Performance Analysis of the Cylinder Gas Film Seal between Dual-Rotor Reverse Shafts Considering Lubrication and Centrifugal Expansion Effects

Abstract

:1. Introduction

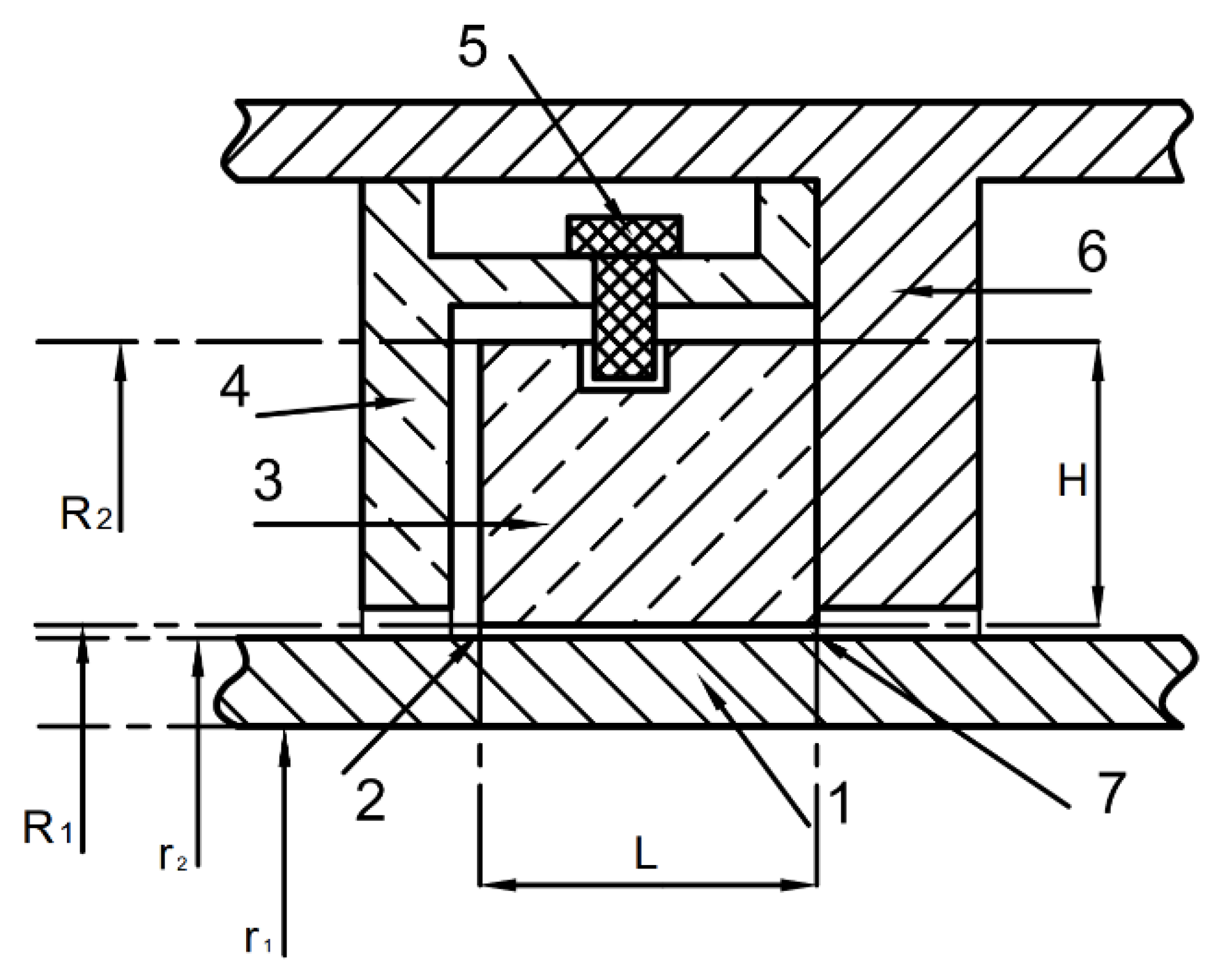

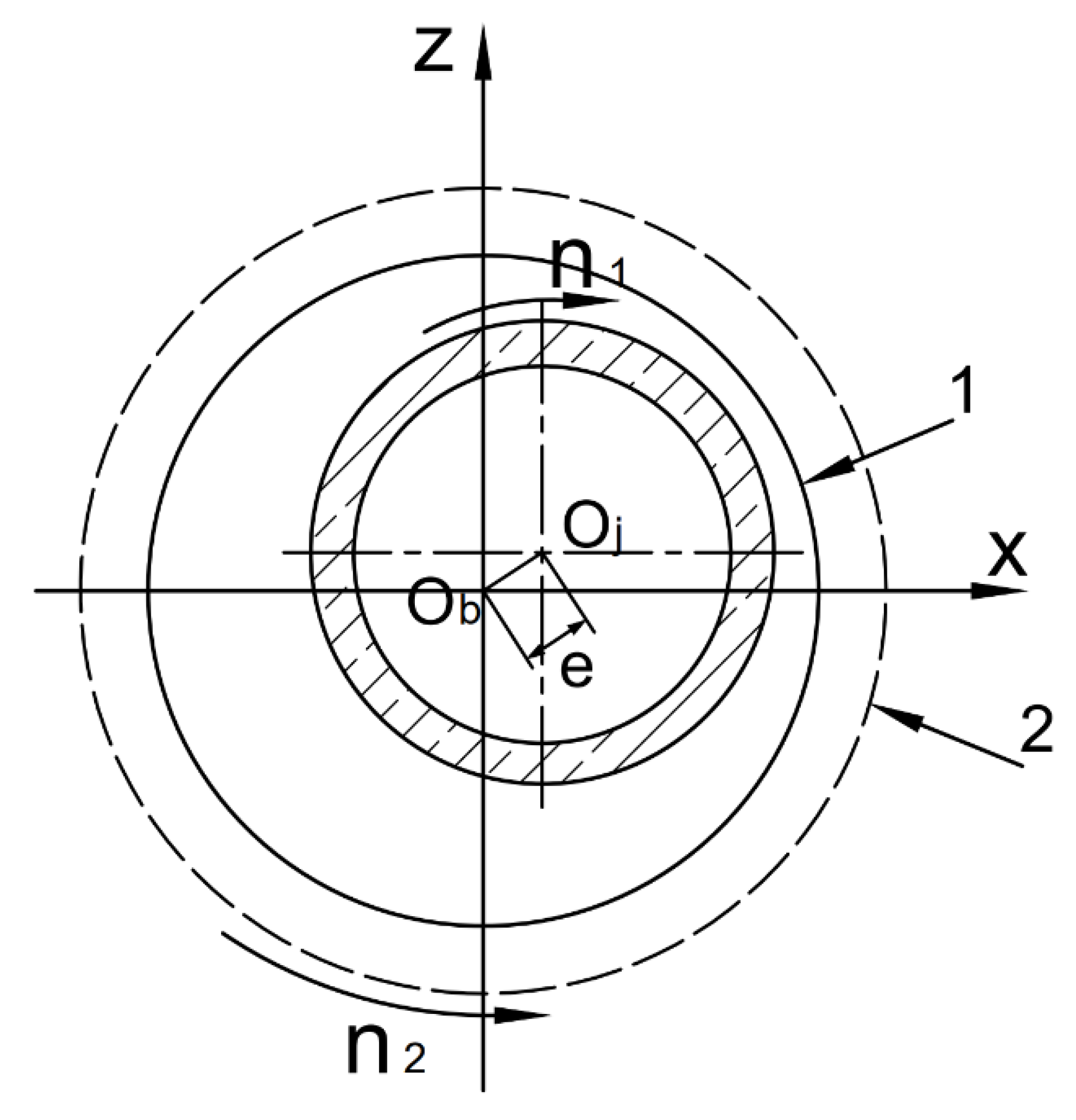

2. Geometry of Cylinder Gas Film Seal between Shafts

3. Force Balance Conditions

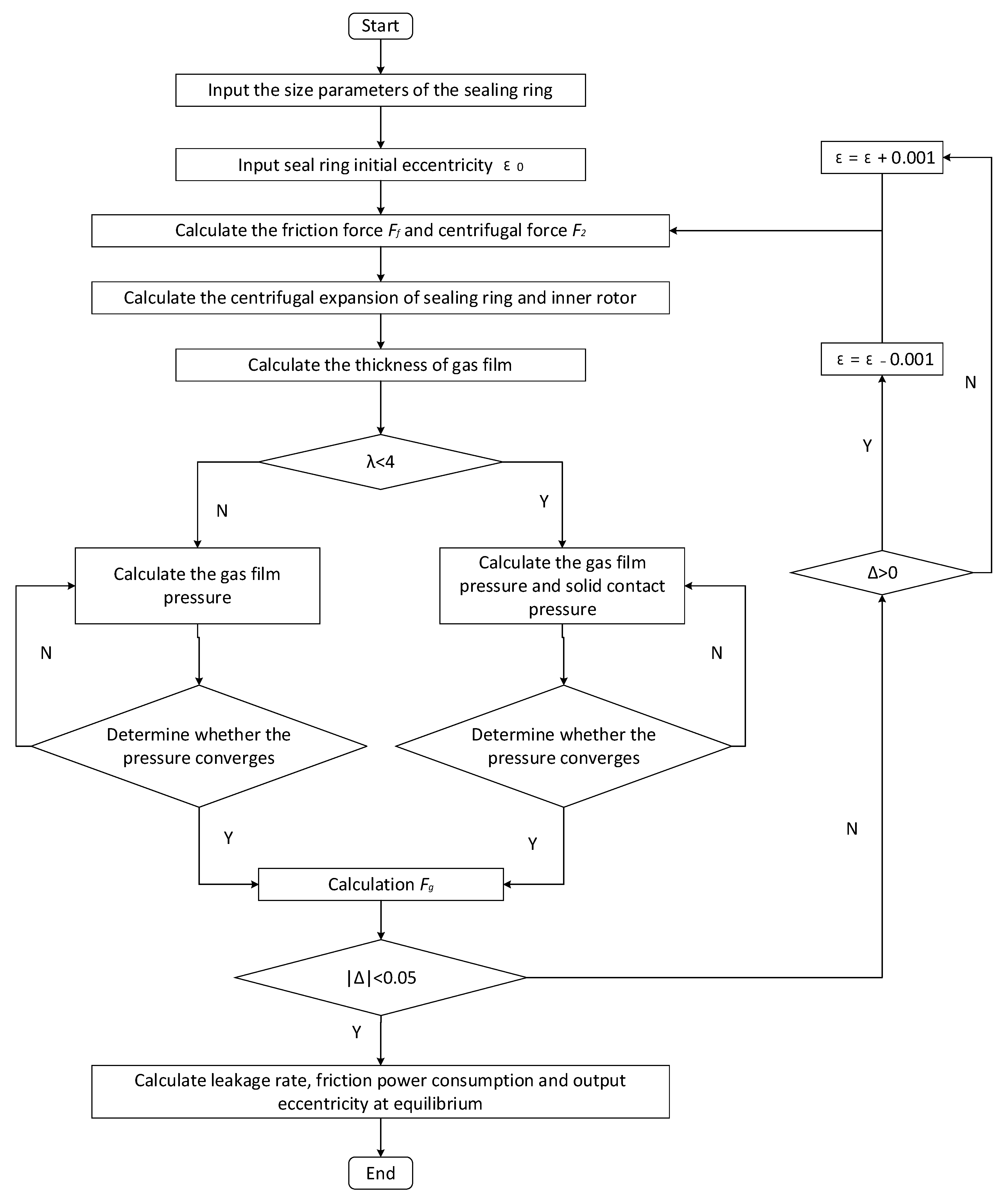

4. Numerical Computational Method for Sealing Performance

4.1. Method for Calculating the Bearing Capacity of Gas Film

4.1.1. Gas Film Thickness

4.1.2. Gas Film Force

- The fluid in the gap is fully developed laminar flow;

- The fluid is viscous and conforms to Newton’s law of viscosity;

- The gas film thickness is very small compared with other geometric sizes, and the ratio is generally less than 10−4;

- The fluid is an isothermal ideal gas and

- The fluid satisfies the no-slip boundary condition at the gas-solid boundary.

