Parallel Water Column Technique for Obtaining a Smooth Output Power of the Pump as a Turbine at a Variable Water Flow Rate

Abstract

:1. Introduction

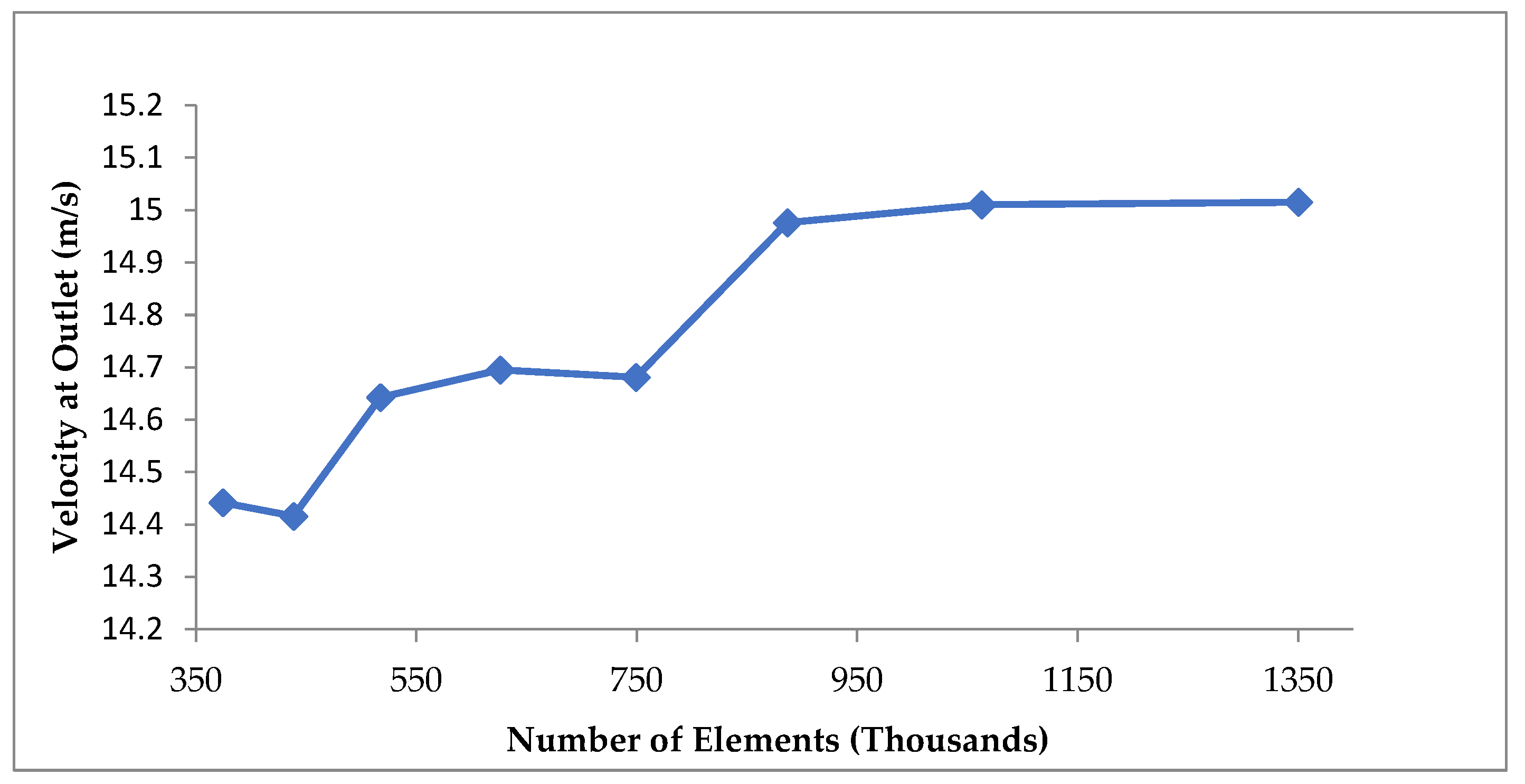

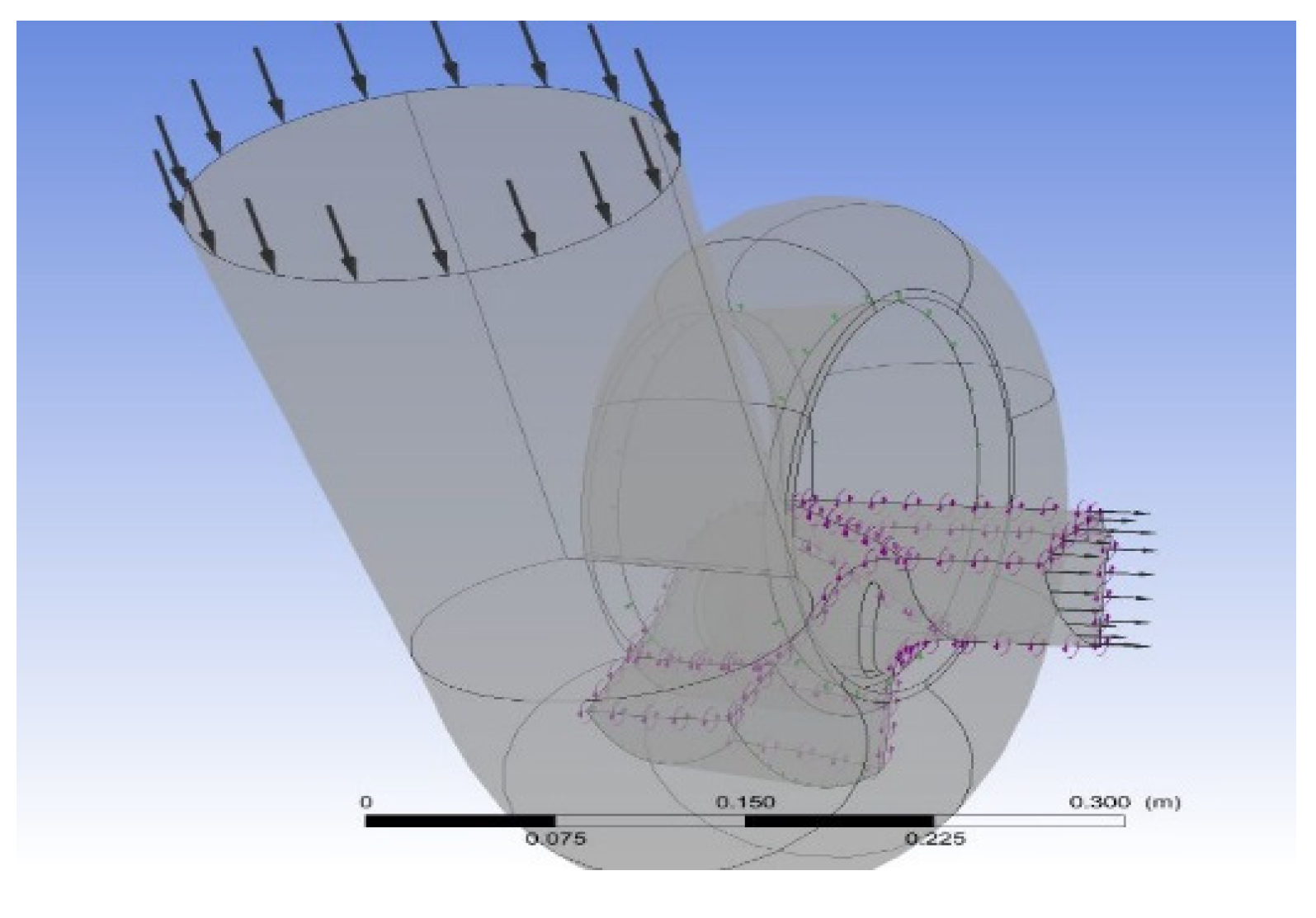

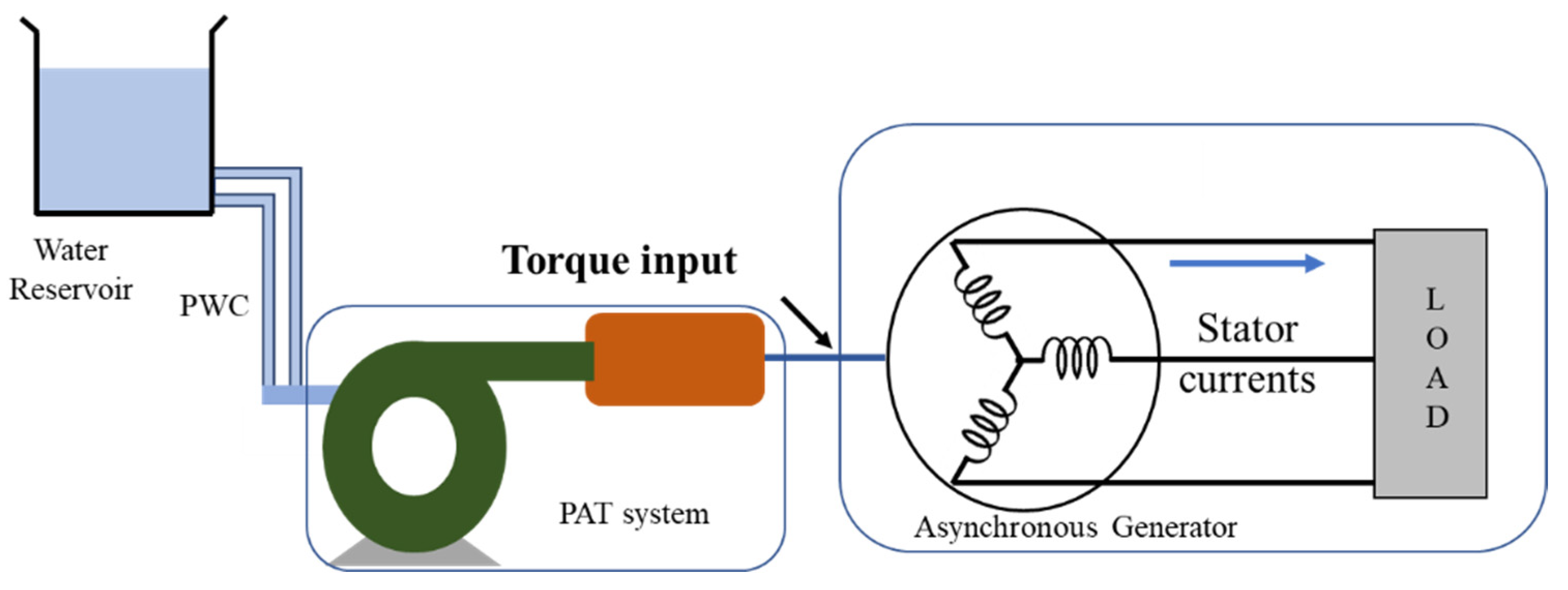

2. Materials and Methods

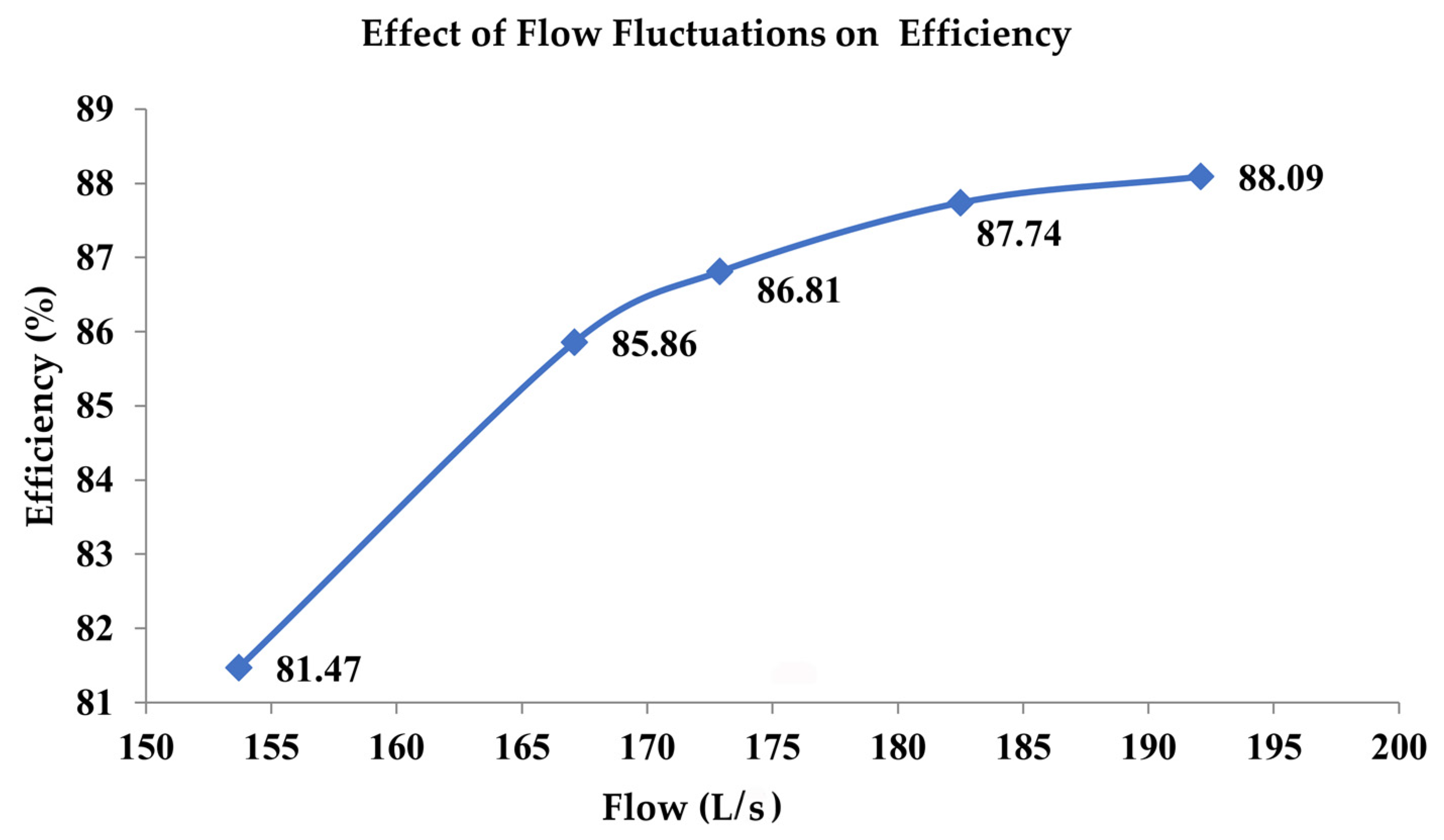

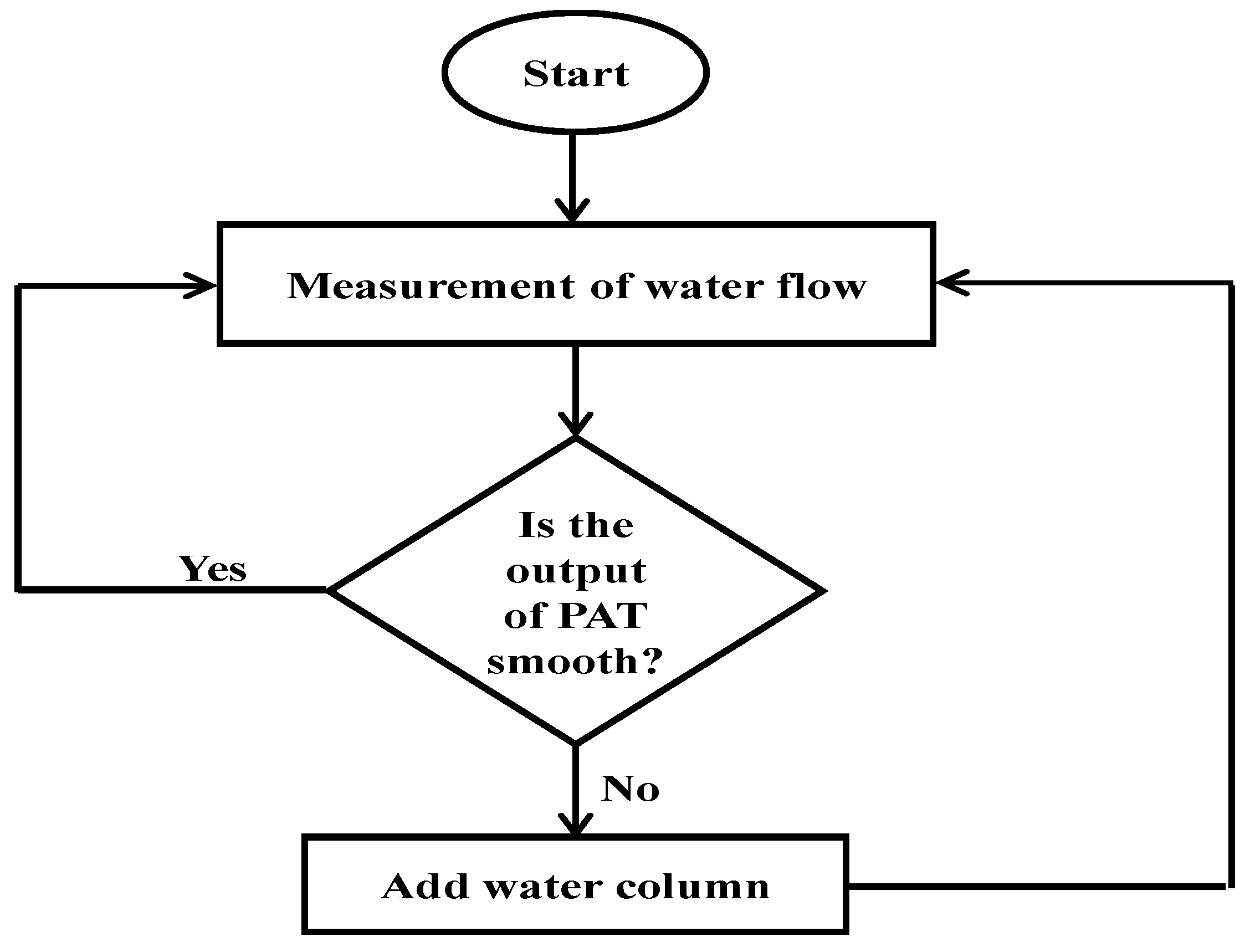

2.1. Effect of Flow Variations on the Output of PAT

