Research on Interdependence between Specific Rock Cutting Energy and Specific Drilling Energy

Abstract

:Featured Application

Abstract

1. Introduction

2. Mechanics of Rock Cutting and Boring

3. Materials and Methods

3.1. Laboratory Measurements

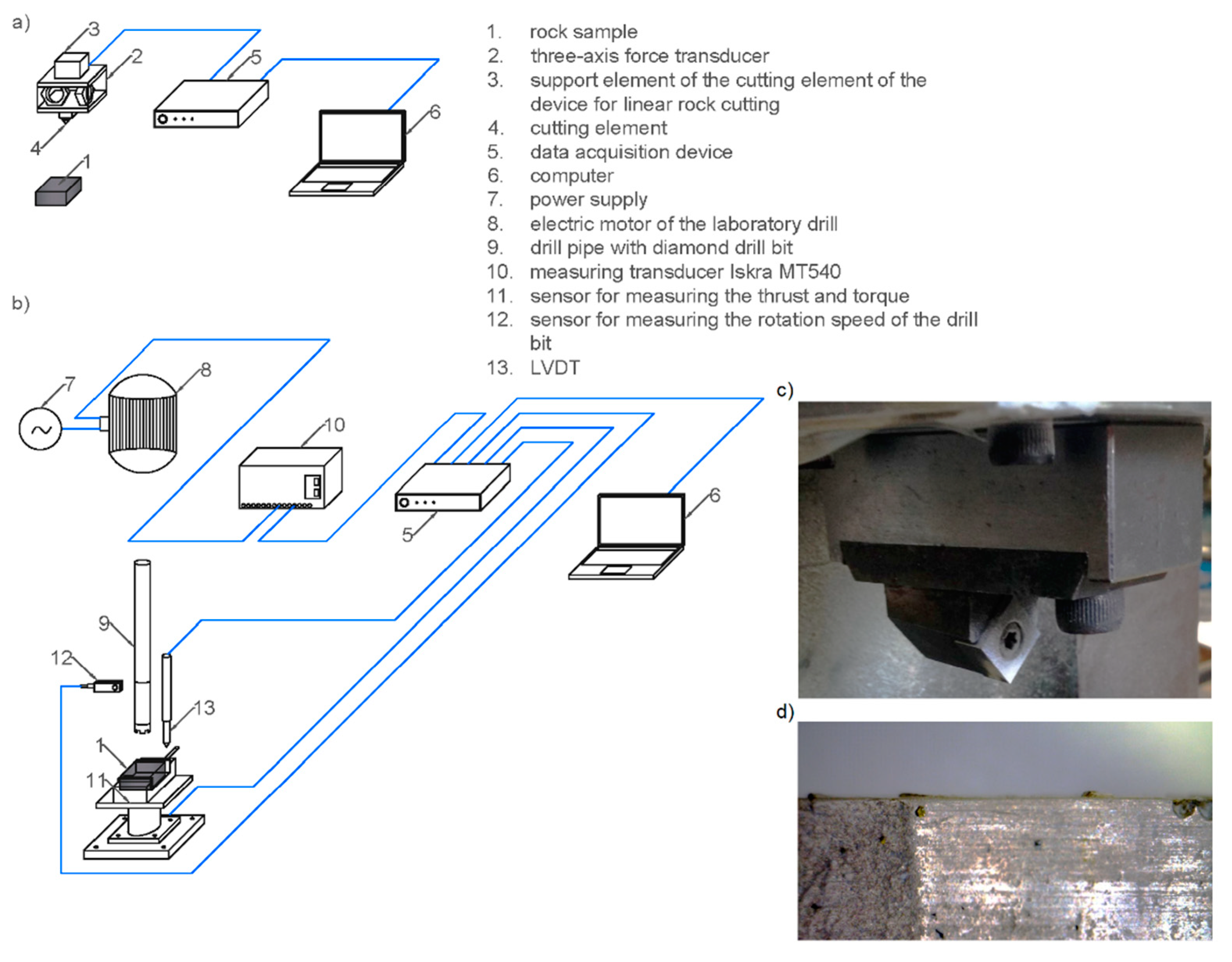

- a measuring system for measuring electrical power used up by cutting or drilling applied in laboratory and field tests (Figure 2a);

- a measuring system with a force transducer was used on the device for linear rock cutting, and a measuring system with a force and torque transducer was used on the laboratory drill (Figure 2b).

