Research on Feature Identification and Trajectory Planning of Pavement Cracks

Abstract

:1. Introduction

2. Research Significance

3. Intelligent Pavement Crack Detection and Repair Algorithm

3.1. Algorithmic Framework

3.2. Image Filtering Stage

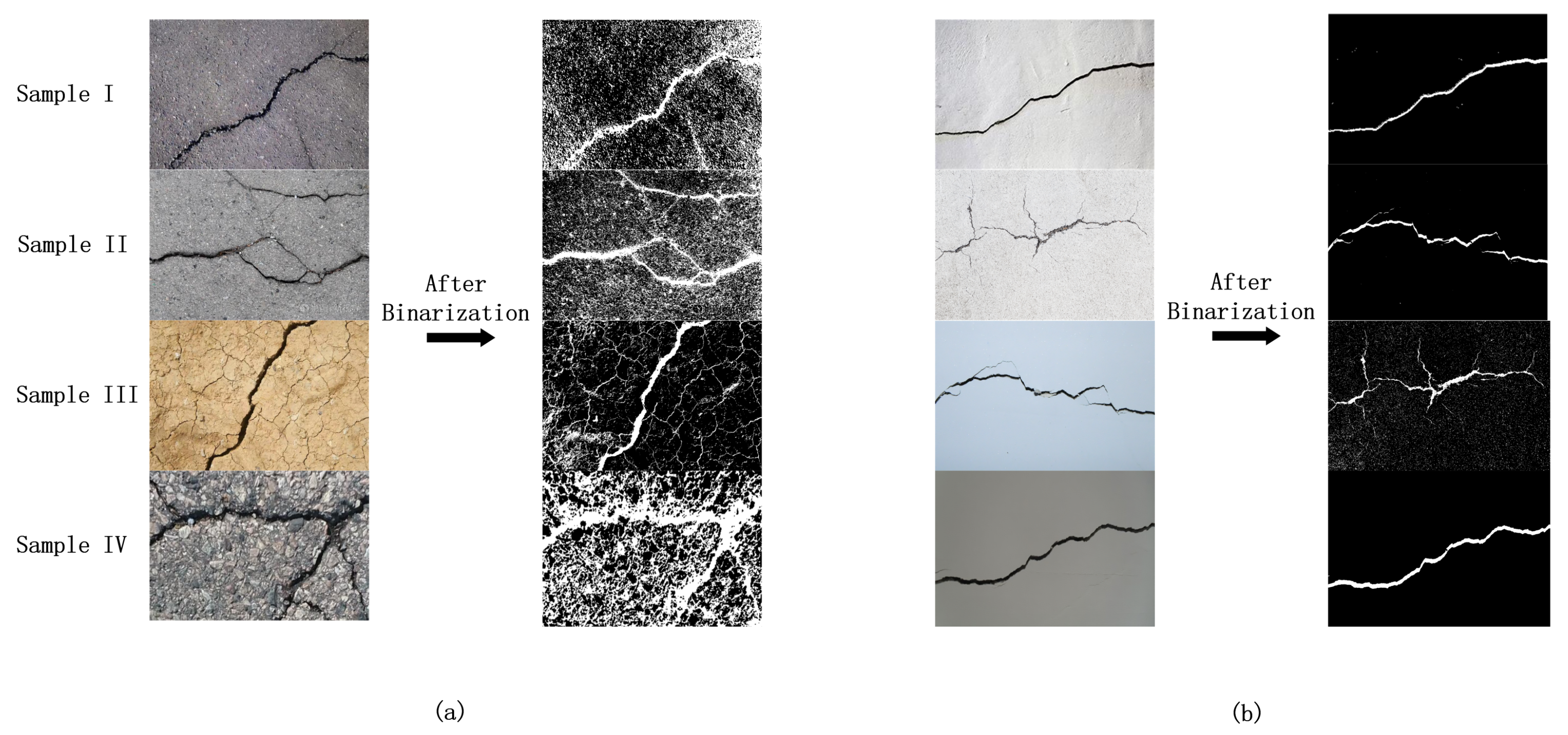

3.2.1. Image Classification Policy Engine

3.2.2. Wide Crack Feature Extraction Policy

3.2.3. Narrow Crack Feature Extraction Policy

- (i)

- Establish a label matrix of the same size and a one-dimensional array for storing the area size of each connected component according to the pixel matrix of the incoming image.

