Composites Containing Felt Wastes from the Automotive Industry

Abstract

:1. Introduction

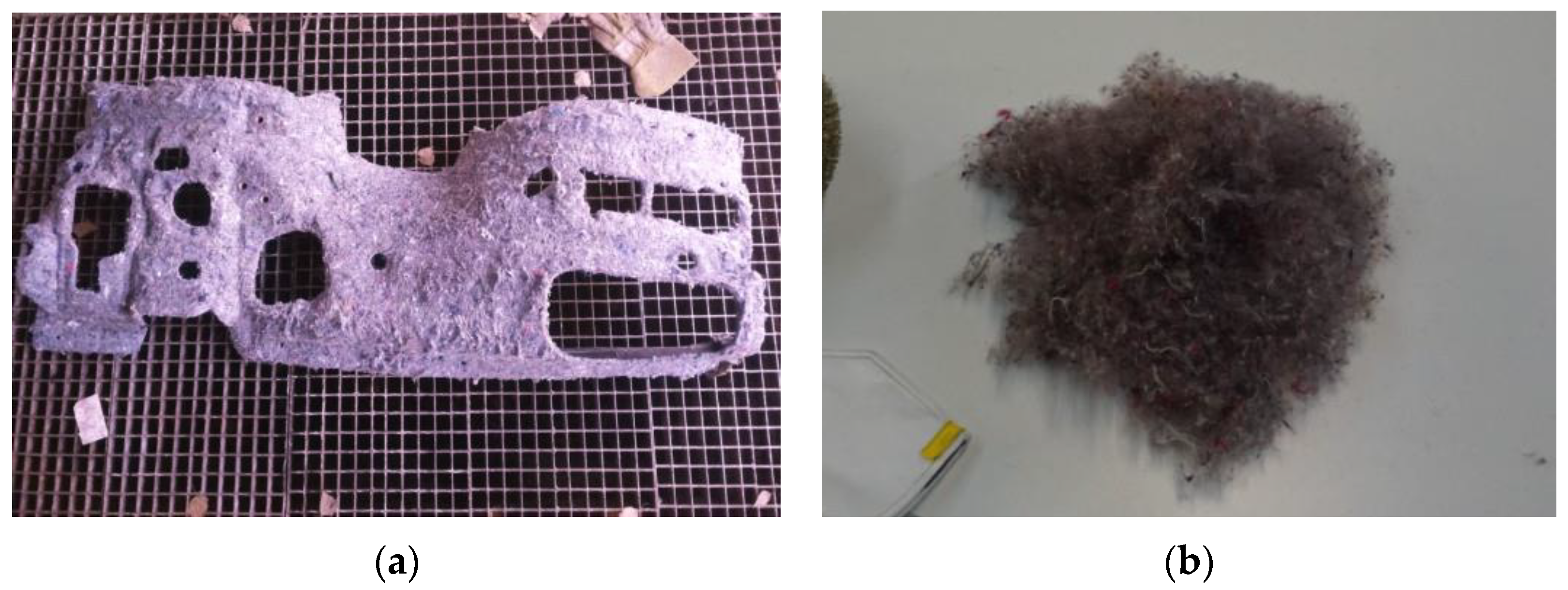

1.1. Materials

1.2. Testing Procedures

