Damage Diagnosis of Frame Structure Based on Convolutional Neural Network with SE-Res2Net Module

Abstract

1. Introduction

2. Convolutional Neural Network

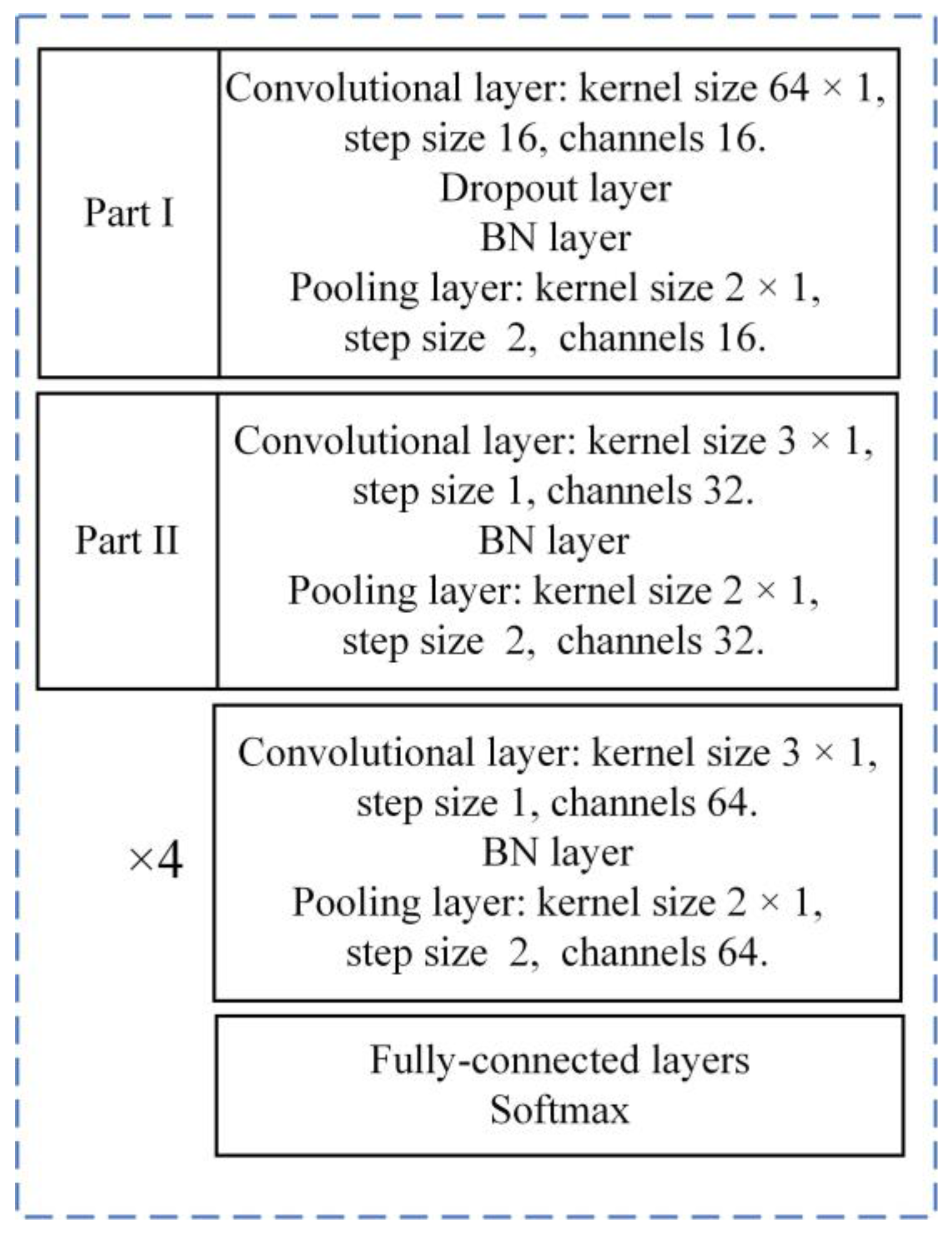

2.1. TICNN Model

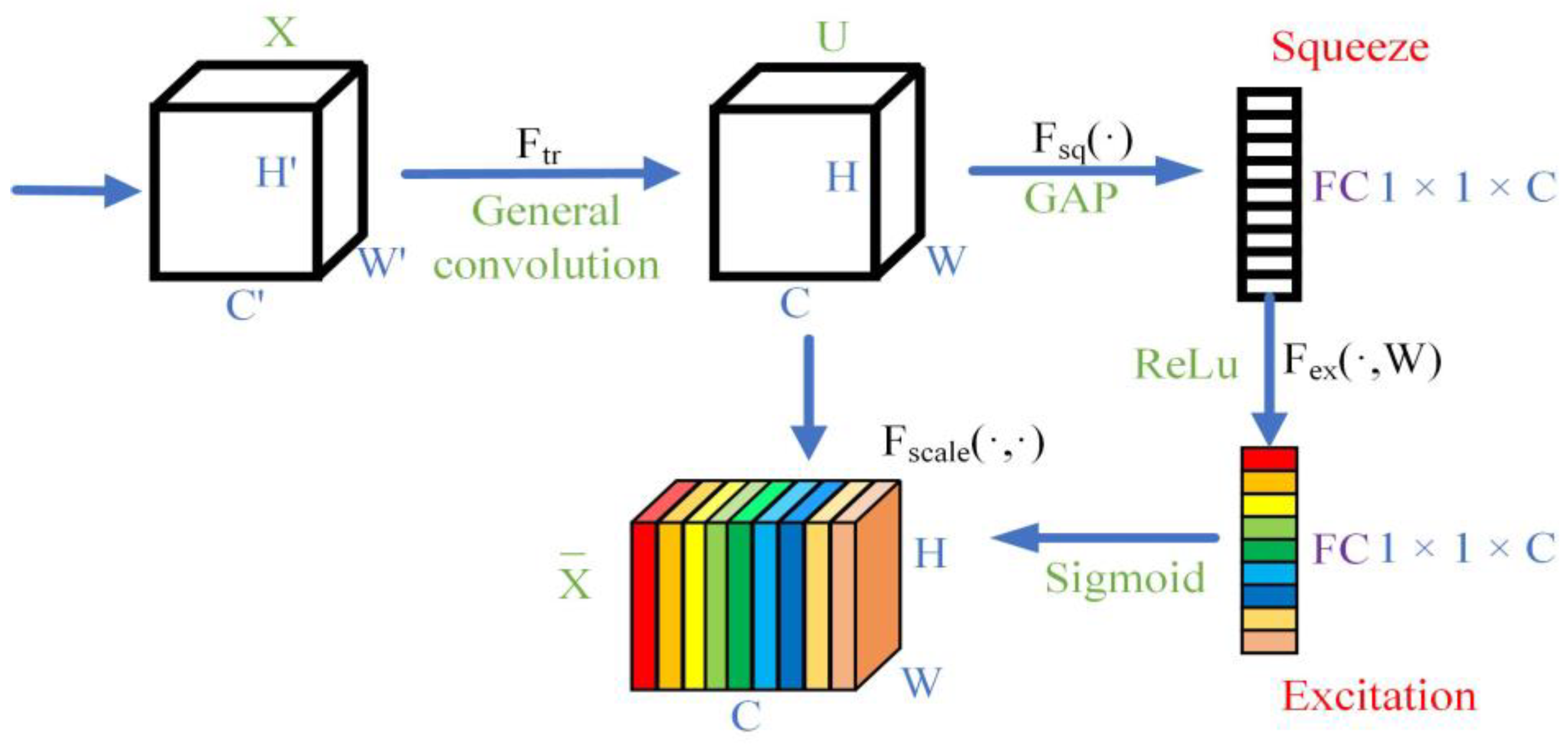

2.2. SENet Module

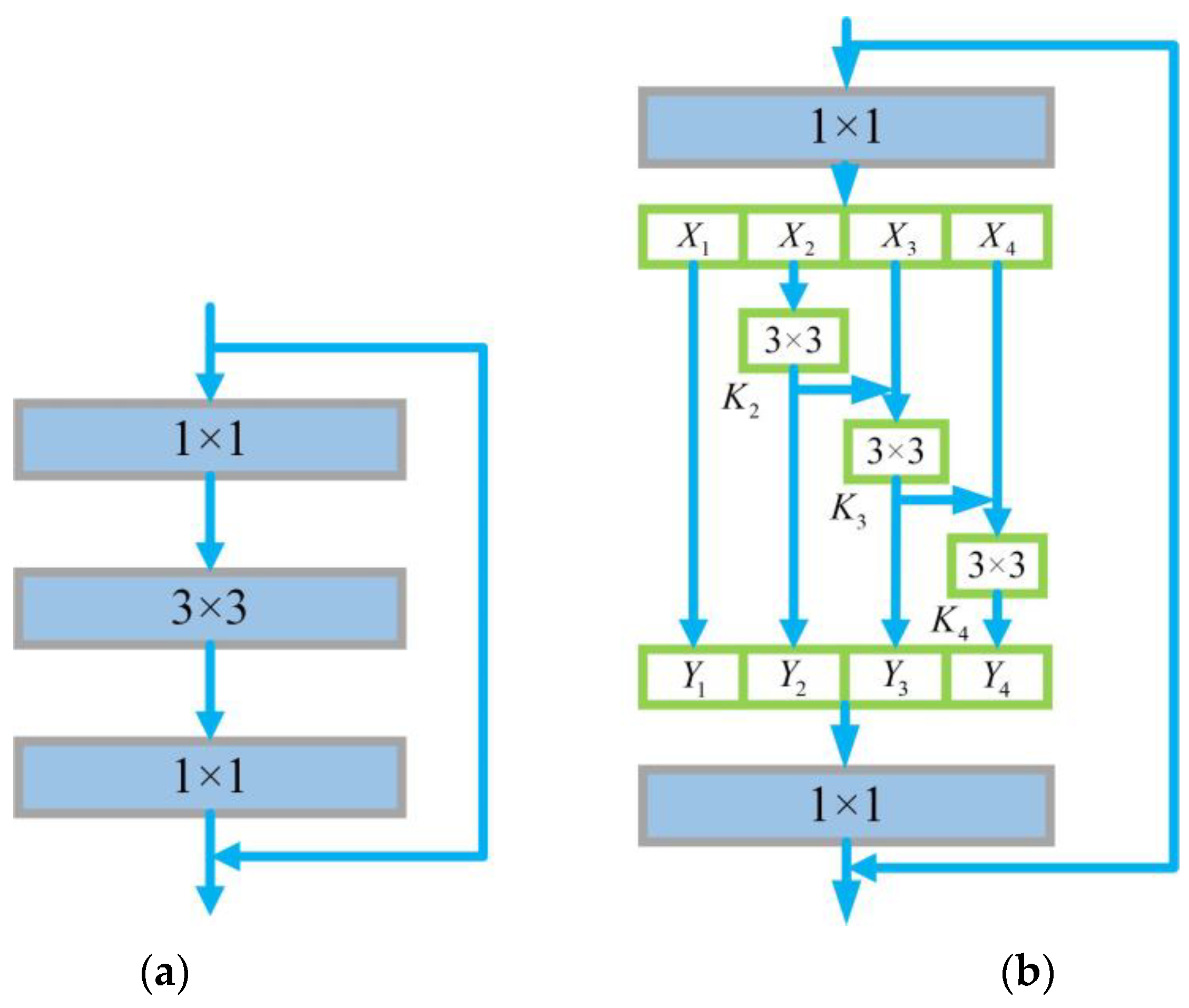

2.3. Res2Net Module

2.4. SE-Res2Net Module

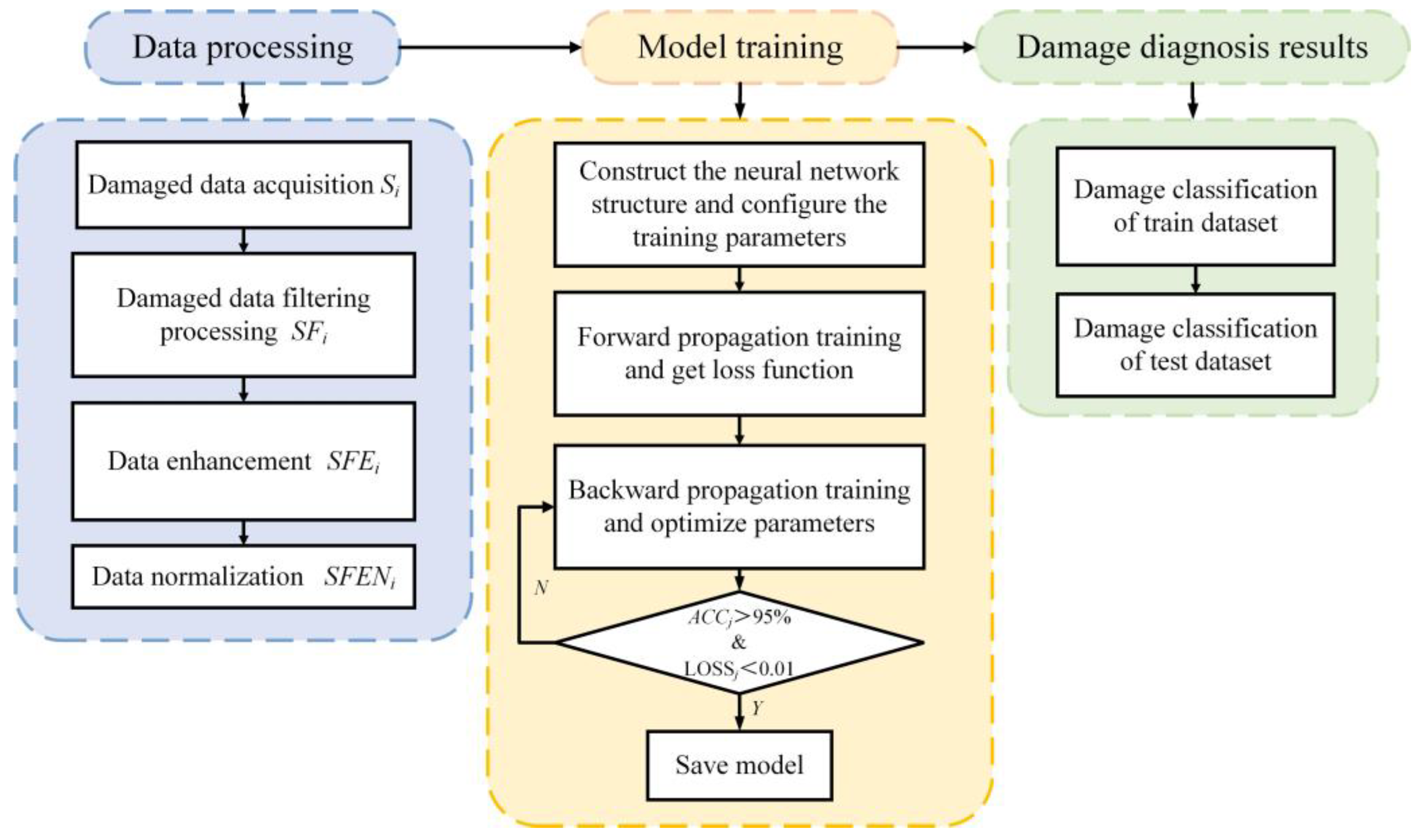

3. Damage Diagnosis Model and Process

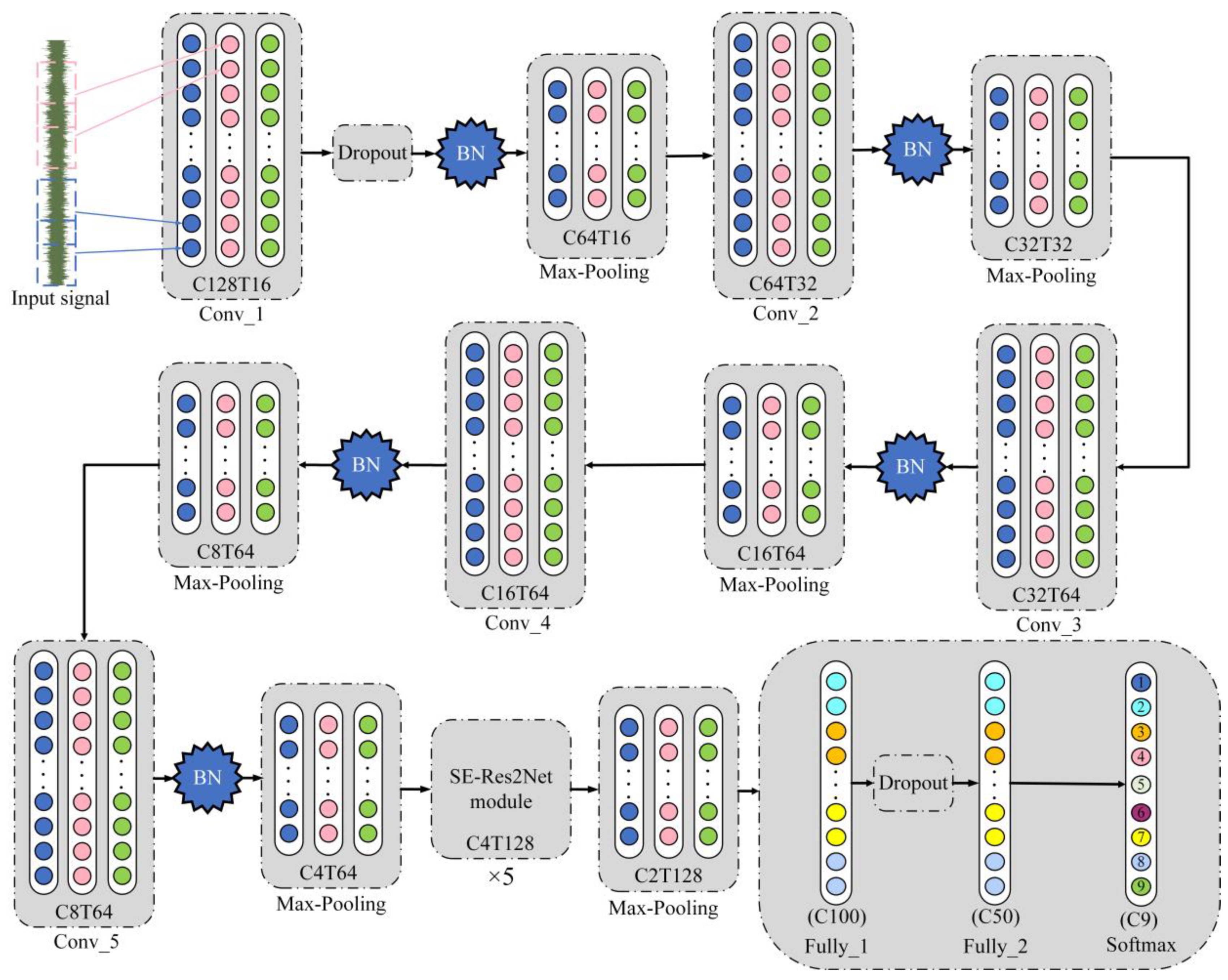

3.1. Structure of the Proposed Model

3.2. Model Parameters

3.3. Damage Diagnosis Process

- (1)

- Data processingThe data processing process was as follows. Firstly, the vibration signal was collected by the sensor, then the vibration signal was filtered, and finally the vibration signal after filtering was processed by data slicing and enhancement and data normalization.

- Data acquisition and filteringThe data of each damage case is represented by Si, where i represents the case. Generally, the noise in the construction environment is Gaussian noise [44]. Therefore, a Gaussian low-pass filter was used to process the data collected by sensors, making it smoother, since it can reduce the influence of high-frequency noise on the results. The formula is shown in Equation (1). The filtered data is represented by SFi:where is the standard deviation of input signal x.