- (ii)

- Traverse the pixel points of the binarized image row by row or column by column to obtain their pixel values.

- (iii)

- If the values of the four adjacent pixels at the upper left of the traversed pixel are not all 0, assign the same label value to the pixel and the adjacent pixels that are not 0, and record the number of consecutive pixels currently traversed. The working principle of the algorithm is shown in Figure 9.

- (iv)

- Loop through the pixel matrix until the adjacent pixels of the traversed pixels are all 0, treat the pixel set with the same label value as a connected component, store its area in the area array, and update the label value to record the next connected components.

- (v)

- Traverse the image multiple times until the elements of the label matrix and the area array would no longer change. Retrieve the largest area value in the area array, which corresponding connected component is just the desired crack feature quantity.

3.3. Canny Marginalization and Hough Space Transformation

- a.

- The algorithm uses the normal form to represent each line in the image coordinate space: , where r represents the distance from the origin of the coordinate system to the straight line, and represents the angle formed by the coordinate point and the x-axis. Therefore, in Hough space, any straight line can be represented by a parameter pair and points on the same line have the same parameter pair. If many feature points in a parameter space hold the same parameter pair, it means that in the Cartesian coordinate system the corresponding number of feature points in are collinear. After this step, each line in the binarized image is represented in the form .

- b.

- For each coordinate point in the parameter space, the algorithm counts the corresponding parameter pair in the Hough space, then we could establish an array which contains the count values of all parameter pairs.

- c.

- The algorithm uses a voting mechanism to traverse the parameter pairs corresponding to all feature points with non-zero pixel values in the image matrix, and vote for the model parameters. When there are feature points with the same , the corresponding parameter pair is increased by one vote. After the execution of this step, we can obtain the global statistics of the parameter pairs, so that the parameter pairs with high statistical times can be set as the contour lines recognized by the Hough space algorithm.

- d.

- An appropriate threshold is set according to the size of the pixel matrix and the parameter pair with a high number of votes is retained, and the corresponding straight line constitute the Hough space fitting line set of the image.

- i.

- Through the image coordinate angle, the edge directions are divided into four directions: vertical, horizontal, 45°, and 135°. The corresponding gradients are also four directions orthogonal to the edge direction.

- ii.

- For a horizontal edge, its gradient is vertical, and the gradient direction angle satisfies: ; for a 135°edge, its gradient is 45°, and the gradient direction angle satisfies: ; for a vertical edge, its gradient is in the horizontal direction, and the gradient direction angle satisfies:; while for a 45° edge, its gradient is 135°, and the gradient direction angle satisfies: .

- iii.

- As shown in Figure 11, along the above-mentioned four types of gradient directions, the algorithm compares the value of the traversed pixel with the values of its neighborhood. For each pixel traversed by the algorithm, if its pixel value is the maximum value in the neighborhood centered on it, its pixel value is retained, otherwise, its pixel value is set to 0.