- ,

- ,

- ,

- ,

4.1.3. Conservation of Momentum [24]

4.1.4. Bearing Capacity of the Gas Film under Mixed Lubrication Conditions [25]

4.2. Sealing Performance Indexes

4.2.1. Calculating Gas Leakage Rate [10]

4.2.2. Calculation of Friction Power Consumption [23]

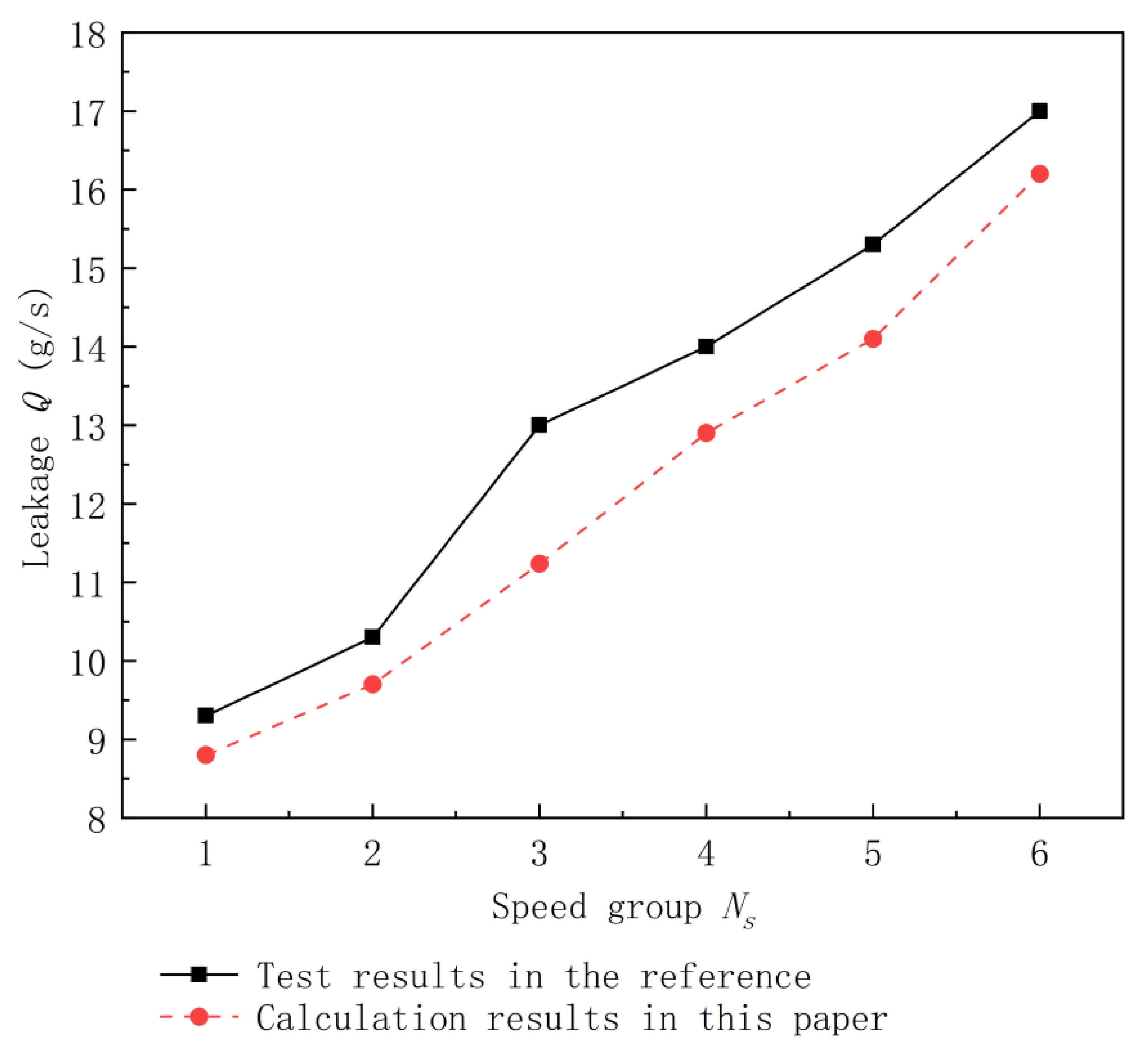

4.3. Verification of Analysis Method

5. Results and Discussion

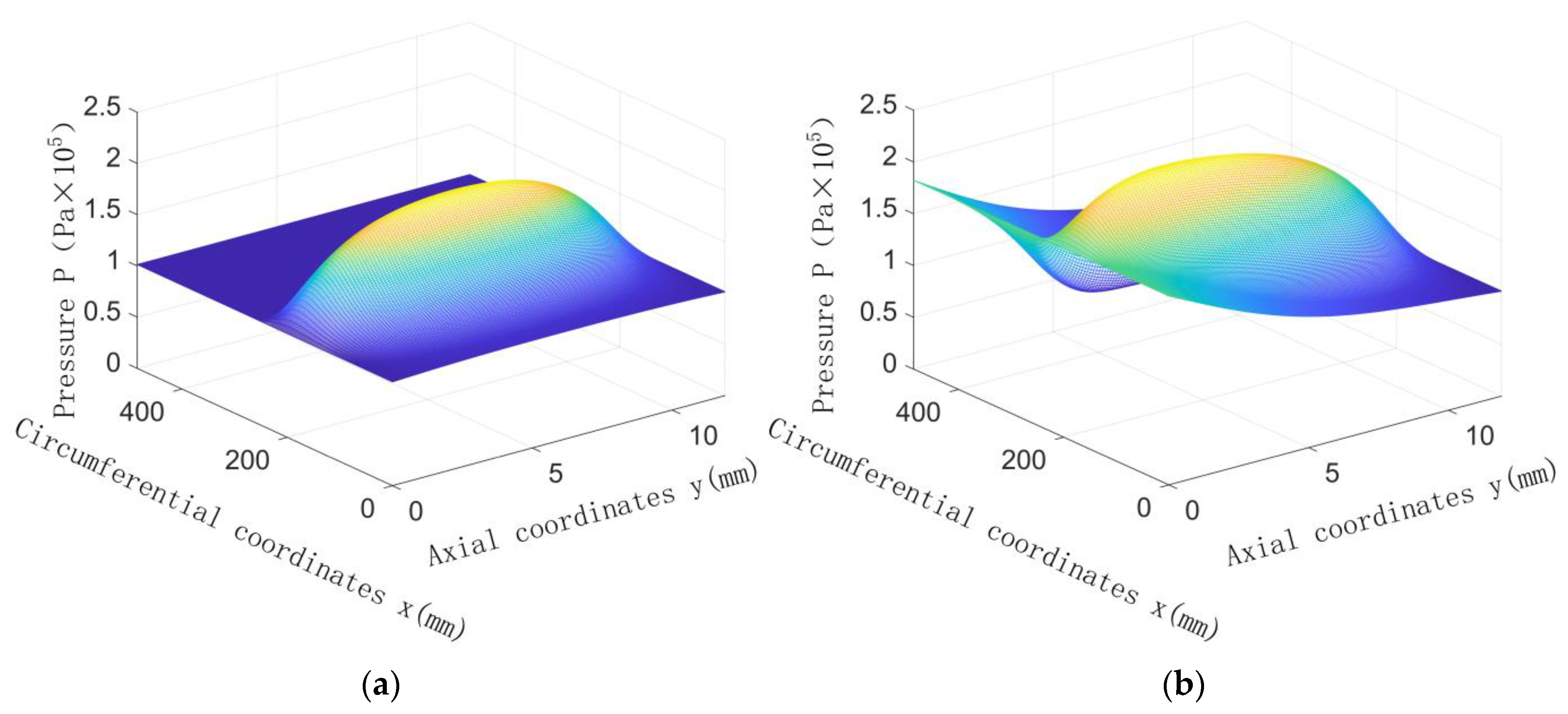

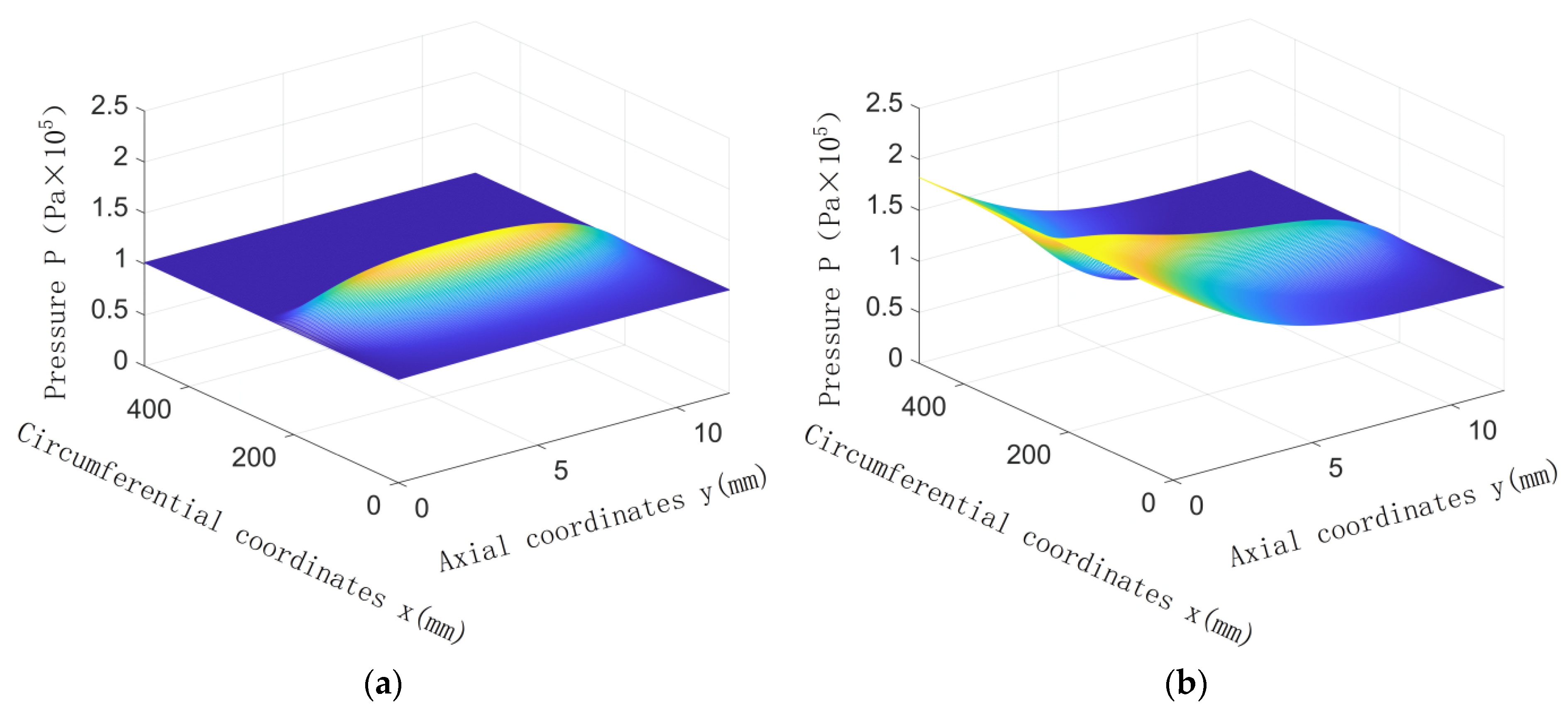

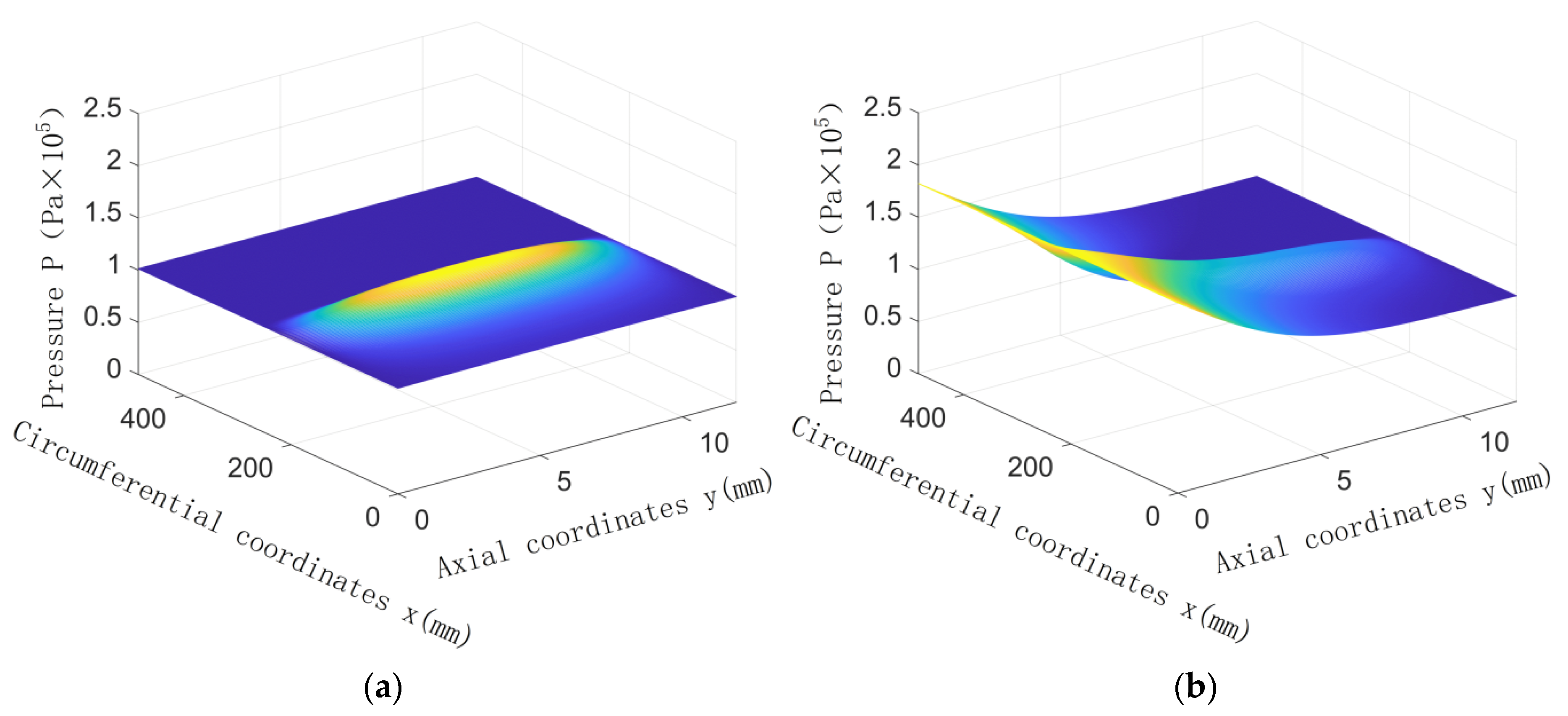

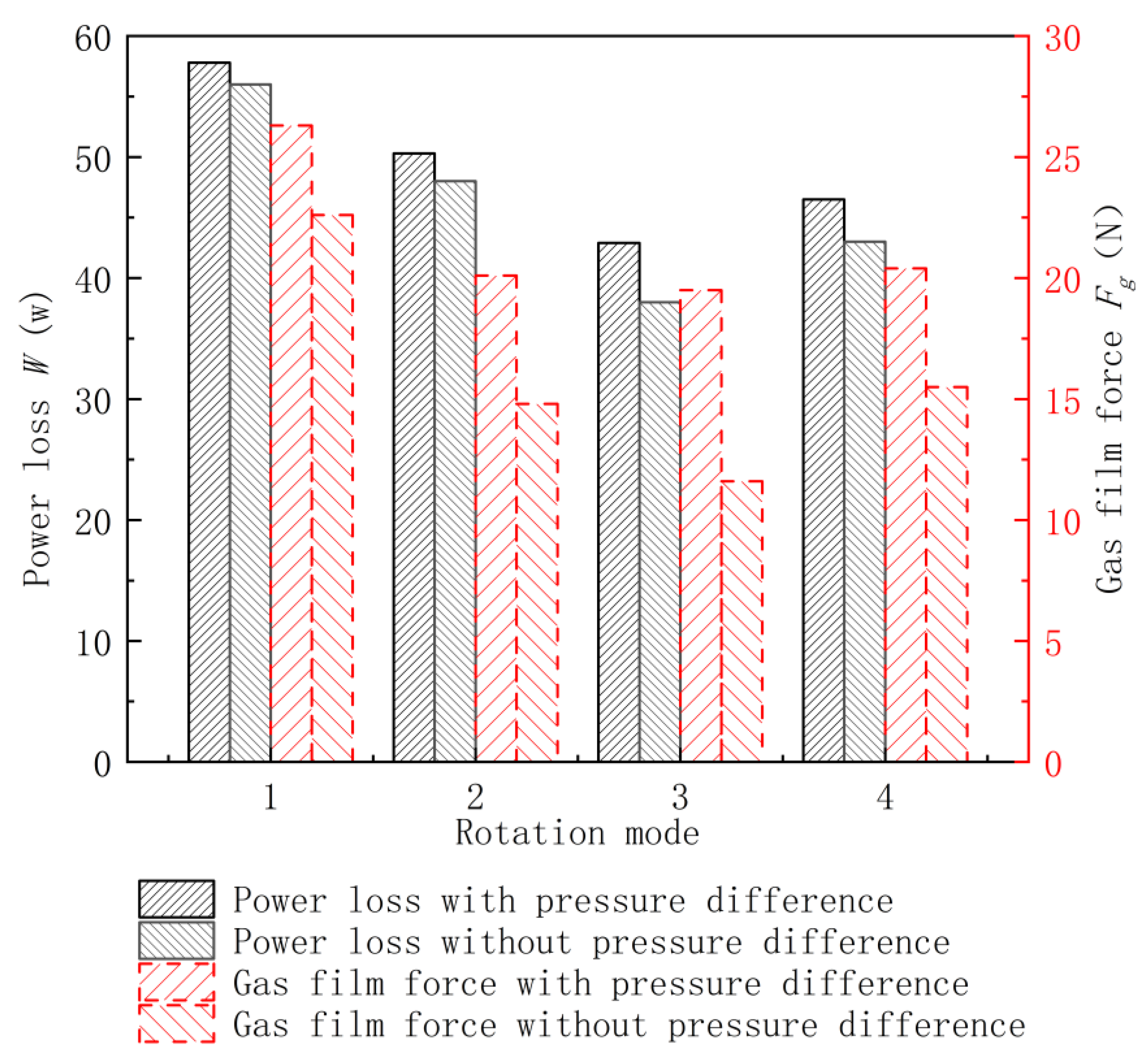

5.1. Effects of Dual-Rotor Rotation Direction on Sealing Performance

5.2. Effects of Rotor Speed on Sealing Performance

5.2.1. Changes in Inner Rotor Speed

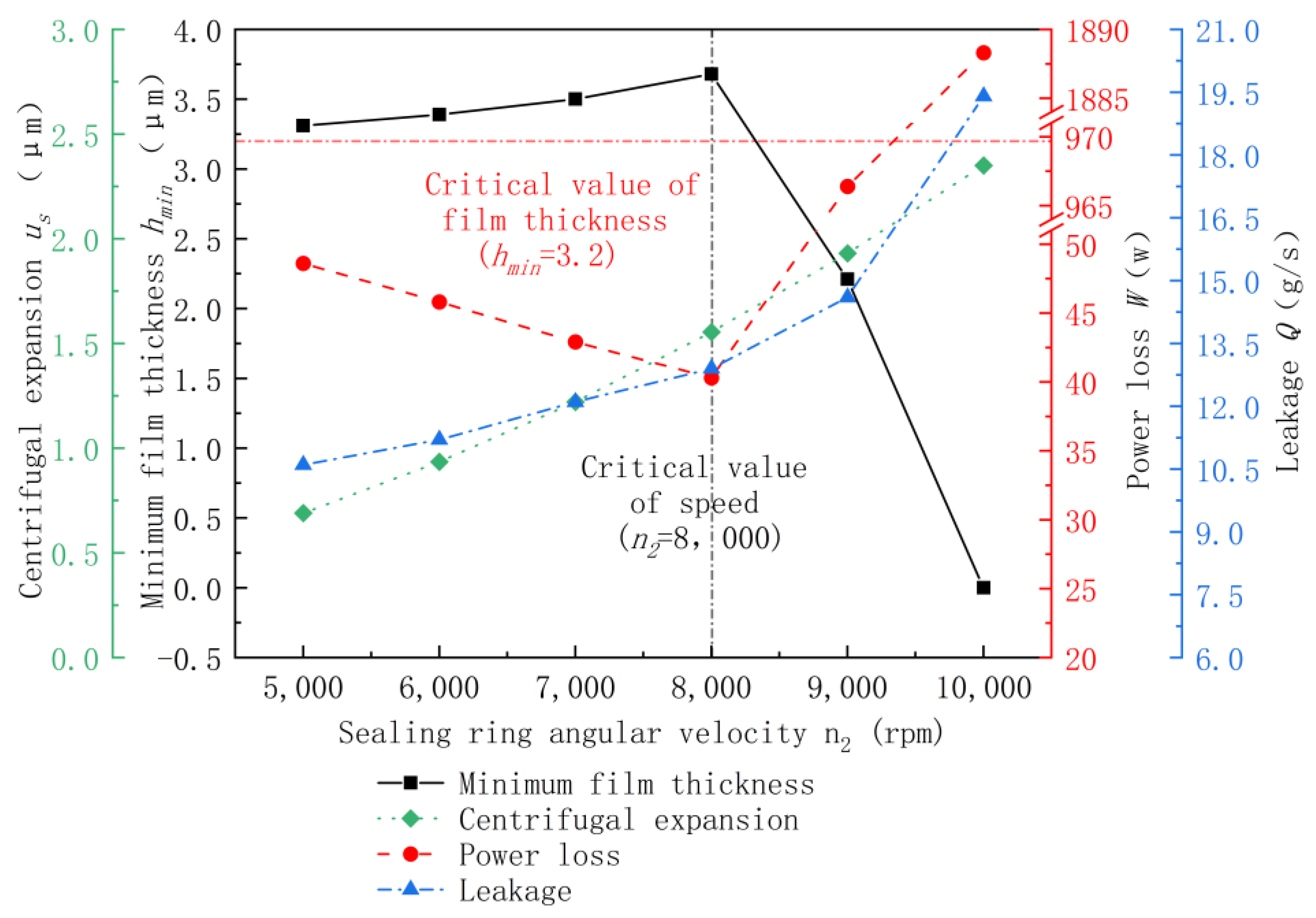

5.2.2. Changes in Outer Rotor Speed

5.2.3. Synchronous Changes in the Speed of Inner and Outer Rotors

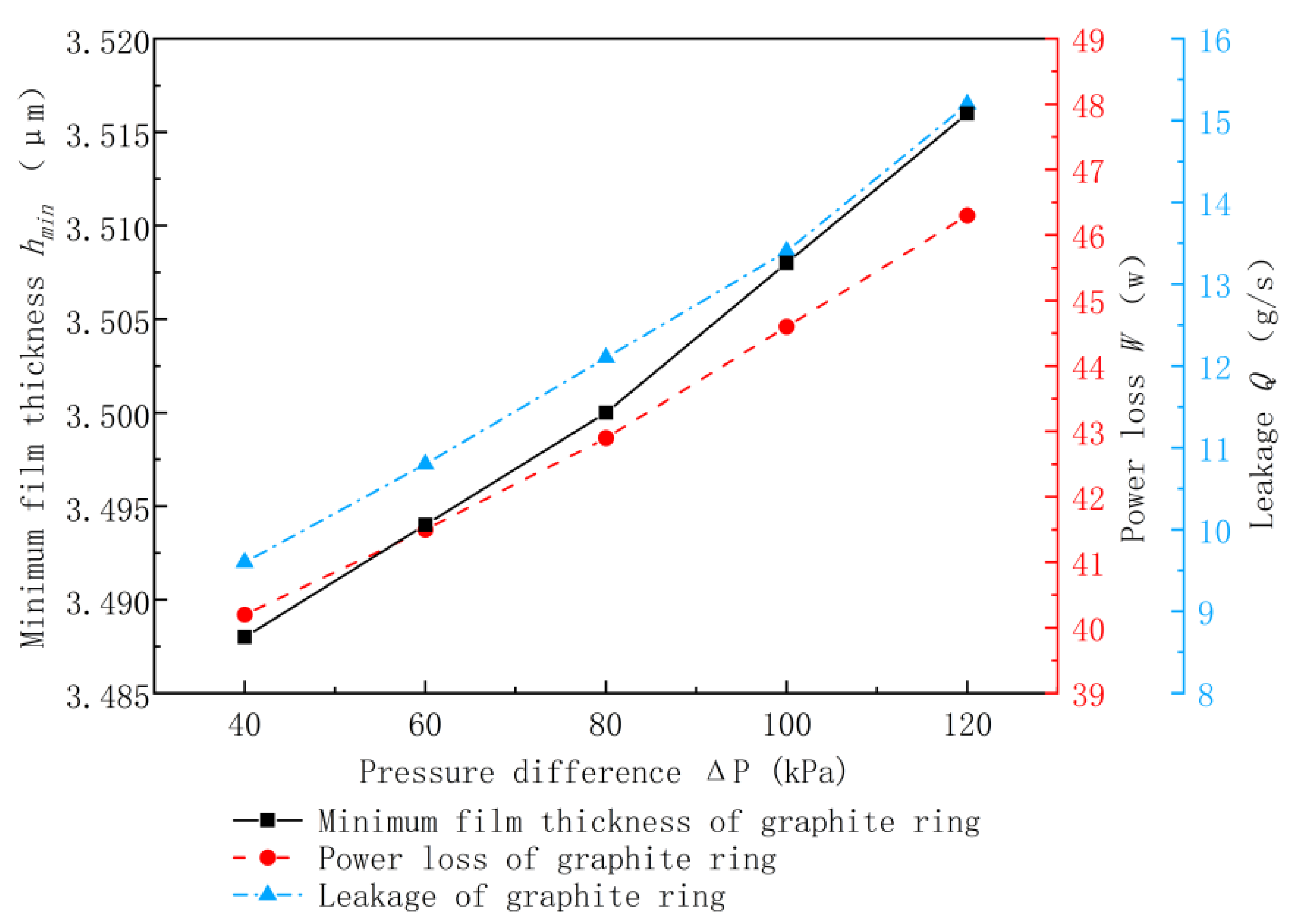

5.3. Differential Pressure Effects on Sealing Performance

6. Conclusions

- When the inner and outer rotors rotate in the same direction, the fluid’s dynamic pressure effect on the gas film gap is the most significant, and the gas film forces are maximised. When the inner and outer rotors are in counter-rotation, the dynamic pressure effect is the weakest, and the gas film force is minimised. When only one rotor rotates, the gas film force generated will be between the two aforementioned extremes. The inlet differential