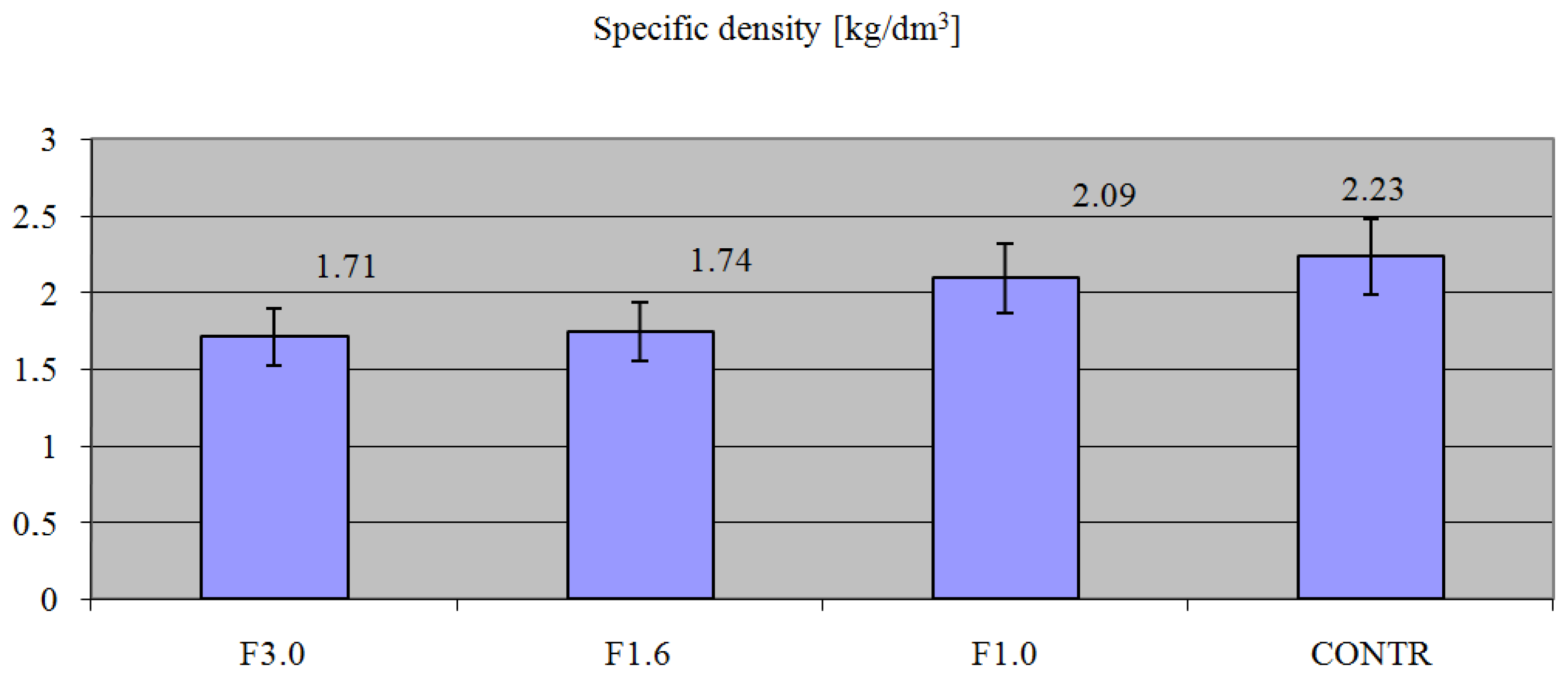

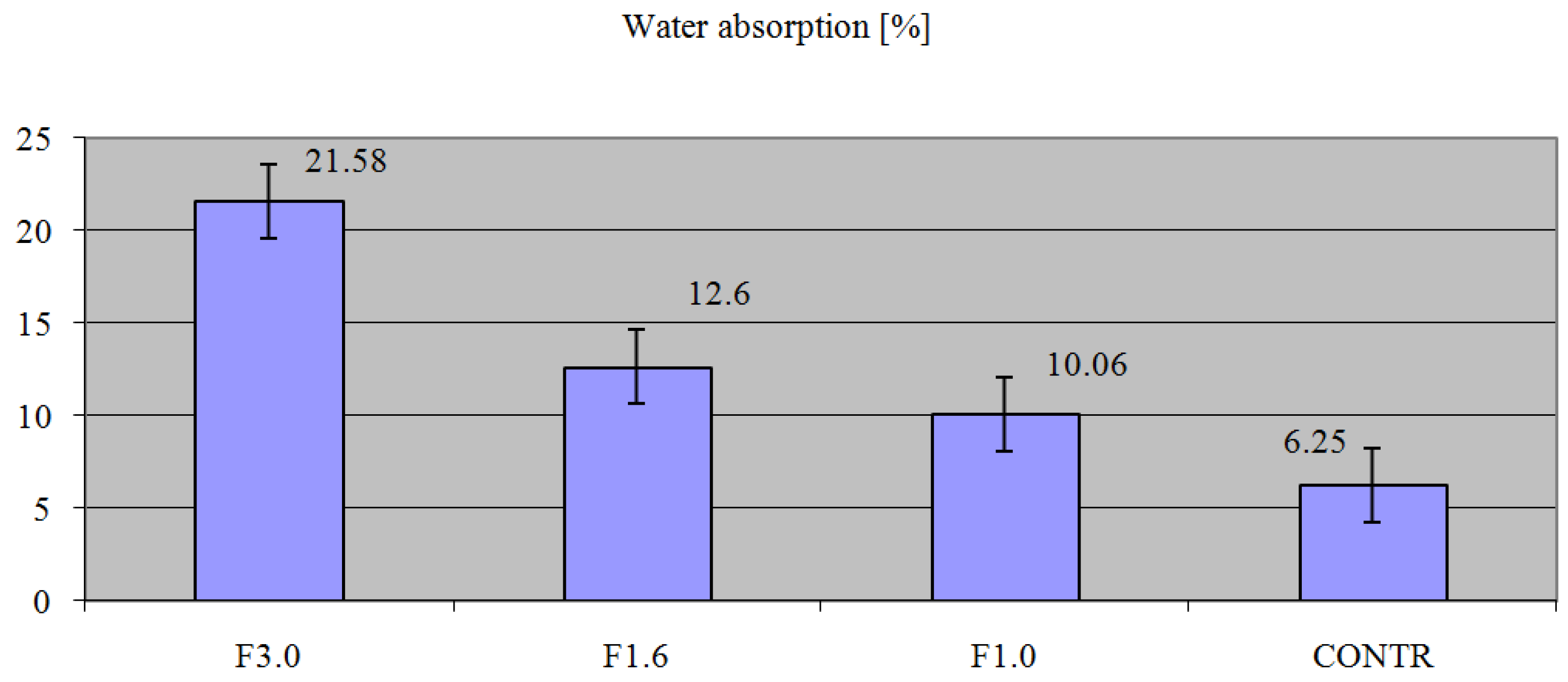

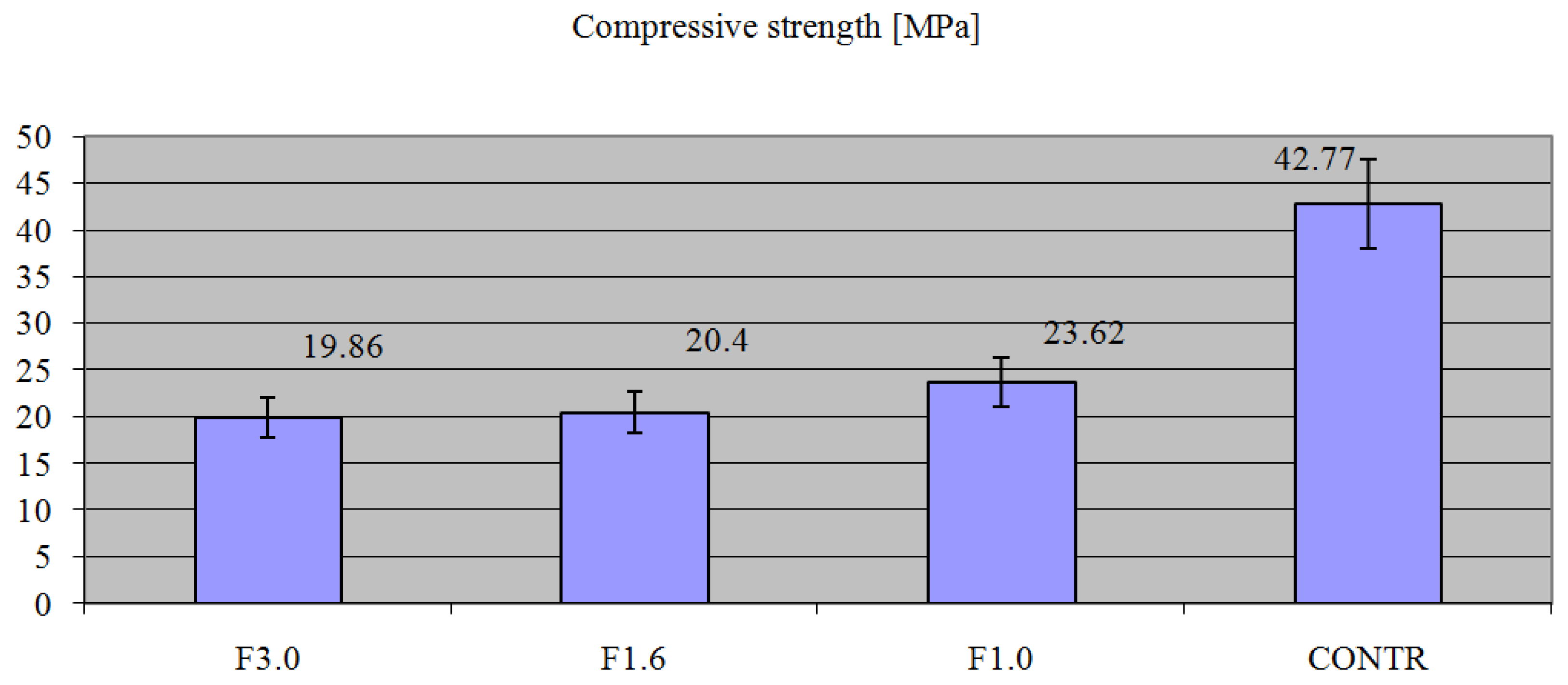

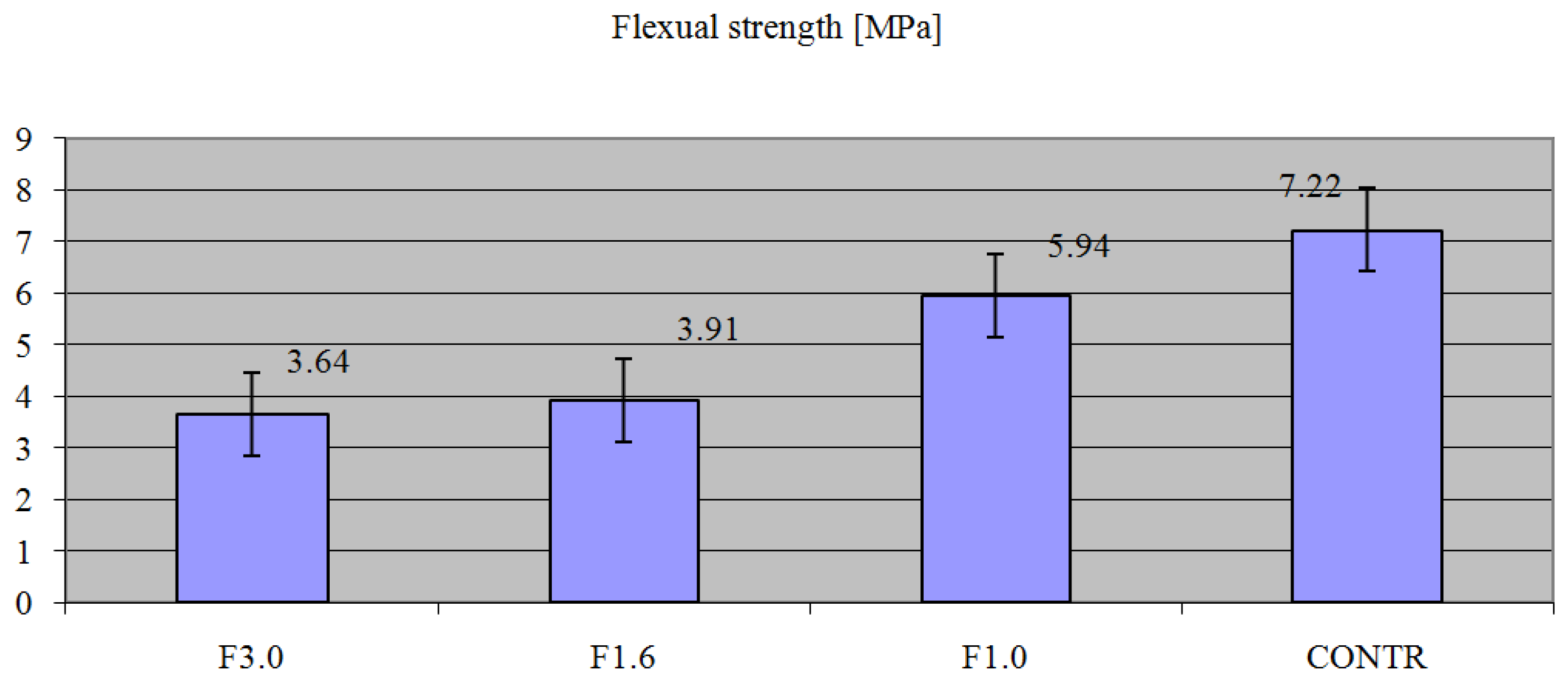

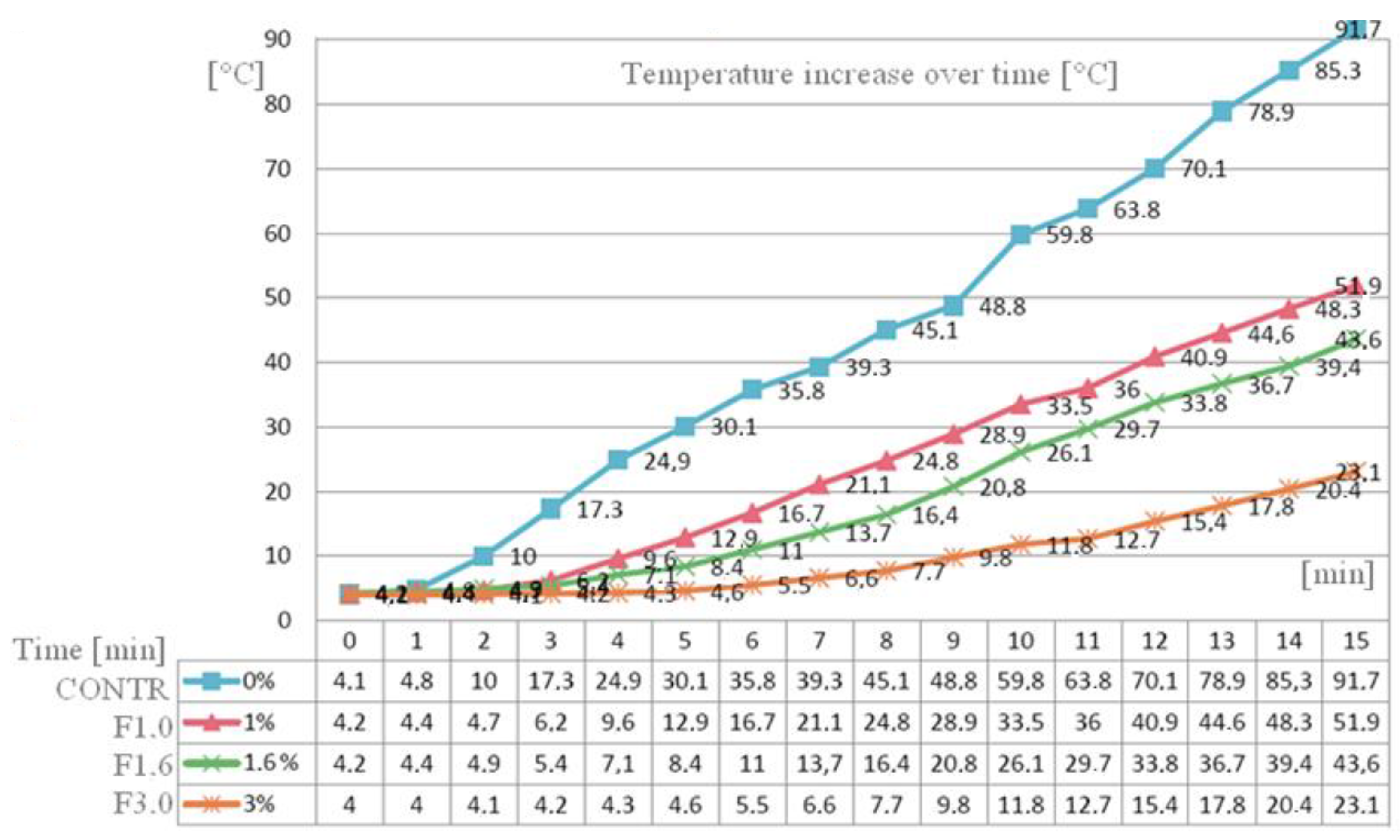

