Effects of Heat Treatment and Diamond Burnishing on Fatigue Behaviour and Corrosion Resistance of AISI 304 Austenitic Stainless Steel

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

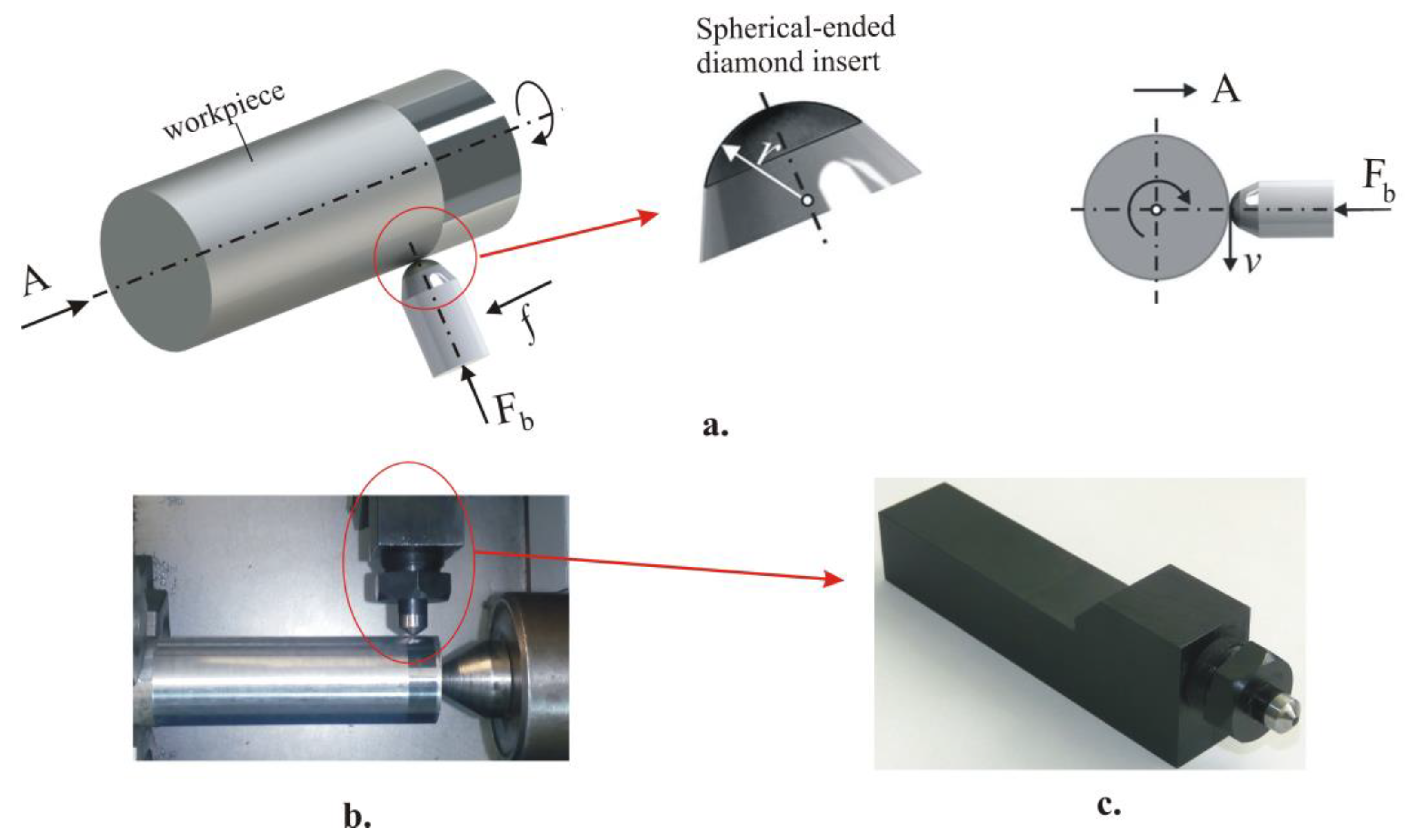

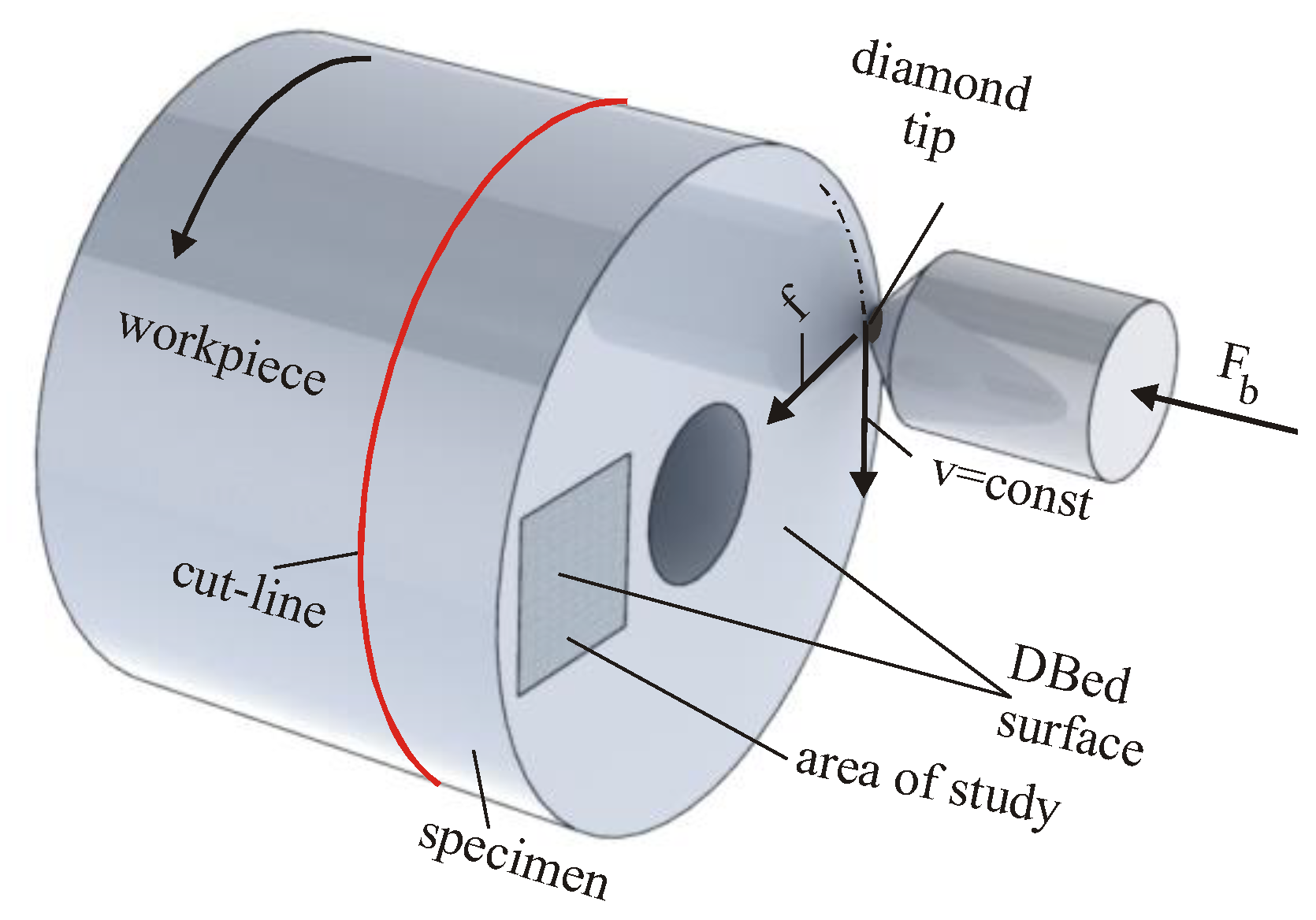

2.2. Diamond Burnishing Implementation

2.3. Specimen Treatment and Designation

2.4. Surface Integrity

2.5. Fatigue Tests

2.6. Corrosion Resistance

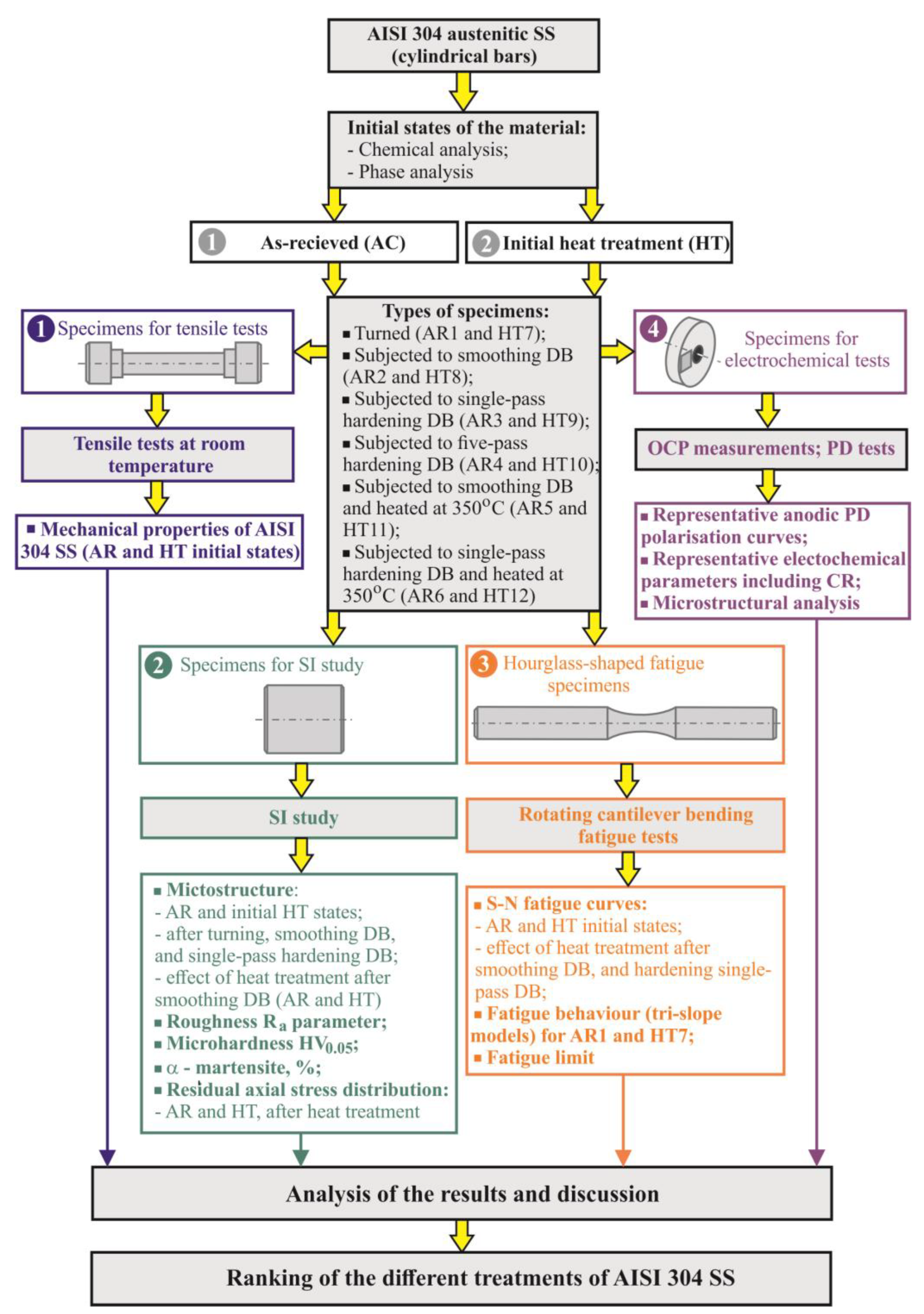

2.7. Flow Chart

3. Results and Discussion

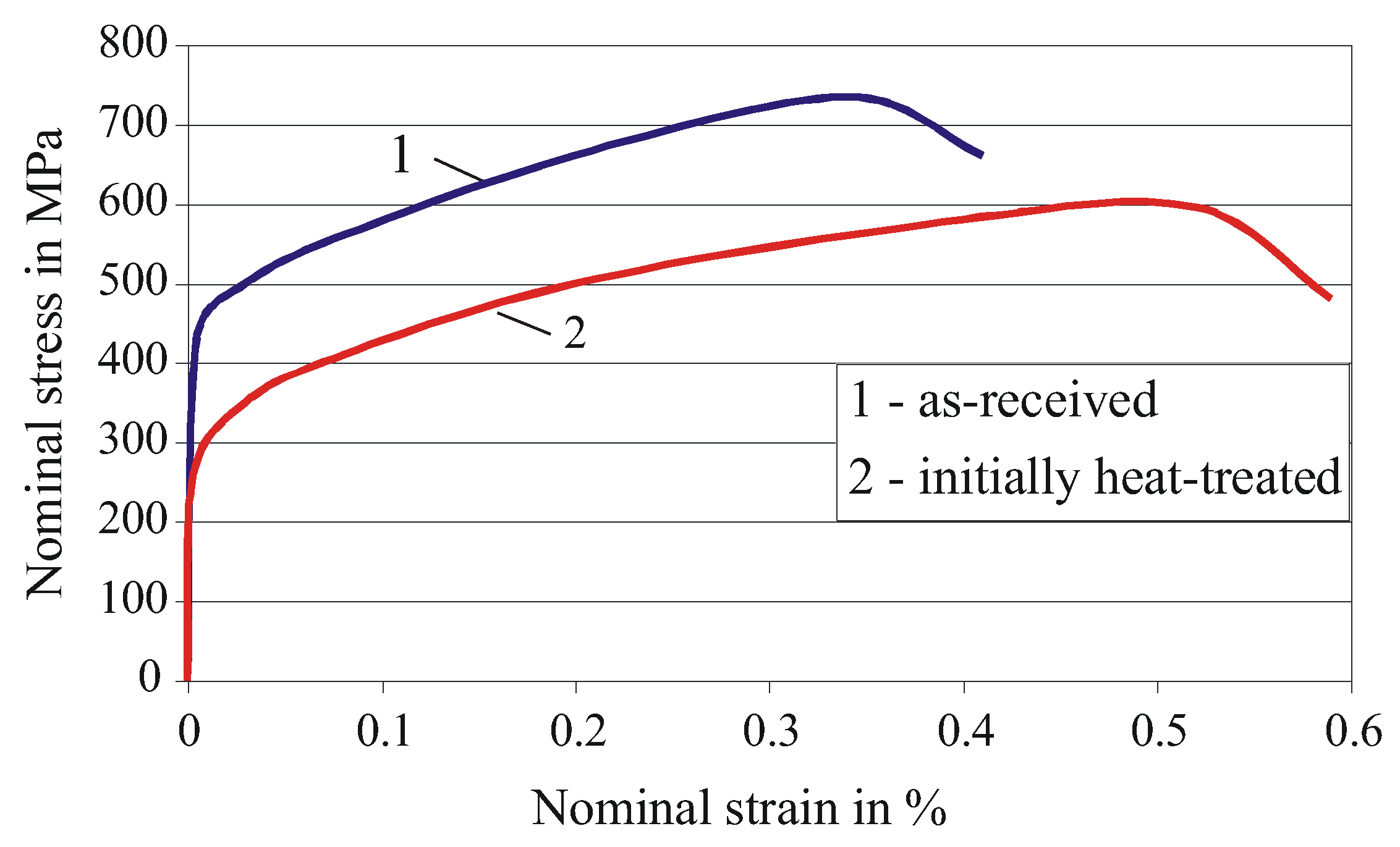

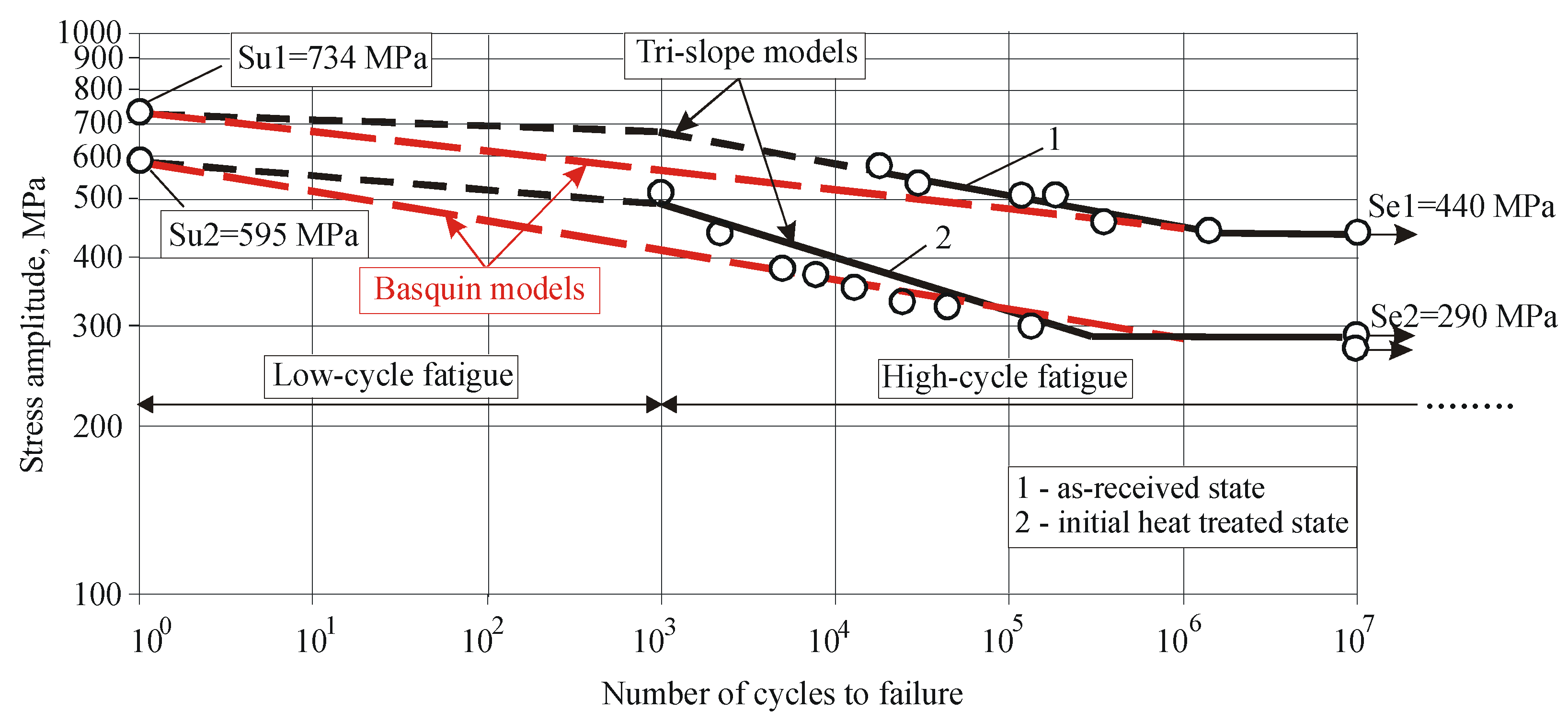

3.1. Main Mechanical Characteristics

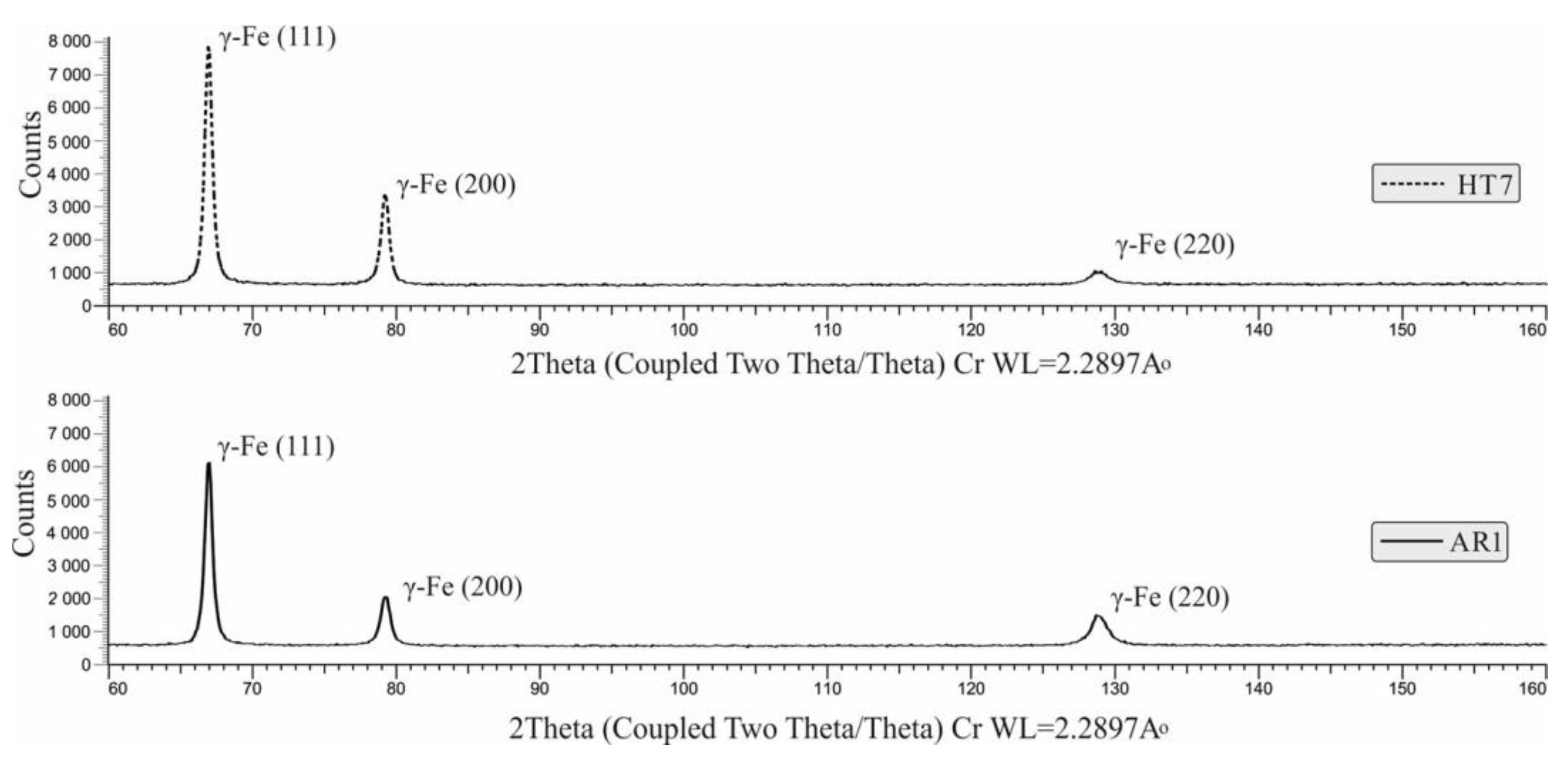

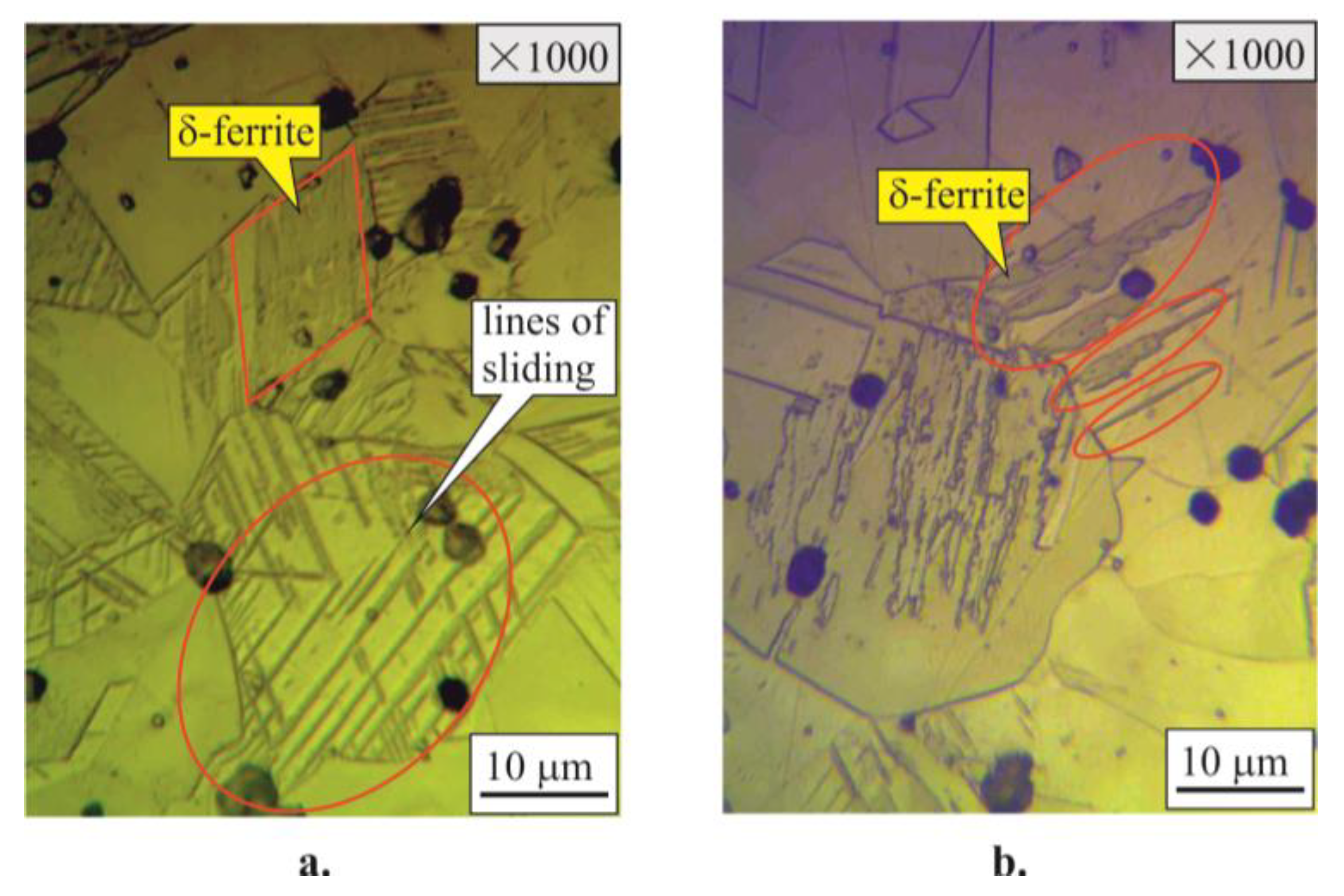

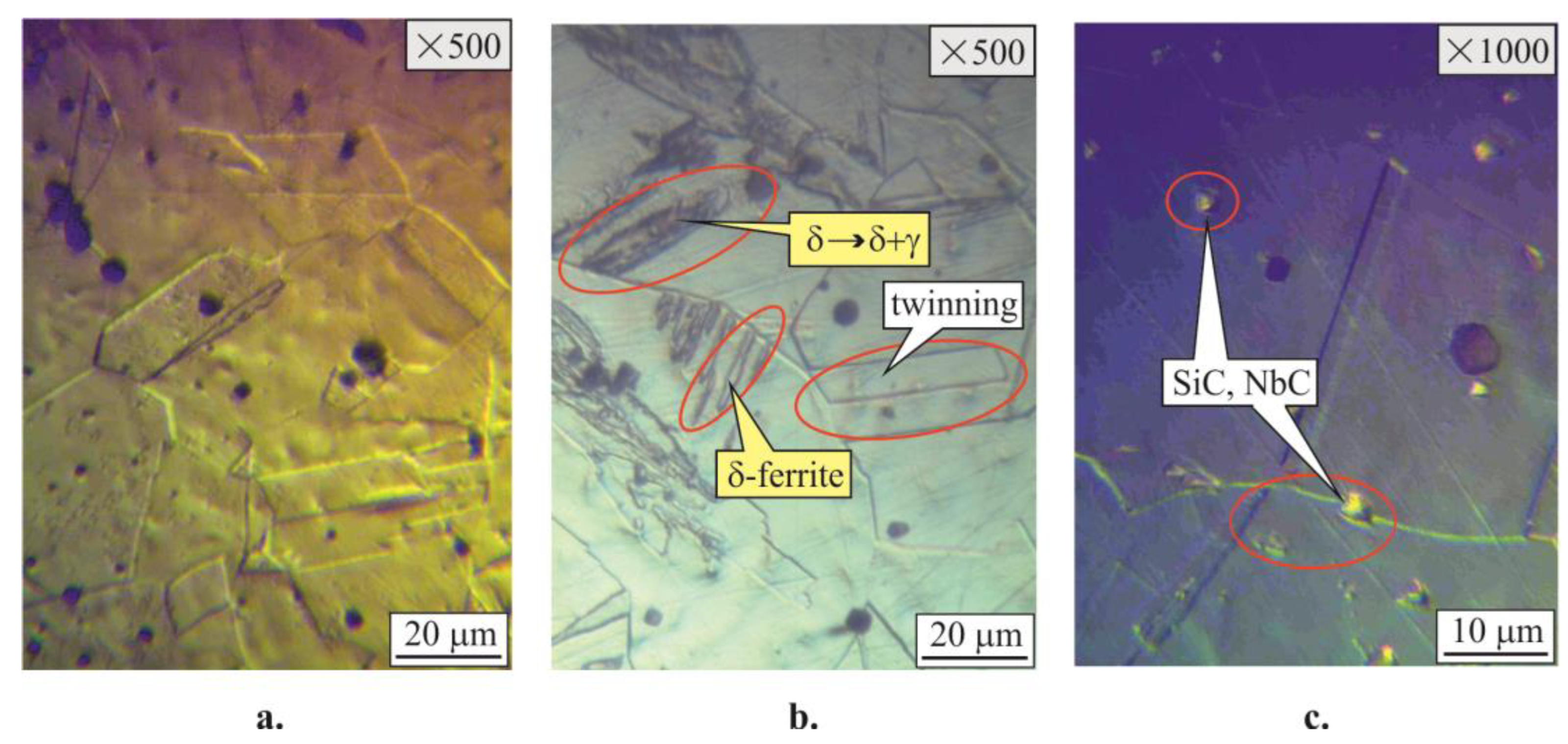

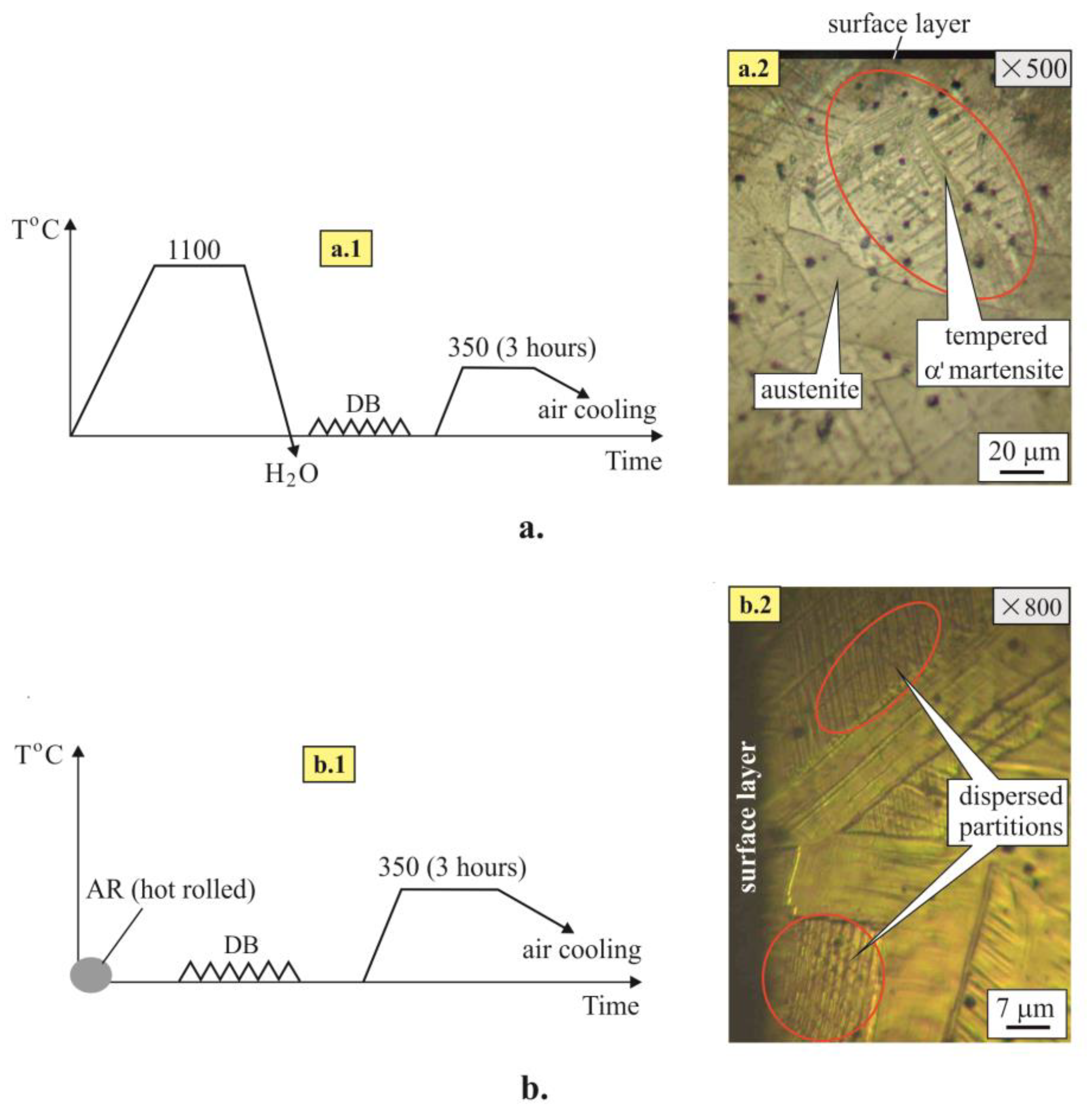

3.2. Effect of DB and Heat Treatment on the Microstructure of 304 SS

3.2.1. Initial State of the Microstructures

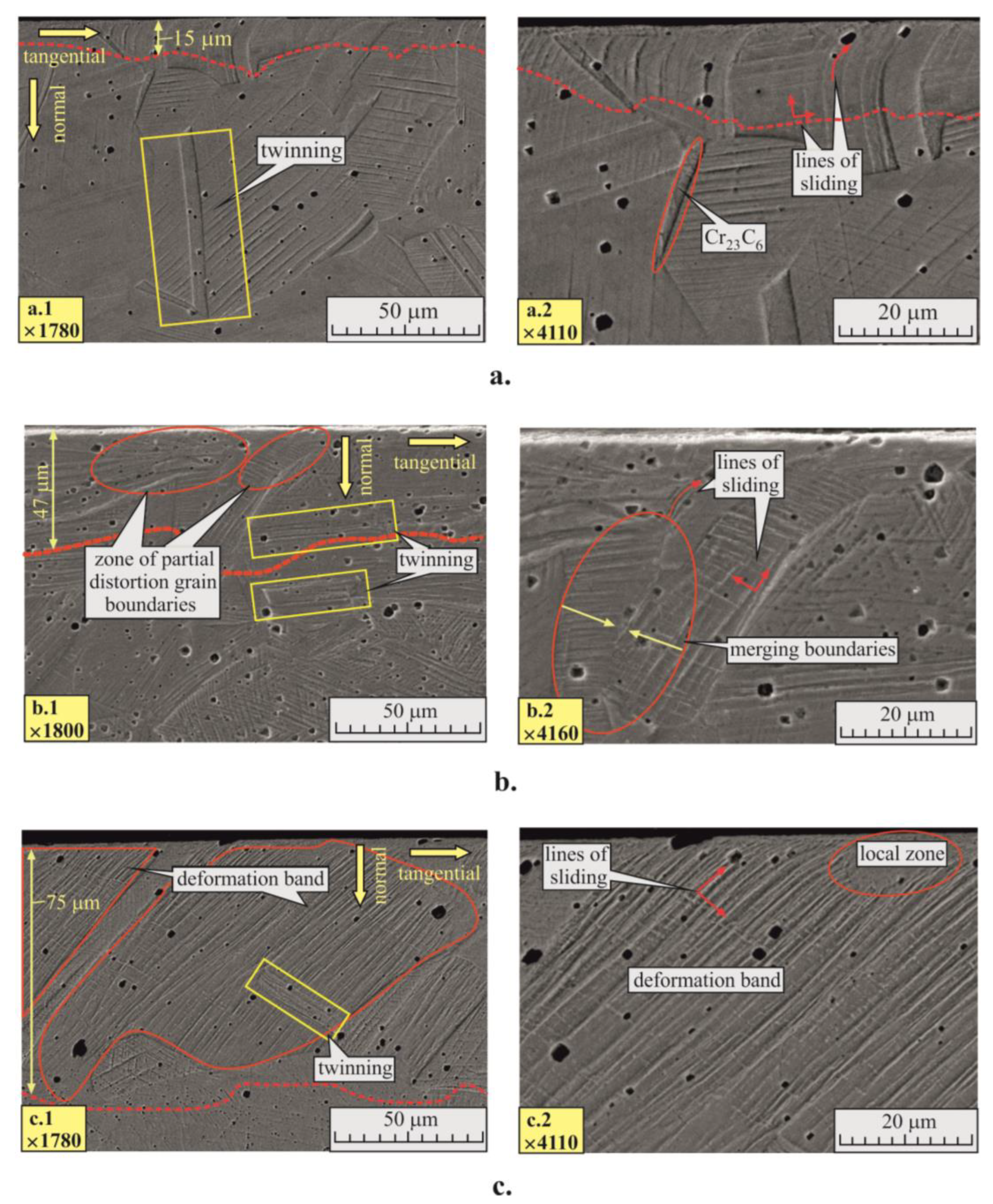

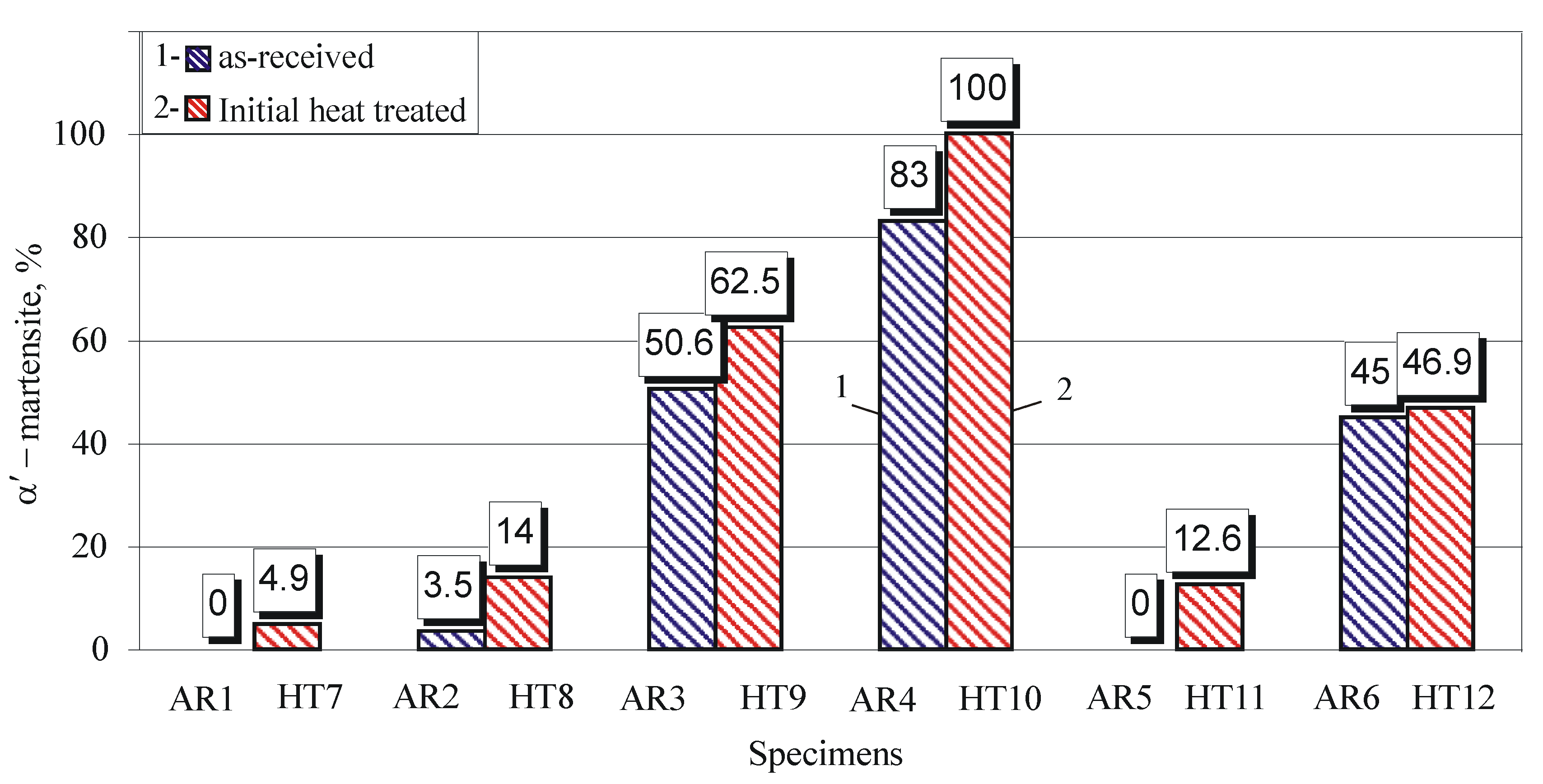

3.2.2. Effect of DB on the Microstructure Evolution

3.2.3. Effect of Heat Treatment after DB

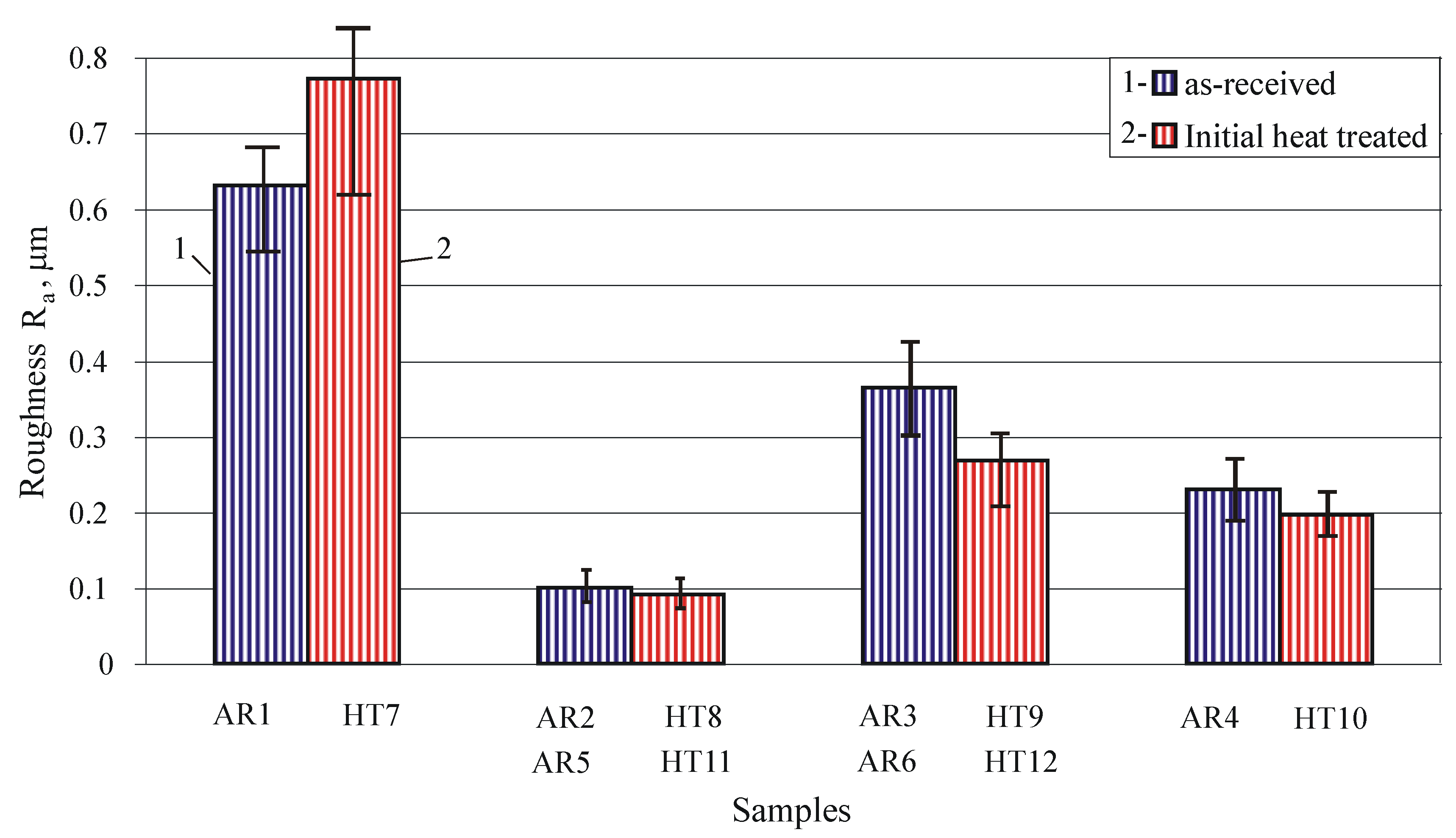

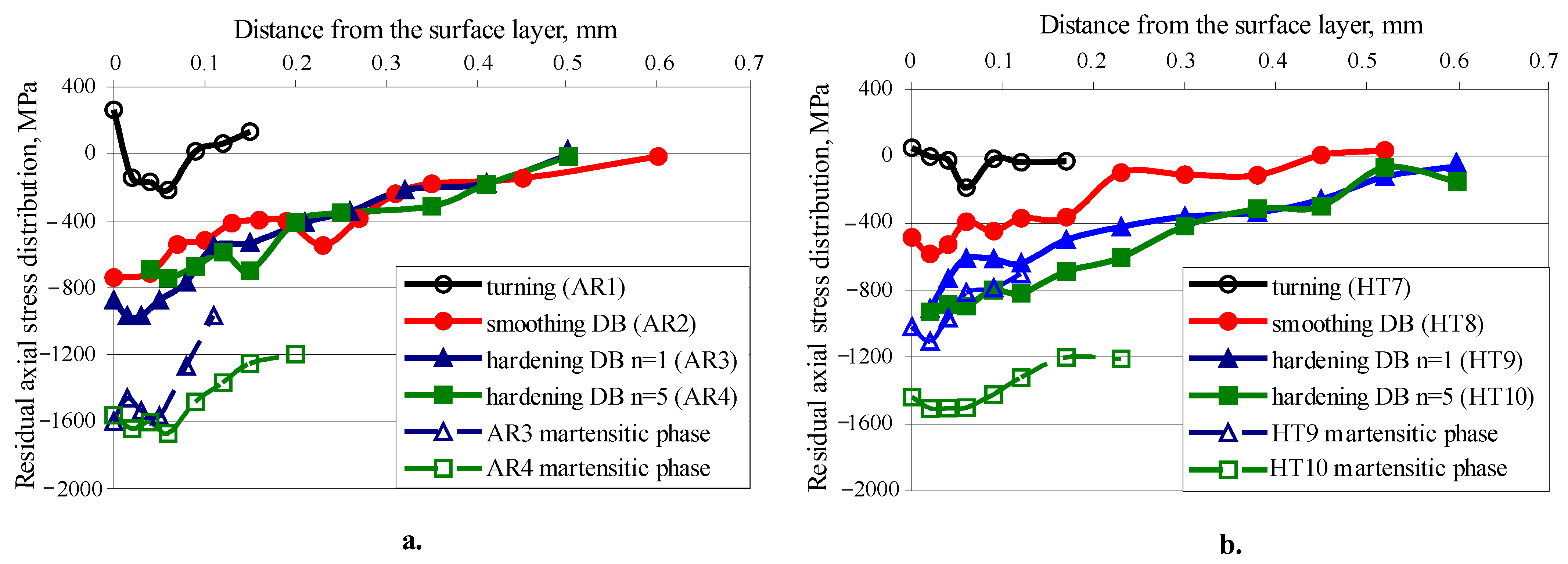