2.2. Water Column Theory

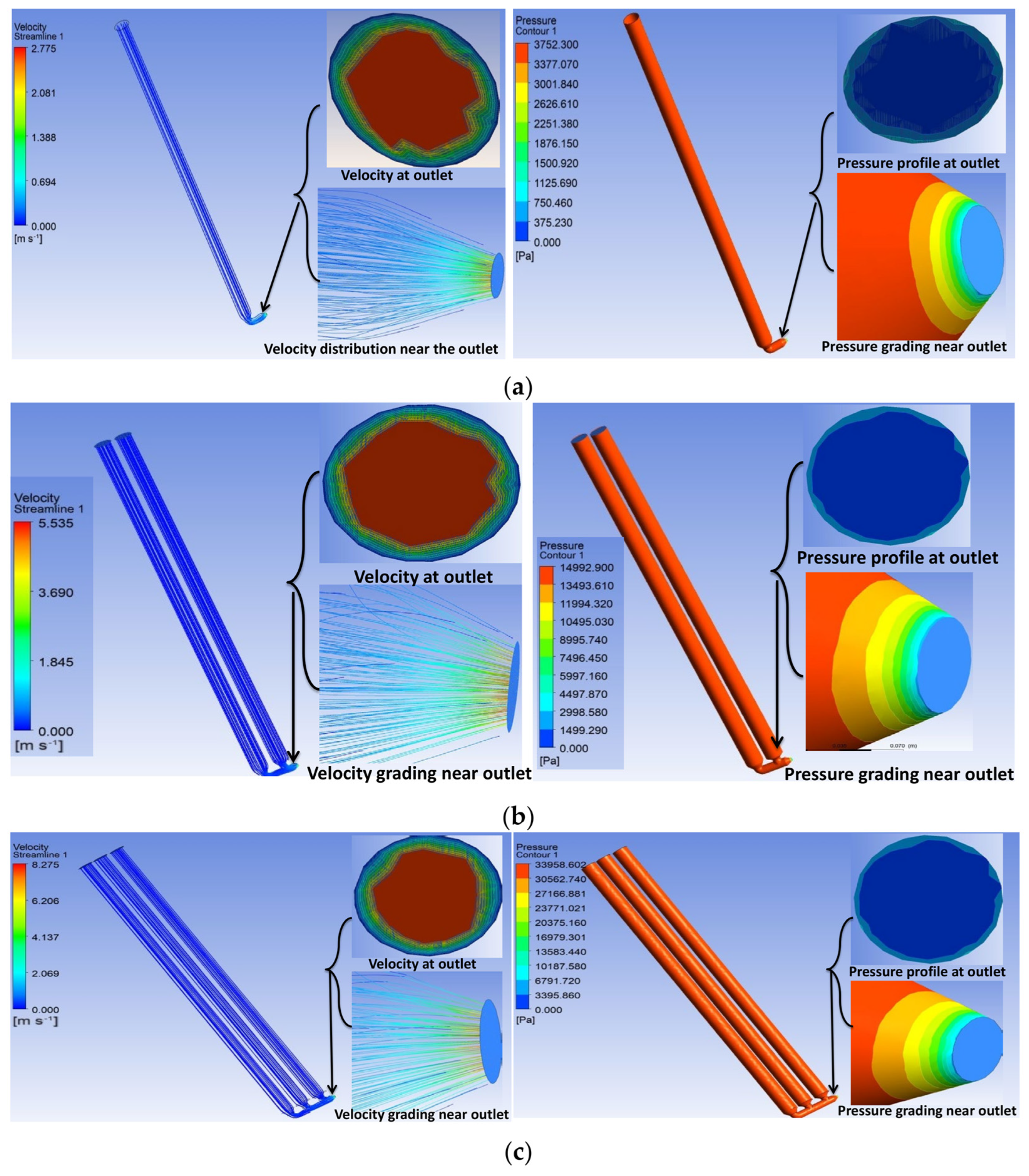

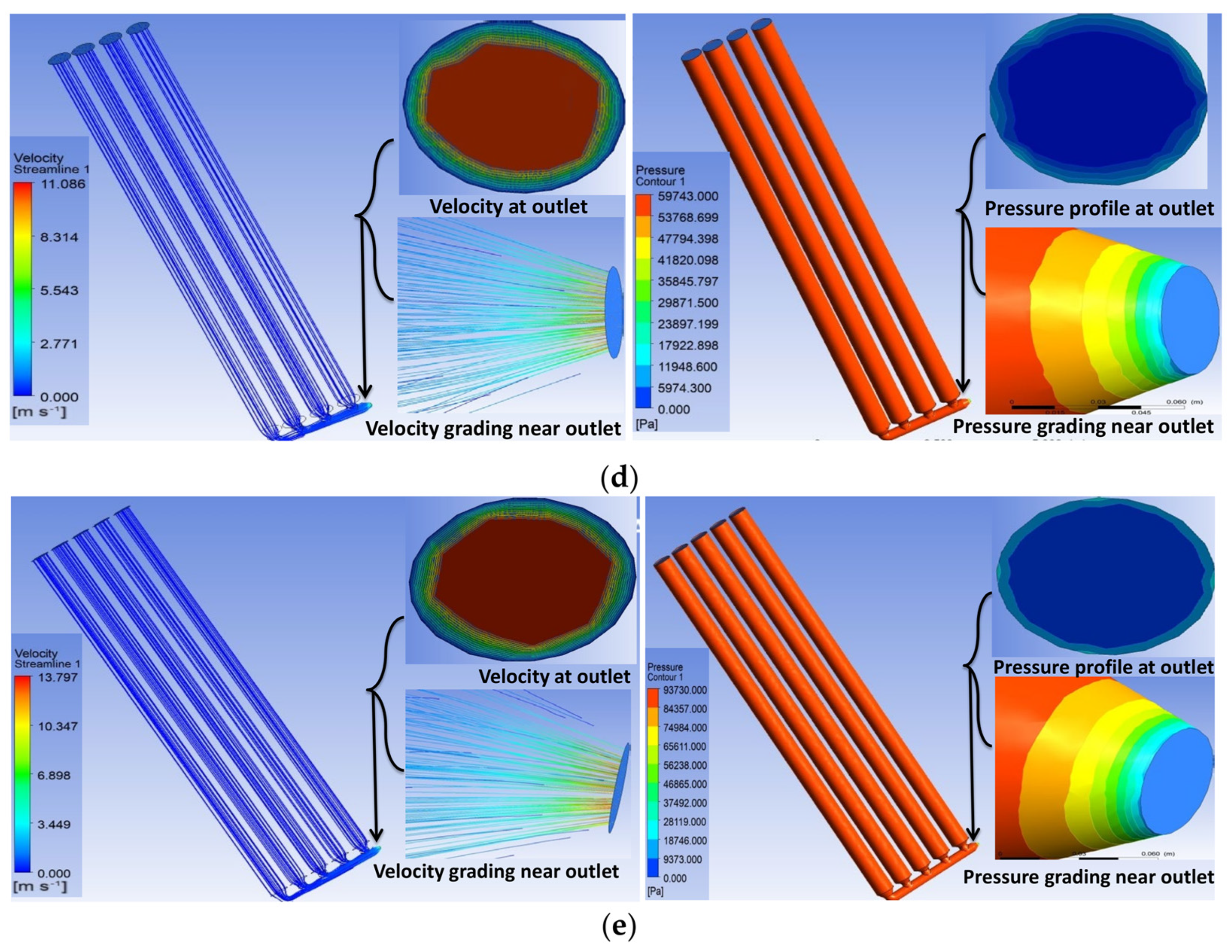

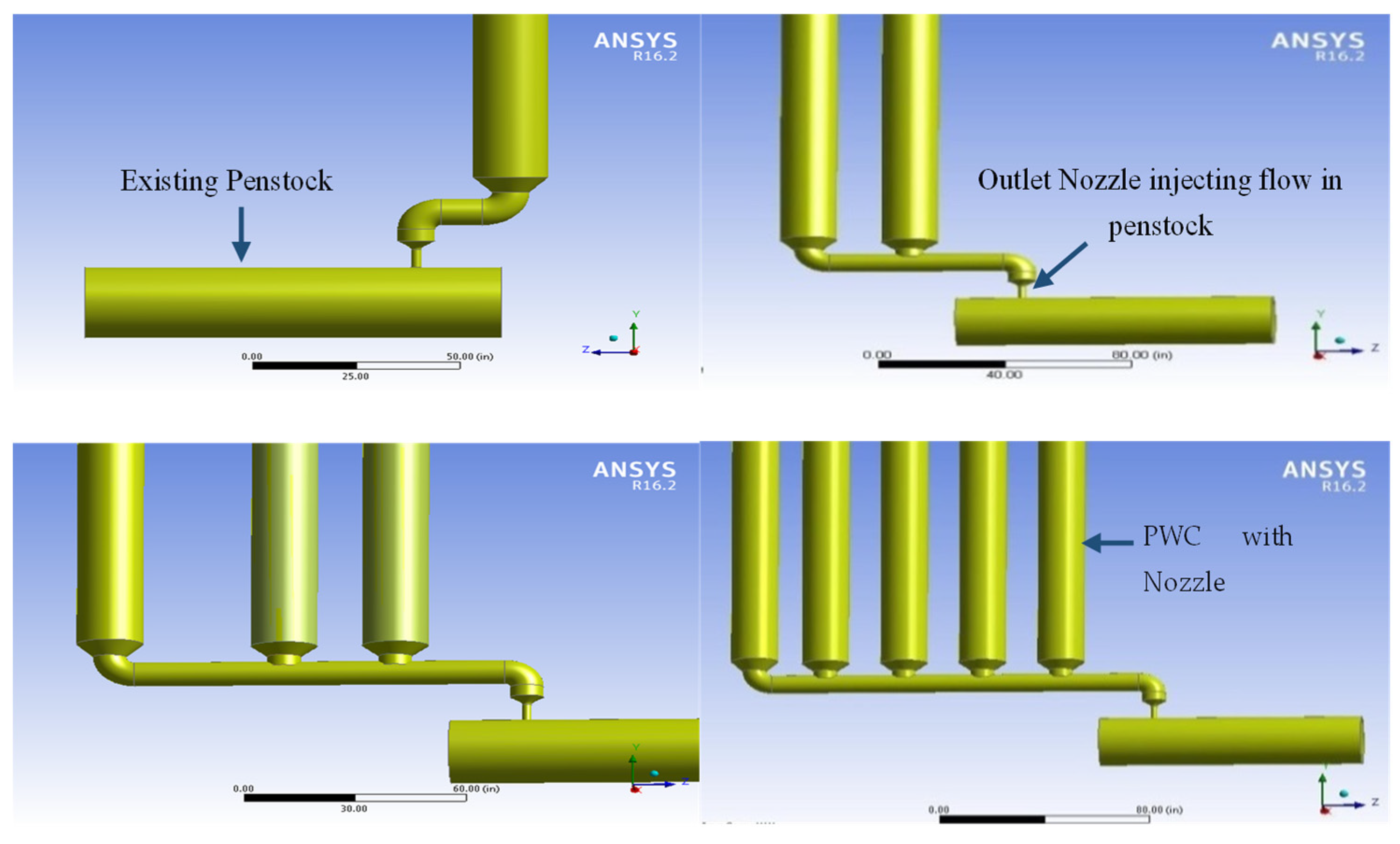

2.3. PWC Technique with the Design of Experiment

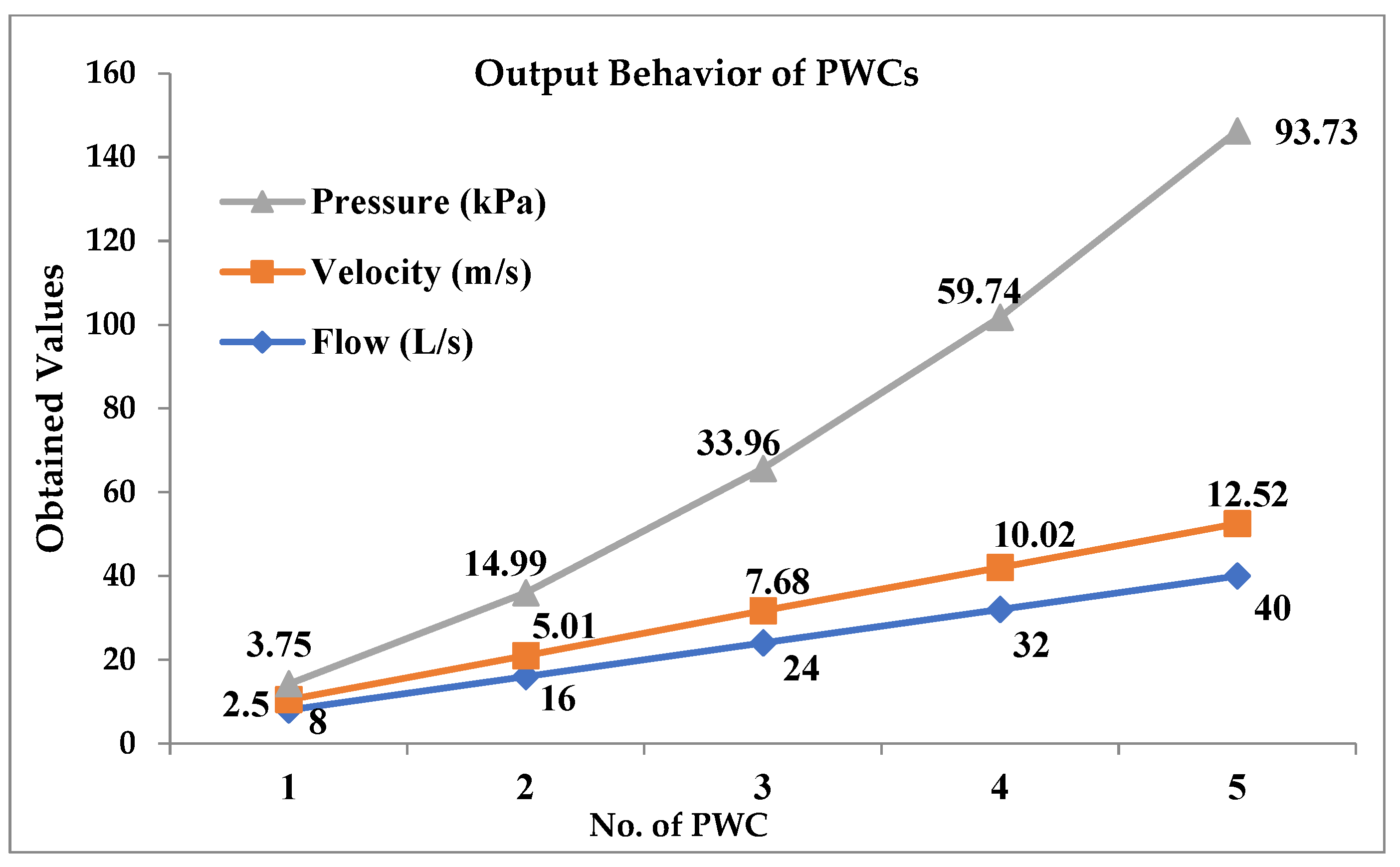

2.4. Findings from the Design Experiment

3. Optimal Number of PWCs for a Smooth Output of the PAT

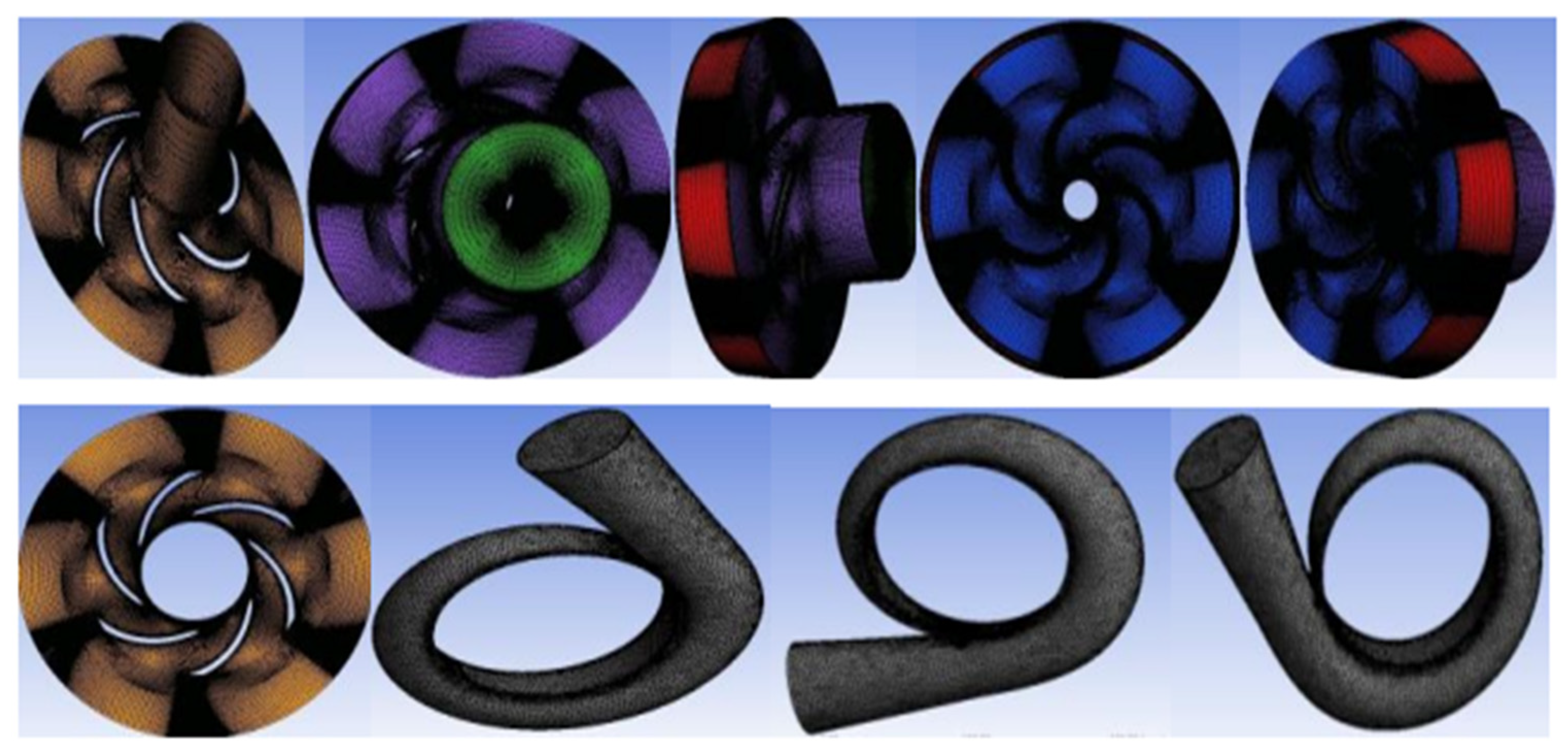

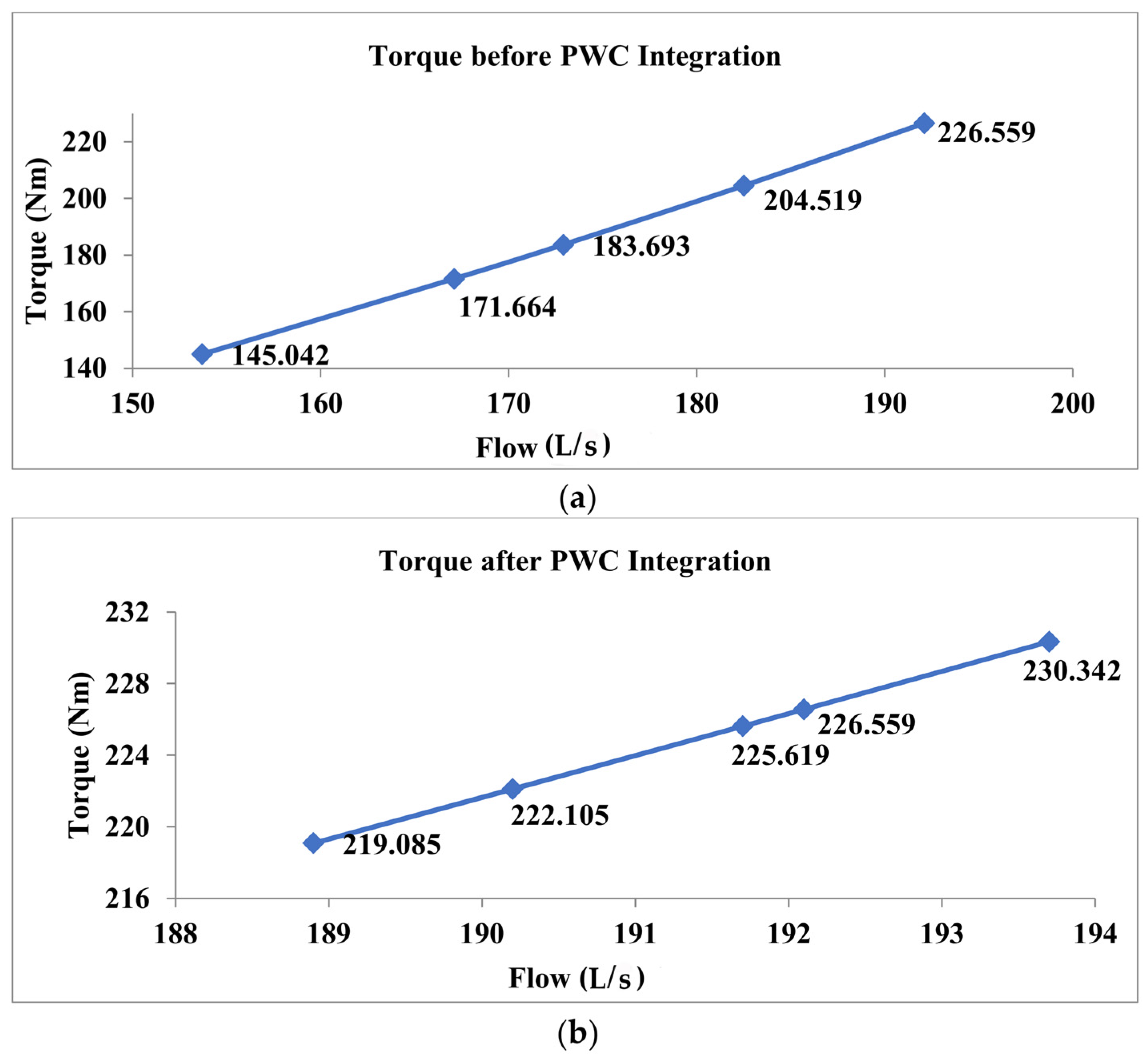