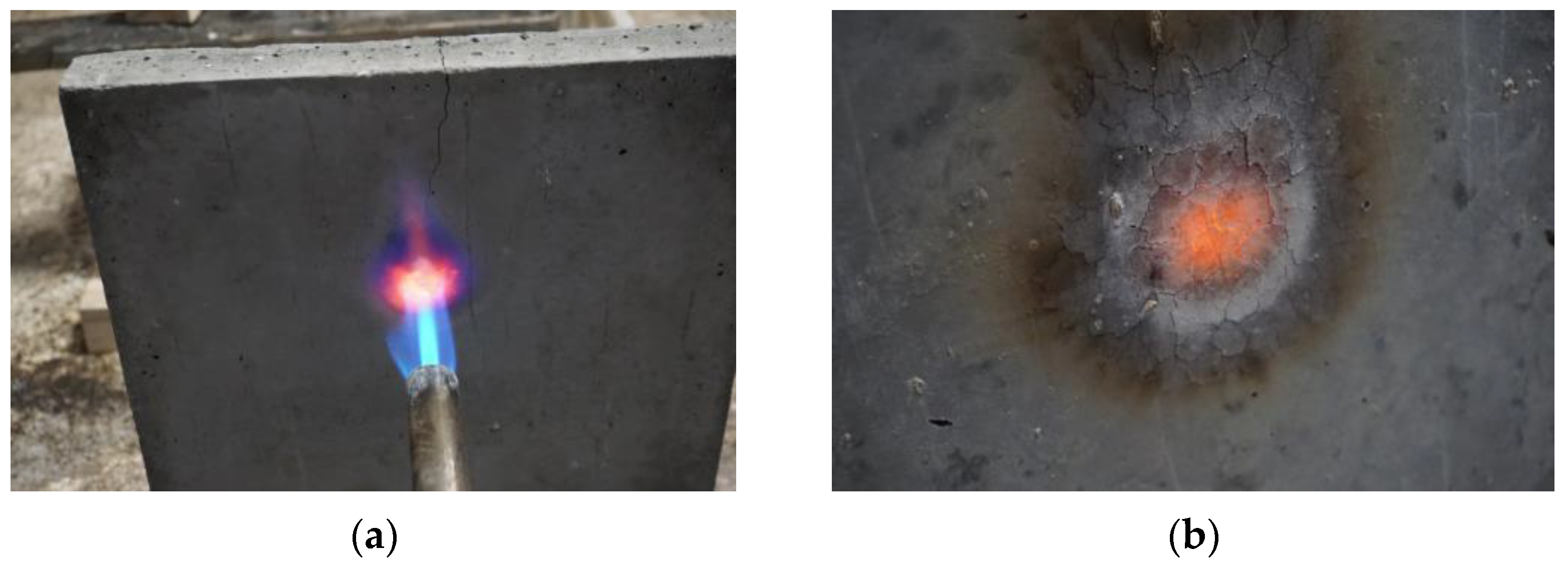

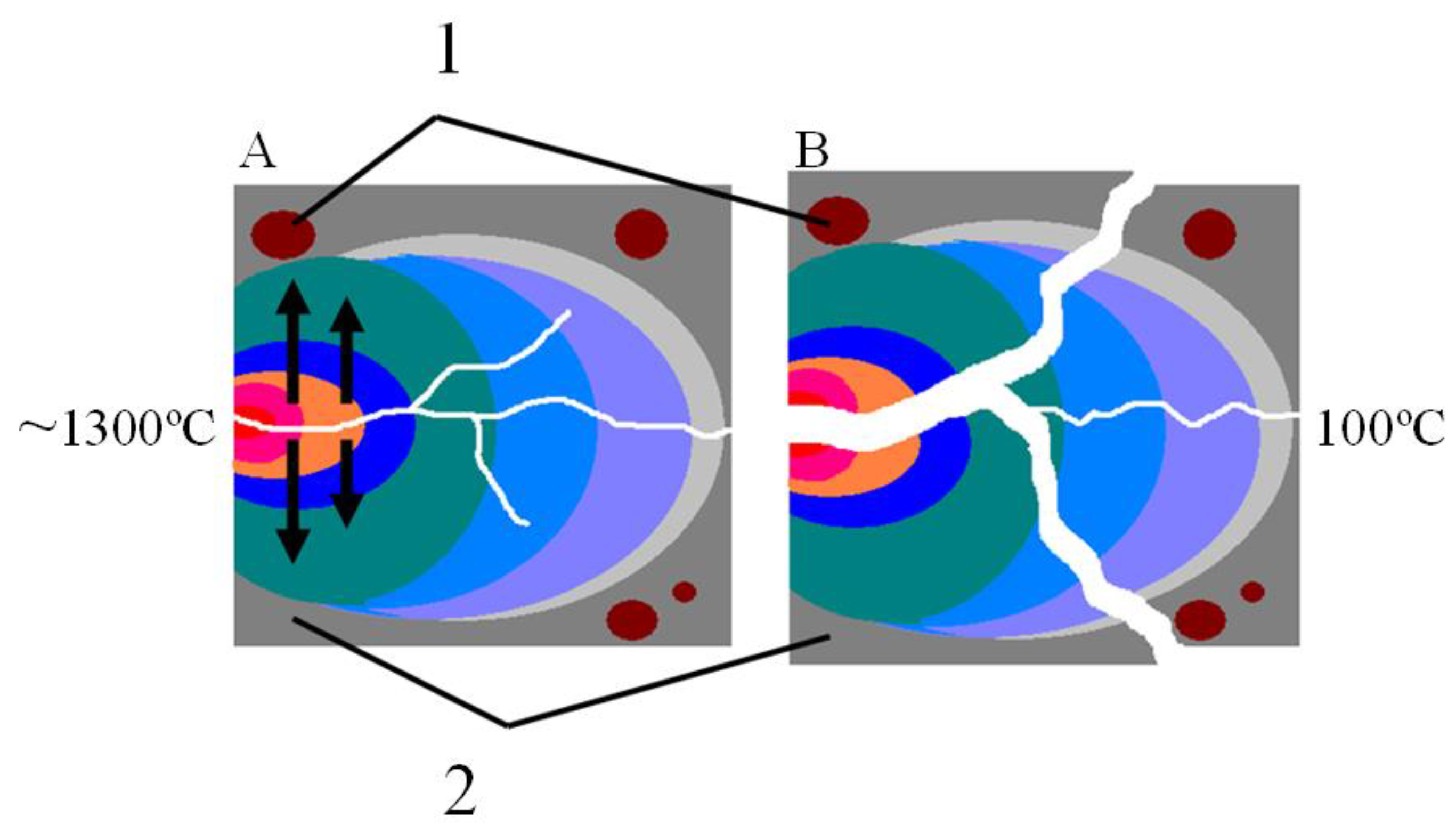

2. Research Results and Analysis

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Famielec, J.; Wąsowicz, K.; Żaba-Nieroda, R.; Famielec, S. Informational determinants of municipal waste management in a municipality: A case study. Soc. Inequal. Econ. Growth 2019, 58, 301–311. [Google Scholar]