3.2. Field Measurements

4. Results

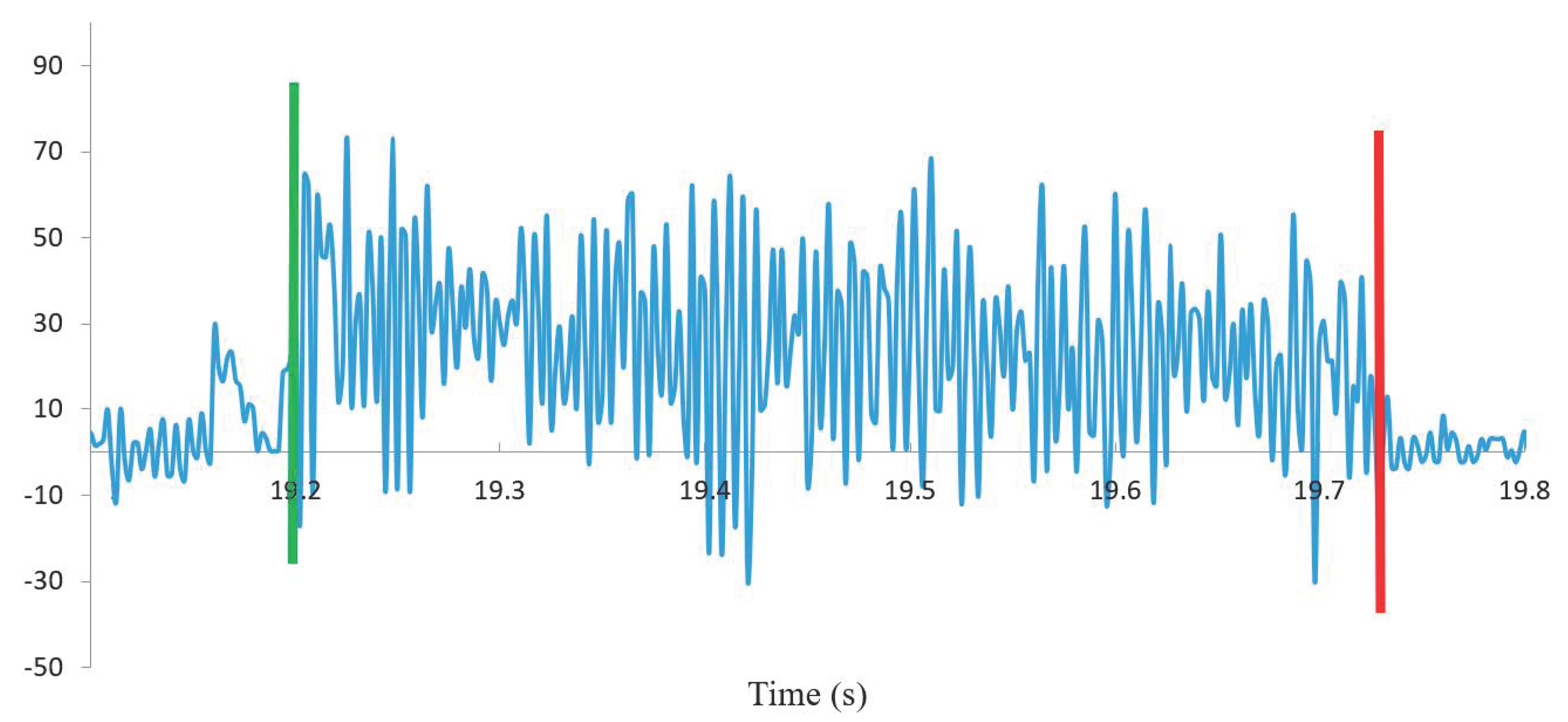

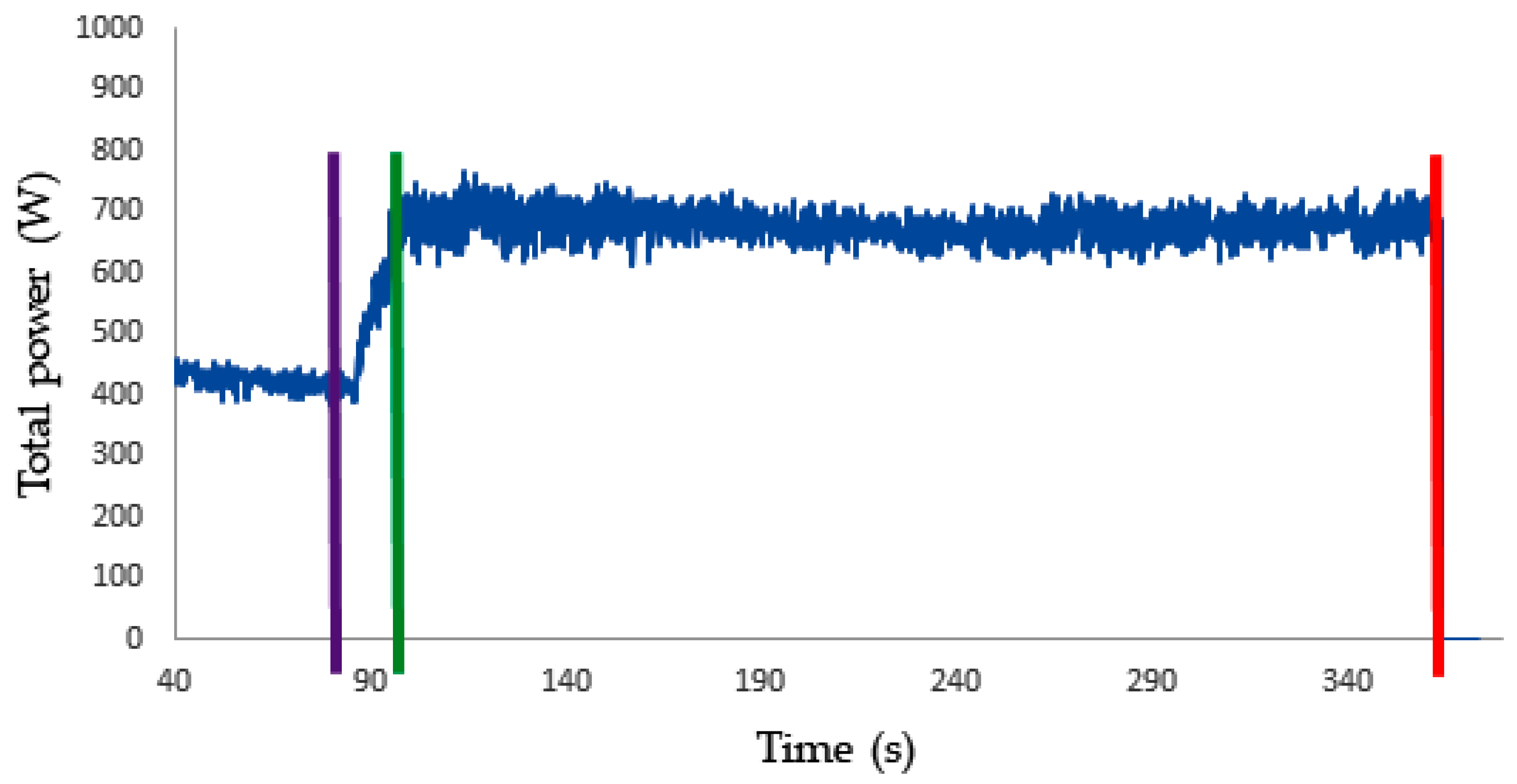

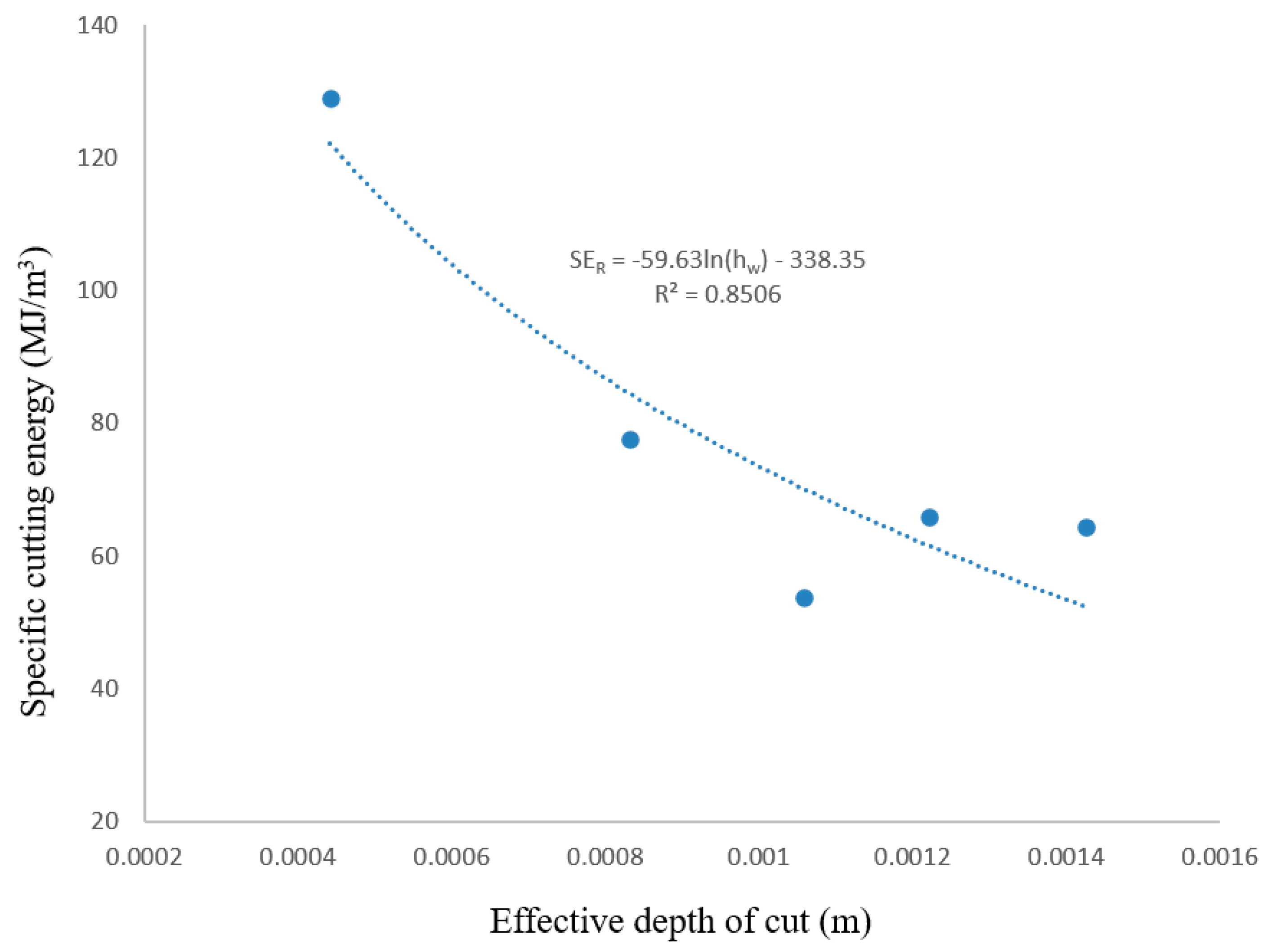

4.1. Calculation of Specific Cutting Energy and Specific Drilling Energy from Results of Laboratory Measurements

4.2. Calculation of Specific Cutting Energy and Specific Drilling Energy from the Results of Field Measurements

5. Analysis of Calculation Results and Discussion

6. Conclusions

- There is a strong and moderate linear dependence of specific rock cutting energy on specific drilling energy, depending on whether a power measurement system or a force and torque transducer measurement system was used to measure drilling energy. This confirms the hypothesis about the existence of a significant linear dependence of specific rock cutting energy on specific drilling energy for machines or devices with the same or similar rock breakage mechanics and different operating and design characteristics.

- Cutting and drilling SE are linearly related since both depend on similar parameters, with the main parameter affecting both energies being rock strength. The difference between the two energies results from the geometrical parameters of the cutting and drilling tools and the efficiency of the different machines.

