The Efficiency Evaluation of the Reactive Extrusion Process for Polyethylene Terephthalate (PET). Monitoring of the Industrial Foil Manufacturing Process by In-Line Rheological Measurements

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental

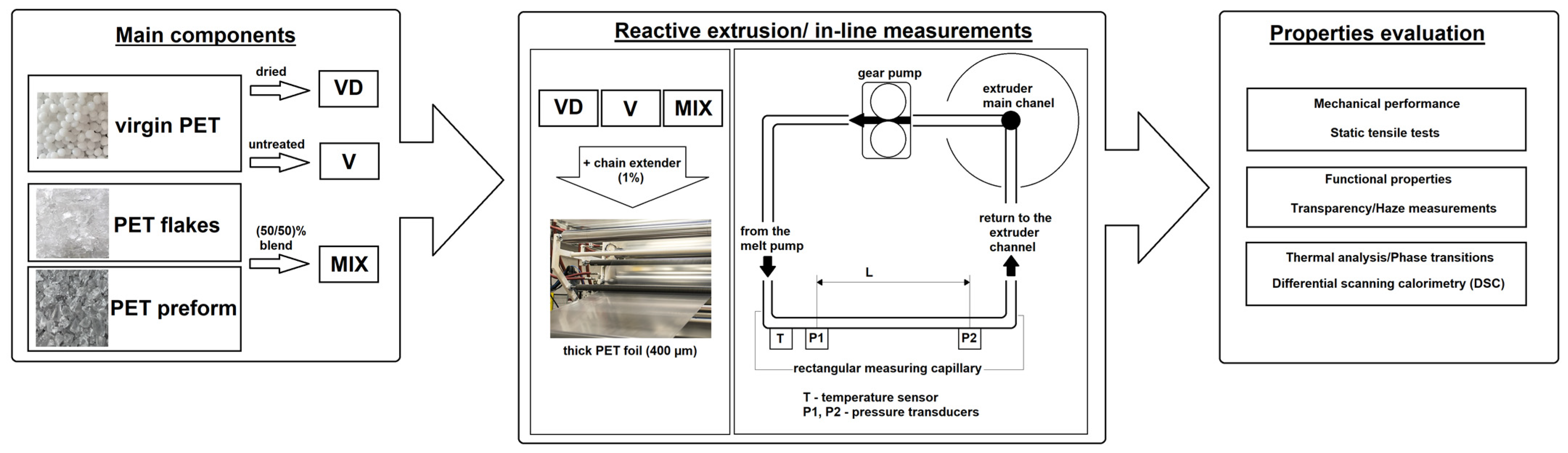

2.1. Materials

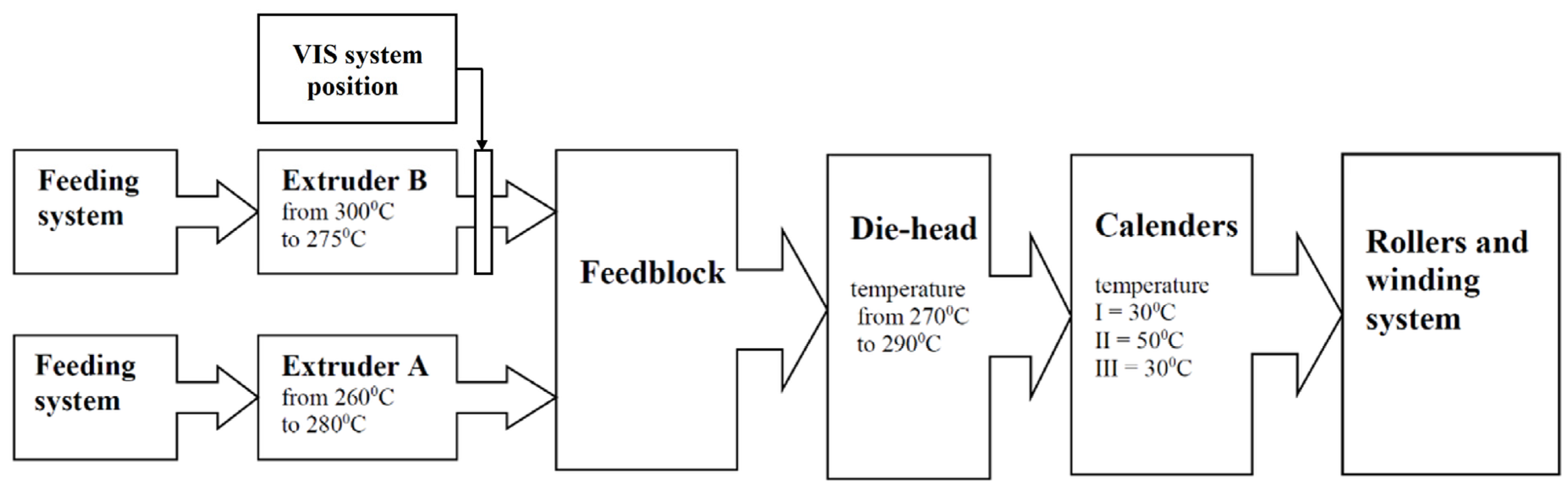