4. Torque Calculation and Generator Behavior

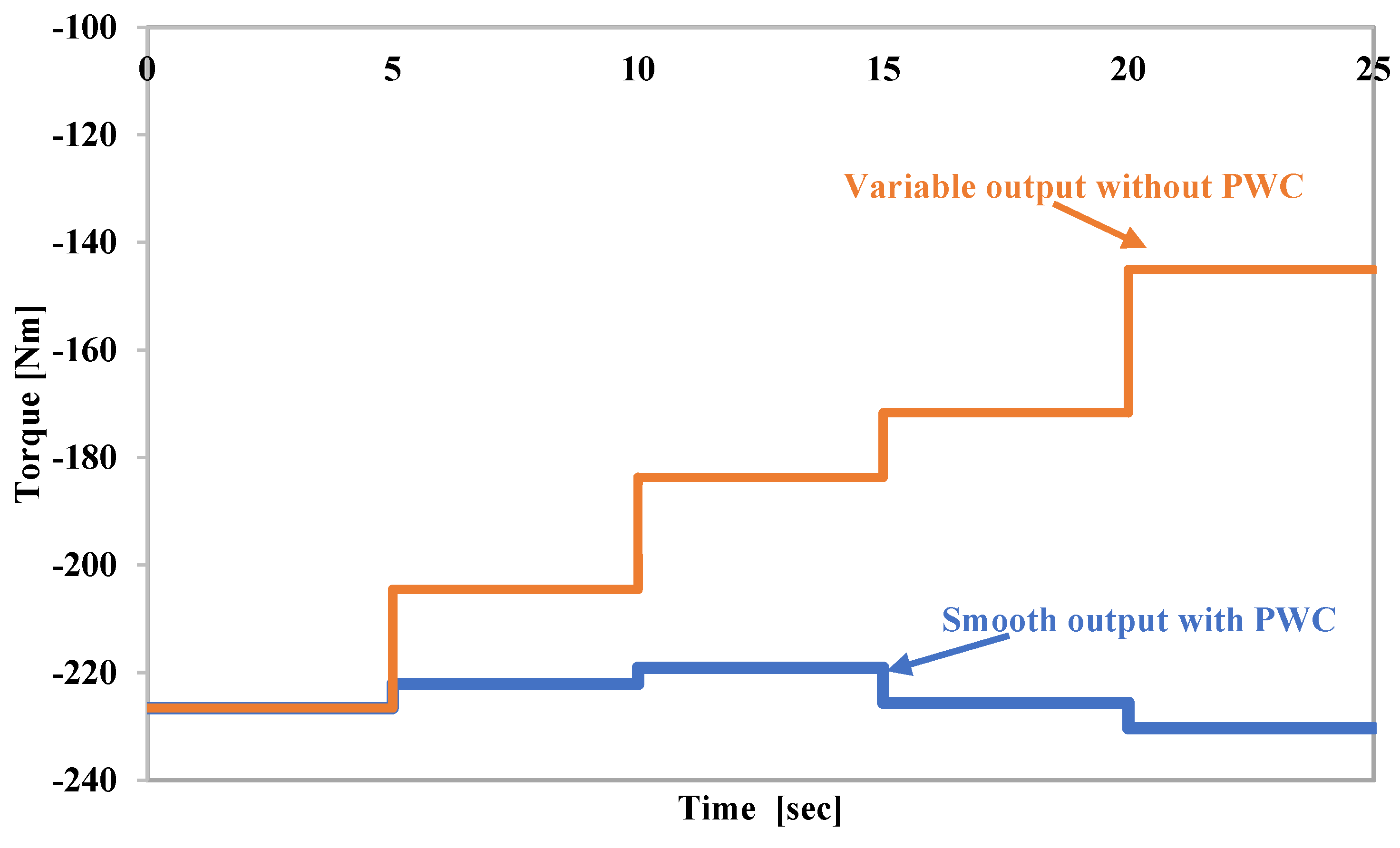

4.1. Torque Produced by PAT on Different Flow Values

4.2. Generator Behavior on the Variable and Smooth Torque

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | area of water discharge [m2] |

| F | force [N] |

| g | gravitational acceleration [m/s2] |

| H | head height [m] |

| m | mass of water [kg] |