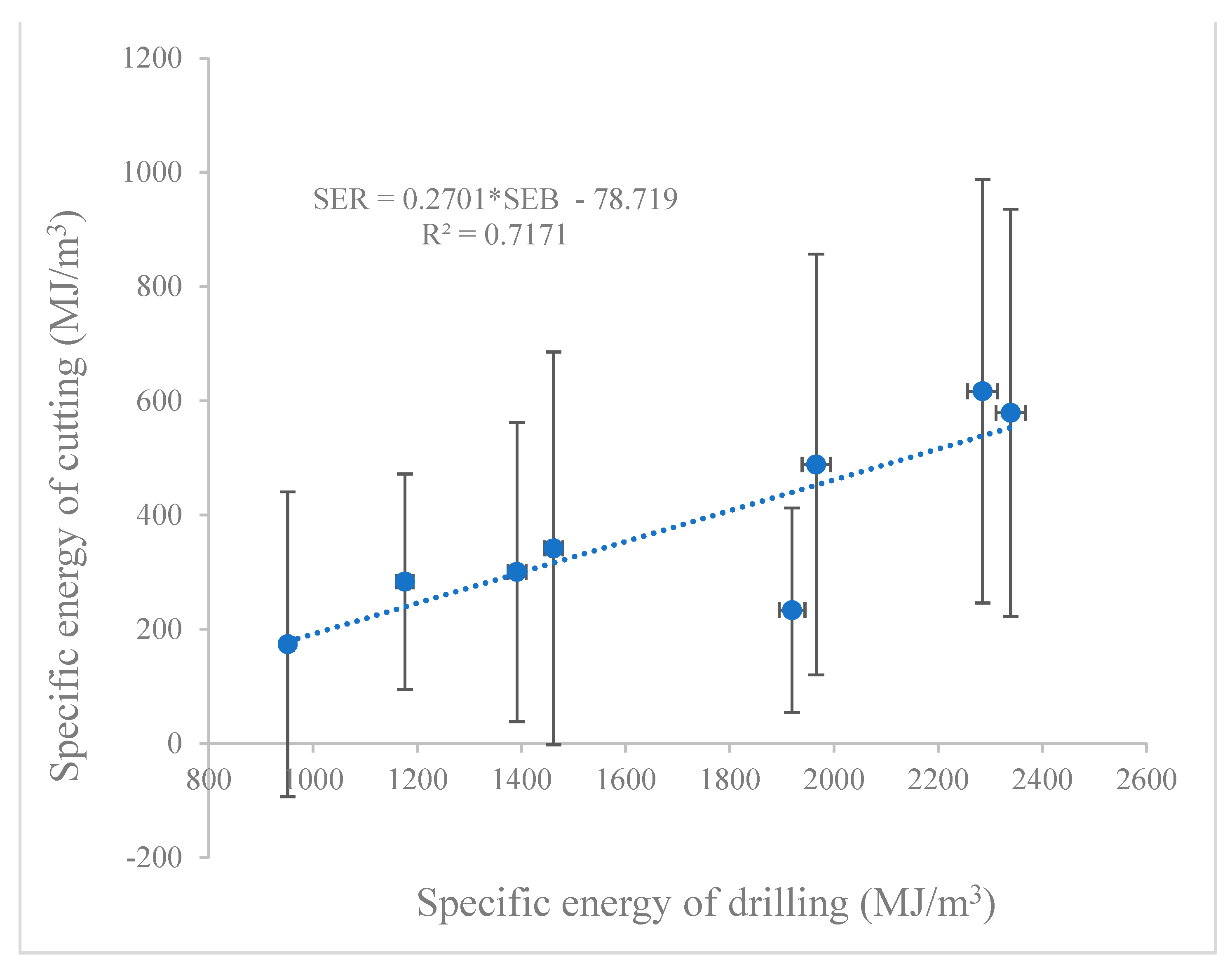

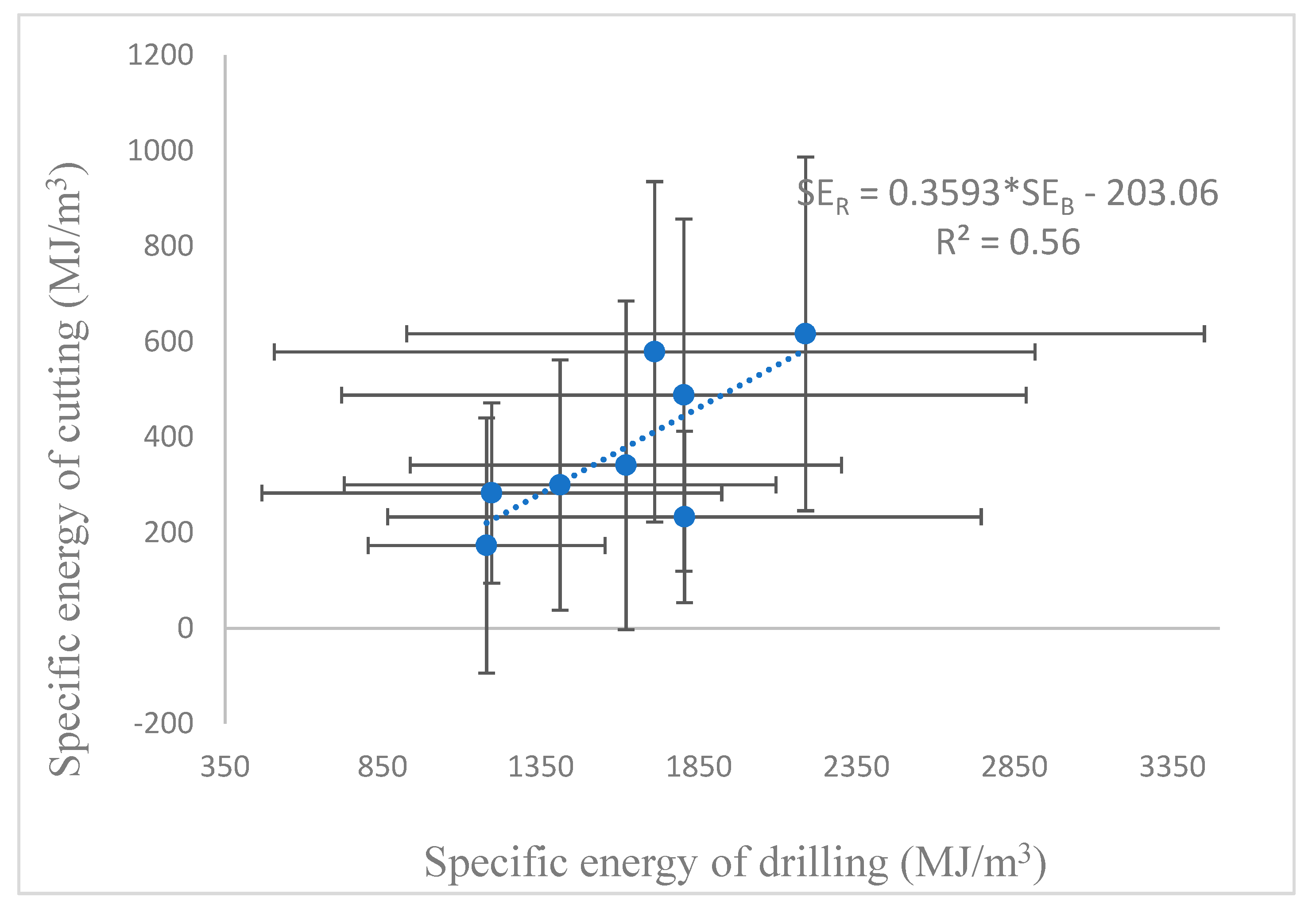

- The analysis of the measurement uncertainty of the laboratory test results has shown that the power measurement system provides more reliable values compared to the data obtained with the force or torque transducer measurement system. This is evident from Figure 7 and Figure 8, which show the expanded combined standard uncertainty for each type of measurement (in the x and y axes). Both figures show a certain correlation of the measured quantities. In Figure 7, the coefficient of determination is higher than in Figure 8, which is attributed to the smaller experimental error in the electrical power measuring system setup. Future work should focus on reducing the uncertainty components of the measurement setup.

- The results of laboratory tests and field measurements of specific energies performed on the same group of rocks (Redi) correlate very well, confirming the possibility of using the method for determining specific energy in cutting and drilling rocks in the laboratory and in the field. This indicates that a linear rock cutter and a laboratory drill can be used to simulate the operation of a chain saw and a hydraulic rotary drill. In addition, all measured values of specific cutting and drilling energy can be easily converted from MJ to kwh, allowing easy estimation of energy costs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Teale, R. The Concept of Specific Energy in Rock Drilling. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1965, 2, 57–73. [Google Scholar] [CrossRef]

- Inyang, H.I. Developments in Drag Bit Cutting of Rocks for Energy Infrastructure. Int. J. Min. Reclam. Environ. 2002, 16, 248–260. [Google Scholar] [CrossRef]

