraction of 0–4 and 0–20 for q = 0.15 |

| REF2 | Reference mixture with a slump class of S4 and a strength class of C25/C30 |

| EAFS8C1 | Mixture based on REF2 with EAFS aggregate size fraction of 0–4 and 0–20 for q = 0.20 (low cement amount) |

| EAFS8D1 | Mixture based on REF2 with EAFS aggregate size fraction of 0–4 and 0–20 for q = 0.15 (low cement amount) |

| FRC_EAFS | EAFS8D1 mixture with the incorporation of RTSF |

| Characterization Type | Tests | Specimen Type | N° of Specimens | Standards |

|---|---|---|---|---|

| Fresh properties | Slump | ― | ― | EN 12350-2 |

| Mechanical properties | Uniaxial compression | Cylinder (ϕ = 150 mm; H = 300 mm) | 12 | EN 12390-13 |

| Elasticity modulus | Cylinder (ϕ = 150 mm; H = 300 mm) | 9 | EN 12390-3 | |

| Physical properties | Water absorption by immersion at atmospheric pressure | Cubic (100 × 100 × 100 mm) | 3 | LNEC E 394 based on the RILEM Recommendation CPC11.1 |

| Water absorption by immersion at vacuum | Cylinder (ϕ = 50 mm; H = 40 mm) | 6 | LNEC E 395 based on the RILEM Recommendation CPC11.3 | |

| Water absorption by capillarity | Cylinder (ϕ = 150 mm; H = 300 mm) | 3 | LNEC E 393 RILEM Recommendation CPC11.2 | |

| Air and water permeability | Cylinder (ϕ = 50 mm; H = 40 mm) | 6 | Leeds Permeability Cell (LPC) developed at Leeds University | |

| Accelerated carbonation | Rectangular prism (100 × 100 × 400 mm) | 6 | BS 1881-210 |