pressure weakens the adverse dynamic pressure effects at the counter-rotation interface and improves the gas film’s bearing capacity to some extent. When the differential pressure is 80 kPa and under the calculation condition herein, the gas film force increases by about 68.1% more than without differential pressure when the inner and outer rotors are in counter-rotation. When the inner and outer rotors rotate in the same direction, the gas film force increases by about 16.37% more than without differential pressure. When rotating in the same direction, the gas film force is 34.87% greater, and the friction power consumption is 34.73% greater than when the two rotors are in counter-rotation.

- For the seal between counter-rotating shafts, when the outer rotor speed is fixed but the inner rotor speed increases, the seal’s leakage rate and friction power consumption decrease. Before the minimum film thickness reaches the critical film thickness, contact with the rough peak increases friction power consumption significantly. When the inner rotor speed is fixed but the outer rotor speed increases, the centrifugal expansion and the leakage rate of the sealing ring increase, but the friction power consumption decreases first and then increases. When the absolute difference in the speed of the inner and outer rotors is fixed, and the inner and outer rotors are synchronously accelerated, the leakage increases due to the increase in the centrifugal expansion of the sealing ring; however, the friction power consumption decreases.

- For the seal between counter-rotating shafts, when the sealing differential pressure increases, the seal’s leakage rate and friction power consumption increase significantly.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Sealing clearance | |

| Eccentric distance | |

| Material elastic modulus | |

| Elastic modulus of inner rotor | |

| Elastic modulus of sealing ring | |

| Comprehensive modulus | |

| Gravitational acceleration | |

| Film thickness | |

| Average gap | |

| Maximum film thickness of gas film | |

| Minimum film thickness of gas film | |

| Sealing ring thickness | |

| Fluid force | |

| Centrifugal force | |

| Reaction force of outer rotor to seal ring | |

| Friction between seal ring and seal seat | |

| Total bearing capacity | |

| Aerodynamic pressure | |

| Rough peak contact force | |

| Seal ring gravity | |

| Width of sealing ring | |

| Seal ring quality | |

| Friction torque | |

| Number of rough peak contacts | |

| Inner rotor angular velocity | |

| Sealing ring angular velocity | |

| Speed group serial number | |

| Test speed group serial number | |

| Gas pressure | |

| Rough peak contact pressure | |

| Environmental pressure | |

| Mean hydrodynamic pressure | |

| Inlet pressure | |

| Outlet pressure | |