- Data slicing and enhancementWhen the number of samples in the training dataset is small, the trained model cannot complete sufficient training, which will lead to over-fitting and thus cannot meet the ideal requirements. When the number of samples in the training dataset is larger, the model can learn more features and gain stronger generalization abilities. Therefore, in order to increase the number of samples in the training dataset and improve the training results, it was necessary to adopt the sliding window method for data enhancement. Different numbers of data samples can be obtained by adjusting the size of the sliding window. The sliding window method can obtain enough data samples. The filtered data SFi after data enhancement using the sliding window method is expressed as SFEi. For example, for a signal with K vibration points, the size of sliding window is set to W, and the step of sliding window is set to S, then samples with a number of N can be obtained. The formula can be written as:

- Data normalizationData normalization can process data according to the statistical distribution of samples. Normalized data tend to be smoother in training and can accelerate the convergence rate of the model, making the training process more stable. The dataset after data enhancement SFEi is normalized between [–1, 1], and SFENi represents the normalized data:

- (2)

- Model trainingIn model training, the structure of the model needs to be built first before the training dataset can be input into the model. The loss function of the model can be obtained after forward propagation, and the model’s parameters are optimized through backward propagation. Finally, the model which meets the training requirements is saved.

- (3)

- Damage diagnosis resultsDamage diagnosis results can be obtained by analyzing the results of the training dataset and test dataset. The diagnostic results of the training dataset will be displayed after the training is completed. To obtain the diagnosis results of the test dataset, firstly the trained model needs to be saved and then input the test dataset into it to obtain the results. Finally, according to the classification accuracy of the training dataset and the test dataset, the performance of the model is analyzed to determine whether the damage diagnosis ability of the model meets the requirements.