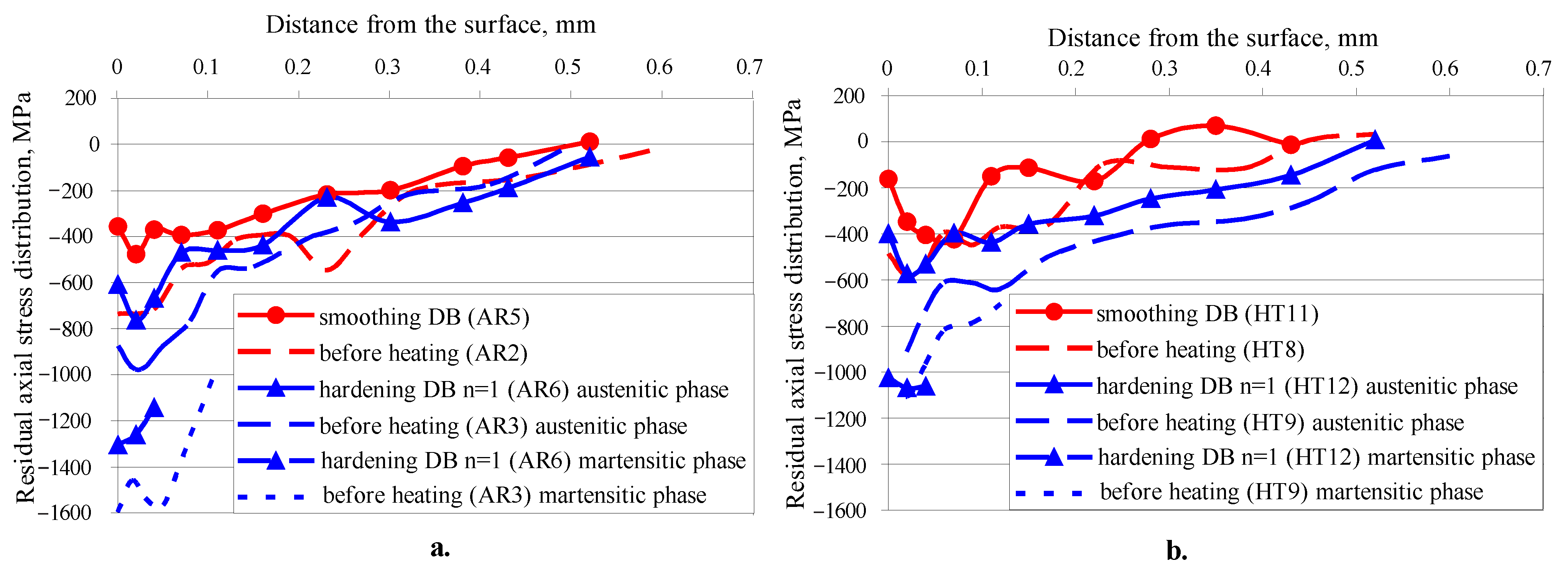

3.3. Effect of DB and Heat Treatment on the SI of 304 SS

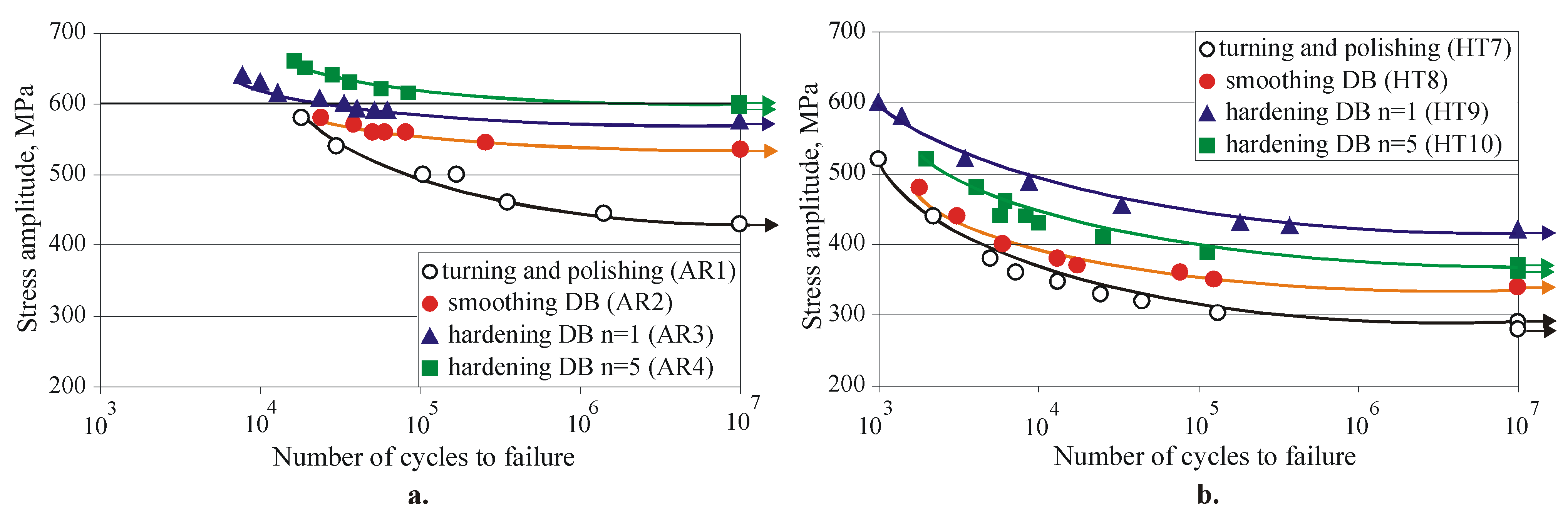

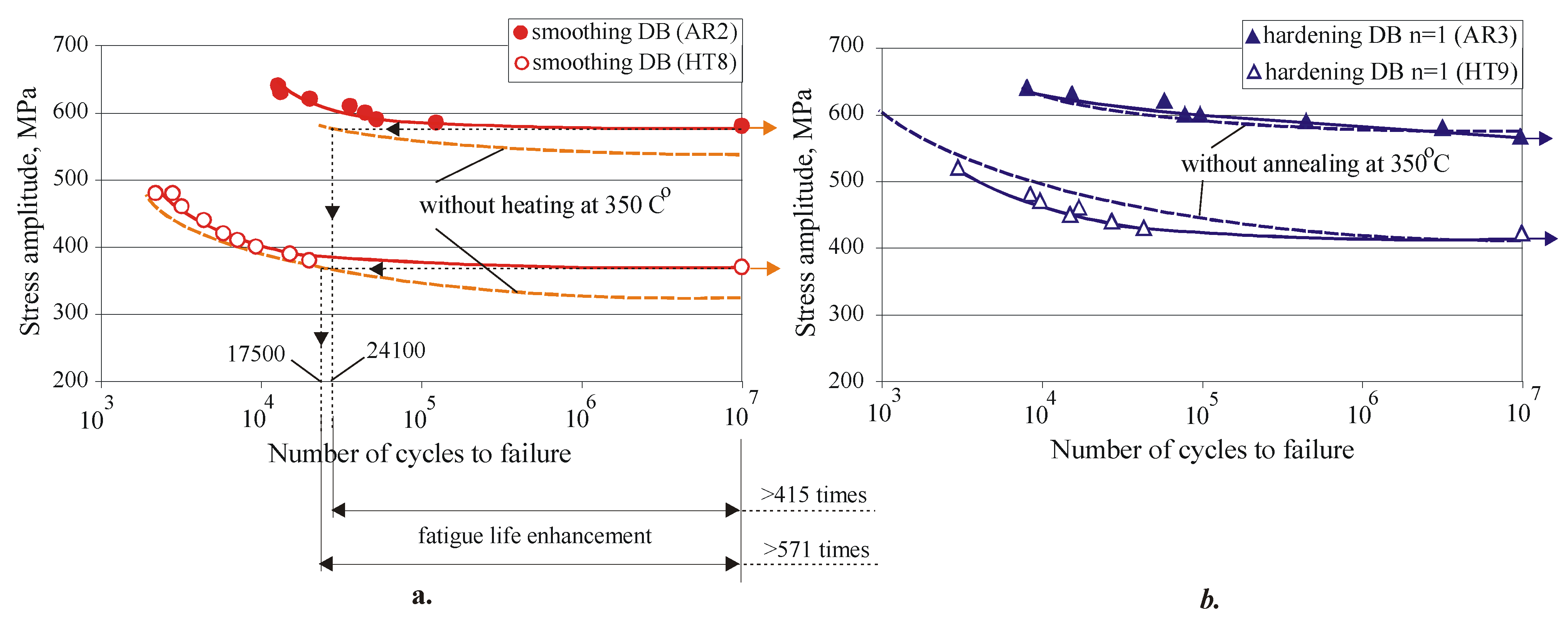

3.4. Effect of DB and Heat Treatment on Fatigue Behaviour of 304 SS

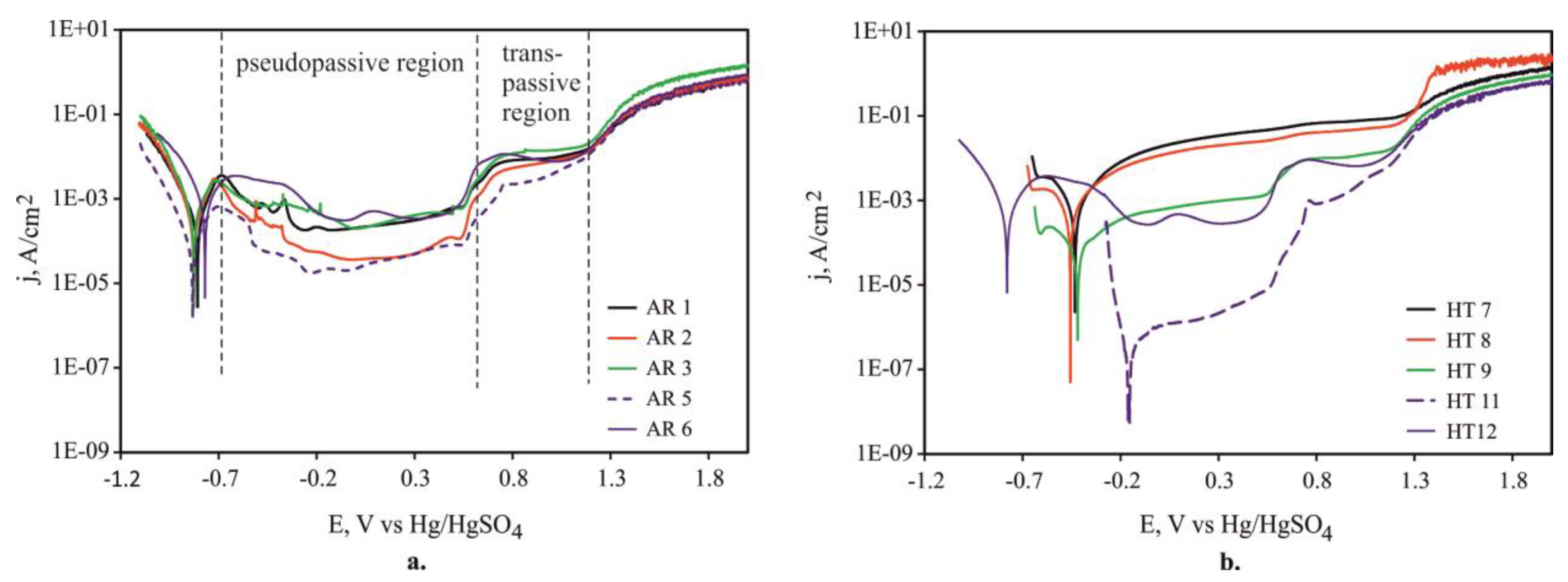

3.5. Effect of DB and Heat Treatment on Corrosion Resistance of 304 SS

3.6. Integral Efficiency of DB and Heat Treatment Types of 304 Austenitic SS

4. Conclusions

- For the as-received and initially heat-treated states, smoothing DB provided the lowest roughness: and , respectively. Both DB processes, smoothing and hardening, led to smaller roughness parameters for initially heat-treated samples, a consequence of the increased plasticity of the steel after quenching. The maximum surface micro-hardness was obtained after hardening DB and subsequent heating at 350 °C for three hours for both initial states 677 and 691 HV, respectively, and the micro-hardness improvement, compared with turning, was 75.4% and 82.8%, respectively.