- Trzebiatowska, P.J. Chemical recycling of plastics. Chem. News 2022, 6, 157–181. [Google Scholar]

- Turnau, I. The state and needs of research on the history of textile techniques. Q. J. Hist. Sci. Technol. 1979, 24, 389–408. [Google Scholar]

- Bernard, P.C.; Poter, D. Textiles: Fiber to Fabric; Macgraw-Hill: London, England, 1975. [Google Scholar]

- Rudnicka, A.; Koszewska, M. Sewn with Class. The Clothing Industry towards Social and Environmental Challenges; University of Łódź Publishing House: Łódz, Poland, 2020. [Google Scholar]

- Garyson, M. Encyclopedia of Textiles, Fiberes and Nonwoven Fabrics; John Wiley & Sons Inc.: London, UK, 1984. [Google Scholar]

- Mayekar, A.J. Nonwoven Industry for the Future. Textile Trends 2003, 46, 29. [Google Scholar]

- Pokharna, A.K. Processing of Different Hair Wool for Value Added Products; National Agricultural Technology Project, Final Report, Division of Wool Technology; Central Sheep and Wool Research Institute Avikanagar: Rajasthan, India, 2004. [Google Scholar]

- Marsh, J.T. Introduction to Textile Finishing; Chapman Publication: London, UK, 1979. [Google Scholar]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H. Concrete containing waste glass as an environmentally friendly aggregate: A review on fresh and mechanical characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Bascetin, A.; Adiguzel, D.; Eker, H.; Odabas, E. Effects of puzzolanic materials in surface paste disposal by pilot-scale tests: Observation of physical changes. Int. J. Environ. Sci. Technol. 2021, 18, 949–964. [Google Scholar] [CrossRef]

- Eker, H.; Bascetin, A. The study of strength behaviour of zeolite in cemented paste backfill. Geomech. Eng. 2022, 29, 421–434. [Google Scholar] [CrossRef]

- Jin, R.; Chen, Q. Investigation of concrete recycling in the U. S. construction industry. Procedia Eng. 2015, 118, 894–901. [Google Scholar]

- Pangsy-Kania, S. System zarządzania rozwojem w Polsce i rola w nim dokumentów strategicznych. Studia z Polityki Publicznej 2015, 7, 120–137. [Google Scholar] [CrossRef]

- Małaszkiewicz, D.; Pawluczuk, E. Influence of recycled aggregate on selected technical properties of concrete, Prace Naukowe Instytutu Budownictwa Politechniki Wrocławskiej. Stud. Mater. 2006, 87, 405–410. [Google Scholar]

- Hare, B.; Golebiowska, I. The future of concrete with recycled concrete aggregate. Inż. Ap. Chem. 2014, 53, 390–392. [Google Scholar]

- Anink, D.; Boonstra, C.; Mak, J. Handbook of Sustainable Building, An Environmental Preference Method for Selection of Materials for Use in Construction and Refurbishment; Chapman Publication: London, UK, 1996. [Google Scholar]

- Ajdukiewicz, A.; Kliszczewicz, A. Ad hoc and rheological properties of structural concretes on recycled aggregates. Zesz. Nauk. Politech. Rzeszowskiej. Bud. I Inżynieria Sr. 2012, 3, 173–180. [Google Scholar]

- Ahn, T.H.; Kishi, T. Crack self-healing behaviour of cementitious composites incorporating various mineral admixtures. J. Adv. Concrete Technol. 2010, 8, 171–186. [Google Scholar] [CrossRef]

- Jevtić, D.; Zakić, D.; Savić, A. Achieving sustainability of concrete by recycling of solid waste materials. Mech. Test. Diagn. 2012, 2, 22–39. [Google Scholar]

- Hansen, T.C.; Narud, H. Strength of recycled concrete made from crushed concrete coarse aggregate. Concr. Int.-Des. Constr. 2003, 5, 35–48. [Google Scholar]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Res. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Best Practice Guide for the Use of Recycled Aggregates in New Concrete; CCANZ Technical Report; Cement and Concrete Association: Wellington, New Zealand, 2014.

- Ziolkowski, A. Universal History. Antiquity; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2009. [Google Scholar]

- Senthamarai, R.M.; Devadas, A.; Manoharan, P.; Gobinath, D. Concrete made from ceramic industry waste: Durability propertis. Constr. Build. Mater. 2011, 25, 2413–2419. [Google Scholar] [CrossRef]

- De Brito, J.; Pereira, J.R. Mechanical behaviour of non-structural concrete made with recycled ceramic aggregates. Cement Concr. Compos. 2005, 27, 429–433. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Reusing ceramic wastes in concrete. Constr. Build. Mater. 2010, 24, 832–838. [Google Scholar] [CrossRef]

- Debieb, A.; Farid, K.; Kenai, S. The use of coarse and fine crushed bricks as aggregate in concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Devenny, A.; Khalaf, F.M. Use of crushed brick as coarse aggregate in concrete. Mason. Int. 1999, 12, 81–84. [Google Scholar]

- Khalaf, F.M.; DeVenny, A.S. Recycling of demolished masonry rubble as coarse aggregate in concrete: Review. J. Mater. Civ. Eng. 2004, 16, 331–340. [Google Scholar] [CrossRef]

- Khalloo, A.R. Properties of concrete using crushed clinker brick as coarse aggregate. ACI Mater. J. 1994, 91, 401–407. [Google Scholar]

- Khatie, M. Properties of concrete incorporating fine recycled aggregate. Cement Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Guerra, I. Eco-efficient concrete: The effects of using recycled ceramic material from sanitary installations on the mechanical properties of concrete. Waste Manag. 2009, 29, 643–646. [Google Scholar] [CrossRef] [PubMed]

- Medina, C.; Frias, M.; De Rojas, M.I. Microstructure and properties of recycled concretes using ceramic sanitary ware industry waste as coarse aggregate. Constr. Build. Mater. 2012, 31, 112–118. [Google Scholar] [CrossRef]

- Medina, C.; De Rojas, M.S.; Frias, M. Reuse of sanitary ceramic wastes as coarse aggregate in eco-efficient concretes. Cement Concr. Compos. 2012, 34, 48–54. [Google Scholar] [CrossRef]