| Gas pressure and solid contact pressure | |

| Mass leakage rate | |

| Inner diameter of inner rotor | |

| Outer diameter of inner rotor | |

| Radius of all identical asperities | |

| Inner diameter of sealing ring | |

| Outer diameter of sealing ring | |

| Contact area between seal ring and seal seat | |

| T | Environment temperature |

| t | Time |

| v | Poisson’s ratio of material |

| v1 | Poisson’s ratio of inner rotor |

| v2 | Poisson’s ratio of sealing ring |

| W | Friction power consumption |

| Wn | Tangential force |

| Wt | Normal force |

| x | Circumferential coordinates |

| y | Axial coordinates |

| ε | Eccentricity |

| η | Air viscosity |

| θ | Circumferential angle |

| λ | Film thickness ratio |

| μ | Friction coefficient |

| Centrifugal expansion of sealing ring | |

| Centrifugal expansion of sealing ring | |

| Material density | |

| Material density of inner rotor | |

| Seal ring material density | |

| Comprehensive surface roughness | |

| Shear flow factor | |

| , | Pressure flow factors |

| Gas relative speed | |

| Gas constant | |

| Pressure difference |

References

- He, Q.; Huang, W.; Hu, G.; Li, Y.; Liu, Y.; Wang, Y. Development of aeroengine gas film seal technology. Aircr. Engine 2021, 47, 106–113. [Google Scholar]

- Wang, H.; Zhang, D. Research on sealing technology of aeroengine. Sci. Consult. 2018, 52. [Google Scholar]