2.2. Sample Preparation

2.3. Methods

3. Results and Discussion

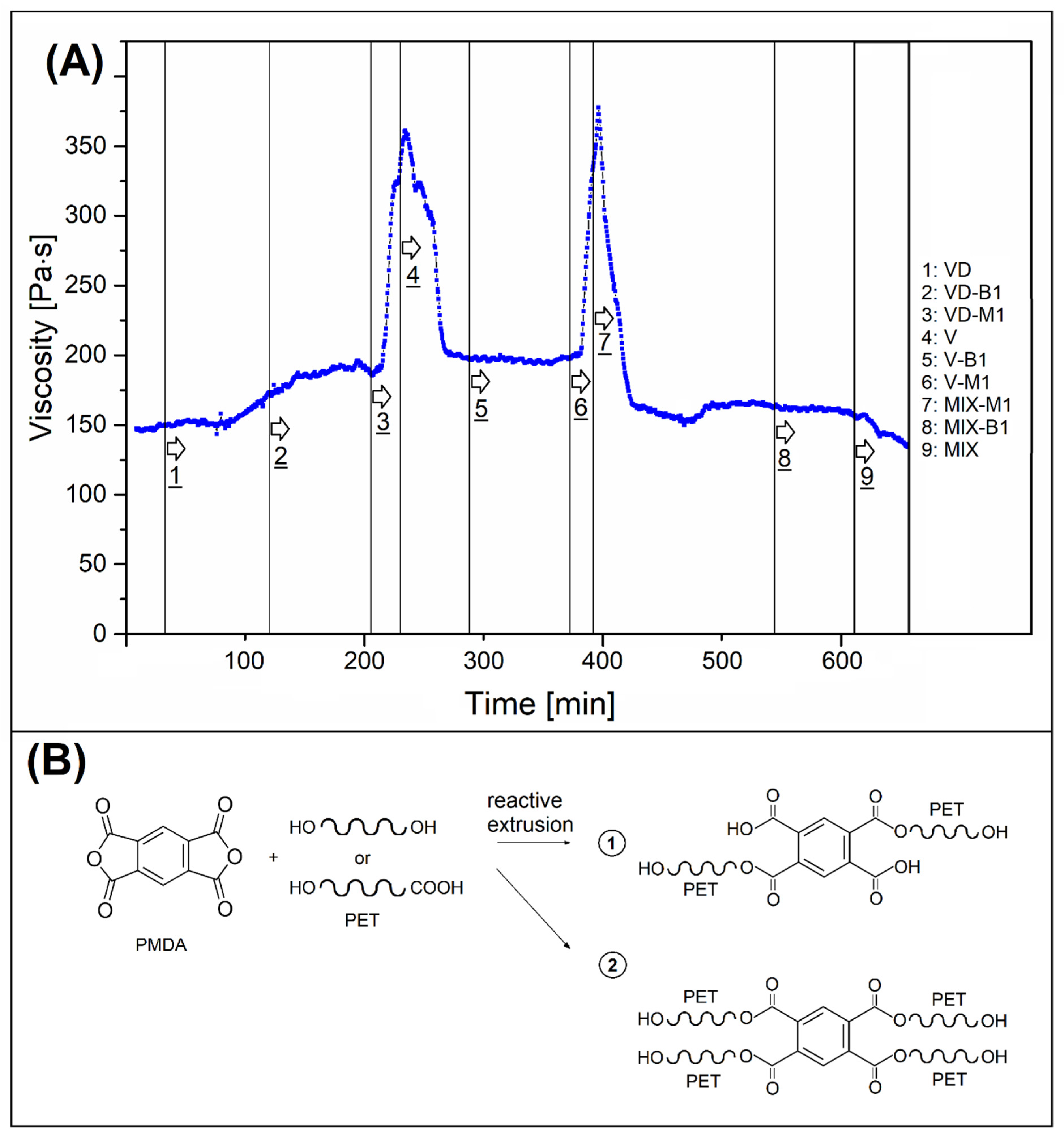

3.1. In-Line Rheological Tests—Viscosity Difference for Standard and Reactive Extrusion

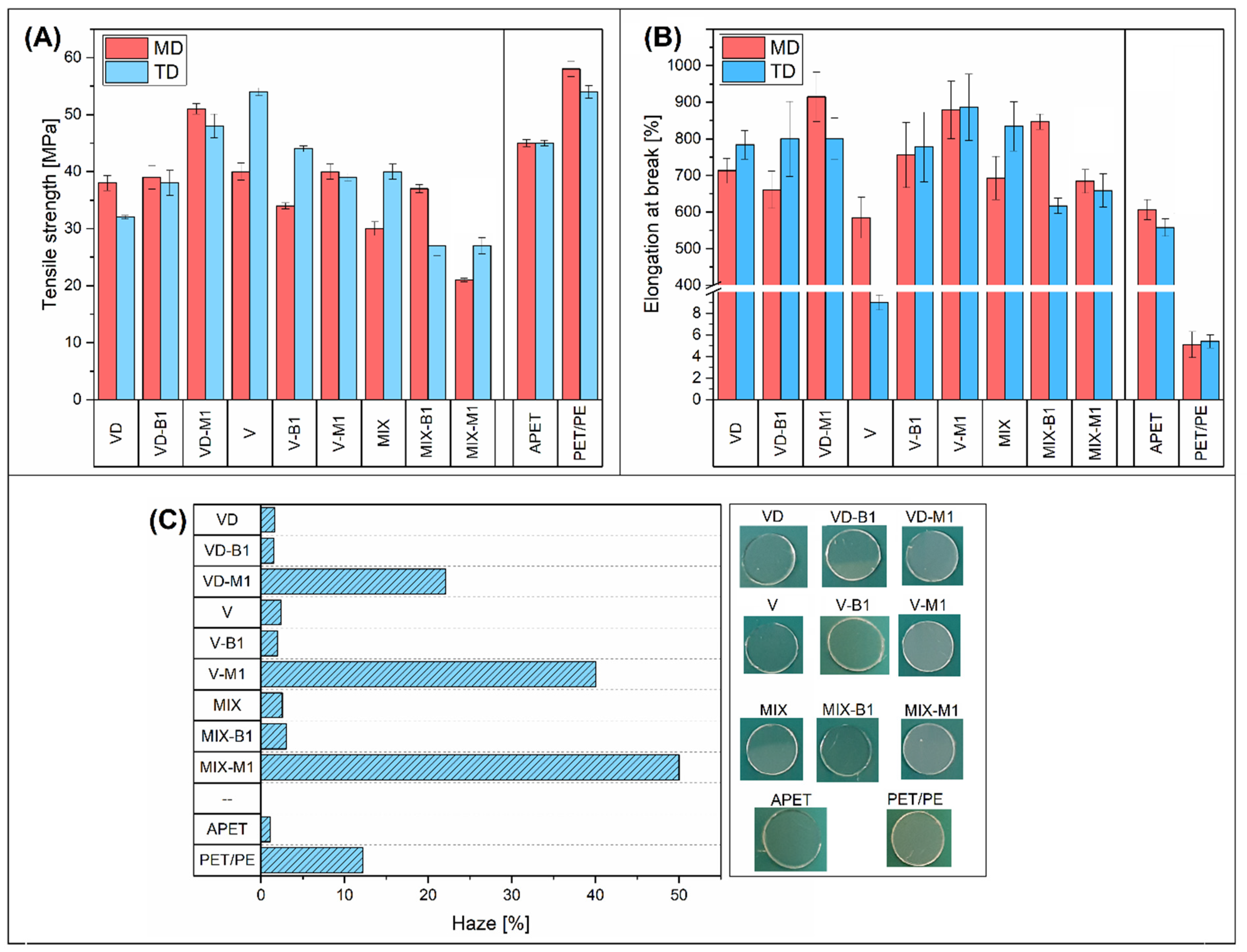

3.2. The Properties of the Manufactured Foil

4. Conclusions

- -

- It can be stated with satisfaction that the observed results confirm the effectiveness of the in-line system in detecting changes in PET viscosity. The recorded changes in rheological characteristics result from the use of various types of material composition, including reactive additives increasing the composition IV coefficient.