4. Experiments

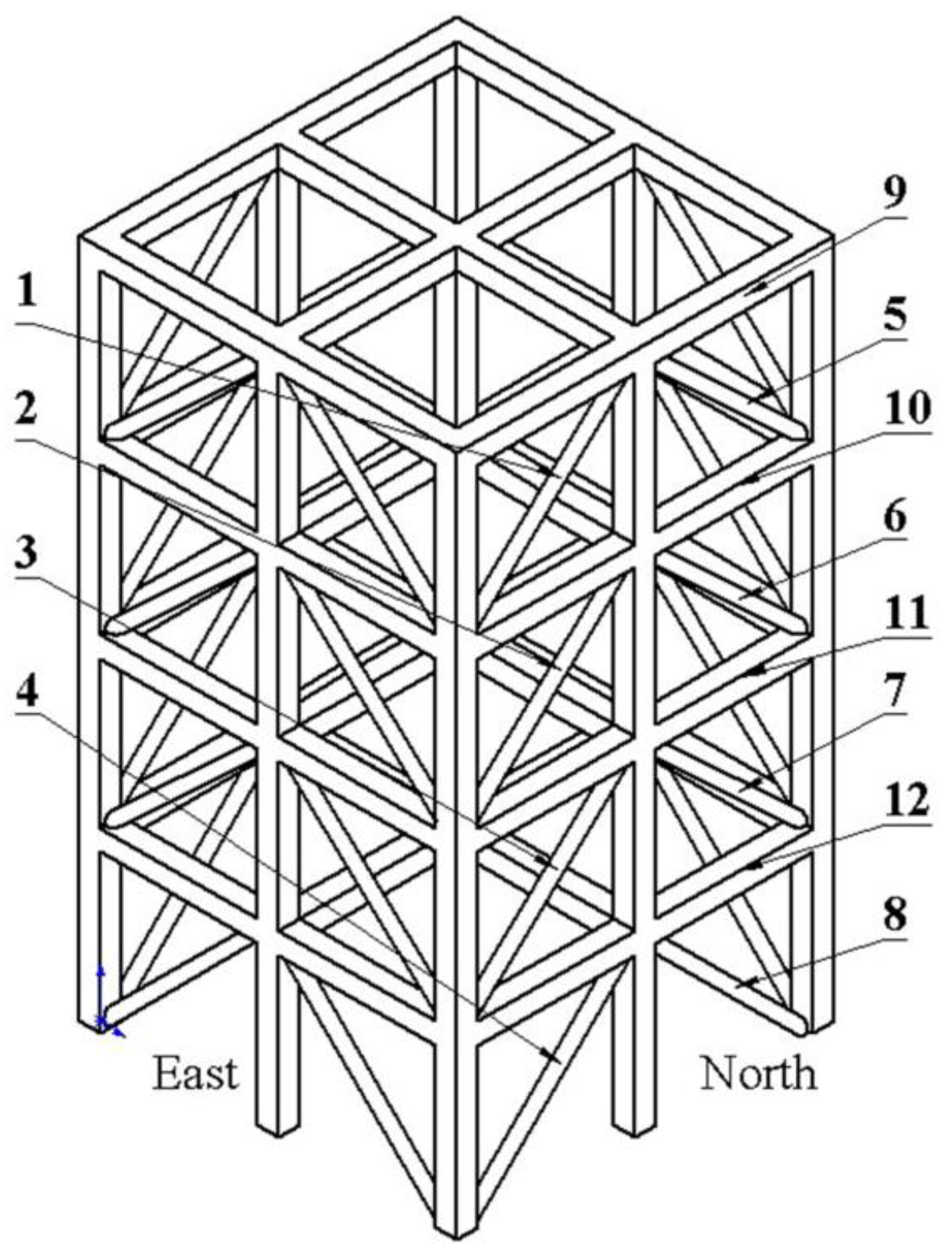

4.1. Experimental Object

4.2. Experimental Data

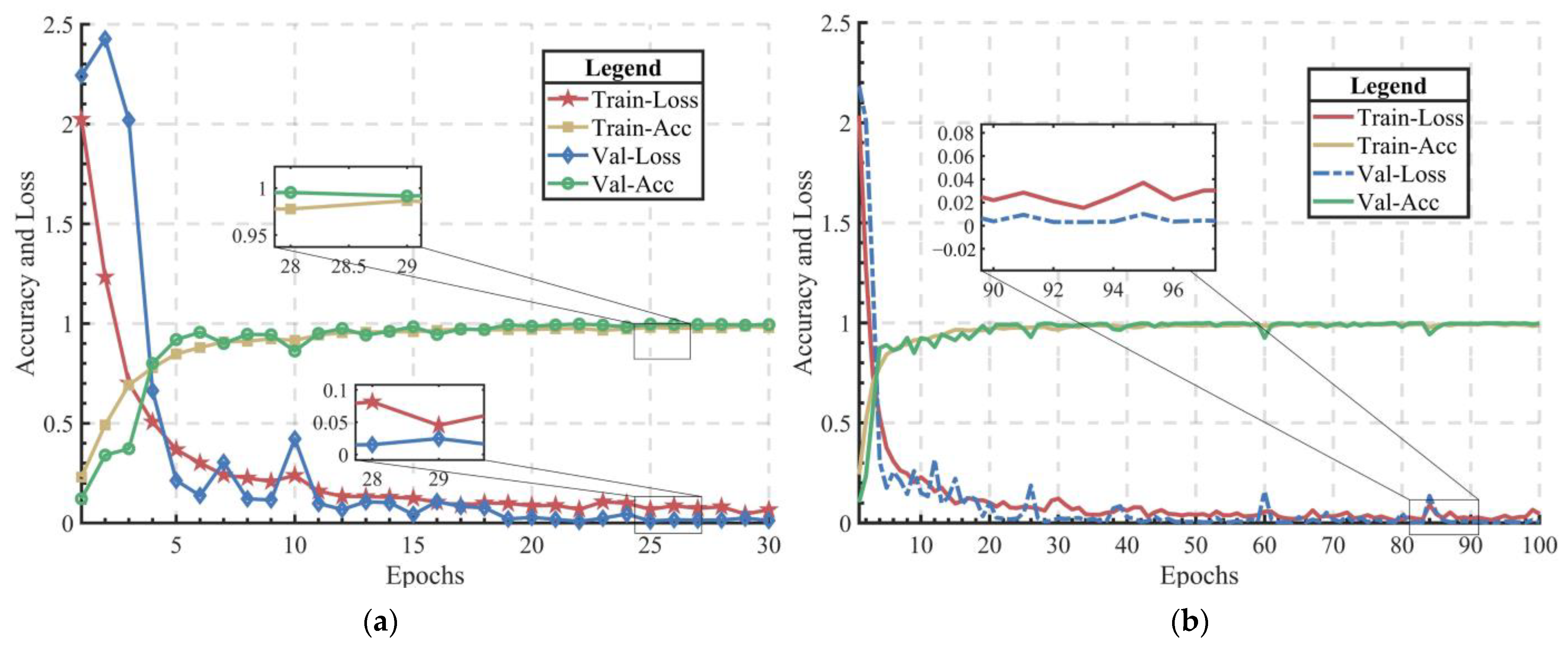

4.3. Damage Type Diagnosis Experiment

- (1)

- Analysis of training results

- (2)

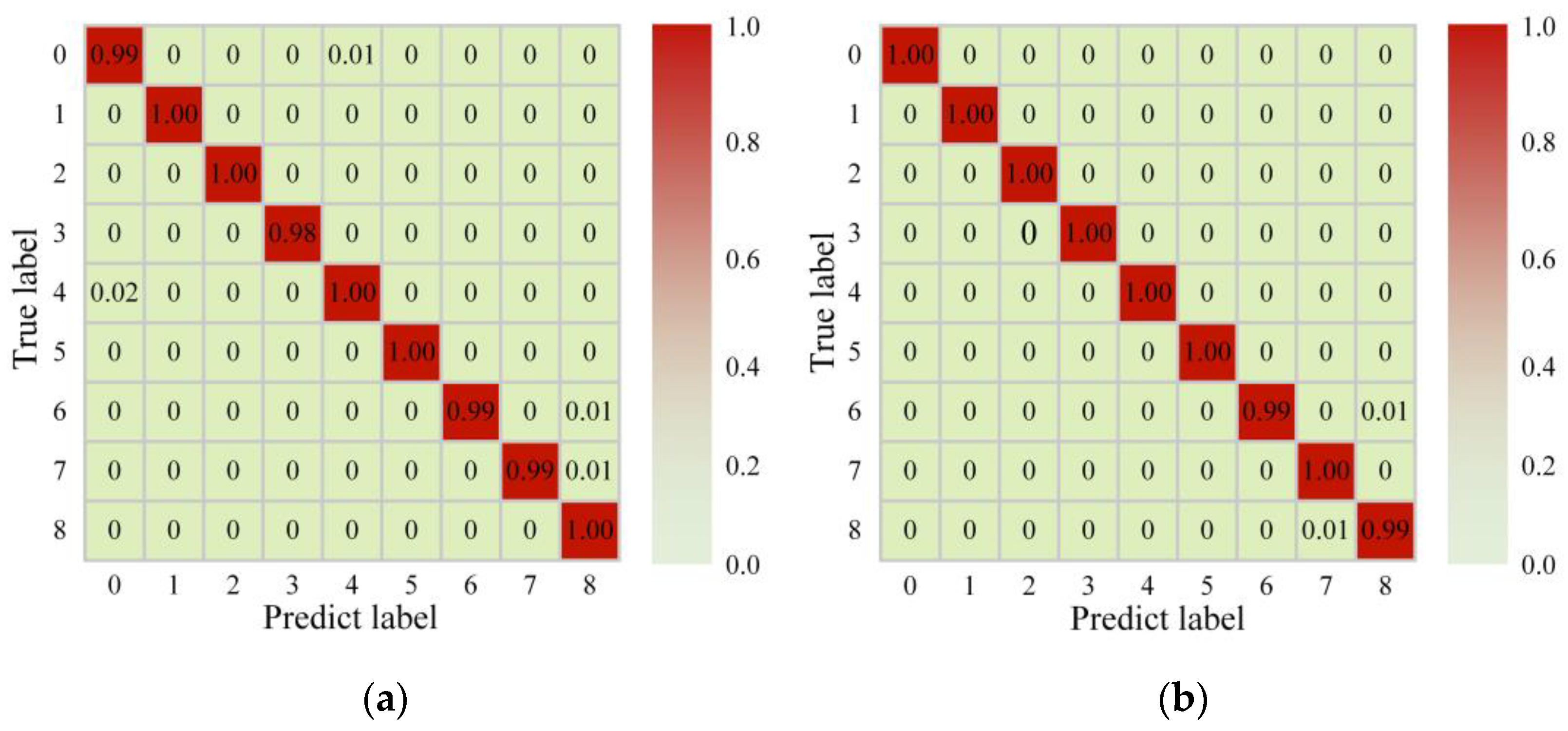

- Confusion matrix analysis

- (3)