- Rowsell, P.J. Automatic Optimization of Rotary Drilling Parameters. Ph.D. Thesis, Department of Mining Engineering at University of Nottingham, Nottingham, England, UK, 1991. [Google Scholar]

- Ersoy, A. Automatic drilling control based on minimum drilling specific energy using PDC and WC bits. Min. Technol. 2003, 112, 86–96. [Google Scholar] [CrossRef]

- Akün, M.E.; Karpuz, C. Drillability studies of surface-set diamond drilling in Zonguldak region sandstones from Turkey. Int. J. Rock Mech. Min. Sci. 2005, 42, 473–479. [Google Scholar] [CrossRef]

- Balci, C.; Demircin, M.A.; Copur, H.; Tuncdemir, H. Estimation of optimum specific energy based on rock properties for assessment of roadheader performance. J. S. Afr. Inst. Min. Metall. 2004, 104, 633–642. [Google Scholar]

- LaBelle, D. Lithological Classification by Drilling. Thesis Proposal, Carnegie Mellon University, Pittsburgh, PA, USA, 2001. [Google Scholar]

- Exadaktylos, G.; Stavropoulou, M.; Xiroudakis, G.; de Broissia, M.; Schwarz, H. A Spatial Estimation Model for Continuous Rock Mass Characterization from the Specific Energy of a TBM. Rock Mech. Rock Eng. 2008, 41, 797–834. [Google Scholar] [CrossRef]

- Lakshminarayana, C.R.; Tripathi, A.K.; Pal, S.K. Experimental Investigation on Potential Use of Drilling Parameters to Quantify Rock Strength. Int. J. Geo-Eng. 2021, 12, 23. [Google Scholar] [CrossRef]

- Copur, H. Linear Stone Cutting Tests with Chisel Tools for Identification of Cutting Principles and Predicting Performance of Chain Saw Machines. Int. J. Rock Mech. Min. Sci. 2010, 47, 104–120. [Google Scholar] [CrossRef]

- Korman, T.; Kujundžić, T.; Kuhinek, D. Simulation of Chain Saw Cutting Process with Linear Cutting Machine. Int. J. Rock Mech. Min. Sci. 2015, 78, 283–289. [Google Scholar] [CrossRef]

- Korman, T.; Kujundžić, T.; Lukačić, H.; Martinić, M. The Impact of Area and Shape of Tool Cut on Chain Saw Performance. Rud.-Geol.-Naft. Zb. 2016, 31, 1–12. [Google Scholar] [CrossRef]

- Romoli, L. Cutting Force Monitoring of Chain Saw Machines at the Variation of the Rake Angle. Int. Int. J. Rock Mech. Min. Sci. 2018, 101, 33–40. [Google Scholar] [CrossRef]

- Ersoy, A.; Atici, U. Performance characteristics of circular diamond saws in cutting different types of rocks. Diamond Relat. Mater. 2004, 13, 22–37. [Google Scholar] [CrossRef]

- Liu, C.; Zheng, X.; Shahani, N.M.; Li, P.; Wang, C.; Guo, X. An Experimental Investigation into the Borehole Drilling and Strata Characteristics. PLoS ONE 2021, 16, e0253663. [Google Scholar] [CrossRef] [PubMed]

- Arbabsiar, M.H.; Farsangi, M.A.E.; Mansouri, H. A new model for predicting the advance rate of a Tunnel Boring Machine (TBM) in hard rock conditions. Rud.-Geol.-Naft. Zb. 2020, 35, 57–74. [Google Scholar] [CrossRef]

- Finfinger, G.L.; Peng, S.S.; Gu, Q.; Wilson, G.; Thomas, B. An approach to identifying geological properties from roof bolter drilling parameters. In Proceedings of the 19th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV, USA, 8–10 August 2000. [Google Scholar]

- Mikaeil, R.; Esmailzadeh, A.; Aghaei, S.; Haghshenas, S.S.; Jafarpour, A.; Mohammadi, J.; Ataei, M. Evaluating the sawability of rocks by chain-saw machines using the promethee technique. Rud.-Geol.-Naft. Zb. 2021, 36, 25–36. [Google Scholar] [CrossRef]

- Balci, C.; Copur, H.; Bilgin, N.; Ozdemir, L.; Jones, G.R. Cuttability and drillability studies towards predicting performance of mechanical miners excavating in hyperbaric conditions of deep seafloor mining. Int. J. Rock Mech. Min. Sci. 2020, 130, 104338. [Google Scholar] [CrossRef]

- Bout, G.; Brito, D.; Gómez, R.; Carvajal, G.; Ramírez, G. Physics-Based Observers for Measurement-While-Drilling System in down-the-Hole Drills. Mathematics 2022, 10, 4814. [Google Scholar] [CrossRef]

- Isheyskiy, V.; Sanchidrián, J.A. Prospects of Applying MWD Technology for Quality Management of Drilling and Blasting Operations at Mining Enterprises. Minerals 2020, 10, 925. [Google Scholar] [CrossRef]

- Babaei Khorzoughi, M.; Hall, R. Processing of Measurement While Drilling Data for Rock Mass Characterization. Int. J. Min. Sci. Technol. 2016, 26, 989–994. [Google Scholar] [CrossRef]