- Lopez, V. Eco-efficient concretes: Impact of the use of white ceramic powder on the mechanical properties of concrete. Biosyst. Eng. 2007, 96, 559–564. [Google Scholar] [CrossRef]

- Medina, C.; Banfill PF, G.; De Rojas, M.S.; Frías, M. Rheological and calorimetric behaviour of cements blended with containing ceramic sanitary ware and construction/demolition waste. Constr. Build. Mater. 2014, 40, 822–831. [Google Scholar] [CrossRef]

- Halicka, A.; Ogrodnik, P.; Zegardło, B. Using ceramic sanitary ware waste as concrete aggregate. Constr. Build. Mater. 2014, 48, 295–305. [Google Scholar] [CrossRef]

- Zegardło, B.; Szeląg, M.; Ogrodnik, P. Ultra-high strength concrete made with recycled aggregate from sanitary ceramic wastes—The method of production and the interfacial transition zone. Constr. Build. Mater. 2016, 122, 736–742. [Google Scholar] [CrossRef]

- Ogrodnik, P.; Zegardło, B.; Radzikowska, M. Use of post-production sanitary ceramic waste as a filler for cementitious composites with high chemical resistance. Chem. Ind. 2017, 96, 1100–1104. [Google Scholar]

- Ogrodnik, P.; Zegardło, B.; Szeląg, M. The use of heat-resistant concrete made with ceramic sanitary ware waste for a thermal energy storage. Appl. Sci. 2017, 7, 1303. [Google Scholar] [CrossRef] [Green Version]

- Zegardło, B.; Szeląg, M.; Ogrodnik, P. Concrete resistant to spalling made with recycled aggregate from sanitary ceramic wastes—effect of moisture and porosity on destructive processes occurring in fire conditions. Constr. Build. Mater. 2018, 173, 58–68. [Google Scholar] [CrossRef]

- Zegardło, B.; Brzyski, P.; Rymuza, K.; Bombik, A. Analysis of the Effects of Aggressive Environments Simulating Municipal Sewage on Recycled Concretes Based on Selected Ceramic Waste. Materials 2018, 11, 2565. [Google Scholar] [CrossRef] [PubMed]

- Mróz, K.; Tekieli, M.; Hager, I. Feasibility study of digital image correlation in determining strains in concrete exposed to fire. Materials 2020, 13, 2516. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Majdi, A.; Alqurashi, M.; Deifalla, A.F. Overview of Concrete Performance Made with Waste Rubber Tires. A Step Towar. Sustain. Concr. Mater. 2022, 15, 55–118. [Google Scholar]

- Fashandi, H.; Pakravan, H.R.; Latifi, M. Application of modified carpet waste cuttings for production of eco-efficient lightweight concrete. Constr. Build. Mater. 2019, 198, 629–637. [Google Scholar] [CrossRef]

- Charak, A.; Karloopia, J.; Srivatsan, T.S. Sustainable and Climate-Friendly Economic and Technological Development from the Use of Metal Matrix Composites. Met.-Matrix Compos. 2022, 15, 155–174. [Google Scholar]

- Dai, X.; Ren, L.; Guo, Z.; Yilmaz, E.; Fang, K.; Jiang, H. Strength analysis and optimization of alkali activated slag backfills through response surface methodology. Front. Mater. 2022, 9, 46–48. [Google Scholar] [CrossRef]

- Şahin, D.; Çullu, M.; Eker, H. The effect of different fineness values of Afşin Elbistan fly ash on permeability in concrete. Challenge 2020, 6, 73–83. [Google Scholar]

- Bascetin, A.; Adiguzel, D.; Eker, H.; Tuylu, S. The investigation of geochemical and geomechanical properties in surface paste disposal by pilot-scale tests. Int. J. Min. Reclam. Environ. 2022, 1, 126089. [Google Scholar] [CrossRef]

- Adiguzel, D.; Tuylu, S.; Eker, H. Utilization of tailings in concrete products: A review. Constr. Build. Mater. 2022, 360, 129574–129577. [Google Scholar] [CrossRef]

- Xotta, G.; Mazucco, G.; Salomoni, V.A.; Majorana, C.E.; Willam, K.J. Composite behavior of concrete materials under high temperatures. Int. J. Solids Struct. 2015, 65, 86–99. [Google Scholar] [CrossRef]

- Ming-Xiang, X.; Richard, J.Y. Mechanical behaviour of ultra-high strength concrete at elevated temperatures and fire resistance of ultra-high strength concrete filled steel tubes. Mater. Des. 2016, 104, 414–427. [Google Scholar] [CrossRef]

- Kun Dong, H. Development of bond strength model for CFRP-to-concrete joints at high temperatures. Composites 2016, 95, 264–271. [Google Scholar] [CrossRef]

- Abyzov, V.A. Lightweight Refractory Concrete Based on Aluminum-Magnesium- Phosphate Binder. Procedia Eng. 2016, 150, 1440–1445. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Shaky, A.M. Factors governing the shear response of prestressed concrete hollowcore slabs under fire conditions. Fire Saf. J. 2017, 88, 67–88. [Google Scholar] [CrossRef]

- Ogrodnik, P.; Zegardło, B.; Halicka, A. Preliminary analysis of the possibility of using waste sanitary ceramics in the function of aggregate for concretes working in high temperature conditions. Bezpieczeństwo I Tech. Pożarnicza 2012, 1, 49–56. [Google Scholar]

- Bieda, W.; Laurecka, H. Fireproof Masses, Concretes and Prefabricated Elements; Wydawnictwo Śląsk: Katowice, Poland, 1981. [Google Scholar]

- Chan, G.F.; Peng, M. Anson, Comparison between high-strength concrete and normal-strength concrete subjected to high temperature. Mater. Struct. 1996, 29, 616–619. [Google Scholar]

- Chen, Q. The Influence of High Temperature on Explosive Spalling Behavior and Mechanical Properties of Reactive Powder Concrete. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2010. [Google Scholar]

- Harmarthy, T.Z. Effect of Moisture on the Fire Endurance of Building Elements. ASTM Publ. STP Phila. 1965, 385, 74–95. [Google Scholar]

- Baoant, Z.P. Analysis of pore pressure, thermal stresses and fracture in rapidly heated concrete. In Proceedings of the International Workshop on Fire Performance of High-Strength Concrete (NIST Special Publication 919), Gaithersburg, MD, USA, 13–14 February 1997; pp. 155–164. [Google Scholar]

- Kalifa, P.; Menneteau, F.D. Quenard, Spalling and pore pressure in HPC at high temperature. Cement Concr. Res. 2000, 30, 1915–1927. [Google Scholar]

- Ishikawa, S. Explosion preventive structure of high-strength concrete method. Mater. Struct. 1996, 29, 616–619. [Google Scholar]

- Sarvaranta, L.; Mikkola, E. Fibre motar composites under fire conditions: Effects of ageing and moisture content of specimens. Mater. Struct. 1994, 27, 532–538. [Google Scholar]