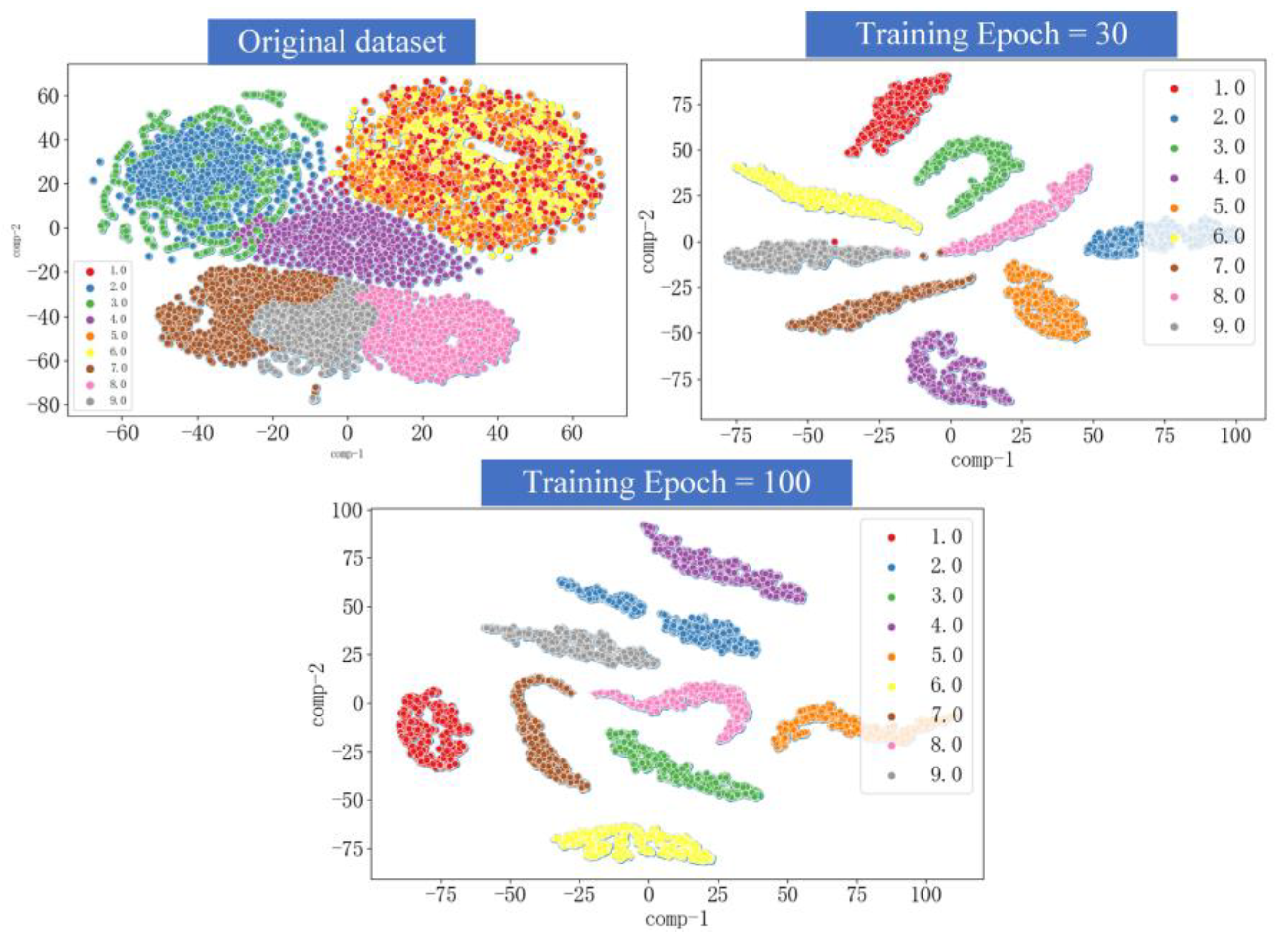

- T-SNE visualization

- (4)