| q | Mixtures | Slump (mm) | Slump Class |

|---|---|---|---|

| REF1 | 110 | S3 | |

| 0.35 | EAFS6 | 30 | S1 |

| EAFS2 | 164 | S4 | |

| EAFS3A | 10 | S1 | |

| EAFS4 | 0 | S1 | |

| 0.25 | EAFS8B | 20 | S1 |

| EAFS3B | 40 | S1 | |

| 0.20 | EAFS8C | 80 | S2 |

| EAFS5C | 120 | S3 | |

| 0.15 | EAFS8D | 125 | S3 |

| REF2 | 160 | S4 | |

| 0.20 | EAFS8C1 | 50 | S1 |

| 0.15 | EAFS8D1 | 160 | S4 |

| FRC_EAFS | 0 | S1 |

| Specimen | Md (g) | Ms (g) | Mh (g) | Wi (%) | Wim (%) | CoV |

|---|---|---|---|---|---|---|

| REF2_P1 | 2234.8 | 2355.9 | 1322.3 | 11.72 | 11.56 | 0.028 |

| REF2_P2 | 2237.0 | 2359.7 | 1325.5 | 11.87 | ||

| REF2_P3 | 2278.2 | 2394.1 | 1350.7 | 11.11 | ||

| EAFS8D1_P1 | 2646.7 | 2798.2 | 1755.0 | 14.53 | 14.47 | 0.011 |

| EAFS8D1_P2 | 2690.6 | 2840.6 | 1788.0 | 14.25 | ||

| EAFS8D1_P3 | 2666.7 | 2821.1 | 1765.0 | 14.62 | ||

| FRC_EAFS_P1 | 2593.5 | 2762.4 | 1717.5 | 16.16 | 16.22 | 0.005 |

| FRC_EAFS_P2 | 2566.2 | 2736.1 | 1695.2 | 16.32 | ||

| FRC_EAFS_P3 | 2587.5 | 2756.4 | 1711.7 | 16.17 |

| Specimen | Md (g) | Ms (g) | Mh (g) | Wvc (%) | Wvcm (%) | CoV |

|---|---|---|---|---|---|---|

| EAFS8D1_C1 | 160.75 | 174.18 | 111.08 | 21.28 | 21.75 | 0.020 |

| EAFS8D1_C2 | 160.81 | 174.56 | 110.35 | 21.41 | ||

| EAFS8D1_C3 | 159.39 | 173.07 | 109.39 | 21.48 | ||

| EAFS8D1_C4 | 156.96 | 171.40 | 107.65 | 22.65 | ||

| EAFS8D1_C5 | 159.36 | 173.20 | 109.32 | 21.67 | ||

| EAFS8D1_C6 | 154.43 | 168.14 | 105.86 | 22.00 |

| Time (min0.5) | Absorption Mass ( mg) | Wc (mg/mm2) | Wcm (mg/mm2) | ||||

|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C1 | C2 | C3 | ||

| 0.00 | 11,676.7 | 11,659.9 | 11,669.48 | 0.000 | 0.000 | 0.000 | 0.000 |

| 7.75 | 11,688.02 | 11,669.92 | 11,682.42 | 0.658 | 0.585 | 0.752 | 0.665 |

| 10.95 | 11,689.94 | 11,671.98 | 11,684.76 | 0.770 | 0.705 | 0.888 | 0.788 |

| 13.42 | 11,696.3 | 11,674.84 | 11,688.14 | 1.139 | 0.872 | 1.085 | 1.032 |

| 15.49 | 11,696.3 | 11,678.32 | 11,691.74 | 1.139 | 1.076 | 1.294 | 1.170 |

| 17.32 | 11,698.52 | 11,680.34 | 11,694.12 | 1.268 | 1.194 | 1.432 | 1.298 |

| 34.64 | 11,718.84 | 11,701.12 | 11,716.7 | 2.450 | 2.407 | 2.745 | 2.534 |

| 36.33 | 11,720.82 | 11,702.44 | 11,718.02 | 2.565 | 2.484 | 2.822 | 2.623 |

| 37.95 | 11,722.36 | 11,703.76 | 11,719.74 | 2.654 | 2.561 | 2.922 | 2.712 |

| 39.50 | 11,723.88 | 11,705.2 | 11,721.82 | 2.742 | 2.645 | 3.042 | 2.810 |