- For all treatments, the as-received state showed a higher fatigue strength compared with the initially heat-treated state due to the finer-grained structure; the presence of carbides at the grain boundaries, which increase the strength and hardness; and the significant hot-mechanical strengthening during the production process of the as-received hot-rolled bar. The largest increase in the fatigue limit compared with turning was achieved by five-pass hardening DB: from 440 to 605 MPa, i.e., by 37.5%.

- The fatigue strength of the specimens subjected to smoothing DB significantly increased for both initial states when, after SCW, the specimens were heated at 350 °C for three hours, although relaxation of the residual stresses introduced by DB and reverse partial martensitic transformation were observed. For the as-received state, the fatigue limit increased from 540 to 580 MPa, i.e., by 7.4%, while the increase for the initial heat-treated state was 8.82%, from 340 to 370 MPa. Furthermore, the slope of the fatigue curves was small, and the fatigue life increase was significant: more than 415 times for the as-received state and more than 571 times for the initially heat-treated state A possible reason for the increased fatigue strength is the time-dependent diffusion-based strain ageing of the plastically deformed surface and subsurface layers affected by DB. Another possible reason, for the as-received initial state, is the dispersion of carbides along the grain boundary, thereby increasing the resistance to inter-crystalline deformation.

- Clearly expressed correlation of the volume fraction of the martensite phase, surface roughness, and residual stresses with the corrosion behaviour of DB 304 SS specimens in 0.5 M H2SO4 was not observed. When the goal is to maximise the surface corrosion resistance, it is appropriate to combine single-pass smoothing DB and subsequent heating at 350 °C for three hours. To minimise the CR, the smoothing DB was significantly more effective for the initially heat-treated state compared with the as-received material. The consecutive impacts by quenching at 1100 °C, smoothing DB, and subsequent heating at 350 °C for three hours (HT11) had a synergistic effect on the corrosion rate of 304 SS due to the favourable complex action of many factors (microstructure, austenitic and martensitic phases ratio, plastic deformation, residual stresses, and surface topography). For the as-received state, smoothing DB and subsequent heat treatment simultaneously led to a high fatigue limit (equal to that obtained by hardening single-pass DB) and a low CR.