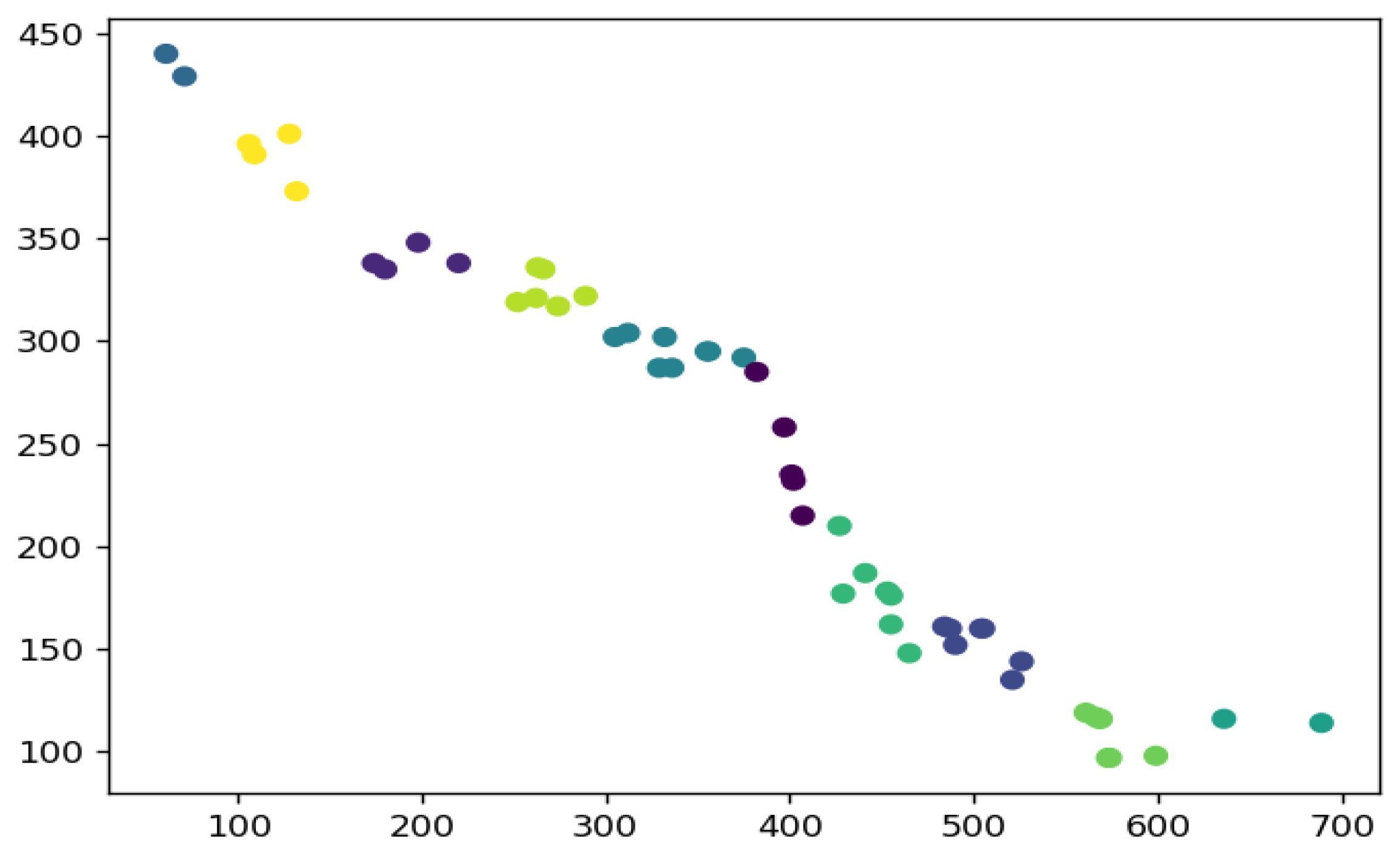

3.4. K-Means Clustering and Fitting Trajectory Output

4. Experimental Design

4.1. Construction of the Intelligent Pavement Crack Detection and Repair Prototype

4.2. Experimental Results and Analysis

4.2.1. Algorithm Simulation Fitting Verification

Algorithm Accuracy Analysis

Algorithm Execution Efficiency Analysis

Performance Analysis

4.2.2. Experiment Verification

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Othman, Z.; Abdullah, A.; Kasmin, F.; Ahmad, S.S.S. Road crack detection using adaptive multi resolution thresholding techniques. TELKOMNIKA (Telecommun. Comput. Electron. Control) 2019, 17, 1874–1881. [Google Scholar]

- Safaei, N.; Smadi, O.; Masoud, A.; Safaei, B. An Automatic Image Processing Algorithm Based on Crack Pixel Density for Pavement Crack Detection and Classification. Int. J. Pavement Res. Technol. 2021, 15, 159–172. [Google Scholar] [CrossRef]