| 40.99 | 11,725.6 | 11,706.9 | 11,723.16 | 2.842 | 2.744 | 3.120 | 2.902 |

| 51.38 | 11,736.38 | 11,717.72 | 11,735.5 | 3.469 | 3.376 | 3.838 | 3.561 |

| 52.54 | 11,736.64 | 11,717.8 | 11,735.82 | 3.484 | 3.381 | 3.856 | 3.574 |

| 53.67 | 11,738.86 | 11,719.1 | 11,737.08 | 3.613 | 3.457 | 3.929 | 3.666 |

| 54.77 | 11,739.68 | 11,720.2 | 11,738.46 | 3.661 | 3.521 | 4.010 | 3.731 |

| 55.86 | 11,740.8 | 11,721.3 | 11,739.62 | 3.726 | 3.585 | 4.077 | 3.796 |

| 63.87 | 11,748.54 | 11,729.1 | 11,748.28 | 4.176 | 4.041 | 4.581 | 4.266 |

| 64.81 | 11,748.8 | 11,729 | 11,749.1 | 4.191 | 4.035 | 4.628 | 4.285 |

| 65.73 | 11,749.84 | 11,729.6 | 11,749.36 | 4.251 | 4.070 | 4.643 | 4.322 |

| 67.53 | 11,751.76 | 11,731.2 | 11,751.36 | 4.363 | 4.163 | 4.760 | 4.429 |

| 74.30 | 11,757.22 | 11,736.64 | 11,757.78 | 4.680 | 4.481 | 5.133 | 4.765 |

| 75.89 | 11,758.22 | 11,737.64 | 11,758.64 | 4.739 | 4.539 | 5.183 | 4.820 |

| 77.46 | 11,759.08 | 11,738.56 | 11,759.74 | 4.789 | 4.593 | 5.247 | 4.876 |

| Time (min0.5) | Absorption Mass ( mg) | Wc (mg/mm2) | Wcm (mg/mm2) | ||||

|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C1 | C2 | C3 | ||

| 0.00 | 15,513.04 | 15,462.02 | 15,443.78 | 0.00 | 0.00 | 0.00 | 0.00 |

| 7.75 | 15,522.58 | 15,471.74 | 15,452.7 | 1.34 | 1.42 | 1.34 | 1.37 |

| 10.95 | 15,530.22 | 15,479.26 | 15,458.8 | 1.87 | 1.97 | 1.84 | 1.89 |

| 13.42 | 15,536.04 | 15,485.84 | 15,465.48 | 2.30 | 2.39 | 2.18 | 2.29 |

| 15.49 | 15,541.16 | 15,491.28 | 15,470.76 | 2.62 | 2.76 | 2.56 | 2.65 |

| 17.32 | 15,545.3 | 15,495.68 | 15,474.46 | 2.91 | 3.07 | 2.85 | 2.94 |

| 34.64 | 15,592.54 | 15,544.06 | 15,519.78 | 3.14 | 3.31 | 3.06 | 3.17 |

| 36.33 | 15,596.04 | 15,547.44 | 15,522.9 | 5.78 | 6.03 | 5.60 | 5.80 |

| 37.95 | 15,599.12 | 15,550.54 | 15,525.96 | 5.97 | 6.22 | 5.77 | 5.99 |

| 39.50 | 15,601.96 | 15,553.3 | 15,528.46 | 6.14 | 6.40 | 5.94 | 6.16 |

| 40.99 | 15,604.54 | 15,556.1 | 15,530.78 | 6.30 | 6.55 | 6.08 | 6.31 |

| 51.38 | 15,629.54 | 15,580.64 | 15,553.42 | 6.45 | 6.71 | 6.21 | 6.46 |

| 52.54 | 15,631.36 | 15,582.72 | 15,555.38 | 7.84 | 8.09 | 7.48 | 7.81 |

| 53.67 | 15,633.16 | 15,584.64 | 15,556.94 | 7.94 | 8.21 | 7.59 | 7.91 |

| 54.77 | 15,635.18 | 15,586.5 | 15,558.7 | 8.04 | 8.32 | 7.68 | 8.01 |

| 55.86 | 15,637.16 | 15,588.12 | 15,560.26 | 8.16 | 8.42 | 7.78 | 8.12 |

| 63.87 | 15,654.38 | 15,606.02 | 15,576.56 | 8.27 | 8.51 | 7.87 | 8.21 |