- The obtained correlations between some characteristics of SI and the electrochemical corrosion behaviour of DB 304 SS specimens can be a basis for future research aimed at clearly distinguishing and evaluating the influence of individual main characteristics of SI resulting from DB on the corrosion resistance of this steel. Thus, with information on the SI of a given component, its corrosion behaviour can be predicted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CR | corrosion rate |

| DB | diamond burnishing |

| OCP | open circuit potential |

| PD | potentiodynamic |

| RC | reference condition |

| SCW | surface cold working |

| SI | surface integrity |

| SMAT | surface mechanical attrition treatment |

| SPD | surface plastic deformation |

| SS | stainless steel(s) |

| XRD | X-ray diffraction |

References

- Rashkov, N.D. Heat Treatment of Steels; Technika: Sofia, Bulgaria, 1977. (In Bulgarian) [Google Scholar]

- Balevski, A.T. Metal Science; Technika: Sofia, Bulgaria, 1988. (In Bulgarian) [Google Scholar]

- Borgioli, F. From austenitic stainless steel to expanded austenite–S phase: Formation, characteristics and properties of an elusive metastable phase. Metals 2020, 10, 187. [Google Scholar] [CrossRef] [Green Version]

- Plaster, H.J. A Tribute to Benjamin Chew Tilghman. In Proceedings of the 5th International Conference on Shot Peening, Oxford, UK, 13–17 September 1993; pp. 2–9. [Google Scholar]

- Scibner, I.A. Burnishing Tool. U.S. Patent 1,171,146, 8 February 1916. [Google Scholar]

- Maximov, J.T.; Duncheva, G.V.; Amudjev, I.M.; Krumov, K.K.; Kuzmanov, T.V. A new single-roller burnishing technique decreasing roughness obtained. J. Mater. Sci. Eng. Adv. Technol. 2010, 2, 177–202. [Google Scholar]

- Chen, X.H.; Lu, J.; Lu, L.; Lu, K. Tensile properties of a nanocrystalline 316L austenitic stainless steel. Scr. Mater. 2005, 52, 1039–1044. [Google Scholar] [CrossRef]

- Ghosh, S.; Bibhanshu, N.; Suwas, S.; Chatterjee, K. Surface mechanical attrition treatment of additively manufactured 316L stainless steel yields gradient nanostructure with superior strength and ductility. Mater. Sci. Eng. A 2021, 820, 141540. [Google Scholar] [CrossRef]

- Gatey, A.M.; Hosmani, S.S.; Singh, R.P. Surface mechanical attrition treated AISI 304L steel: Role of process parameters. Surf. Eng. 2016, 32, 69–78. [Google Scholar] [CrossRef]