- Analysis of test dataset results

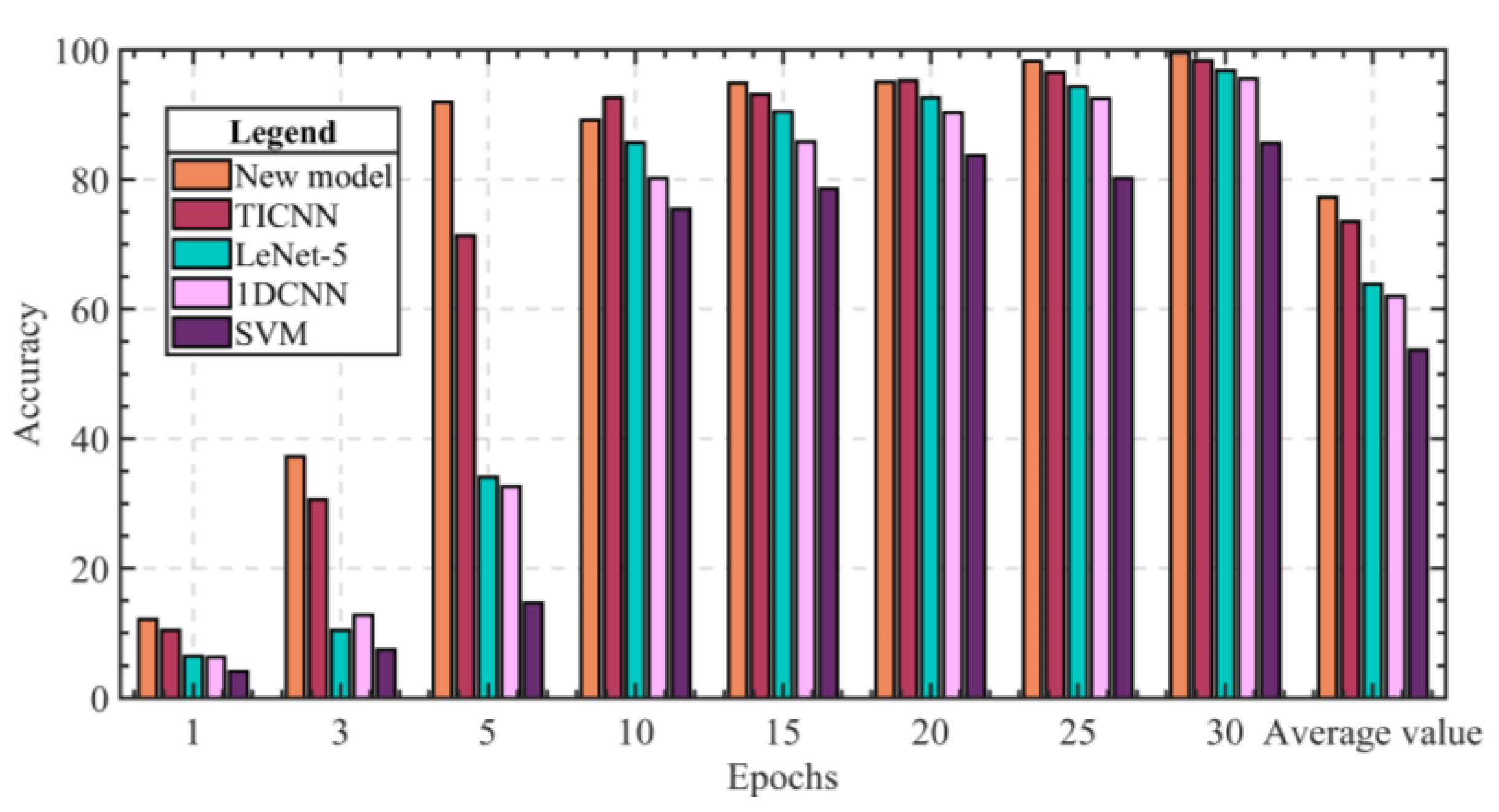

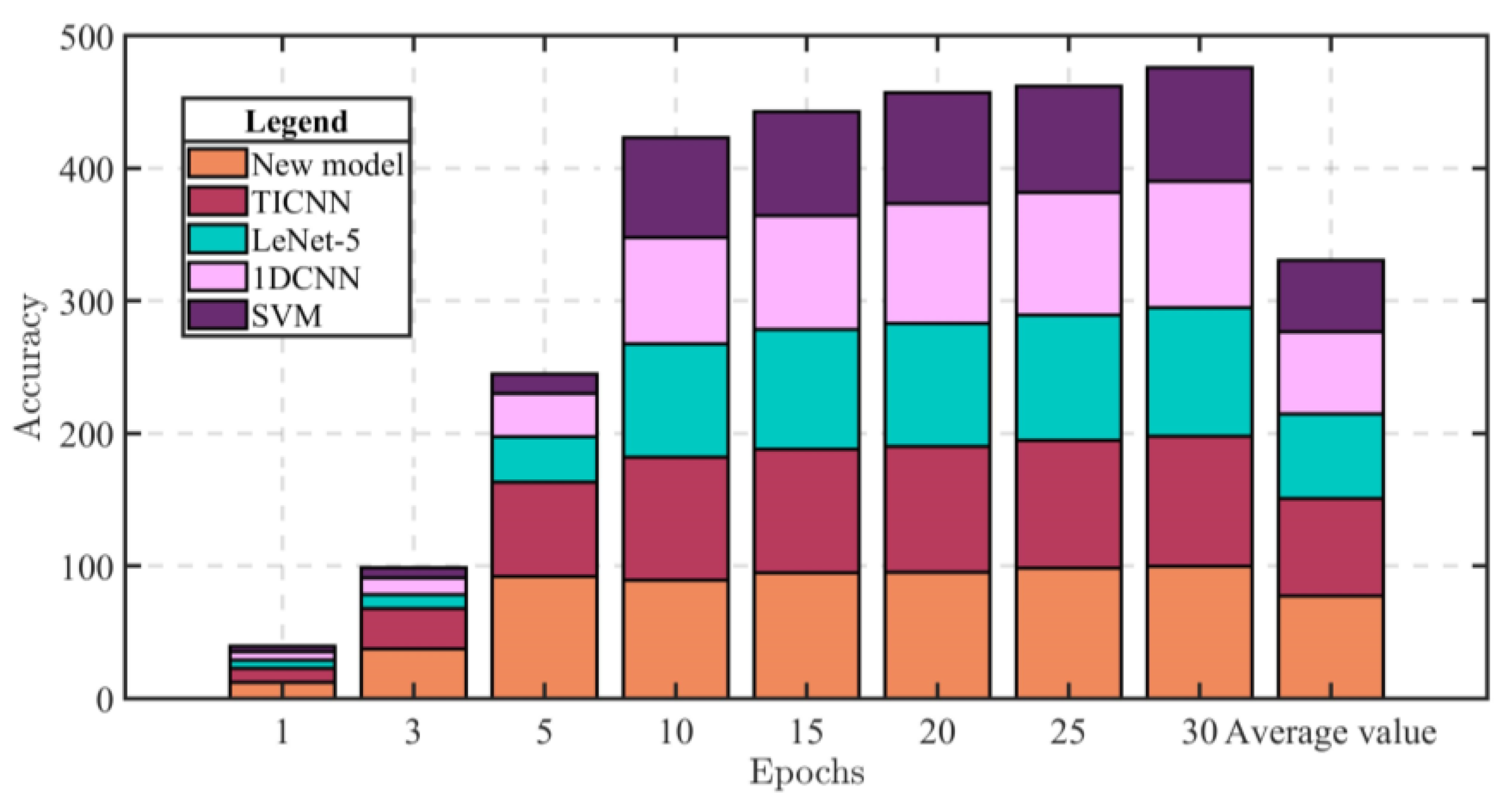

4.4. Comparative Experiment of Diagnostic Accuracy

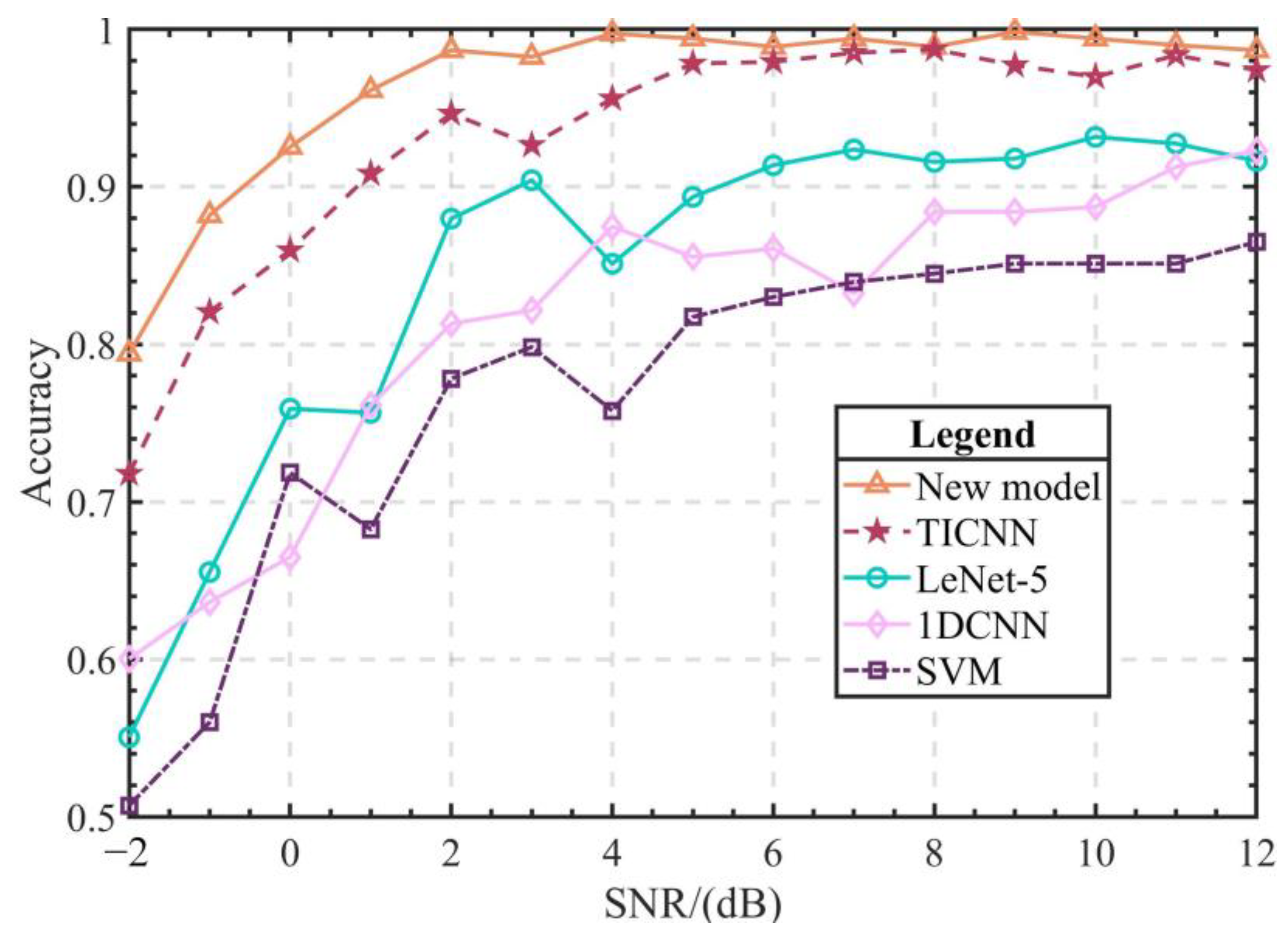

4.5. Comparative Experiment of Anti-Noise Ability

5. Conclusions

- (1)

- The training process of the proposed new model has a fast convergence speed and high multi-classification accuracy; the accuracy of the training dataset is 99.78% and the accuracy of the test dataset is 100%.