- Safaei, N.; Smadi, O.; Safaei, B.; Masoud, A. Efficient Road Crack Detection Based on an Adaptive Pixel-Level Segmentation Algorithm. Transp. Res. Rec. 2021, 2675, 370–381. [Google Scholar] [CrossRef]

- Ouyang, A.; Luo, C.; Zhou, C. Surface Distresses Detection of Pavement Based on Digital Image Processing. In Proceedings of the Computer and Computing Technologies in Agriculture IV: 4th IFIP TC 12 Conference, CCTA 2010, Nanchang, China, 22–25 October 2010. [Google Scholar]

- Akagic, A.; Buza, E.; Omanovic, S.; Karabegović, A. Pavement crack detection using Otsu thresholding for image segmentation. In Proceedings of the 2018 41st International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 21–25 May 2018; pp. 1092–1097. [Google Scholar]

- Koch, C.; Georgieva, K.; Kasireddy, V.; Akinci, B.; Fieguth, P.W. A review on computer vision based defect detection and condition assessment of concrete and asphalt civil infrastructure. Adv. Eng. Inform. 2015, 29, 196–210. [Google Scholar]

- Sari, Y.; Prakoso, P.B.; Baskara, A.R. Road Crack Detection using Support Vector Machine (SVM) and OTSU Algorithm. In Proceedings of the 2019 6th International Conference on Electric Vehicular Technology (ICEVT), Bali, Indonesia, 18–21 November 2019; pp. 349–354. [Google Scholar]

- Kaur, E.H. Crack Detection and Parameter Estimation on Road Images Using Canny-Prewitt Operator and Hough Transformation. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 5, 1300–1309. [Google Scholar]

- Nasser, M. Automatic Road Digitizing of Segmented Aerial Images for Urban Areas Based on K-means and Hough Transformation. In Proceedings of the 2018 International Conference on Computer, Control, Electrical, and Electronics Engineering (ICCCEEE), Khartoum, Sudan, 12–14 August 2018; pp. 1–4. [Google Scholar]

- Zhang, K.; Zhang, Y.; Cheng, H.D. CrackGAN: Pavement Crack Detection Using Partially Accurate Ground Truths Based on Generative Adversarial Learning. IEEE Trans. Intell. Transp. Syst. 2020, 22, 1306–1319. [Google Scholar]

- Yang, F.; Zhang, L.; Yu, S.; Prokhorov, D.V.; Mei, X.; Ling, H. Feature Pyramid and Hierarchical Boosting Network for Pavement Crack Detection. IEEE Trans. Intell. Transp. Syst. 2019, 21, 1525–1535. [Google Scholar]

- Kim, B.; Yuvaraj, N.; Preethaa, K.R.S.; Pandian, R.A. Surface crack detection using deep learning with shallow CNN architecture for enhanced computation. Neural Comput. Appl. 2021, 33, 9289–9305. [Google Scholar] [CrossRef]

- Sheerin Sitara, N.; Kavitha, S.; Raghuraman, G. Review and Analysis of Crack Detection and Classification Techniques based on Crack Types. Int. J. Appl. Eng. Res. 2021, 13, 6056–6062. [Google Scholar]

- Hou, H.; Lin, W. A New Approach for the Detection of Concrete Cracks Based on Adaptive Morphological Filtering. In Fuzzy Systems and Data Mining VI; IOS Press: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Han, H.; Deng, H.; Dong, Q.; Gu, X.; Zhang, T.; Wang, Y. An Advanced Otsu Method Integrated with Edge Detection and Decision Tree for Crack Detection in Highway Transportation Infrastructure. Adv. Mater. Sci. Eng. 2021, 12. [Google Scholar] [CrossRef]

- Ukpe, K.C.; Kabari, L.G. Digitized Paintings For Crack Detection Furthermore, Restoration Using Median Filter Furthermore, Threshold Algorithm. Int. J. Hum. Comput. Stud. 2021, 3, 13–19. [Google Scholar]

- Iswanto, B.H.; Alma; Sugihartono, I. Feature Extraction of Tea Leaf Images using Dual-Tree Complex Wavelet Transform and Gray Level Co-occurrence Matrix. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; p. 012092. [Google Scholar]