- Dureau, C.; Novelli, M.; Arzaghi, M.; Massion, R.; Bocher, P.; Nadot, Y.; Grosdidier, T. On the influence of ultrasonic surface mechanical attrition treatment (SMAT) on the fatigue behaviour of the 304L austenitic stainless steel. Metals 2020, 10, 100. [Google Scholar] [CrossRef] [Green Version]

- Azar, V.; Hashemi, B.; Yazdi, M.R. The effect of shot peening on fatigue and corrosion behaviour of 316L stainless steel in Ringer’s solution. Surf. Coat. Technol. 2010, 204, 3546–3551. [Google Scholar] [CrossRef]

- Iswanto, P.T.; Akhyar, H.; Utomo, F.F. Effect of shot peening at different Almen intensities on fatigue behaviour of AISI 304. Metalurgija 2018, 57, 295–298. [Google Scholar]

- Kakiuchi, T.; Uematsu, Y.; Hasegawa, N.; Kondoh, E. Effect of ultrasonic shot peening on high cycle fatigue behaviour in type 304 stainless steel at elevated temperature. J. Soc. Mater. Sci. Jpn. 2016, 65, 325–330. [Google Scholar] [CrossRef] [Green Version]

- Juijerm, P.; Altenberger, I. Fatigue performance enhancement of steels using mechanical surface treatments. J. Met. Mater. Miner. 2007, 17, 59–65. [Google Scholar]