- (2)

- Compared with other similar models, the proposed new model has the highest accuracy of 99.6% when the training epoch reaches 30, and the average value of accuracy can reach 77.3%, which is higher than other models. Therefore, the proposed new model can achieve higher accuracy in the early stage of training and has better performance than other models.

- (3)

- In the comparative experiment of anti-noise ability, the anti-noise ability of the proposed new model is about 4~5% stronger than that of convolution neural network with training interference. Compared with other models, the new model performs better and has stronger anti-noise performance. It can accurately diagnose the damage of a structural frame in a strong noise environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zeng, Z. Application and Development of Neural Network Technology in Mechanical Engineering. Sci. Technol. Innov. Appl. 2020, 18, 153–154. [Google Scholar]

- Gul, M.; Catabas, N. Structural health monitoring and damage assessment using a novel time series analysis methodology with sensor clustering. J. Sound Vib. 2011, 330, 1196–1210. [Google Scholar] [CrossRef]

- Yin, X. Discussion on the existing problems and Solutions in contemporary civil construction. Sci. Technol. Innov. Appl. 2013, 32, 241–248. [Google Scholar]

- Shun, L.; Hai, G.; Dian, L. Review of Vibration signal Processing Methods. Chin. J. Sci. Instrum. 2013, 34, 1907–1915. [Google Scholar]

- Heng, L.; Hydrogen, Z.; Xian, Q. Bearing Fault Diagnosis Method Based on Short-time Fourier Transform and Convolutional Neural Network. J. Vib. Shock 2018, 37, 124–131. [Google Scholar]

- Zhi, L.; Ming, Z.; Fu, C. Research on Mechanical Fault Diagnosis Method Based on Empirical Wavelet Transform. Chin. J. Sci. Instrum. 2014, 35, 2423–2432. [Google Scholar]

- Huang, P.; Liao, G.; Yang, Z. A fast SAR imaging method for ground moving target using a second-order WVD transform. IEEE Trans. Geosci. Remote Sens. 2015, 54, 1940–1956. [Google Scholar] [CrossRef]

- Manhertz, G.; Bereczky, A. STFT spectrogram based on hybrid evaluation method for rotating machine transient vibration analysis. Mech. Syst. Signal Process. 2021, 154, 107583. [Google Scholar] [CrossRef]

- Deng, W.; Zhang, S.; Zhao, H. A novel fault diagnosis method based on integrating empirical wavelet transform and fuzzy entropy for motor bearing. IEEE Access 2018, 6, 35042–35056. [Google Scholar] [CrossRef]

- Singru, P.; Krishnakumar, V.; Natarajan, D. Bearing failure prediction using Wigner-Ville distribution, modified Poincare mapping and fast Fourier transform. J. Vibro Eng. 2018, 20, 127–137. [Google Scholar] [CrossRef]

- Zhang, C.; Yuan, G.; Ming, M. Review on the development and application of Artificial Neural network model. Comput. Eng. Appl. 2021, 57, 57–69. [Google Scholar]

- Zhang, S.; Li, X.; Zong, M. Efficient KNN classification with different numbers of nearest neighbors. IEEE Trans. Neural Netw. Learn. Syst. 2017, 29, 1774–1785. [Google Scholar] [CrossRef]

- Gen, Y.; Wang, J.; Jin, L. Application of Decision Tree Algorithm in Diagnosis Machinery Fault Information Mining. Mach. Des. Manuf. 2022, 371, 168–176. [Google Scholar]

- Chen, M.; Ming, L.; Qiang, G. Rolling Bearing Fault Diagnosis Based on Sparrow Search Algorithm Optimization Support Vector Machine. Sci. Technol. Eng. 2021, 21, 4025–4029. [Google Scholar]

- Saravanan, N.; Ramachandran, K.I. Incipient gear box fault diagnosis using discrete wavelet transform (DWT) for feature extraction and classification using artificial neural network (ANN). Expert Syst. Appl. 2010, 37, 4168–4181. [Google Scholar] [CrossRef]

- Lu, J.; Qian, W.; Li, S. Enhanced K-nearest neighbor for intelligent fault diagnosis of rotating machinery. Appl. Sci. 2021, 11, 919. [Google Scholar] [CrossRef]

- Yan, X.; Jia, M. A novel optimized SVM classification algorithm with multi-domain feature and its application to fault diagnosis of rolling bearing. Neurocomputing 2018, 313, 47–64. [Google Scholar] [CrossRef]

- Jie, G.; Xian, X. Research on transformer fault diagnosis based on support vector machine. Hydropower N. Energy 2020, 34, 28–31. [Google Scholar]

- Zoph, B.; Vasudevan, V.; Shlens, J. Learning transferable architectures for scalable image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Salt Lake City, UT, USA, 18–23 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 8697–8710. [Google Scholar]

- Henaff, O. Data-efficient image recognition with contrastive predictive coding. In Proceedings of the 37th International Conference on Machine Learning, Virtual, 13–18 July 2020; Volume 39, pp. 4182–4192. [Google Scholar]

- Sharma, N.; Jain, V.; Mishra, A. An analysis of convolutional neural networks for image classification. Procedia Comput. Sci. 2018, 132, 377–384. [Google Scholar] [CrossRef]

- Lguensat, R.; Tandeo, P.; Ailliot, P. The analog data assimilation. Mon. Weather Rev. 2017, 145, 4093–4107. [Google Scholar] [CrossRef]

- Lv, L.; Li, D.; Cui, C. Nuclease-aided target recycling signal amplification strategy for ochratoxin A monitoring. Biosens. Bioelectron. 2017, 87, 136–141. [Google Scholar] [CrossRef]

- Zhao, Y.; Shi, Y.; Wang, Z. The Improved YOLOV5 Algorithm and Its Application in Small Target Detection. In Proceedings of the Intelligent Robotics and Applications: 15th International Conference, ICIRA 2022, Harbin, China, 1–3 August 2022; Springer International Publishing: Cham, Switzerland, 2022; pp. 679–688. [Google Scholar]

- Wang, Y.; Yan, J.; Yang, Z. A novel 1DCNN and domain adversarial transfer strategy for small sample GIS partial discharge pattern recognition. Meas. Sci. Technol. 2021, 32, 122–131. [Google Scholar] [CrossRef]

- Simonyan, K.; Zisserman, A. Very Deep Convolutional Networks for Large-Scale Image Recognition; ICLR.UK: University of Oxford: Oxford, UK, 2015; pp. 1–7. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton G, E. Imagenet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- Zeiler M, D.; Fergus, R. Visualizing and understanding convolutional networks. In Proceedings of the Computer Vision–ECCV 2014: 13th European Conference, Zurich, Switzerland, 6–12 September 2014; Springer International Publishing: Berlin/Heidelberg, Germany, 2014; pp. 818–833. [Google Scholar]

- Zhang, Y.; Wang, J.; Zhang, X. Conciseness is better: Recurrent attention LSTM model for document-level sentiment analysis. Neurocomputing 2021, 462, 144–156. [Google Scholar] [CrossRef]

- Jiang, H.; Qin, F.; Cao, J. Recurrent neural network from adder’s perspective: Carry-lookahead RNN. Neural Netw. 2021, 144, 13–21. [Google Scholar] [CrossRef]

- Wang, D.; Tang, L.; Zhu, J. Dairy goat detection based on Faster R-CNN from surveillance video. Comput. Electron. Agric. 2018, 154, 55–63. [Google Scholar] [CrossRef]