- Mellor, M. Mechanics of Cutting and Boring—Part 2: Kinematic of Axial Rotation Machines; Spec. Rep. 76-16; US Army Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1976. [Google Scholar]

- Mellor, M. Mechanics of Cutting and Boring—Part 3: Kinematics of Continuous Belt Machines; Spec. Rep. 76-17; US Army Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1976. [Google Scholar]

- Mellor, M. Mechanics of Cutting and Boring—Part 4: Dynamics and Energetics of Parallel Motion Tools; Spec. Rep. 77-7; US Army Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1977. [Google Scholar]

- Mellor, M. Mechanics of Cutting and Boring—Part 8: Dynamics and Energetics of Continuous Belt Machines; Spec. Rep. 78-11; US Army Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1978. [Google Scholar]

- Mellor, M. Mechanics of Cutting and Boring—Part 7: Dynamics and Energetics of Axial Rotation Machines; Spec. Rep. 81-26; US Army Cold Regions Research and Engineering Laboratory: Hanover, NH, USA, 1981. [Google Scholar]

- Korman, T. Influence of Constructional and Operational Parameters on Chain Saw Performance. Ph.D. Thesis, Faculty of Mining. Geology and Petroleum Engineering at University of Zagreb, Zagreb, Croatia, 2014. [In Croatian with English Abstract]. [Google Scholar]

- Chiaia, B.; Borri-Brunetto, M.; Carpinteri, A. Mathematical modelling of the mechanics of core drilling in geomaterials. Mach. Sci. Technol. 2013, 17, 1–25. [Google Scholar] [CrossRef]

- Kuhinek, D.; Zorić, I.; Hrženjak, P. Development of Virtual Instrument for Uniaxial Compression Testing of Rock Samples. Meas. Sci. Rev. 2011, 11, 99–103. [Google Scholar] [CrossRef] [Green Version]

- Antoljak, D.; Kuhinek, D.; Korman, T.; Kujundžić, T. Dependency of specific energy of rock cutting on specific drilling energy. Rud.-Geol.-Naft. Zb. 2018, 33, 23–32. [Google Scholar] [CrossRef]

- Antoljak, D. Dependence of Rock Cutting Specific Energy on the Specific Energy of Drilling. Ph.D. Thesis, Faculty of Mining. Geology and Petroleum Engineering at University of Zagreb, Zagreb, Croatia, 2020. [In Croatian with English Abstract]. [Google Scholar]

- Schrand, D. Cross-Talk Compensation Using Matrix Methods. Sens. Transducers. 2007, 79, 1157–1163. [Google Scholar]

- Maurer, W.C. The state of rock mechanics knowledge in drilling. In Proceedings of the 8th U.S. Symposium on Rock Mechanics (USRMS), Minneapolis, MN, USA, 15–17 September 1966. [Google Scholar]

- Gertsbakh, I. Measurement Theory for Engineers, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar] [CrossRef]

- Cruz de Oliveira, E.; Fernandes de Aguiar, P. Least squares regression with errors in both variables: Case studies. Quim Nova. 2013, 36, 885–889. [Google Scholar] [CrossRef] [Green Version]

| Kinematic Quantities | Unit | Chain Saw | Rotary Drill |

| The path resultant of the cutting element s | M | ||

| The speed resultant of the cutting element v | m/s | ||

| Dynamic Quantities | Chain Saw | Rotary Drill | |

| Horizontal component of the cutting or drilling force of one cutting element Fc | N | ||

| Vertical component of the cutting or drilling force of one cutting element Fn | N | ||

| The cutting or drilling force resultant of one cutting element R’ | N | ||

| Torque of one cutting element M’ | Nm | not applicable | |

| Horizontal component of cutting or drilling force FC | N | ||

| Vertical component of the cutting or drilling force FN | N | ||

| Resultant of total cutting or drilling force R | N | ||

| Torque M | Nm | not applicable |

| Sampling Location (Exploitation Field) | Kanfanar | Redi | Žaganj Dolac | |||||

|---|---|---|---|---|---|---|---|---|

| Rock Type/the Name of the Rock Sample | Oncolytic Limestone | Recrystallized Organic Limestone | Rudist Limestone | |||||

| Roof Layer A | Roof Layer B | Roof Layer E/F | Roof Layer G | Roof Layer H | Roof Layer I | Redi | Rasotica | |

| Rock sample designation | 21, 22, 23 | 24, 25, 26 | 04, 05, 09 | 06, 07, 10 | 03, 08, 11, 13, 14, 15 | 01, 02, 12 | 00, 19, 20 | 16, 17, 18 |