| n | number of water columns |

| P | pressure [Pa] |

| Pout | output power [W] |

| PAT | pump as turbine |

| PWC | parallel water columns |

| Q | flow of water [L/s] |

| v | velocity of water [m/s] |

| w | weight of water |

| η | efficiency [%] |

| ρ | density of water [kg/m3] |

References

- Olabi, A.; Abdelkareem, M.A. Renewable energy and climate change. Renew. Sustain. Energy Rev. 2022, 158, 112111. [Google Scholar] [CrossRef]

- Bilgili, F.; Lorente, D.B.; Kuşkaya, S.; Ünlü, F.; Gençoğlu, P.; Rosha, P. The role of hydropower energy in the level of CO2 emissions: An application of continuous wavelet transform. Renew. Energy 2021, 178, 283–294. [Google Scholar] [CrossRef]

- Jurasz, J.; Ciapala, B. Solar–hydro hybrid power station as a way to smooth power output and increase water retention. Sol. Energy 2018, 173, 675–690. [Google Scholar] [CrossRef]

- Wang, Z.; Yen-Ku, K.; Li, Z.; An, N.B.; Abdul-Samad, Z. The transition of renewable energy and ecological sustainability through environmental policy stringency: Estimations from advance panel estimators. Renew. Energy 2022, 188, 70–80. [Google Scholar] [CrossRef]

- International Energy Agency. Available online: https://www.iea.org/reports/renewables-information-overview/supply (accessed on 6 January 2022).