- -

- The research shows that the effectiveness of many commercial additives of this type is questionable; they have low efficiency or require an optimization process, which would be problematic and costly to carry out on a high-performance industrial line.

- -

- The comparative analysis of the key tensile properties did not show any significant changes in the film performance, which can be considered a positive result.

- -

- In the case of the most efficient M1 compound, there is a significant drop in transparency (haze). It does not eliminate this type of product from use; however, to some extent, it limits the applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hilliou, L.; Covas, J.A. In-Process Rheological Monitoring of Extrusion-Based Polymer Processes. Polym. Int. 2021, 70, 24–33. [Google Scholar] [CrossRef]

- Kastner, C.; Altmann, D.; Kobler, E.; Steinbichler, G. Development of a Rheology Die and Flow Characterization of Gas-Containing Polymer Melts. Polymers 2021, 13, 3305. [Google Scholar] [CrossRef]

- Silva, J.; Santos, A.C.; Canevarolo, S.V. In-Line Monitoring Flow in an Extruder Die by Rheo-Optics. Polym. Test. 2015, 41, 63–72. [Google Scholar] [CrossRef] [Green Version]

- Klozinski, A.; Barczewski, M. Comparison of Off-Line, on-Line and in-Line Measuring Techniques Used for Determining the Rheological Characteristics of Polyethylene Composites with Calcium Carbonate. Polimery/Polymers 2019, 64, 83–92. [Google Scholar] [CrossRef]

- Kloziński, A.; Jakubowska, P. The Effect of the Addition of a Slip Agent on the Rheological Properties of Polyethylene: Off-Line and in-Line Measurements. J. Polym. Eng. 2019, 39, 422–431. [Google Scholar] [CrossRef]

- Fernandez, A.; Muniesa, M.; Javierre, C. In-Line Rheological Testing of Thermoplastics and a Monitored Device for an Injection Moulding Machine: Application to Raw and Recycled Polypropylene. Polym. Test. 2014, 33, 107–115. [Google Scholar] [CrossRef]

- Lewandowski, K.; Piszczek, K.; Zajchowski, S.; Mirowski, J. Rheological Properties of Wood Polymer Composites at High Shear Rates. Polym. Test. 2016, 51, 58–62. [Google Scholar] [CrossRef]

- Khan, A.U.; Mahmood, N.; Bazmi, A.A. Direct Comparison between Rotational and Extrusion Rheometers. Mater. Res. 2009, 12, 477–481. [Google Scholar] [CrossRef]

- Covas, J.A.; Maia, J.M.; Machado, A.V.; Costa, P. On-Line Rotational Rheometry for Extrusion and Compounding Operations. J. Nonnewton. Fluid Mech. 2008, 148, 88–96. [Google Scholar] [CrossRef]

- Barczewski, M.; Barczewski, R.; Chwalczuk, T. The In-Line Detection Method of Sharkskin Melt Flow Instability during Polyethylene Extrusion Based on Pressure Analysis. J. Manuf. Process. 2020, 59, 153–166. [Google Scholar] [CrossRef]

- Barczewski, M.; Lewandowski, K.; Schmidt, M.; Szostak, M. Melt Fracture and Rheology of Linear Low Density Polyethylene—Calcium Carbonate Composites. Polym. Eng. Sci. 2017, 57, 998–1004. [Google Scholar] [CrossRef]

- Lewandowski, K.; Piszczek, K.; Skórczewska, K.; Mirowski, J.; Zajchowski, S.; Wilczewski, S. Rheological Properties of Wood Polymer Composites at High Shear Rates—Evaluation of Additional Pressure Losses as a Result of Inlet Effects. Compos. Part A Appl. Sci. Manuf. 2022, 154, 106804. [Google Scholar] [CrossRef]

- Trotta, G.; Stampone, B.; Fassi, I.; Tricarico, L. Study of Rheological Behaviour of Polymer Melt in Micro Injection Moulding with a Miniaturized Parallel Plate Rheometer. Polym. Test. 2021, 96, 107068. [Google Scholar] [CrossRef]

- Zhang, N.; Gilchrist, M.D. Characterization of Thermo-Rheological Behavior of Polymer Melts during the Micro Injection Moulding Process. Polym. Test. 2012, 31, 748–758. [Google Scholar] [CrossRef]

- Awaja, F.; Pavel, D. Recycling of PET. Eur. Polym. J. 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