| Bulk density (kg/m3) | 2683 | 2688 | 2505 | 2308 | 2507 | 2626 | 2551 | 2655 |

| Chain Saw | |||

| Type | Pellegrini Ch-60 | ||

| Voltage | 380 | (V) | |

| Frequency | 50 | (Hz) | |

| Total power | 37 | (kW) | |

| Dimensions (Length × Width × Height) | 1.8 × 2.0 × 1.4 | (m) | |

| Blade length | 4.25 | (m) | |

| Weight (without rails) | 6500 | (kg) | |

| Speed of cutting chain | 0–1.4 | (m/s) | |

| Length of cutting segments | 1.028 | (m) | |

| Width of cutting segments | 0.4 | (m) | |

| Cutting tool material | Tungsten carbide | ||

| Tool dimensions (Length × Width × Height) | 12.7 × 12.7 × 6.5 | (mm) | |

| Hydraulic Rotary Drill | |||

| Type | Lochtmans LGR FAST65 | ||

| Power of rotation | 3420 | (W) | |

| Hydraulic power | 1500 | (W) | |

| Maximum current | 9.5 | (A) | |

| Voltage | 230 | (V) | |

| Frequency | 50 | (Hz) | |

| Number of rotations—idle (load) | 1st gear | 350 (230) | (min−1) |

| 2nd gear | 800 (520) | (min−1) | |

| 3rd gear | 1475 (965) | (min−1) | |

| Average rate of penetration | 0.50 | (m/min) | |

| Working pressure of hydraulic aggregate | 110/120 | (bar) | |

| Volume of hydraulic oil tank | 20 | (L) | |

| Drilling rig height | 1000 | (mm) | |

| Weight | 210 | (kg) | |

| Dimensions (Length × Width × Height) | 700 × 550 × 2000 | (mm) | |

| Type of drilling bit | Natural diamond core bit | ||

| Outer (inner) diameter of drilling bit | 50 (44) | (mm) | |

| Group No. | Group | Specific Cutting Energy | Expanded Measurement Uncertainty | Specific Drilling Energy | Expanded Measurement Uncertainty | Specific Drilling Energy | Expanded Measurement Uncertainty | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Electrical Power Measuring System | Measuring System with Force and Torque Transducer | |||||||||

| (MJ/m3) | (MJ/m3) | (%) | (MJ/m3) | (MJ/m3) | (%) | (MJ/m3) | (MJ/m3) | (%) | ||

| 1 | Redi. Trogir | 233.04 | ±179.05 | 78.58 | 1919.37 | ±24.87 | 1.32 | 1805.12 | ±939.51 | 53.96 |

| 2 | Rasotica. Brač | 283.15 | ±188.48 | 64.59 | 1176.59 | ±15.46 | 1.31 | 1194.67 | ±728.20 | 61.03 |

| 3 | Roof layer A. Kanfanar | 616.52 | ±370.76 | 59.12 | 2285.05 | ±28.78 | 1.26 | 2188.48 | ±1263.21 | 57.7 |

| 4 | Roof layer B. Kanfanar | 578.73 | ±356.76 | 61.64 | 2339.06 | ±28.12 | 1.2 | 1710.3 | ±1204.61 | 71.01 |

| 5 | Roof layer E/F. Kanfanar | 299.9 | ±262.08 | 92.56 | 1391.6 | ±17.42 | 1.3 | 1411.14 | ±683.92 | 48.94 |

| 6 | Roof layer G. Kanfanar | 173.39 | ±267.01 | 164.43 | 951.53 | ±11.02 | 1.16 | 1178.39 | ±374.51 | 32.53 |

| 7 | Roof layer H. Kanfanar | 341.34 | ±344.05 | 102.06 | 1461.67 | ±17.60 | 1.2 | 1619.83 | ±682.82 | 46.84 |

| 8 | Roof layer I. Kanfanar | 488.26 | ±368.61 | 74.71 | 1965.91 | ±27.29 | 1.39 | 1803.06 | ±1083.57 | 62.84 |

| Average value | 376.79 | ±292.10 | 87.21 | 1686.35 | ±21.32 | 1.27 | 1613.87 | ±870.04 | 54.36 | |

| Minimum value | 173.39 | 179.05 | 59.12 | 951.53 | 11.02 | 1.16 | 1178.39 | 374.51 | 32.53 | |

| Maximum value | 616.52 | 370.76 | 164.43 | 2339.06 | 28.78 | 1.39 | 2188.48 | 1263.21 | 71.01 | |

| Standard deviation | 164.16 | 79.26 | 34.64 | 514.66 | 6.76 | 0.08 | 341.92 | 305.26 | 11.76 | |

| Indicator | Electrical Power Measuring System | Measuring System with Force Transducer/Measuring System with Force and Torque Transducer |

|---|---|---|

| Sensitivity at shallow cutting depths | low | high |

| Applicability | laboratory/field 1 | laboratory |

| Complexity | low | high |

| Reliability | high | low |

| Measuring uncertainty | low | high |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antoljak, D.; Kuhinek, D.; Korman, T.; Kujundžić, T. Research on Interdependence between Specific Rock Cutting Energy and Specific Drilling Energy. Appl. Sci. 2023, 13, 2280. https://doi.org/10.3390/app13042280

Antoljak D, Kuhinek D, Korman T, Kujundžić T. Research on Interdependence between Specific Rock Cutting Energy and Specific Drilling Energy. Applied Sciences. 2023; 13(4):2280. https://doi.org/10.3390/app13042280

Chicago/Turabian StyleAntoljak, Davor, Dalibor Kuhinek, Tomislav Korman, and Trpimir Kujundžić. 2023. "Research on Interdependence between Specific Rock Cutting Energy and Specific Drilling Energy" Applied Sciences 13, no. 4: 2280. https://doi.org/10.3390/app13042280