- Moussa, N.B.; Gharbi, K.; Chaieb, I.; Fredj, N.B. Improvement of AISI 304 austenitic stainless steel low-cycle fatigue life by initial and intermitten deep rolling. Int. J. Adv. Manuf. Technol. 2019, 101, 435–449. [Google Scholar] [CrossRef]

- Maximov, J.T.; Duncheva, G.V.; Anchev, A.P.; Ganev, N.; Amudjev, I.M.; Dunchev, V.P. Effect of slide burnishing method on the surface integrity of AISI 316Ti chromium-nickel steel. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 194. [Google Scholar] [CrossRef]

- Maximov, J.T.; Duncheva, G.V.; Anchev, A.P.; Dunchev, V.P.; Argirov, Y.B. Effect of diamond burnishing on fatigue behaviour of AISI 304 chromium-nickel austenitic stainless steel. Materials 2022, 15, 4768. [Google Scholar] [CrossRef]

- Hao, Y.; Deng, B.; Zhong, C.; Jiang, Y.; Li, J. Effect of surface mechanical attrition treatment on corrosion behaviour of 316 stainless steel. J. Iron Steel Res. Int. 2009, 16, 68–72. [Google Scholar] [CrossRef]

- Balusamy, T.; Sankara Narayanan, T.S.N.; Ravichandran, K.; Park, I.S.; Lee, M.H. Influence of surface mechanical attrition treatment (SMAT) on the corrosion behaviour of AISI 304 stainless steel. Corros. Sci. 2013, 74, 332–344. [Google Scholar] [CrossRef]

- Ran, M.; Zhang, C.; Wen, L.; Zhou, H.; Zheng, W. Effect of surface mechanical attrition treatment on stainless steel corrosion. Surf. Eng. 2021, 37, 739–748. [Google Scholar] [CrossRef]

- Balusamy, T.; Kumar, S.; Sankara Narayanan, T.S.N. Effect of surface nanocrystallization on the corrosion behaviour of AISI 409 stainless steel. Corros. Sci. 2010, 52, 3826–3834. [Google Scholar] [CrossRef]

- Lu, A.Q.; Zhang, Y.; Li, Y.; Liu, G.; Zang, Q.H.; Liu, C.M. Effect of nanocrystalline and twin boundaries on corrosion behaviour of 316L stainless steel using SMAT. Acta Metall. Sin. (Engl. Lett.) 2006, 19, 183–189. [Google Scholar] [CrossRef]

- Konefal, K.; Korzynski, M.; Byczkowska, Z.; Korzynska, K. Improved corrosion resistance of stainless steel X6CrNiMoTi17-12-2 by slide diamond burnishing. J. Mater. Process. Technol. 2013, 213, 1997–2004. [Google Scholar] [CrossRef]

- Labanowski, J.; Ossowska, A. Influence of burnishing on stress corrosion cracking susceptibility of duplex steel. J. Achievemens Mater. Manuf. Eng. 2006, 19, 46–52. [Google Scholar]

- ISO 6892-1:2019; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- DIFFRAC. DQUANT. Quantitative Analysis from Calibration to Reporting; Bruker AXS GmbH: Karlsruhe, Germany, 2018. [Google Scholar]

- Maximov, J.T.; Anchev, A.P.; Duncheva, G.V.; Ganev, N.; Selimov, K.F. Influence of the process parameters on the surface roughness, micro-hardness, and residual stresses in slide burnishing of high-strength aluminum alloys. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3067–3078. [Google Scholar] [CrossRef]

- Maximov, J.T.; Duncheva, G.V.; Anchev, A.P.; Dunchev, V.P. Smoothing, deep or mixed diamond burnishing of low-alloy steel components–optimization procedures. J. Adv. Manuf. Technol. 2020, 106, 1917–1929. [Google Scholar] [CrossRef]

- Ecoroll Catalogue. Tools and Solutions for Metal Surface Improvement; Ecoroll Corporation Tool Technology: Milford, OH, USA, 2006. [Google Scholar]

- Maximov, J.T.; Duncheva, G.V.; Anchev, A.P.; Ganev, N.; Dunchev, V.P. Effect of cyclic hardening on fatigue performance of slide burnishing components made of low-alloy medium carbon steel. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1414–1425. [Google Scholar] [CrossRef]

- Basquin, O.H. The exponential law of endurance tests. In Proceedings of the Thirteenth Annual Meeting of American Society for Testing Materials, Atlantic City, NJ, USA, 28 June–2 July 1910; Volume X, pp. 625–630. [Google Scholar]

- Stephens, R.I.; Fatemi, A.; Stephens, R.R.; Fuchs, H.O. Metal Fatigue in Engineering; John Wiley & Sons Inc.: New York, NY, USA, 2001. [Google Scholar]

- Oguzie, E.E.; Li, J.; Liu, Y.; Chen, D.; Li, Y.; Yang, K.; Wang, F. The effect of Cu addition on the electrochemical corrosion and passivation behavior of stainless steel. Electrochim. Acta 2010, 55, 5028. [Google Scholar] [CrossRef]

- Liu, X.; Frankel, G.S. Effects of compressive stress on localized corrosion in AA2024-T3. Corros. Sci. 2006, 48, 3309–3329. [Google Scholar] [CrossRef] [Green Version]

- Shahryari, A.; Kamal, W.; Omanovic, S. The effect of surface roughness on the efficiency of the cyclic potentiodynamic passivation (CPP) method in the improvement of general and pitting corrosion resistance of 316LVM stainless steel. Mater. Lett. 2008, 62, 3906–3909. [Google Scholar] [CrossRef]

| Fe | C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Nb | Ti | V | W | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 71.5 | 0.036 | 0.193 | 1.52 | 0.03 | 0.026 | 17.7 | 8.3 | 0.182 | 0.25 | 0.042 | 0.003 | 0.07 | 0.05 | balance |

| Specimen Group | Young’s Modulus, GPa | Yield Limit, MPa | Tensile Strength, MPa | Elongation, % | Percentage Reduction of Area, % | Hardness, HB |

|---|---|---|---|---|---|---|

| (1) as received | 200 | 432 | 734 | 41 | 68.8 | 245 |

| (2) heat treated | 195 | 258 | 595 | 59 | 76.6 | 158 |

| Initial State | Specimens | Ess (mV vs. Hg/HgSO4) | Ecorr (mV vs. Hg/HgSO4) | Jcorr (mA·cm−2) | Rp (Ω) | CR (mm/yr) |

|---|---|---|---|---|---|---|

| as-received | AR 1 | −818 | −808 | 0.392 | 318.9 | 0.0041 |

| AR 2 | −857 | −827 | 0.311 | 338.7 | 0.0033 | |

| AR 3 | −851 | −827 | 0.518 | 238.2 | 0.0055 | |

| AR 5 | −851 | −833 | 0.098 | 1359 | 0.001 | |

| AR 6 | −764 | −770 | 1.814 | 156 | 0.019 | |

| heat treated | HT 7 | −401 | −432 | 1.103 | 229.4 | 0.0116 |

| HT 8 | −426 | −456 | 1.620 | 290 | 0.0171 | |

| HT 9 | −389 | −419 | 0.366 | 2190 | 0.0039 | |

| HT 11 | −22 | −159 | 0.0004 | 411,000 | 0.000004 | |

| HT 12 | −773 | −779 | 0.876 | 257 | 0.009 |

| № | Specimen | Ranking of the Different Treatments of 304 SS | ||||

|---|---|---|---|---|---|---|

| Criteria (Requirements) | Integral Efficiency | |||||

| Roughness | Micro-Hardness | Fatigue Limit | Corrosion Rate | |||

| 1 | AR1 | 5 | 9 | 3 | 5 | 22 |

| 2 | AR2 | 2 | 8 | 2 | 3 | 15 |

| 3 | AR3 | 4 | 4 | 1 | 6 | 15 |

| 4 | AR5 | 2 | 6 | 1 | 2 | 11 |

| 5 | AR6 | 4 | 2 | 1 | 10 | 17 |

| 6 | HT7 | 6 | 10 | 7 | 8 | 31 |

| 7 | HT8 | 1 | 7 | 6 | 9 | 23 |

| 8 | HT9 | 3 | 3 | 4 | 4 | 14 |

| 9 | HT11 | 1 | 5 | 5 | 1 | 12 |

| 10 | HT12 | 3 | 1 | 4 | 7 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maximov, J.; Duncheva, G.; Anchev, A.; Dunchev, V.; Argirov, Y.; Nikolova, M. Effects of Heat Treatment and Diamond Burnishing on Fatigue Behaviour and Corrosion Resistance of AISI 304 Austenitic Stainless Steel. Appl. Sci. 2023, 13, 2570. https://doi.org/10.3390/app13042570

Maximov J, Duncheva G, Anchev A, Dunchev V, Argirov Y, Nikolova M. Effects of Heat Treatment and Diamond Burnishing on Fatigue Behaviour and Corrosion Resistance of AISI 304 Austenitic Stainless Steel. Applied Sciences. 2023; 13(4):2570. https://doi.org/10.3390/app13042570

Chicago/Turabian StyleMaximov, Jordan, Galya Duncheva, Angel Anchev, Vladimir Dunchev, Yaroslav Argirov, and Maria Nikolova. 2023. "Effects of Heat Treatment and Diamond Burnishing on Fatigue Behaviour and Corrosion Resistance of AISI 304 Austenitic Stainless Steel" Applied Sciences 13, no. 4: 2570. https://doi.org/10.3390/app13042570

APA StyleMaximov, J., Duncheva, G., Anchev, A., Dunchev, V., Argirov, Y., & Nikolova, M. (2023). Effects of Heat Treatment and Diamond Burnishing on Fatigue Behaviour and Corrosion Resistance of AISI 304 Austenitic Stainless Steel. Applied Sciences, 13(4), 2570. https://doi.org/10.3390/app13042570