- International Hydro Power Association (IHA). Available online: https://www.hydropower.org/iha/discover-facts-about-hydropower (accessed on 6 January 2022).

- Tkac, S. Hydro power plants, an overview of current types and technology. SSP-J. Civ. Eng. 2018, 13, 115–126. [Google Scholar]

- Paish, O. Small hydro power: Technology and current status. Renew. Sustain. Energy Rev. 2002, 6, 537–556. [Google Scholar] [CrossRef]

- Kaunda, C.S.; Kimambo, C.Z.; Nielsen, T.K. Hydropower in the Context of Sustainable Energy Supply: A Review of Technologies and Challenges. Int. Sch. Res. Not. 2012, 2012, 730631. [Google Scholar] [CrossRef]

- Alatorre-Frenk, C. Cost Minimization in Micro-Hydro System Using. PAT. Dissertation, University of Warwickshire, Coventry, UK, 1994. [Google Scholar]

- Aggidis, G.A.; Luchinskaya, E.; Rothschild, R.; Howard, D.C. The costs of small-scale hydro power production: Impact on the development of existing potential. Renew. Energy 2012, 35, 2632–2638. [Google Scholar] [CrossRef]

- Hossain, I.M.; Ferdous, S.M.; Salehin, S.; Saleque, A.M.; Jamal, T. Pump-as-turbine (PAT) for small scale power generation: A comparative analysis. In Proceedings of the 2014 3rd International Conference on the Developments in Renewable Energy Technology (ICDRET), Dhaka, Bangladesh, 29–31 May 2014. [Google Scholar]

- Binamaa, M.; Sua, W.-T.; Li, X.-B.; Weia, X.-Z.; Anc, S. Investigation on pump as turbine (PAT) technical aspects for micro hydropower schemes: A state-of-the-art review. Renew. Sustain. Energy Rev. 2017, 79, 148–179. [Google Scholar] [CrossRef]

- Morabito, A.; Furtado, G.A. Variable speed regulation for pump as turbine in micro pumped hydro energy storage application. In Proceedings of the 38th IAHR Congress, Panama City, Panama, 1–6 September 2019. [Google Scholar]

- Deyou, L.; Hongji, W.; Goaming, X.; Ruxhi, G.; Zhansheng, L. Unsteady simulation and analysis for hump characteristics of a pump turbine model. Renew. Energy 2015, 77, 32–42. [Google Scholar] [CrossRef]

- Nobile, E.; Sari, G.; Schwery, A. Variable Speed Hydro Pumped Storage as Flexible Enabler of Intermittent Renewable Penetration. In Proceedings of the 2018 IEEE Power & Energy Society General Meeting (PESGM), Portland, OR, USA, 5–10 August 2018; pp. 1–5. [Google Scholar]

- Elbatran, A.H.; Yakoob, O.B.; Ahmed, Y.M. Operation, performance and economic analysis of low head micro-hydropower turbines for rural and remote areas: A review. Renew. Sustain. Energy Rev. 2015, 43, 40–50. [Google Scholar] [CrossRef]

- Derakhshan, S.; Kasaeian, N. Optimization, Numerical, and Experimental Study of a Propeller Pump as Turbine. J. Energy Resour. Technol. 2014, 136, 012005. [Google Scholar] [CrossRef]

- Yang, S.-S.; Kong, F.-Y.; Jiang, W.-M.; Qu, X.-Y. Effects of impeller trimming influencing pump as turbine. Comput. Fluids 2012, 67, 72–78. [Google Scholar] [CrossRef]

- Yang, S.-S.; Liu, H.-L.; Kong, F.-Y.; Dai, C. Experimental, Numerical, and Theoretical Research on Impeller Diameter Influencing Centrifugal Pump-as-Turbine. J. Energy Eng. 2013, 139, 299–307. [Google Scholar] [CrossRef]

- Yang, S.-S.; Wang, C.; Chen, K.; Yuan, X. Research on Blade Thickness Influencing Pump as Turbine. Adv. Mechan. Eng. 2014, 6, 190530. [Google Scholar] [CrossRef]

- Yang, S.-S.; Kong, F.-Y.; Qu, X.-Y.; Jiang, W.-M. Influence of blade number on the performance and pressure pulsations in a pump used as a turbine. J. Fluids Eng. 2012, 134, 124503. [Google Scholar] [CrossRef]

- Lugauer, F.J.; Kainz, J.; Gehlich, E.; Gaderer, M. Roadmap to Profitability for a Speed-Controlled Micro-Hydro Storage System Using Pumps as Turbines. Sustainability 2022, 14, 653. [Google Scholar] [CrossRef]

- Binama, M.; Kan, K.; Chen, H.-X.; Zheng, Y.; Zhou, D.-Q.; Su, W.-T.; Ge, X.-F.; Ndayizigiye, J. A Numerical Investigation into the PAT Hydrodynamic Response to Impeller Rotational Speed Variation. Sustainability 2021, 13, 7998. [Google Scholar] [CrossRef]

- Hunt, J.D.; Zakeri, B.; Lopes, R.; Barbosa, P.S.F.; Nascimento, A.; de Castro, N.J.; Brandão, R.; Schneider, P.S.; Wada, Y. Existing and new arrangements of pumped-hydro storage plants. Renew. Sustain. Energy Rev. 2020, 129, 109914. [Google Scholar] [CrossRef]

- Bansal, R.K. A Textbook of Fluid Mechanics and Hydraulic Machines; Laxmi Publication (P) Ltd.: New Delhi, India, 2010. [Google Scholar]

- ANSYS Fluent Tutorial Guide. Release 18.0, January 2017. Available online: www.ansys.com (accessed on 5 December 2021).

- Zhou, L.; Hang, J.; Bai, L.; Krzemianowski, Z.; El-Emam, M.A.; Yasser, E.; Agarwal, R. Application of entropy production theory for energy losses and other investigation in pumps and turbines: A review. Appl. Energy 2022, 318, 119211. [Google Scholar] [CrossRef]

- Weidong, C.; Lingiun, Y.; Bing, L.; Yining, Z. The influence of impeller eccentricity on centrifugal pump. Adv. Mech. Eng. 2017, 9, 1–17. [Google Scholar] [CrossRef] [Green Version]

- El-Emam, M.; Zhou, L.; Yasser, E.; Bai, L.; Shi, W. Computational Methods of Erosion Wear in Centrifugal Pump: A State-of-the-Art Review. Arch. Comput. Methods Eng. 2022, 29, 3789–3814. [Google Scholar] [CrossRef]

- Wei, Y.; Shi, Y.; Shi, W.; Pan, B. Numerical Analysis and Experimental Study of Unsteady Flow Characteristics in an Ultra-Low Specific Speed Centrifugal Pump. Sustainability 2022, 14, 16909. [Google Scholar] [CrossRef]

- Simulink Getting Started Guide, Release 2015. Available online: www.mathworks.com (accessed on 15 December 2021).