- Wu, W.J.; Sun, X.L.; Chen, Q.; Qian, Q. Recycled Poly(Ethylene Terephthalate) from Waste Textiles with Improved Thermal and Rheological Properties by Chain Extension. Polymers 2022, 14, 510. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, Y.; Wang, K.; Xia, Y.; Gao, H.; Luo, K.; Cao, Z.; Qi, J. Effect of the Trifunctional Chain Extender on Intrinsic Viscosity, Crystallization Behavior, and Mechanical Properties of Poly(Ethylene Terephthalate). ACS Omega 2020, 5, 19247–19254. [Google Scholar] [CrossRef]

- Bolt, R.R.A.; Leitch, J.A.; Jones, A.C.; Nicholson, W.I.; Browne, D.L. Continuous Flow Mechanochemistry: Reactive Extrusion as an Enabling Technology in Organic Synthesis. Chem. Soc. Rev. 2022, 51, 4243–4260. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. A New Approach to Supertough Poly(Lactic Acid): A High Temperature Reactive Blending. Macromol. Mater. Eng. 2016, 301, 1443–1453. [Google Scholar] [CrossRef]

- Nofar, M.; Oğuz, H. Development of PBT/Recycled-PET Blends and the Influence of Using Chain Extender. J. Polym. Environ. 2019, 27, 1404–1417. [Google Scholar] [CrossRef]

- Tang, X.; Guo, W.; Yin, G.; Li, B.; Wu, C. Reactive Extrusion of Recycled Poly(Ethylene Terephthalate) with Polycarbonate by Addition of Chain Extender. J. Appl. Polym. Sci. 2007, 104, 2602–2607. [Google Scholar] [CrossRef]

- Liu, B.; Xu, Q. Effects of Bifunctional Chain Extender on the Crystallinity and Thermal Stability of PET. J. Mater. Sci. Chem. Eng. 2013, 1, 9–15. [Google Scholar] [CrossRef] [Green Version]

- Qu, M.; Lu, D.; Deng, H.; Wu, Q.; Han, L.; Xie, Z.; Qin, Y.; Schubert, D.W. A Comprehensive Study on Recycled and Virgin PET Melt-Spun Fibers Modified by PMDA Chain Extender. Mater. Today Commun. 2021, 29, 103013. [Google Scholar] [CrossRef]

- Härth, M.; Dörnhöfer, A. Film Blowing of Linear and Long-Chain Branched Poly(Ethylene Terephthalate). Polymers 2020, 12, 1605. [Google Scholar] [CrossRef]

- Scheirs, J. Additives for the Modification of Poly(Ethylene Terephthalate) to Produce Engineering-Grade Polymers; John Wiley & Sons: Hoboken, NJ, USA, 2004; ISBN 0471498564. [Google Scholar]

- Arayesh, H.; Golshan Ebrahimi, N.; Khaledi, B.; Khabazian Esfahani, M. Introducing Four Different Branch Structures in PET by Reactive Processing––A Rheological Investigation. J. Appl. Polym. Sci. 2020, 137, 49243. [Google Scholar] [CrossRef]

- Wittmann, L.M.; Drummer, D. Two Layer Sheets for Processing Post-Consumer Materials. Polymers 2022, 14, 1507. [Google Scholar] [CrossRef] [PubMed]

- Kloziński, A.; Sterzyński, T. Evaluation of Correction Factors in Rheological Investigations of Polyethylene. Part II. Power Low Index, Rabinowitsch Correction. Polimery 2007, 52, 583–590. [Google Scholar] [CrossRef]

- Filip, P.; Hausnerova, B.; Hnatkova, E. Continuous Rheological Description of Highly Filled Polymer Melts for Material Extrusion. Appl. Mater. Today 2020, 20, 100754. [Google Scholar] [CrossRef]

- Wilczynski, K.; Buziak, K.; Lewandowski, A.; Nastaj, A.; Wilczynski, K.J. Rheological Basics for Modeling of Extrusion Process of Wood Polymer Composites. Polymers 2021, 13, 622. [Google Scholar] [CrossRef]

- Kloziński, A.; Sterzyński, T. Bagley Correction Evaluation on the Basis of Measurements in Extrusion Line. Polimery 2005, 50, 459–462. [Google Scholar] [CrossRef]

- Abchiche, H.; Mellal, M.; Bensakhria, A.; Trari, M. Comparative Study of Correction Methods of Wall Slip Effects for CMC Solutions. Comptes Rendus Mec. 2015, 343, 322–330. [Google Scholar] [CrossRef]