| 64.81 | 15,655.98 | 15,607.5 | 15,578.1 | 9.23 | 9.52 | 8.78 | 9.18 |

| 65.73 | 15,657.3 | 15,608.8 | 15,579.4 | 9.32 | 9.60 | 8.87 | 9.26 |

| 67.53 | 15,660.7 | 15,612.1 | 15,582.66 | 9.39 | 9.67 | 8.94 | 9.33 |

| 74.30 | 15,673.64 | 15,625.1 | 15,594.98 | 9.58 | 9.86 | 9.12 | 9.52 |

| 75.89 | 15,676.36 | 15,627.92 | 15,598.04 | 10.30 | 10.59 | 9.81 | 10.24 |

| 77.46 | 15,678.88 | 15,630.22 | 15,600.12 | 10.46 | 10.75 | 9.98 | 10.40 |

| Time (min0.5) | Absorption Mass ( mg) | Wc (mg/mm2) | Wcm (mg/mm2) | ||||

|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C1 | C2 | C3 | ||

| 0.00 | 13,386.32 | 13,406.08 | 13,308.64 | 0.00 | 0.00 | 0.00 | 0.00 |

| 7.75 | 13,402.76 | 13,419.58 | 13,325.06 | 0.94 | 0.78 | 0.96 | 0.90 |

| 10.95 | 13,407.16 | 13,423.16 | 13,329.14 | 1.20 | 0.99 | 1.20 | 1.13 |

| 13.42 | 13,412.06 | 13,427.1 | 13,332.96 | 1.48 | 1.22 | 1.43 | 1.37 |

| 15.49 | 13,417.9 | 13,432.06 | 13,338.44 | 1.81 | 1.51 | 1.75 | 1.69 |

| 17.32 | 13,421.28 | 13,435.36 | 13,341.88 | 2.00 | 1.70 | 1.95 | 1.89 |

| 34.64 | 13,461.02 | 13,466.16 | 13,376.86 | 4.28 | 3.49 | 4.00 | 3.93 |

| 36.33 | 13,463.92 | 13,468.1 | 13,379.52 | 4.45 | 3.61 | 4.16 | 4.07 |

| 37.95 | 13,466.78 | 13,471.1 | 13,382.76 | 4.61 | 3.78 | 4.35 | 4.25 |

| 39.50 | 13,470.4 | 13,473.68 | 13,385.56 | 4.82 | 3.93 | 4.51 | 4.42 |

| 40.99 | 13,473.26 | 13,476.32 | 13,387.98 | 4.99 | 4.08 | 4.65 | 4.57 |

| 51.38 | 13,494.86 | 13,493.92 | 13,407.46 | 6.22 | 5.11 | 5.80 | 5.71 |

| 52.54 | 13,496.48 | 13,494.64 | 13,408.48 | 6.32 | 5.15 | 5.86 | 5.77 |

| 53.67 | 13,499.24 | 13,496.72 | 13,410.8 | 6.48 | 5.27 | 5.99 | 5.91 |

| 54.77 | 13,501.32 | 13,498.38 | 13,412.74 | 6.60 | 5.37 | 6.11 | 6.02 |

| 55.86 | 13,503.5 | 13,500.18 | 13,415.08 | 6.72 | 5.47 | 6.24 | 6.14 |

| 63.87 | 13,519.2 | 13,513.22 | 13,429.3 | 7.62 | 6.23 | 7.08 | 6.98 |

| 64.81 | 13,521.12 | 13,514.28 | 13,430.72 | 7.73 | 6.29 | 7.16 | 7.06 |

| 65.73 | 13,522.64 | 13,515.7 | 13,432.1 | 7.82 | 6.37 | 7.24 | 7.14 |

| 67.53 | 13,525.8 | 13,518.1 | 13,434.96 | 8.00 | 6.51 | 7.41 | 7.31 |

| 74.30 | 13,538.6 | 13,527.84 | 13,446.26 | 8.73 | 7.08 | 8.07 | 7.96 |

| 75.89 | 13,540.94 | 13,529.48 | 13,448.34 | 8.87 | 7.17 | 8.19 | 8.08 |

| 77.46 | 13,543.32 | 13,531.04 | 13,450.64 | 9.00 | 7.26 | 8.33 | 8.20 |

| Specimen | Lm (mm) | Am (mm2) | T10m (s) | v (×10−8 m3/s) | KG (×10−16 m2) | KGm (×10−16 m2) | CoV |