- Alberizzi, J.C.; Renzi, M.; Nigro, A.; Rossi, M. Study of a Pump-as-Turbine (PAT) speed control for a Water Distribution Network (WDN) in South-Tyrol subjected to high variable water flow rated. Energy Procedia 2018, 148, 226–233. [Google Scholar] [CrossRef]

| Dimensions/Settings | Values |

|---|---|

| Head | 10 m |

| Diameter of the outlet nozzle | 0.0635 m |

| Upper diameter of each water column | 0.4572 m |

| Diameter of the nozzle used at the bottom of each water column | 0.2286 m |

| Working fluid | Water (liquid) |

| Outlet pressure | 0 Pascals |

| Turbulence model | k-ω (SST) |

| Density of water | 1000 kg/m3 |

| Boundaries | |

| Inlet | Velocity inlet |

| Outlet | Pressure outlet |

| Wall function | Standard |

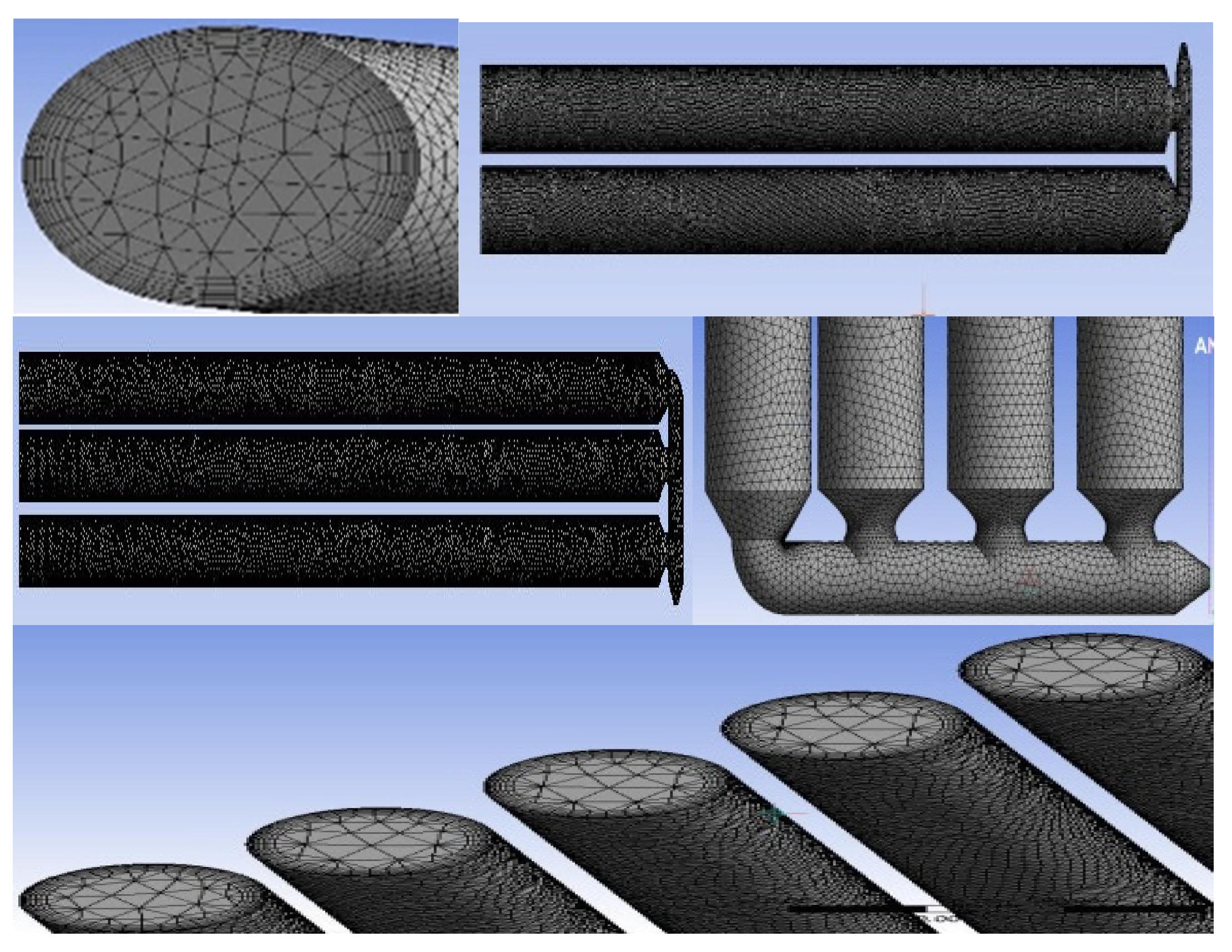

| No. of PWC | Element Size | Method of Meshing | Inflation Layers | No. of Elements |

|---|---|---|---|---|

| 1 | 40 | Tetrahedrons | 7 | 274,274 |

| 2 | 40 | Tetrahedrons | 7 | 358,456 |

| 3 | 40 | Tetrahedrons | 7 | 543,020 |

| 4 | 40 | Tetrahedrons | 7 | 736,088 |

| 5 | 40 | Tetrahedrons | 7 | 926,713 |

| Flow (L/s) | Reduced Flow (L/s) | PWC Added (8 L/s Each) | Additional Flow (L/s) | New Flow (L/s) |

|---|---|---|---|---|

| 192.1 | Nil | No | Nil | 192.1 |

| 182.2 | 9.9 | 1 | 8 | 190.2 |

| 172.9 | 19.2 | 2 | 16 | 188.9 |

| 167.1 | 25 | 3 | 24 | 191.7 |

| 153.7 | 38.4 | 5 | 40 | 193.7 |

| Domain | Nodes | Elements | Tetrahedra | Wedges | Hexahedra |

|---|---|---|---|---|---|

| R1(Passage) | 663,175 | 627,640 | 0 | 0 | 627,640 |

| S1(B75) | 82,927 | 258,746 | 165,196 | 93,550 | 0 |

| All Domains | 746,102 | 886,386 | 165,196 | 93,550 | 627,640 |

| Before PWC Integration | After PWC Integration | ||||

|---|---|---|---|---|---|

| Flow (L/s) | Torque (Nm) | Deviation (%) | Flow (L/s) | Torque (Nm) | Deviation (%) |

| 192.1 | 226.559 | 0 | 192.1 | 226.559 | 0 |

| 182.5 | 204.519 | 9.73 | 190.2 | 222.105 | 1.97 |

| 172.9 | 183.693 | 18.92 | 188.9 | 219.085 | 3.3 |

| 167.1 | 171.664 | 24.23 | 191.7 | 225.619 | 0.41 |

| 153.7 | 145.042 | 35.98 | 193.7 | 230.342 | 1.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, S.; Humza, M.; Yazdan, T.; Abbas, G.; Cho, H.-W. Parallel Water Column Technique for Obtaining a Smooth Output Power of the Pump as a Turbine at a Variable Water Flow Rate. Appl. Sci. 2023, 13, 3232. https://doi.org/10.3390/app13053232

Hussain S, Humza M, Yazdan T, Abbas G, Cho H-W. Parallel Water Column Technique for Obtaining a Smooth Output Power of the Pump as a Turbine at a Variable Water Flow Rate. Applied Sciences. 2023; 13(5):3232. https://doi.org/10.3390/app13053232

Chicago/Turabian StyleHussain, Sajjad, Muhammad Humza, Tanveer Yazdan, Ghulam Abbas, and Han-Wook Cho. 2023. "Parallel Water Column Technique for Obtaining a Smooth Output Power of the Pump as a Turbine at a Variable Water Flow Rate" Applied Sciences 13, no. 5: 3232. https://doi.org/10.3390/app13053232

APA StyleHussain, S., Humza, M., Yazdan, T., Abbas, G., & Cho, H.-W. (2023). Parallel Water Column Technique for Obtaining a Smooth Output Power of the Pump as a Turbine at a Variable Water Flow Rate. Applied Sciences, 13(5), 3232. https://doi.org/10.3390/app13053232