- Meng, L.; Wu, D.; Kelly, A.; Woodhead, M.; Liu, Y. Experimental Investigation of the Rheological Behaviors of Polypropylene in a Capillary Flow. J. Appl. Polym. Sci. 2016, 133, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Awad, S.A.; Khalaf, E.M. Improvement of the Chemical, Thermal, Mechanical and Morphological Properties of Polyethylene Terephthalate–Graphene Particle Composites. Bull. Mater. Sci. 2018, 41, 67. [Google Scholar] [CrossRef] [Green Version]

- Torres, N.; Robin, J.J.; Boutevin, B. Study of Thermal and Mechanical Properties of Virgin and Recycled Poly(Ethylene Terephthalate) before and after Injection Molding. Eur. Polym. J. 2000, 36, 2075–2080. [Google Scholar] [CrossRef]

- Aging, T.; Panowicz, R.; Konarzewski, M.; Durejko, T.; Szala, M.; Łazi, M. Properties of Polyethylene Terephthalate (PET) after Thermo-Oxidative Aging. Materials 2021, 14, 3833. [Google Scholar]

- Yang, Z.; Xin, C.; Mughal, W.; Li, X.; He, Y. High-Melt-Elasticity Poly(Ethylene Terephthalate) Produced by Reactive Extrusion with a Multi-Functional Epoxide for Foaming. J. Appl. Polym. Sci. 2018, 135, 45805. [Google Scholar] [CrossRef]

- Itoh, T.; Uchida, T.; Izu, N.; Matsubara, I.; Shin, W. Effect of Core-Shell Ceria/Poly(Vinylpyrrolidone) (PVP) Nanoparticles Incorporated in Polymer Films and Their Optical Properties. Materials 2013, 6, 2119–2129. [Google Scholar] [CrossRef] [Green Version]

- Alvarado Chacon, F.; Brouwer, M.T.; Thoden van Velzen, E.U. Effect of Recycled Content and RPET Quality on the Properties of PET Bottles, Part I: Optical and Mechanical Properties. Packag. Technol. Sci. 2020, 33, 347–357. [Google Scholar] [CrossRef]

- Kráčalík, M.; Studenovský, M.; Mikešová, J.; Kovářová, J.; Sikora, A.; Thomann, R.; Friedrich, C. Recycled PET-Organoclay Nanocomposites with Enhanced Processing Properties and Thermal Stability. J. Appl. Polym. Sci. 2007, 106, 2092–2100. [Google Scholar] [CrossRef]

- Anis, A.; Elnour, A.Y.; Alam, M.A.; Al-Zahrani, S.M.; Al Fayez, F.; Bashir, Z. Aluminum-Filled Amorphous-PET, a Composite Showing Simultaneous Increase in Modulus and Impact Resistance. Polymers 2020, 12, 2038. [Google Scholar] [CrossRef]

- Negoro, T.; Thodsaratpreeyakul, W.; Takada, Y.; Thumsorn, S.; Inoya, H.; Hamada, H. Role of Crystallinity on Moisture Absorption and Mechanical Performance of Recycled PET Compounds. Energy Procedia 2016, 89, 323–327. [Google Scholar] [CrossRef] [Green Version]

- Elamri, A.; Zdiri, K.; Harzallah, O.; Lallam, A.; Elamri, A.; Zdiri, K.; Harzallah, O.; Lallam, A.; Lallam, A. Progress in Polyethylene Terephthalate Recycling. In Polyethylene Terephthalate: Uses, Properties and Degradation; Nova Science Publishers: New York, NY, USA, 2017; Volume 1, ISBN 9781536119916. [Google Scholar]

- Bashir, Z.; Al-Aloush, I.; Al-Raqibah, I.; Ibrahim, M. Evaluation of Three Methods for the Measurement of Crystallinity of PET Resins, Preforms, and Bottles. Polym. Eng. Sci. 2000, 40, 2442–2455. [Google Scholar] [CrossRef]

- Benvenuta Tapia, J.J.; Hernández Valdez, M.; Cerna Cortez, J.; Díaz García, V.M.; Landeros Barrios, H. Improving the Rheological and Mechanical Properties of Recycled PET Modified by Macromolecular Chain Extenders Synthesized by Controlled Radical Polymerization. J. Polym. Environ. 2018, 26, 4221–4232. [Google Scholar] [CrossRef]