|---|---|---|---|---|---|---|---|

| EAFS8D1_C1 | 39.13 | 1640.66 | 9.279 | 5.290 | 0.584 | 0.558 | 0.07 |

| EAFS8D1_C2 | 39.02 | 1649.10 | 10.082 | 4.869 | 0.533 | ||

| EAFS8D1_C3 | 39.15 | 1642.63 | 9.060 | 5.418 | 0.597 | ||

| EAFS8D1_C4 | 39.37 | 1642.63 | 9.036 | 5.432 | 0.602 | ||

| EAFS8D1_C5 | 39.38 | 1640.30 | 10.635 | 4.616 | 0.513 | ||

| EAFS8D1_C6 | 38.45 | 1634.56 | 10.274 | 4.778 | 0.520 |

| Specimen | dpm (mm) | KW (×10−18 m2) | KWm (×10−18 m2) | CoV |

|---|---|---|---|---|

| EAFS8D1_C1 | 9.47 | 3.751 | 4.20 | 0.40 |

| EAFS8D1_C2 | 10.82 | 4.929 | ||

| EAFS8D1_C3 | 11.57 | 5.646 | ||

| EAFS8D1_C4 | 11.96 | 6.366 | ||

| EAFS8D1_C5 | 8.84 | 3.324 | ||

| EAFS8D1_C6 | 5.29 | 1.210 |

| t1 (Days) | REF2 | EAFS8D1 | FRC_EAFS |

|---|---|---|---|

| 28 |  |  |  |

| 56 |  |  |  |

| 70 |  |  |  |

| 90 |  |  |  |

| 122 |  |  |  |

| 143 |  |  |  |

| 149 |  |  |  |

| 163 |  |  |  |

| 170 |  |  |  |

| 174 |  |  |  |

| 186 |  |  |  |

| t1 (Days) | X1m (mm) | ||

|---|---|---|---|

| REF2 | EAFS8D1 | FRC_EAFS | |

| 28 | 19.12 | 15.41 | 17.07 |

| 56 | 27.22 | 20.63 | 23.17 |

| 63 | 27.85 | 22.26 | 22.80 |

| 70 | 28.70 | 24.89 | 23.44 |

| 90 | 28.83 | 24.67 | 24.61 |

| 122 | 34.11 | 28.79 | 28.97 |

| 143 | 38.10 | 32.10 | 33.15 |

| 149 | 38.36 | 32.69 | 34.83 |

| 163 | 41.31 | 35.72 | 34.61 |

| 170 | 43.71 | 36.13 | 36.24 |

| 174 | 43.19 | 36.29 | 35.64 |

| 186 | 42.29 | 37.00 | 35.83 |

| t1 (Days) | Rc65 (kg∙year/m5) | Rc65m (kg∙year/m5)/CoV | ||||

|---|---|---|---|---|---|---|

| REF2 | EAFS8D1 | FRC_EAFS | REF2 | EAFS8D1 | FRC_EAFS | |

| 28 | 37.75 | 58.17 | 47.39 | 48.92/0.189 | 65.30/0.076 | 63.42/0.119 |

| 56 | 75.51 | 64.92 | 51.44 | |||

| 63 | 40.06 | 62.69 | 59.75 | |||

| 70 | 41.92 | 55.73 | 62.82 | |||

| 90 | 53.39 | 72.93 | 73.27 | |||

| 122 | 51.70 | 72.59 | 71.69 | |||

| 143 | 48.58 | 68.45 | 64.19 | |||

| 149 | 49.94 | 68.74 | 60.58 | |||

| 163 | 47.10 | 62.99 | 67.10 | |||

| 170 | 43.87 | 64.22 | 63.85 | |||

| 174 | 45.99 | 65.15 | 67.54 | |||

| 186 | 51.28 | 67.01 | 71.46 | |||

| Water Permeability Coefficient, KW (m/s) | Water Permeability Coefficient, KW (m2) | Quality Class |

|---|---|---|

| ≥1 × 10−10 | ≥1.3 × 10−17 | Reduced |

| 1 × 10−12–1 × 10−10 | 1.3 × 10−19–1.3 × 10−17 | Normal |

| ≤1 × 10−12 | ≤1.3 × 10−19 | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neves, A.; Almeida, J.; Cruz, F.; Miranda, T.; Cunha, V.M.C.F.; Rodrigues, M.; Costa, J.; Pereira, E.B. Design Procedures for Sustainable Structural Concretes Using Wastes and Industrial By-Products. Appl. Sci. 2023, 13, 2087. https://doi.org/10.3390/app13042087

Neves A, Almeida J, Cruz F, Miranda T, Cunha VMCF, Rodrigues M, Costa J, Pereira EB. Design Procedures for Sustainable Structural Concretes Using Wastes and Industrial By-Products. Applied Sciences. 2023; 13(4):2087. https://doi.org/10.3390/app13042087

Chicago/Turabian StyleNeves, Ana, João Almeida, Fábio Cruz, Tiago Miranda, Vítor M. C. F. Cunha, Mafalda Rodrigues, José Costa, and Eduardo B. Pereira. 2023. "Design Procedures for Sustainable Structural Concretes Using Wastes and Industrial By-Products" Applied Sciences 13, no. 4: 2087. https://doi.org/10.3390/app13042087

APA StyleNeves, A., Almeida, J., Cruz, F., Miranda, T., Cunha, V. M. C. F., Rodrigues, M., Costa, J., & Pereira, E. B. (2023). Design Procedures for Sustainable Structural Concretes Using Wastes and Industrial By-Products. Applied Sciences, 13(4), 2087. https://doi.org/10.3390/app13042087