- Dirusso, E. Design Analysis of a Self-Acting Spiral-Groove Ring Seal for Counter-Rotating Shafts; NASA: Seattle, WA, USA, 1983. [Google Scholar]

- Wu, N.; Zhao, Z. Experimental study on the feasibility of gas film seal between reversing shafts. Aircr. Engine 2001, 4, 20–25, 42. (In Chinese) [Google Scholar]

- Chen, Y.; Peng, X.D.; Jiang, J.B.; Yan, T.H.; Wu, S.Q.; Zhu, J.J. Foil End Face Gas Film Seal Structure with Dynamic Pressure Floating Seal Dam. CN Patent CN202110551887.3, 19 October 2021. (In Chinese). [Google Scholar]

- Ying, Z.W. A Non-Contact Double End Mechanical Seal with Gas Film for Fans. CN Patent CN202020533710.1, 4 December 2020. (In Chinese). [Google Scholar]

- Chen, Y.; Peng, X.D.; Jiang, J.B.; Yan, T.H.; Wu, S.Q.; Zhu, J.J. A Structure of Foil End Face Gas Film Seal with Enhanced Circumferential Flow Induced Opening. CN Patent CN201811286214.4, 21 February 2020. (In Chinese). [Google Scholar]

- Peng, X.D.; Chen, Y.; Jiang, J.B.; Meng, X.K. Foil End Face Gas Film Seal Structure with Microporous Texture on the Foil Surface. CN Patent CN201610552505.8, 12 October 2016. (In Chinese). [Google Scholar]

- Hou, G.; Su, H.; Huang, Y.; Chen, C. An analysis method of pressure characteristic for cylindrical intershaft gas film seal considering centrifugal expansion, rotor misalignment and precession. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 935–945. [Google Scholar] [CrossRef]