- Zheng, J.; Min, C.; Jun, C. Multi-scale Fuzzy Entropy and Its Application in Rolling Bearing Fault Diagnosis. J. Vib. Eng. 2014, 27, 145–151. [Google Scholar]

- Tamilselvan, P.; Wang, P. Failure diagnosis using deep belief learning based health state classification. Reliab. Eng. Syst. Saf. 2013, 115, 124–135. [Google Scholar] [CrossRef]

- Song, H.; Hai, S. Intelligent Fault Diagnosis of aero-engine High-speed Bearing Based on Elevated Convolutional Neural Network. J. Aeronaut. Astronaut. 2021, 43, 1–15. [Google Scholar]

- Janssens, O.; Slavkovikj, V.; Vervisch, B. Convolutional neural network based on fault detection for rotating machinery. J. Sound Vib. 2016, 377, 331–345. [Google Scholar] [CrossRef]

- Wang, J.; Zhuang, J.; Duan, L. A multi-scale convolution neural network for featureless fault diagnosis. In Proceedings of the 2016 International Symposium on Flexible Automation (ISFA), Cleveland, OH, USA, 1–3 August 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 65–70. [Google Scholar]

- Abdeljaber, A.; Younis, O.; Avci, N.; Kiranyaz, S. 1-DCNNs for structural damage detection: Verification on a structural health monitoring benchmark data. Neurocomputing 2018, 275, 1308–1317. [Google Scholar] [CrossRef]

- Dyke S, J.; Bernal, D.; Beck, J. Experimental phase II of the structural health monitoring benchmark problem. In Proceedings of the 16th ASCE Engineering Mechanics Conference, Chicago, IL, USA, 17 July 2003; ASCE: Reston, VA, USA, 2003; pp. 1–9. [Google Scholar]

- Zhang, W.; Chuan, L.; Peng, G. A deep convolutional neural network with new training methods for bearing fault diagnosis under noisy environment and different working load. Mech. Syst. Signal. Process. 2018, 100, 349–543. [Google Scholar] [CrossRef]

- Hu, J.; Shen, L.; Sun, G. Squeeze-and-excitation networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 7132–7141. [Google Scholar]

- Gao, S.; Cheng, M.; Zhao, K. Res2net: A new multi-scale backbone architecture. IEEE Trans. Pattern Anal. Mach. Intell. 2019, 43, 652–662. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 770–778. [Google Scholar]

- Szegedy, C.; Ioffe, S.; Vanhoucke, V.; Alemi, A. Inception-v4, inception-resnet and the impact of residual connections on learning. In Proceedings of the AAAI Conference on Artificial Intelligence, San Francisco, CA, USA, 4–9 February 2017; AAAI: Washington, DC, USA, 2017; pp. 1–15. [Google Scholar]

- Xiao, W.; Jiu, S. A novel Gaussian noise filtering Algorithm. J. Beihua Univ. 2011, 12, 606–609. [Google Scholar]

- Ren, J.; Cai, C.; Chi, Y.; Xue, Y. Integrated Damage Location Diagnosis of Frame Structure Based on Convolutional Neural Network with Inception Module. Sensors 2022, 23, 418. [Google Scholar] [CrossRef]

- Xu, H.; Cai, C.; Chi, Y. Damage Location Diagnosis of Frame Structure Based on a Novel Convolutional Neural Network. Appl. Sci. 2022, 12, 12411. [Google Scholar] [CrossRef]

| Step Size | 4 | 8 | 12 | 16 | 20 | 24 | 32 |

|---|---|---|---|---|---|---|---|

| Accuracy | 0.9823 | 0.9976 | 0.9914 | 0.9862 | 0.9907 | 0.9842 | 0.9855 |

| Loss | 0.0082 | 0.0034 | 0.0110 | 0.0093 | 0.0106 | 0.0163 | 0.0156 |

| Layer Type | Kernel/Step Size | Channels | Output Size (Width × Depth) | Zero Padding |

|---|---|---|---|---|

| Conv_1 | 64 × 1/8 × 1 | 16 | 128 × 16 | Yes |

| Max-pooling | 2 × 1/2 × 1 | 16 | 64 × 16 | No |

| Conv_2 | 32 × 1/4 × 1 | 32 | 64 × 32 | Yes |

| Max-pooling | 2 × 1/2 × 1 | 32 | 32 × 32 | No |

| Conv_3 | 3 × 1/1 × 1 | 64 | 32 × 64 | Yes |

| Max-pooling | 2 × 1/2 × 1 | 64 | 16 × 64 | No |

| Conv_4 | 3 × 1/1 × 1 | 64 | 16 × 64 | Yes |

| Max-pooling | 2 × 1/2 × 1 | 64 | 8 × 64 | No |

| Conv_5 | 3 × 1/1 × 1 | 64 | 8 × 64 | Yes |

| Max-pooling | 2 × 1/2 × 1 | 64 | 4 × 64 | No |

| SE-Res2Net_1 | 128 | 4 × 128 | ||

| SE-Res2Net_2 | 128 | 4 × 128 | ||

| SE-Res2Net_3 | 128 | 4 × 128 | ||

| SE-Res2Net_4 | 128 | 4 × 128 | ||

| SE-Res2Net_5 | 128 | 4 × 128 | ||

| Max-pooling | 2 × 1/2 × 1 | 128 | 2 × 128 | No |

| Fully_1 | 100 | 1 | 100 × 1 | |

| Fully_2 | 50 | 1 | 50 × 1 | |

| Softmax | 9 | 1 | 9 × 1 |

| Damaged Cases | Specific Operation |

|---|---|

| 1 | Undamaged |

| 2 | Remove structures numbered 1 in the east |

| 3 | Remove structures numbered 1 and 4 in the east |

| 4 | Remove structures numbered 1–4 in the east |

| 5 | Remove structures numbered 1–8 in the east |

| 6 | Remove structures numbered 3 and 7 in the north |

| 7 | Remove structures numbered 1–8 in all four sides |

| 8 | Loosen structures numbered 11 and 12 in the east on the basis of case 7 |

| 9 | Loosen structures numbered 9–12 in the east on the basis of case 7 |

| Model | Epoch | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 3 | 5 | 10 | 15 | 20 | 25 | 30 | Average Value | |

| New model | 12.1 | 37.3 | 91.9 | 89.2 | 94.9 | 95 | 98.3 | 99.6 | 77.3 |

| TICNN | 10.5 | 30.6 | 71.4 | 92.7 | 93.1 | 95.2 | 96.5 | 98.4 | 73.5 |

| LeNet-5 | 6.4 | 10.4 | 34.1 | 85.7 | 90.5 | 92.7 | 94.3 | 96.8 | 63.9 |

| 1DCNN | 6.3 | 12.8 | 32.6 | 80.2 | 85.8 | 90.4 | 92.5 | 95.5 | 62 |

| SVM | 4.1 | 7.5 | 14.7 | 75.4 | 78.6 | 83.7 | 80.2 | 85.6 | 53.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, W.; Liu, Z.; Cai, C.; Xue, Y.; Ren, J. Damage Diagnosis of Frame Structure Based on Convolutional Neural Network with SE-Res2Net Module. Appl. Sci. 2023, 13, 2545. https://doi.org/10.3390/app13042545

Fu W, Liu Z, Cai C, Xue Y, Ren J. Damage Diagnosis of Frame Structure Based on Convolutional Neural Network with SE-Res2Net Module. Applied Sciences. 2023; 13(4):2545. https://doi.org/10.3390/app13042545

Chicago/Turabian StyleFu, Wenmei, Zhiqiang Liu, Chaozhi Cai, Yingfang Xue, and Jianhua Ren. 2023. "Damage Diagnosis of Frame Structure Based on Convolutional Neural Network with SE-Res2Net Module" Applied Sciences 13, no. 4: 2545. https://doi.org/10.3390/app13042545

APA StyleFu, W., Liu, Z., Cai, C., Xue, Y., & Ren, J. (2023). Damage Diagnosis of Frame Structure Based on Convolutional Neural Network with SE-Res2Net Module. Applied Sciences, 13(4), 2545. https://doi.org/10.3390/app13042545