- Montava-Jorda, S.; Lascano, D.; Quiles-Carrillo, L.; Montanes, N.; Boronat, T.; Martinez-Sanz, A.V.; Ferrandiz-Bou, S.; Torres-Giner, S. Mechanical Recycling of Partially Bio-Based and Recycled Polyethylene Terephthalate Blends by Reactive Extrusion with Poly(Styrene-Co-Glycidyl Methacrylate). Polymers 2020, 12, 174. [Google Scholar] [CrossRef] [Green Version]

- Awaja, F.; Daver, F.; Kosior, E.; Cser, F. The Effect of Chain Extension on the Thermal Behaviour and Crystallinity of Reactive Extruded Recycled Pet. J. Therm. Anal. Calorim. 2004, 78, 865–884. [Google Scholar] [CrossRef]

- Raffa, P.; Coltelli, M.B.; Savi, S.; Bianchi, S.; Castelvetro, V. Chain Extension and Branching of Poly(Ethylene Terephthalate) (PET) with Di- and Multifunctional Epoxy or Isocyanate Additives: An Experimental and Modelling Study. React. Funct. Polym. 2012, 72, 50–60. [Google Scholar] [CrossRef]

- Kiliaris, P.; Papaspyrides, C.D.; Pfaendner, R. Reactive-Extrusion Route for the Closed-Loop Recycling of Poly(Ethylene Terephthalate). J. Appl. Polym. Sci. 2007, 104, 1671–1678. [Google Scholar] [CrossRef]

| Material | Virgin PET (V) (%) | Recycled PET (MIX) (%) | IV Modifiers | Thickness (µm) | |