- Doherty, P.; Ali, F.; Nadjai, A.; Choi, S. Explosive spalling of concrete columns with steel and polypropylene fibres subjected to severe fire. J. Struct. Fire Eng. 2012, 3, 95–104. [Google Scholar] [CrossRef]

- Bilodeau, A.; Kodur, V.K.R.; Hoff, G.C. Optimization of the type and amount of polypropylene fibres for preventing the spalling of lightweight concrete subjected to hydrocarbon fire. Cement Concr. Compos. 2004, 26, 163–174. [Google Scholar] [CrossRef]

- Momose, H.; Sakuramoto, F.; Yanagita, K. Experimental Study on Fire Resistance of Ultra-high Strength Concrete with Design Strength of 150N/mm2 mixed with Polypropylene Fiber. Jpn. Concr. Inst. 2003, 25, 995–1000. [Google Scholar]

- Mores, E.G.; Sangiacomo, L.; Novaes de Oliveira, A. Innovative thermal and acoustic insulation foam by using recycled ceramic shell and expandable (EPS) wastes. Waste Manag. 2019, 89, 336–344. [Google Scholar] [CrossRef]

- Hind, A.; Mahdi, K.; Kareem, A.; Jasim, A.; Shaban, H. Manufacturing and improving the characteristics of the isolation of concrete composites by additive Styrofoam particulate. Energy Procedia 2019, 157, 158–163. [Google Scholar]

- Mrozik, Ł.; Pawel, P. Practical Options for the Production and Use of Lightweight Concretes Using EPS Regranulate. In Sustainable Construction; UTP University Publishing House: Poznań, Poland, 2016; pp. 172–177. [Google Scholar]

- Piekarski, P.; Mrozik, Ł.; Grzybowska, A. Properties of lightweight concretes based on expanded polystyrene regranulate. Build. Mater. 2017, 537, 98–99. [Google Scholar]

- Wesołowska, M.; Szczepaniak, P.; Gajewski, J. NZEBs built of elements based on styrofoam re-granulate. IOP Conf. Ser. Mater. Sci. Eng. 2018, 415, 012004. [Google Scholar] [CrossRef]

- Wim, N.; Wandee, T. Fabrication and Mechanical Properties of Hybrid Composites between Pineapple fiber/Styrofoam Particle/Paper Tissue. Mater. Today 2019, 17, 1444–1450. [Google Scholar]

- Yang, X.; Fan, W.; Wang, H.; Shi, Y.; Wang, S.; Liew, R.K.; Ge, S. Recycling of bast textile wastes into high value-added products: A review. Environ. Chem. Lett. 2022, 1, 1–17. [Google Scholar] [CrossRef]

- Reis, J.M. Effect of textile waste on the mechanical properties of polymer concrete. Mater. Res. 2009, 12, 63–67. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M.; Sam AR, M.; Lim NH, A.S.; Samadi, M. Enhanced performance for aggressive environments of green concrete composites reinforced with waste carpet fibers and palm oil fuel ash. J. Clean. Prod. 2018, 185, 252–265. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J. Damage performance and compressive behavior of early-age green concrete with recycled nylon fiber fabric under an axial load. Constr. Build. Mater. 2019, 209, 105–114. [Google Scholar] [CrossRef]

- Meddah, M.S.; Bencheikh, M. Properties of concrete reinforced with different kinds of industrial waste fibre materials. Constr. Build. Mater. 2009, 23, 3196–3205. [Google Scholar] [CrossRef]

- Wang, Y. Concrete reinforcement with recycled fibers from carpet industrial waste. J. Clean. Prod. 1997, 9, 103–104. [Google Scholar]

- Wang, Y.; Wu, H.C.; Li, V.C. Concrete reinforcement with recycled fibers. J. Civ. Eng. 2000, 12, 314–319. [Google Scholar] [CrossRef]

- Ghosni, N.; Samali, B.; Vessalas, K. Evaluation of mechanical properties of carpet fibre reinforced concrete. In From Materials to Structures: Advancement Through Innovation; M.M.A.: London, UK, 2013; pp. 275–279. [Google Scholar]

- Mohammadhosseini, H.; Yatim, J.M. Microstructure and residual properties of green concrete composites incorporating waste carpet fibers and palm oil fuel ash at elevated temperatures. J. Clean. Prod. 2017, 144, 8–21. [Google Scholar] [CrossRef]

- Girardi, F.; Giannuzzi, G.M.; Mazzei, D. Recycled additions for improving the thermal conductivity of concrete in preparing energy storage systems. Constr. Build. Mater. 2017, 135, 565–579. [Google Scholar] [CrossRef]

- Ozger, O.B.; Girard, F.; Giannuzzi, G.M. Effect of nylon fibres on mechanical and thermal properties of hardened concrete for energy storage systems. Mater. Des. 2013, 51, 989–997. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Lim, N.H.; Sam, A. Effects of elevated temperatures on residual properties of concrete reinforced with waste polypropylene carpet fibres. Arab. J. Eng. 2018, 43, 1673–1686. [Google Scholar] [CrossRef]

- EN 934-2:2009+A1; Admixtures for Concrete, Mortar and Grout-Part 2: Concrete Admixtures-Definitions, Requirements, Conformity, Marking and Labelling. Polski Komitet Normalizacyjny: Warsaw, Poland, 2012.

- EN 12350-2:2011; Testing Fresh Concrete. Slump-Test. Polski Komitet Normalizacyjny: Warsaw, Poland, 2011.

- PN-EN 12390-7:2011; Testing Hardened Concrete. Density of Hardened Concrete. Polish Committee Standardisation: Warsaw, Poland, 2011.

- PN-EN 13755:2008; Natural Stone Test Methods. Determination of Water Absorption at Atmospheric Pressure. Polski Komitet Normalizacyjny: Warsaw, Poland, 2008.

- PN-EN 12390-5:2009; Testing Hardened Concrete. Flexural Strength of Test Specimens. Polish Committee Standardisation: Warsaw, Poland, 2009.

- PN-EN 12390-3:2011; Testing Hardened Concrete. Compressive Strength of Test Specimens. Polski Komitet Normalizacyjny: Warsaw, Poland, 2011.