- Hou, G.; Su, H.; Chen, G.; Tian, Y. Performance analysis of compliant cylindrical intershaft seal. Sci. Prog. 2020, 103, 0036850420941957. [Google Scholar] [CrossRef] [PubMed]

- Hou, G.; Su, H.; Chen, G. An analysis method for the performance of compliant cylindrical intershaft gas film seal considering centrifugal expansion effect. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 2728–2739. [Google Scholar] [CrossRef]

- Beermann, L.; Julius, W.; Hans, B. Measurements and modeling of the movement behavior of a radial adaptive seal. J. Eng. Gas Turb. Power 2019, 141, 111011. [Google Scholar] [CrossRef]

- Beermann, L.; Julius, W.; Corina, S.; Bauer, H.-J. Experimental investigation of the sealing performance of a new adaptive seal system. In Proceedings of the Global Power and Propulsion Society: Proceedings of GPPS Forum 18, Zurich, Switzerland, 10–12 January 2018; pp. 1–9. [Google Scholar]

- Sun, J.; Liu, M.; Xu, Z.; Liao, T.; Hu, X.; Li, Y.; Wang, J. Coupled fluid–solid numerical simulation for flow field characteristics and supporting performance of flexible support cylindrical gas film seal. Aerospace 2021, 8, 97. [Google Scholar] [CrossRef]

- Sun, J.; Liu, M.; Xu, Z.; Liao, T. Research on operating parameters of T-groove cylindrical gas film seal based on computational fluid dynamics. Adv. Compos. Lett. 2019, 28, 0963693519864373. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Liu, M.; Kang, Y.; Sun, J.; Xiong, Z. Study on Numerical Calculation of Gas Film Groove Parameters on T-shaped Cylinder. Agric. Equip. Veh. Eng. 2022, 60, 90–95. (In Chinese) [Google Scholar]

- Yu, S.; Ding, J.; Wang, S. Simulation and test of dynamic pressure effect of gas film in cylindrical seals. J. Chem. Eng. 2020, 71, 3220–3228. (In Chinese) [Google Scholar]

- Dai, D.; Liu, M. CFD Numerical Analysis of Flexible Support Cylindrical Gas Film Seal. Electron. Technol. 2018, 31, 60–63+67. (In Chinese) [Google Scholar]

- Wang, Z.; Liang, X. Research on Thermoelastohydrodynamic Lubrication of Internal Combustion Engine Sliding Bearing Based on Micro convex Contact Theory. J. Lubr. Seal. 2014, 39, 33–37. (In Chinese) [Google Scholar]

- Yang, X.; Chen, G. Performance Analysis of C/C Composite Cylindrical Inverted Inter Axial Gas Film Seal; Northwestern Polytechnical University: Xi’an, China, 2022. (In Chinese) [Google Scholar]

- Patir, N.; Cheng, H.S. An average flow model for determining effects of three-dimensional roughness on partial hydrodynamic lubrication. J. Lubr. Technol. 1978, 100, 12–17. [Google Scholar] [CrossRef]

- Huang, P. Numerical Calculation Method of Lubrication; Higher Education Press: Beijing, China, 2012; pp. 113–116. (In Chinese) [Google Scholar]

- Ma, G.; Zhao, W.; Shen, X. Analysis of parameters and performance for spiral grooved cylindrical gas film seal. Procedia Eng. 2011, 23, 115–119. [Google Scholar] [CrossRef] [Green Version]

- Chao, W.; Hua, S. Performance Analysis of Gas Film Seal with Rotor Tilt between Reverse Shafts; Northwestern Polytechnical University: Xi’an, China, 2022. (In Chinese) [Google Scholar]

- Bhushan, B. Contact mechanics of rough surfaces in tribology: Multiple asperity contact. Tribol. Lett. 1998, 4, 1–35. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Outer diameter of inner rotor r2 | 77.24 mm |

| Inner diameter of sealing ring | 77.25 mm |

| Seal ring radial height | 5 mm |

| Seal ring width | 11.9 mm |

| Inlet pressure | 0.14~0.22 MPa |

| Outlet pressure | 0.1013 MPa |

| Inner rotor speed | 5000~10,000 r/min |

| Outer rotor speed | 8000~13,000 r/min |

| Air viscosity | |

| Operation temperature | 930 K |

| Gas constant | 287 J/Kg⋅K |

| Material | Elasticity Modulus (GPa) | Poisson’s Ratio | Density (g/cm3) |

|---|---|---|---|

| Graphite | 18 | 0.3 | 1.8 |

| Structural steel | 91 | 0.34 | 4.44 |

| Outer Rotor Speed (rpm) | Inner Rotor Speed (rpm) | |

|---|---|---|

| 1 | 5000 | −8000 |

| 2 | 7000 | −10,000 |

| 3 | 9000 | −12,000 |

| 4 | 10,000 | −14,000 |

| 5 | 11,000 | −15,000 |

| 6 | 12,000 | −16,000 |

| Rotation Mode | Outer Rotor Speed n2 (rpm) | Inner Rotor Speed n1 (rpm) |

|---|---|---|

| Mode 1 | 7000 | 10,000 |

| Mode 2 | 7000 | 0 |

| Mode 3 | 7000 | −10,000 |

| Mode 4 | 0 | 7000 |

| Speed Combination Number | Outer Rotor Speed (rpm) | Inner Rotor Speed (rpm) |

|---|---|---|

| 1 | 5000 | −8000 |

| 2 | 6000 | −9000 |

| 3 | 7000 | −10,000 |

| 4 | 8000 | −11,000 |

| 5 | 9000 | −12,000 |

| 6 | 10,000 | −13,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, S.; Su, H. Performance Analysis of the Cylinder Gas Film Seal between Dual-Rotor Reverse Shafts Considering Lubrication and Centrifugal Expansion Effects. Appl. Sci. 2023, 13, 3076. https://doi.org/10.3390/app13053076

Zhao S, Su H. Performance Analysis of the Cylinder Gas Film Seal between Dual-Rotor Reverse Shafts Considering Lubrication and Centrifugal Expansion Effects. Applied Sciences. 2023; 13(5):3076. https://doi.org/10.3390/app13053076

Chicago/Turabian StyleZhao, Shuaike, and Hua Su. 2023. "Performance Analysis of the Cylinder Gas Film Seal between Dual-Rotor Reverse Shafts Considering Lubrication and Centrifugal Expansion Effects" Applied Sciences 13, no. 5: 3076. https://doi.org/10.3390/app13053076