|---|---|---|---|---|---|

| MassPET (M) | Belar (B) | ||||

| VD * | 100 | - | - | - | 400 |

| VD-B1 | 99 | - | 1 | 400 | |

| VD-M1 | 99 | - | 1 | - | 400 |

| V | 100 | - | - | - | 400 |

| V-B1 | 99 | - | - | 1 | 400 |

| V-M1 | 99 | - | 1 | - | 400 |

| MIX-M1 | - | 99 | 1 | - | 400 |

| MIX-B1 | - | 99 | - | 1 | 400 |

| MIX | - | 100 | - | - | 400 |

| Reference materials | |||||

| APET | Mono film prepared from 100% amorphous PET resin | 250 | |||

| PET/PE | PET foil laminated on both sides with PE foil | 250 | |||

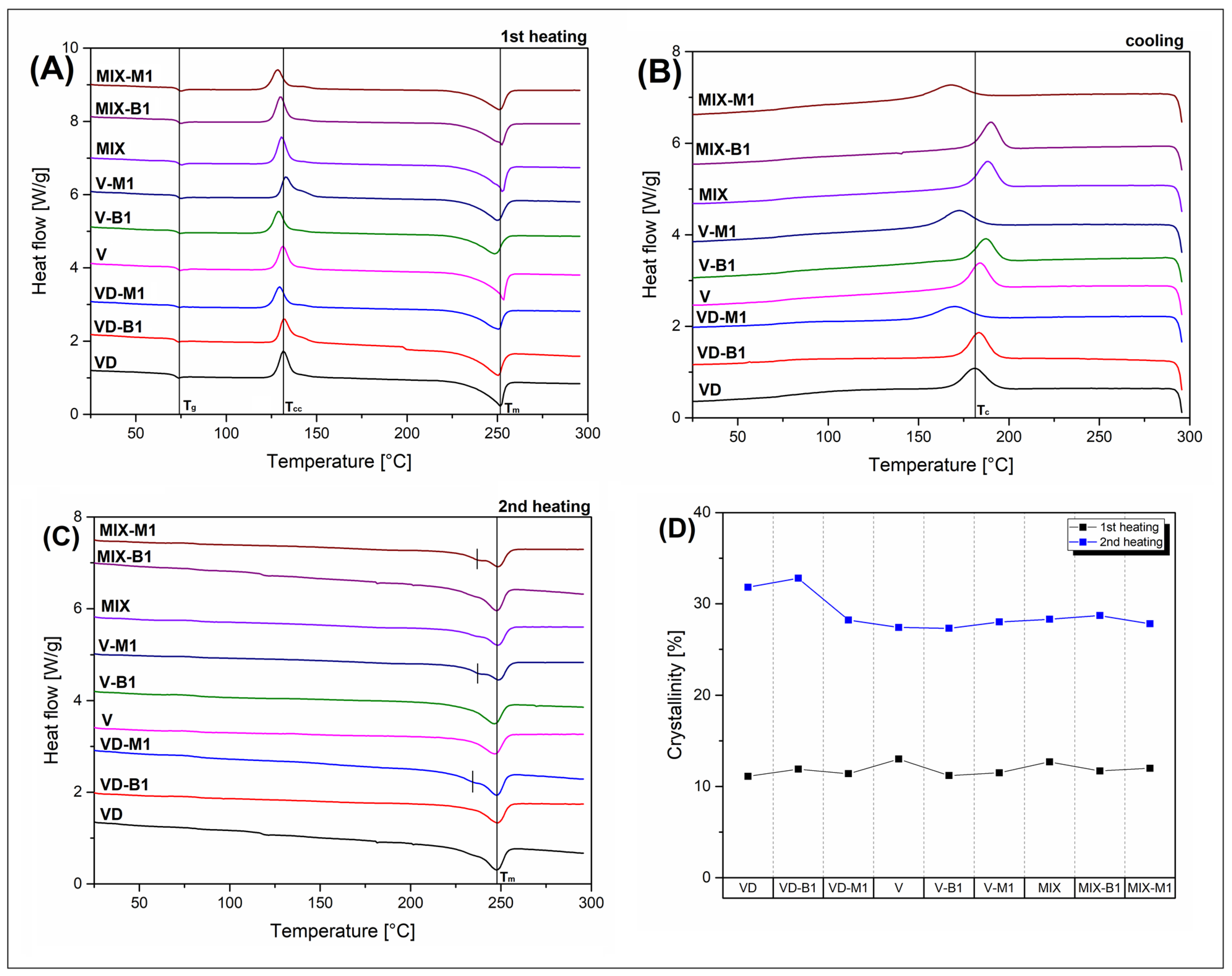

| Sample | Peak Position (°C) | Enthalpy, ΔH (J/g) | Crystallinity (Content) * (%) | Crystallization Peak (°C) | ||

|---|---|---|---|---|---|---|

| Cold Cryst. | Melting | Cold Cryst. | Melting | |||

| VD | 137.7 | 251.8 | 33.9 | 49.5 | 11.1 (31.8) | 180.8 |

| VD-B1 | 132.0 | 250.4 | 34.1 | 50.8 | 11.9 (32.8) | 183.5 |

| VD-M1 | 129.6 | 250.5 | 29.4 | 45.4 | 11.4 (28.2) | 169.9 |

| V | 131.3 | 253.2 | 30.4 | 48.7 | 13.0 (27.4) | 183.9 |

| V-B1 | 128.9 | 248.3 | 30.8 | 46.4 | 11.2 (27.3) | 187.3 |

| V-M1 | 133.0 | 250.3 | 31.1 | 47.2 | 11.5 (28.0) | 172.6 |

| MIX | 130.7 | 253.1 | 32.1 | 49.8 | 12.7 (28.3) | 188.4 |

| MIX-B1 | 130.0 | 252.7 | 31.7 | 48.0 | 11.7 (28.7) | 190.1 |

| MIX-M1 | 128.5 | 250.8 | 30.3 | 47.2 | 12.0 (27.8) | 168.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szymczak, P.; Dziadowiec, D.; Andrzejewski, J.; Szostak, M. The Efficiency Evaluation of the Reactive Extrusion Process for Polyethylene Terephthalate (PET). Monitoring of the Industrial Foil Manufacturing Process by In-Line Rheological Measurements. Appl. Sci. 2023, 13, 3434. https://doi.org/10.3390/app13063434

Szymczak P, Dziadowiec D, Andrzejewski J, Szostak M. The Efficiency Evaluation of the Reactive Extrusion Process for Polyethylene Terephthalate (PET). Monitoring of the Industrial Foil Manufacturing Process by In-Line Rheological Measurements. Applied Sciences. 2023; 13(6):3434. https://doi.org/10.3390/app13063434

Chicago/Turabian StyleSzymczak, Piotr, Damian Dziadowiec, Jacek Andrzejewski, and Marek Szostak. 2023. "The Efficiency Evaluation of the Reactive Extrusion Process for Polyethylene Terephthalate (PET). Monitoring of the Industrial Foil Manufacturing Process by In-Line Rheological Measurements" Applied Sciences 13, no. 6: 3434. https://doi.org/10.3390/app13063434

APA StyleSzymczak, P., Dziadowiec, D., Andrzejewski, J., & Szostak, M. (2023). The Efficiency Evaluation of the Reactive Extrusion Process for Polyethylene Terephthalate (PET). Monitoring of the Industrial Foil Manufacturing Process by In-Line Rheological Measurements. Applied Sciences, 13(6), 3434. https://doi.org/10.3390/app13063434