- Gil, A.; Pacheco, F.; Christ, R.; Bolina, F.; Khayat, K.H.; Tutikian, B. Comparative Study of Concrete Panels’ Fire Resistance. ACI Mater. J. 2017, 114, 1673–1686. [Google Scholar] [CrossRef]

- Abbas, A.S.; Kadhum, M.M. Impact of fire on mechanical properties of slurry infiltrated fiber concrete (SIFCON). Civ. Eng. J. 2020, 6, 12–23. [Google Scholar] [CrossRef]

- Morita, T.; Beppu, M.; Suzuki, M. An experimental study on the temperature and structural behavior of a concrete wall exposed to fire after a high-velocity impact by a hard projectile. Fire Saf. J. 2017, 91, 506–516. [Google Scholar] [CrossRef]

| Lp. | Parameter | Standards | Value |

|---|---|---|---|

| 1 | Density [ g/cm3] | 0.35+/−0.02 | 0.360 |

| 2 | Breaking strength | ≤50 kg/cm2 | ≤55 kg/cm2 |

| 3 | Tensile strength at break | ≤110% | 90% |

| 4 | Free sulphuric acid content | ≤0.30% | 0.25% |

| 5 | Botanical impurities content | ≤0.35% | 0.18% |

| 6 | Mineral impurities content | ≤0.12% | 0.01% |

| 7 | Fire protection properties | ≤70 mm/min | ≤10 mm/min |

| 8 | Thermal resistance | max. up to 150 °C | 150 °C |

| 9 | Yarn fibre thickness | - | 0.08–0.3 mm |

| 10 | Fibre material | - | Polyesters, elastane, polyamide |

| Feature | Unit. | Average Score | Requirements |

|---|---|---|---|

| Start of binding | min | 233 | >60 |

| End of bond | min | 291 | |

| Water efficiency | % | 27.5 | |

| Constant volume | mm | 1.1 | <10 |

| Specific surface area | cm2/g | 3688 | |

| Compressive strength: after 2 days | MPa | 23.9 | <10 |

| Compressive strength: after 28 days | MPa | 55.9 | 42.5–62.5 |

| Chemical analysis: SO3 | % | 2.77 | <3.0 |

| Chemical analysis: Cl | % | 0.070 | <0.10 |

| Chemical analysis: Na2Oeq. | % | 0.53 | <0.6 |

| Property | Description |

|---|---|

| Form | Liquid |

| Chloride content | <0.1% |

| Alkali content | <2.0% |

| Compressive strength | After 7 days, concrete tested ≥ 110% control concrete After 28 days, concrete tested ≥ 110% control concrete |

| Air content | Test mixture ≤ 2% by volume above the content in the mixture control |

| Water reduction earnings | In the test mixture ≥ 5% w compared to the control mixture |

| Density (20 °C): | 1.075+/−0.02 kg/dm3 |

| pH: | 5+/−1 |

| Grain size | 0.15 um |

| Parameter | Unit | Value | Evaluation Method |

|---|---|---|---|

| Form | - | fine powder | Visual |

| Colour | - | grey | Visual |

| Fragrance | - | odourless | - |

| Density | g/cm3 | 2.05 | EN 1097-6 |

| Bulk density | g/cm3 | 1.1 | EN 1097-3 |

| Alkalinity | pH | less than 11.5 | PN-EN-ISO 10523 |

| (a) | |||||||||

| Component | Quantity of Substrate [kg] in the Test Mixture | Substrate Density [kg/m3] | Volume of Test Mixture [m3] | Conversion Rate of Ingredient per 1 m3 of Concrete Mix | Amount of Substrate [kg/m3] Concrete Mix | Component Volume [m3] | |||

| Cement CEM I 42.5N—SR 3/NA | 9.270 | 3100.00 | 0.002990 | 109.52 | 1015.28 | 0.3275 | |||

| Felt | 0.455 | 360.00 | 0.001264 | 109.52 | 49.83 | 0.1384 | |||

| Water | 4.323 | 1000.00 | 0.004323 | 109.52 | 473.47 | 0.4735 | |||

| Qplastplasticiser | 0.138 | 1050.00 | 0.000131 | 109.52 | 15.11 | 0.0144 | |||

| Microsilica | 0.928 | 2200.00 | 0.000422 | 109.52 | 101.64 | 0.0464 | |||

| SUMA | 15.114 | 0.009130 | 1655.34 | 1.0002 | |||||

| (b) | |||||||||

| Component | Substrate Density kg/m3 | For F3.0 Mix (3% Recycled) | For F1.6 Mix (1.6% Recycled) | For F1.0 Mix (1% Recycled) | For CONTR (0% Recycled) | ||||

| Amount of Substrate in kg/m3 Concrete Mix | Component Volume [m3] in 1 m3 Concrete Mixture | Amount of Substrate in kg/m3 of Concrete Mix | Component Volume [m3] in 1 m3 Concrete Mixture | Amount of Substrate in kg/m3 of Concrete Mix | Component Volume [m3] in 1 m3 Concrete Mixture | Amount of Substrate in kg/m3 of Concrete Mix | Component Volume [m3] in 1 m3 Concrete Mixture | ||

| Cement CEM I 42.5N—SR 3/NA | 3100.00 | 1015.28 | 0.3275 | 1015.28 | 0.3275 | 1015.28 | 0.3275 | 1015.28 | 0.3275 |

| Sand 0–2 mm | 2480.00 | - | - | 38.69 | 0.0156 | 73.38 | 0.0296 | 114.43 | 0.0461 |

| Gravel 2–4 mm | 2650.00 | - | - | 114.48 | 0.0432 | 156.85 | 0.0592 | 244.55 | 0.0923 |

| Felt | 360.00 | 49.83 | 0.1384 | 28.44 | 0.0790 | 18.53 | 0.0515 | - | - |

| Water | 1000.00 | 473.47 | 0.4735 | 473.47 | 0.4735 | 473.47 | 0.4735 | 473.47 | 0.4735 |

| Qplastplasticiser | 1050.00 | 15.11 | 0.0144 | 15.11 | 0.0144 | 15.11 | 0.0144 | 15.11 | 0.0144 |

| Microsilica | 2200.00 | 101.64 | 0.0462 | 101.64 | 0.0462 | 101.64 | 0.0462 | 101.64 | 0.0462 |

| SUMA | 1655.34 | 1.0000 | 1787.11 | 0.9994 | 1854.27 | 1.0018 | 1964.49 | 1.0000 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zegardło, B.; Maraveas, C.; Kaleszko, S.; Bombik, A. Composites Containing Felt Wastes from the Automotive Industry. Appl. Sci. 2023, 13, 2375. https://doi.org/10.3390/app13042375

Zegardło B, Maraveas C, Kaleszko S, Bombik A. Composites Containing Felt Wastes from the Automotive Industry. Applied Sciences. 2023; 13(4):2375. https://doi.org/10.3390/app13042375

Chicago/Turabian StyleZegardło, Bartosz, Chrysanthos Maraveas, Sylwester Kaleszko, and Antoni Bombik. 2023. "Composites Containing Felt Wastes from the Automotive Industry" Applied Sciences 13, no. 4: 2375. https://doi.org/10.3390/app13042375

APA StyleZegardło, B., Maraveas, C., Kaleszko, S., & Bombik, A. (2023). Composites Containing Felt Wastes from the Automotive Industry. Applied Sciences, 13(4), 2375. https://doi.org/10.3390/app13042375