- Chen, X.; Li, J.; Huang, S.; Cui, H.; Liu, P.; Sun, Q. An Automatic Concrete Crack-Detection Method Fusing Point Clouds and Images Based on Improved Otsu’s Algorithm. Sensors 2021, 21, 1581. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.; Dong Fang, J.; Wu, Y.; Kang, K. Research on improved image edge detection based on Hough transform. In Proceedings of the International Conference on Image Processing and Intelligent Control (IPIC 2021), Lanzhou, China, 30 July–1 August 2021. [Google Scholar]

- Sekehravani, E.A.; Babulak, E.; Masoodi, M. Implementing canny edge detection algorithm for noisy image. Bull. Electr. Eng. Inform. 2020, 9, 1404–1410. [Google Scholar]

- Kullarkar, S.P.; Jain, S.V. A Hybrid Approach for Detection and Removal of Raindrops Using kmeans Clustering and Hough Transformation. HELIX 2018, 8, 4056–4060. [Google Scholar]

| High Density Noise Wide Crack Type | Low Density Noise Narrow Crack Type | |||||||

|---|---|---|---|---|---|---|---|---|

| Sample | Sample I | Sample II | Sample III | Sample IV | Sample I | Sample II | Sample III | Sample IV |

| Global Variance Value | 898.5224 | 947.9831 | 806.3760 | 1124.1458 | 129.5714 | 116.9045 | 287.2469 | 221.6327 |

| Parameters | Description |

|---|---|

| Sensor Type | BL-100NZ-485 |

| X-axis Origin Sensor Location | 250 mm (from the left limit sensor) |

| Y-axis Travel Range | 150 mm (from the left limit sensor) |

| Z-axis Travel Range | 50 mm (from the left limit sensor) |

| W-axis Travel Range | 250 mm (from the left limit sensor) |

| Laser-type | 635 nm |

| Sensor measurement accuracy | 1 mm |

| Pulse volume of servo motor | 1412.7 (pulse volume/ms) |

| Equipment | Model |

|---|---|

| Four-axis motion control card | Googoltech GT2-400-ACC2-VB-G-A |

| High-definition camera | Hikvision B12- V2-I(POE) |

| Servo driver | Delta-China ASDA-B2-0721-B 750W |

| Crack Image | Type 1 (mm) | Type 1 (mm) | Type 1 (mm) | Type 1 (mm) | Type 1 (mm) | Type 1 (mm) | Type 1 (mm) | Average Error (mm) | Accuracy |

|---|---|---|---|---|---|---|---|---|---|

| Crack Type 1 | 1.624 | 1.858 | 0.855 | 1.825 | 2.601 | 1.724 | 1.023 | 1.644 | 100% |

| Crack Type 1 | 1.530 | 1.942 | 0.874 | 1.005 | 1.429 | 0.743 | 0.962 | 1.212 | 85.8% |

| Crack Type 1 | 1.211 | 1.047 | 0.753 | 0.969 | 1.953 | 1.277 | 0.857 | 1.152 | 100% |

| Crack Type 1 | 0.742 | 0.249 | 1.105 | 0.791 | 0.412 | 0.363 | 0.693 | 0.622 | 100% |

| Crack Type 1 | 0.653 | 1.673 | 1.692 | 2.052 | 1.559 | 0.901 | 0.612 | 1.306 | 85.8% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Cai, S.; Lin, B.; Lin, J. Research on Feature Identification and Trajectory Planning of Pavement Cracks. Appl. Sci. 2023, 13, 2241. https://doi.org/10.3390/app13042241

Zhou Z, Cai S, Lin B, Lin J. Research on Feature Identification and Trajectory Planning of Pavement Cracks. Applied Sciences. 2023; 13(4):2241. https://doi.org/10.3390/app13042241

Chicago/Turabian StyleZhou, Zhaomeng, Sijie Cai, Bingjing Lin, and Jianchun Lin. 2023. "Research on Feature Identification and Trajectory Planning of Pavement Cracks" Applied Sciences 13, no. 4: 2241. https://doi.org/10.3390/app13042241